Radiation Damage of Reactor Pressure Vessel Steels Studied by Positron Annihilation Spectroscopy—A Review

Abstract

:1. Introduction

2. Experimental

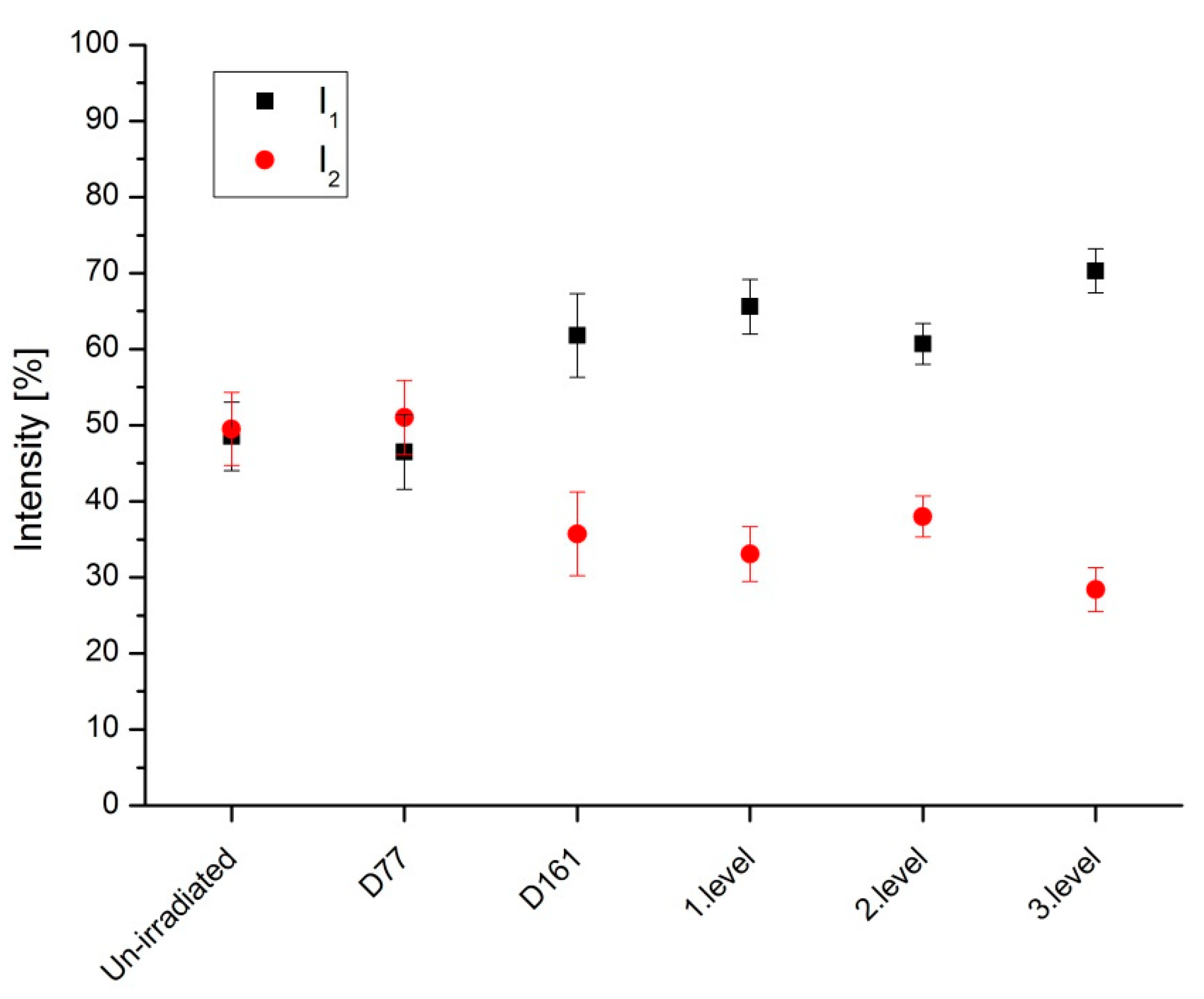

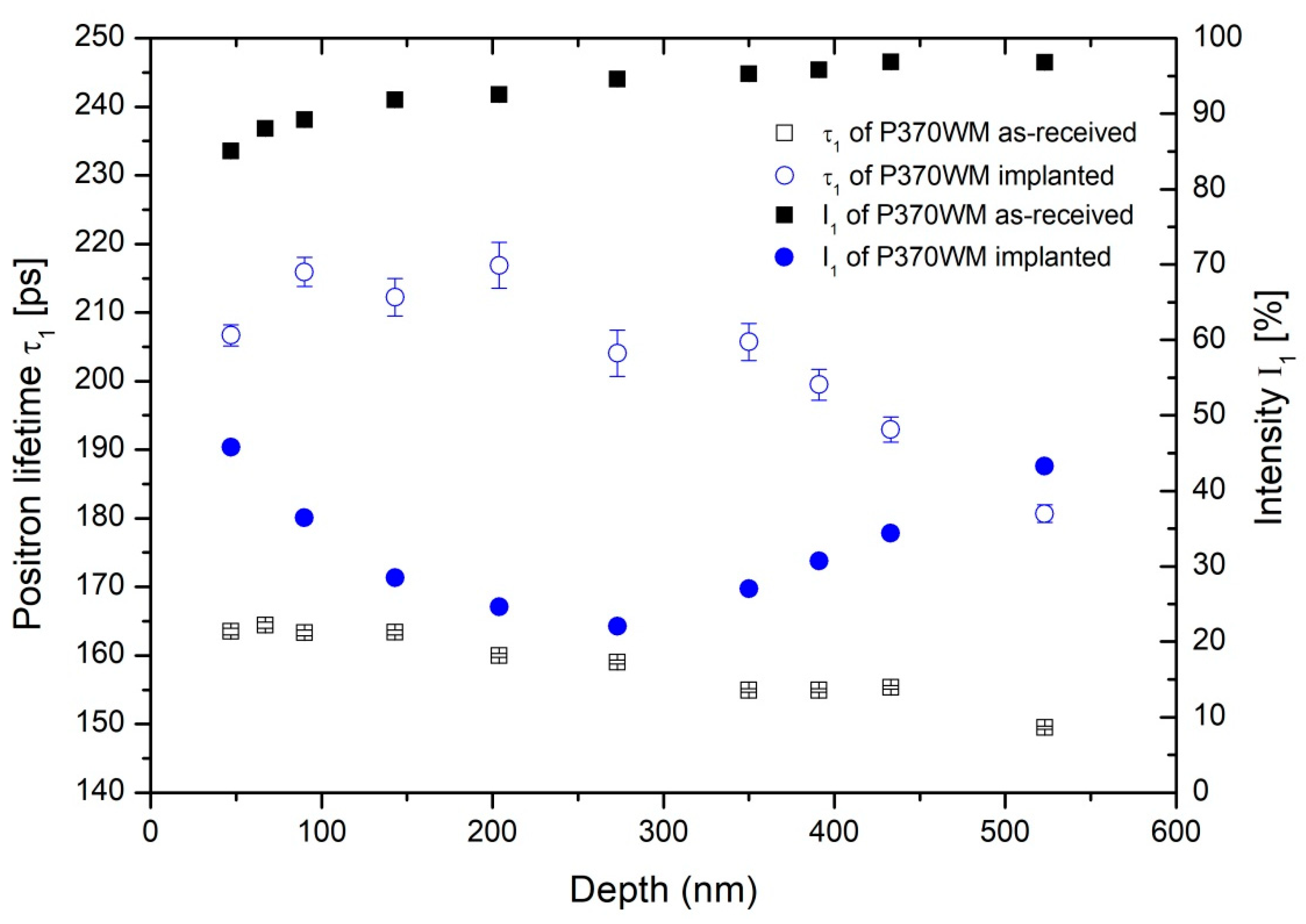

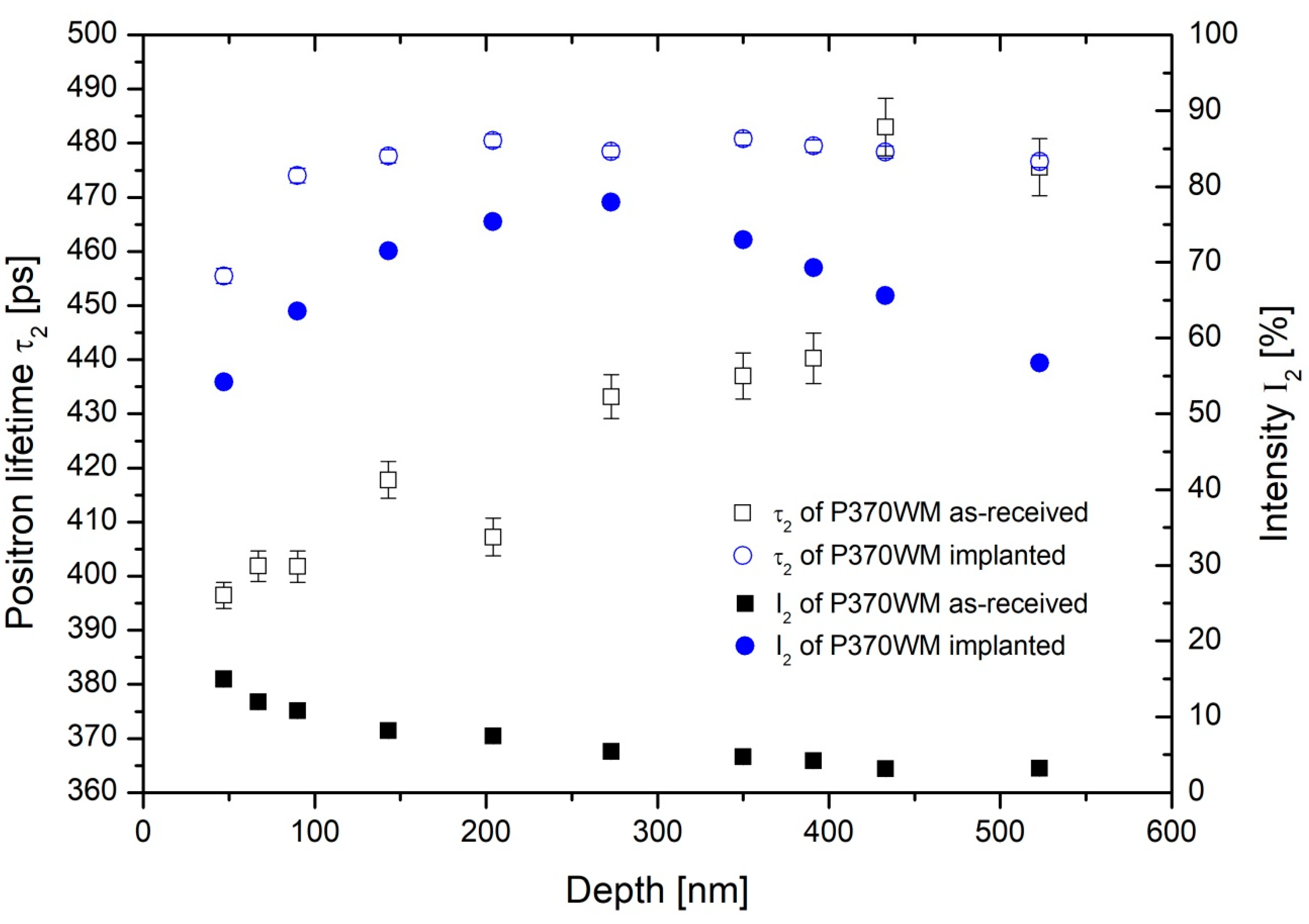

