Enhancing the Mechanical Properties of AZ80 Alloy by Combining Extrusion and Three Pass Calibre Rolling

Abstract

1. Introduction

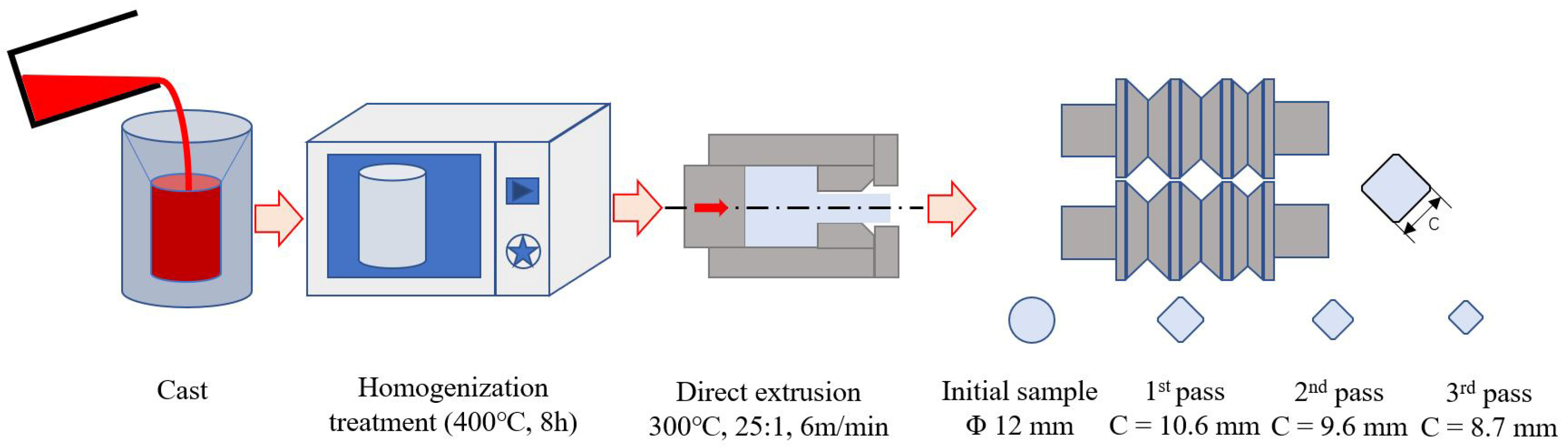

