Molecular Dynamics Study on the Impact of Cu Clusters at the BCC-Fe Grain Boundary on the Tensile Properties of Crystal

Abstract

1. Introduction

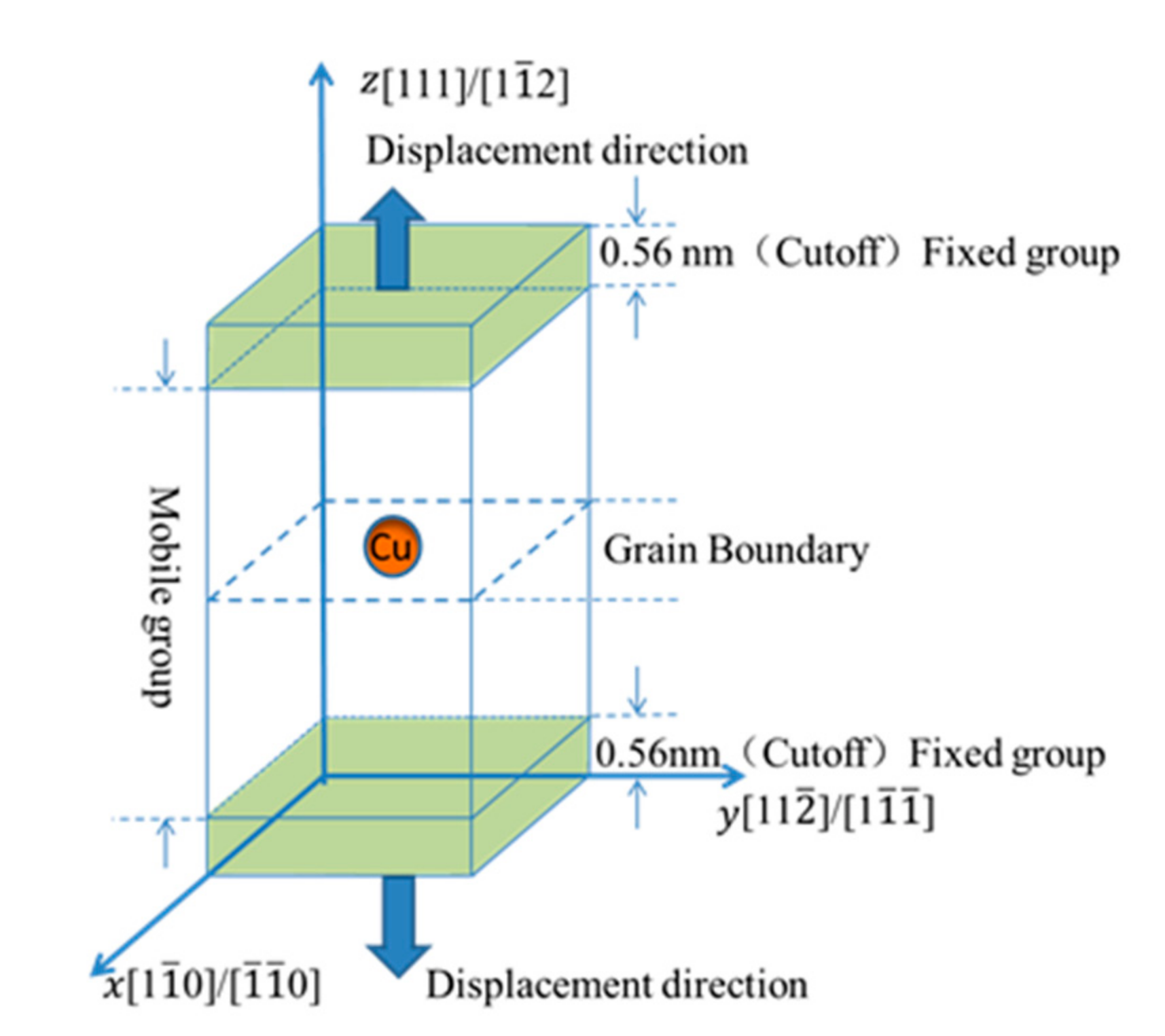

2. Simulation Method

3. Results and Discussion

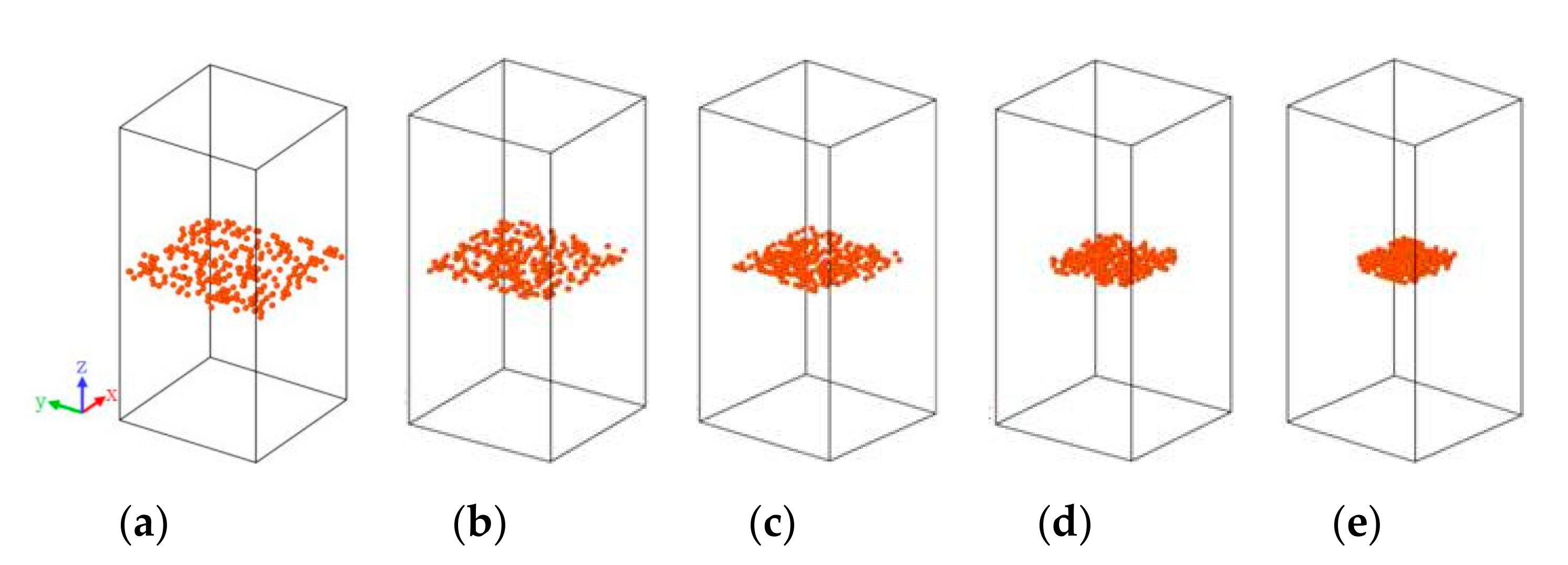

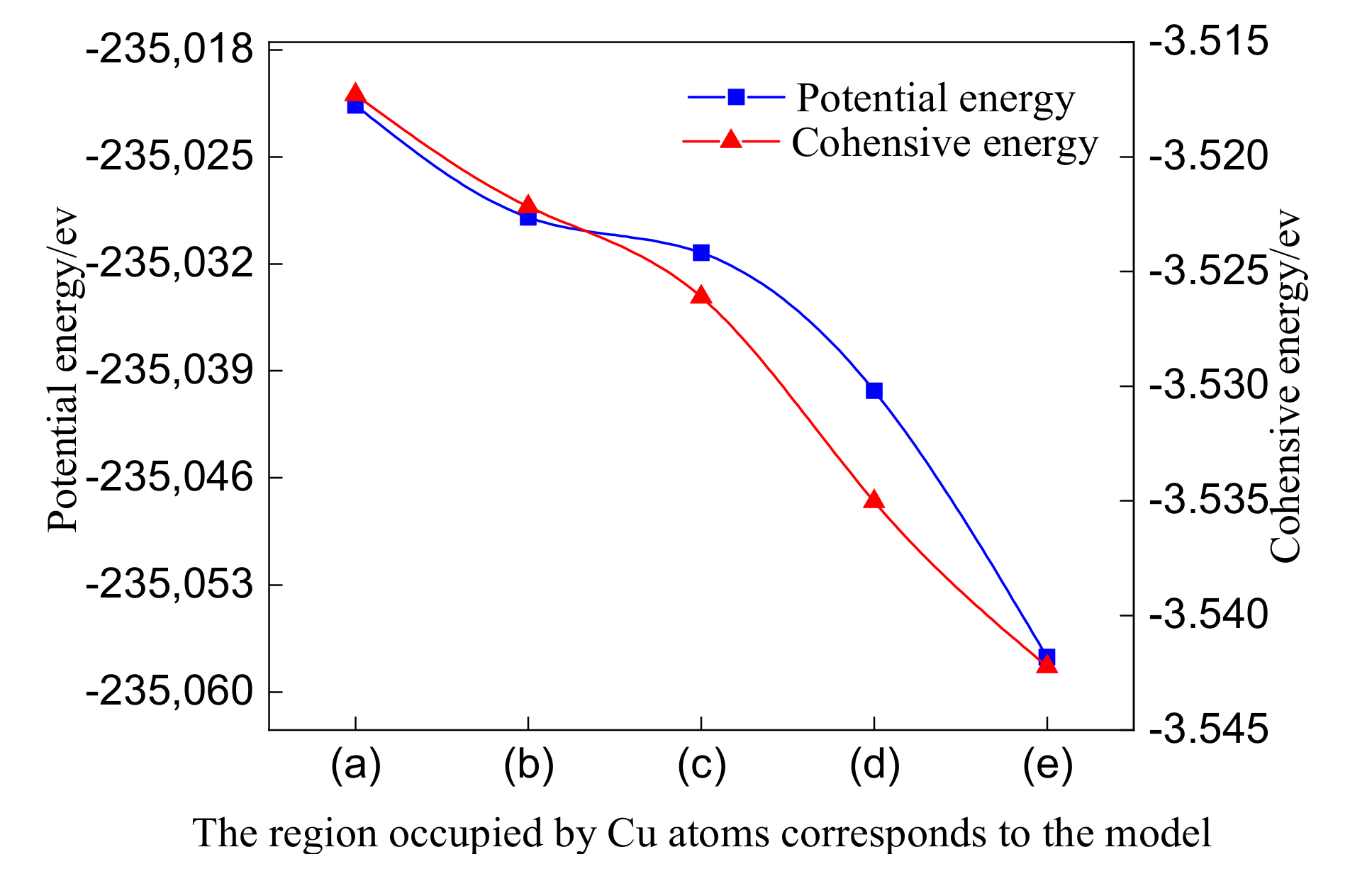