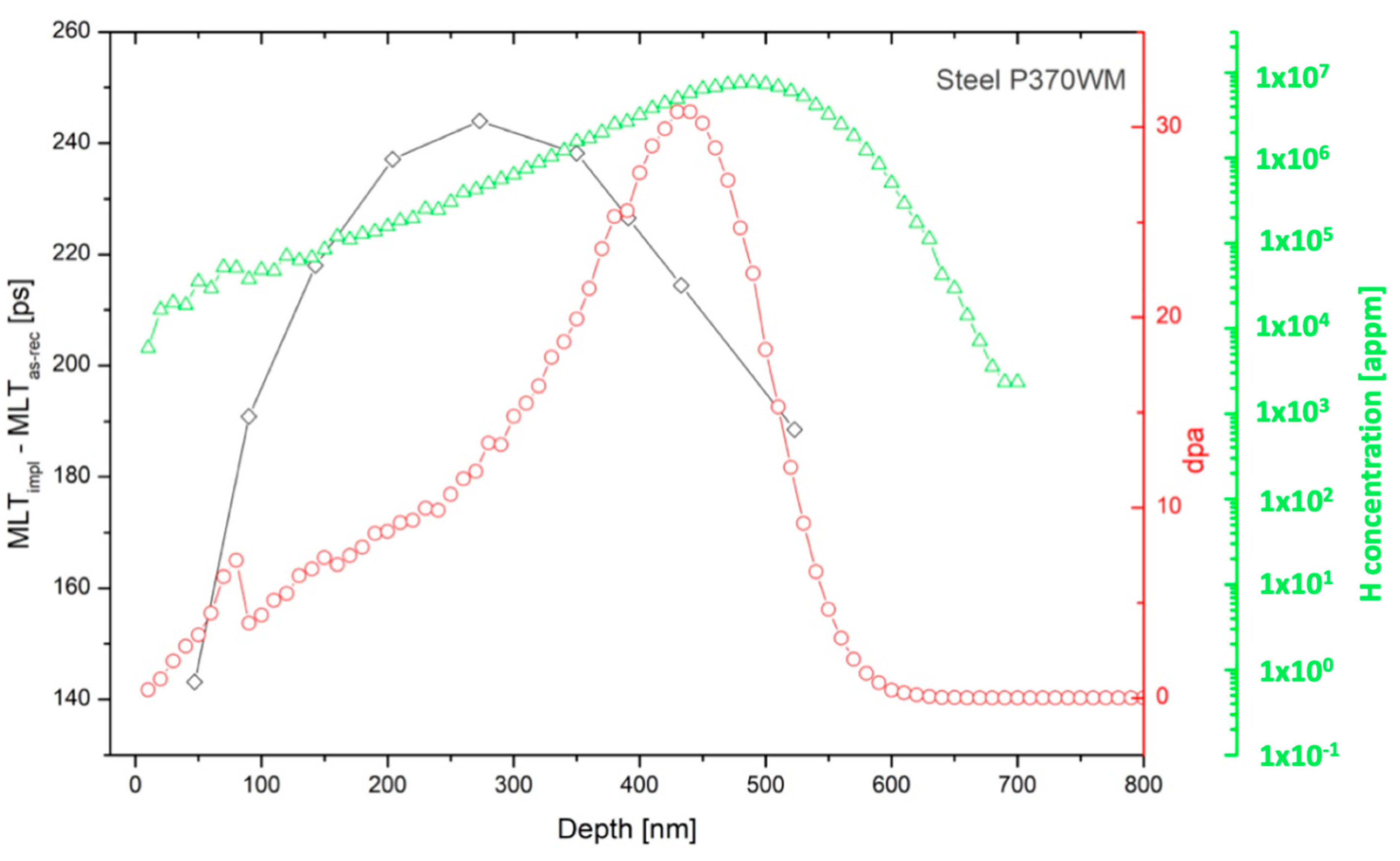

3. Results and Discussion

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Slugen, V. Safety of VVER-440 Reactors—Barriers Against Fission Products Release; Springer: London, UK, 2011. [Google Scholar]

