Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations

Abstract

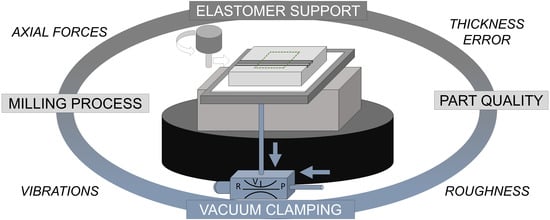

1. Introduction

2. Materials and Methods

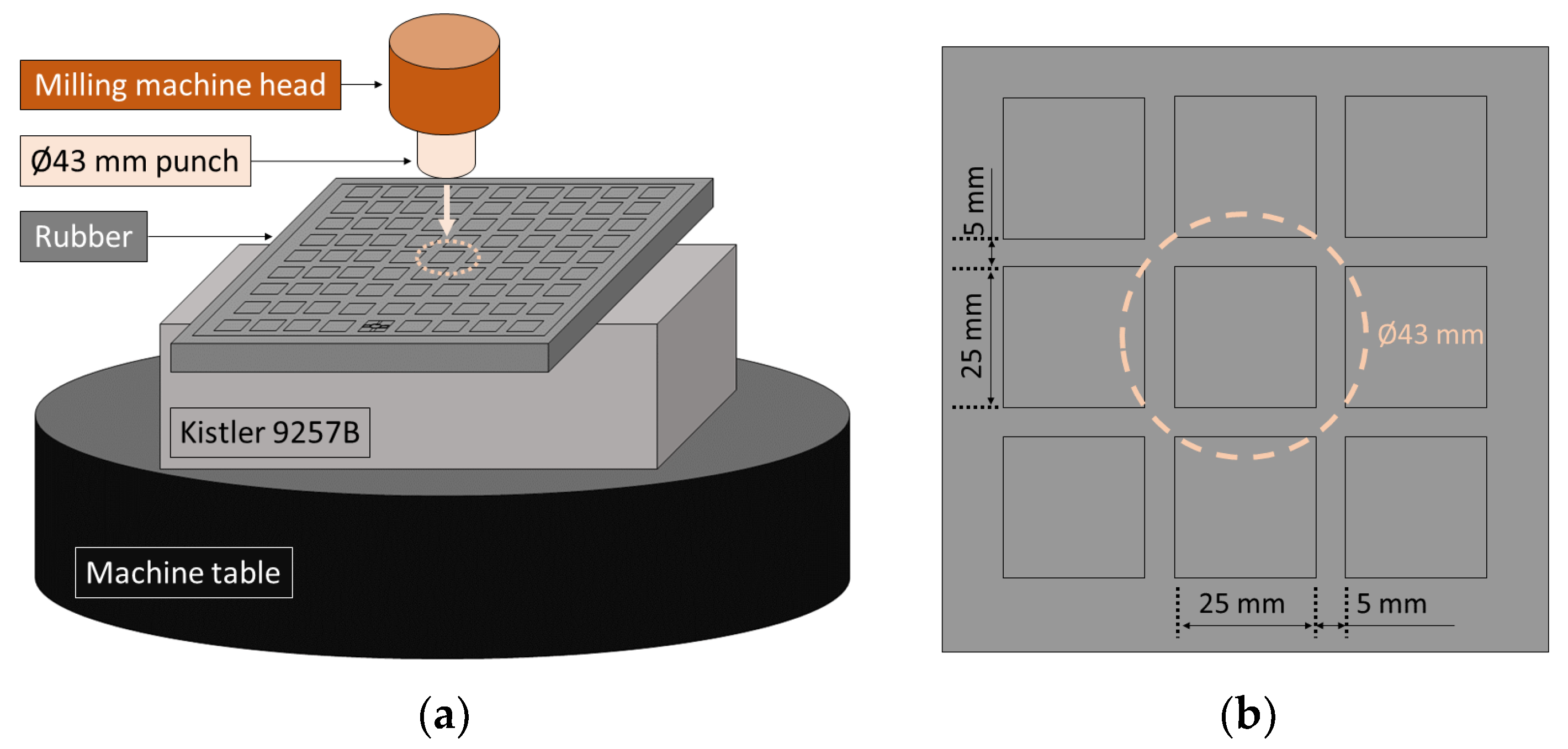

2.1. Compression Tests

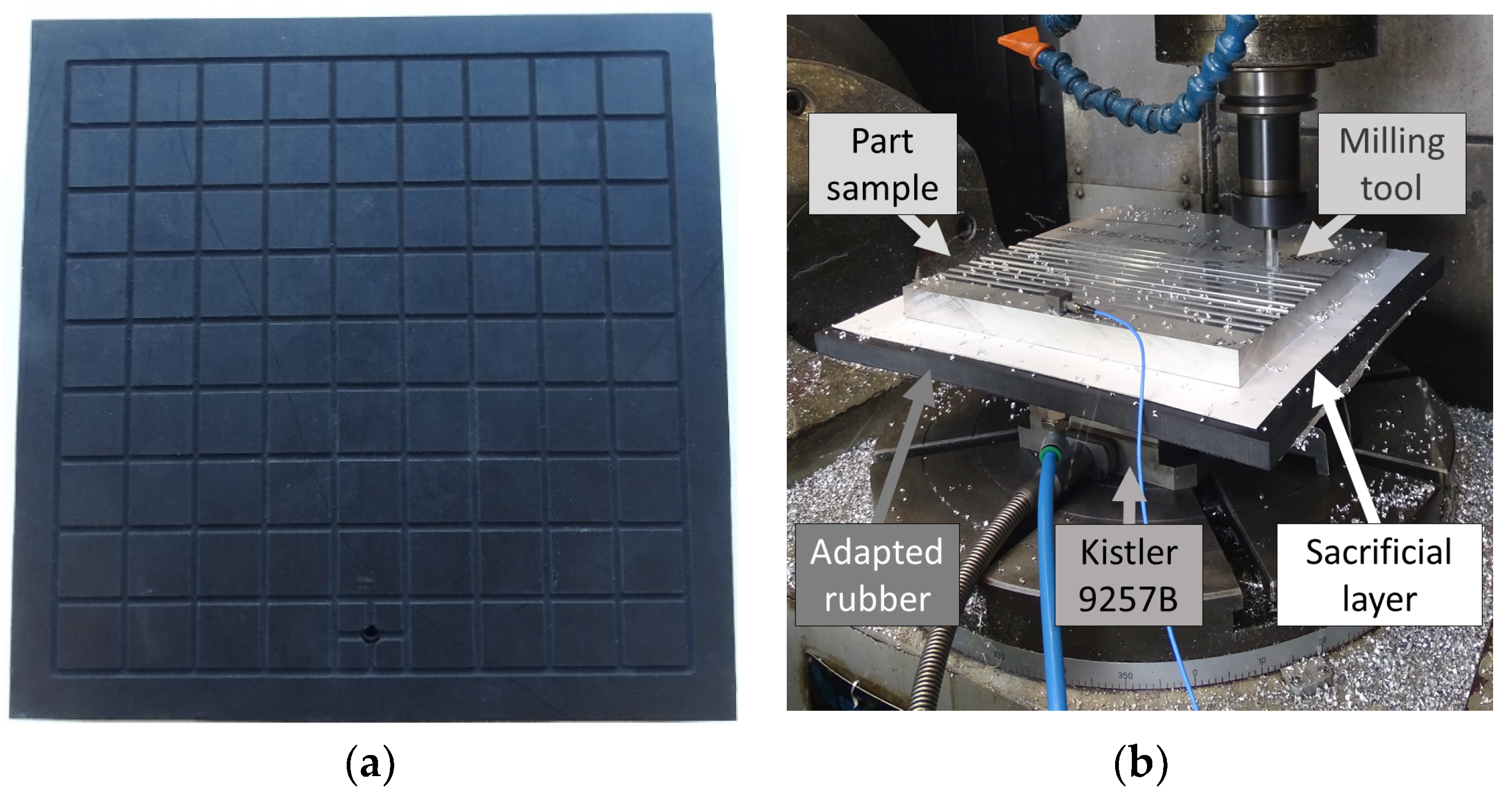

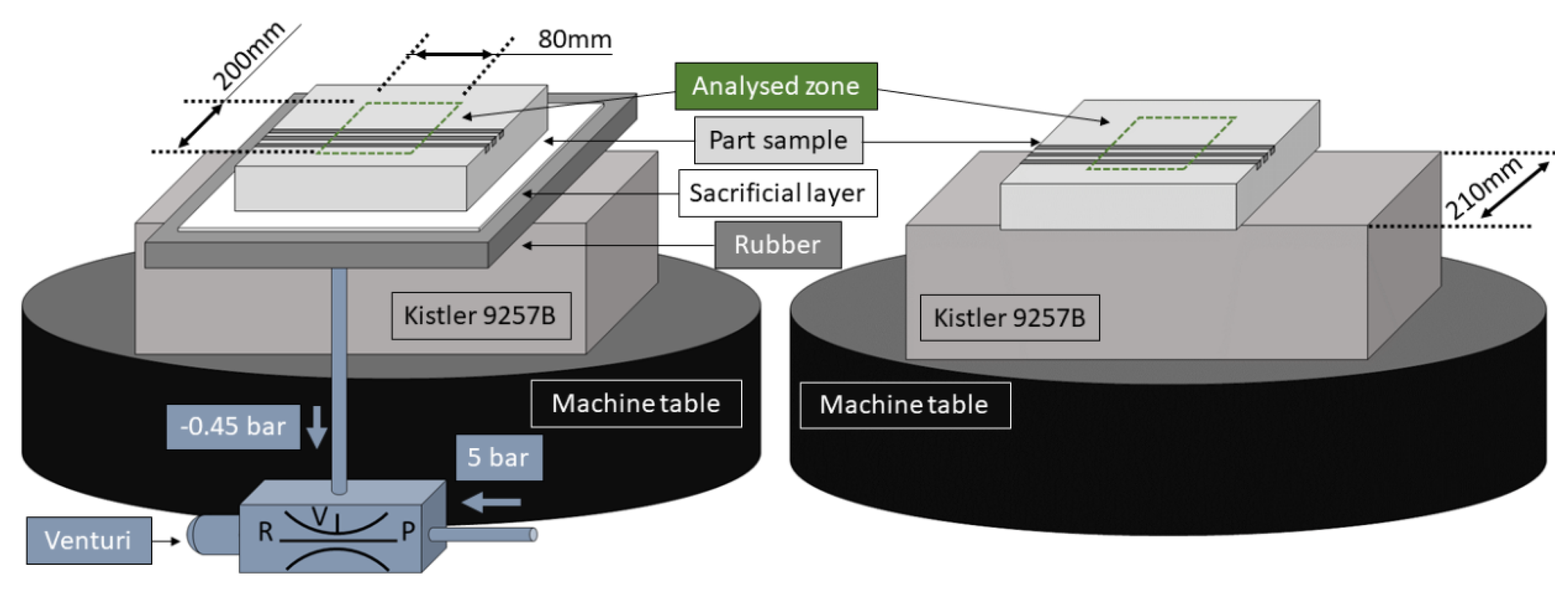

2.2. Milling Tests

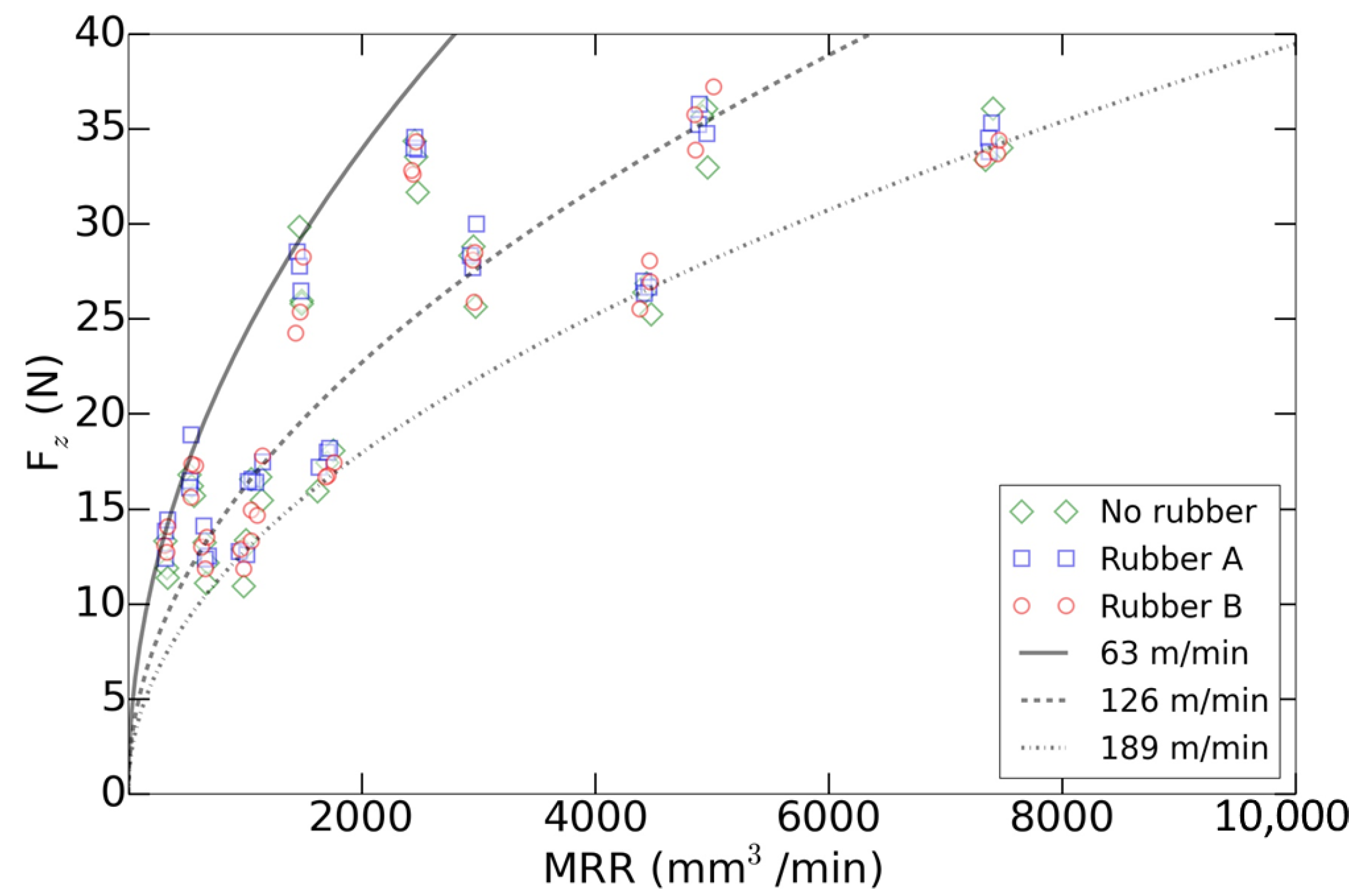

2.3. Force Mechanistic Model in the Tool Axis Direction with a Bull-Nose Mill

3. Results

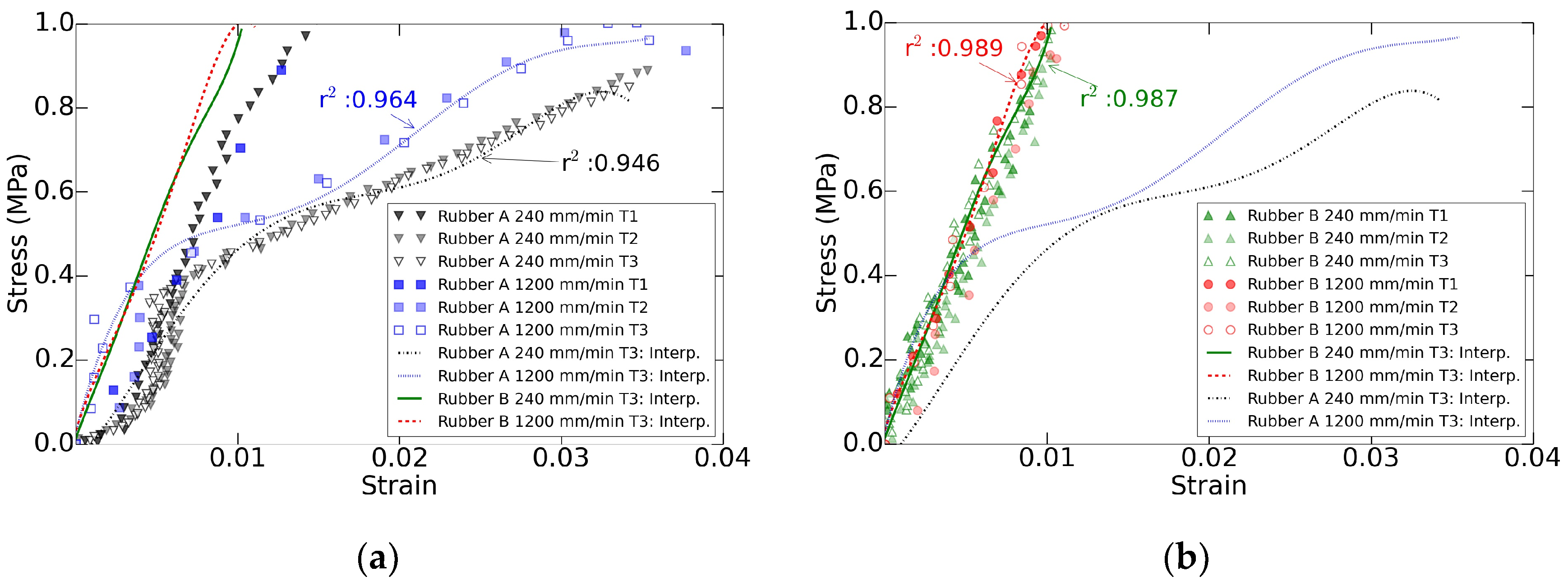

3.1. Rubbers Compressive Behaviour

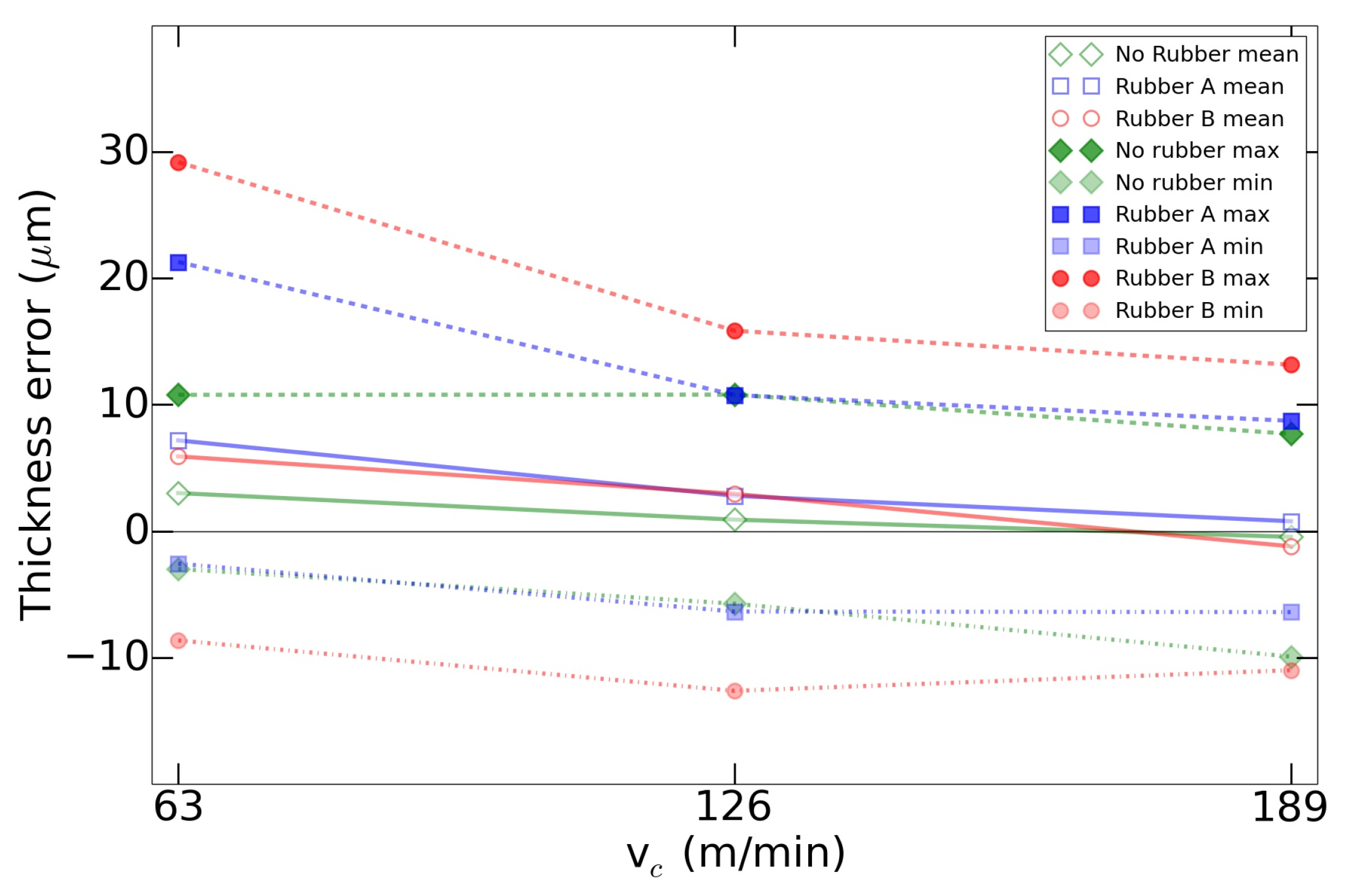

3.2. Thickness Error

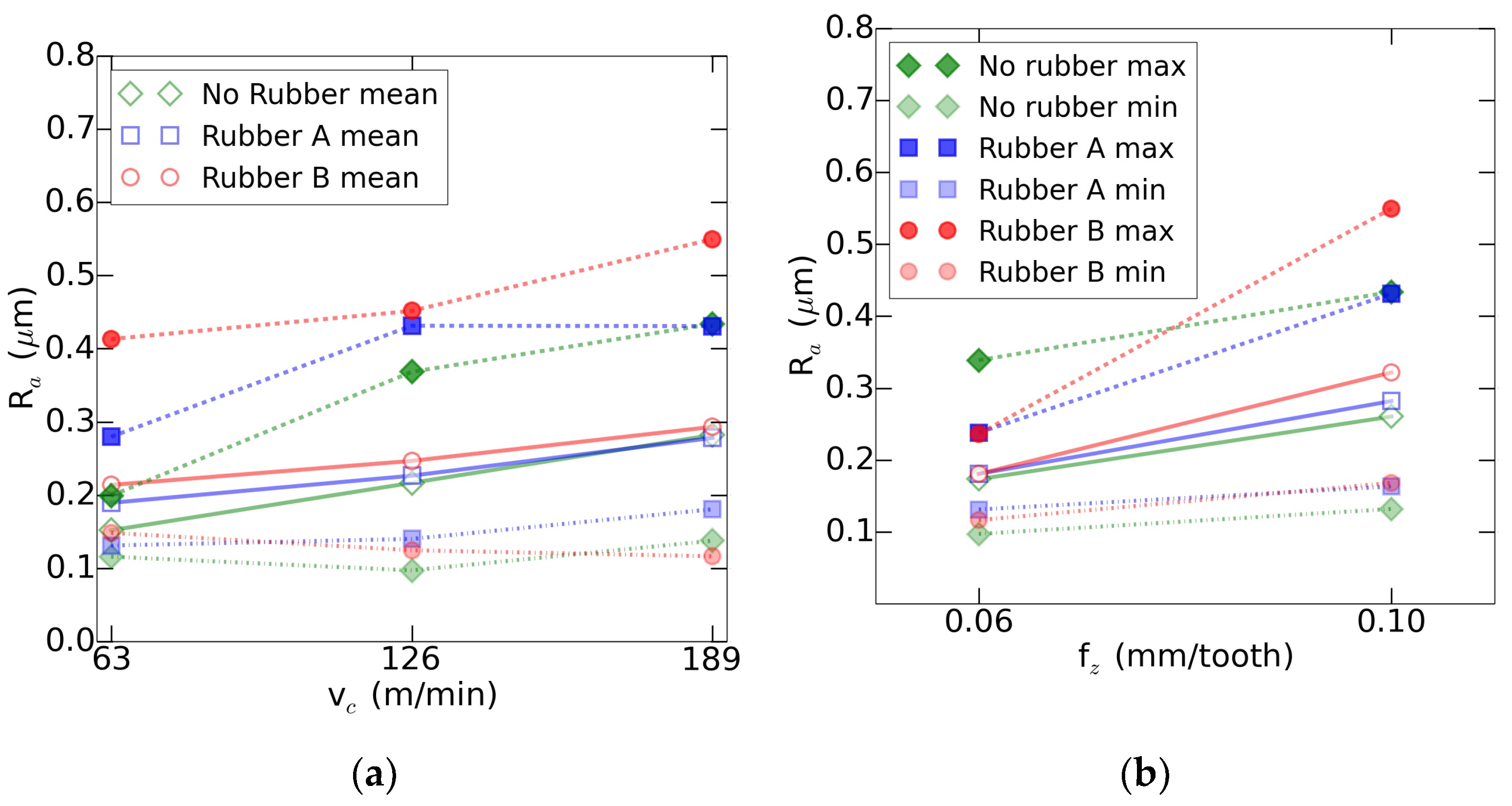

