Rapid Joining of Commercial-Purity Ti to 304 Stainless Steel Using Joule Heating Diffusion Bonding: Interfacial Microstructure and Strength of the Dissimilar Joint

Abstract

1. Introduction

2. Experimental Procedures

2.1. Materials

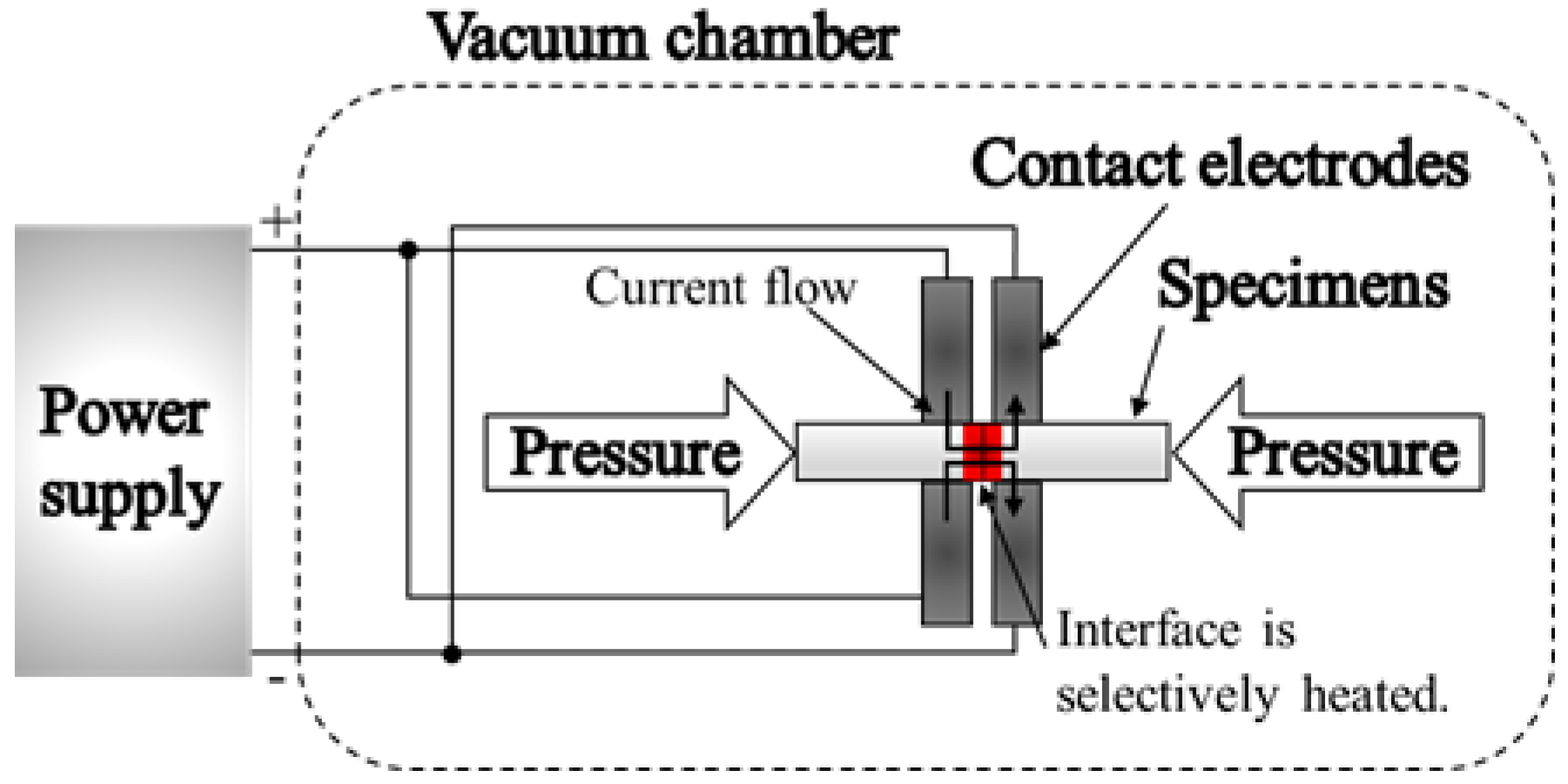

2.2. JHDB

2.3. Mechanical and Microstructual Tests

3. Results and Discussion

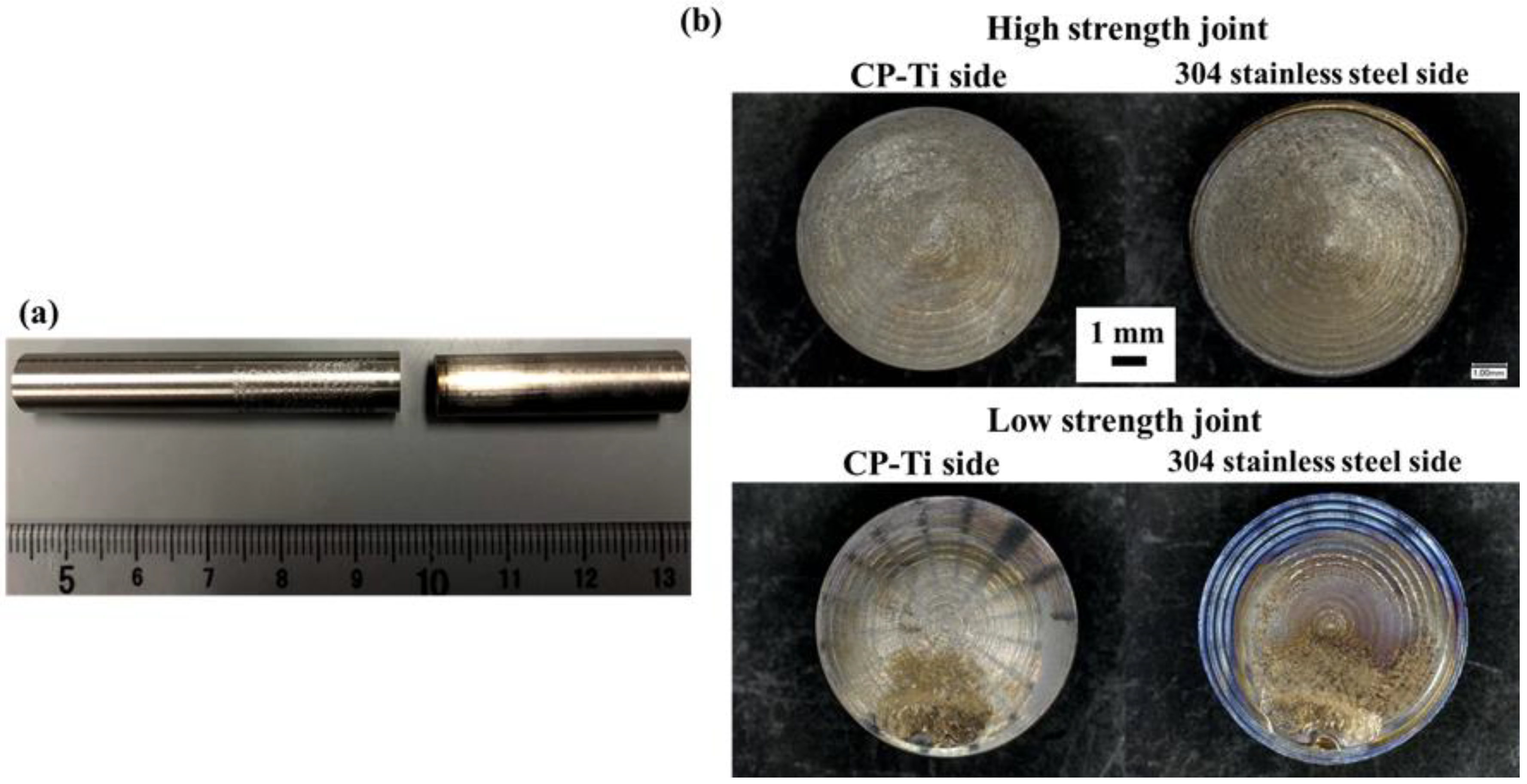

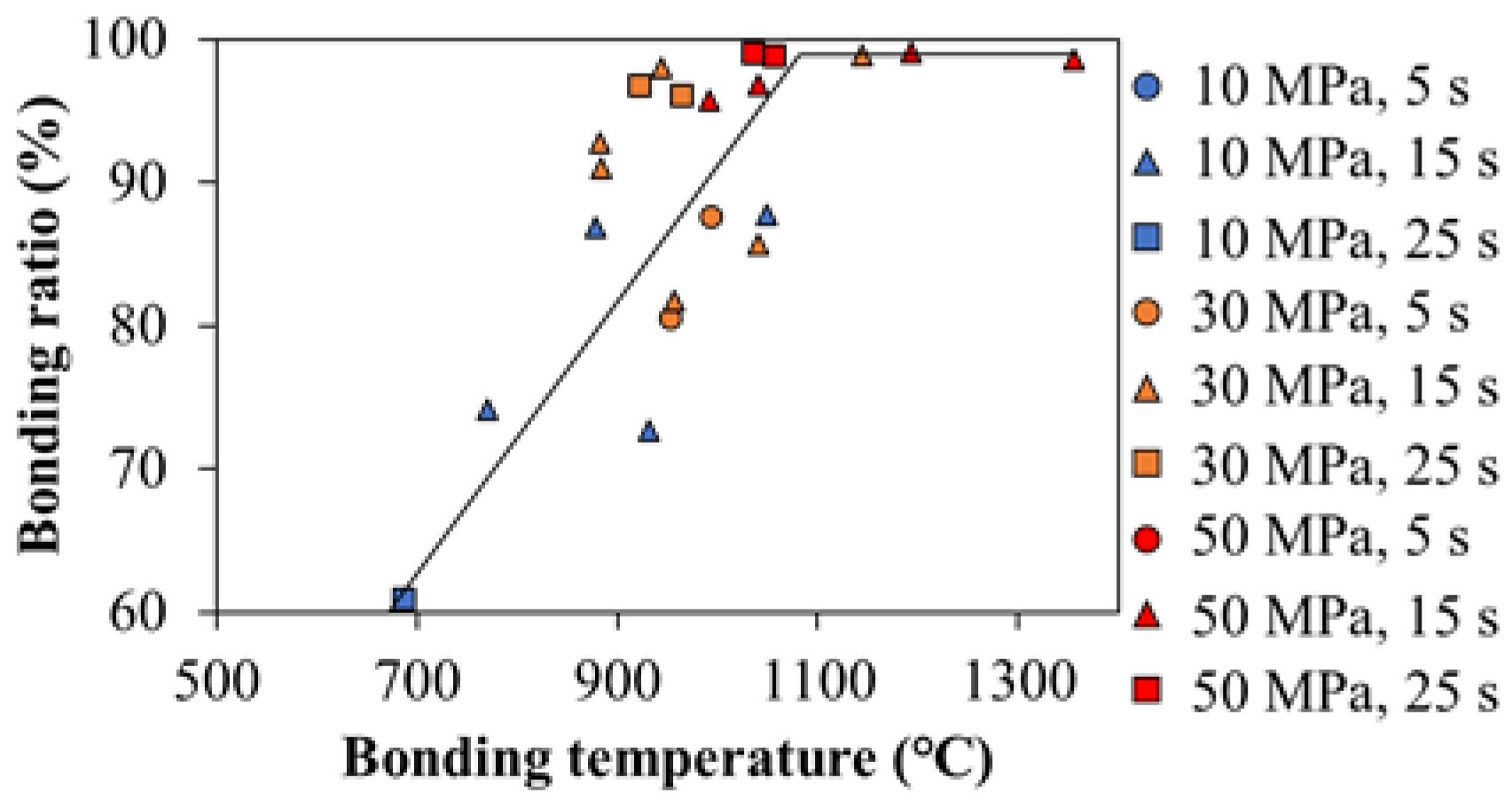

3.1. Appearnace of the Joint

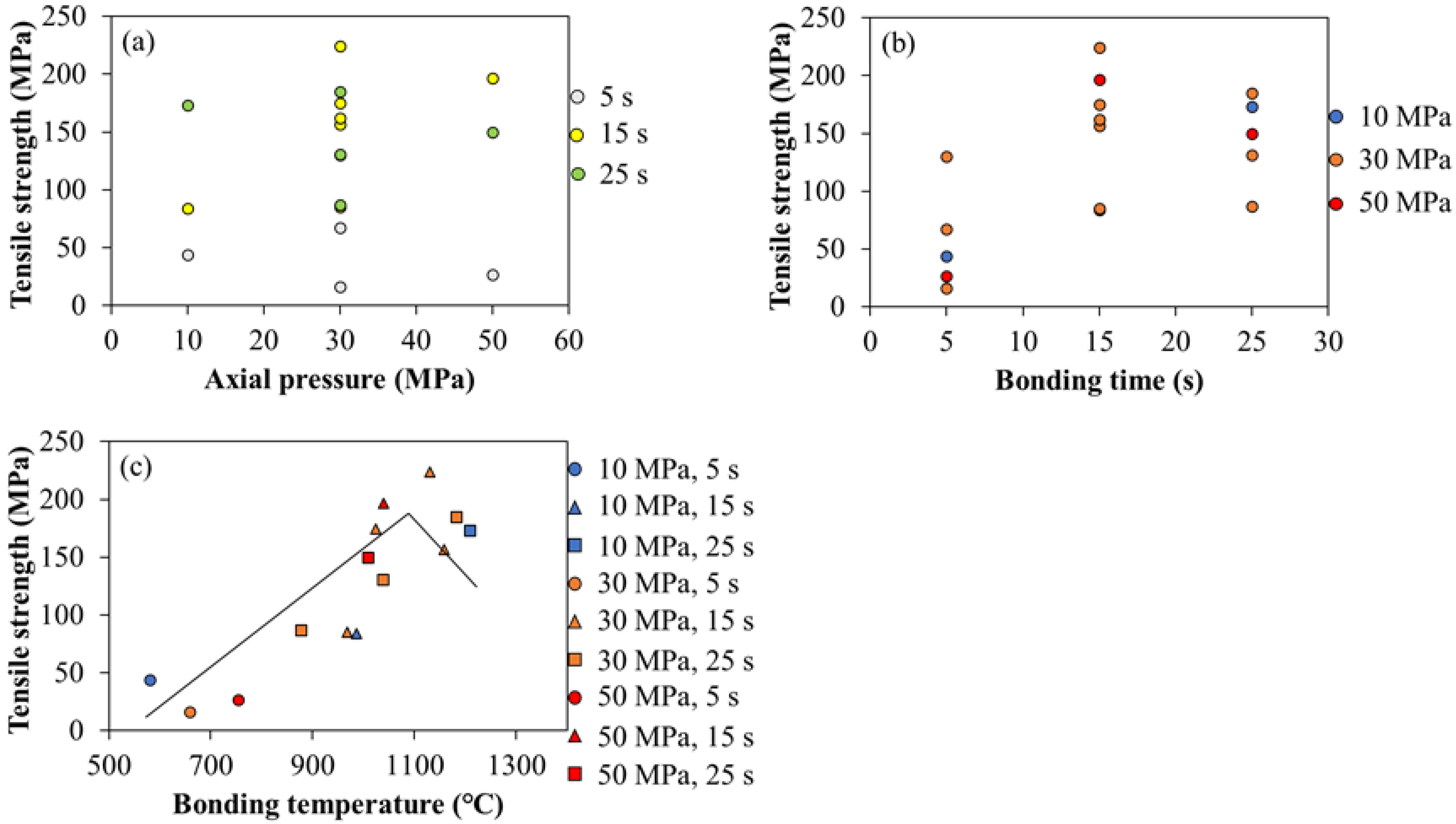

3.2. Tensile Strength

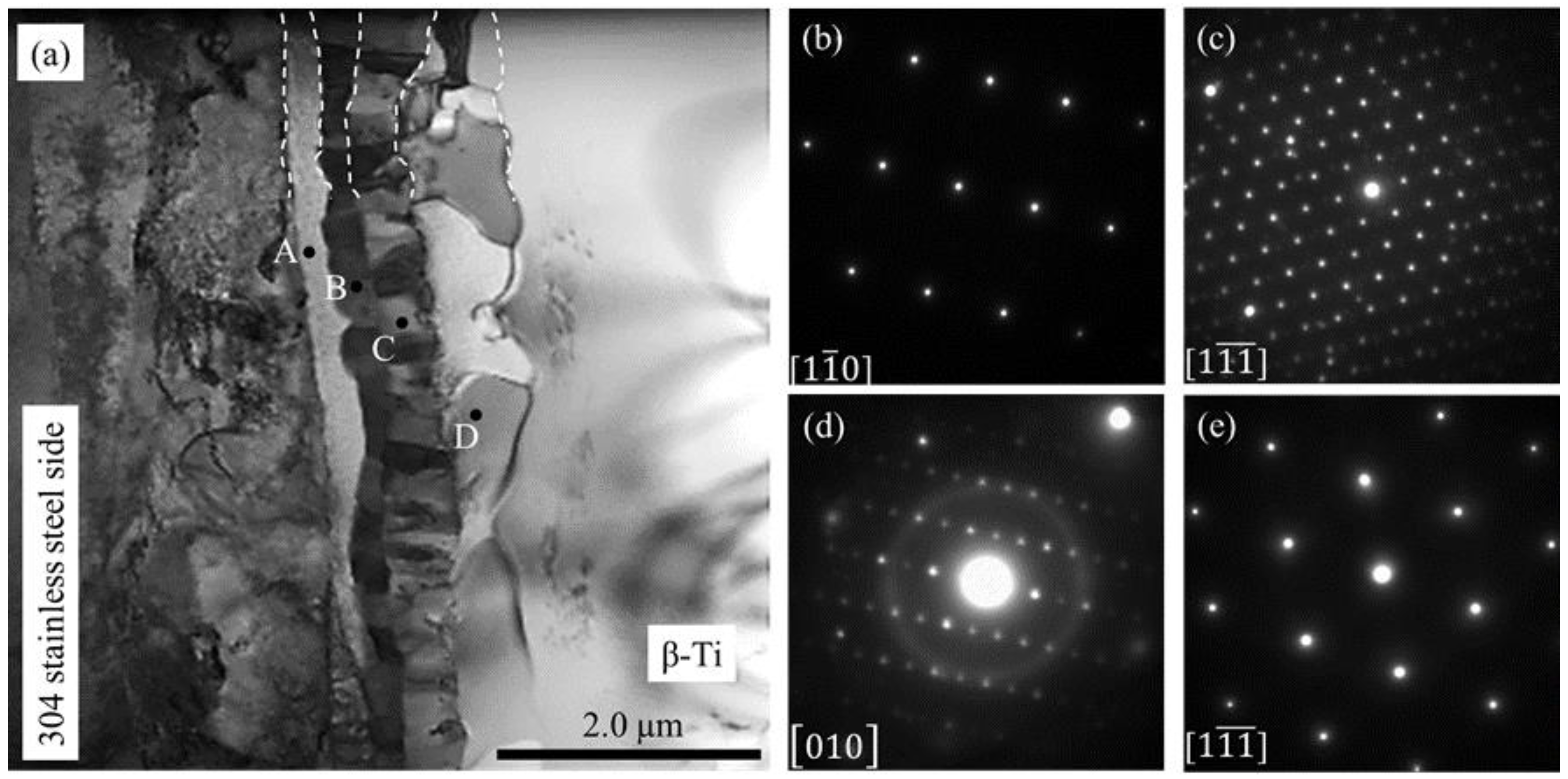