- Davies, L.M. A comparison of Western and Eastern nuclear reactor pressure vessel steels. Int. J. Press. Vessel. Pip. 1999, 76, 163–208. [Google Scholar] [CrossRef]

- Van Duysen, J.C.; de Bellefon, C.M. 60th Anniversary of electricity production from light water reactors: Historical review of the contribution of materials science to the safety of the pressure vessel. J. Nucl. Mater. 2017, 484, 209–227. [Google Scholar] [CrossRef] [Green Version]

- Hoffelner, W. Materials for Nuclear Power Plant; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Phythian, W.J.; English, C.A. Microstructural evolution in reactor pressure vessel steels. J. Nucl. Mater. 1993, 205, 162–177. [Google Scholar] [CrossRef]

- Slugen, V.; Kögel, G.; Sperr, P.; Triftshäuser, W. Positron annihilation studies of neutron irradiated and thermally treated reactor pressure vessel steels. J. Nucl. Mater. 2002, 302, 89–95. [Google Scholar] [CrossRef]

- Slugen, V.; Hein, H.; Sojak, S.; Veternikova, J.; Petriska, M.; Sabelova, V.; Pavuk, M.; Hinca, R.; Stacho, M. Evaluation of the Reactor Pressure Vessel Steels by Positron Annihilation. J. Nucl. Mater. 2013, 442, 499–506. [Google Scholar] [CrossRef]

- Pecko, S.; Sojak, S.; Slugen, V. Comparative study of irradiated and hydrogen implantation damaged German RPV steels from PAS point of view. Appl. Surf. Sci. 2014, 312, 172–175. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Fluss, M.J.; Hosemann, P.; Marian, J. Charged-particle irradiation for neutron radiation damage studies. Charact. Mater. 2012, 2111–2127. [Google Scholar] [CrossRef]

- Bourcier, R.J.; Follstaedt, D.M.; Dugger, M.T.; Myers, S.M. Mechanical characterizationof several ion-implanted alloys: Nanoindentation testing, wear testing and finite element modeling. Nucl. Instr. Meth. Phys. Res. 1991, 59, 905–908. [Google Scholar] [CrossRef]

- Odette, G.R. On the dominant mechanism of irradiation embrittlement of reactor pressure vessel steels. Scr. Metall. 1983, 17, 1183–1188. [Google Scholar] [CrossRef]

- Veternikova, J.S.; Degmova, J.; Pekarcikova, M.; Simko, F.; Petriska, M.; Skarba, M.; Mikula, P.; Pupala, M. Thermal stability study for candidate stainless steels of GEN IV reactors. Appl. Surf. Sci. 2016, 387, 965–970. [Google Scholar] [CrossRef]

- Was, G.S. Challenges to the use of ion irradiation for emulating reactor irradiation. J. Mater. Res. 2015, 30, 1158–1182. [Google Scholar] [CrossRef]

- Röder, R.; Heintze, C.; Pecko, S.; Akhmadaliev, S.; Bergner, F.; Ulbricht, A.; Altstadt, E. Nanoindentation of ion-irradiated reactor pressure vessel steels—Model-based interpretation and comparison with neutron irradiation. Philos. Mag. 2018, 98, 911–933. [Google Scholar] [CrossRef]

- Shimodaria, M.; Toyama, T.; Yoshida, K.; Inoue, K.; Ebisawa, N.; Tomura, K.; Yoshiie, T.; Konstantinovic, M.; Gerard, R.; Nagai, Y. Contribution of irradiation-induced defects to hardening of low-copper reactor pressure vessel steels. Acta Mater. 2018, 155, 402–409. [Google Scholar] [CrossRef]

- Toyama, T.; Kuramoto, A.; Nagai, Y.; Imoue, K.; Nozawa, Y.; Shimizu, Y.; Matsukawa, Y.; Hasegawa, M.; Valo, M. Effects of post-irradiation annealing and re-irradiation on microstructure in surveillance test specimens of the Loviisa-1 reactor studied by atom probe tomography and positron annihilation. J. Nucl. Mater. 2014, 449, 207–212. [Google Scholar] [CrossRef]