3.3. Roughness

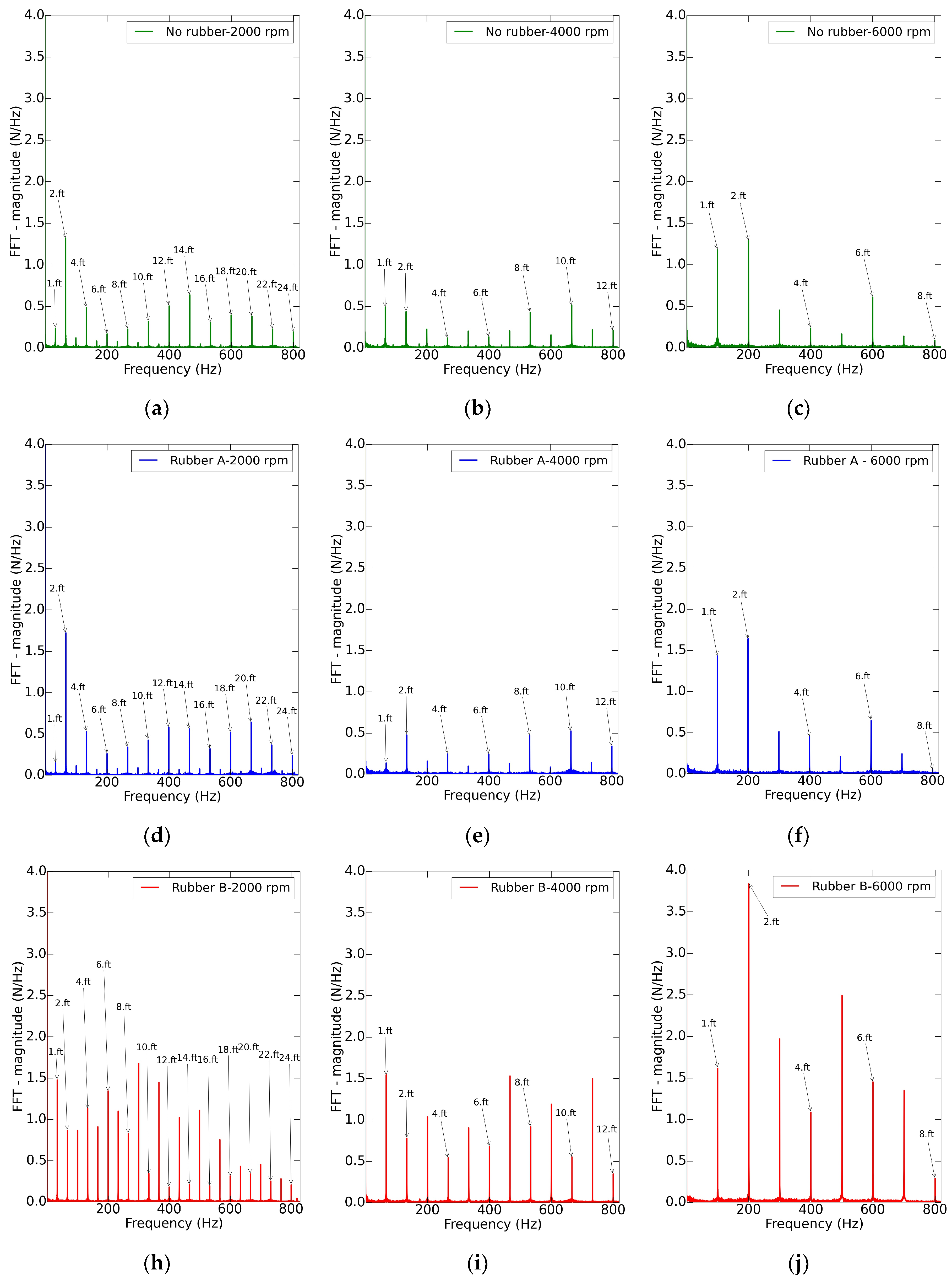

3.4. Force Model

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Herranz, S.; Campa, F.J.; De Lacalle, L.L.; Rivero, A.; Lamikiz, A.; Ukar, E.; Sánchez, J.A.; Bravo, U. The milling of airframe components with low rigidity: A general approach to avoid static and dynamic problems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2005, 219, 789–801. [Google Scholar] [CrossRef]

- Del Sol, I.; Rivero, A.; López de Lacalle, L.N.; Gamez, A.J. Thin-Wall Machining of Light Alloys: A Review of Models and Industrial Approaches. Materials 2019, 12, 2012. [Google Scholar] [CrossRef]