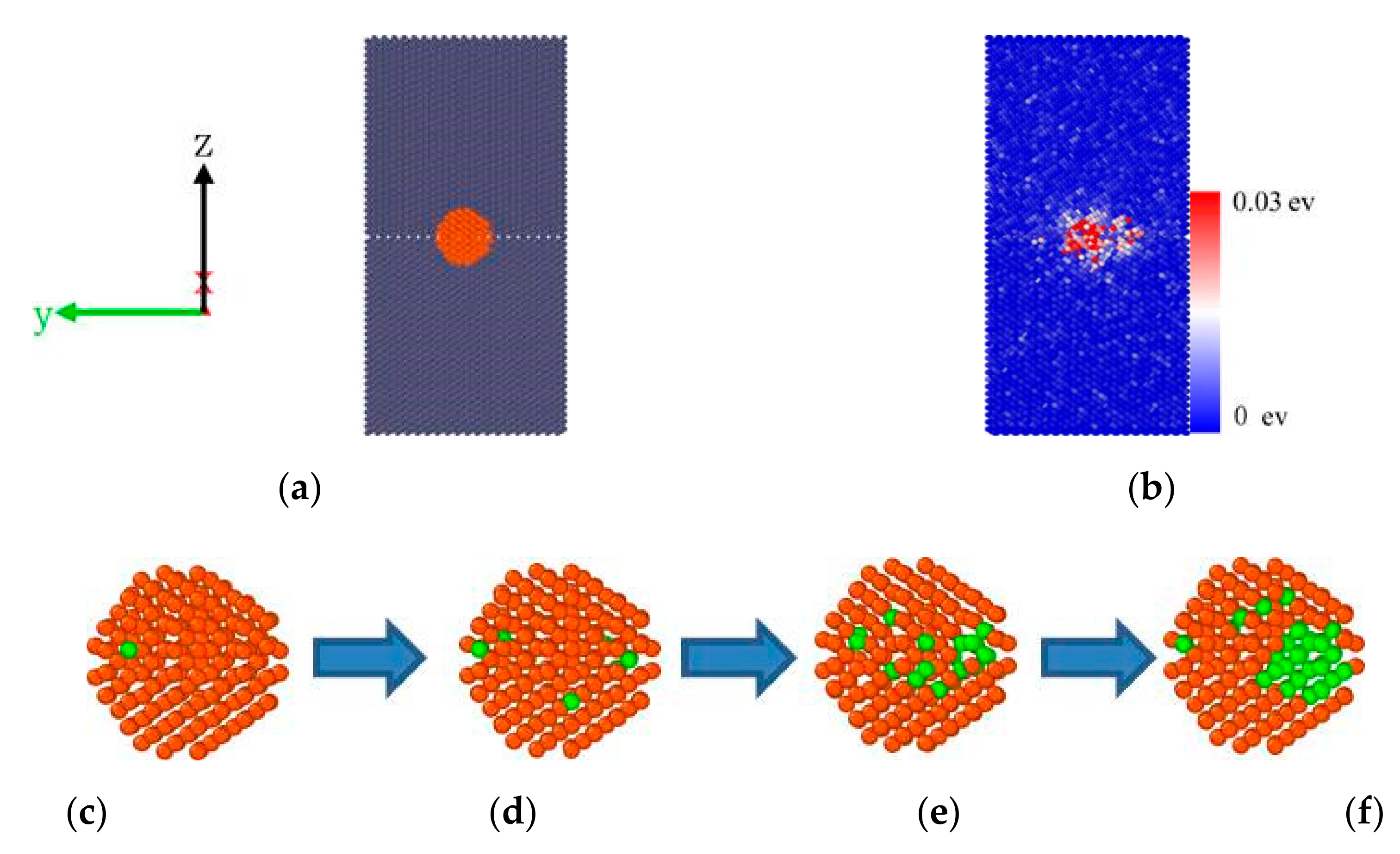

3.1. Segregation Energy and Cohesive Energy of Cu Atoms

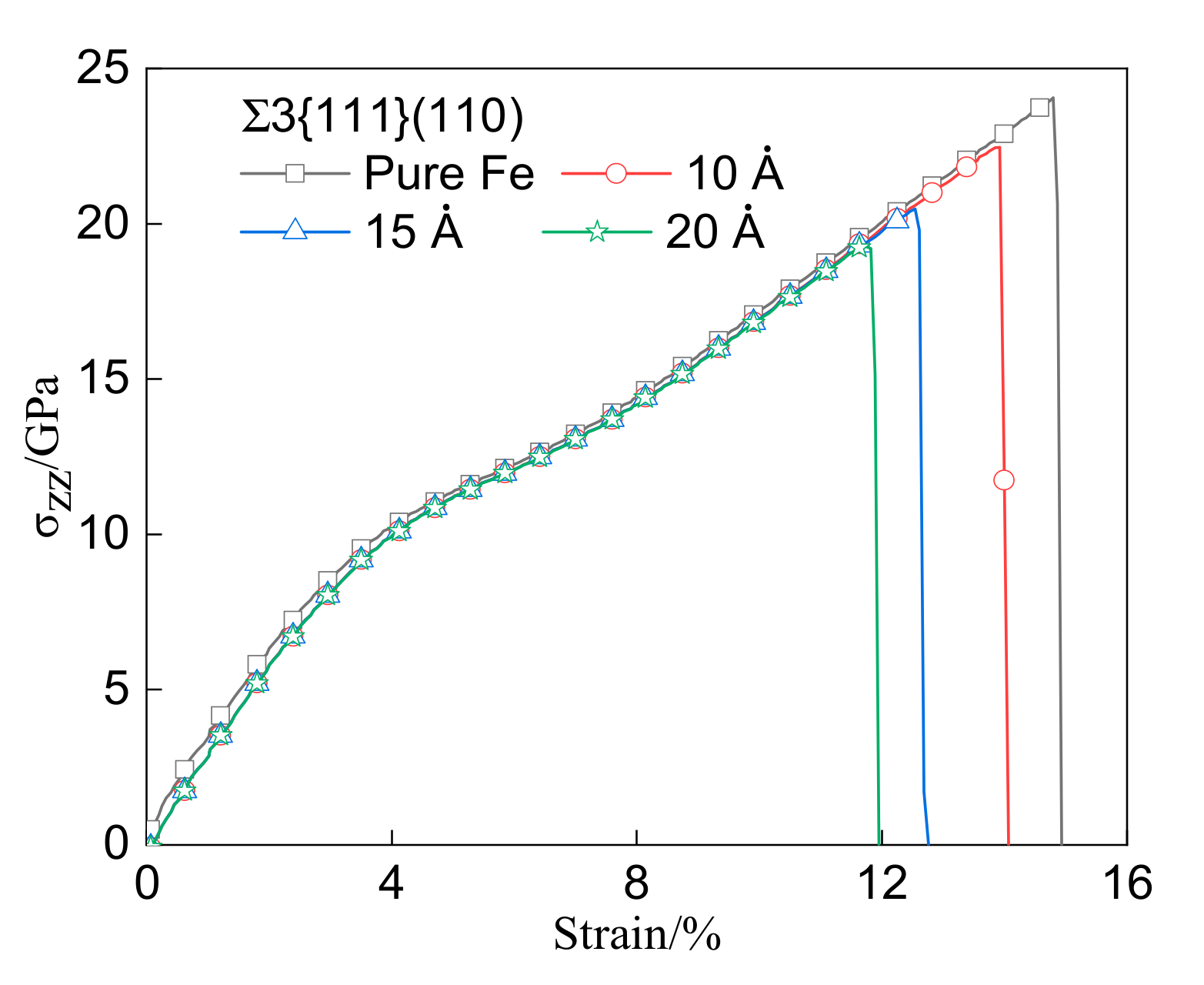