- Nishi, T.; Hashimoto, N.; Ohnuki, S.; Yamamoto, T.; Odette, G.R. Effects of alloying elements on radiation hardening based on loop formation of electron-irradiated light water reactor pressure vessel model steels. J. Nucl. Mater. 2011, 417, 936–939. [Google Scholar] [CrossRef]

- Gokhman, A.; Pecko, S.; Slugen, V. Cluster dynamics study of damage accumulation in helium-implanted Fe–2.5at%Cr alloy. Radiat. Eff. Defect. Solids 2015, 170, 130–137. [Google Scholar] [CrossRef]

- Krsjak, V.; Degmova, J.; Sojak, S.; Slugen, V. Effect of displacements damage and helium production rates on the nucleation and growth of helium bubbles—Postron annihilation spectroscopy aspects. J. Nucl. Mater. 2018, 499, 38–46. [Google Scholar] [CrossRef]

- Zhu, H.P.; Wang, Z.G.; Cui, M.H.; Li, B.S.; Gao, X.; Sun, J.R.; Yao, C.F.; Wei, K.F.; Shen, T.F.; Pang, L.L.; et al. Temperature dependent surface modification of T91 steel under 3.25 MeV Fe-ion implantation. Appl. Surf. Sci. 2015, 326, 1–6. [Google Scholar] [CrossRef]

- Hautojärvi, P. Positrons in Solids; Springer: Berlin/Heidelberg, Germany, 1979. [Google Scholar]

- Dupasquier, A.; Mills, A.P., Jr. Positron Spectroscopy of Solids; IOS Press: Amsterdam, The Netherlands, 1995. [Google Scholar]

- Koutsky, J.; Kocik, J. Radiation Damage of Structural Materials; Academia: Prague, Czech Republic, 1994. [Google Scholar]

- Cizek, J.; Prochazka, I.; Kocik, J.; Keilova, E. Positron lifetime study of reactor pressure vessel steels. Phys. Stat. Sol. A 2000, 178, 651–658. [Google Scholar] [CrossRef]

- Slugen, V.; Hascik, J.; Gröne, R.; Bartik, P.; Zeman, A.; Kögel, G.; Sperr, P.; Triftshäuser, W. Investigation of Reactor Steels. Mater. Sci. Forum 2001, 363, 47–51. [Google Scholar]

- Lambrecht, M.; Almazouzi, A. Positron annihilation study of neutron irradiated model alloys and of a reactor pressure vessel steel. J. Nucl. Mater. 2009, 385, 334–338. [Google Scholar] [CrossRef]

- Krsjak, V.; Kuriplach, J.; Shen, T.; Sabelova, V.; Sato, K.; Dai, Y. Helium behavior in ferritic/martensitic steels irradiated in spallation target. J. Nucl. Mater. 2015, 456, 382–388. [Google Scholar] [CrossRef]

- Kryukov, A.; Debarberis, L.; Ballesteros, A.; Krsjak, V.; Burcl, R.; Rogozhkin, S.V.; Nikitin, A.A.; Aleev, A.A.; Zaluzhnyi, A.G.; Grafutin, V.I.; et al. Integrated analysis of WWER-440 RPV weld re-embrittlement after annealing. J. Nucl. Mater. 2012, 429, 190–200. [Google Scholar] [CrossRef]

- Sato, K.; Ikemura, K.; Krsjak, V.; Vieh, C.; Brun, R.; Xu, Q.; Yoshiie, T.; Dai, Y. Defect structures of F82H irradiated at SINQ using positron annihilation spectroscopy. J. Nucl. Mater. 2016, 468, 281–284. [Google Scholar] [CrossRef]

- Heintze, C.; Bergner, F.; Akhmadaliev, S.; Altstadt, E. Ion irradiation combined with nanoindentation as a screening test procedure for irradiation hardening. J. Nucl. Mater. 2016, 472, 196–205. [Google Scholar] [CrossRef]