3.3. Microstructures

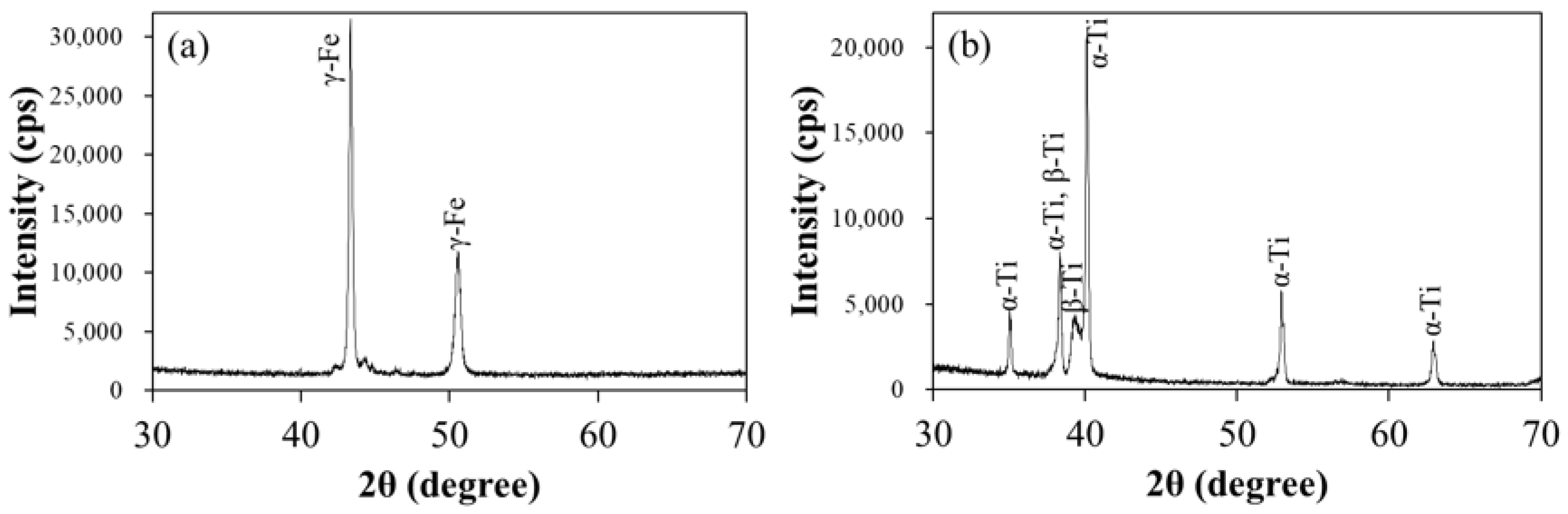

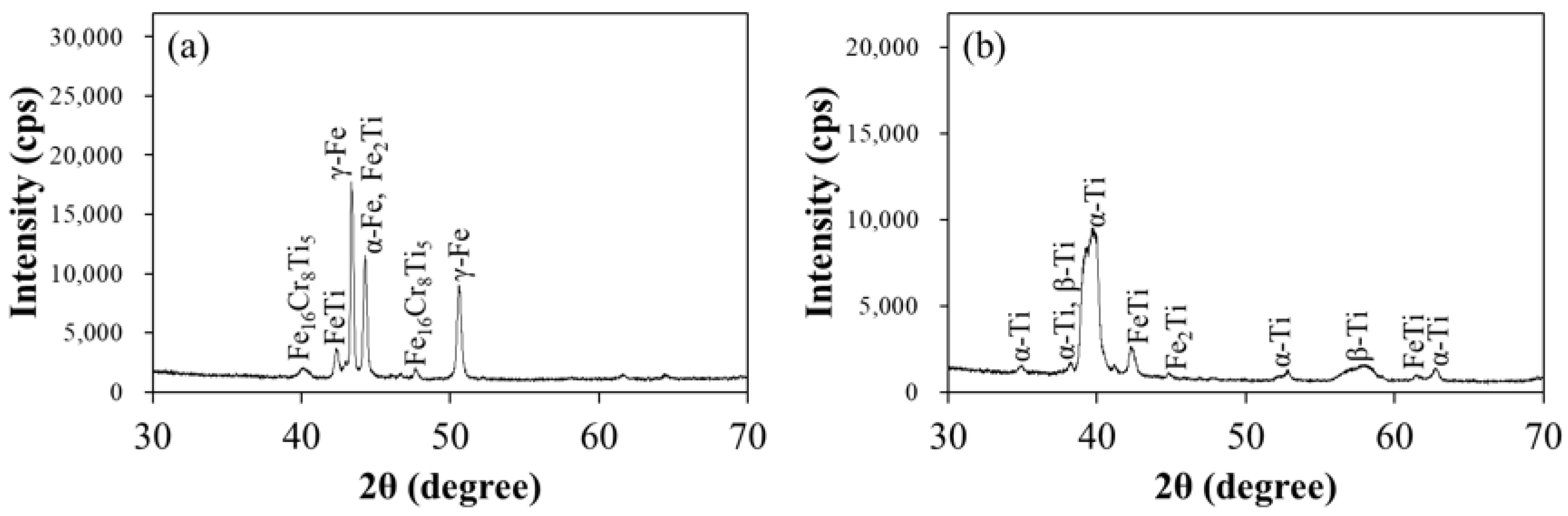

3.4. XRD Analysis of the Fracture Surface

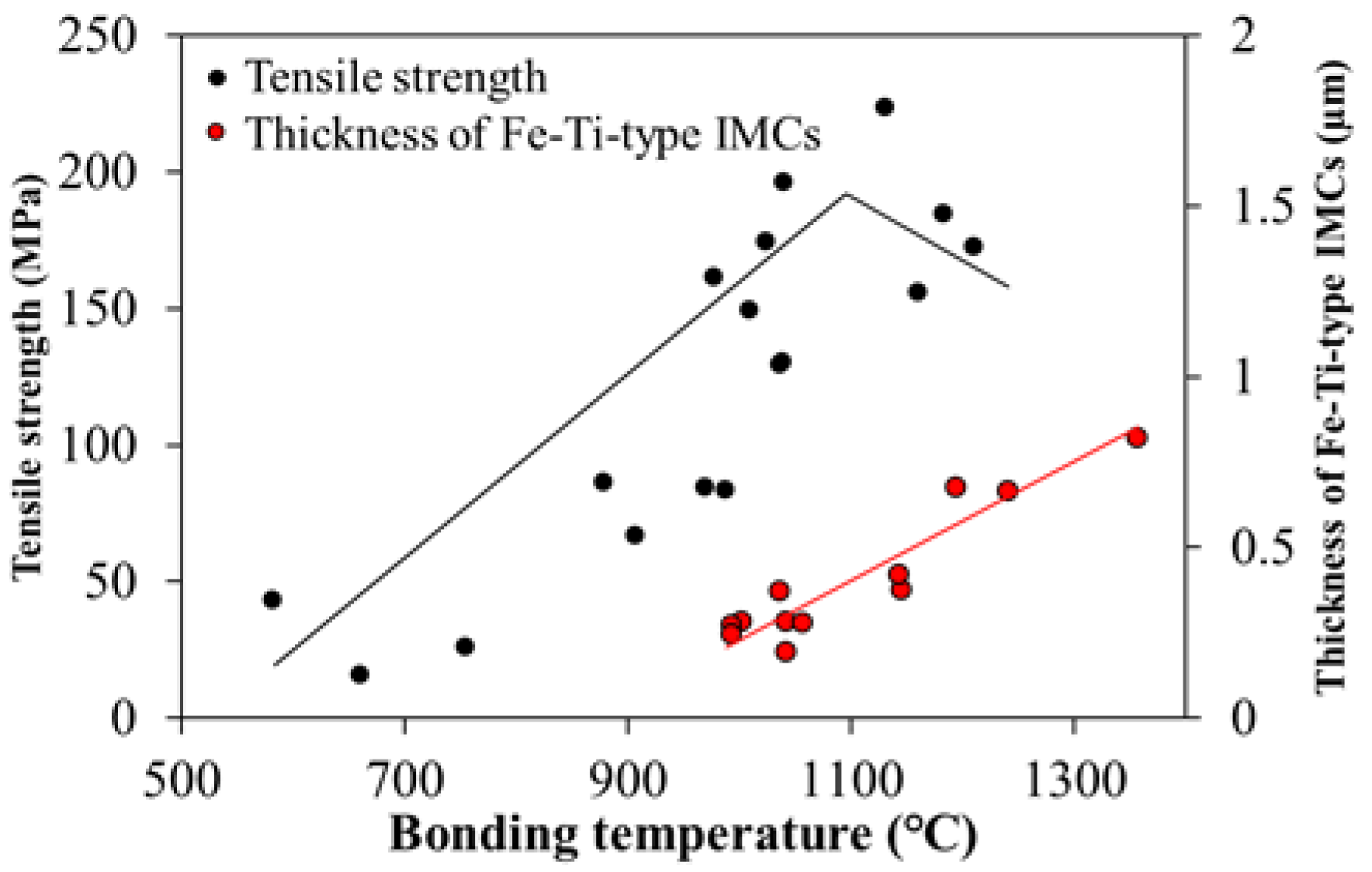

3.5. Relationship between the Tensile Strength of the Joint and the Thickness of the Reaction Layer

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Axial Pressure (MPa) | Bonding Time (s) | Bonding Temperature (°C) | Subjected Testing |

|---|---|---|---|

| 10 | 5 | 580 | Tensile test |

| 640 | Observation | ||

| 650 | Observation | ||

| 15 | 950 | Observation | |

