Phase Transformation-Induced Improvement in Hardness and High-Temperature Wear Resistance of Plasma-Sprayed and Remelted NiCrBSi/WC Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Microstructural Characterizations

2.3. Adhesion Strength, Microhardness and Tribology Test

3. Results and Discussion

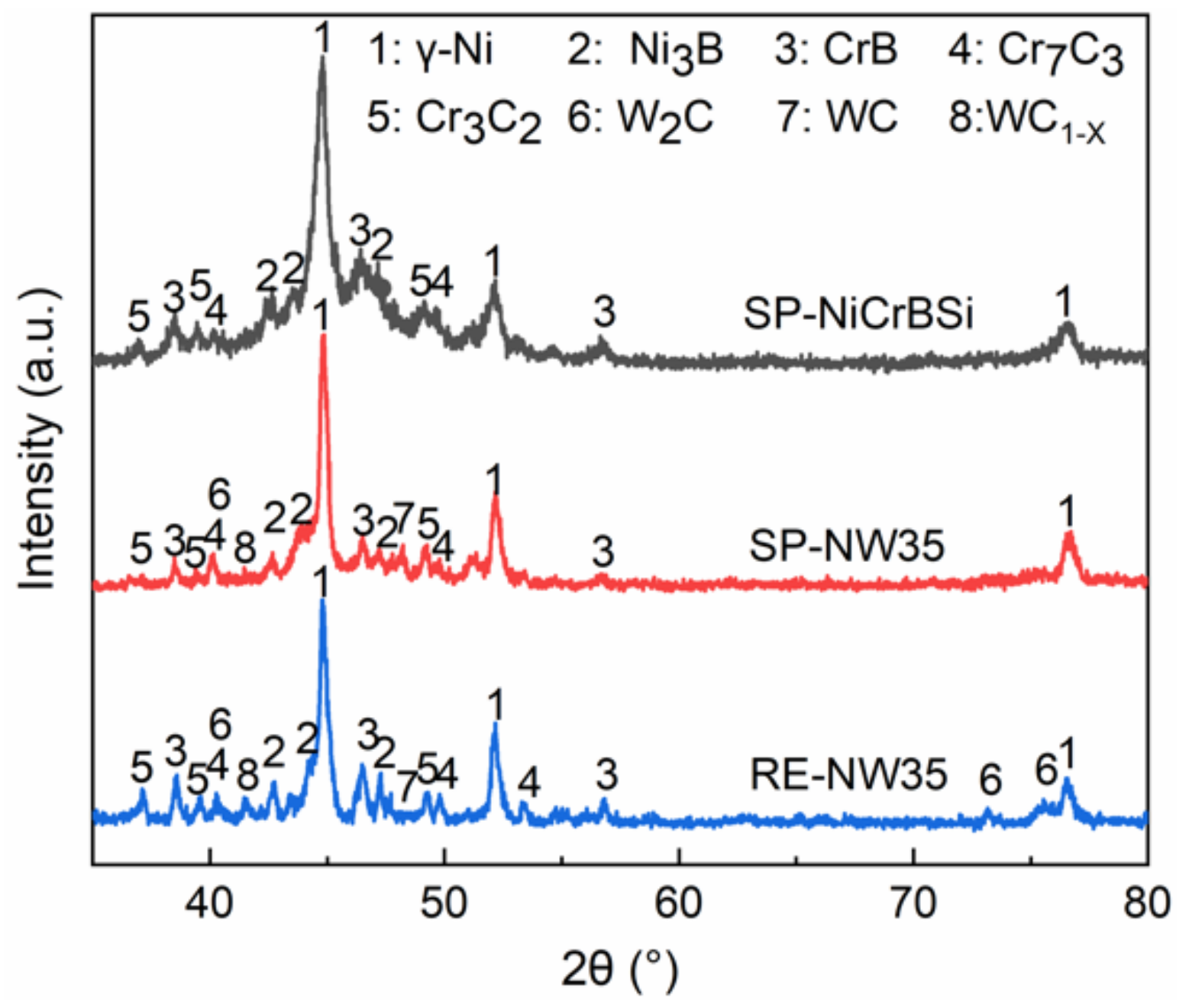

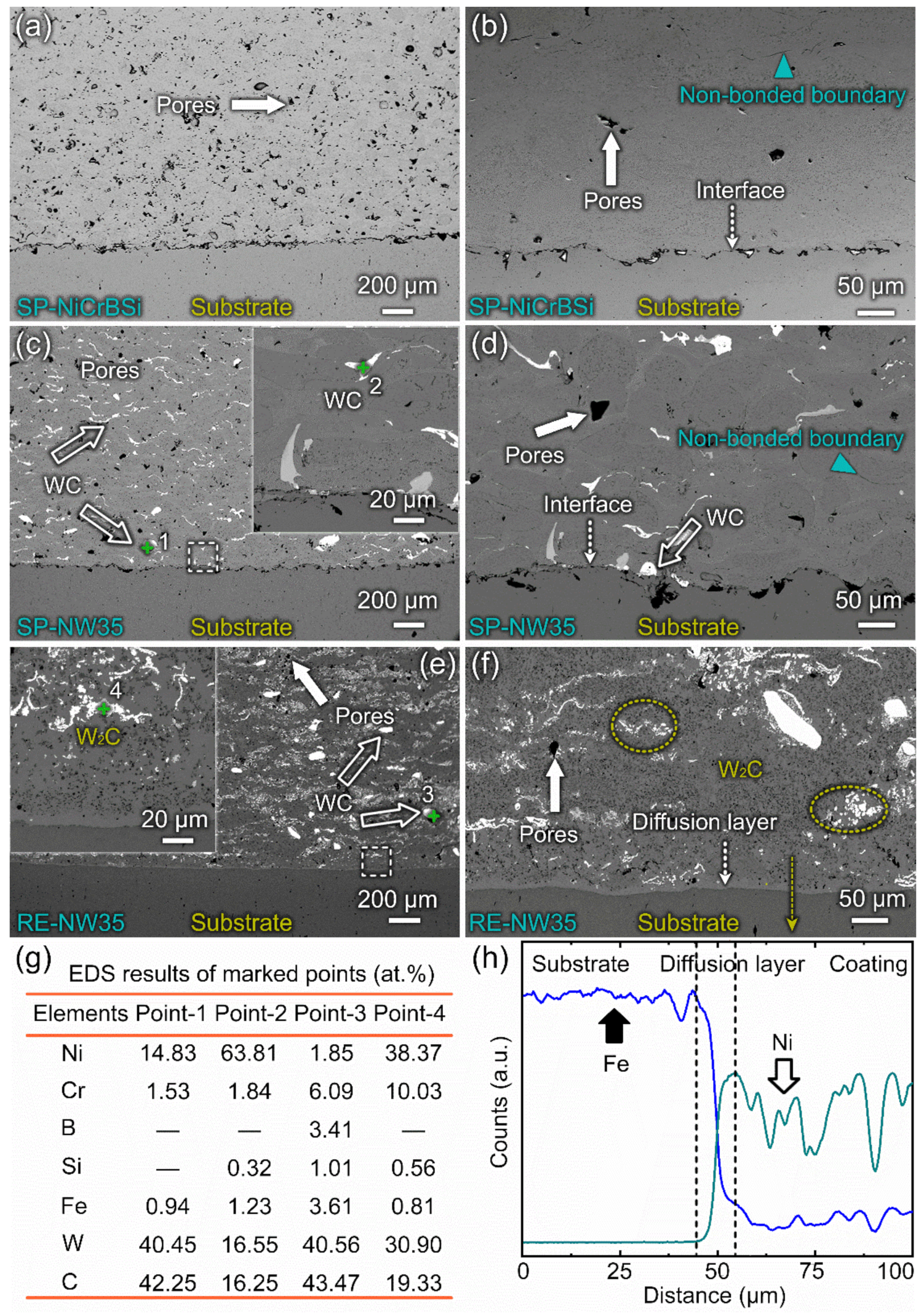

3.1. Microstructure Features

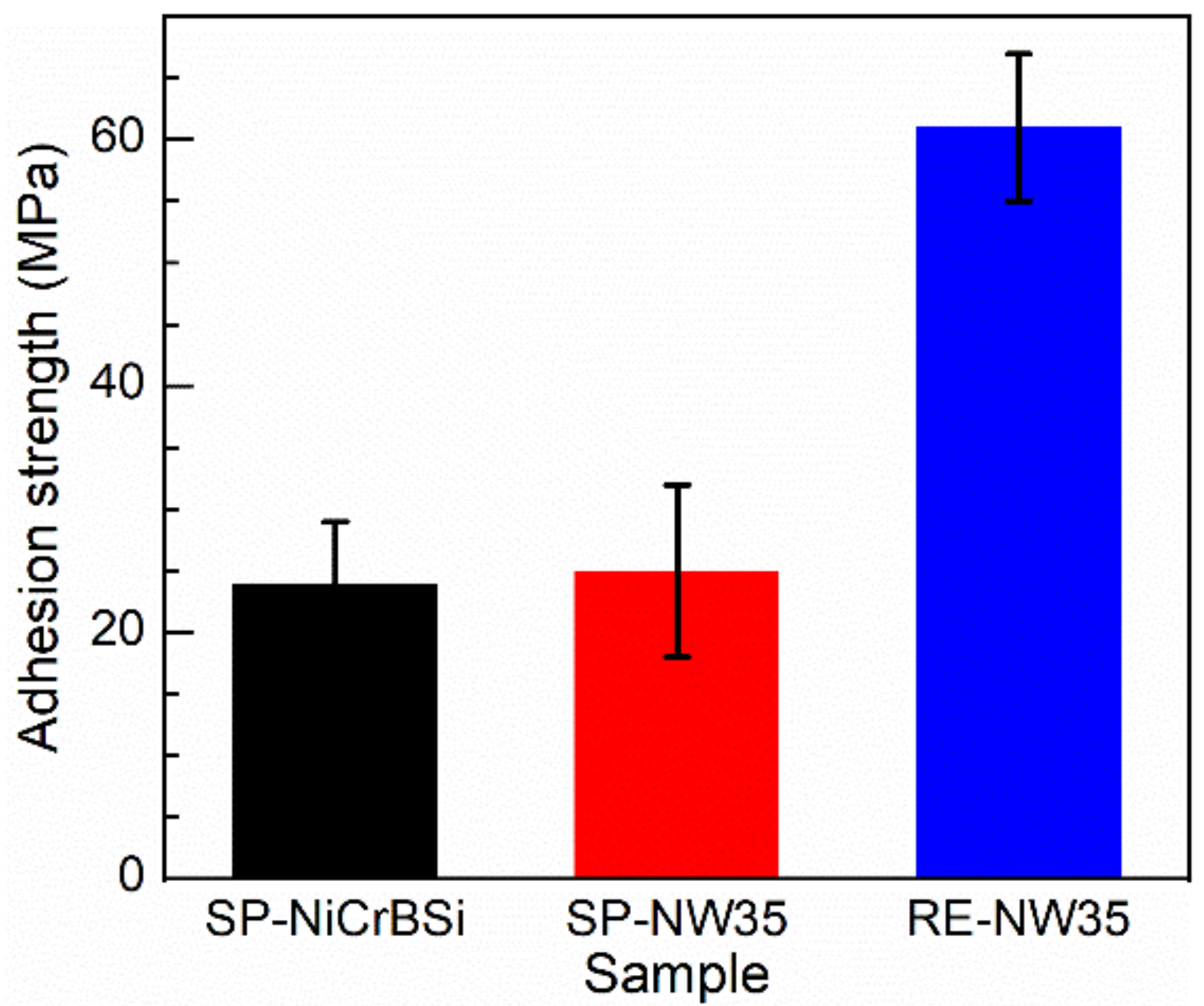

3.2. Adhesion Strength

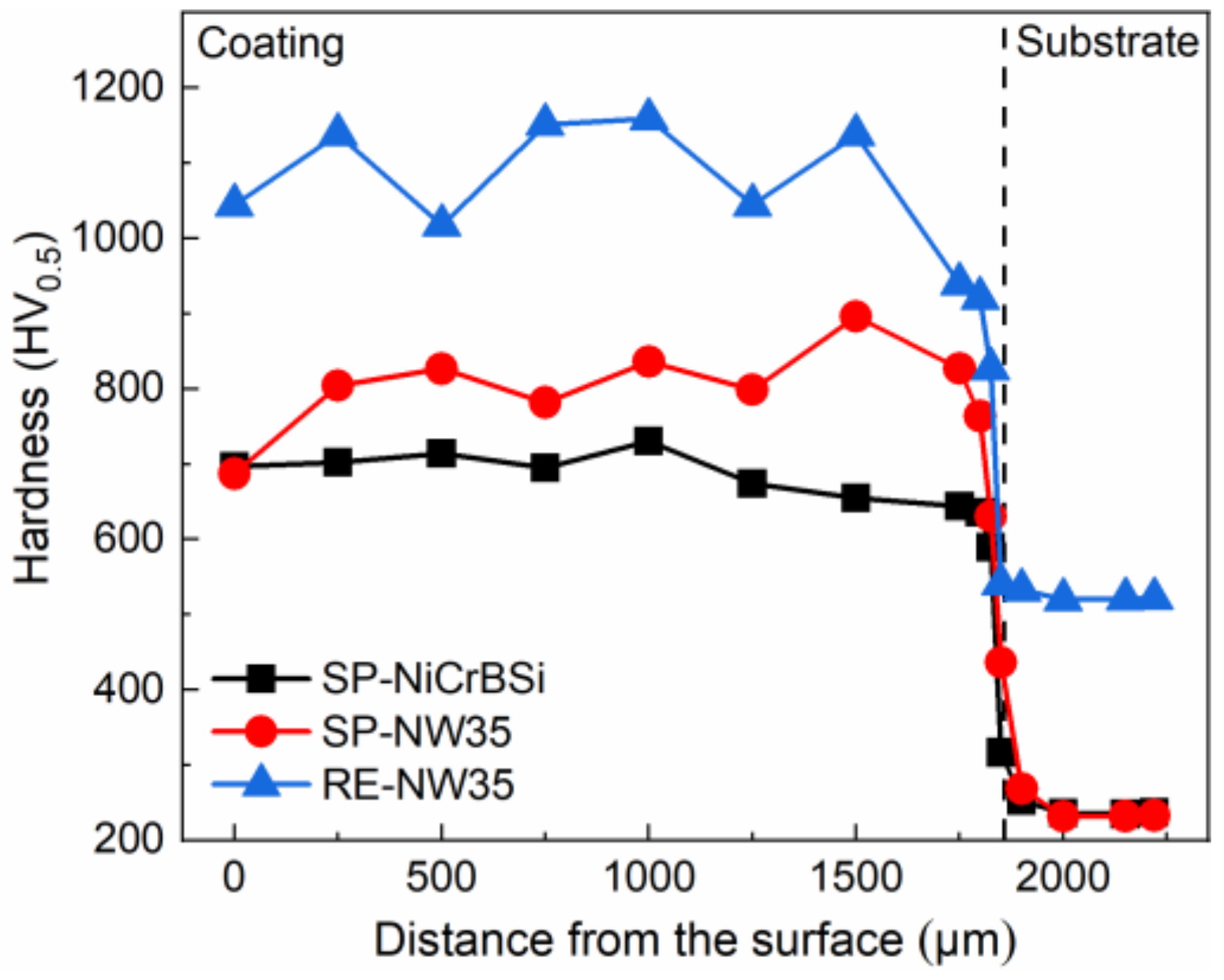

3.3. Hardness