- Pecko, S.; Sojak, S.; Slugen, V. Comparison of irradiated and hydrogen implanted German RPV steels. Nucl. Instrum. Methods Phys. Res. B 2015, 365, 222–224. [Google Scholar] [CrossRef]

- Slugeň, V.; Pecko, S.; Sojak, S. Experimental studies of irradiated and hydrogen implantation damaged reactor steels. J. Nucl. Mater. 2016, 468, 285–288. [Google Scholar] [CrossRef]

- Hein, H.; Keim, E.; Seibert, H.S.T.; Gundermann, A. Final results from the crack initiation and arrest of irradiated steel materials project on fracture mechanical assessments of pre-irradiated RPV steels used in German PWR. J. ASTM Int. 2009, 6, 1–18. [Google Scholar] [CrossRef]

- Grafutin, V.; Prokopev, E.P. Positron annihilation spectroscopy in materials structure studies. Phys. Uspekhi 2002, 45, 59–74. [Google Scholar] [CrossRef]

- Garner, F.A. Impact of the injected interstitial on the correlation of charged particle and neutron-induced radiation damage. J. Nucl. Mater. 1983, 117, 177–197. [Google Scholar] [CrossRef]

- Stoller, R.E.; Toloczko, M.B.; Was, G.S.; Certain, A.G.; Dwaraknath, S.; Garner, F.A. On the use of SRIM for computing radiation damage exposure. Nucl. Instrum. Methods Phys. Res. Sect. B 2013, 310, 75–80. [Google Scholar] [CrossRef]

- Krsjak, V.; Degmova, J.; Lauko, R.; Snopek, J.; Saro, M.; Sedlackova, K.; Sojak, S.; Petriska, M.; Farkas, G.; Dai, Y.; et al. Positron annihilation spectroscopy studies of irradiated Fe-based alloys using different radioisotope sources. Nucl. Instrum. Methods Phys. Res. B 2018, 434, 73–80. [Google Scholar] [CrossRef]

- Hautojärvi, P.; Pöllönen, L.; Vehanen, A.; Yli-Kauppila, J. Vacancies and carbon impurities in α-iron: Neutron irradiation. J. Nucl. Mater. 1983, 114, 250–259. [Google Scholar] [CrossRef]

- Vehanen, A.; Hautojärvi, P.; Johansson, J.; Yli-Kauppila, J.; Moser, P. Vacancies and carbon impurities in α-iron: Electron irradiation. Phys. Rev. B 1982, 25, 762–780. [Google Scholar] [CrossRef]

- Brauer, G.; Liszkay, L.; Molnar, B.; Krause, R. Microstructural aspects of neutron embrittlement of reactor pressure vessel steels—A view from positron annihilation spectroscopy. Nucl. Eng. Desg. 1991, 127, 47–68. [Google Scholar] [CrossRef]

- Slugen, V.; Krsjak, V.; Egger, W.; Petriska, M.; Sojak, S.; Vetrenikova, J. Fe-Cr alloys behaviour after Helium implantation. J. Nucl. Mater. 2011, 409, 163–166. [Google Scholar] [CrossRef]

- Sperr, P.; Egger, W.; Kögel, G.; Dollinger, G.; Hugenschmedt, C.; Repper, R.; Piochacz, C. Status of the pulsed low energy positron beam system (PLEPS) at the Munich Research Reactor FRM-II. Appl. Surf. Sci. 2008, 255, 35–38. [Google Scholar] [CrossRef]

- Hugenschmidt, C. Positron in surface physics. Surf. Sci. Rep. 2016, 71, 547–594. [Google Scholar] [CrossRef] [Green Version]

- Hugenschmidt, C.; Löwe, B.; Mayer, J.; Piochacz, C.; Pikart, P.; Repper, R.; Stadlbauer, M.; Scheckenbach, K. Unprecedented intensity of a low-energy positron beam. Nucl. Instrum. Meth. A 2008, 593, 616–618. [Google Scholar] [CrossRef]

