The Influence of Aluminum Content on Oxidation Resistance of New-Generation ODS Alloy at 1200 °C

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Description of the Microstructure of As‑Annealed ODS Alloys

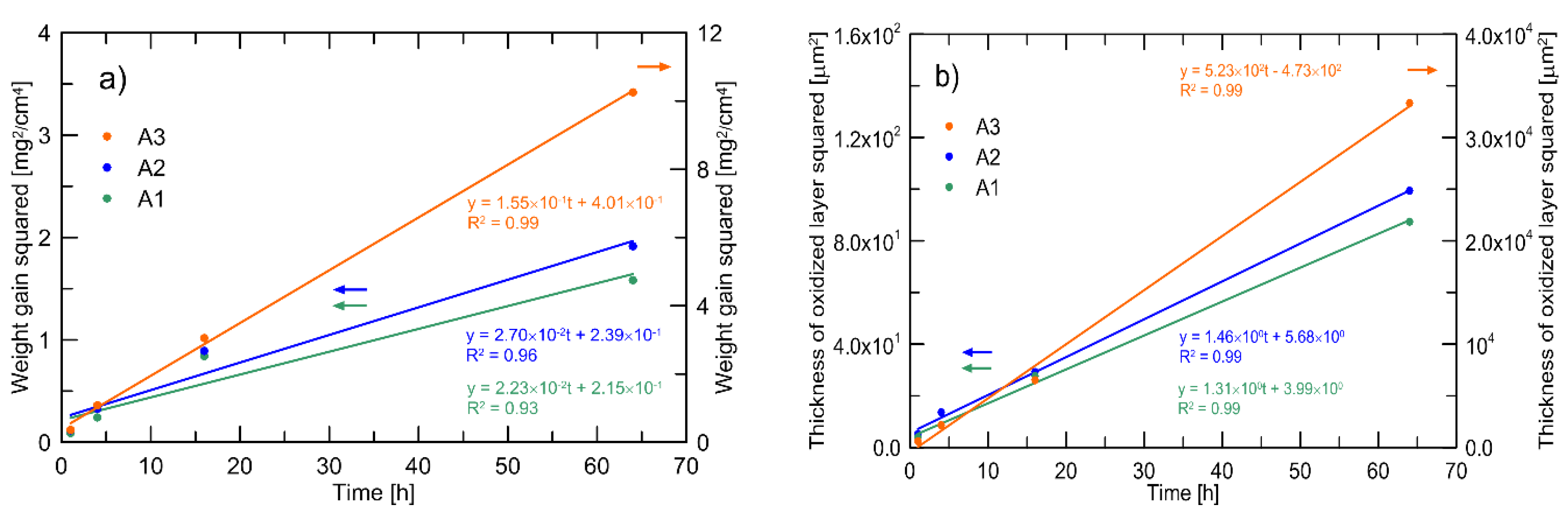

3.2. Oxidation Kinetics

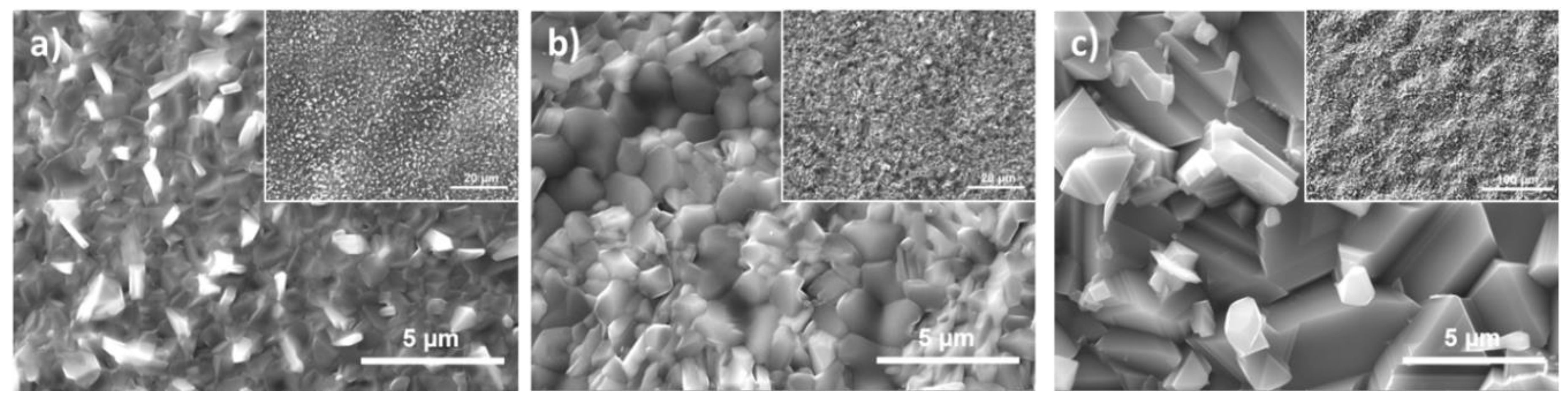

3.3. Surface Morphology and Phase Composition of the Oxides

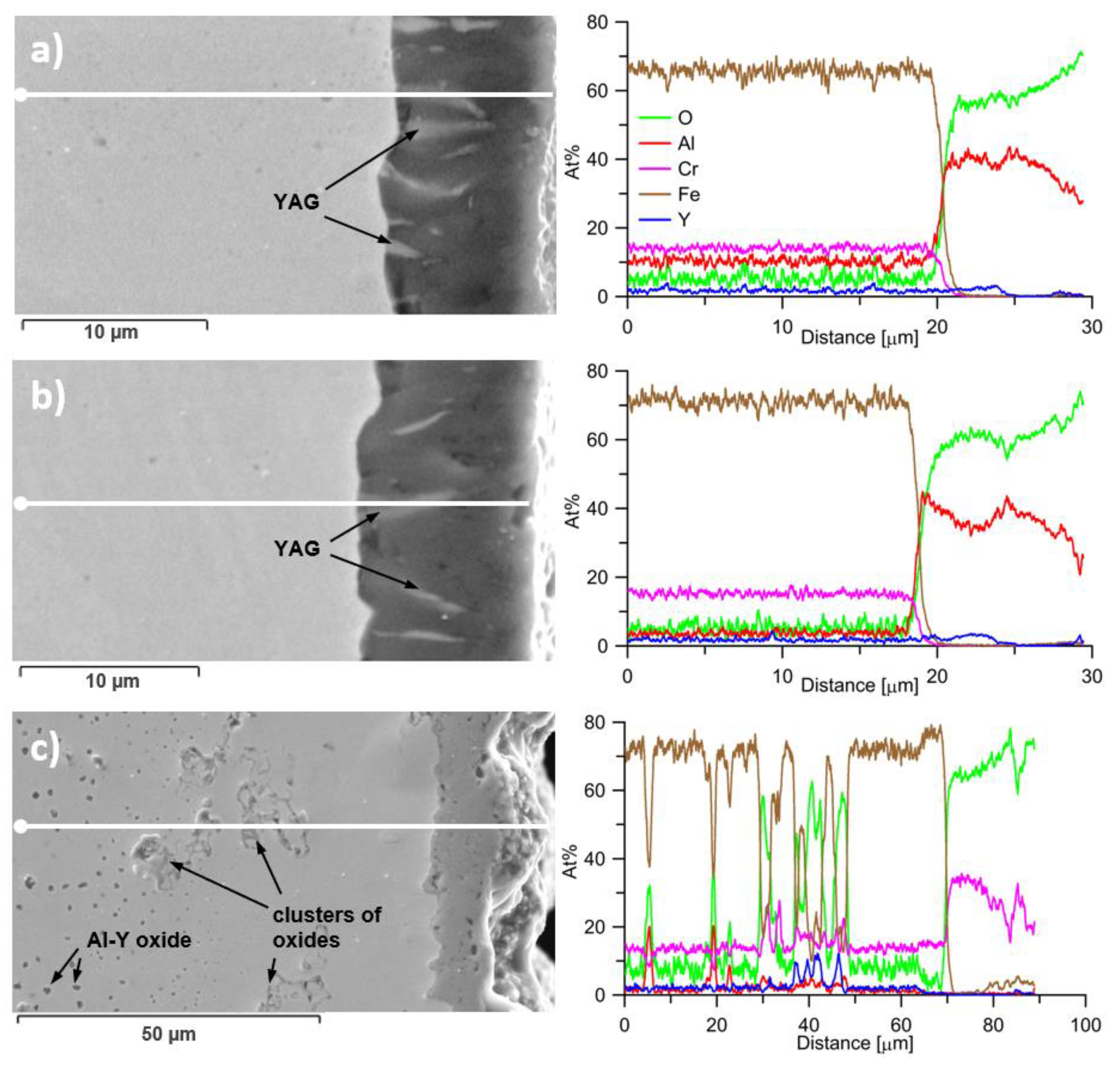

3.4. The Analysis of Cross‑Sections of the Oxidized Layers

3.5. Discussion of the Effect of Al Content on Oxidization Mechanisms

4. Conclusions

- The new-generation ODS alloys are successfully prepared by hot consolidation of mechanically alloyed powders followed by annealing.

- The oxidation tests using the limited number of test specimens are performed at 1200 °C on air for 1 h, 4 h, 16 h and 64 h. The oxidation kinetics obeys the non‑parabolic law.

- In the case of sufficiently high Al content x = 2.0 wt.% and 5.5 wt.%, a compact corundum-based oxide layer of α‑Al2O3 is formed on the surface, which protects the alloys from internal oxidation very effectively.

- In the case of a low Al content x = 0.3 wt.%, a mixture of Fe, Cr oxides forms a porous and non-compact layer on the specimen surface, which cannot protect the alloy from internal oxidation and degradation of mechanical properties.