- Chen, W.; Xue, J.; Tang, D.; Chen, H.; Qu, S. Deformation prediction and error compensation in multilayer milling processes for thin-walled parts. Int. J. Mach. Tools Manuf. 2009, 49, 859–864. [Google Scholar] [CrossRef]

- Yue, C.; Gao, H.; Liu, X.; Liang, S.Y.; Wang, L. A review of chatter vibration research in milling. Chin. J. Aeronaut. 2019, 32, 215–242. [Google Scholar] [CrossRef]

- Eynian, M. Vibration frequencies in stable and unstable milling. Int. J. Mach. Tools Manuf. 2015, 90, 44–49. [Google Scholar] [CrossRef]

- Gurdal, O.; Ozturk, E.; Sims, N.D. Analysis of Process Damping in Milling. Procedia CIRP 2016, 55, 152–157. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Wang, J.-J.J. A pole/zero cancellation approach to reducing forced vibration in end milling. Int. J. Mach. Tools Manuf. 2010, 50, 601–610. [Google Scholar] [CrossRef]

- Perez, I.; Madariaga, A.; Cuesta, M.; Garay, A.; Arrazola, P.J.; Ruiz, J.J.; Rubio, F.J.; Sanchez, R. Effect of cutting speed on the surface integrity of face milled 7050-T7451 aluminium workpieces. Procedia CIRP 2018, 71, 460–465. [Google Scholar] [CrossRef]

- Campa, F.J.; Lopez de Lacalle, L.N.; Celaya, A. Chatter avoidance in the milling of thin floors with bull-nose end mills: Model and stability diagrams. Int. J. Mach. Tools Manuf. 