Microstructure and Mechanical Evolution of Cu-2.7Be Sheets via Annealing

Abstract

1. Introduction

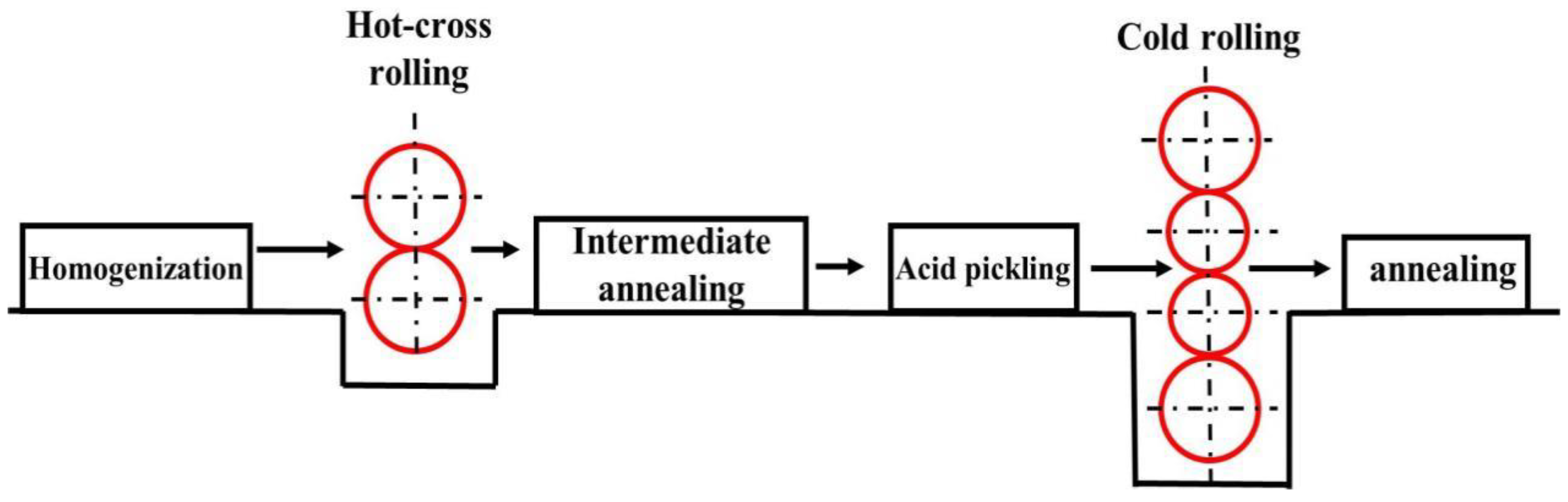

2. Experimental Process

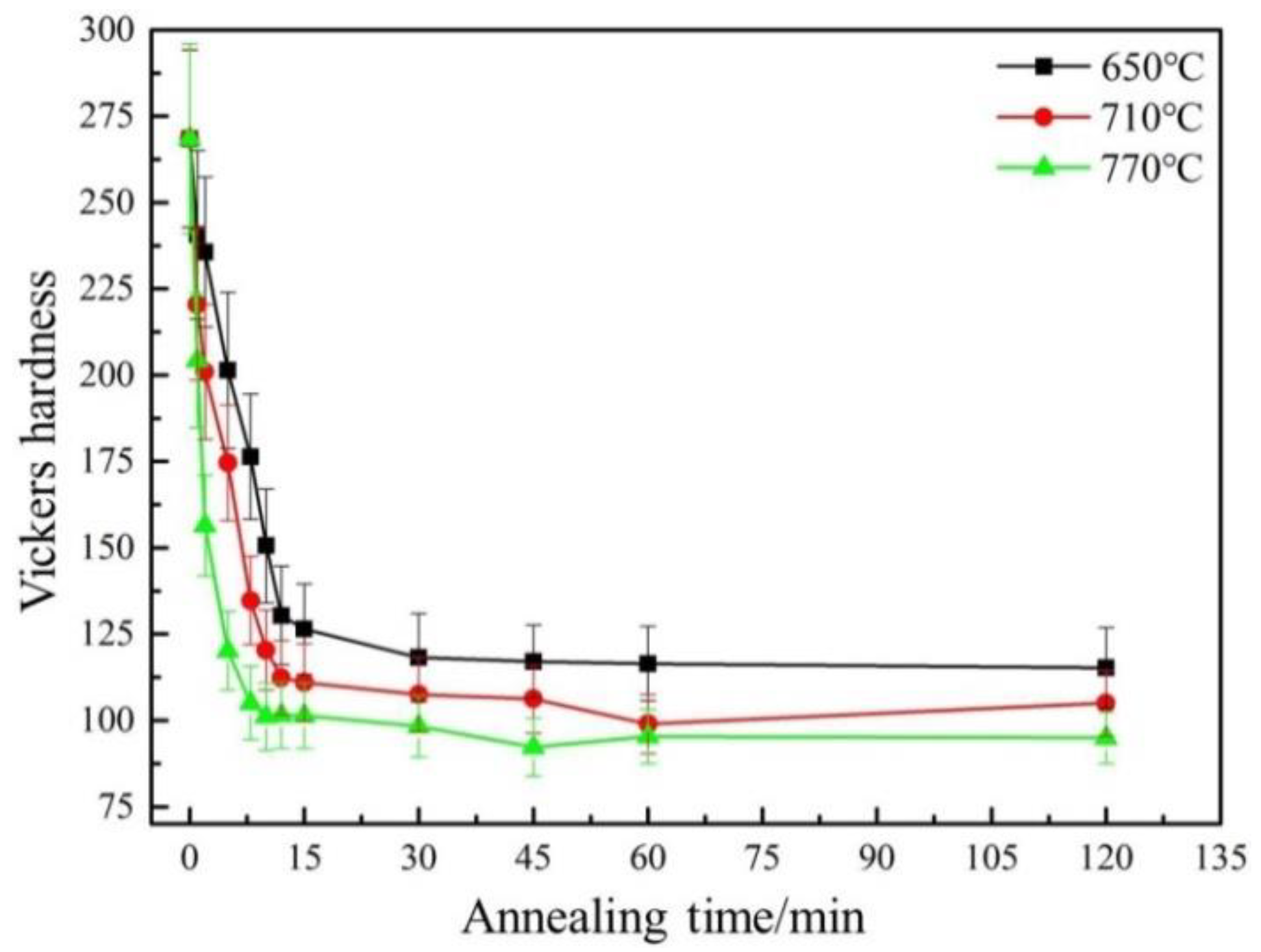

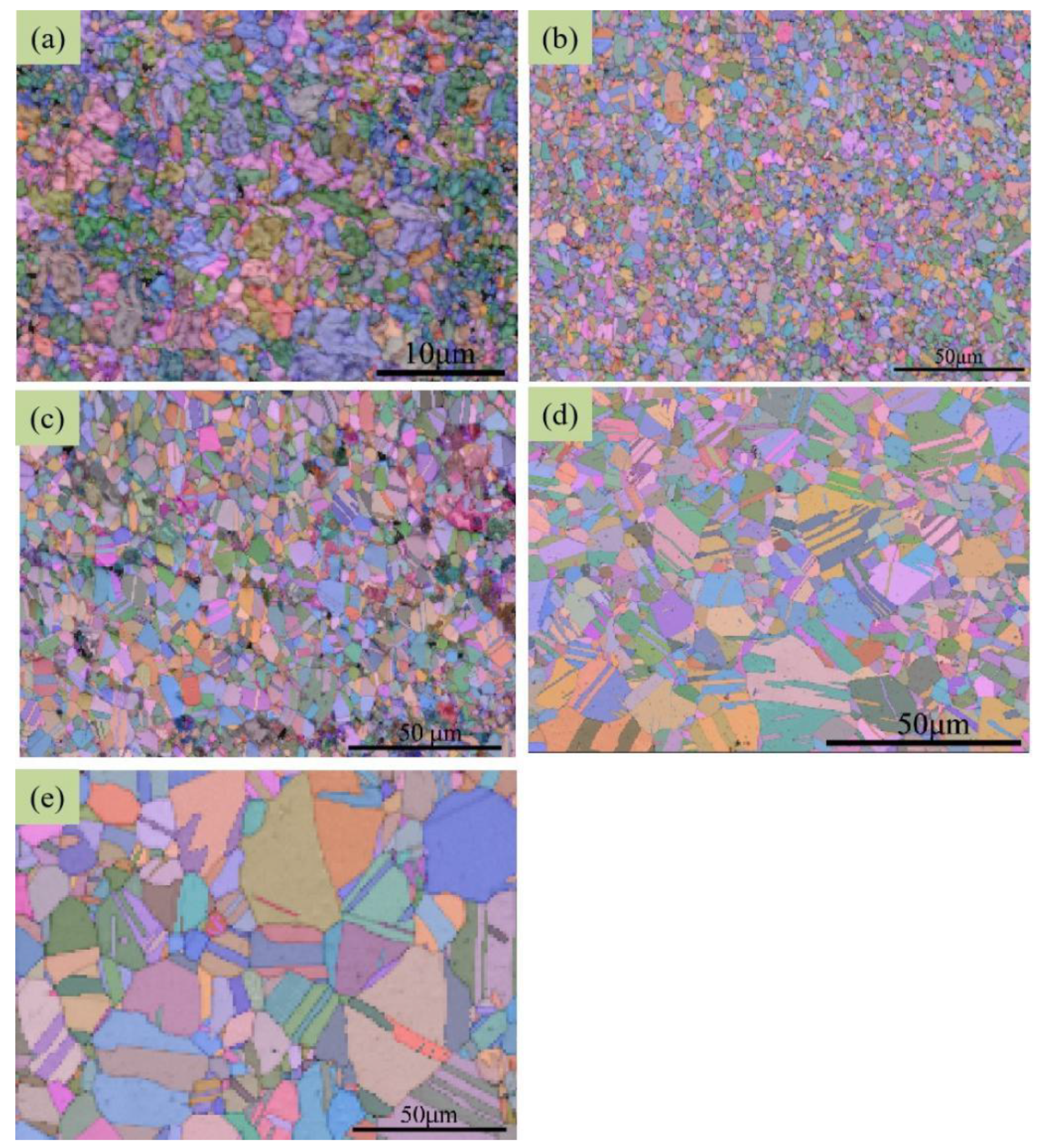

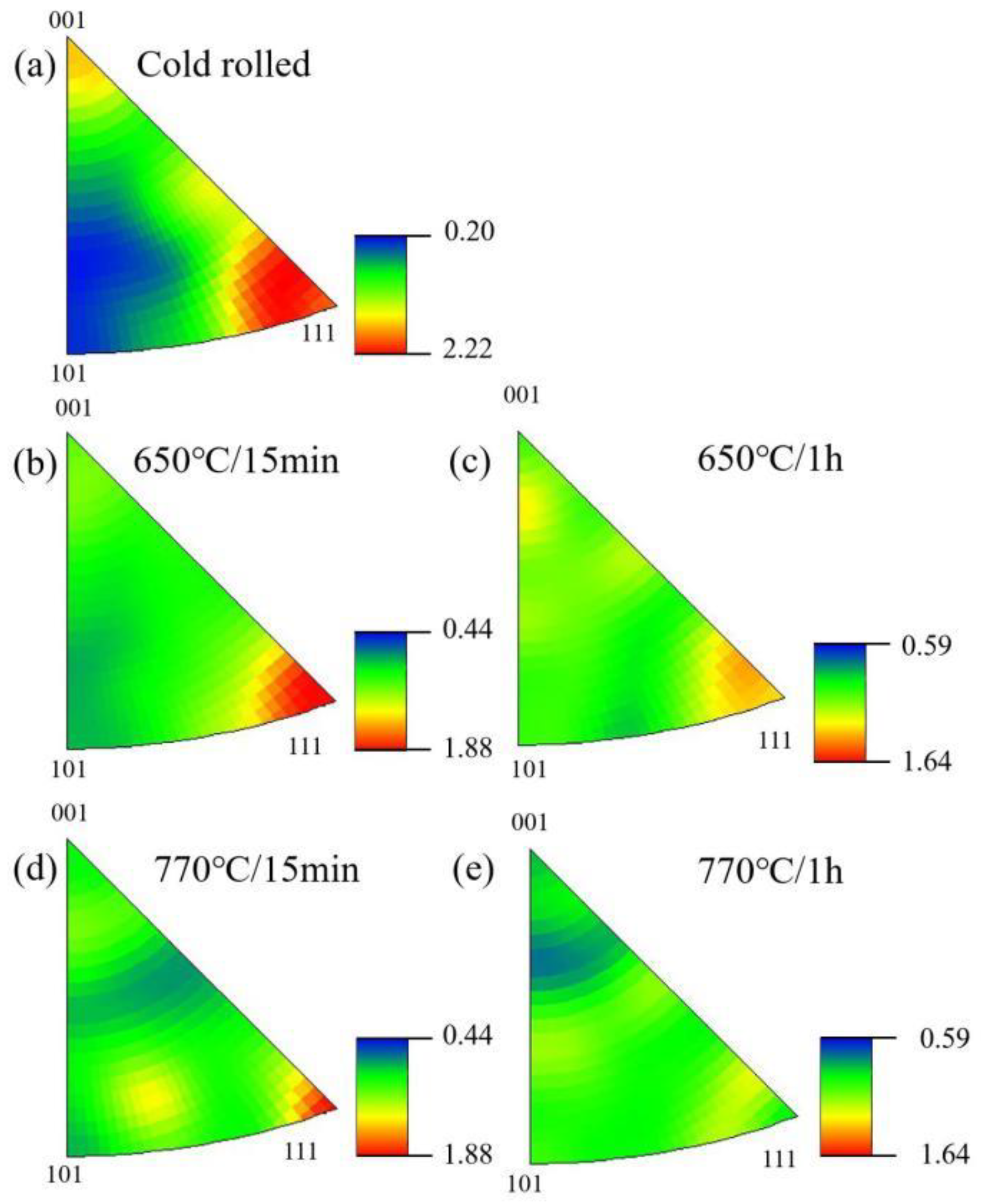

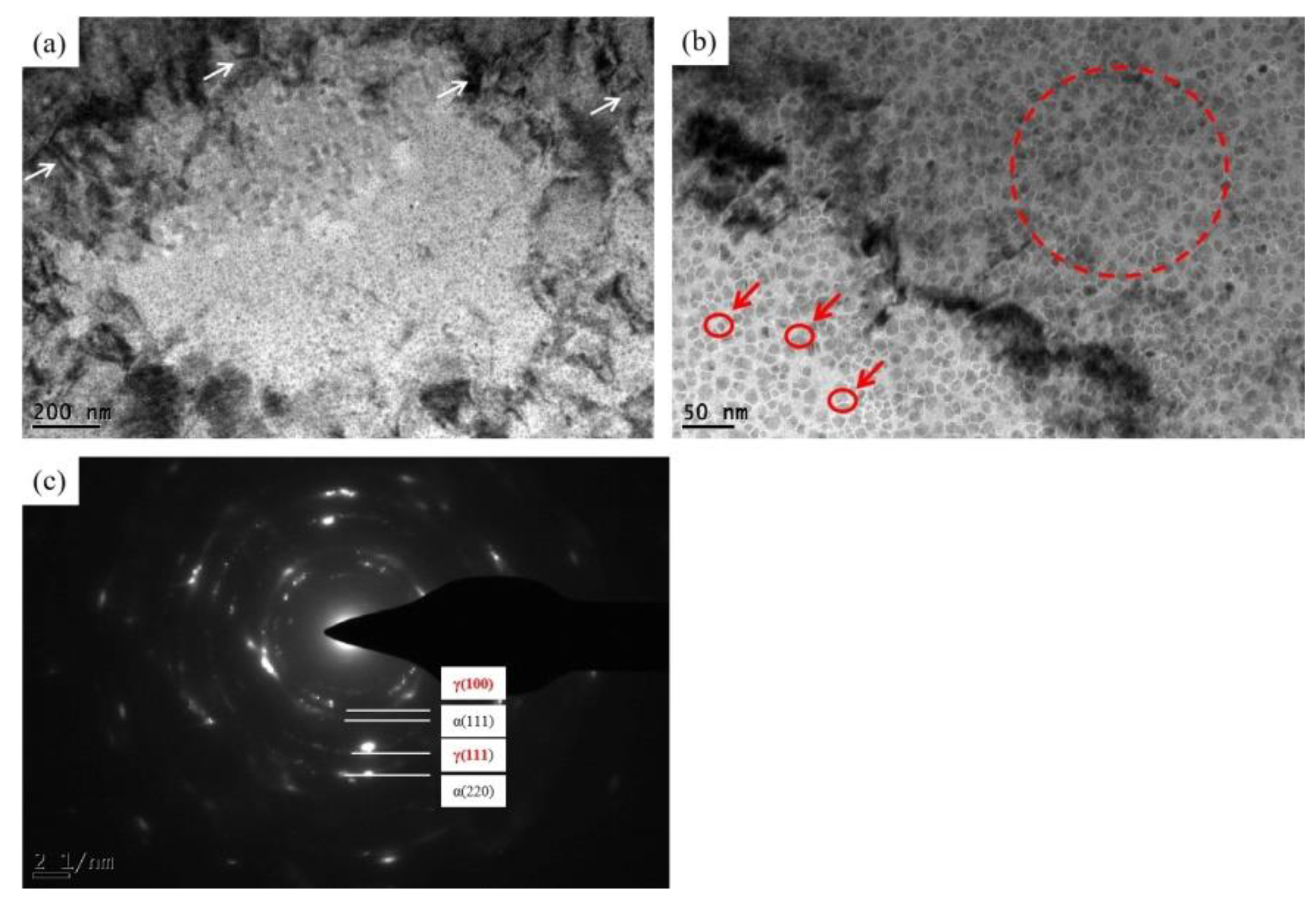

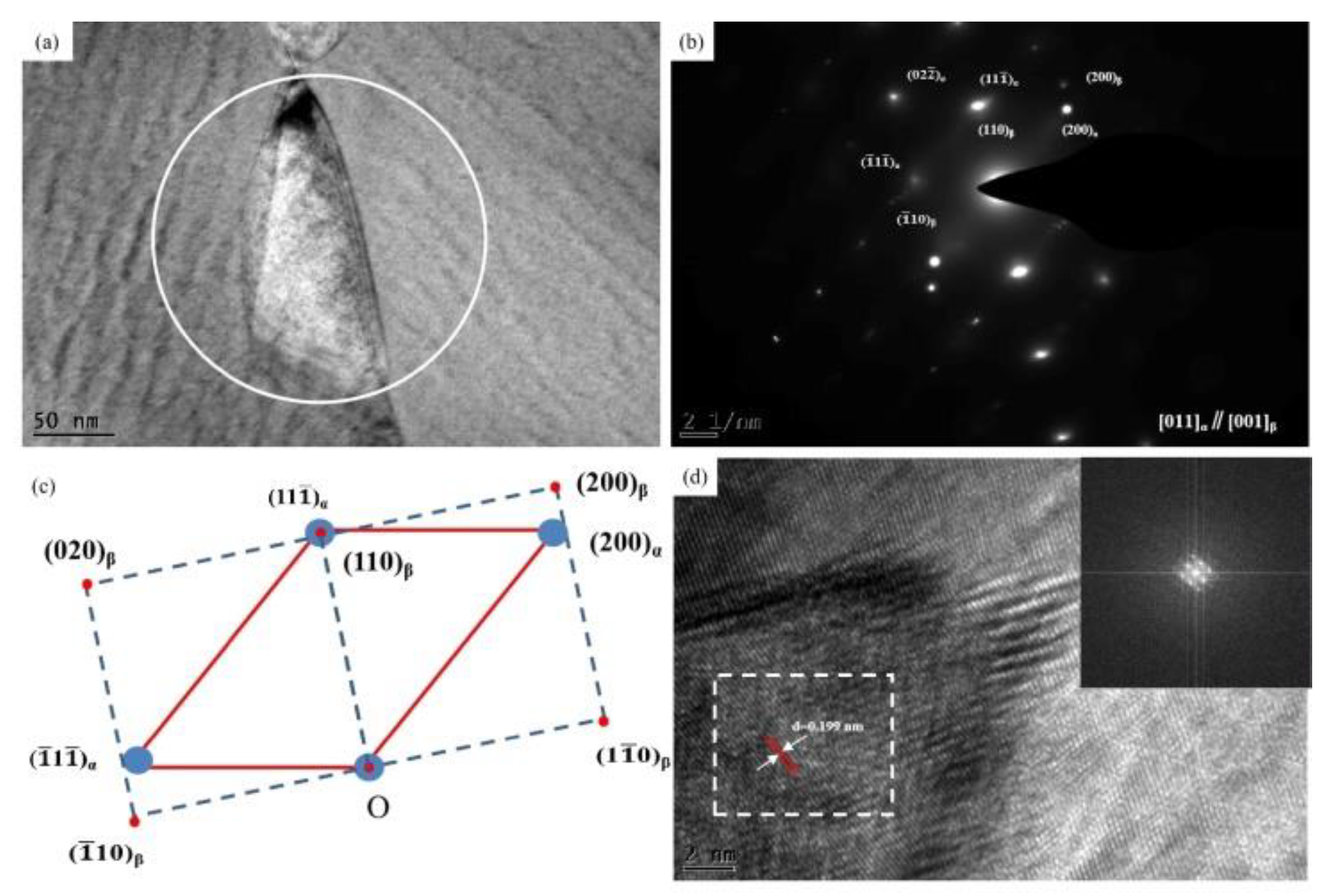

