The Challenge of Digitalization in the Steel Sector

Abstract

1. Introduction

- The proactive identification of skill needs and demands for the construction appropriate training and curricula, including strategizing for the implementation of new vocational education content and pedagogies across the sector, within both companies and education and training institutions;

- The identification, development, and promotion of successful sectoral recruitment and upskilling schemes, and the development of some training tools for efficient management of knowledge fostering talent development and overcoming of recruitment difficulties.

2. The Framework of the Industrial Digital Transformation

2.1. Digital Transformation in the European Industry

- Ensuring a continuous responsiveness to fulfil the changing future demand and securing the market position;

- Preserving competitiveness with efficient processes, and cost and resources saving;

- Achieving higher product quality;

- Maximizing plant performance, by also minimizing maintenance and low capital lock-up;

- Planning a flexible production by guaranteeing timeliness of delivery [10].

2.2. Digitalization in the European Steel Industry

3. European Research Activities on Digitalization in the Steel Sector

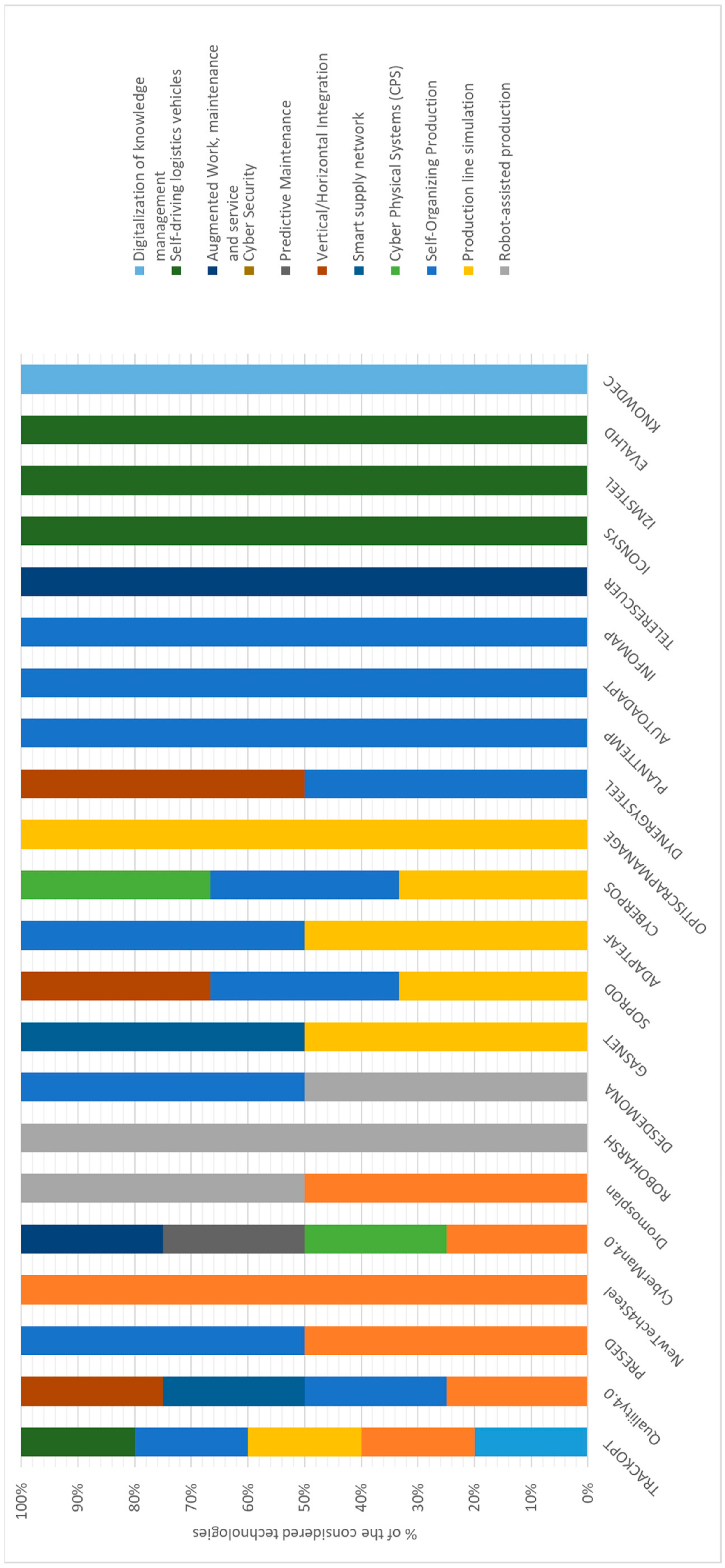

3.1. Digitalization & Enabling Technologies

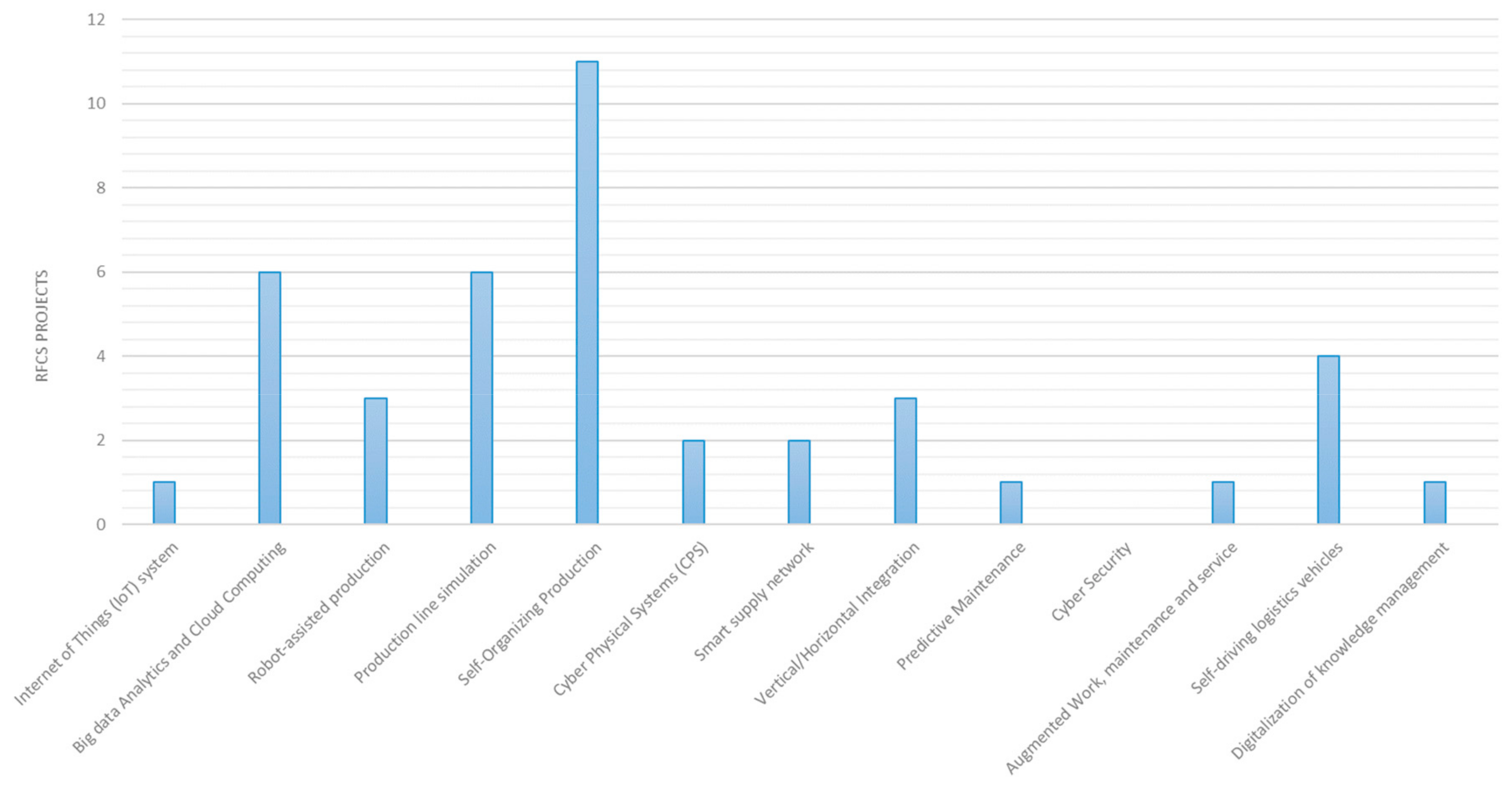

- Internet of Things (IoT) system: The IoT refers to an inter-networking world where electronic sensors, actuators, or other digital devices are networked and connected with the purpose of collecting and exchanging data [42]. According to [43], the composition of an online monitoring system based on an IoT system architecture can be characterized of four layers: Sensing, network, service resource, and application layers. Such a proposed system has been implemented and demonstrated through a real, continuous steel casting production line and integrated with the TeamCenter platform.

- Big data Analytics and Cloud Computing: In the manufacturing industries, including the steel industry, the conventional database technology can have some difficulties in finishing the capture, storage, management, and analysis of large volumes of structured and unstructured data. Big data analytics is related to algorithms based on historical data identifying quality problems and reducing the product failures. On the steel products, the Big-Data solutions are currently used for quality monitoring and improvement. This technology uses new processing modes in order to obtain significant information from different data types, and, to understand them in-depth, gain insight, and make discoveries for precise