- Hyodo, T.; Wada, K.; Yagishita, A.; Kosuge, T.; Saito, Y.; Kurihara, T.; Kikuchi, T.; Shirakawa, A.; Sanami, T.; Ikeda, M.; et al. KEK-IMSS slow positron facility. J. Phys. Conf. Ser. 2011, 262, 012026. [Google Scholar] [CrossRef]

- Wada, K.; Hyodo, T.; Kosuge, T.; Saito, Y.; Ikeda, M.; Oshawa, S.; Shidara, T.; Michishio, K.; Tachibana, T.; Terabe, H.; et al. New experiment stations at KEK Slow Positron Facility. J. Phys. Conf. Ser. 2013, 443, 012082. [Google Scholar] [CrossRef] [Green Version]

- Krause-Rehberg, R.; Sachert, S.; Brauer, G.; Rogov, A.; Noak, K. EPOS—An intense positron beam project at the ELBE radiation source in Rossendorf. Appl. Surf. Sci. 2006, 252, 3106–3110. [Google Scholar] [CrossRef]

- Sato, K.; Xu, Q.; Yoshiie, T.; Sano, T.; Kawabe, H.; Nagai, Y.; Nagumo, K.; Inoue, K.; Toyama, T.; Oshima, N.; et al. Development of a mono-energetic positron beam line at the Kyoto University Research Reactor. Nucl. Instrum. Meth. Phys. Res. Sect. B Beam Interact. Mater. Atoms 2015, 342, 104–107. [Google Scholar] [CrossRef]

- Cizek, J.; Becvar, F.; Prochazka, I. Three-detector setup for positron-lifetime spectroscopy of solids containing 60Co radionuclide. Nucl. Instrum. Methods Phys. Res. A 2000, 450, 325–337. [Google Scholar] [CrossRef]

- Dai, Y.; Krsjak, V.; Kuksenko, V.; Schaeublin, R. Microstructural changes of ferritic/martensitic steels after irradiation in spallation target environments. J. Nucl. Mater. 2018, 511, 508–522. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Specimen | German PWR Generation | C [%] | Si [%] | Mn [%] | P [%] | S [%] | Cr [%] | Mo [%] | Ni [%] | Cu [%] |

|---|---|---|---|---|---|---|---|---|---|---|

| P370 WM | 1 | 0.08 | 0.15 | 1.14 | 0.015 | 0.013 | 0.74 | 0.60 | 1.11 | 0.22 |

| Hydrogen Implantation | Implanted Dose [C/cm2] | Number of Implanted Ions [cm−2] | Dose in Implanted Region [dpa] |

|---|---|---|---|

| 1. Level | 0.10 | 6.24 × 1017 | 0.5 |

| 2. Level | 0.82 | 5.12 × 1018 | 4 |

| 3. Level | 3.20 | 2.21 × 1019 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slugeň, V.; Sojak, S.; Egger, W.; Krsjak, V.; Simeg Veternikova, J.; Petriska, M. Radiation Damage of Reactor Pressure Vessel Steels Studied by Positron Annihilation Spectroscopy—A Review. Metals 2020, 10, 1378. https://doi.org/10.3390/met10101378

Slugeň V, Sojak S, Egger W, Krsjak V, Simeg Veternikova J, Petriska M. Radiation Damage of Reactor Pressure Vessel Steels Studied by Positron Annihilation Spectroscopy—A Review. Metals. 2020; 10(10):1378. https://doi.org/10.3390/met10101378

Chicago/Turabian StyleSlugeň, Vladimír, Stanislav Sojak, Werner Egger, Vladimir Krsjak, Jana Simeg Veternikova, and Martin Petriska. 2020. "Radiation Damage of Reactor Pressure Vessel Steels Studied by Positron Annihilation Spectroscopy—A Review" Metals 10, no. 10: 1378. https://doi.org/10.3390/met10101378