Research Status and Progress of Welding Technologies for Molybdenum and Molybdenum Alloys

Abstract

:1. Introduction

2. Analysis on Weldability of Mo and Mo Alloy

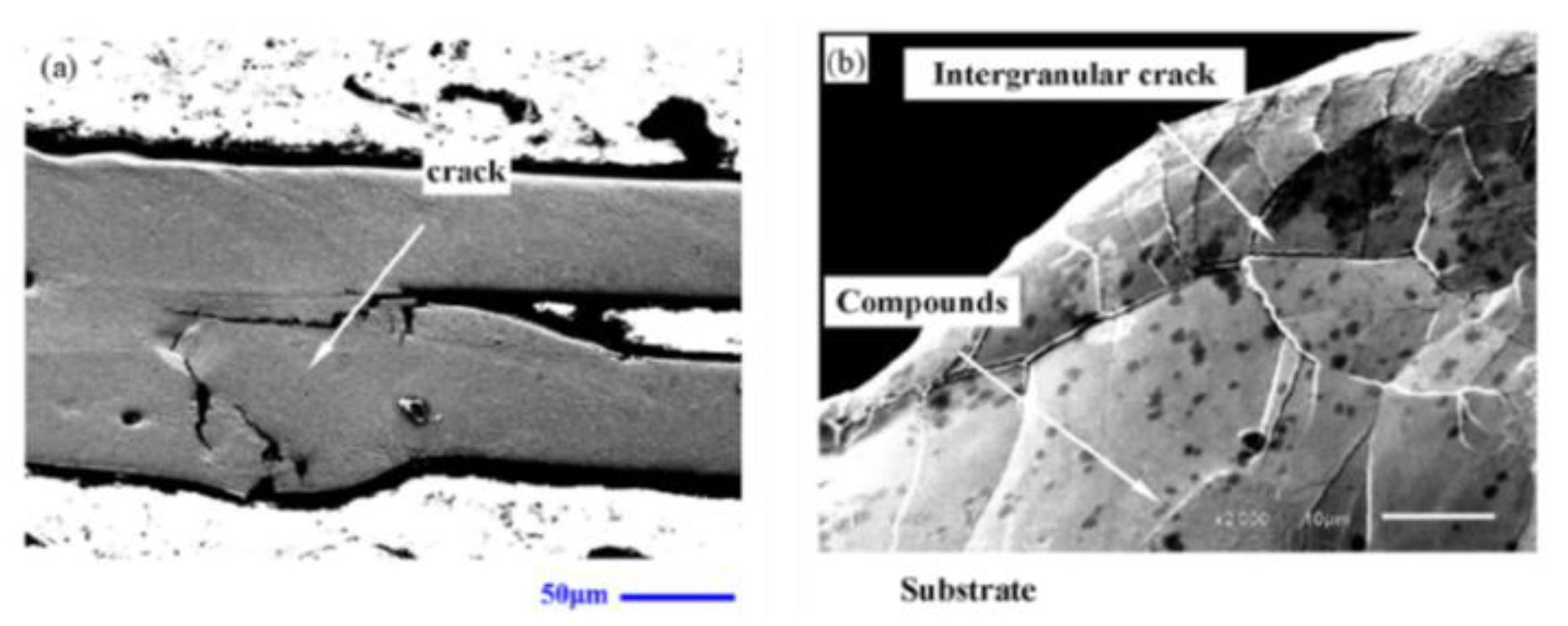

2.1. Room-Temperature Brittleness

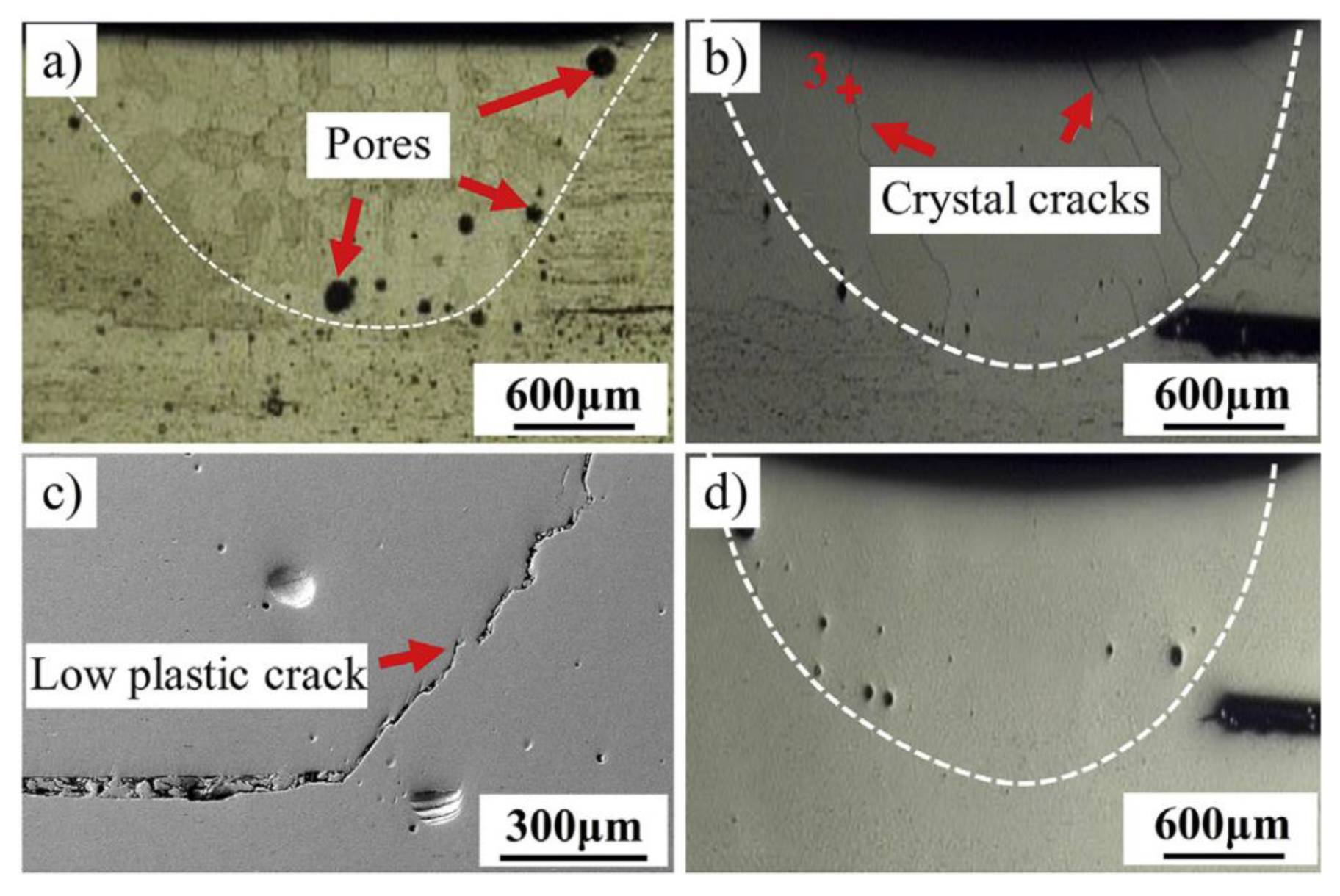

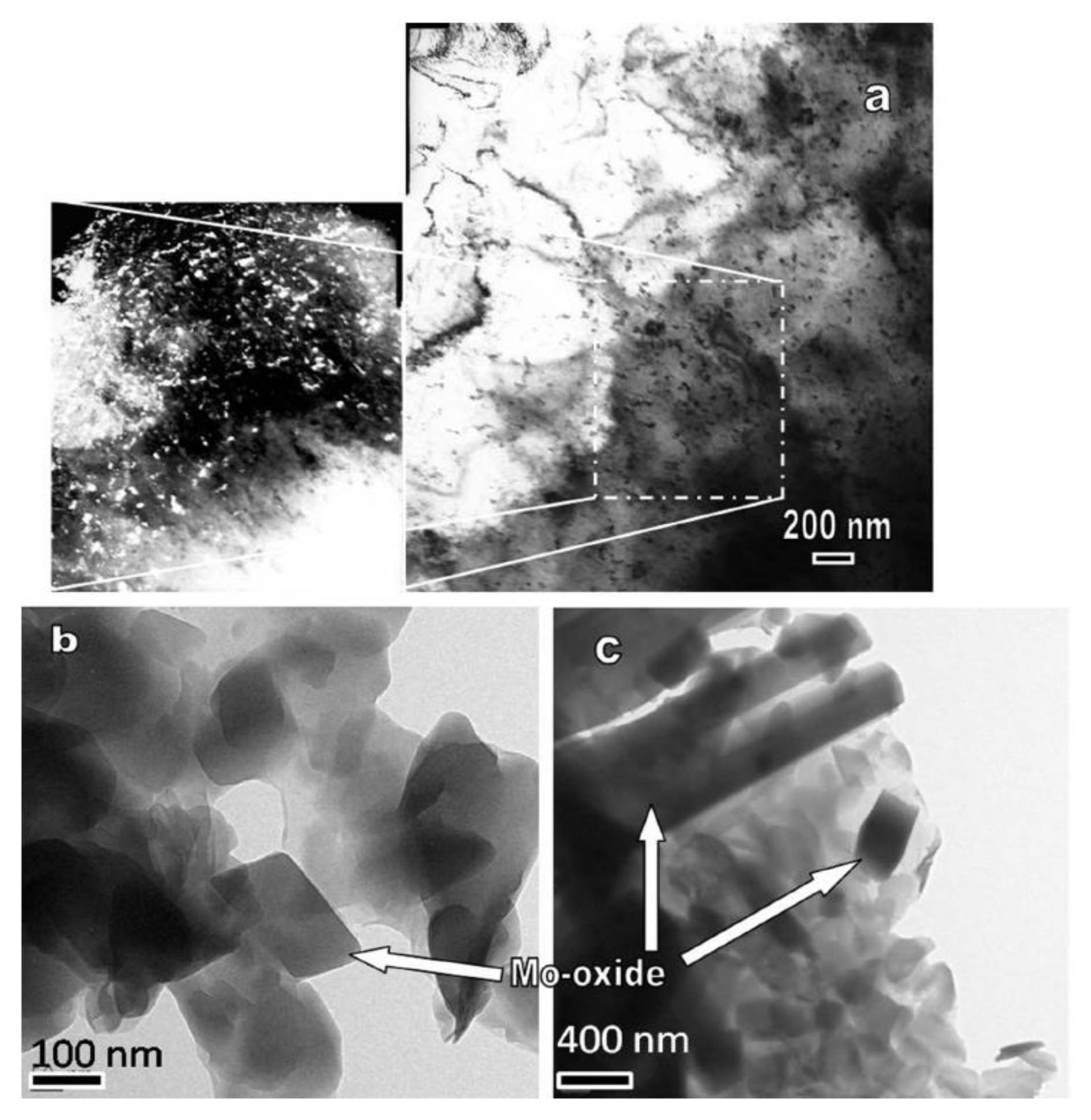

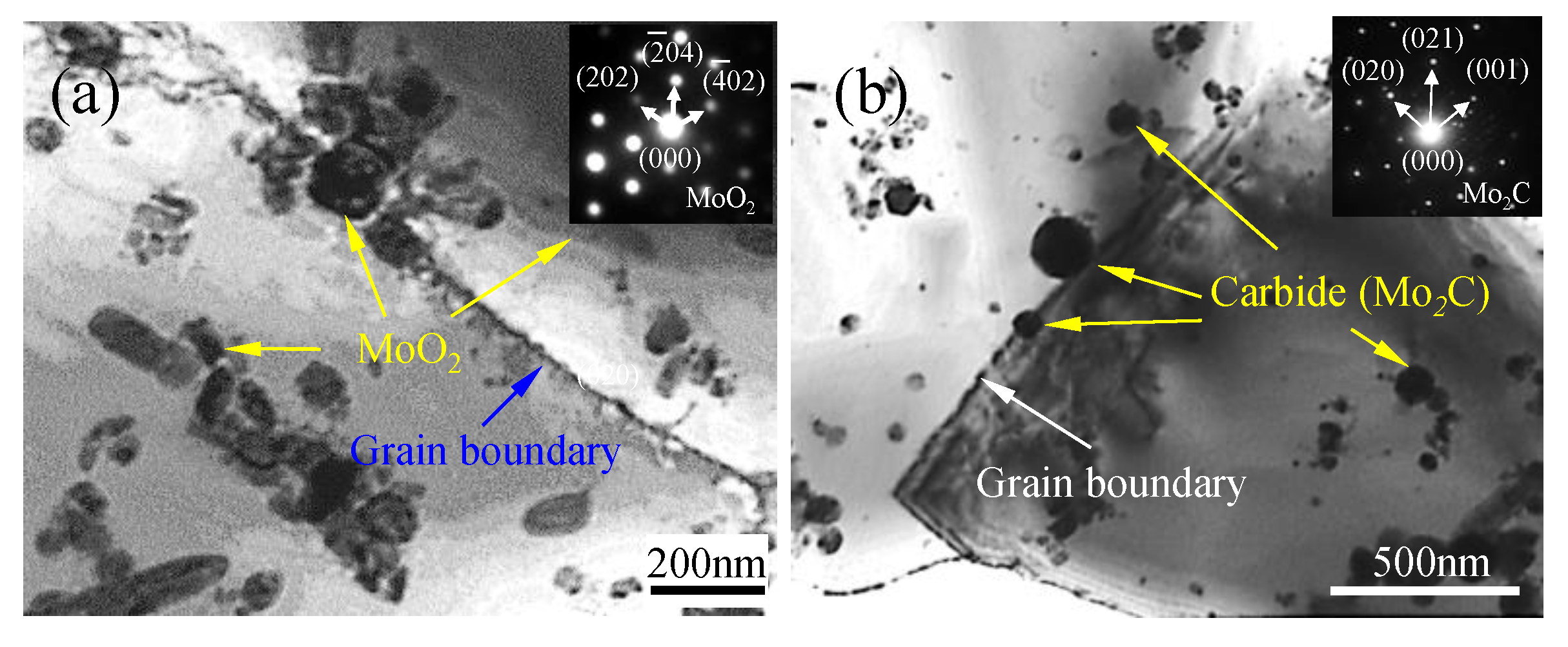

2.2. Pore Defects

3. Research Progress in Welding of Mo and Mo Alloys

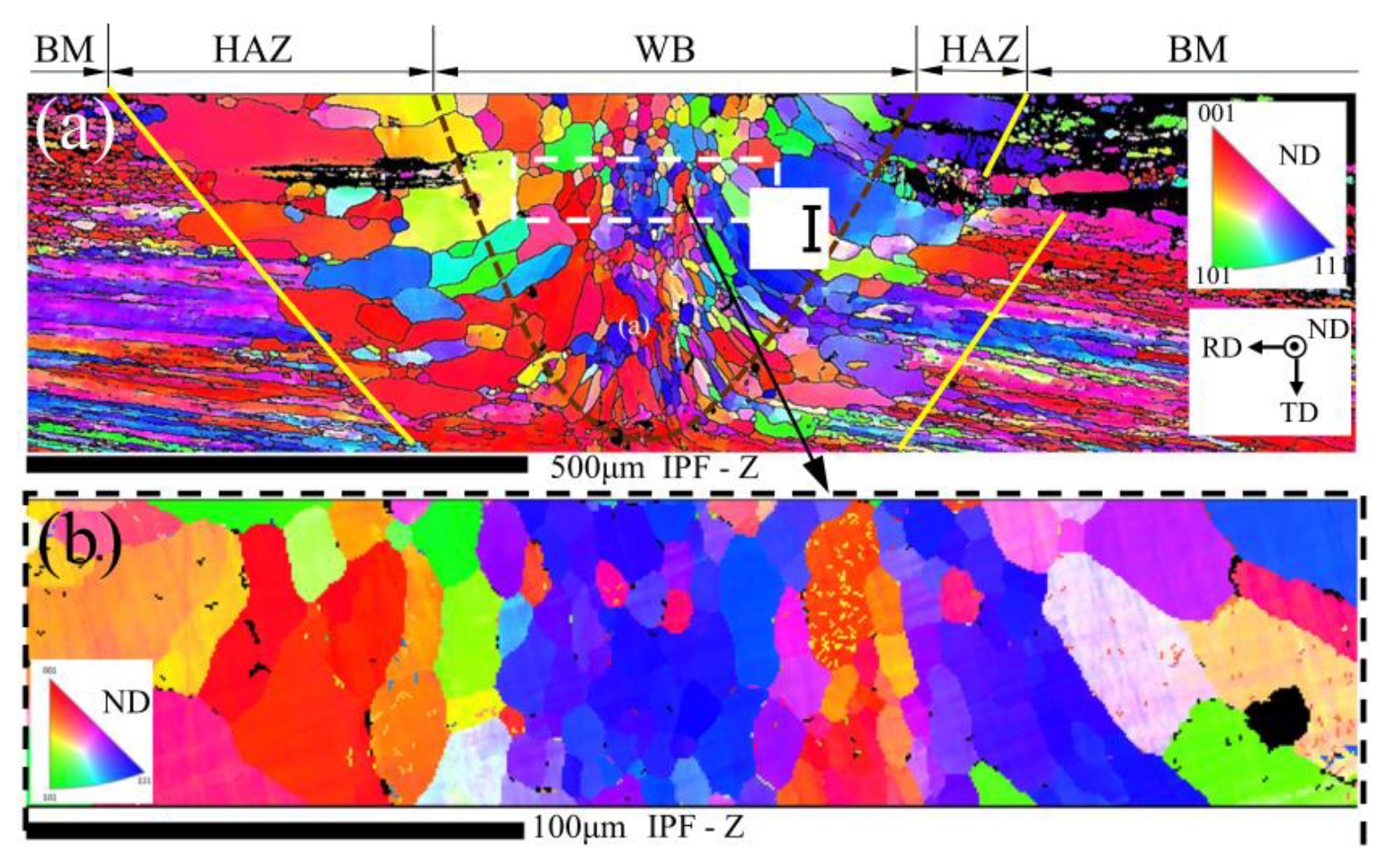

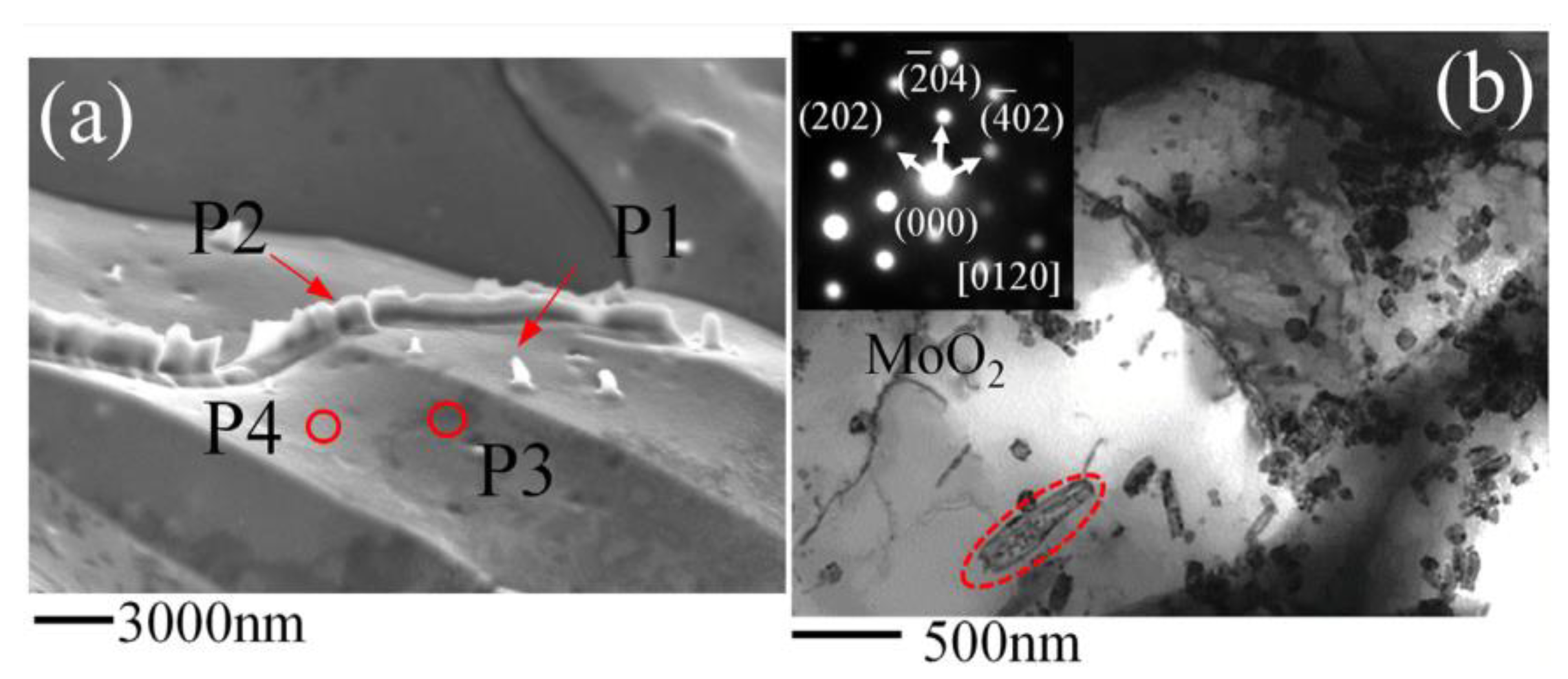

3.1. EBW

3.2. TIG Welding

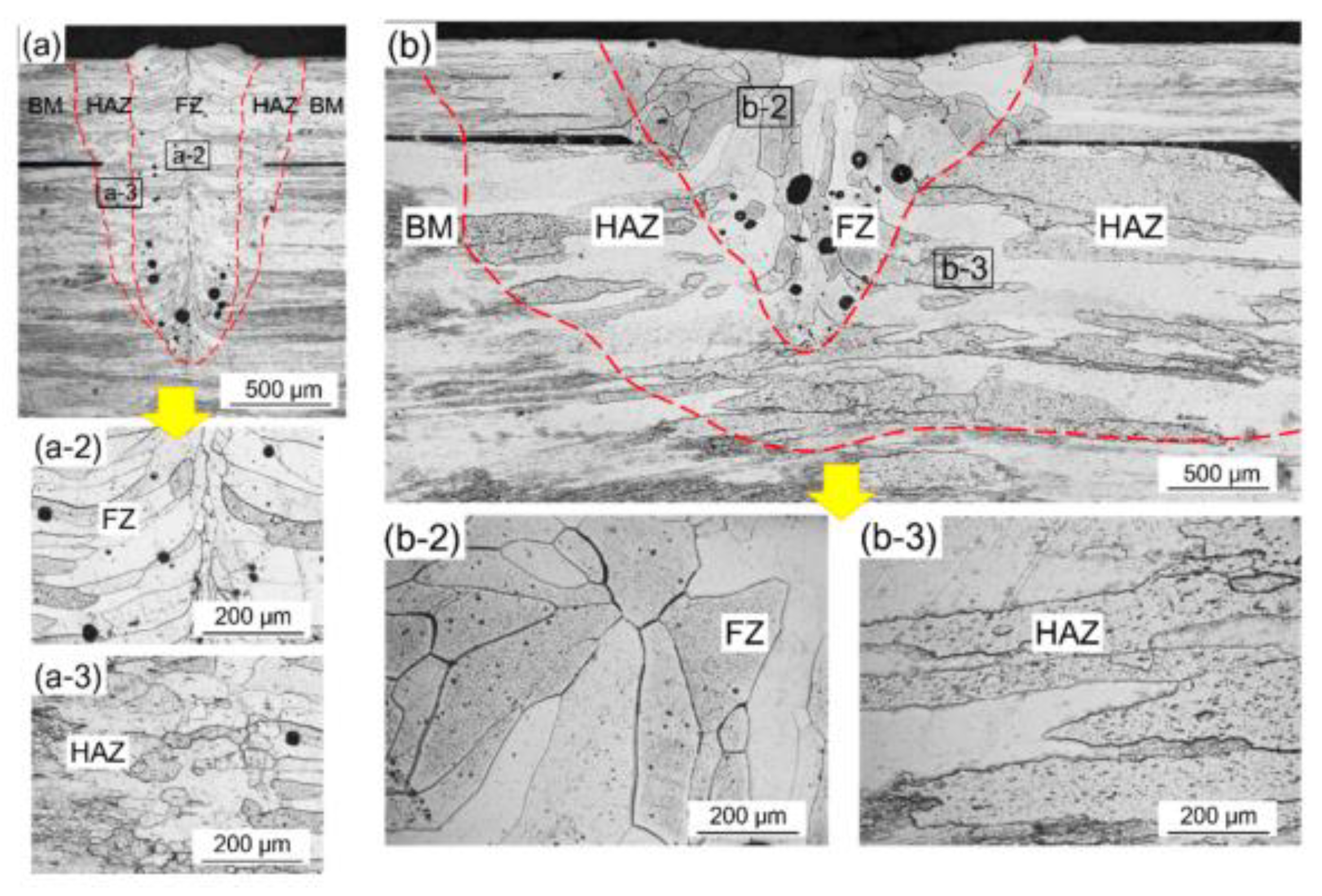