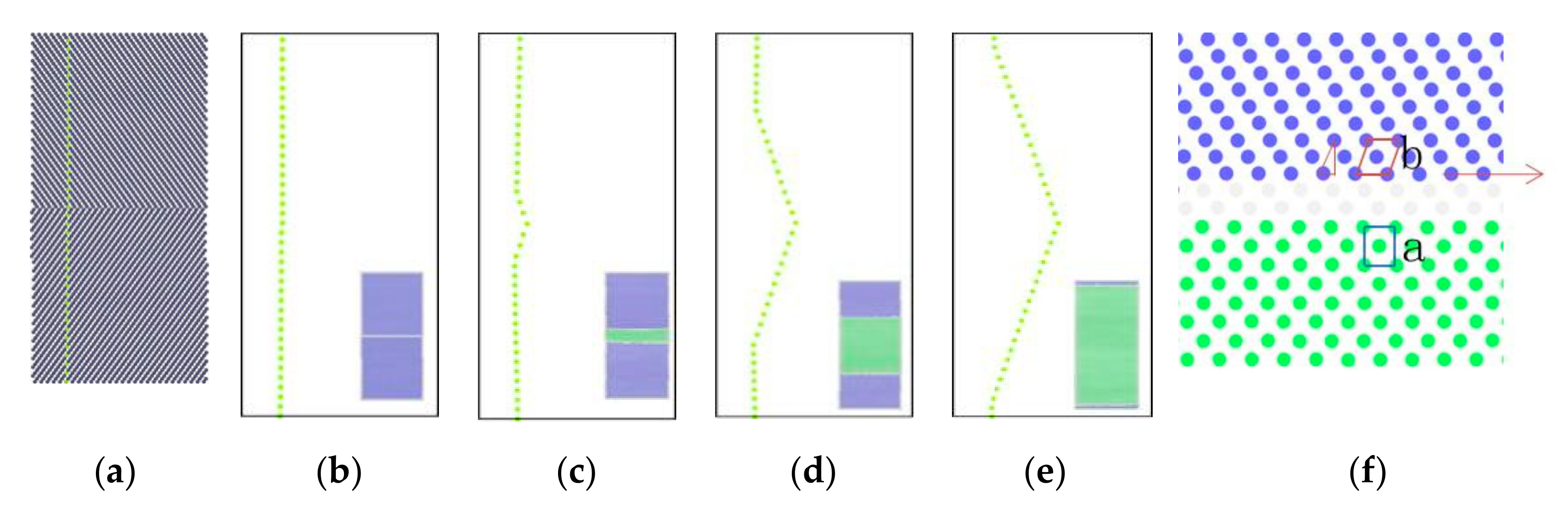

3.2. The Impact of the Size of Cu Clusters at {111} Grain Boundary on the Tensile Properties of Crystal

3.3. The Influence of the Size of Cu Clusters at {112} Grain Boundary on the Tensile Properties of Crystal

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar] [CrossRef]