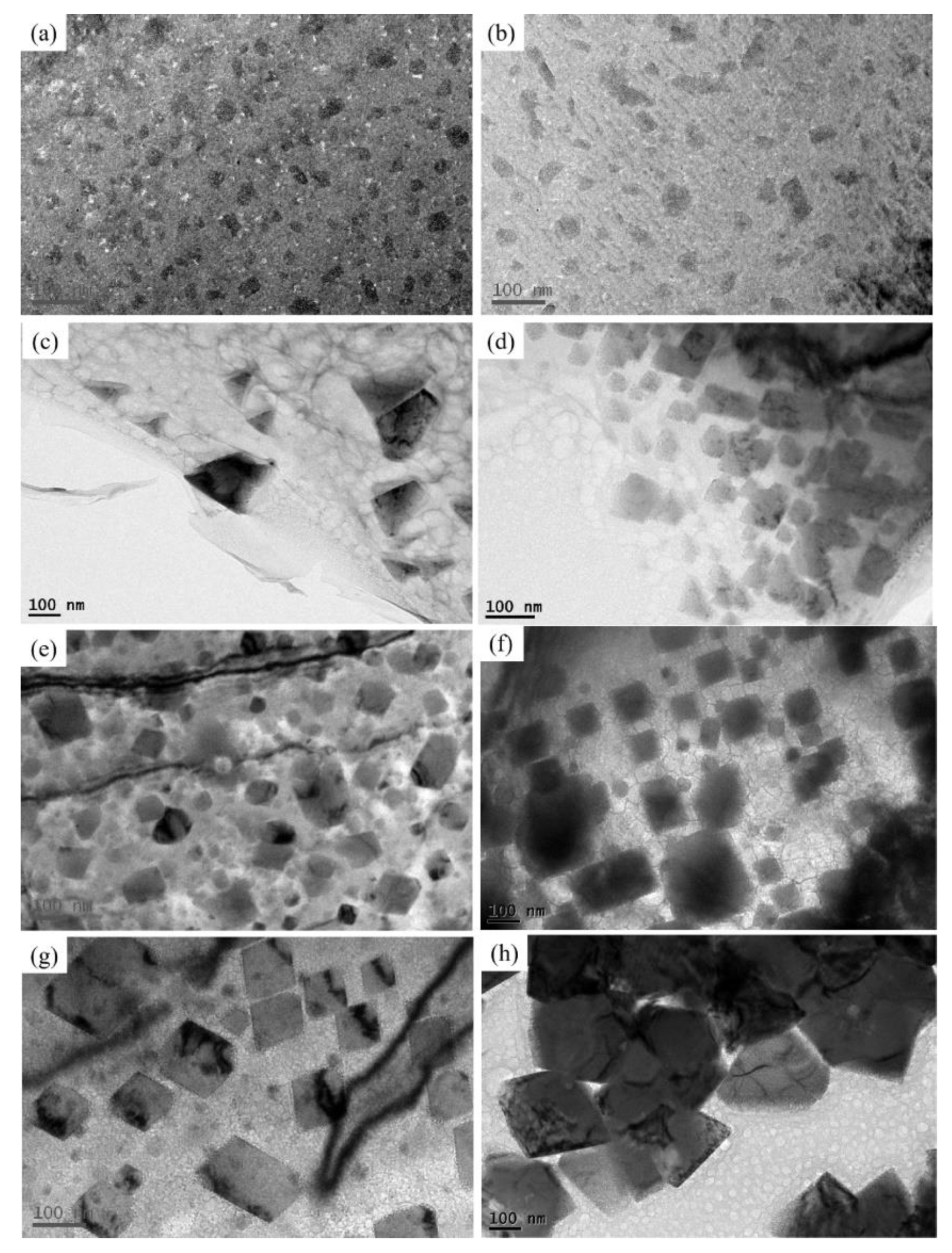

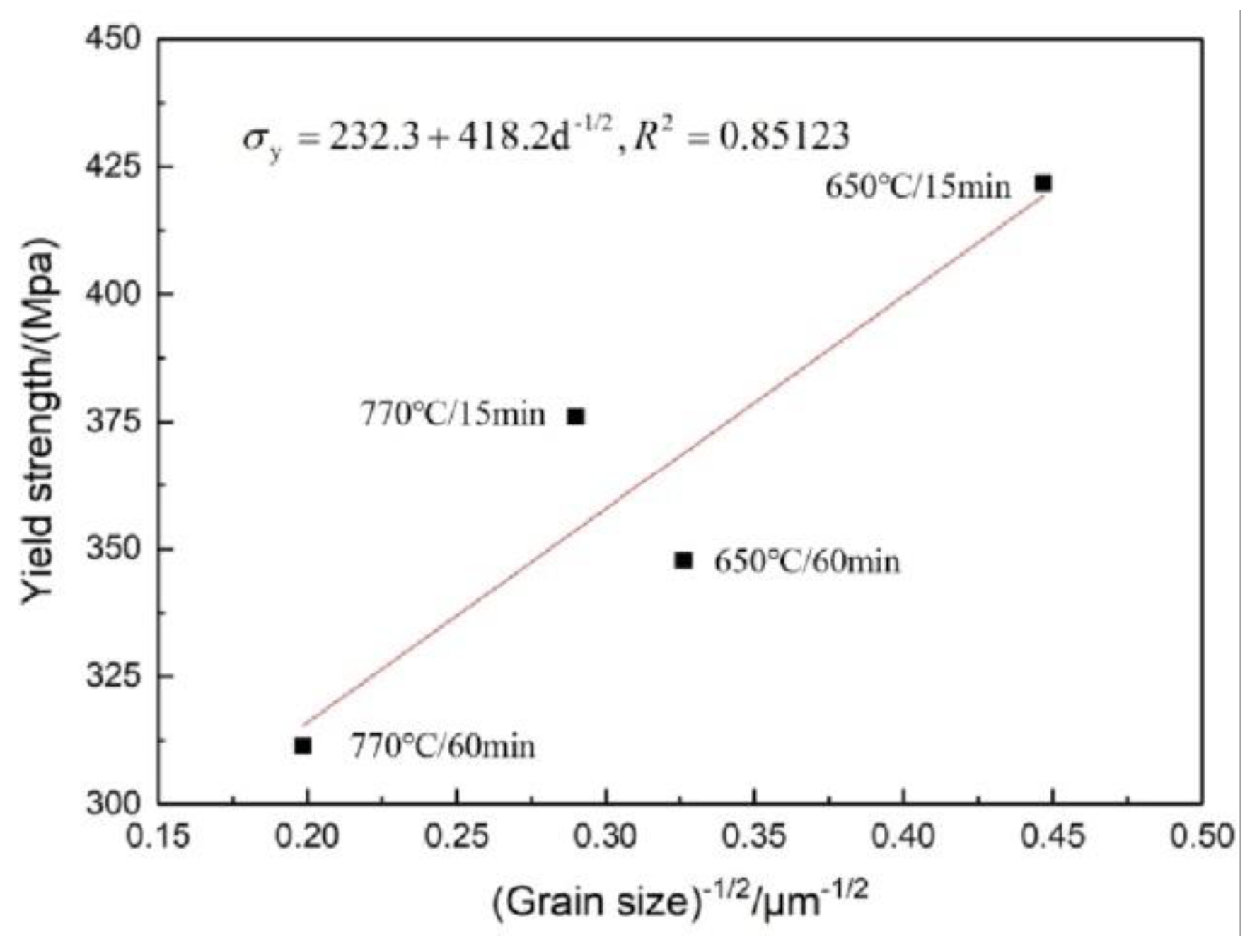

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Michijima, M. Secondary electron multiplier as a detector of very feeble ion current down to 10–19 Amperes. Jpn. J. Appl. Phys. 1962, 1, 110. [Google Scholar] [CrossRef]