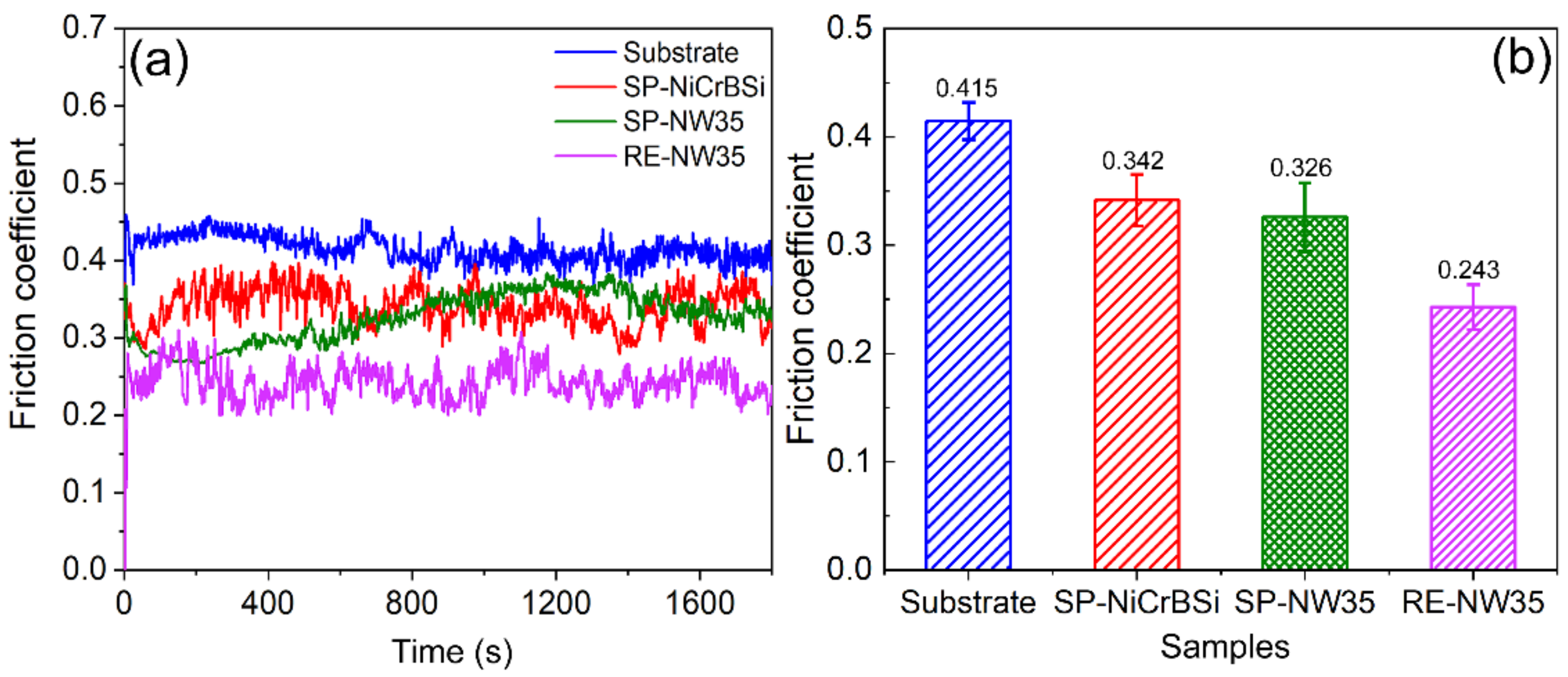

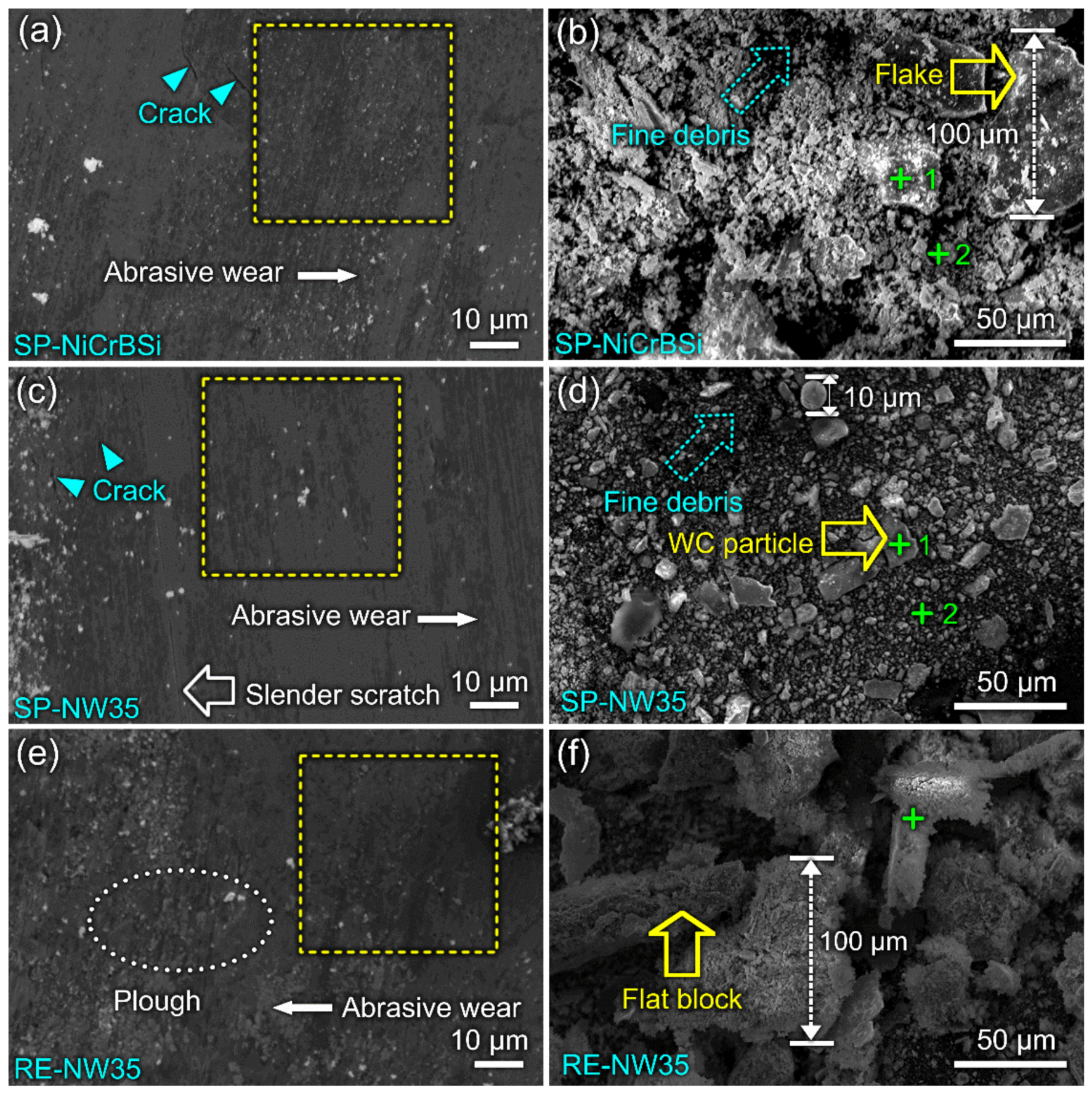

3.4. Wear Performance

4. Conclusions

- The SP-NiCrBSi coating shows a typical plasma-sprayed coating structure with a certain number of pores. The SP-NW35 coating primarily contains the WC reinforcements. After remelting, decarburization of WC takes place, resulting in the formation of W2C particles in the RE-NW35. The remelting process also reduces the pores and eliminates the non-bonded boundaries in the RE-NW35.

- The average hardness of the SP-NiCrBSi, SP-NW35 and RE-NW35 coatings is 673.82 ± 40.56, 785.14 ± 72.79 and 1061.23 ± 107.23 HV, respectively. The improved hardness of SP-NW35 is mainly attributed to the presence of reinforcements of WC. The hardness of RE-NW35 is significantly improved, which is attributed to the dispersion strengthening produced by small W2C particles, the reduction of pores and elimination of the non-bonded boundaries.

- The tribology result shows that the friction coefficients of the three coatings are 0.342 ± 0.021, 0.326 ± 0.042 and 0.243 ± 0.015, respectively, at 600 °C. The SP-NiCrBSi and SP-NW35 coatings display comparable wear volumes of 2.072 ± 0.42 and 1.884 ± 0.02 mm3, respectively. Although SP-NW35 has higher hardness than SP-NiCrBSi, the dropped WC particles during the tribology test may become abrasive, degrading the wear resistance of SP-NW35. After the remelting, the RE-NW35 coating possesses lower wear volume of 0.629 ± 0.02 mm3 as compared to the other two coating samples. The reduced pores in RE-NW35 decrease the cracking susceptibility and the increased hardness of RE-NW35 could against the micro-cutting during tribology.