- As the Fe-15Cr-xAl-4Y2O3 new-generation ODS alloys contains a high amount of Y2O3, the corundum-based oxide layer of the grades with the high Al content x = 2.0 wt.% and 5.5 wt.% reacts with the Y2O3 and YAG dendrites grow in the layer.

- The Al content exceeding 2 wt.% ensures an excellent oxidation resistance of the new-generation ODS alloys. Nevertheless, for long‑term oxidation resistance grade A1 with higher Al content 5.5 wt.% is expected to provide an improved performance.

Author Contributions

Funding

Conflicts of Interest

References

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Liu, Y.; Zhang, Z.; Han, X. Microstructural and compositional design of Ni-based single crystalline superalloys—A review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Yu, H.; Xu, W.; van der Zwaag, S. Microstructure and dislocation structure evolution during creep life of Ni-based single crystal superalloys. J. Mater. Sci. Technolog. 2020, 45, 207–214. [Google Scholar] [CrossRef]

- Wasilkowska, A.; Bartsch, M.; Messerschmidt, U.; Herzog, R.; Czyrska-Filemonowicz, A. Creep mechanisms of ferritic oxide dispersion strengthened alloys. J. Mater. Process. Technol. 2003, 133, 218–224. [Google Scholar] [CrossRef]

- Material Data Sheet, INCOLOY, Alloy MA 956, Special Metals Corporation, USA, 2004. Available online: http://specialmetals.ir/images/technical_info/Fer-base/Incoloy-alloy-MA956.pdf (accessed on 26 October 2020).

- Klueh, R.L.; Shingledecker, J.P.; Swindeman, R.W.; Hoelzer, D.T. Oxide dispersion-strengthened steels: A comparison of some commercial and experimental alloys. J. Nucl. Mater. 2005, 341, 103–114. [Google Scholar] [CrossRef]

- Yano, Y.; Sekio, Y.; Tanno, T.; Kato, S.; Inoue, T.; Oka, H.; Ohtsuka, S.; Furukawa, T.; Uwaba, T.; Kaito, T.; et al. Ultra-high temperature creep rupture and transient burst strength of ODS steel claddings. J. Nucl. Mater. 2019, 516, 347–353. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional coarsening in nickel-base single crystals with high volume fractions of coherent precipitates. Acta Metall. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Svoboda, J.; Lukas, P. Model of creep in 〈001〉-oriented superalloy single crystals. Acta Mater. 1998, 46, 3421–3431. [Google Scholar] [CrossRef]

- Svoboda, J.; Lukas, P. Creep deformation modelling of superalloy single crystals. Acta Mater. 2000, 48, 2519–2528. [Google Scholar] [CrossRef]