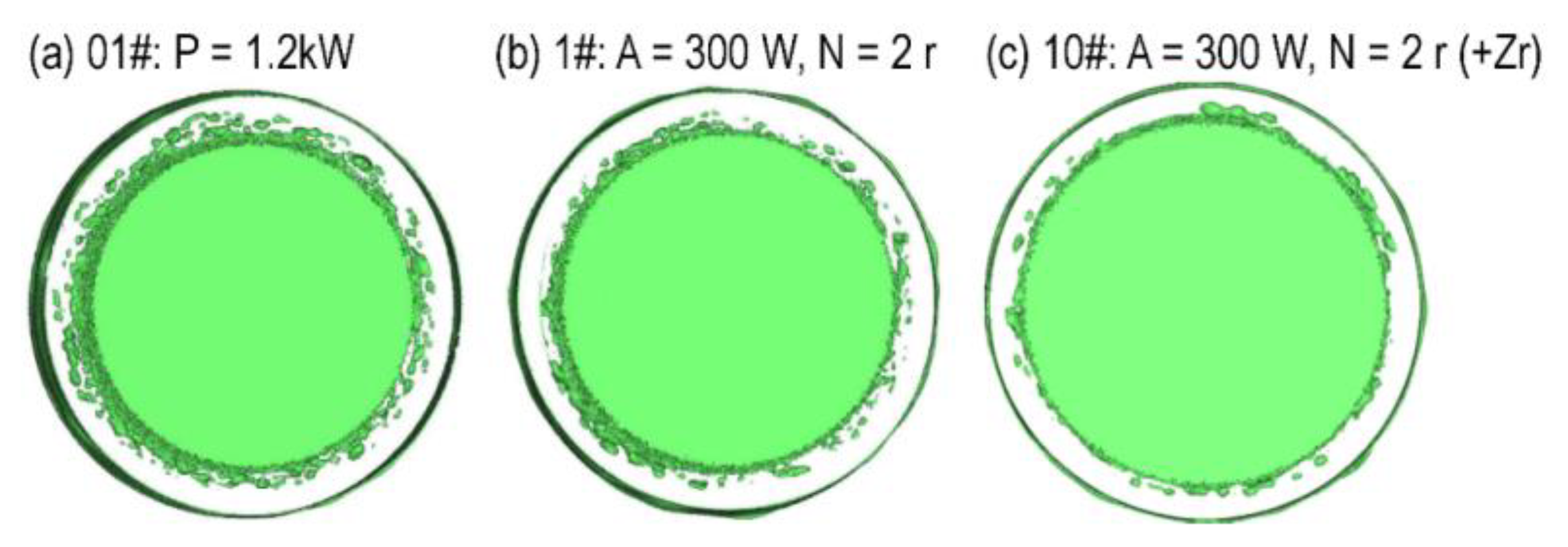

3.3. Laser Welding

3.4. ERW

3.5. Brazing

3.6. Friction Welding

4. Summary and Prospects

4.1. Advantages and Disadvantages of Various Methods for Welding Mo and Mo Alloys

4.2. Demands and Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Doane, D.V.; Timmons, G.A.; Hallada, C.J. Molybdenum and Molybdenum Alloys. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley Sons, Inc.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Scott, M.; Knowlson, P. The welding and brazing of the refractory metals niobium, tantalum, molybdenum and tungsten—A review. J. Less Common Met. 1963, 5, 205–244. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, G. Pulsed Nd:YAG laser fine spot welding for attachment of refractory mini-pins. SPIE LASE 2013, 8608, 885–905. [Google Scholar]

- Kramer, D.P.; Mcdougal, J.R.; Booher, B.A.; Ruhkamp, J.D. Electron beam and Nd-YAG laser welding of niobium-1% zirconium and molybdenum-44.5% rhenium thin select material. In Proceedings of the Energy Conversion Engineering Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; Volume 2, pp. 956–961. [Google Scholar]

- Chatterjee, A.; Kumar, S.; Tewari, R.; Dey, G.K. Welding of mo-based alloy using electron beam and laser-gtaw hybrid welding techniques. Metall. Mater. Trans. A 2016, 47, 1–10. [Google Scholar] [CrossRef]

- Ott, L.; Robb, K.; Wang, D. Corrigendum to “Preliminary assessment of accident-tolerant fuels on LWR performance during normal operation and under DB and BDB accident conditions” [J. Nucl. Mater. 448 (2014) 520–533]. J. Nucl. Mater. 2015, 461, 178–179. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Pei, J.-Y.; Zhang, L.-L.; Long, J.; Zhang, J.-X.; Na, S.-J.; Zhang, L.-J.; Pei, J.-Y.; Liang-Liang, Z. Laser seal welding of end plug to thin-walled nanostructured high-strength molybdenum alloy cladding with a zirconium interlayer. J. Mater. Process. Technol. 2019, 267, 338–347. [Google Scholar] [CrossRef]

- Pint, B.A.; Terrani, K.A.; Yamamoto, Y.; Snead, L.L. Material Selection for Accident Tolerant Fuel Cladding. Met. Mater. Trans. E 2015, 2, 190–196. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.-L.; Zhang, L.-J.; Long, J.; Sun, X.; Zhang, J.-X.; Na, S.-J. Enhanced mechanical performance of fusion zone in laser beam welding joint of molybdenum alloy due to solid carburizing. Mater. Des. 2019, 181, 107957. [Google Scholar] [CrossRef]