Author Contributions

Funding

Conflicts of Interest

References

- Liang, Q.; Liu, X.; Li, P.; Ding, P.; Zhang, X. Development and application of high-temperature constitutive model of HNi55-7-4-2 alloy. Metals 2020, 10, 1250. [Google Scholar] [CrossRef]

- Sang, P.; Chen, L.-Y.; Zhao, C.; Wang, Z.-X.; Wang, H.; Lu, S.; Song, D.; Xu, J.-H.; Zhang, L.-C. Particle size-dependent microstructure, hardness and electrochemical corrosion behavior of atmospheric plasma sprayed NiCrBSi coatings. Metals 2019, 9, 1342. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, T.; Wang, H.; Sang, P.; Lu, S.; Wang, Z.-X.; Chen, S.; Zhang, L.-C. Phase interaction induced texture in a plasma sprayed-remelted NiCrBSi coating during solidification: An electron backscatter diffraction study. Surf. Coat. Technol. 2019, 358, 467–480. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, T.; Lu, S.; Wang, Z.-X.; Chen, S.; Zhang, L.-C. Improved hardness and wear resistance of plasma sprayed nanostructured NiCrBSi coating via short-time heat treatment. Surf. Coat. Technol. 2018, 350, 436–444. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.-Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Chen, K.; Zeng, L.; Li, Z.; Chai, L.; Wang, Y.; Chen, L.-Y.; Yu, H. Effects of laser surface alloying with Cr on microstructure and hardness of commercial purity Zr. J. Alloys Compd. 2019, 784, 1106–1112. [Google Scholar] [CrossRef]

- Chai, L.J.; Wang, S.Y.; Wu, H.; Guo, N.; Pan, H.C.; Chen, L.Y.; Murty, K.L.; Song, B. α→β Transformation characteristics revealed by pulsed laser-induced non-equilibrium microstructures in duplex-phase Zr alloy. Sci. China Tech. Sci. 2017, 60, 1255–1262. [Google Scholar] [CrossRef]

- Chai, L.; Chen, K.; Zhi, Y.; Murty, K.L.; Chen, L.Y.; Yang, Z. Nanotwins induced by pulsed laser and their hardening effect in a Zr alloy. J. Alloys Compd. 2018, 748, 163–170. [Google Scholar] [CrossRef]

- Wang, L.; Xie, L.; Lv, Y.; Zhang, L.-C.; Chen, L.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W. Microstructure evolution and superelastic behavior in Ti-35Nb-2Ta-3Zr alloy processed by friction stir processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef]

- Wang, L.; Qu, J.; Chen, L.; Meng, Q.; Zhang, L.C.; Qin, J.; Zhang, D.; Lu, W. Investigation of deformation mechanisms in β-Type Ti-35Nb-2Ta-3Zr Alloy via FSP leading to surface strengthening. Metall. Mater. Trans. A 2015, 46, 4813–4818. [Google Scholar] [CrossRef]

- Wang, Z.-X.; Chen, G.-Q.; Chen, L.-Y.; Xu, L.; Lu, S. Degradation behavior of micro-arc oxidized ZK60 magnesium alloy in a simulated body fluid. Metals 2018, 8, 724. [Google Scholar] [CrossRef]

- Jambor, M.; Trško, L.; Klusák, J.; Fintová, S.; Kajánek, D.; Nový, F.; Bokůvka, O. Effect of severe shot peening on the very-high cycle notch fatigue of an AW 7075 alloy. Metals 2020, 10, 1262. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Y.; Zhou, H.; Chen, X.; Liu, Y.; Xiao, L.; Huan, X.; Zhao, Y.; Zhu, Y. Mechanical properties and microstructures of commercial-purity aluminum processed by rotational accelerated shot peening plus cold rolling. Adv. Eng. Mater. 2020, 22, 1900478. [Google Scholar] [CrossRef]

- Pawlowski, L. Finely grained nanometric and submicrometric coatings by thermal spraying: A review. Surf. Coat. Technol. 2008, 202, 4318–4328. [Google Scholar] [CrossRef]

- Song, Y.S.; Lee, I.-G.; Lee, D.Y.; Kim, D.-J.; Kim, S.; Lee, K. High-temperature properties of plasma-sprayed coatings of YSZ/NiCrAlY on Inconel substrate. Mater. Sci. Eng. A 2002, 332, 129–133. [Google Scholar] [CrossRef]

- Nishinoiri, S.; Enoki, M.; Tomita, K. In situ monitoring of microfracture during plasma spray coating by laser AE technique. Sci. Tech. Adv. Mater. 2003, 4, 623–631. [Google Scholar] [CrossRef]

- Verné, E.; Ferraris, M.; Ventrella, A.; Paracchini, L.; Krajewski, A.; Ravaglioli, A. Sintering and plasma spray deposition of bioactive glass-Matrix composites for medical applications. J. Eur. Ceram. Soc. 1998, 18, 363–372. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y.; Wang, L. Surface modification of titanium and titanium alloys: Technologies, developments and future interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Otsubo, F.; Era, H.; Kishitake, K. Structure and phases in nickel-base self-fluxing alloy coating containing high chromium and boron. J. Therm. Spray Technol. 2000, 9, 107–113. [Google Scholar] [CrossRef]

- Lei, J.; Shi, C.; Zhou, S.; Gu, Z.; Zhang, L.C. Enhanced corrosion and wear resistance properties of carbon fiber reinforced Ni-based composite coating by laser cladding. Surf. Coat. Technol. 2018, 334, 274–285. [Google Scholar] [CrossRef]

- Shi, C.; Lei, J.; Zhou, S.; Dai, X.; Zhang, L.C. Microstructure and mechanical properties of carbon fibers strengthened Ni-based coatings by laser cladding: The effect of carbon fiber contents. J. Alloys Compd. 2018, 744, 146–155. [Google Scholar] [CrossRef]

- Houdková, Š.; Smazalová, E.; Vostřák, M.; Schubert, J. Properties of NiCrBSi coating, as sprayed and remelted by different technologies. Surf. Coat. Technol. 2014, 253, 14–26. [Google Scholar] [CrossRef]

- Singh, H.; Sidhu, B.S.; Puri, D.; Prakash, S. Use of plasma spray technology for deposition of high temperature oxidation/corrosion resistant coatings—A review. Mater. Corros. 2007, 58, 92–102. [Google Scholar] [CrossRef]