decision making. An accurate prediction of surface on steel slab defects can be based on the online collected data from the production line and it is important for adjusting the process online as well as for reducing their occurrence. The main problem is that the samples for normal cases and defects are usually unbalanced. According to [44], a one-class Support Vector Machine (SVM) classifier based on online collected process data and environmental factors for only normal cases was proposed in order to predict the occurrence of defects for steel slabs. ML-based approaches can provide a relevant support in extracting useful information and relevant knowledge from the available data and enabling the development of data-driven models e.g., for a wide variety of applications, such as material properties prediction [45] and product defects detection and identification [46]. Cloud computing gives on-demand computing services with high reliability, scalability, and availability in a distributed environment. Thanks to this technology, everything is treated as a service (i.e., XaaS), e.g., SaaS (Software as a Service), PaaS (Platform as a Service), and IaaS (Infrastructure as a Service) [47].

- Robot-assisted production: This technology is based on the use of humanoid robots in order to perform operations, such as assembly and packaging. Due to an increasing demand for higher quality, faster delivery time, and reduction of cost in the manufacturing industry in the last few decades, automation and robotics have achieved more and more importance. For instance, if in the steelmaking plant, existing technologies are enhanced with robots and automation, an improvement of surface quality of the steel products could be achieved [48,49].

- Production line simulation: In the steel sector, approaches for the simulation optimization solution have been developed. In particular, investigating potential changes to the designs and operations is the aim of the development of decision support systems [50,51]. Novel numerical techniques, such as meshless methods in the simulation systems of the steel sector, have been also exploited. In [52], a rolling simulation system capable of simulating rolling of slabs and blooms, as well as round or square billets, in different symmetric or asymmetric forms in continuous, reversing, or combined rolling has been elaborated. Vertnik et al. [53] developed a meshless Local Radial Basis Function Collocation Method (LRBFCM) for the solution of three-dimensional (3D) turbulent molten steel flow and solidification under the influence of electromagnetic stirring (EMS) and they demonstrate its application to continuous casting process of steel billets.