| 990 | Tensile test | ||

| 25 | 1140 | Observation | |

| 1210 | Tensile test | ||

| 1240 | Observation | ||

| 30 | 5 | 630 | Observation |

| 660 | Tensile test | ||

| 770 | Observation | ||

| 880 | Observation | ||

| 910 | Observation | ||

| 930 | Observation | ||

| 1040 | Observation | ||

| 1050 | Observation | ||

| 15 | 880 | Observation | |

| 940 | Observation | ||

| 960 | Observation | ||

| 970 | Observation | ||

| 980 | Observation | ||

| 1000 | Observation | ||

| 1020 | Tensile test | ||

| 1040 | Observation | ||

| 1130 | Observation | ||

| 1140 | Observation | ||

| 1160 | Observation | ||

| 25 | 880 | Observation | |

| 990 | Observation | ||

| 1040 | Observation | ||

| 1180 | Tensile test | ||

| 1190 | Observation | ||

| 1360 | Observation | ||

| 50 | 5 | 690 | Observation |

| 750 | Tensile test | ||

| 910 | Observation | ||

| 15 | 920 | Observation | |

| 960 | Observation | ||

| 1040 | Tensile test | ||

| 25 | 1010 | Tensile test | |

| 1040 | Observation | ||

| 1060 | Observation |

References

- Akbari Mousavi, S.A.A.; Sartangi, P.F. Effect of post-weld heat treatment on the interface