- Planche, M.P.; Liao, H.; Normand, B.; Coddet, C. Relationships between NiCrBSi particle characteristics and corresponding coating properties using different thermal spraying processes. Surf. Coat. Technol. 2005, 200, 2465–2473. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Wang, Z.; Yue, X.; Ji, P.-J.; Shu, S.-L. Simultaneously improved strength and toughness of in situ bi-phased TiB2–Ti(C,N)–Ni cermets by Mo addition. J. Alloys Compd. 2019, 820, 153068. [Google Scholar] [CrossRef]

- Yang, H.; Yue, X.; Wang, Z.; Shao, Y.; Shu, S. Strengthening mechanism of TiC/Al composites using Al-Ti-C/CNTs with doping alloying elements (Mg, Zn and Cu). J. Mater. Res. Tech. 2020, 9, 6475–6487. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Wang, Z.; Shu, S.-L.; Lu, J.-B. Effect of Ta addition on the microstructures and mechanical properties of in situ bi-phase (TiB2-TiCxNy)/(Ni-Ta) cermets. Ceram. Int. 2020, 45, 4408–4417. [Google Scholar] [CrossRef]

- Serres, N.; Hlawka, F.; Costil, S.; Langlade, C.; MacHi, F. Microstructures and mechanical properties of metallic NiCrBSi and composite NiCrBSi-WC layers manufactured via hybrid plasma/laser process. Appl. Surf. Sci. 2011, 257, 5132–5137. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, J.; Chen, J.; Zhao, J.; Yu, Y.; Zhou, H. High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC-Ni composite coatings. Wear 2011, 270, 492–498. [Google Scholar] [CrossRef]

- Rachidi, R.; Bachir, E.; Delaunois, F.; Vitry, V.; Deschuyteneer, D. Wear performance of thermally sprayed NiCrBSi and NiCrBSi-WC coatings under two different wear modes. J. Mater. Environ. Sci. 2017, 8, 4550–4559. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Huang-Bin, L.I.; Tan, Y.F.; Gang, W.U.; Tan, H.; Zhang, S.B. Tribological properties of NiCrBSi/WC spray-welding coatings in corrosive mediums. Mach. Build. Automat. 2006, 2. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-ZZHD200602021.htm (accessed on 14 December 2020).

- Zakharova, E.S.; Markova, I.Y.; Maslov, A.L.; Polushin, N.I.; Laptev, A.I. Morphology of powders of tungsten carbide used in wear-resistant coatings and deposition on the PDC drill bits. J. Phys. Conf. 2017, 857, 012058. [Google Scholar] [CrossRef]

- Gell, M.; Xie, L.; Ma, X.; Jordan, E.H.; Padture, N.P. Highly durable thermal barrier coatings made by the solution precursor plasma spray process. Surf. Coat. Technol. 2004, 177, 97–102. [Google Scholar] [CrossRef]

- Ahmaniemi, S.; Vuoristo, P.; Mantyla, T.; Gualco, C.; Bonadei, A.; Maggio, R.D. Thermal cycling resistance of modified thick thermal barrier coatings. Surf. Coat. Technol. 2004, 190, 378–387. [Google Scholar] [CrossRef]

- Fukumasa, O.; Osaki, K.; Fujimoto, S.; Lungu, C.P.; Lungu, A.M. Low friction coatings prepared by high performance type spray gun. Surf. Coat. Technol. 2003, 169–170, 415–418. [Google Scholar] [CrossRef]

- Li, H.; Khor, K.; Yu, L.; Cheang, P. Microstructure modifications and phase transformation in plasma-sprayed WC–Co coatings following post-spray spark plasma sintering. Surf. Coat. Technol. 2005, 194, 96–102. [Google Scholar] [CrossRef]

- Calin, M.; Zhang, L.C.; Eckert, J. Tailoring of microstructure and mechanical properties of a Ti-based bulk metallic glass-forming alloy. Scripta Mater. 2007, 57, 1101–1104. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, L.C.; Zhang, W.Y.; Das, J.; Kim, K.B.; Eckert, J. Interfacial reaction during the fabrication of Ni60Nb40 metallic glass particles-reinforced Al based MMCs. Mater. Sci. Eng. A 2007, 444, 206–213. [Google Scholar] [CrossRef]

- Zhang, L.C.; Jia, Z.; Lyu, F.; Liang, S.X.; Lu, J. A review of catalytic performance of metallic glasses in wastewater treatment: Recent progress and prospects. Prog. Mater. Sci. 2019, 105, 100576. [Google Scholar] [CrossRef]

- Zhang, L.C.; Xu, J.; Ma, E. Consolidation and properties of ball-milled Ti50Cu18Ni22Al4Sn6 glassy alloy by equal channel angular extrusion. Mater. Sci. Eng. A 2006, 434, 280–288. [Google Scholar] [CrossRef]

- Jia, Z.; Duan, X.; Zhang, W.; Wang, W.; Sun, H.; Wang, S.; Zhang, L.-C. Ultra-sustainable Fe78Si9B13 metallic glass as a catalyst for activation of persulfate on methylene blue degradation under UV-Vis light. Sci. Rep. 2016, 6, 38520. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.C.; Shen, Z.Q.; Xu, J. Mechanically milling-induced amorphization in Sn-containing Ti-based multicomponent alloy systems. Mater. Sci. Eng. A 2005, 394, 204–209. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Xu, J.; Eckert, J. Thermal stability and crystallization kinetics of mechanically alloyed TiC/Ti-based metallic glass matrix composite. J. Appl. Phys. 2006, 100, 033514. [Google Scholar] [CrossRef]

- Zhang, L.C.; Xu, J. Glass-forming ability of melt-spun multicomponent (Ti, Zr, Hf)–(Cu, Ni, Co)–Al alloys with equiatomic substitution. J. Non-Cryst. Solids 2004, 347, 166–172. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Kim, K.B.; Yu, P.; Zhang, W.Y.; Kunz, U.; Eckert, J. Amorphization in mechanically alloyed (Ti, Zr, Nb)-(Cu, Ni)-Al equiatomic alloys. J. Alloys Compd. 2007, 428, 157–163. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Wang, H.; Zhao, C.; Lu, S.; Wang, Z.-X.; Sha, J.; Chen, S.; Zhang, L.-C. Automatic remelting and enhanced mechanical performance of a plasma sprayed NiCrBSi coating. Surf. Coat. Technol. 2019, 369, 31–43. [Google Scholar] [CrossRef]