- Self-Organizing Production: Such technology involves the automatic coordination of machines, leading to the optimization of their utilization and output. The self-organizing production is related to the decentral instead of central solutions. A new combination of resources, equipment, and personnel, based on a close interaction within them with a master computer, is included and an increase of the automation, leading to the real time control of production networks.

- CPS: Is a system where computation, networking, and physical processes are integrated. The physical processes are monitored and controlled by embedded computers and networks, with feedback loops where they affect computations and vice versa [54].

- Smart supply network: Better supply decisions are possible thanks to the monitoring of the entire supply network. Several factors and objectives have to be taken into consideration in a supply chain of a steel industry. The smart supply networks optimize the steelworks production processes from the beginning to the end of products by using models as part of the integrated supply chain.

- Vertical/Horizontal Integration: Horizontal integration concerns the integration between a resource and an information network within the value chain. Vertical integration is related to networked manufacturing systems within the intelligent factories of the future and personalized customer manufacturing [55].

- Predictive Maintenance: It allows repair prior to breakdown thanks to a remote monitoring of equipment. The combination of equipment monitoring together with intelligent decision methods implement the predictive maintenance techniques. In order to support decision-making and to assist steel companies to improve their competitiveness, ML and Data Mining techniques can be used to draw insights from the data and accurately predict results.

- Cyber Security: Such technology should be taken into consideration, especially for the Internet-based services. A procedural model for a Cyber-Security analysis based on reference architecture model Industry 4.0 and a VDI/VDE guideline 2182 are shown for the use case of a Cloud-based monitoring of the production in [56].

- Augmented Work, Maintenance, and Service: The operating guidance, the remote assistance, and the documentation are favored by applying the fourth dimension, which is the use of the augment reality. This is one of the most interesting enabling technology for companies, especially for improving the maintenance services. For instance, remote maintenance based on remote connection can be carried out by a service technician who is virtually connected. This results in travel costs and time saving, and with quick problem solving.

- Self-driving logistics vehicles: Such technology is based on completely automated transportation systems. The use of intelligent software to support intralogistics operations helps companies to improve processes and to make faster them. In the steelworks, the supply and the disposal of raw materials and the transport of intermediate products as well as the removal of finished products and the handling of by-products, for instance bulk material or slag, are very important. The use of an intelligent transport control system can allow one to plan and control the internal transport orders, resulting in an increase of productivity and service levels, cutting costs.

- Digitalization of knowledge management. Due to an increasing competitive market, the steel sector has been committed to facing significant challenges in the digitalization. Although this process has already started, further improvement can be achieved. On this subject, the knowledge and experience of the technical staff represents the basis of this improvements. The main barriers about the usage of this knowledge and experience are represented by their heterogeneous distribution over the individual staff members, human obliviousness, and knowledge erosion by leaving staff members.