2011, 51, 43–53. [Google Scholar] [CrossRef]

- Altintaş, Y.; Budak, E. Analytical Prediction of Stability Lobes in Milling. CIRP Ann. 1995, 44, 357–362. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Wang, J.-J.J. Effects of cutting conditions on dynamic cutting factor and process damping in milling. Int. J. Mach. Tools Manuf. 2011, 51, 320–330. [Google Scholar] [CrossRef]

- Gameros, A.; Lowth, S.; Axinte, D.; Nagy-Sochacki, A.; Craig, O.; Siller, H.R. State-of-the-art in fixture systems for the manufacture and assembly of rigid components: A review. Int. J. Mach. Tools Manuf. 2017, 123, 1–21. [Google Scholar] [CrossRef]

- Butt, M.A.; Yang, Y.; Pei, X.; Liu, Q. Five-axis milling vibration attenuation of freeform thin-walled part by eddy current damping. Precis. Eng. 2018, 51, 682–690. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, D.; Liu, Q. Milling vibration attenuation by eddy current damping. Int. J. Adv. Manuf. Technol. 2015, 81, 445–454. [Google Scholar] [CrossRef]

- Fei, J.; Lin, B.; Yan, S.; Ding, M.; Xiao, J.; Zhang, J.; Zhang, X.; Ji, C.; Sui, T. Chatter mitigation using moving damper. J. Sound Vib. 2017, 410, 49–63. [Google Scholar] [CrossRef]