- Ruttenberg, F.; Haas, T. Surface composition and morphology vs secondary-electron yield of Be–Cu dynodes. J. Vac. Sci. Technol. 1975, 12, 1043–1046. [Google Scholar] [CrossRef]

- Allen, J.S. An improved electron multiplier particle counter. Rev. Sci. Instrum. 1947, 18, 739–749. [Google Scholar] [CrossRef]

- Laurenson, L.; Koch, J. The secondary electron emission characteristics of clean and contaminated copper beryllium sheet. Br. J. Appl. Phys. 1965, 16, 889. [Google Scholar] [CrossRef]

- Salser, G.E. Rejuvenation of electron multipliers used in mass spectrometers. Rev. Sci. Instrum. 1966, 37, 674–675. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Zhou, F.; Liu, W.; Wang, F. Influence of activation parameters on the thickness of MgO thin film on Ag-3Mg alloy and its secondary electron emission property. Mater. Res. Bull. 2017, 96, 35–39. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Ren, Z.; Yang, F.; Wang, Y. Secondary electron emission of Y2O3–Mo cermet cathode. Mater. Res. Bull. 2010, 45, 324–328. [Google Scholar] [CrossRef]

- Li, J.; Hu, W.; Hao, L.; Wu, S. Influence of the substrate temperature on the microstructure and electron-induced secondary electron emission properties of MgO/Au composite film. Mater. Res. Bull. 2018, 100, 308–312. [Google Scholar] [CrossRef]

- Shih, A.; Yater, J.; Pehrsson, P.; Butler, J.; Hor, C.; Abrams, R. Secondary electron emission from diamond surfaces. J. Appl. Phys. 1997, 82, 1860–1867. [Google Scholar] [CrossRef]