3.2. Past and Ongoing Research Activities Funded by the Research Fund for Coal and Steel

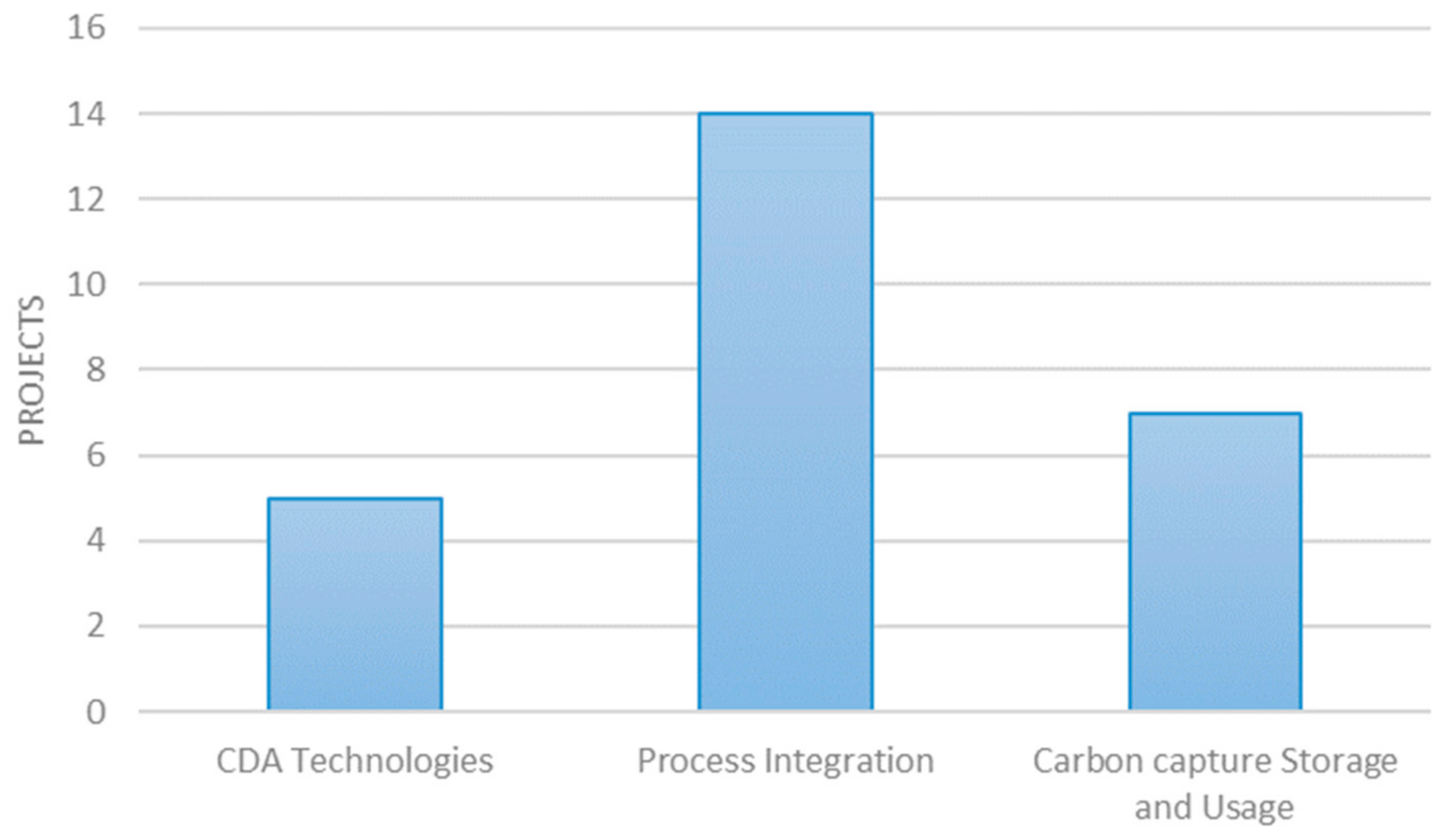

3.3. Other European Funding Programs for Digitalization and Low Carbon Technologies for the Steel Sector

4. The Future of Digitalization in the Steel Sector

- Digital Data,

- Automation,

- Connectivity,

- Digital Customer Access.

4.1. Digitalization Impact on the Workforce

4.2. Digitalization and Economic Impact

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| RFCS Projects | ||||

|---|---|---|---|---|

| AdaptEAF | DroMoSPlan | I2MSteel | Plant Temp | Telerescuer |

| AUTOADAPT | DYNERGYSteel | IConSys | PRESED | TRACKOPT |

| CYBERMAN4.0 | ENCOP | INFOMAP | ROBOHARSH | |

| Cyber-POS | EvalHD | NEWTECH4STEEL | QUALITY4.0 | |

| DESDEMONA | GASNET | OptiScrapManage | SoProd | |

| EUREKA | H2020 | SPIRE | FP7 |

|---|---|---|---|

| BRICK | WATERWATT | DISIRE | AREUS |

| OREXPRESS | FACTS4WORKERS | COPRO | |

| TAM | FUDIPO | ||

| H2PREDICTOR | MORSE | ||

| RECOBA | |||

| COCOP |

| CDA | PI | CCU |

|---|---|---|

| HYBRIT | IDEOGAS | Biocon-co2 |

| GrInHy | OSMet S2 | CarbonNext |

| H2FUTURE | HISARNA B, C &D | I3UPGRADE |

| IERO | ACASOS | FresMe |

| SALCOS | CO2RED | M4CO2 |

| REGTGF | Carbon4PUR | |

| RenewableSteelGases | Steelanol | |

| SHOCOM | ||

| Torero | ||

| GREENEAF | ||

| GREENEAF2 | ||

| ENCOP | ||

| IDEOGAS | ||

| LoCO2Fe | ||

| STEPWISE |

References

- Schumacher, A.; Sihn, W.; Erol, S. In Automation, Digitization and Digitalization and Their Implications for Manufacturing Processes. In Proceedings of the International Scientific Conference on Innovation and Sustainability, Bucharest, Romania, 28–29 October 2016; pp. 1–6. [Google Scholar]

- Clerck, J. Digitization, Digitalization and Digital Transformation: The Differences. i-SCOOP. 2017. Available online: https://www.i-scoop.eu/digital-transformation/digitization-digitalization-digital-transformation-disruption/ (accessed on 20 February 2020).

- Groover, M.P. Automation, Production Systems, and Computer-Integrated Manufacturing; Prentice Hall Press: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Maintenance Q&As. Available online: https://www.onupkeep.com/answers/predictive-maintenance/industry-3-0-vs-industry-4-0/ (accessed on 6 December 2019).

- European Commission. Blueprint for Sectoral Cooperation on Skills-towards an EU Strategy Addressing the Skills Needs of the Steel Sector: European Vision on Steel-Related Skills of Today and Tomorrow—Study; European Commission: Bruxelles, Belgium, 2019. [Google Scholar]

- European Commission. Germany: Industry 4.0, Digital Transformation Monitor; European Commission: Bruxelles, Belgium, 2017. [Google Scholar]

- Bogner, E.; Voelklein, T.; Schroedel, O.; Franke, J. Study based analysis on the current digitalization degree in the manufacturing industry in Germany. Procedia CIRP 2016, 57, 14–19. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee, the Committee of the Regions and the European Investment Bank Investing in a Smart, Innovative and Sustainable Industry a Renewed EU Industrial Policy Strategy, com/2017/0479 Final; European Commission: Bruxelles, Belgium, 2017. [Google Scholar]

- Beltrametti, L.; Guarnacci, N.; Intini, N.; La Forgia, C. La Fabbrica Connessa. La Manifattura Italiana (Attra) Verso Industria 4.0; goWare & Edizioni Guerini e Associati: Milano, Italy, 2017. [Google Scholar]

- SMS Group #Magazine. Available online: https://www.sms-group.com/sms-group-magazine/overview/digitalization-in-the-steel-industry/ (accessed on 6 December 2019).