2. Materials and Methods

2.1. Materials and Processing

2.2. Characterization

2.3. Mechanical Performance Test

3. Results and Discussion

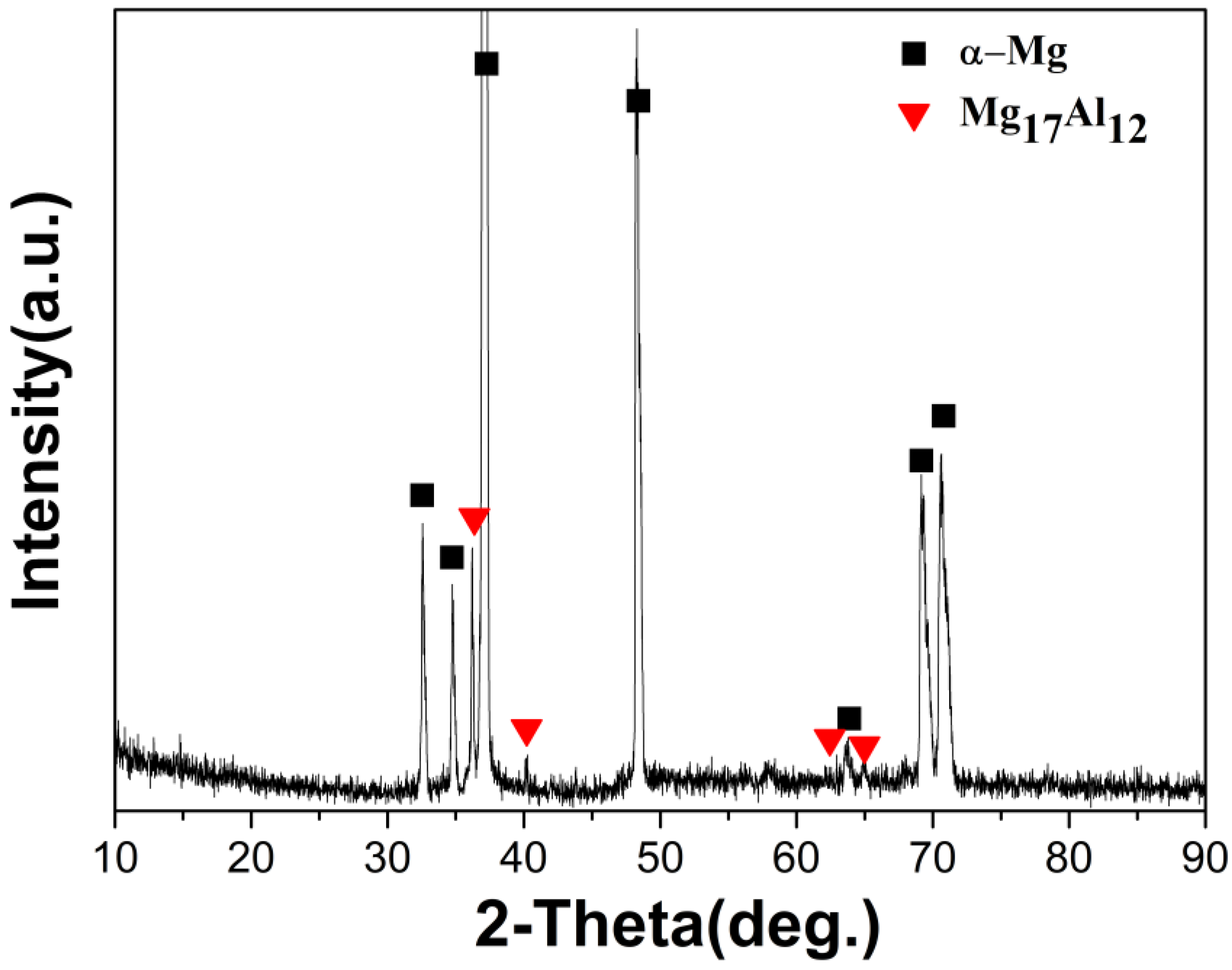

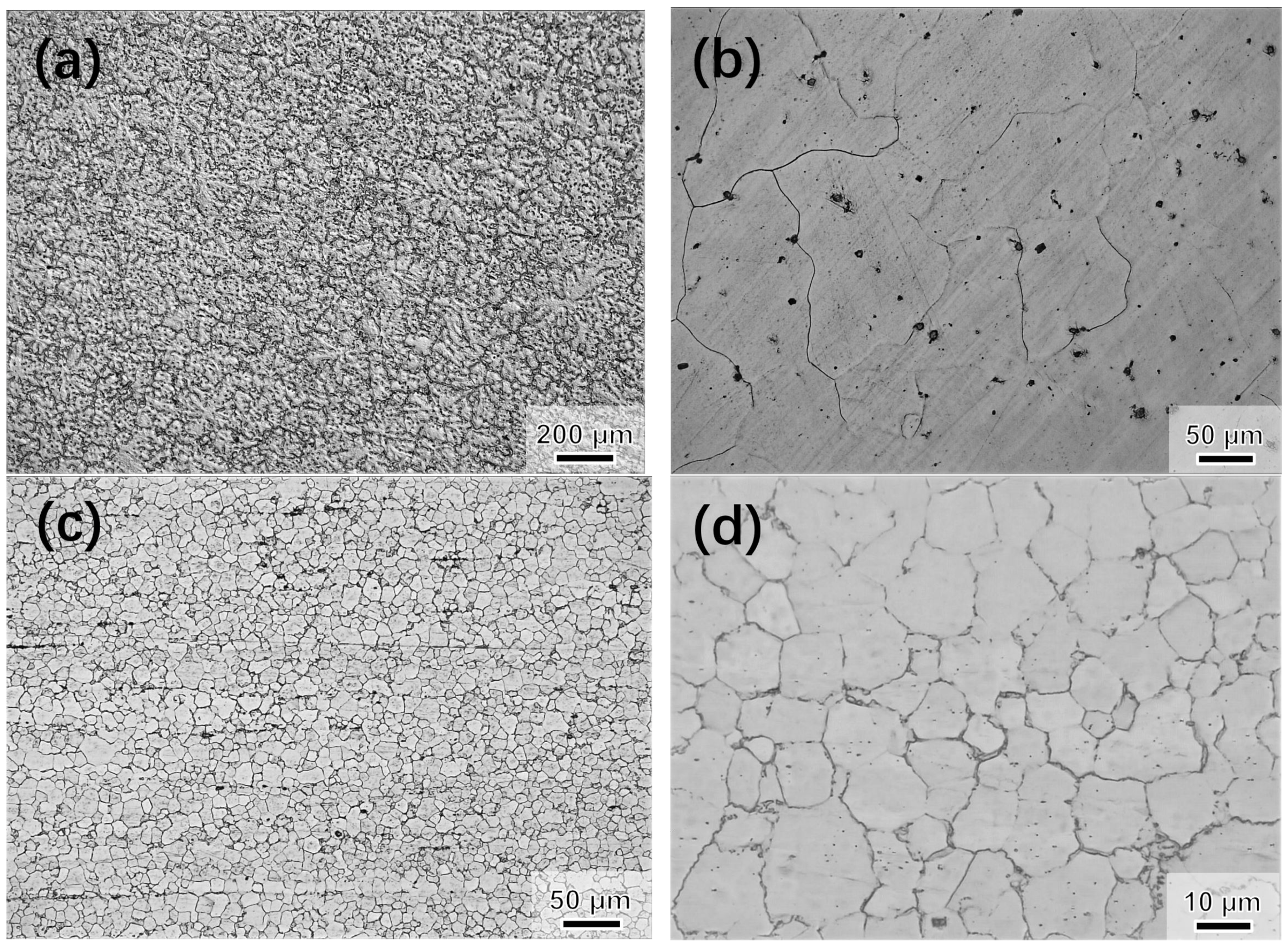

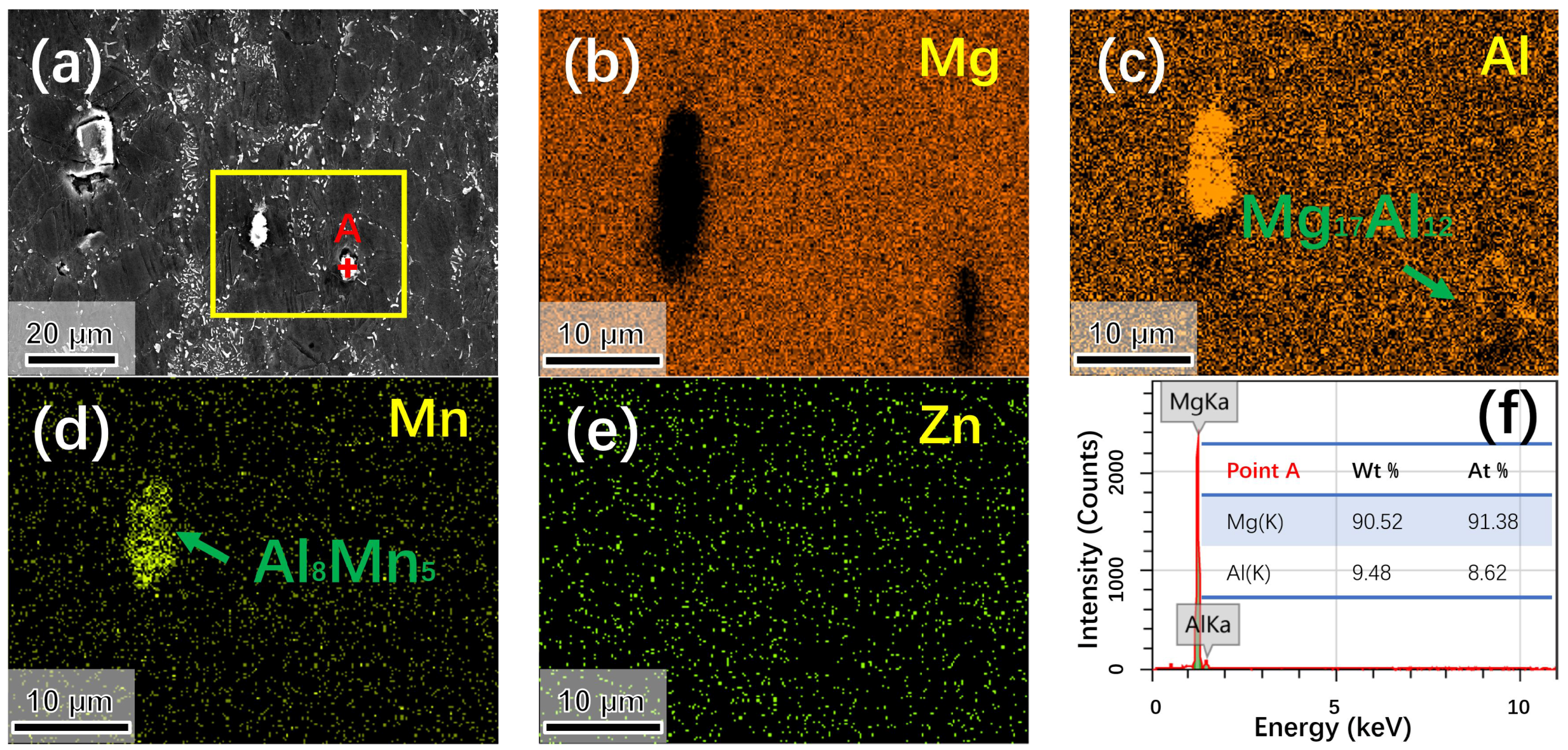

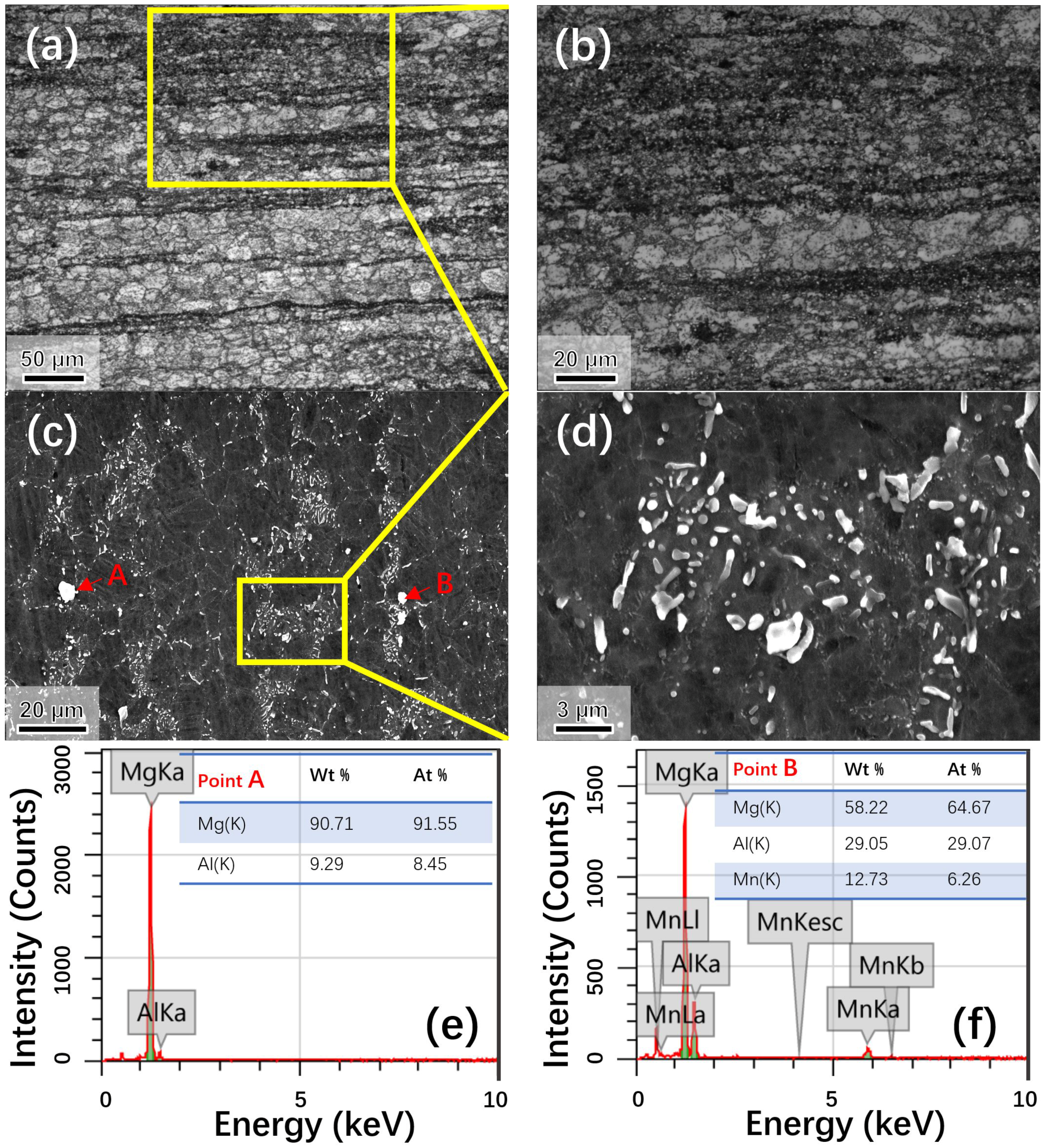