- Miller, M.K.; Hoelzer, D.T.; Kenik, E.A.; Russell, K.F. Stability of ferritic MA/ODS alloys at high temperatures. Intermetallics 2005, 13, 387–392. [Google Scholar] [CrossRef]

- Shen, J.; Yang, H.; Li, Y.; Kano, S.; Matsukawa, Y.; Satoh, Y.; Abe, H. Microstructural stability of an as-fabricated 12Cr-ODS steel under elevated-temperature annealing. J. Alloys Compd. 2017, 695, 1946–1955. [Google Scholar] [CrossRef]

- Oksiuta, Z.; Lewandowska, M.; Kurzydłowski, K.J. Mechanical properties and thermal stability of nanostructured ODS RAF steels. Mech. Mater. 2013, 67, 15–24. [Google Scholar] [CrossRef]

- Korb, G.; Rühle, M.; Martinz, H.-P. New Iron-Based ODS-Superalloys for High Demanding Applications. In Volume 5: Manufacturing Materials and Metallurgy; Ceramics; Structures and Dynamics; Controls, Diagnostics and Instrumentation, Turbo EXPO: Power for Land, Sea and Air, Orlando, FL, USA, 3‑6 June 1991; ASME: New York, NY, USA, 1991; 8p. [Google Scholar] [CrossRef]

- Kazimierzak, B.; Prignon, J.M.; Fromont, R.I. An ODS material with outstanding creep and oxidation resistance above 1100 °C. Mater. Des. 1992, 204, 67–70. [Google Scholar] [CrossRef]

- Byun, T.S.; Yoon, J.H.; Hoelzer, D.T.; Lee, Y.B.; Kang, S.H.; Maloy, S.A. Process development for 9Cr nanostructured ferritic alloy (NFA) with high fracture toughness. J. Nucl. Mater. 2014, 449, 290–299. [Google Scholar] [CrossRef]

- Ramar, A.; Oksiuta, Z.; Baluc, N.; Schäublin, R. Effect of mechanical alloying on the mechanical and microstructural properties of ODS EUROFER 97. Fusion Eng. Des. 2007, 82, 15–24. [Google Scholar] [CrossRef]

- Husák, R.; Hadraba, H.; Chlup, Z.; Heczko, M.; Kruml, T.; Puchý, V. ODS EUROFER Steel Strengthened by Y-(Ce, Hf, La, Sc, and Zr) Complex Oxides. Metals 2019, 9, 1148. [Google Scholar] [CrossRef]

- Rösler, J.; Arzt, E.A. A new model-based creep equation for dispersion strengthened materials. Acta Metall. Mater. 1990, 38, 671–683. [Google Scholar] [CrossRef]

- Fischer, F.D.; Svoboda, J.; Fratzl, P. A thermodynamic approach to grain growth and coarsening. Philos. Mag. 2003, 83, 1075–1093. [Google Scholar] [CrossRef]

- Bártková, D.; Šmíd, M.; Mašek, B.; Svoboda, J.; Šiška, F. Kinetic study of static recrystallization in an Fe–Al–O ultra-fine-grained nanocomposite. Phil. Mag. Lett. 2017, 97, 379–385. [Google Scholar] [CrossRef]

- Svoboda, J.; Horník, V.; Stratil, L.; Hadraba, H.; Mašek, B.; Khalaj, O.; Jirková, H. Microstructure Evolution in ODS Alloys with a High-Volume Fraction of Nano Oxides. Metals 2018, 8, 1079. [Google Scholar] [CrossRef]

- Liu, G.; Xu, Y.-L.; Yang, C.-X.; Xiao, X.-S.; Chen, X.-M.; Zhang, X.-M.; Meng, X.-J. Effects of Alloy Elements on Oxidation Resistance and Stress-Rupture Property of P92 Steel. Acta Metall. Sin. 2015, 28, 129–138. [Google Scholar] [CrossRef][Green Version]

- Yuan, J.; Wu, X.; Wang, W.; Zhu, S.; Wang, F. Investigation on the Enhanced Oxidation of Ferritic/Martensitic Steel P92 in Pure Steam. Materials 2014, 7, 2772–2783. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Zheng, J.; Chen, L.; Misra, R.D.K. High temperature oxidation behavior of ferritic stainless steel containing W and Ce. Corros. Sci. 2018, 142, 79–92. [Google Scholar] [CrossRef]

