Prediction of Fatigue Crack Growth Behaviour in Ultrafine Grained Al 2014 Alloy Using Machine Learning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Method

2.2. Machine Learning Methods

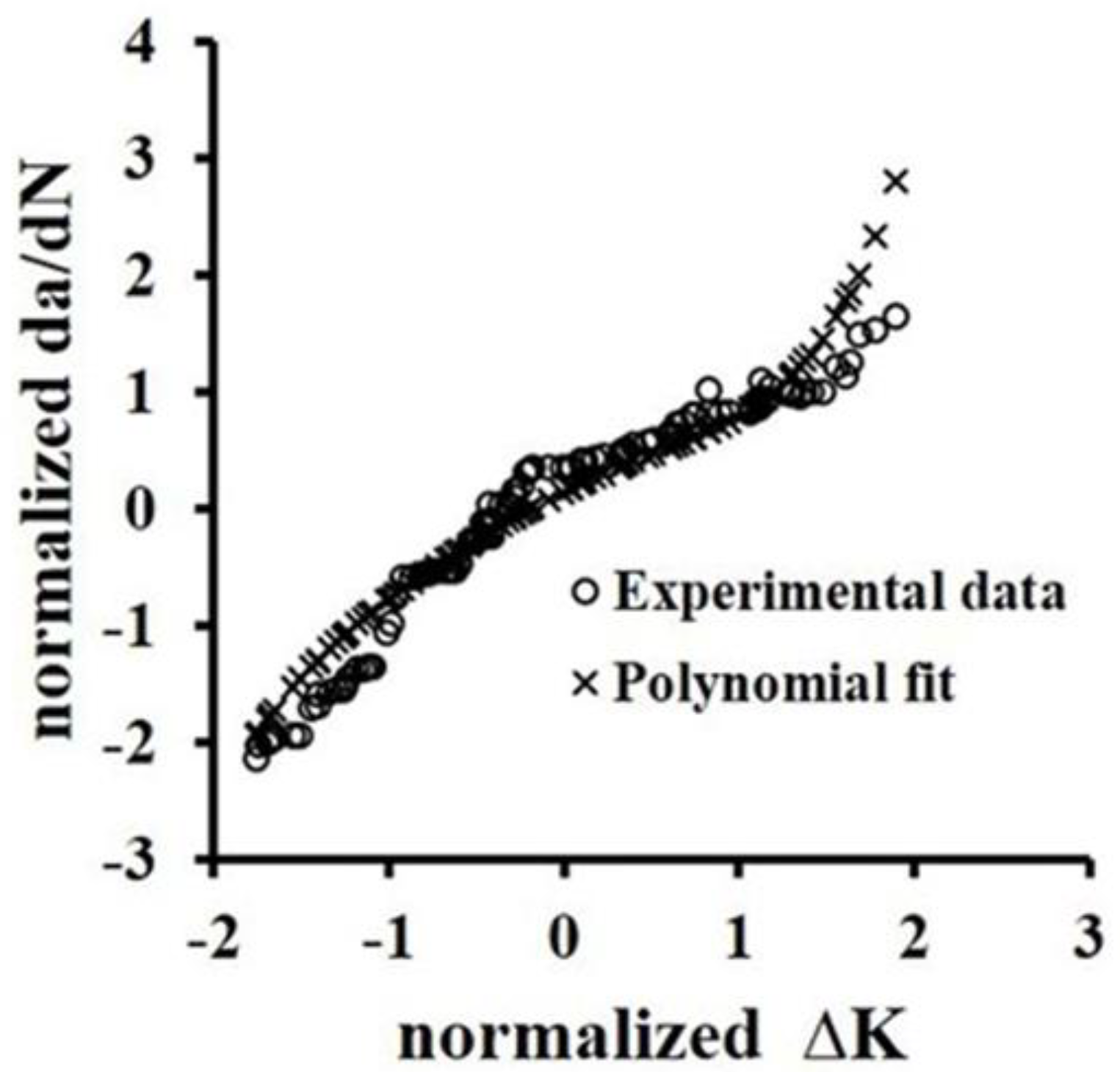