3.1. Microstructure of AZ80 Before Calibre Rolling

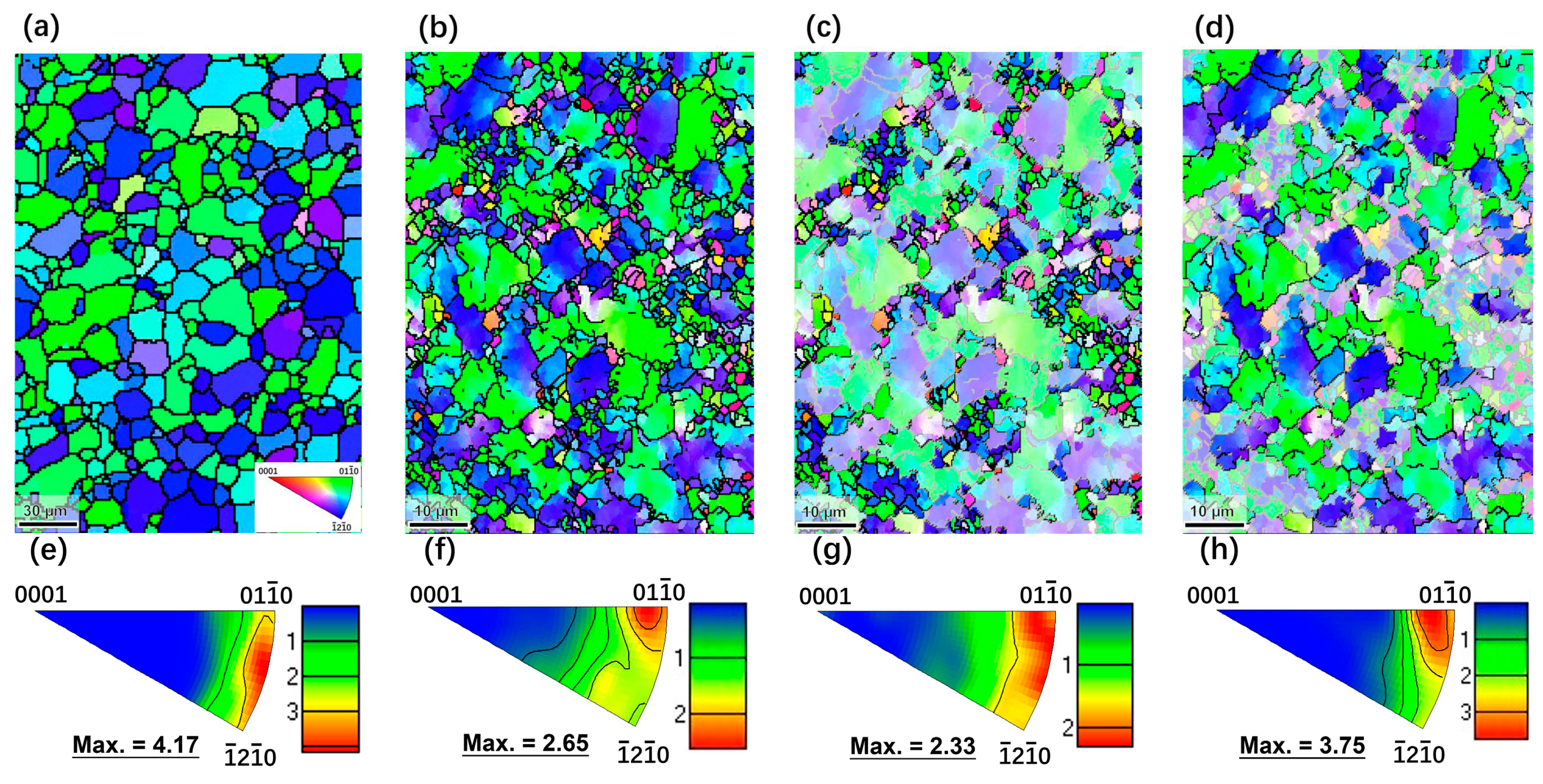

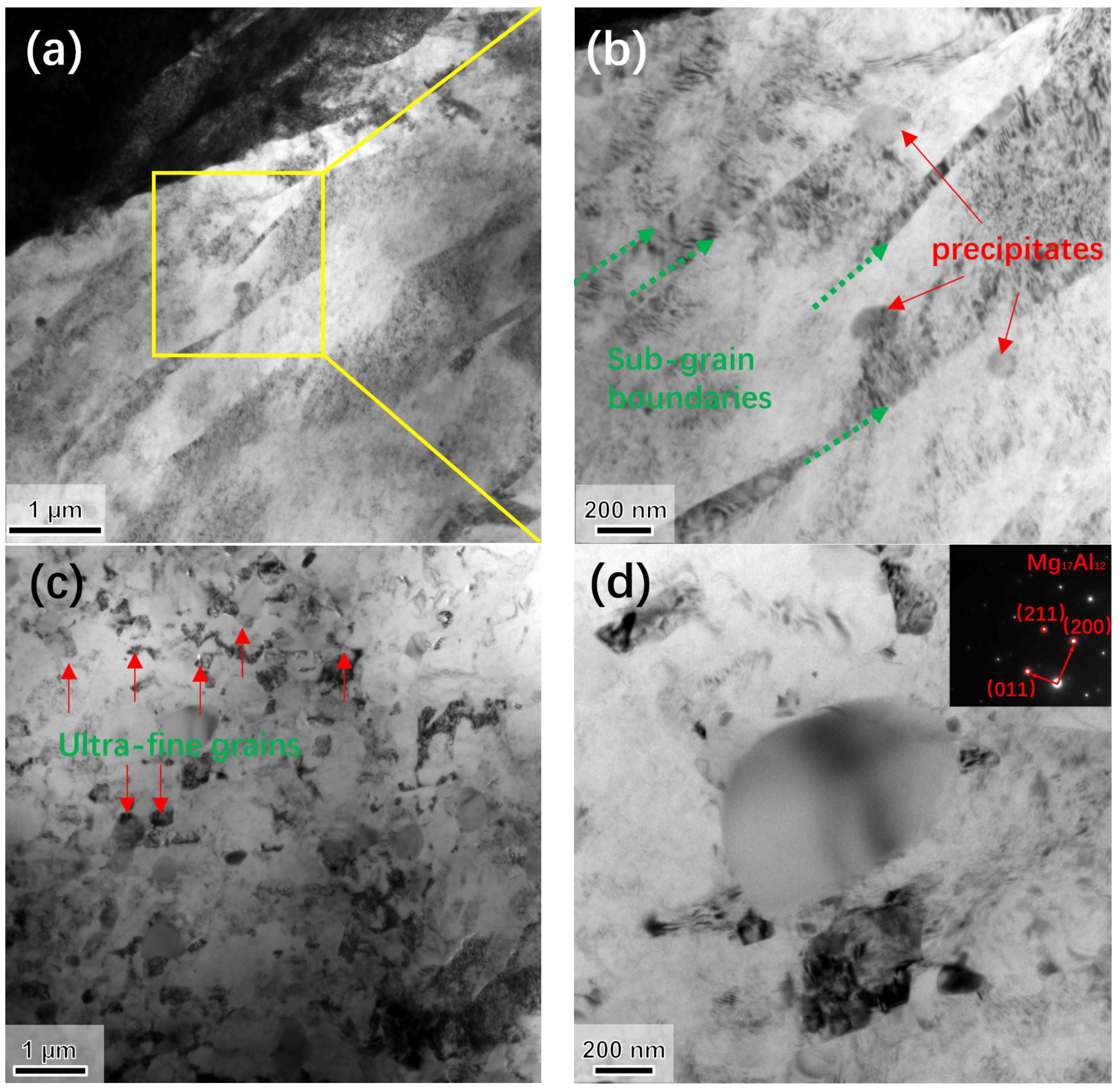

3.2. Microstructure of CRed AZ80