- Wang, B.; Wu, E.; Wang, Y.; Xiong, L.; Liu, S. Activation treatment effects on characteristics of BeO layer and secondary electron emission properties of an activated Cu–Be alloy. Appl. Surf. Sci. 2015, 355, 19–25. [Google Scholar] [CrossRef]

- Yoshida, K.; Ishizaka, T.; Kuroda, M.; Ikawa, S. The effects of texture on formability of aluminum alloy sheets. Acta Mater. 2007, 55, 4499–4506. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Wang, L.; Li, J. Improved formability of Mg–3Al–1Zn alloy by pre-stretching and annealing. Scr. Mater. 2012, 67, 495–498. [Google Scholar] [CrossRef]

- Huang, X.; Chino, Y.; Mabuchi, M.; Matsuda, M. Influences of grain size on mechanical properties and cold formability of Mg–3Al–1Zn alloy sheets with similar weak initial textures. Mater. Sci. Eng. A 2014, 611, 152–161. [Google Scholar] [CrossRef]

- Engler, O.; Hirsch, J. Texture control by thermomechanical processing of AA6xxx Al–Mg–Si sheet alloys for automotive applications—A review. Mater. Sci. Eng. A 2002, 336, 249–262. [Google Scholar] [CrossRef]

- Wang, R.; Shen, X.; Liu, Y.; Li, J. Effects of Ga Addition on the Formability of Main Phase and Microstructure of Hot-Deformed Ce-Fe-B Magnets. IEEE Trans. Magn. 2016, 52, 1–6. [Google Scholar] [CrossRef]

- Narayanasamy, R.; Ravindran, R.; Manonmani, K.; Satheesh, J. A crystallographic texture perspective formability investigation of aluminium 5052 alloy sheets at various annealing temperatures. Mater. Des. 2009, 30, 1804–1817. [Google Scholar] [CrossRef]

- Ota, S.; Muramatsu, N.; Sengoku, K.; Watanabe, C.; Monzen, R. Mechanical and electrical properties and microstructure in Cu-Ni-Bc alloys.Mechanical and electrical properties and microstructure in Cu-Ni-Bc alloys. J. Soc. Mater. Sci. 2007, 54, 531–536. [Google Scholar] [CrossRef]

- Yagmur, L. Effect of microstructure on internal friction and Young’s modulus of aged Cu–Be alloy. Mater. Sci. Eng. A 2009, 523, 65–69. [Google Scholar] [CrossRef]

- Monzen, R.; Shimada, Y.; Watanabe, C. Mechanical properties of Cu-Ni-Be system alloys. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2010. [Google Scholar]

- Yagmur, L.; Duygulu, O.; Aydemir, B. Investigation of metastable γ′ precipitate using HRTEM in aged Cu–Be alloy. Mater. Sci. Eng. A 2011, 528, 4147–4151. [Google Scholar] [CrossRef]

- Guoliang, X.; Qiangsong, W.; Xujun, M.; Baiqing, X.; Lijun, P. The precipitation behavior and strengthening of a Cu–2.0 wt% Be alloy. Mater. Sci. Eng. A 2012, 558, 326–330. [Google Scholar] [CrossRef]

- Zhu, D.B.; Liu, C.; Liu, Y.D.; Han, T.; Gao, Y.H.; Jiang, S.H. Evolution of the texture, mechanical properties, and microstructure of Cu-2.7Be alloys during hot cross-rolling. Appl. Phys. A 2015, 120, 1605–1613. [Google Scholar] [CrossRef]

- Guan, Y.; Liu, C.Y.; Gao, Y.H.; Zhu, D.B.; Han, T.; Jiang, S.N. Effect of annealing on microstructure and tensile properties of cold-rolled Cu-2.7Be sheets. Mater. Charact. 2017, 129, 156–162. [Google Scholar] [CrossRef]

- Tekkaya, A.E.; Lange, K. An Improved Relationship between Vickers Hardness and Yield Stress for Cold Formed Materials and its Experimental Verification. CIRP Ann. 2000, 49, 205–208. [Google Scholar] [CrossRef]

- Schneider, J.-M.; Bigerelle, M.; Iost, A. Statistical analysis of the Vickers hardness. Mater. Sci. Eng. A 1999, 262, 256–263. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Takayama, A.; Yang, X.; Miura, H.; Sakai, T. Continuous static recrystallization in ultrafine-grained copper processed by multi-directional forging. Mater. Sci. Eng. A 2008, 478, 221–228. [Google Scholar] [CrossRef]

- Ghassemali, E.; MRiestra, M.; Bogdanoff, T.; Kumar, B.S.; Seifeddine, S. Hall-Petch equation in a hypoeutectic Al-Si cast alloy: Grain size vs. secondary dendrite arm spacing. Procedia Eng. 2017, 207, 19–24. [Google Scholar] [CrossRef]

- Huang, X.; Xie, G.; Liu, X.; Fu, H.; Shao, L.; Hao, Z. The influence of precipitation transformation on Young’s modulus and strengthening mechanism of a Cu–Be binary alloy. Mater. Sci. Eng. A 2020, 772, 138592. [Google Scholar] [CrossRef]

- Lang, Y.; Zhou, G.; Hou, L.; Zhang, J.; Zhuang, L. Significantly enhanced the ductility of the fine-grained Al–Zn–Mg–Cu alloy by strain-induced precipitation. Mater. Des. 2015, 88, 625–631. [Google Scholar] [CrossRef]