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Stahl Institute VDEh. Annual Report of Steel Institute Vdeh 2016—Summary of Main Topics of Technical-Scientific Joint Cooperation and Work; Stahl Institute VDEh: Dusseldorf, Germany, 2016. [Google Scholar]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Lorenz, M.; Rüßmann, M.; Strack, R.; Lueth, K.L.; Bolle, M. Man and Machine in Industry 4.0: How will Technology Transform the Industrial Workforce through 2025; The Boston Consulting Group: Boston, MA, USA, 2015; Volume 2. [Google Scholar]

- European Commission. Available online: https://ec.europa.eu/digital-single-market/news/fresh-look-use-robots-shows-positive-effect-automation (accessed on 6 December 2019).

- European Commission. Digital Single Market. Available online: https://ec.europa.eu/digital-single-market/en/download-scoreboard-reports (accessed on 6 December 2019).

- Briken, K.; Chillas, S.; Krzywdzinski, M.; Marks, A.; Pfeiffer, S. Industrie 4.0 in the making–discourse patterns and the rise of digital despotism. In The New Digital Workplace: How New Technologies Revolutionise Work; Downes, R., Ed.; Red Globe Press: London, UK, 2017. [Google Scholar]

- Pfeiffer, S. The vision of “industrie 4.0” in the making—A case of future told, tamed, and traded. Nanoethics 2017, 11, 107–121. [Google Scholar] [CrossRef] [PubMed]

- Botthof, A.; Hartmann, E.A. Zukunft der Arbeit in Industrie 4.0; Springer: Berlin, Germany, 2015. [Google Scholar]

- Abel, J.; Hirsch-Kreinsen, H.; Ittermann, P. Einfacharbeit in der Industrie: Strukturen, Verbreitung und Perspektiven; Edition Sigma: Berlin, Germany, 2014. [Google Scholar]

- World Economic Forum. Digital Transformation Initiative—Mining and Metals Industry; World Economic Forum: Cologny, Switzerland, 2017. [Google Scholar]

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer: Berlin, Germany, 2017. [Google Scholar]

- European Commission. Re-Finding Industry-Report from the High-Level Strategy Group on Industrial Technologies; European Commission: Bruxelles, Belgium, 2018. [Google Scholar]

- Liu, S.X. Innovation design: Made in china 2025. Des. Manag. Rev. 2016, 27, 52–58. [Google Scholar]

- European Commission. A Blueprint for Sectoral Cooperation on Skills (Wave II); European Commission: Bruxelles, Belgium, 2018. [Google Scholar]

- European Commission. Steel: Preserving Sustainable Jobs and Growth in Europe. COM(2016)(155); European Commission: Bruxelles, Belgium, 2016. [Google Scholar]

- Peters, H. How Could Industry 4.0 Transform the Steel Industry, Steel Times International. In Proceedings of the Future Steel Forum, Warsaw, Poland, 14–15 June 2017. [Google Scholar]

- E15CZ. Available online: https://www.e15.cz/byznys/technologie-a-media/ceskym-firmam-muze-ujet-inovacni-vlak-ctvrtina-z-nich-nema-zadnou-koncepci-digitalizace-1351646 (accessed on 6 December 2019).

- Thomas, B.G. Review on modeling and simulation of continuous casting. Steel Res. Int. 2018, 89, 1700312. [Google Scholar] [CrossRef]

- Herzog, K.; Winter, G.; Kurka, G.; Ankermann, K.; Binder, R.; Ringhofer, M.; Maierhofer, A.; Flick, A. The digitalization of steel production. BHM Berg Hüttenmännische Mon. 2017, 162, 504–513. [Google Scholar] [CrossRef]

- Je-ho, C. The fourth industrial revolution: The winds of change are blowing in the steel industry. Asian Steel Watch 2016, 2, 6–15. [Google Scholar]

- Roudier, S.; Sancho, L.D.; Remus, R.; Aguado-Monsonet, M. Best Available Techniques (bat) Reference Document for Iron and Steel Production: Industrial Emissions Directive 2010/75/eu: Integrated Pollution Prevention and Control; Joint Research Centre (Seville site): Seville, Spain, 2013. [Google Scholar]

- Porzio, G.F.; Fornai, B.; Amato, A.; Matarese, N.; Vannucci, M.; Chiappelli, L.; Colla, V. Reducing the energy consumption and CO2 emissions of energy intensive industries through decision support systems—An example of application to the steel industry. Appl. Energy 2013, 112, 818–833. [Google Scholar] [CrossRef]

- Kovačič, M.; Šarler, B. Genetic programming prediction of the natural gas consumption in a steel plant. Energy 2014, 66, 273–284. [Google Scholar] [CrossRef]

- Kovačič, M.; Stopar, K.; Vertnik, R.; Šarler, B. Comprehensive electric arc furnace electric energy consumption modeling: A pilot study. Energies 2019, 12, 2142. [Google Scholar] [CrossRef]

- Neef, C.; Hirzel, S.; Arens, M. Industry 4.0 in the European Iron and Steel Industry: Towards an Overview of Implementations and Perspectives; Fraunhofer Institute for Systems and Innovation Research ISI: Karlsruhe, Germany, 2018. [Google Scholar]

- Naujok, N.; Stamm, H. Industry 4.0 in Steel: Status, Strategy, Roadmap and Capabilities. In Proceedings of the Future Steel Forum, Warsaw, Poland, 6–7 June 2018; Available online: https://futuresteelforum.com/content-images/speakers/Dr-Nils-Naujok-Holger-Stamm-Industry-4.0-in-steel.pdf (accessed on 20 December 2019).

- Digital Twin Technology in the Steel Industry. Available online: https://www.estep.eu/assets/Final-Programme-Digital-Twin-WS-21-22-November.pdf (accessed on 20 December 2019).