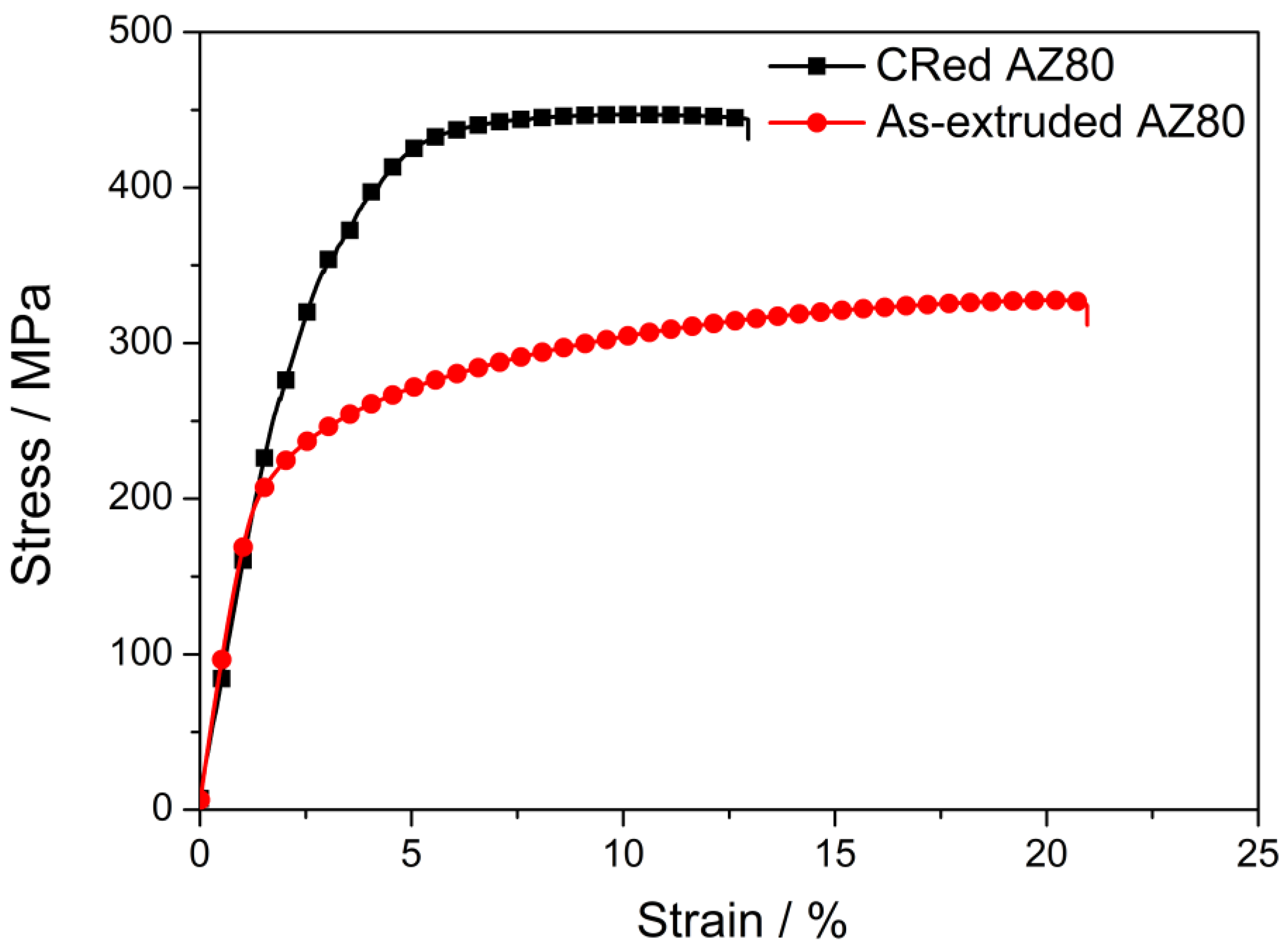

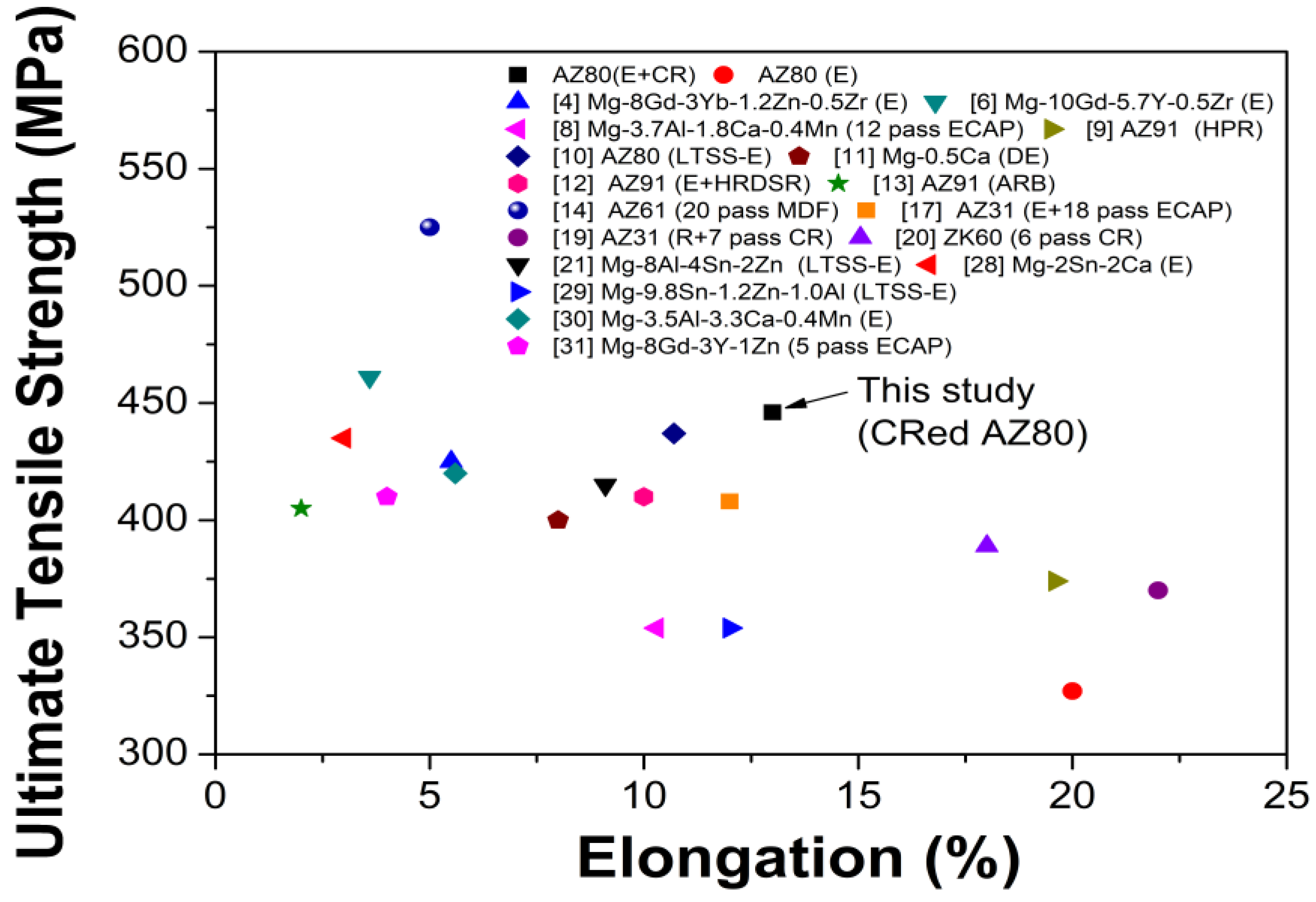

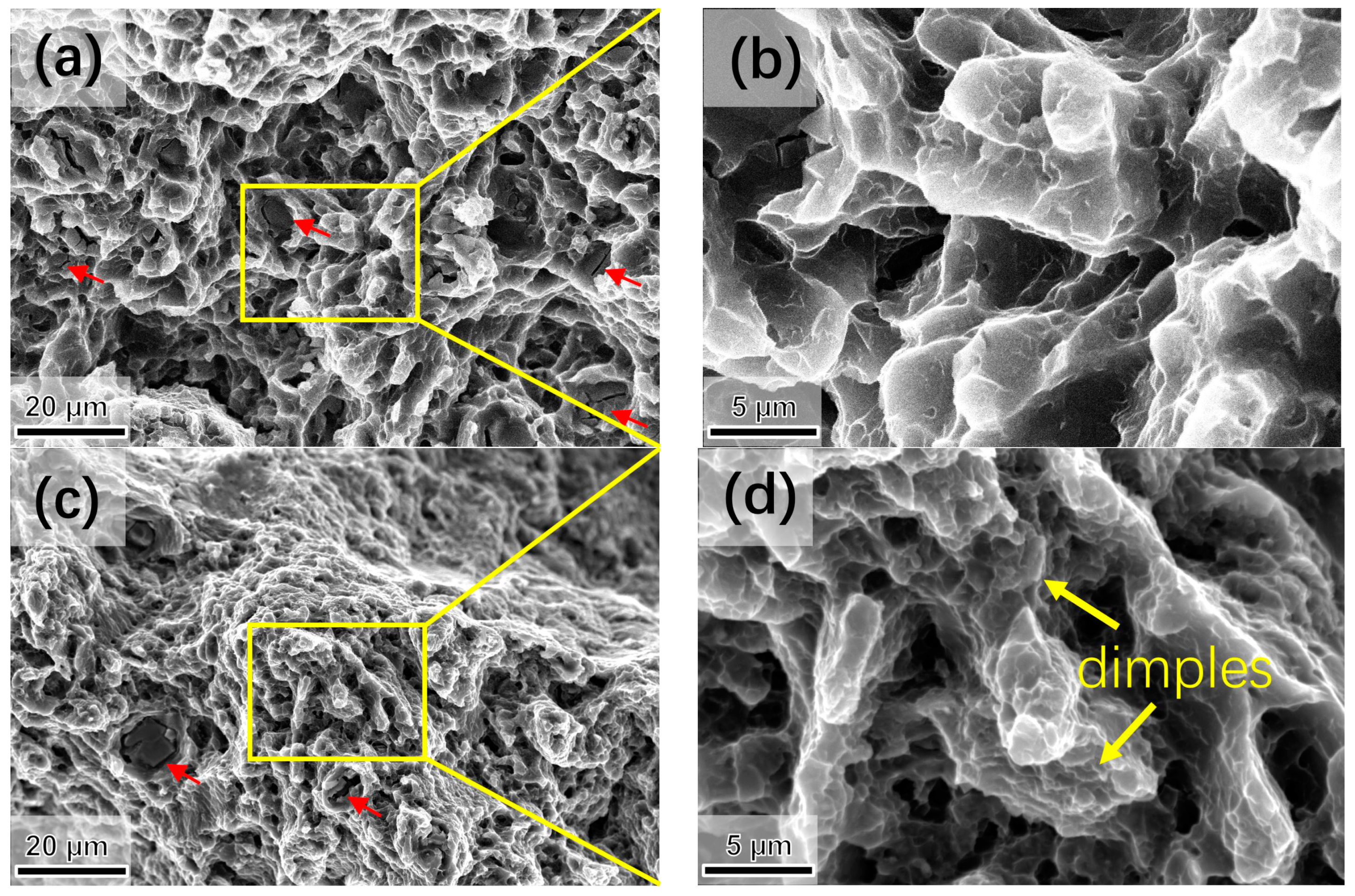

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Suh, B.C.; Shim, M.S.; Shin, K.S.; Kim, N.J. Current issues in magnesium sheet alloys: Where do we go from here? Scr. Mater. 2014, 84, 1–6. [Google Scholar] [CrossRef]