- Matsubara, A.; Taniyama, Y.; Wang, J.; Kono, D. Design of a support system with a pivot mechanism for suppressing vibrations in thin-wall milling. CIRP Ann. 2017, 66, 381–384. [Google Scholar] [CrossRef]

- Zhang, Y.; Sims, N.D. Milling workpiece chatter avoidance using piezoelectric active damping: A feasibility study. Smart Mater. Struct. 2005, 14, N65. [Google Scholar] [CrossRef]

- Wang, M.; Fei, R. Chatter suppression based on nonlinear vibration characteristic of electrorheological fluids. Int. J. Mach. Tools Manuf. 1999, 39, 1925–1934. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, D.; Wu, B.; Luo, M.; Chen, B. Vibration suppression of thin-walled workpiece machining considering external damping properties based on magnetorheological fluids flexible fixture. Chin. J. Aeronaut. 2016, 29, 1074–1083. [Google Scholar] [CrossRef]

- Yang, Y.; Xie, R.; Liu, Q. Design of a passive damper with tunable stiffness and its application in thin-walled part milling. Int. J. Adv. Manuf. Technol. 2017, 89, 2713–2720. [Google Scholar] [CrossRef]

- Shoyama, T.; Fujimoto, K. Direct measurement of high-frequency viscoelastic properties of pre-deformed rubber. Polym. Test. 2018, 67, 399–408. [Google Scholar] [CrossRef]

- Chung, D.D.L. Review: Materials for vibration damping. J. Mater. Sci. 2001, 36, 5733–5737. [Google Scholar] [CrossRef]

- Ge, C.; Rice, B. Impact damping ratio of a nonlinear viscoelastic foam. Polym. Test. 2018, 72, 187–195. [Google Scholar] [CrossRef]

- Albooyeh, A.R. The effect of addition of Multiwall Carbon Nanotubes on the vibration properties of Short Glass Fiber reinforced polypropylene and polypropylene foam composites. Polym. Test. 2019, 74, 86–98. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, J.; Zhao, D.; Lu, Y.; Wang, W.; Zhang, L.; Nishi, T. Natural rubber/nitrile butadiene rubber/hindered phenol composites with high-damping properties. Int. J. Smart Nano Mater. 2015, 6, 239–250. [Google Scholar] [CrossRef][Green Version]

- Shit, S.C.; Shah, P. A Review on Silicone Rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Kolluru, K.; Axinte, D. Novel ancillary device for minimising machining vibrations in thin wall assemblies. Int. J. Mach. Tools Manuf. 2014, 85, 79–86. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Song, Q.; Wang, B. Analysis and implementation of chatter frequency dependent constrained layer damping tool holder for stability improvement in turning process. J. Mater. Process. Technol. 2019, 266, 687–695. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S.; Ahmed, R.; Teodoriu, C. Review of elastomer seal assemblies in oil & gas wells: Performance evaluation, failure mechanisms, and gaps in industry standards. J. Pet. Sci. Eng. 2019, 179, 1046–1062. [Google Scholar] [CrossRef]

- Mitra, S.; Ghanbari-Siahkali, A.; Almdal, K. A novel method for monitoring chemical degradation of crosslinked rubber by stress relaxation under tension. Polym. Degrad. Stab. 2006, 91, 2520–2526. [Google Scholar] [CrossRef]

- Da Rocha, E.B.D.; Linhares, F.N.; Gabriel, C.F.S.; De Sousa, A.M.F.; Furtado, C.R.G. Stress relaxation of nitrile rubber composites filled with a hybrid metakaolin/carbon black filler under tensile and compressive forces. Appl. Clay Sci. 2018, 151, 181–188. [Google Scholar] [CrossRef]

- Mallipudi, P.K.; Ramanaiah, N. Effect of Carbon Black on the Performance of Nitrile Rubber For Analyzing Free Layered Surface Damping Treatment. Mater. Today Proc. 2019, 18, 3371–3379. [Google Scholar] [CrossRef]

- Olsson, A.K. Finite Element Procedures in Modelling the Dynamic Properties of Rubber; Department of Construction Sciences, Structural Mechanics, Lund University: Lund, Sweden, 2007. [Google Scholar]

- Mullins, L. Softening of Rubber by Deformation. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Balasubramanian, P.; Ferrari, G.; Amabili, M. Identification of the viscoelastic response and nonlinear damping of a rubber plate in nonlinear vibration regime. Mech. Syst. Signal Process. 2018, 111, 376–398. [Google Scholar] [CrossRef]

- Austrell, P.-E.; Olsson, A.K. Modelling procedures and properties of rubber in rolling contact. Polym. Test. 2013, 32, 306–312. [Google Scholar] [CrossRef]

- ASTM D 395. Standard test method for rubber. In Philadelphia: Annual Book of ASTM Standards; American Society for Testing and Materials: West Conshohocken, PA, USA, 1955. [Google Scholar]

- Del Sol, I.; Rivero, A.; Salguero, J.; Fernández-Vidal, S.R.; Marcos, M. Tool-path effect on the geometric deviations in the machining of UNS A92024 aeronautic skins. Procedia Manuf. 2017, 13, 639–646. [Google Scholar] [CrossRef][Green Version]

- Del Sol, I.; Rivero, A.; Gamez, A.J. Effects of Machining Parameters on the Quality in Machining of Aluminium Alloys Thin Plates. Metals 2019, 9, 927. [Google Scholar] [CrossRef]

- Engin, S.; Altintas, Y. Mechanics and dynamics of general milling cutters.: Part I: Helical end mills. Int. J. Mach. Tools Manuf. 2001, 41, 2195–2212. [Google Scholar] [CrossRef]