- Strategic Research Agenda (SRA). Available online: https://www.estep.eu/assets/SRA-Update-2017Final.pdf (accessed on 21 December 2019).

- Peters, K.; Malfa, E.; Colla, V. The European steel technology platform’s strategic research agenda: A further step for the steel as backbone of EU resource and energy intense industry sustainability. Metall. Ital. 2019, 111, 5–17. [Google Scholar]

- Man and Machine in Industry 4.0: How Will Technology Transform the Industrial Workforce Through 2015? Available online: http://englishbulletin.adapt.it/wp-content/uploads/2015/10/BCG_Man_and_Machine_in_Industry_4_0_Sep_2015_tcm80-197250.pdf (accessed on 21 December 2019).

- Xia, F.; Yang, L.; Wang, L.; Vinel, A. Internet of things. Int. J. Commun. Syst. 2012, 25, 1101–1102. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, M.; Zhou, Z.; Shen, W. An IoT-based online monitoring system for continuous steel casting. IEEE Internet Things J. 2016, 3, 1355–1363. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Kang, L.W.; Weng, M.F. Big Data Analytics: Prediction of Surface Defects on Steel Slabs Based on One Class Support Vector Machine. In Proceedings of ASME 2016 Conference on Information Storage and Processing Systems, Santa Clara, CA, USA, 20–21 June 2016. [Google Scholar]

- Fragassa, C.; Babic, M.; Perez Bergmann, C.P.; Minak, G. Predicting the Tensile Behaviour of Cast Alloys by a Pattern Recognition Analysis on Experimental Data. Metals 2019, 9, 557. [Google Scholar] [CrossRef]

- Tian, S.; Xu, K. An Algorithm for Surface Defect Identification of Steel Plates Based on Genetic Algorithm and Extreme Learning Machine. Metals 2017, 7, 311. [Google Scholar] [CrossRef]

- Xun, X. From cloud computing to cloud manufacturing. Robot. Comput. Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Demetlika, P.; Ferrari, R.; Galasso, L.M.; Romano, F. Robotic system for a “zero-operator” continuous casting floor. In Proceedings of AISTech 2014—Iron and Steel Technology Conference, Indianapolis, IN, USA, 5–8 May 2014. [Google Scholar]

- Egger, M.W.; Priesner, A.; Lehner, J.; Nogratnig, H.; Lechner, H.; Wimmer, G. Successful revamping of sublance manipulators fort the LD converters at Voestalpine Stahl Gmbh. In Proceedings of AISTech 2014- Iron and Steel Technology Conference, Indianapolis, IN, USA, 5–8 May 2014. [Google Scholar]

- Rauch, Ł.; Bzowski, K.; Kuziak, R.; Uranga, P.; Gutierrez, I.; Isasti, N.; Jacolot, R.; Kitowski, J.; Pietrzyk, M. Computer-Integrated Platform for Automatic, Flexible, and Optimal Multivariable Design of a Hot Strip Rolling Technology Using Advanced Multiphase Steels. Metals 2019, 9, 737. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J.; Guan, M.; Hong, Y.; Gao, S.; Guo, W.; Liu, Q. Fine Description of Multi-Process Operation Behavior in Steelmaking-Continuous Casting Process by a Simulation Model with Crane Non-Collision Constraint. Metals 2019, 9, 1078. [Google Scholar] [CrossRef]

- Hanoglu, U.; Šarler, B. Hot rolling simulation system for steel based on advanced meshless solution. Metals 2019, 9, 788. [Google Scholar] [CrossRef]

- Vertnik, R.; Mramor, K.; Šarler, B. Solution of three-dimensional temperature and turbulent velocity field in continuously cast steel billets with electromagnetic stirring by a meshless method. Eng. Anal. Bound. Elem. 2019, 104, 347–363. [Google Scholar] [CrossRef]

- Cyber-Physical Systems. Available online: http://cyberphysicalsystems.org (accessed on 21 December 2019).

- Zhou, K.; Liu, T.; Lifeng, Z. Industry 4.0: Towards Future Industrial. In Proceedings of 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015. [Google Scholar]

- Flatt, H.; Schriegel, S.; Jasperneite, J.; Trsek, H.; Adamczyk, H. Analysis of the Cyber-Security of industry 4.0 technologies based on RAMI 4.0 and identification of requirements. In Proceedings of IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016. [Google Scholar]

- Arens, M.; Neef, C.; Beckert, B.; Hirzel, S. Perspectives for digitising energy-intensive industries—Findings from the European iron and steel industry. In Proceedings of eceee Industrial Summer Study; ECEEE: Stockholm, Sweden, 2018; pp. 259–268. [Google Scholar]

- Iannino, V.; Colla, V.; Denker, J.; Göttsche, M. A CPS-based simulation platform for long production factories. Metals 2019, 9, 1025. [Google Scholar] [CrossRef]

- DroMoSplan, Workers Safety Improvement and Significant Reduction of Maintenance Costs by Monitoring and Inspecting Steel Plants with a New Type of Autonomous Flying Drones. Available online: http://www.dromosplan.eu/homepage (accessed on 21 December 2019).