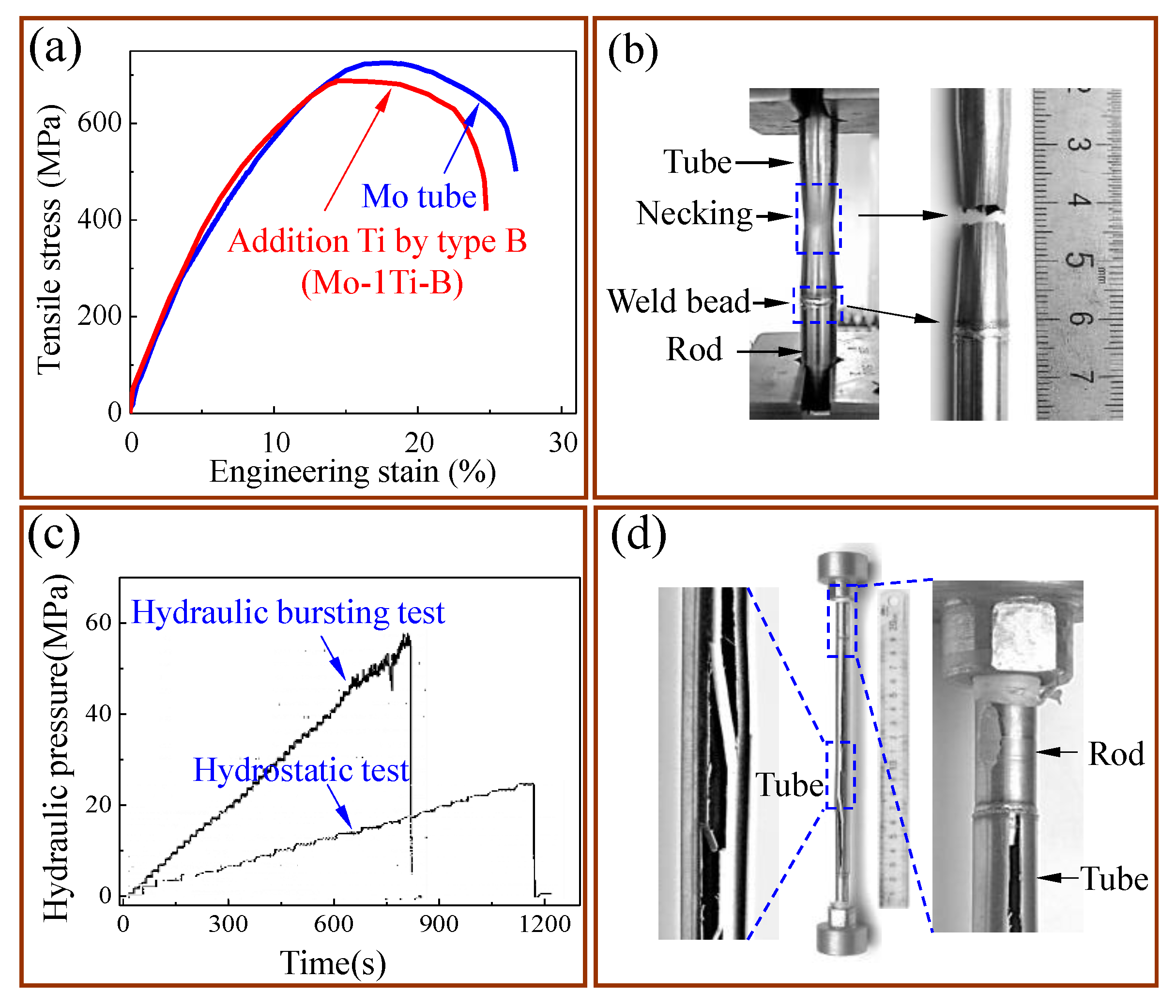

- Zhang, L.-L.; Zhang, L.-J.; Long, J.; Ning, J.; Zhang, J.-X.; Na, S.-J. Effects of titanium on grain boundary strength in molybdenum laser weld bead and formation and strengthening mechanisms of brazing layer. Mater. Des. 2019, 169, 107681. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Liu, J.-Z.; Pei, J.-Y.; Ning, J.; Zhang, L.-L.; Long, J.; Zhang, G.-F.; Zhang, J.-X.; Na, S.-J. Effects of Power Modulation, Multipass Remelting and Zr Addition Upon Porosity Defects in Laser Seal Welding of End Plug to Thin-Walled Molybdenum Alloy. J. Manuf. Process. 2019, 41, 197–207. [Google Scholar] [CrossRef]

- Xie, M.X.; Li, Y.X.; Shang, X.T.; Wang, X.W.; Pei, J.Y. Microstructure and Mechanical Properties of a Fiber Welded Socket-Joint Made of Powder Metallurgy Molybdenum Alloy. Metals 2019, 9, 640. [Google Scholar] [CrossRef] [Green Version]

- Xie, M.-X.; Li, Y.-X.; Shang, X.-T.; Wang, X.; Pei, J.-Y. Effect of Heat Input on Porosity Defects in a Fiber Laser Welded Socket-Joint Made of Powder Metallurgy Molybdenum Alloy. Materials 2019, 12, 1433. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, T.-L.; Wang, T.-L.; Pan, M.-L.; Le, H.-L.; Le, C.-T. Electron-beam welding of molybdenum. J. Tsinghua Univ. (Sci. Technol.) 1964, 2, 15–34. [Google Scholar]

- Yang, Q.; Zhu, Q.; Wang, L.; Wang, N. Microstructure and Properties of Mo Plates by Electron Beam Welding. Hot Work. Technol. 2014, 13, 158–161. [Google Scholar]

- Zheng, W.; Liu, J.; Ma, Z. Vacuum electron beam welding trait of 16mm Molybdenum. Hot Work. Technol. 2012, 41, 153–154. [Google Scholar]

- Morito, F. Tensile properties and microstructures of electron beam welded molybdenum and TZM. J. Less Common Met. 1989, 146, 337–346. [Google Scholar] [CrossRef]

- Morito, F. Characteristics of EB-weldable molybdenum and Mo-Re alloys. JOM 1993, 45, 54–58. [Google Scholar] [CrossRef]

- Morito, F. Weldability and fracture of molybdenum-rhenium welds. Met. Powder Rep. 1998, 53, 46. [Google Scholar] [CrossRef]

- Morito, V.N. Slyunyaev Impurity-induced embrittlement of heat-affected zone in welded Mo-based alloys. Int. J. Refract. Met. Hard Mater. 1997, 15, 325–339. [Google Scholar]

- Stütz, M.; Oliveira, D.; Rüttinger, M.; Reheis, N.; Kestler, H.; Enzinger, N. Electron Beam Welding of TZM Sheets. Mater. Sci. Forum 2016, 879, 1865–1869. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Shu, X.; Zhang, B.; Feng, J. Study on microstructure and performance of molybdenum joint welded by electron beam. Vacuum 2018, 154, 1–5. [Google Scholar] [CrossRef]

- Chen, G.; Yin, Q.; Chen, G.; Zhang, B.; Feng, J. Beam deflection effects on the microstructure and defect creation on electron beam welding of molybdenum to Kovar. J. Mater. Process. Technol. 2019, 267, 280–288. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.P.; Zhang, X.Y. TZM molybdenum alloy TIG welding process and microstructure of welded joints. Heat Treat. Met. 2012, 37, 41–44. [Google Scholar]