- Serres, N.; Hlawka, F.o.; Costil, S.; Langlade, C.; Machi, F. Microstructures of Metallic NiCrBSi Coatings Manufactured via Hybrid Plasma Spray and In Situ Laser Remelting Process. J. Therm. Spray Technol. 2011, 20, 336–343. [Google Scholar] [CrossRef]

- Miao, S.M.; Lei, M.K. Surface morphology of Cr2O3 coatings on steel irradiated by high-intensity pulsed ion beam. Nucl. Instrum. Methods Phys. Res. 2006, 243, 335–339. [Google Scholar] [CrossRef]

- Iwaszko, J. Surface remelting treatment of plasma-sprayed Al2O3+13 wt.% TiO2 coatings. Surf. Coat. Technol. 2006, 201, 3443–3451. [Google Scholar] [CrossRef]

- Cui, C.; Ye, F.; Song, G. Laser surface remelting of Fe-based alloy coatings deposited by HVOF. Surf. Coat. Technol. 2012, 206, 2388–2395. [Google Scholar] [CrossRef]

- Wu, Y.Z.; Liao, W.-B.; Wang, F.; Wang, M.-L.; Yu, C.-Y.; Wang, Z.; Guo, Z.-X.; Liu, Z.-Y.; Cao, Y.-B.; Huang, J.-J. Effect of electron beam remelting treatments on the performances of plasma sprayed zirconia coatings. J. Alloys Compd. 2018, 756, 33–39. [Google Scholar] [CrossRef]

- Tian-shun, D.; Li, L.; Bin-guo, F.; Guo-lu, L.; Hai-dou, W.; Yang, F. Investigation of rolling/sliding contact fatigue behaviors of induction remelted Ni-based coating. Surf. Coat. Technol. 2019, 372, 451–462. [Google Scholar] [CrossRef]

- ASTM. Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings; ASTM International: West Conshohocken, PA, USA, 2014; E2109-01; Available online: http://www.astm.org (accessed on 14 December 2020).

- Tian, J.J.; Yao, S.W.; Luo, X.T.; Li, C.X.; Li, C.J. An effective approach for creating metallurgical self-bonding in plasma-spraying of NiCr-Mo coating by designing shell-core-structured powders. Acta Mater. 2016, 110, 19–30. [Google Scholar] [CrossRef]

- Zhang, L.C.; Shen, Z.Q.; Xu, J. Glass formation in a (Ti, Zr, Hf)–(Cu, Ni, Ag)–Al high-order alloy system by mechanical alloying. J. Mater. Res. 2003, 18, 2141–2149. [Google Scholar] [CrossRef]

- Liang, S.X.; Jia, Z.; Liu, Y.J.; Zhang, W.; Wang, W.; Lu, J.; Zhang, L.C. Compelling rejuvenated catalytic performance in metallic glasses. Adv. Mater. 2018, 30, 1802764. [Google Scholar] [CrossRef]

- Zhang, L.C.; Xu, J.; Ma, E. Mechanically alloyed amorphous Ti50(Cu0.45Ni0.55)44–xAlxSi4B2 alloys with supercooled liquid region. J. Mater. Res. 2002, 17, 1743–1749. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Prasad, S.V.; Zabinski, J.S. Nanocrystalline carbide/amorphous carbon composites. J. Appl. Phys. 1997, 82, 855–858. [Google Scholar] [CrossRef]

- Gao, Y.; Song, X.; Liu, X.; Wei, C.; Wang, H.; Guo, G. On the formation of WC1−x in nanocrystalline cemented carbides. Scripta Mater. 2013, 68, 108–110. [Google Scholar] [CrossRef]

- Pawlak, W.; Kubiak, K.J.; Wendler, B.G.; Mathia, T.G. Wear resistant multilayer nanocomposite WC1−x/C coating on Ti–6Al–4V titanium alloy. Tri. Inter. 2015, 82, 400–406. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, L.; Xu, H.; Xiao, J.; Zhang, G.; Liao, H. Role of Mo on tribological properties of atmospheric plasma-sprayed Mo-NiCrBSi composite coatings under dry and oil-lubricated conditions. J. Alloys Compd. 2017, 727, 841–850. [Google Scholar] [CrossRef]

- Bergant, Z.; Trdan, U.; Grum, J. Effect of high-temperature furnace treatment on the microstructure and corrosion behavior of NiCrBSi flame-sprayed coatings. Corros. Sci. 2014, 88, 372–386. [Google Scholar] [CrossRef]

- Niranatlumpong, P.; Koiprasert, H. Phase transformation of NiCrBSi–WC and NiBSi–WC arc sprayed coatings. Surf. Coat. Technol. 2011, 206, 440–445. [Google Scholar] [CrossRef]

- Kılıçay, K.; Buytoz, S.; Ulutan, M. Microstructural and tribological properties of induction cladded NiCrBSi /WC composite coatings. Surf. Coat. Technol. 2020, 397, 125974. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Zhang, L.C.; Lu, W.; Zhang, L.; Wang, L.; Zhang, D. Effects of alloyed Si on the autoclave corrosion performance and periodic corrosion kinetics in Zr-Sn-Nb-Fe-O alloys. Corros. Sci. 2015, 100, 651–662. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Lu, W.; Zhang, L.C.; Wang, L.; Zhang, D. Effect of low-temperature pre-deformation on precipitation behavior and microstructure of a Zr-Sn-Nb-Fe-Cu-O alloy during fabrication. J. Nucl. Sci. Technol. 2016, 53, 496–507. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Cui, Y.-W.; Zhang, L.-C. Recent development in beta titanium alloys for biomedical applications. Metals 2020, 10, 1139. [Google Scholar] [CrossRef]

- Chen, L.Y.; Sang, P.; Zhang, L.; Song, D.; Chu, Y.Q.; Chai, L.; Zhang, L.C. Homogenization and growth behavior of second-phase particles in a deformed Zr-Sn-Nb-Fe-Cu-Si-O alloy. Metals 2018, 8, 759. [Google Scholar] [CrossRef]