- McGuire, M.F. Stainless Steels for Design Engineers, 1st ed.; ASM International: Materials Park, OH, USA, 2008; p. 296. ISBN 978-0-87170-717-8. [Google Scholar]

- Huntz, A.M.; Reckmann, A.; Haut, C.; Sévérac, C.; Herbst, M.; Resende, F.C.T.; Sabioni, A.C.S. Oxidation of AISI 304 and 439 stainless steels. Mater. Sci. Eng. A 2007, 447, 266–276. [Google Scholar] [CrossRef]

- Fujikawa, H.; Newcomb, S.B. High temperature oxidation behaviour of high Al content ferritic and austenitic stainless steels with and without rare-earth element addition. Oxid. Met. 2012, 77, 85–92. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, X.; Fan, L.; Li, J.; Yu, X.; Xiao, X.; Jiang, L. Improved oxidation resistance of 15 wt.% Cr ferritic stainless steels containing 0.08–2.45 wt.% Al at 1000 °C in air. Corros. Sci. 2015, 100, 311–312. [Google Scholar] [CrossRef]

- Liu, T.; Wang, C.; Shen, H.; Chou, W.; Iwata, N.Y.; Kimura, A. The effects of Cr and Al concentrations on the oxidation behavior of oxide dispersion strengthened ferritic alloys. Corros. Sci. 2013, 76, 310–316. [Google Scholar] [CrossRef]

- Opila, E.J. Volatility of Common Protective Oxides in High Temperature Water Vapor: Current Understanding and Unanswered Questions. Mater. Sci. Form. 2004, 461, 765–774. [Google Scholar] [CrossRef]

- Yamauchi, A.; Kurokawa, K.; Takahashi, H. Evaporation of Cr2O3 in Atmospheres containing H2O. Oxid. Met. 2003, 59, 517–527. [Google Scholar] [CrossRef]

- Saunders, S.R.J.; Monteiro, M.; Rizzo, F. The oxidation behaviour of metals and alloys at high temperatures in atmospheres containing water vapour: A review. Prog. Mater. Sci. 2008, 53, 775–837. [Google Scholar] [CrossRef]

- Young, D.J.; Pint, B.A. Chromium Volatilization Rates from Cr2O3 Scales into Flowing Gases Containing Water Vapor. Oxid. Met. 2006, 66, 137–153. [Google Scholar] [CrossRef]

- Berthod, P. Kinetics of High Temperature Oxidation and Chromia Volatilization for a Binary Ni–Cr Alloy. Oxid. Met. 2005, 64, 235–252. [Google Scholar] [CrossRef]

- Hojná, A.; Michalička, J.; Hadraba, H.; Di Gabriele, F.; Duchoň, J.; Rozumová, L.; Husák, R. Fracture Resistance of 14Cr ODS Steel Exposed to a High Temperature Gas. Metals 2017, 7, 560. [Google Scholar] [CrossRef]

- Gu, C.; Liu, R.; Wang, C.; Sun, Y.; Zhang, S. Effect of Aluminum on Microstructure and High-Temperature Oxidation Resistance of Austenitic Heat-Resistant Steel. Metals 2020, 10, 176. [Google Scholar] [CrossRef]

- Klam, H.-J. Temperature and oxidation resistance of the ODS materials MA 956 and PM 2000. J. Phys. IV 1993, 3, C7-731–C7-734. [Google Scholar] [CrossRef][Green Version]

- Swadźba, R.; Swadźba, L.; Wiedermann, J.; Hetmańczyk, M.; Witala, B. Characterization of Alumina Scales Grown on a 2nd Generation Single Crystal Ni Superalloy During Isothermal Oxidation at 1050, 1100 and 1150 °C. Oxid. Met. 2014, 82, 195–208. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Physica B 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Recent Developments of the Program Fullprof. Commun. Powder Diff. (IUCr) 2001, 26, 12–19. Available online: https://www.iucr.org/__data/assets/pdf_file/0019/21628/cpd26.pdf (accessed on 26 October 2020).