2.2.1. Data Pre-Processing

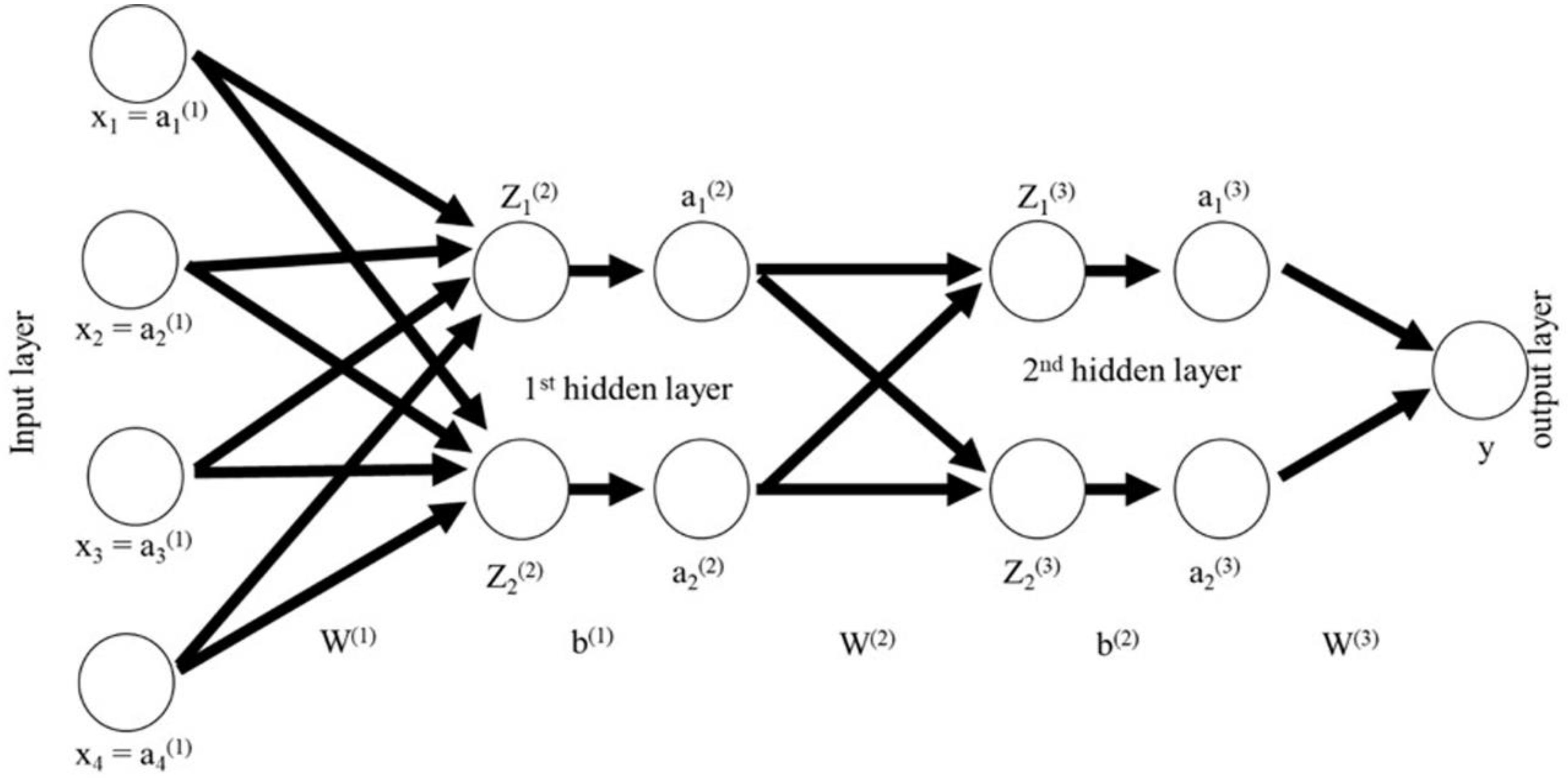

2.2.2. Back Propagation Neural Network