- Yvon, P.; Le Flem, M.; Cabet, C.; Seran, J.L. Structural materials for next generation nuclear systems: Challenges and the path forward. Nucl. Eng. Des. 2015, 294, 161–169. [Google Scholar] [CrossRef]

- Du, Y.K.; He, X.F.; Jia, L.X. Study on the contribution mechanism of Cu precipitates to α-Fe irradiation hardening. Mater. Rep. 2018, 32, 307–312. [Google Scholar]

- Zhang, X.; Hattar, K.; Chen, Y.; Shao, L.; Li, J.; Sun, C.; Yu, K.; Li, N.; Taheri, M.L.; Wang, H.; et al. Radiation damage in nanostructured materials. Prog. Mater. Sci. 2018, 96, 217–321. [Google Scholar] [CrossRef]

- Graeme, A. Controlling Radiation Damage. Science 2010, 327, 1587–1588. [Google Scholar]

- Kuksenko, V.; Pareige, C. Intra granular precipitation and grain boundary segregation under neutron irradiation in a low purity Fe–Cr based alloy. J. Nucl. Mater. 2012, 425, 125–129. [Google Scholar] [CrossRef]

- Kilmametov, A.; Balogh, A.; Ghafari, M.; Gammer, C.; Mangler, C.; Rentenberger, C.; Valiev, R.; Hahn, H. Radiation effects in bulk nanocrystalline FeAl alloy. Radiat. Eff. Defects Solids 2012, 167, 631–639. [Google Scholar] [CrossRef]

- Demkowicz, M.J.; Hoagland, R.G.; Hirth, J.P. Interface Structure and Radiation Damage Resistance in Cu-Nb Multilayer Nanocomposites. Phys. Rev. Lett. 2008, 100, 136102. [Google Scholar] [CrossRef]

- Wang, J.; Madsen, G.K.H.; Drautz, R. Grain boundaries in bcc-Fe: A density-functional theory and tight-binding study. Model. Simul. Mater. Sci. Eng. 2018, 26, 025008. [Google Scholar] [CrossRef]

- Lidiard, A.B. The migration of phosphorus in ferritic iron alloys under irradiation. Philos. Mag. A 1999, 79, 1493–1499. [Google Scholar]

- Samaras, M. Multiscale Modelling: The role of helium in iron. Mater. Today 2009, 12, 46–53. [Google Scholar] [CrossRef]

- Terentyev, D.; He, X. Effect of Cr precipitates and He bubbles on the strength of <110> tilt grain boundaries in BCC Fe: An atomistic study. Comput. Mater. Sci. 2011, 50, 925–933. [Google Scholar] [CrossRef]

- Solanki, K.N.; Tschopp, M.A.; Bhatia, M.A.; Rhodes, N.R. Atomistic Investigation of the Role of Grain Boundary Structure on Hydrogen Segregation and Embrittlement in α-Fe. Metall. Mater. Trans. A 2013, 44, 1365–1375. [Google Scholar]

- Lejček, P.; Všianská, M.; Šob, M. Recent trends and open questions in grain boundary segregation. J. Mater. Res. 2018, 33, 2647–2660. [Google Scholar] [CrossRef]

- Wang, J.; Gao, X.; Gao, N.; Wang, Z.; Cui, M.; Wei, K.; Yao, C.; Sun, J.R.; Li, B.; Zhu, Y.; et al. Grain size effects on He bubbles distribution and evolution. J. Nucl. Mater. 2015, 457, 182–185. [Google Scholar] [CrossRef]

- Wang, W.Y.; Wang, Y.; Wang, W.Y.; Darling, K.A.; Kecskes, L.J.; Liu, Z.-K. Solute effects on the Σ3 111[11-0] tilt grain boundary in BCC Fe: Grain boundary segregation, stability, and embrittlement. Comput. Mater. Sci. 2020, 171, 109271. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Jin, H.; Elfimov, I.; Militzer, M. Study of the interaction of solutes with Σ5 (013) tilt grain boundaries in iron using density-functional theory. J. Appl. Phys. 2014, 115, 093506. [Google Scholar]