microstructure of explosively welded titanium–stainless steel composite. Mater. Sci. Eng. A 2008, 494, 329–336. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Yadegari, M.; Ebrahimi, A.R.; Karami, A. Effect of heat treatment on interface microstructure and bond strength in explosively welded Ti/304L stainless steel clad. Mater. Sci. Technol. 2013, 29, 69–75. [Google Scholar] [CrossRef]

- Satoh, G.; Yao, Y.L.; Qiu, C. Strength and microstructure of laser fusion-welded Ti–SS dissimilar material pair. Int. J. Adv. Manuf. Technol. 2013, 66, 469–479. [Google Scholar] [CrossRef]

- Arun Negemiya, A.; Rajakumar, S.; Balasubramanian, V. High-temperature diffusion bonding of austenitic stainless steel to titanium dissimilar joints. Mater. Res. Express 2019, 6, 066572. [Google Scholar] [CrossRef]

- Yu, C.; Wu, M.F.; Lu, H. Factors influencing formation and growth of coarse Ti–Fe compound in Ti–Fe eutectic reaction. Sci. Technol. Weld. Join. 2006, 11, 265–270. [Google Scholar] [CrossRef]

- Ghosh, M.; Laik, A.; Bhanumurthy, K.; Kale, G.B.; Krishnan, J.; Chatterjee, S. Evolution of interface microstructure and strength properties in titanium—Stainless steel diffusion bonded transition joints. Mater. Sci. Technol. 2004, 20, 1578–1584. [Google Scholar] [CrossRef]

- Ghosh, M.; Bhanumurthy, K.; Kale, G.B.; Krishnan, J.; Chatterjee, S. Diffusion bonding of titanium to 304 stainless steel. J. Nucl. Mater. 2003, 322, 235–241. [Google Scholar] [CrossRef]

- Akbar, A.A.A.; Mahdi, B.S.; Aluwi, A.J. Characterization of diffusion bonding of stainless steel AISI 316 and pure titanium sheets using copper interlayer. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 032041. [Google Scholar] [CrossRef]