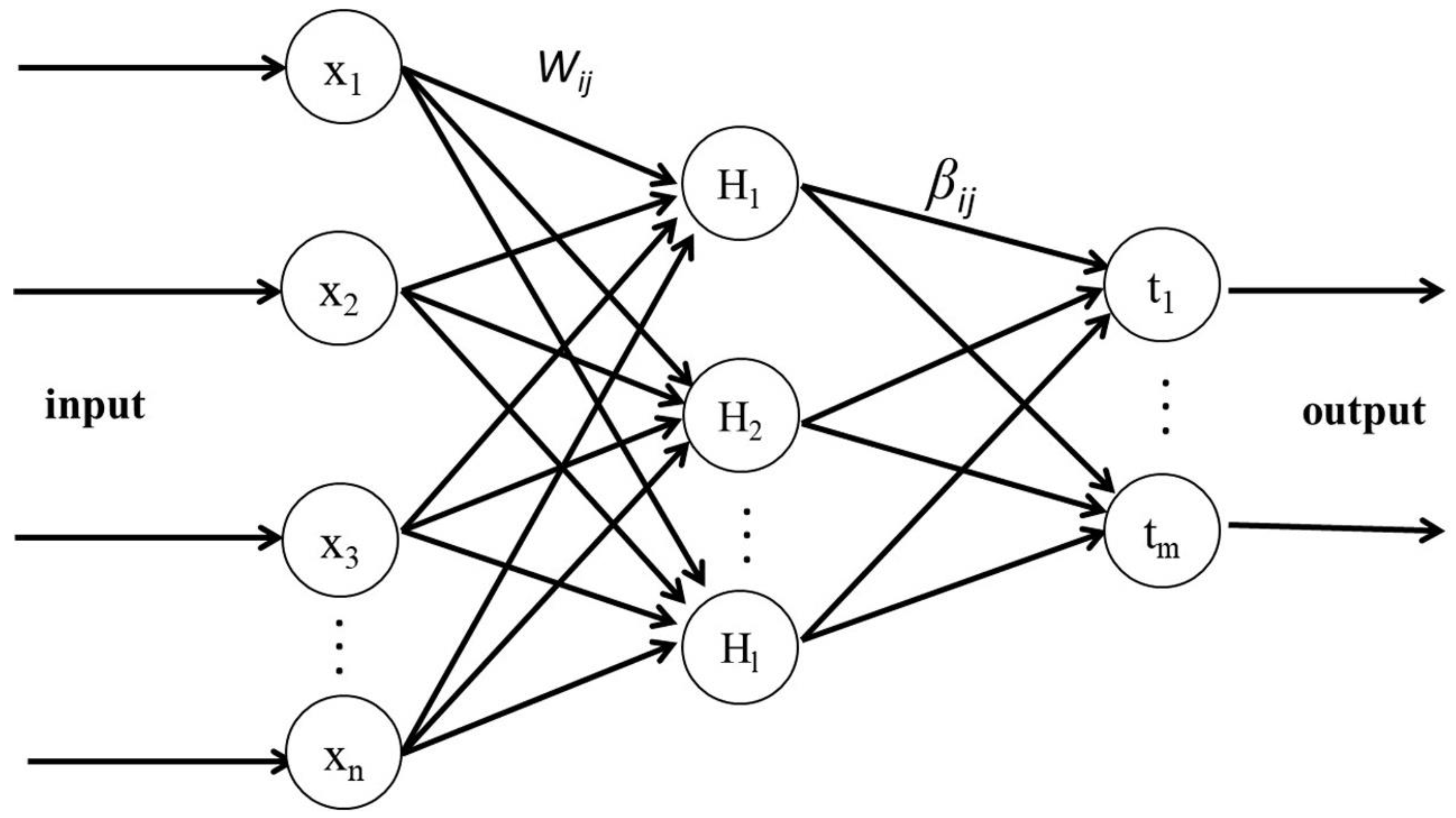

2.2.3. Extreme Learning Machine

3. Results and Discussion