- Qinglei, J.; Yajiang, L.; Puchkov, U.; Juan, W.; Chunzhi, X. Microstructure characteristics in TIG welded joint of Mo-Cu composite and 18-8 stainless steel. Int. J. Refract. Met. Hard Mater. 2010, 28, 429–433. [Google Scholar] [CrossRef]

- Wang, H. Effects of weld doping on weldability of commercial purity molybdenum. China Molybdenum Ind. 1995, 6, 20–22. [Google Scholar]

- Matsuda, F.; Ushio, M.; Nakata, K.; Edo, Y. Weldability of molybdenum and its alloy sheet (report i) (materials, metallurgy, weldability). Trans. Jwri 1979, 8, 217–229. [Google Scholar]

- Kolarikova, M.; Kolarik, L.; Vondrous, P. Welding of thin molybdenum sheets by EBW and GTAW. In Proceedings of the 23rd Ingernational DAAAM Symposium 2012, Zadar, Croatia, 24–27th October 2012; Volume 23, pp. 1005–1008. [Google Scholar]

- Liu, P.; Feng, K.Y.; Zhang, G.M. A novel study on laser lap welding of refractory alloy 50mo–50re of small-scale thin sheet. Vacuum 2016, 136, 10–13. [Google Scholar] [CrossRef]

- An, G.; Sun, J.; Sun, Y.; Cao, W.; Zhu, Q.; Bai, Q.; Zhang, L.-J. Fiber Laser Welding of Fuel Cladding and End Plug Made of La2O3 Dispersion-Strengthened Molybdenum Alloy. Materials 2018, 11, 1071. [Google Scholar] [CrossRef] [Green Version]

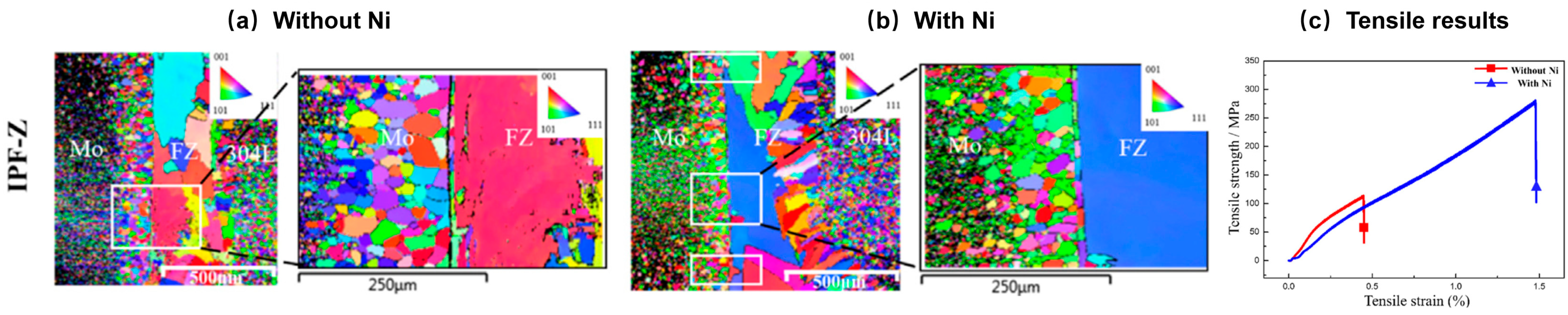

- Zhang, L.-J.; Wang, C.-H.; Zhang, Y.-B.; Guo, Q.; Ma, R.-Y.; Zhang, J.-X.; Na, S.-J. The mechanical properties and interface bonding mechanism of Molybdenum/SUS304L by laser beam welding with nickel interlayer. Mater. Des. 2019, 182, 108002. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, G.; Ning, J.; Zhang, L.; Long, J.; Zhang, G. Influence of Beam Offset on Dissimilar Laser Welding of Molybdenum to Titanium. Materials 2018, 11, 1852. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.-J.; Lu, G.; Ning, J.; Zhu, Q.; Zhang, J.-X.; Na, S.-J. Effects of minor Zr addition on the microstructure and mechanical properties of laser welded dissimilar joint of titanium and molybdenum. Mater. Sci. Eng. A 2019, 742, 788–797. [Google Scholar] [CrossRef]

- Lin, L.; Huang, Y.; Hao, K.; Chen, Y. Cracking in dissimilar laser welding of tantalum to molybdenum. Opt. Laser Technol. 2018, 102, 54–59. [Google Scholar]

- Ning, J.; Hong, K.; Inamke, G.; Shin, Y.; Zhang, L. Analysis of microstructure and mechanical strength of lap joints of TZM alloy welded by a fiber laser. J. Manuf. Process. 2019, 39, 146–159. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Liu, J.-Z.; Bai, Q.-L.; Wang, X.-W.; Sun, Y.-J.; Li, S.-G.; Gong, X. Effect of preheating on the microstructure and properties of fiber laser welded girth joint of thin-walled nanostructured Mo alloy. Int. J. Refract. Met. Hard Mater. 2019, 78, 219–227. [Google Scholar] [CrossRef]

- Gao, X.-L.; Li, L.-K.; Liu, J.; Wang, X.-Q.; Yu, H.-K. Effect of laser offset on microstructure and mechanical properties of laser welding of pure molybdenum to stainless steel. Int. J. Refract. Met. Hard Mater. 2020, 88, 105186. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, X.; Zeng, Q.; Zhai, T.; Leonhardt, T.; Farrell, J.; Umstead, W.; Effgen, M.P. Optimization of resistance spot welding on the assembly of refractory alloy 50Mo–50Re thin sheet. J. Nucl. Mater. 2007, 366, 417–425. [Google Scholar] [CrossRef]

- Ferrenz, E.E.; Amare, A.; Arumainayagam, C.R. An improved method to spot-weld difficult junctions. Rev. Sci. Instruments 2001, 72, 4474–4476. [Google Scholar] [CrossRef]

- Xia, C.; Wu, L.; Xu, X.; Zou, J. Phase constitution and fracture analysis of vacuum brazed joint of 50Mo-50Re refractory alloys. Vacuum 2017, 136, 97–100. [Google Scholar] [CrossRef]

- Song, X.G.; Tian, X.; Zhao, H.Y.; Si, X.Q.; Han, G.H.; Feng, J.C. Interfacial microstructure and joining properties of titanium-zirconium-molybdenum alloy joints brazed using ti-28ni eutectic brazing alloy. Mater. Sci. Eng. A 2015, 653, 115–121. [Google Scholar] [CrossRef]