- Colla, V.; Schroeder, A.; Buzzelli, A.; Abbà, D.; Faes, L.; Romaniello, L. Introduction of Symbiotic Human-robot Cooperation in the Steel Sector: An Example of Social Innovation. Matériaux Tech. 2017, 105, 505. [Google Scholar] [CrossRef]

- Colla, V.; Matino, R.; Faes, A.; Schivalocchi, M.; Romaniello, L. A robot performs the maintenance of the ladle sliding gate. Stahl Eisen 2019, 9, 44–47. [Google Scholar]

- Marchiori, F.; Belloni, A.; Benini, M.; Cateni, S.; Colla, V.; Ebel, A.; Pietrosanti, C. Integrated Dynamic Energy Management for Steel Production. Energy Procedia 2017, 105, 2772–2777. [Google Scholar] [CrossRef]

- Marchiori, F.; Benini, M.; Cateni, S.; Colla, V.; Vignali, A.; Ebel, A.; Neuer, M.; Piedimonte, L. Agent-based approach for energy demand-side management. Stahl Eisen 2018, 138, 25–29. [Google Scholar]

- Colla, V.; Matino, I.; Dettori, S.; Petrucciani, A.; Zaccara, A.; Weber, V.; Romaniello, L. Assessing the efficiency of the off-gas network management in integrated steelworks. Matériaux Tech. 2019, 107, 502. [Google Scholar] [CrossRef]

- Matino, I.; Dettori, S.; Colla, V.; Weber, V.; Salame, S. Forecasting blast furnace gas production and demand through echo state neural network-based models: Pave the way to off-gas optimized management. Appl. Energy 2019, 253, 113578. [Google Scholar] [CrossRef]

- Matino, I.; Dettori, S.; Colla, V.; Weber, W.; Salame, S. Two innovative modelling approaches in order to forecast consumption of blast furnace gas by hot blast stoves. Energy Procedia 2019, 158, 4043–4048. [Google Scholar] [CrossRef]

- Dettori, S.; Matino, I.; Colla, V.; Weber, V.; Salame, S. Neural Network-based modeling methodologies for energy transformation equipment in integrated steelworks processes. Energy Procedia 2018, 158, 4061–4066. [Google Scholar] [CrossRef]

- Colla, V.; Matino, I.; Dettori, S.; Cateni, S.; Matino, R. Reservoir computing approaches applied to energy management in industry. Commun. Comput. Inf. Sci. 2019, 1000, 66–79. [Google Scholar]

- Iannino, V.; Vannocci, M.; Vannucci, M.; Colla, V.; Neuer, M. A multi-agent approach for the self-optimization of steel production. Int. J. Simul. Syst. Sci. Technol. 2018, 19, 20.1–20.7. [Google Scholar] [CrossRef]

- Vannocci, M.; Ritacco, A.; Castellano, A.; Galli, F.; Vannucci, M.; Iannino, V.; Colla, V. Flatness Defect Detection and Classification in Hot Rolled Steel Strips Using Convolutional Neural Networks. Lect. Notes Comput. Sci. 2019, 11507, 220–234. [Google Scholar] [CrossRef]

- Colla, V.; Nastasi, G.; Maddaloni, A.; Holzknecht, N.; Heckenthaler, T.; Hartmann, G. Intelligent control station for improved quality management in flat steel production. IFAC Pap. OnLine 2016, 49, 226–231. [Google Scholar] [CrossRef]

- Brandenburger, J.; Colla, V.; Nastasi, G.; Ferro, F.; Schirm, C.; Melcher, J. Big Data Solution for Quality Monitoring and Improvement on Flat Steel Production. IFAC Pap. OnLine 2016, 49, 55–60. [Google Scholar] [CrossRef]

- Smart Steel: RFCS—Support Steelmaking and Use in the 21th Century. Available online: https://aceroplatea.es/docs/RFCS_SmartSteel2016.pdf (accessed on 21 December 2019).

- Research and Innovation Funding 2014–2020. Available online: https://ec.europa.eu/research/fp7/index_en.cfm (accessed on 21 December 2019).

- Hecht, M. Industrie 4.0 der Dillinger Weg. Stahl Eisen 2017, 137(4), 61–70. [Google Scholar]

- Eureka Projects. Available online: http://www.eurekanetwork.org/eureka-projects (accessed on 21 December 2019).

- SPIRE. Available online: https://www.spire2030.eu/ (accessed on 21 December 2019).

- Datengetriebenes Prognosemodell für den BOF-Konverter—Anwendung von Data Mining in der AG der Dillinger Hüttenwerke. Available online: https://idw-online.de/en/attachmentdata36931.pdf (accessed on 21 December 2019).

- SmartSteel Gets Support from Vinnova—The Journey toward the “Internet of Materials” Continues. Available online: https://www.ssab.com/company/newsroom/media-archive/2017/05/05/07/01/smartsteel-gets-support-from-vinnova---the-journey-toward-the-internet-of-materials-continues (accessed on 21 December 2019).

- Foundation, E.M. Towards the Circular Economy; Cowes Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- EUROFER. DISCUSSION PAPER: Towards an EU Masterplan for a Low Carbon-Competitive European Steel Value Chain; EUROFER: Brussels, Belgium, 2018. [Google Scholar]

- Maddaloni, A.; Porzio, G.F.; Nastasi, G.; Colla, V.; Branca, T.A. Multi-objective optimization applied to retrofit analysis: A case study for the iron and steel industry. Appl. Therm. Eng. 2015, 91, 638–646. [Google Scholar] [CrossRef]

- Porzio, G.F.; Colla, V.; Matarese, N.; Nastasi, G.; Branca, T.A.; Amato, A.; Fornai, B.; Vannucci, M.; Bergamasco, M. Process integration in energy and carbon intensive industries: An example of exploitation of optimization techniques and decision support. Appl. Therm. Eng. J. 2014, 70, 1148–1155. [Google Scholar] [CrossRef]

- The Digital Transformation of Industry. Available online: www.rolandberger.com/publications/publication_pdf/roland_berger_digital_transformation_of_industry_20150315.Pdf (accessed on 21 December 2019).