- Meng, S.J.; Yu, H.; Fan, S.D.; Li, Q.Z.; Park, S.H.; Suh, J.S.; Kim, Y.M.; Nan, X.L.; Bian, M.Z.; Yin, F.X.; et al. Recent Progress and Development in Extrusion of Rare Earth Free Mg Alloys. Acta Metall. Sin. (Engl. Lett.) 2019, 32, 145–168. [Google Scholar] [CrossRef]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical Properties of Magnesium-Rare Earth Alloy Systems: A Review. Metals 2015, 5, 1–39. [Google Scholar] [CrossRef]

- Li, B.; Guan, K.; Yang, Q.; Niu, X.; Zhang, D.; Lv, S.; Meng, F.; Huang, Y.; Hort, N.; Meng, J. Microstructures and mechanical properties of a hot-extruded Mg-8Gd-3Yb-1.2Zn-0.5Zr (wt%) alloy. J. Alloys Compd. 2019, 776, 666–678. [Google Scholar] [CrossRef]

- Wu, G.; Jafari Nodooshan, H.R.; Zeng, X.; Liu, W.; Li, D.; Ding, W. Microstructure and High Temperature Tensile Properties of Mg–10Gd–5Y–0.5Zr Alloy after Thermo-Mechanical Processing. Metals 2018, 8, 980. [Google Scholar] [CrossRef]

- Homma, T.; Kunito, N.; Kamado, S. Fabrication of extraordinary high-strength magnesium alloy by hot extrusion. Scr. Mater. 2009, 61, 644–647. [Google Scholar] [CrossRef]

- Vinogradov, A.; Vasilev, E.; Kopylov, V.I.; Linderov, M.; Brilevesky, A.; Merson, D. High Performance Fine-Grained Biodegradable Mg-Zn-Ca Alloys Processed by Severe Plastic Deformation. Metals 2019, 9, 186. [Google Scholar] [CrossRef]

- Wang, C.; Ma, A.; Sun, J.; Zhuo, X.; Huang, H.; Liu, H.; Yang, Z.; Jiang, J. Improving Strength and Ductility of a Mg-3.7Al-1.8Ca-0.4Mn Alloy with Refined and Dispersed Al2Ca Particles by Industrial-Scale ECAP Processing. Metals 2019, 9, 767. [Google Scholar]

- Zha, M.; Zhang, X.H.; Zhang, H.; Yao, J.; Wang, C.; Wang, H.Y.; Feng, T.T.; Jiang, Q.C. Achieving bimodal microstructure and enhanced tensile properties of Mg-9Al-1Zn alloy by tailoring deformation temperature during hard plate rolling (HPR). J. Alloys Compd. 2018, 765, 1228–1236. [Google Scholar] [CrossRef]

- Yu, H.; Park, S.H.; You, B.S. Development of extraordinary high-strength Mg-8Al-0.5Zn alloy via a low temperature and slow speed extrusion. Mater. Sci. Eng. A 2014, 610, 445–449. [Google Scholar] [CrossRef]

- Ikeo, N.; Nishioka, M.; Mukai, T. Fabrication of biodegradable materials with high strength by grain refinement of Mg-0.3 at% Ca alloys. Mater. Lett. 2018, 223, 65–68. [Google Scholar] [CrossRef]

- Pérez-Prado, M.T.; del Valle, J.A.; Ruano, O.A. Achieving high strength in commercial Mg cast alloys through large strain rolling. Mater. Lett. 2005, 59, 3299–3303. [Google Scholar] [CrossRef]

- Miura, H.; Maruoka, T.; Yang, X.; Jonas, J.J. Microstructure and mechanical properties of multi-directionally forged Mg-Al-Zn alloy. Scr. Mater. 2012, 66, 49–51. [Google Scholar] [CrossRef]

- Kim, W.J.; Jeong, H.G.; Jeong, H.T. Achieving high strength and high ductility in magnesium alloys using severe plastic deformation combined with low-temperature aging. Scr. Mater. 2009, 61, 1040–1043. [Google Scholar] [CrossRef]

- Huang, H.; Miao, H.; Yuan, G.; Wang, Z.; Ding, W. Fabrication of ultra-high strength magnesium alloys over 540 MPa with low alloying concentration by double continuously extrusion. J. Magnes. Alloy. 2018, 6, 107–113. [Google Scholar] [CrossRef]

- Lee, T.; Shih, D.S.; Lee, Y.; Lee, C.S. Manufacturing Ultrafine-Grained Ti-6Al-4V Bulk Rod Using Multi-Pass Calibre-Rolling. Metals 2015, 5, 777–789. [Google Scholar] [CrossRef]

- Mukai, T.; Somekawa, H.; Inoue, T.; Singh, A. Strengthening Mg-Al-Zn alloy by repetitive oblique shear strain with calibre roll. Scr. Mater. 2010, 62, 113–116. [Google Scholar] [CrossRef]

- Somekawa, H.; Singh, A.; Inoue, T. Enhancement of toughness by grain boundary control in magnesium binary alloys. Mater. Sci. Eng. A 2014, 612, 172–178. [Google Scholar] [CrossRef]

- Lee, J.H.; Kwak, B.J.; Kong, T.; Park, S.H.; Lee, T. Improved tensile properties of AZ31 Mg alloy subjected to various calibre-rolling strains. J. Magnes. Alloy. 2019, 7, 381–387. [Google Scholar] [CrossRef]