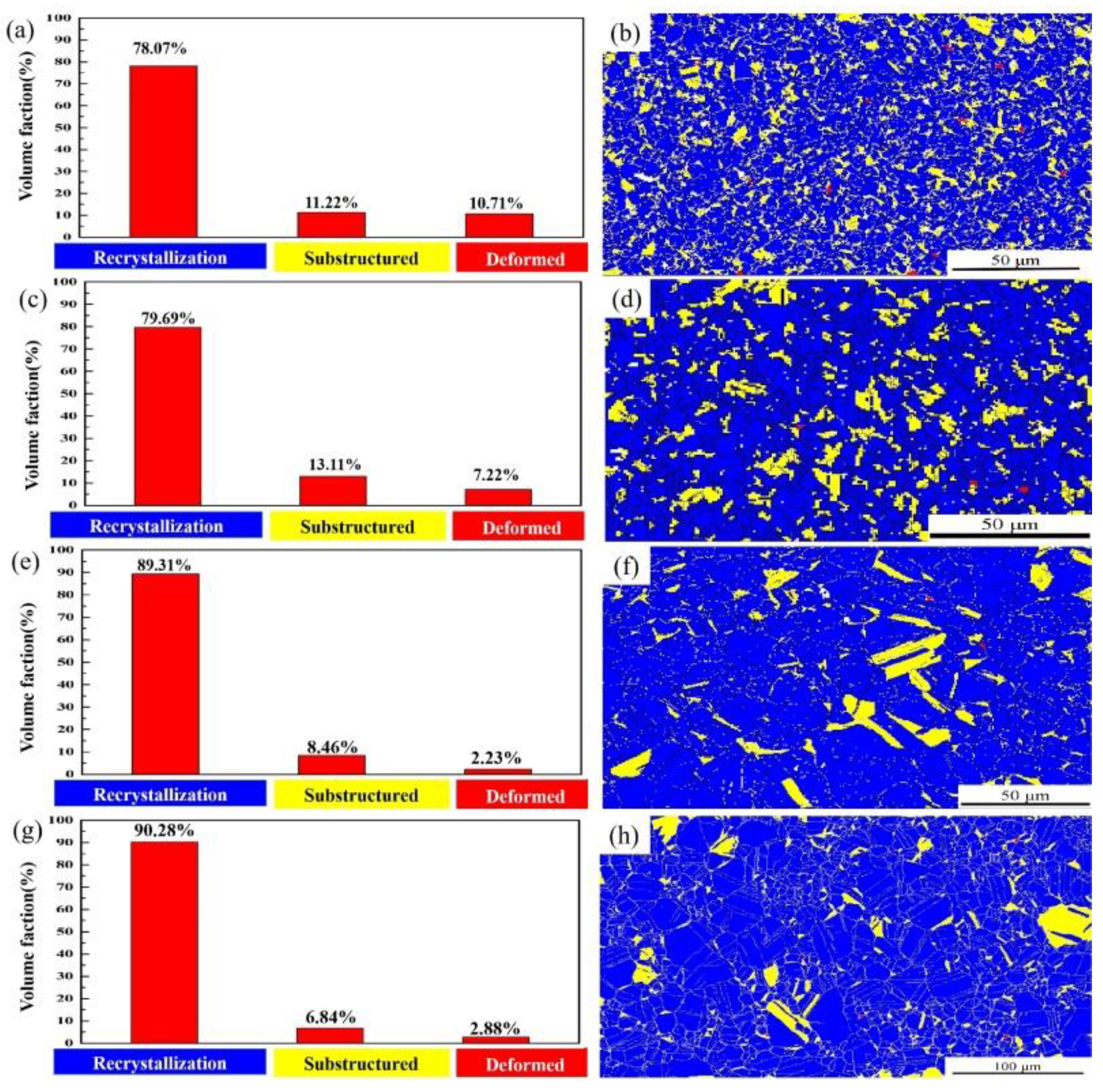

| Sample | Average Grain Size (μm) |

|---|---|

| 650 °C/15 min | 5.01 |

| 650 °C/60 min | 9.38 |

| 770 °C/15 min | 11.89 |

| 770 °C/60 min | 25.37 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, Q.; Yao, B.; Zhu, D.; Chen, D.; Zhang, P. Microstructure and Mechanical Evolution of Cu-2.7Be Sheets via Annealing. Metals 2020, 10, 241. https://doi.org/10.3390/met10020241

Liu Y, Wang Q, Yao B, Zhu D, Chen D, Zhang P. Microstructure and Mechanical Evolution of Cu-2.7Be Sheets via Annealing. Metals. 2020; 10(2):241. https://doi.org/10.3390/met10020241

Chicago/Turabian StyleLiu, Yang, Qinwei Wang, Bingqing Yao, Daibo Zhu, Deshan Chen, and Peng Zhang. 2020. "Microstructure and Mechanical Evolution of Cu-2.7Be Sheets via Annealing" Metals 10, no. 2: 241. https://doi.org/10.3390/met10020241

APA StyleLiu, Y., Wang, Q., Yao, B., Zhu, D., Chen, D., & Zhang, P. (2020). Microstructure and Mechanical Evolution of Cu-2.7Be Sheets via Annealing. Metals, 10(2), 241. https://doi.org/10.3390/met10020241