- Rabadia, C.D.; Liu, Y.J.; Zhao, C.H.; Wang, J.C.; Jawed, S.F.; Wang, L.Q.; Chen, L.Y.; Sun, H.; Zhang, L.C. Improved trade-off between strength and plasticity in titanium based metastable beta type Ti-Zr-Fe-Sn alloys. Mater. Sci. Eng. A 2019, 766, 138340. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Zhang, L.C.; Lu, W.; Wang, L.; Zhang, L.; Zhang, D. Zr-Sn-Nb-Fe-Si-O alloy for fuel cladding candidate: Processing, microstructure, corrosion resistance and tensile behavior. Corros. Sci. 2015, 100, 332–340. [Google Scholar] [CrossRef]

- Liu, L.; Xu, H.; Xiao, J.; Wei, X.; Zhang, G.; Zhang, C. Effect of heat treatment on structure and property evolutions of atmospheric plasma sprayed NiCrBSi coatings. Surf. Coat. Technol. 2017, 325, 548–554. [Google Scholar] [CrossRef]

- Blau, P.J. The significance and use of the friction coefficient. Tri. Inter. 2001, 34, 585–591. [Google Scholar] [CrossRef]

- Deschuyteneer, D.; Petit, F.; Gonon, M.; Cambier, F. Processing and characterization of laser clad NiCrBSi/WC composite coatings—Influence of microstructure on hardness and wear. Surf. Coat. Technol. 2015, 283, 162–171. [Google Scholar] [CrossRef]

- Sheppard, P.; Koiprasert, H. Effect of W dissolution in NiCrBSi–WC and NiBSi–WC arc sprayed coatings on wear behaviors. Wear 2014, 317, 194–200. [Google Scholar] [CrossRef]

- Li, G.J.; Li, J.; Luo, X. Effects of high temperature treatment on microstructure and mechanical properties of laser-clad NiCrBSi/WC coatings on titanium alloy substrate. Mater. Charact. 2014, 98, 83–92. [Google Scholar] [CrossRef]

| Component | Cr | B | Si | Fe | C | W | Ni |

|---|---|---|---|---|---|---|---|

| NiCrBSi | 16.2 | 3.0 | 4.5 | 5.3 | 0 | - | Bal. |

| WC-12Ni | - | - | - | - | 5.4 | 82.6 | 12.0 |

| 2Cr13 stainless steel | 13.0 | - | 0.8 | Bal. | - | - | 0.6 |

| Parameters | SP-NiCrBSi | SP-NW35 | RE-NW35 (Remelting) |

|---|---|---|---|

| Power (kW) | 30 | 30 | 35 |

| Distance to the substrate (mm) | 80 | 90 | 40 |

| Main gas Ar (psi) | 80 | 90 | 80 |

| Secondary gas N2 (dm3/s) | 1 | 1 | 1 |

| Time (min) | 1.5 | 2 | 2.5 |

| Spray step (mm) | 3 | 3 | 3 |

| Powder feed rate (g/s) | 0.3 | 0.3 | - |

| Gun traverse rate (mm/s) | 100 | 100 | 10 |

| Fe | Cr | Ni | O | Si | C | B | W | |

|---|---|---|---|---|---|---|---|---|

| SP-NiCrBSi | 3.87 | 16.5 | 69.36 | 3.70 | 3.89 | 2.69 | - | - |

| SP-NW35 | 4.16 | 17.65 | 65.39 | 3.42 | 2.58 | 2.72 | - | 6.79 |

| RE-NW35 | 3.74 | 17 | 57.01 | 3.13 | 2.96 | 6.10 | - | 12.76 |

| Fe | Cr | Ni | O | Si | C | B | W | |

|---|---|---|---|---|---|---|---|---|

| SP-NiCrBSi-1 | 4.20 | 16.15 | 64.58 | 8.82 | 3.43 | 2.82 | 0.36 | - |

| SP-NiCrBSi-2 | 3.62 | 16.23 | 64.20 | 3.59 | 3.03 | 8.97 | - | - |

| SP-NW35-1 | 0.48 | 0.94 | 2.18 | 1.62 | 0.36 | 5.86 | - | 88.56 |

| SP-NW35-2 | 3.46 | 10.67 | 49.62 | 4.78 | 3.01 | 2.74 | 0.45 | 22.38 |

| RE-NW35 | 1.87 | 3.36 | 32.13 | 6.33 | 0.48 | 3.15 | 1.79 | 50.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sha, J.; Chen, L.-Y.; Liu, Y.-T.; Yao, Z.-J.; Lu, S.; Wang, Z.-X.; Zang, Q.-H.; Mao, S.-H.; Zhang, L.-C. Phase Transformation-Induced Improvement in Hardness and High-Temperature Wear Resistance of Plasma-Sprayed and Remelted NiCrBSi/WC Coatings. Metals 2020, 10, 1688. https://doi.org/10.3390/met10121688

Sha J, Chen L-Y, Liu Y-T, Yao Z-J, Lu S, Wang Z-X, Zang Q-H, Mao S-H, Zhang L-C. Phase Transformation-Induced Improvement in Hardness and High-Temperature Wear Resistance of Plasma-Sprayed and Remelted NiCrBSi/WC Coatings. Metals. 2020; 10(12):1688. https://doi.org/10.3390/met10121688

Chicago/Turabian StyleSha, Jin, Liang-Yu Chen, Yi-Tong Liu, Zeng-Jian Yao, Sheng Lu, Ze-Xin Wang, Qian-Hao Zang, Shu-Hua Mao, and Lai-Chang Zhang. 2020. "Phase Transformation-Induced Improvement in Hardness and High-Temperature Wear Resistance of Plasma-Sprayed and Remelted NiCrBSi/WC Coatings" Metals 10, no. 12: 1688. https://doi.org/10.3390/met10121688

APA StyleSha, J., Chen, L.-Y., Liu, Y.-T., Yao, Z.-J., Lu, S., Wang, Z.-X., Zang, Q.-H., Mao, S.-H., & Zhang, L.-C. (2020). Phase Transformation-Induced Improvement in Hardness and High-Temperature Wear Resistance of Plasma-Sprayed and Remelted NiCrBSi/WC Coatings. Metals, 10(12), 1688. https://doi.org/10.3390/met10121688