- Fu, L.; Du, S. On exploring better friction welding joint of TZM Mo-Base powder alloy and H11 Mold Steel. J. Northwestern Polytech. Univ. 2001, 19, 557–561. [Google Scholar]

- Fujii, H.; Sun, Y.; Kato, H. Microstructure and mechanical properties of friction stir welded pure Mo joints. Scr. Mater. 2011, 64, 657–660. [Google Scholar] [CrossRef]

- Reheis, N.; Tabernig, B.; Kestler, H.; Sigl, L.S.; Pretis, D.D.; Enzinger, N. Friction Welding of TZM Components. In Proceedings of the World Congress on Powder Metallurgy and Particulate Materials, Orlando, FL, USA, 18–22 May 2014. [Google Scholar]

- Ambroziak, A. Friction welding of molybdenum to molybdenum and to other metals. Int. J. Refract. Met. Hard Mater. 2011, 29, 462–469. [Google Scholar] [CrossRef]

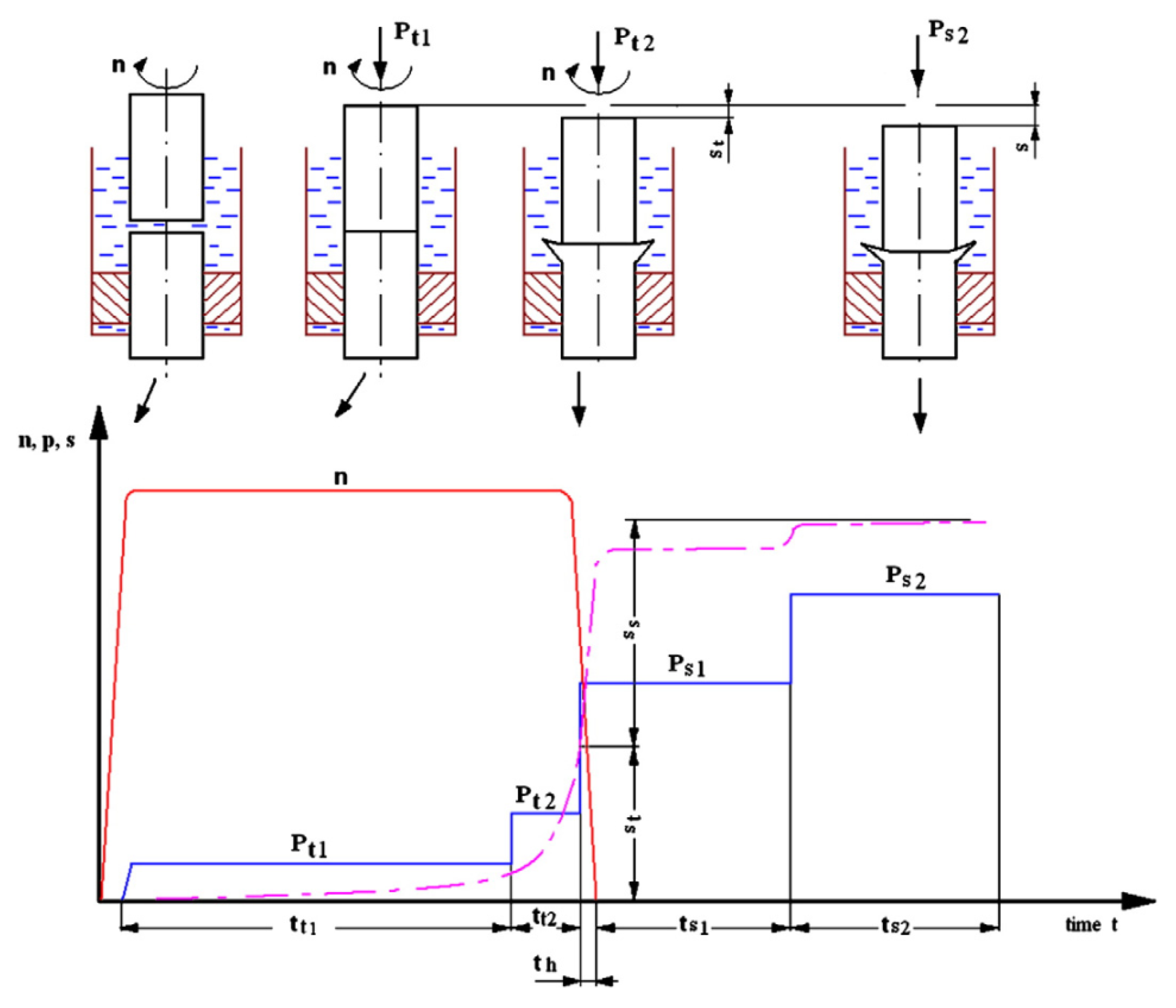

- Stütz, M.; Wagner, J.; Reheis, N.; Kestler, H.; Raiser, E.; Enzinger, N. Rotary Friction Welding of Large Molybdenum Tubes. In Proceedings of the International Conference on Trends in Welding Research, Tokyo, Japan, 11–14 October 2016. [Google Scholar]

- Stütz, M.; Pixner, F.; Wagner, J.; Reheis, N.; Raiser, E.; Kestler, H.; Enzinger, N. Rotary friction welding of molybdenum components. Int. J. Refract. Met. Hard Mater. 2018, 73, 79–84. [Google Scholar] [CrossRef]

- Stütz, M.; Buzolin, R.; Pixner, F.; Poletti, C.; Enzinger, N. Microstructure development of molybdenum during rotary friction welding. Mater. Charact. 2019, 151, 506–518. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Xie, M.; Shang, X.; An, G.; Sun, J.; Wang, N.; Xi, S.; Bu, C.; Zhang, J. Research Status and Progress of Welding Technologies for Molybdenum and Molybdenum Alloys. Metals 2020, 10, 279. https://doi.org/10.3390/met10020279

Zhu Q, Xie M, Shang X, An G, Sun J, Wang N, Xi S, Bu C, Zhang J. Research Status and Progress of Welding Technologies for Molybdenum and Molybdenum Alloys. Metals. 2020; 10(2):279. https://doi.org/10.3390/met10020279

Chicago/Turabian StyleZhu, Qi, Miaoxia Xie, Xiangtao Shang, Geng An, Jun Sun, Na Wang, Sha Xi, Chunyang Bu, and Juping Zhang. 2020. "Research Status and Progress of Welding Technologies for Molybdenum and Molybdenum Alloys" Metals 10, no. 2: 279. https://doi.org/10.3390/met10020279