- Altintas, Y. Analytical Prediction of Three Dimensional Chatter Stability in Milling. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2001, 44, 717–723. [Google Scholar] [CrossRef]

- Chen, J.-S.; Hsu, W.-Y. Characterizations and models for the thermal growth of a motorized high speed spindle. Int. J. Mach. Tools Manuf. 2003, 43, 1163–1170. [Google Scholar] [CrossRef]

- Ratchev, S.; Liu, S.; Huang, W.; Becker, A.A. Milling error prediction and compensation in machining of low-rigidity parts. Int. J. Mach. Tools Manuf. 2004, 44, 1629–1641. [Google Scholar] [CrossRef]

- Rubio-Mateos, A.; Rivero, A.; del Sol, I.; Ukar, E.; Lamikiz, A. Capacitation of flexibles fixtures for its use in high quality machining processes: An application case of the industry 4.0. paradigm. DYNA 2018, 93, 608–612. [Google Scholar] [CrossRef]

- Bi, Q.; Huang, N.; Zhang, S.; Shuai, C.; Wang, Y. Adaptive machining for curved contour on deformed large skin based on on-machine measurement and isometric mapping. Int. J. Mach. Tools Manuf. 2019, 136, 34–44. [Google Scholar] [CrossRef]

- De Lacalle, L.N.L.; Lamikiz, A.; Sánchez, J.A.; de Bustos, I.F. Recording of real cutting forces along the milling of complex parts. Mechatronics 2006, 16, 21–32. [Google Scholar] [CrossRef]

| Properties | Rubber A | Rubber B |

|---|---|---|

| Hardness (Sh·A) | 65 | 90 |

| Density (g/cm3) | 1.45 | 1.43 |

| Polymer (wt.%) | 37.3 | 54.6 |

| Carbon black (wt.%) | 3.5 | 14.4 |

| Other inorganic charges (wt.%) | 59.2 | 31.0 |

| Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Clamping material | Rubber A | Rubber B | No rubber |

| (mm) | 0.2 | 0.8 | - |

| (mm/tooth) | 0.06 | 0.1 | - |

| (rpm) | 2000 | 4000 | 6000 |

| (m/min) | 63 | 126 | 189 |

| (mm/min) | 240; 400 | 480; 800 | 720; 1200 |

| Analysis | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| Normal distribution | AD | 0.276 | 0.322 | 0.447 |

| p-value | 0.628 | 0.510 | 0.257 | |

| Homogeneity of variance | Bartlett’s | 4.480 | 5.160 | 2.310 |

| p-value | 0.723 | 0.640 | 0.941 |

| Factor | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| F-value | 7.040 | 3.200 | 1.990 | |

| p-value | 0.017 | 0.093 | 0.178 | |

| F-value | 0.680 | 0.430 | 0.350 | |

| p-value | 0.420 | 0.520 | 0.562 | |

| F-value | 1.540 | 1.940 | 0.050 | |

| p-value | 0.233 | 0.182 | 0.830 | |

| F-value | 0.000 | 0.080 | 0.090 | |

| p-value | 0.990 | 0.787 | 0.770 | |

| F-value | 0.300 | 0.090 | 0.140 | |

| p-value | 0.593 | 0.774 | 0.716 | |

| F-value | 0.540 | 0.280 | 0.060 | |

| p-value | 0.475 | 0.606 | 0.804 | |

| F-value | 1.200 | 0.010 | 0.350 | |

| p-value | 0.289 | 0.936 | 0.563 |

| Analysis | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| Normal distribution | AD | 0.251 | 0.497 | 0.305 |

| p-value | 0.694 | 0.181 | 0.528 | |

| Homogeneity of variance | Bartlett’s | 3.400 | 12.750 | 5.510 |

| p-value | 0.846 | 0.078 | 0.599 |

| Factor | Parameter | Rubber A | Rubber B | No Rubber |

|---|---|---|---|---|

| F-value | 54.100 | 2.880 | 17.360 | |

| p-value | 0.000 | 0.128 | 0.003 | |

| F-value | 42.240 | 13.910 | 4.850 | |

| p-value | 0.000 | 0.006 | 0.059 | |

| F-value | 0.820 | 2.690 | 0.790 | |

| p-value | 0.391 | 0.140 | 0.399 | |

| F-value | 16.740 | 2.280 | 2.990 | |

| p-value | 0.003 | 0.170 | 0.122 | |

| F-value | 1.070 | 0.110 | 0.590 | |

| p-value | 0.331 | 0.746 | 0.464 | |

| F-value | 8.320 | 0.460 | 0.040 | |

| p-value | 0.020 | 0.519 | 0.844 | |

| F-value | 0.450 | 0.000 | 0.100 | |

| p-value | 0.521 | 0.994 | 0.755 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubio-Mateos, A.; Rivero, A.; Ukar, E.; Lamikiz, A. Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations. Metals 2020, 10, 289. https://doi.org/10.3390/met10020289

Rubio-Mateos A, Rivero A, Ukar E, Lamikiz A. Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations. Metals. 2020; 10(2):289. https://doi.org/10.3390/met10020289

Chicago/Turabian StyleRubio-Mateos, Antonio, Asuncion Rivero, Eneko Ukar, and Aitzol Lamikiz. 2020. "Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations" Metals 10, no. 2: 289. https://doi.org/10.3390/met10020289

APA StyleRubio-Mateos, A., Rivero, A., Ukar, E., & Lamikiz, A. (2020). Influence of Elastomer Layers in the Quality of Aluminum Parts on Finishing Operations. Metals, 10(2), 289. https://doi.org/10.3390/met10020289