- Shirzadi, A.A.; Laik, A.; Tewari, R.; Orsborn, J.; Dey, G.K. Gallium-assisted diffusion bonding of stainless steel to titanium; microstructural evolution and bond strength. Materialia 2018, 4, 115–126. [Google Scholar] [CrossRef]

- Ananthakumar, K.; Kumaran, S. Plasma assisted diffusion joining of CP-titanium-304L stainless steel: Attributes of temperature and time. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Szwed, B.; Konieczny, M. Structural changes during the formation of diffusion bonded joints between titanium and stainless steel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 012082. [Google Scholar] [CrossRef]

- Akbarimousavi, S.A.A.; GohariKia, M. Investigations on the mechanical properties and microstructure of dissimilar cp-titanium and AISI 316L austenitic stainless steel continuous friction welds. Mater. Des. 2011, 32, 3066–3075. [Google Scholar] [CrossRef]

- Maizza, G.; Pero, R.; Marco, F.D.; Ohmura, T. Correlation between the Indentation Properties and Microstructure of Dissimilar Capacitor Discharge Welded WC-Co/High-Speed Steel Joints. Materials 2020, 13, 2657. [Google Scholar] [CrossRef]

- Lin, J.Y.; Nambu, S.; Koseki, T. Evolution of bonding interface during ultrasonic welding between Ni and steels with various microstructure. ISIJ Int. 2020, 60, 330–336. [Google Scholar] [CrossRef]

- Macwan, A.; Kumar, A.; Chen, D.L. Ultrasonic spot welded 6111-T4 aluminum alloy to galvanized high-strength low-alloy steel: Microstructure and mechanical properties. Mater. Des. 2017, 113, 284–296. [Google Scholar] [CrossRef]

- Abbasi, M.; Toroghinejad, M.R. Effects of processing parameters on the bond strength of Cu/Cu roll-bonded strips. J. Mater. Process. Technol. 2010, 210, 560–563. [Google Scholar] [CrossRef]

- Ghosh, M.; Das, S.; Banarjee, P.S.; Chatterjee, S. Variation in the reaction zone and its effects on the strength of diffusion bonded titanium–stainless steel couple. Mater. Sci. Eng. A 2005, 390, 217–226. [Google Scholar] [CrossRef]

- Ghosh, M.; Chatterjee, S. Characterization of transition joints of commercially pure titanium to 304 stainless steel. Mater. Charact. 2002, 48, 393–399. [Google Scholar] [CrossRef]

- Yuan, X.J.; Sheng, G.M.; Qin, B.; Huang, W.Z.; Zhou, B. Impulse pressuring diffusion bonding of titanium alloy to stainless steel. Mater. Charact. 2008, 59, 930–936. [Google Scholar] [CrossRef]

- Hitotani, S. Microstructure of Reaction Phases and Interfacial Strength in Diffusion Bonding of Pure Ti to Pure Fe. Tetsu-to-Hagané 1989, 75, 1695–1702. [Google Scholar] [CrossRef]

| Ti | Fe | N | O | H |

|---|---|---|---|---|

| Bal. | 0.04 | 0.003 | 0.071 | 0.036 |

| Fe | C | Si | Mn | P | S | Ni | Cr | Co |

|---|---|---|---|---|---|---|---|---|

| Bal. | 0.06 | 0.24 | 1.12 | 0.037 | 0.025 | 10.08 | 18.14 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, K.T.; Sato, Y.S.; Tokita, S. Rapid Joining of Commercial-Purity Ti to 304 Stainless Steel Using Joule Heating Diffusion Bonding: Interfacial Microstructure and Strength of the Dissimilar Joint. Metals 2020, 10, 1689. https://doi.org/10.3390/met10121689

Suzuki KT, Sato YS, Tokita S. Rapid Joining of Commercial-Purity Ti to 304 Stainless Steel Using Joule Heating Diffusion Bonding: Interfacial Microstructure and Strength of the Dissimilar Joint. Metals. 2020; 10(12):1689. https://doi.org/10.3390/met10121689

Chicago/Turabian StyleSuzuki, K. T., Y. S. Sato, and S. Tokita. 2020. "Rapid Joining of Commercial-Purity Ti to 304 Stainless Steel Using Joule Heating Diffusion Bonding: Interfacial Microstructure and Strength of the Dissimilar Joint" Metals 10, no. 12: 1689. https://doi.org/10.3390/met10121689

APA StyleSuzuki, K. T., Sato, Y. S., & Tokita, S. (2020). Rapid Joining of Commercial-Purity Ti to 304 Stainless Steel Using Joule Heating Diffusion Bonding: Interfacial Microstructure and Strength of the Dissimilar Joint. Metals, 10(12), 1689. https://doi.org/10.3390/met10121689