- Terentyev, D.; He, X. Dimensionality of interstitial He migration in <110> tilt grain boundaries in α-Fe. Comput. Mater. Sci. 2010, 49, 858–864. [Google Scholar] [CrossRef]

- Bonny, G.; Pasianot, R.C.; Castin, N.; Malerba, L. Ternary Fe–Cu–Ni many-body potential to model reactor pressure vessel steels: First validation by simulated thermal annealing. Philos. Mag. 2009, 89, 3531–3546. [Google Scholar] [CrossRef]

- Zheng, Z.X.; Zhang, L. Atomic scale calculation of structure change of Fe-Cu binary system containing Cu cluster in Fe matrix during heating. Acta Phys. Sin. 2017, 66, 282–292. [Google Scholar]

- Zhu, L.S. Molecular Dynamics Simulation Study on Early Precipitation Behavior of Fe-Cu-Ni Alloy Medium-rich Cu Clusters. Master’s Thesis, Shanghai University, Shanghai, China, 2014. [Google Scholar]

- Azeem, M.M.; Wang, Q.; Zhang, Y.; Liu, S.; Zubair, M. Effect of Grain Boundary on Diffusion of P in Alpha-Fe: A Molecular Dynamics Study. Front. Phys. 2019, 7, 97. [Google Scholar] [CrossRef]

- Xi, T.; Shahzad, M.B.; Xu, D.; Zhao, J.; Yang, C.; Qi, M.; Yang, K. Copper precipitation behavior and mechanical properties of Cu-bearing 316L austenitic stainless steel: A comprehensive cross-correlation study. Mater. Sci. Eng. A 2016, 675, 243–252. [Google Scholar] [CrossRef]

- Li, F.B.; Gao, N.; Li, Y.P. Molecular dynamics study of the effect of he on the tensile properties of W Σ3{112} symmetric grain boundaries. J. Mater. Heat Treat. 2019, 40, 96–104. [Google Scholar]

| Type | In This Work γ/J/m2 | Other Work γ/J/m2 | /ev |

|---|---|---|---|

| {111}Fe-Fe | 1.306 | 1.311 [25] 1.292 [12] | −0.0558 |

| {111}Fe-V | 1.317 | - | −0.2142 |

| {112}Fe-Fe | 0.314 | 0.322 [25] 0.261 [12] | −0.0249 |

| {112}Fe-V | 0.316 | - | −0.1699 |

| Type | {111} Grain Boundary Place /ev | {111} Interior of Cu Cluster at Grain Boundary /ev |

|---|---|---|

| No Cu cluster | 1.868 | - |

| 10 Å Cu cluster | 1.868 | 0.724 |

| 15 Å Cu cluster | 1.869 | 0.799 |

| 20 Å Cu cluster | 1.871 | 0.924 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wang, X.; Li, H.; Li, C.; Li, Y. Molecular Dynamics Study on the Impact of Cu Clusters at the BCC-Fe Grain Boundary on the Tensile Properties of Crystal. Metals 2020, 10, 1533. https://doi.org/10.3390/met10111533

Zhang H, Wang X, Li H, Li C, Li Y. Molecular Dynamics Study on the Impact of Cu Clusters at the BCC-Fe Grain Boundary on the Tensile Properties of Crystal. Metals. 2020; 10(11):1533. https://doi.org/10.3390/met10111533

Chicago/Turabian StyleZhang, Haichao, Xufeng Wang, Huirong Li, Changqing Li, and Yungang Li. 2020. "Molecular Dynamics Study on the Impact of Cu Clusters at the BCC-Fe Grain Boundary on the Tensile Properties of Crystal" Metals 10, no. 11: 1533. https://doi.org/10.3390/met10111533

APA StyleZhang, H., Wang, X., Li, H., Li, C., & Li, Y. (2020). Molecular Dynamics Study on the Impact of Cu Clusters at the BCC-Fe Grain Boundary on the Tensile Properties of Crystal. Metals, 10(11), 1533. https://doi.org/10.3390/met10111533