- Klimiankou, M.; Lindau, R.; Möslang, A.; Schröder, J. TEM study of PM 2000 steel. Powder Metall. 2005, 48, 277–287. [Google Scholar] [CrossRef]

- Czyrska-Filemonowicz, A.; Szot, K.; Wasilkowska, A.; Gil, A.; Quadakkers, W.J. Microscopy (AFM, TEM, SEM) studies of oxide scale formation on FeCrAl based ODS alloys. Solid State Ion. 1999, 117, 13–20. [Google Scholar] [CrossRef]

- Král, P.; Dvořák, J.; Sklenička, V.; Masuda, T.; Horita, Z.; Kuchařová, K.; Kvapilová, M.; Svobodová, M. The Effect of Ultrafine-Grained Microstructure on Creep Behaviour of 9% Cr Steel. Materials 2018, 11, 787. [Google Scholar] [CrossRef]

- Dymáček, P.; Svoboda, J.; Jirková, H.; Stratil, L.; Horník, V. Microstructure evolution and creep strength of new-generation oxide dispersion strengthened alloys with high volume fraction of nano-oxides. Proc. Struc. Integ. 2019, 17, 427–433. [Google Scholar] [CrossRef]

- Birks, N.; Meier, G.H.; Pettit, F.S. Introduction to the High Temperature Oxidation of Metals, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; p. 352. ISBN 9780521480420. [Google Scholar]

- Pérez, P. Influence of the alloy grain size on the oxidation behaviour of PM2000 alloy. Corros. Sci. 2002, 44, 1793–1808. [Google Scholar] [CrossRef]

- Montealegre, M.A.; Strehl, G.; González-Carrasco, J.L.; Borchardt, G. Oxidation behaviour of novel ODS FeAlCr intermetallic alloys. Intermetallics 2005, 13, 896–906. [Google Scholar] [CrossRef]

- Pei, H.; Wen, Z.; Zhang, Y.; Yue, Z. Oxidation behavior and mechanism of a Ni-based single crystal superalloy with single α-Al2O3 film at 1000 °C. Appl. Surf. Sci. 2017, 411, 124–135. [Google Scholar] [CrossRef]

- Huang, T.; Lü, J.; Song, P.; Khan, A.; Chen, R.; Yi, J. Effect of Pt doping on oxide scale formation on yttria-dispersion FeCrAl alloy at 1200 °C. Corros. Sci. 2020, 168, 108580. [Google Scholar] [CrossRef]

- Robino, C.V. Representation of mixed reactive gases on free energy (Ellingham-Richardson) diagrams. Metall. Mater. Trans. B 1996, 27, 65–69. [Google Scholar] [CrossRef]

- Tolpygo, V.K. The Morphology of Thermally Grown α-Al2O3 Scales on Fe-Cr-Al Alloys. Oxid. Met. 1999, 51, 449–477. [Google Scholar] [CrossRef]

- Svoboda, J.; Fischer, F.D.; Vollath, D. Modeling of Formation of Binary-Phase Hollow Nanospheres from Metallic Solid Nanospheres. Acta Mater. 2009, 57, 1912–1919. [Google Scholar] [CrossRef]

- Svoboda, J.; Gamsjäger, E.; Fischer, F.D.; Kozeschnik, E. Modeling of Kinetics of Diffusive Phase Transformation in Binary Systems with Multiple Stoichiometric Phases. J. Phase Equilib. Diff. 2006, 27, 622–628. [Google Scholar] [CrossRef]

- Levin, E.M.; McMurdie, H.F.; Reser, M.K. Phase Diagrams for Ceramists: 1975 Supplement, 1st ed.; American Ceramic Society: Columbus, OH, USA, 1975; p. 513. Available online: https://www.osti.gov/biblio/7351343-phase-diagrams-ceramists-supplement (accessed on 26 October 2020).