- Lee, T.; Kwak, B.J.; Kong, T.; Lee, J.H.; Lee, S.W.; Park, S.H. Enhanced yield symmetry and strength-ductility balance of calibre-rolled Mg-6Zn-0.5Zr with ultrafine-grained structure and bulk dimension. J. Alloys Compd. 2019, 803, 434–441. [Google Scholar] [CrossRef]

- Park, S.H.; Jung, J.-G.; Kim, Y.M.; You, B.S. A new high-strength extruded Mg-8Al-4Sn-2Zn alloy. Mater. Lett. 2015, 139, 35–38. [Google Scholar] [CrossRef]

- Meng, S.; Yu, H.; Zhang, H.; Cui, H.; Wang, Z.; Zhao, W. Microstructure and mechanical properties of extruded pure Mg with Bi addition. Acta Metall. Sin. 2016, 52, 811–820. [Google Scholar]

- Meng, S.; Yu, H.; Zhang, H.; Cui, H.; Park, S.H.; Zhao, W.; You, B.S. Microstructure and mechanical properties of an extruded Mg-8Bi-1Al-1Zn (wt%) alloy. Mater. Sci. Eng. A 2017, 690, 80–87. [Google Scholar] [CrossRef]

- Inoue, T.; Somekawa, H.; Mukai, T. Hardness Variation and Strain Distribution in Magnesium Alloy AZ31 Processed by Multi-pass Calibre Rolling. Adv. Eng. Mater. 2009, 11, 654–658. [Google Scholar] [CrossRef]

- Jung, J.-G.; Park, S.H.; Yu, H.; Kim, Y.M.; Lee, Y.-K.; You, B.S. Improved mechanical properties of Mg–7.6Al–0.4Zn alloy through aging prior to extrusion. Scr. Mater. 2014, 93, 8–11. [Google Scholar] [CrossRef]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle effects on recrystallization in magnesium-manganese alloys: Particle pinning. Mater. Sci. Eng. A 2011, 528, 4239–4247. [Google Scholar] [CrossRef]

- Jung, J.-G.; Park, S.H.; You, B.S. Effect of aging prior to extrusion on the microstructure and mechanical properties of Mg-7Sn-1Al-1Zn alloy. J. Alloys Compd. 2015, 627, 324–332. [Google Scholar] [CrossRef]

- Pan, H.; Qin, G.; Huang, Y.; Ren, Y.; Sha, X.; Han, X.; Liu, Z.-Q.; Li, C.; Wu, X.; Chen, H.; et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Yamamoto, K.; Honma, T.; Kamado, S.; Hono, K. A high-strength Mg-Sn-Zn-Al alloy extruded at low temperature. Scr. Mater. 2008, 59, 1111–1114. [Google Scholar] [CrossRef]

- Xu, S.W.; Oh-ishi, K.; Kamado, S.; Uchida, F.; Homma, T.; Hono, K. High-strength extruded Mg-Al-Ca-Mn alloy. Scr. Mater. 2011, 65, 269–272. [Google Scholar] [CrossRef]

- Garces, G.; Pérez, P.; Barea, R.; Medina, J.; Stark, A.; Schell, N.; Adeva, P. Increase in the Mechanical Strength of Mg-8Gd-3Y-1Zn Alloy Containing Long-Period Stacking Ordered Phases Using Equal Channel Angular Pressing Processing. Metals 2019, 9, 221. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.M.; Ma, E. Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 2004, 52, 1699–1709. [Google Scholar] [CrossRef]

- Witkin, D.; Lee, Z.; Rodriguez, R.; Nutt, S.; Lavernia, E. Al-Mg alloy engineered with bimodal grain size for high strength and increased ductility. Scr. Mater. 2003, 49, 297–302. [Google Scholar] [CrossRef]

- Wang, H.Y.; Yu, Z.P.; Zhang, L.; Liu, C.G.; Zha, M.; Wang, C.; Jiang, Q.C. Achieving high strength and high ductility in magnesium alloy using hard-plate rolling (HPR) process. Sci. Rep. 2015, 5, 17100. [Google Scholar] [CrossRef] [PubMed]

- Yamasaki, M.; Hashimoto, K.; Hagihara, K.; Kawamura, Y. Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy. Acta Mater. 2011, 59, 3646–3658. [Google Scholar] [CrossRef]

| Alloys | Process Parameters | TYS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|---|

| AZ80 | E 1 + 3 pass CR 2, 300 °C | 370 ± 3 | 446 ± 5 | 13 ± 1 |

| AZ80 | E, 300 °C, 6 m/min | 227 ± 4 | 327 ± 3 | 20 ± 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, S.; Yu, H.; Zhou, J.; Han, H.; Li, Y.; Dong, L.; Nan, X.; Li, Z.; Shin, K.S.; Zhao, W. Enhancing the Mechanical Properties of AZ80 Alloy by Combining Extrusion and Three Pass Calibre Rolling. Metals 2020, 10, 249. https://doi.org/10.3390/met10020249

Meng S, Yu H, Zhou J, Han H, Li Y, Dong L, Nan X, Li Z, Shin KS, Zhao W. Enhancing the Mechanical Properties of AZ80 Alloy by Combining Extrusion and Three Pass Calibre Rolling. Metals. 2020; 10(2):249. https://doi.org/10.3390/met10020249

Chicago/Turabian StyleMeng, Shuaiju, Hui Yu, Jun Zhou, Haisheng Han, Yongyan Li, Lishan Dong, Xiaolong Nan, Zhongjie Li, Kwang Seon Shin, and Weimin Zhao. 2020. "Enhancing the Mechanical Properties of AZ80 Alloy by Combining Extrusion and Three Pass Calibre Rolling" Metals 10, no. 2: 249. https://doi.org/10.3390/met10020249

APA StyleMeng, S., Yu, H., Zhou, J., Han, H., Li, Y., Dong, L., Nan, X., Li, Z., Shin, K. S., & Zhao, W. (2020). Enhancing the Mechanical Properties of AZ80 Alloy by Combining Extrusion and Three Pass Calibre Rolling. Metals, 10(2), 249. https://doi.org/10.3390/met10020249