- SPIRE 2050 Vision. Available online: https://www.spire2030.eu/sites/default/files/users/user85/Vision_Document_V5_Pages_Online_0.pdf (accessed on 9 December 2019).

- Strategy&—PwC. Available online: https://www.strategyand.pwc.com/gx/en/insights/industry4-0.html (accessed on 9 December 2019).

- ArcelorMittal. Integrated Annual Review 2018; ArcelorMittal: Luxembourg, 2019. [Google Scholar]

- Pfeiffer, S. Robots, industry 4.0 and humans, or why assembly work is more than routine work. Societies 2016, 6, 16. [Google Scholar] [CrossRef]

- Guerrieri, P.; Evangelista, R.; Meliciani, V. The economic impact of digital technologies in Europe. Econ. Innov. New Technol. 2014, 23(8), 802–824. [Google Scholar]

- Hirsch-Kreinsen, H. The Future of Low-Skilled Industrial Work. 2016. Available online: https://www.researchgate.net/publication/321635390_THE_FUTURE_OF_LOW-SKILLED_INDUSTRIAL_WORK (accessed on 20 February 2020).

- European Commission. Report of the High-Level Expert Group on the Impact of the Digital Transformation on EU Labor Markets; B-1049; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Hirsch-Kreinsen, H. Digitization of industrial work: Development paths and prospects. J. Labour Mark. Res. 2016, 49, 1–14. [Google Scholar] [CrossRef]

- Bonin, H.; Gregory, T.; Zierahn, U. Übertragung der Studie von Frey/Osborne (2013) auf Deutschland; ZEW Kurzexpertise: Mannheim, Germany, 2015. [Google Scholar]

- Skills Panorama, Inspiring Choices on Skills and Jobs in Europe. Available online: https://skillspanorama.cedefop.europa.eu/en/analytical_highlights/skills-forecast-key-eu-trends-2030 (accessed on 9 December 2019).

- European Commission. Smart Steel: RFCS: Support Steelmaking and Use in the 21th Century; B-1049; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Karacay, G. Talent development for industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 123–136. [Google Scholar]

- European Commission. Digital Skills and Jobs Conference—Digital Opportunities for Europe; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Gambin, L.; Hogarth, T.; Murphy, L.; Spreadbury, K.; Warhurst, C.; Winterbotham, M. Research to Understand the Extent, Nature and Impact of Skills Mismatches in the Economy; BIS: London, UK, 2016. [Google Scholar]

- European Commission. Communication from the Commission to the Parliament, the Council, the European Economic and Social Committee and the Committee of Regions Action Plan for a Competitive and Sustainable Steel Industry in Europe/* com/2013/0407 final */; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- DEI WG 2. Strengthening Leadership in Digital Technologies and in Digital Industrial Platforms—Digitization in the Process Industries through the Spire PPP; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- EUROFER. Economic and Steel Market Outlook 2019–2020 European Steel Squeezed between Rising Import Pressure and a Depressed Home Market; EUROFER: Brussels, Belgium, 2019. [Google Scholar]

- Herzog, K.; Günther, W.; Kurka, G.; Ankermann, K.; Binder, R.; Ringhofer, M. Primetals Technologies 2018. The Digital Transformation of Steel Production. Available online: http://seaisi.org/file/12-2%20The%20Digital%20Transformation%20of%20Steel%20Production.pdf (accessed on 20 February 2020).

- Danieli Automation Research Center. Application of digital twinning in the melting shop. Experiences. In Proceedings of ESTEP Workshop on Digital Twinning Techniques, Charleroi, Belgium, 21–22 November 2018. [Google Scholar]

- McKinsey. Industry 4.0 after the Initial Hype: Where Manufacturers are Finding Value and How They Can Best Capture It. McKinsey 2016. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/mckinsey%20digital/our%20insights/getting%20the%20most%20out%20of%20industry%204%200/mckinsey_industry_40_2016.ashx (accessed on 20 February 2020).

- McKinsey. Unlocking the Digital Opportunities in Metals, Metals and Mining Practice. McKinsey: 2018. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Metals%20and%20Mining/Our%20Insights/Unlocking%20the%20digital%20opportunity%20in%20metals/Unlocking-the-digital-opportunity-in-metals_Jan-2018.ashx (accessed on 20 February 2020).

- Klein, A.; Ptaszyk, K.; Runde, W.; Ohm, T.; Bleskov, I.; Passon, M. Application of advanced artificial intelligence in the manufacturing execution system for metals industry. In Proceedings of the METEC and 4th ESTAD (European Steel Technology and Applications Days) 2019, Dusseldorf, Germany, 24–28 June 2019; VDEh: Dusseldorf, Germany, 2019. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Branca, T.A.; Fornai, B.; Colla, V.; Murri, M.M.; Streppa, E.; Schröder, A.J. The Challenge of Digitalization in the Steel Sector. Metals 2020, 10, 288. https://doi.org/10.3390/met10020288

Branca TA, Fornai B, Colla V, Murri MM, Streppa E, Schröder AJ. The Challenge of Digitalization in the Steel Sector. Metals. 2020; 10(2):288. https://doi.org/10.3390/met10020288

Chicago/Turabian StyleBranca, Teresa Annunziata, Barbara Fornai, Valentina Colla, Maria Maddalena Murri, Eliana Streppa, and Antonius Johannes Schröder. 2020. "The Challenge of Digitalization in the Steel Sector" Metals 10, no. 2: 288. https://doi.org/10.3390/met10020288

APA StyleBranca, T. A., Fornai, B., Colla, V., Murri, M. M., Streppa, E., & Schröder, A. J. (2020). The Challenge of Digitalization in the Steel Sector. Metals, 10(2), 288. https://doi.org/10.3390/met10020288