- Hayashi, A.; Hiraide, N.; Inoue, Y. Spallation Behaviour of Oxide Scale on Stainless steels. Oxid. Met. 2016, 85, 87–101. [Google Scholar] [CrossRef]

- Huntz, A.M. Stresses in NiO, Cr2O3 and Al2O3 oxide scales. Mater. Sci. Eng. A 1995, 201, 211–228. [Google Scholar] [CrossRef]

- Svoboda, J.; Fischer, F.D. Incorporation of Vacancy Generation/Annihilation into Reactive Diffusion Concept—Prediction of Kirkendall Porosity. Comp. Mater. Sci. 2017, 127, 136–140. [Google Scholar] [CrossRef]

- Guttmann, V.; Hukelmann, F.; Griffin, D.; Daadbin, A.; Datta, S. Studies of the influence of surface pre-treatment on the integrity of alumina scales on MA 956. Surf. Coat. Technol. 2003, 166, 72–83. [Google Scholar] [CrossRef]

| Grade | Fe | Al | Cr | Y |

|---|---|---|---|---|

| A1 | balance | 5.5 | 14.4 | 2.8 |

| A2 | balance | 2.0 | 14.8 | 2.9 |

| A3 | balance | 0.3 | 15.0 | 3.0 |

| Grade/Alloy | T (°C) | n | kp (g2·cm−4·s−1) | Oxide Layer |

|---|---|---|---|---|

| A1 (5.5 wt.% Al) | 2.82 | 6.19 × 10−12 | α-Al2O3 | |

| A2 (2.0 wt.% Al) | 1200 | 2.94 | 7.49 × 10−12 | α-Al2O3 |

| A3 (0.3 wt.% Al) | 2.51 | 4.30 × 10−11 | (Cr,Fe)2O3, (Cr,Fe)3O4 | |

| Fe-19Cr-5.4Al-0.5Y2O3 (PM 2000) [47] | 1200 | 2.82 a | 5.79 × 10−12 b | α-Al2O3 |

| Ni-30Cr [35] | 1200 | 2.80 a | 6.70 × 10−11 | Cr2O3 |

| 15Cr-0.08Al [29] | 1000 | 1.72 a | 1.73 × 10−13 | Cr2O3 |

| 15Cr-2.45Al [29] | 1000 | 2.57 a | 4.48 × 10−14 | Al2O3 |

| 19Cr-2Mo-0.3Mn-0.5Si [25] | 1100 | 2.70 a | 5.51 × 10−11 | Cr2O3, (Mn,Cr)2O4 |

| Fe-24Al-1Y2O3 (Fe40Al-Grade3) [48] | 1100 | 2.15 a | 6.88 × 10−13 b | α-Al2O3 |

| Fe-20Al-12Cr-1Y2O3 (ALUSI 1) [48] | 1100 | 1.94 a | 1.69 × 10−13 b | α-Al2O3 |

| Ni-9Co-8W-2Mo-6Al-7Ta-4Cr-2Re (DD6) [49] | 1000 | 5.68 a | 2.24 × 10−13 | α-Al2O3 |

| Grade/Alloy | T (°C) | n | kp (μm2·s−1) | Oxide Layer |

|---|---|---|---|---|

| A1 (5.5 wt.% Al) | 2.65 | 3.64 × 10−4 | α-Al2O3 | |

| A2 (2.0 wt.% Al) | 1200 | 2.88 | 4.07 × 10−4 | α-Al2O3 |

| A3 (0.3 wt.% Al) | 2.11 | 1.45 × 10−1 | (Cr,Fe)2O3, (Cr,Fe)3O4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stratil, L.; Horník, V.; Dymáček, P.; Roupcová, P.; Svoboda, J. The Influence of Aluminum Content on Oxidation Resistance of New-Generation ODS Alloy at 1200 °C. Metals 2020, 10, 1478. https://doi.org/10.3390/met10111478

Stratil L, Horník V, Dymáček P, Roupcová P, Svoboda J. The Influence of Aluminum Content on Oxidation Resistance of New-Generation ODS Alloy at 1200 °C. Metals. 2020; 10(11):1478. https://doi.org/10.3390/met10111478

Chicago/Turabian StyleStratil, Luděk, Vít Horník, Petr Dymáček, Pavla Roupcová, and Jiří Svoboda. 2020. "The Influence of Aluminum Content on Oxidation Resistance of New-Generation ODS Alloy at 1200 °C" Metals 10, no. 11: 1478. https://doi.org/10.3390/met10111478

APA StyleStratil, L., Horník, V., Dymáček, P., Roupcová, P., & Svoboda, J. (2020). The Influence of Aluminum Content on Oxidation Resistance of New-Generation ODS Alloy at 1200 °C. Metals, 10(11), 1478. https://doi.org/10.3390/met10111478