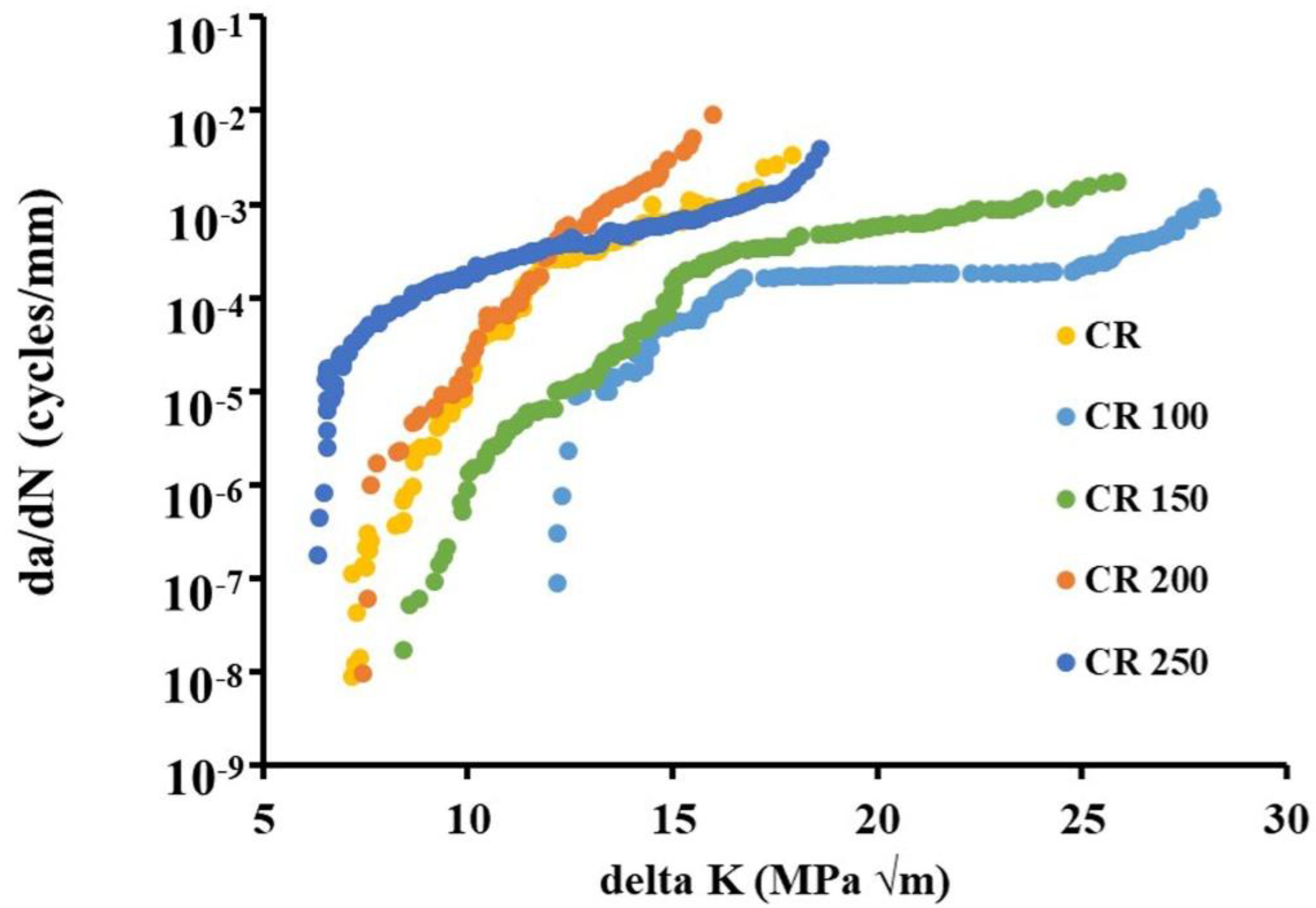

3.1. Experimental Data

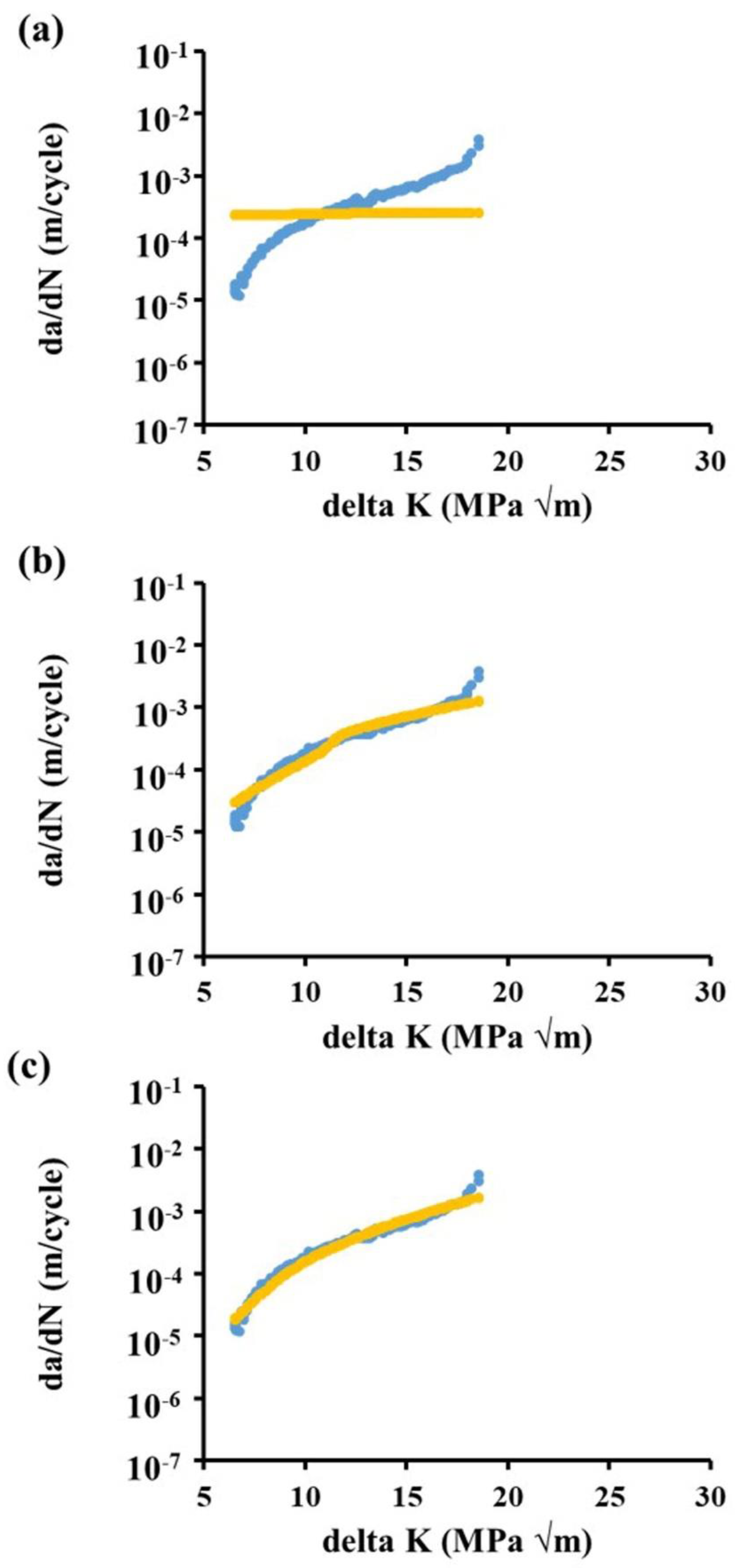

3.2. Machine Learning

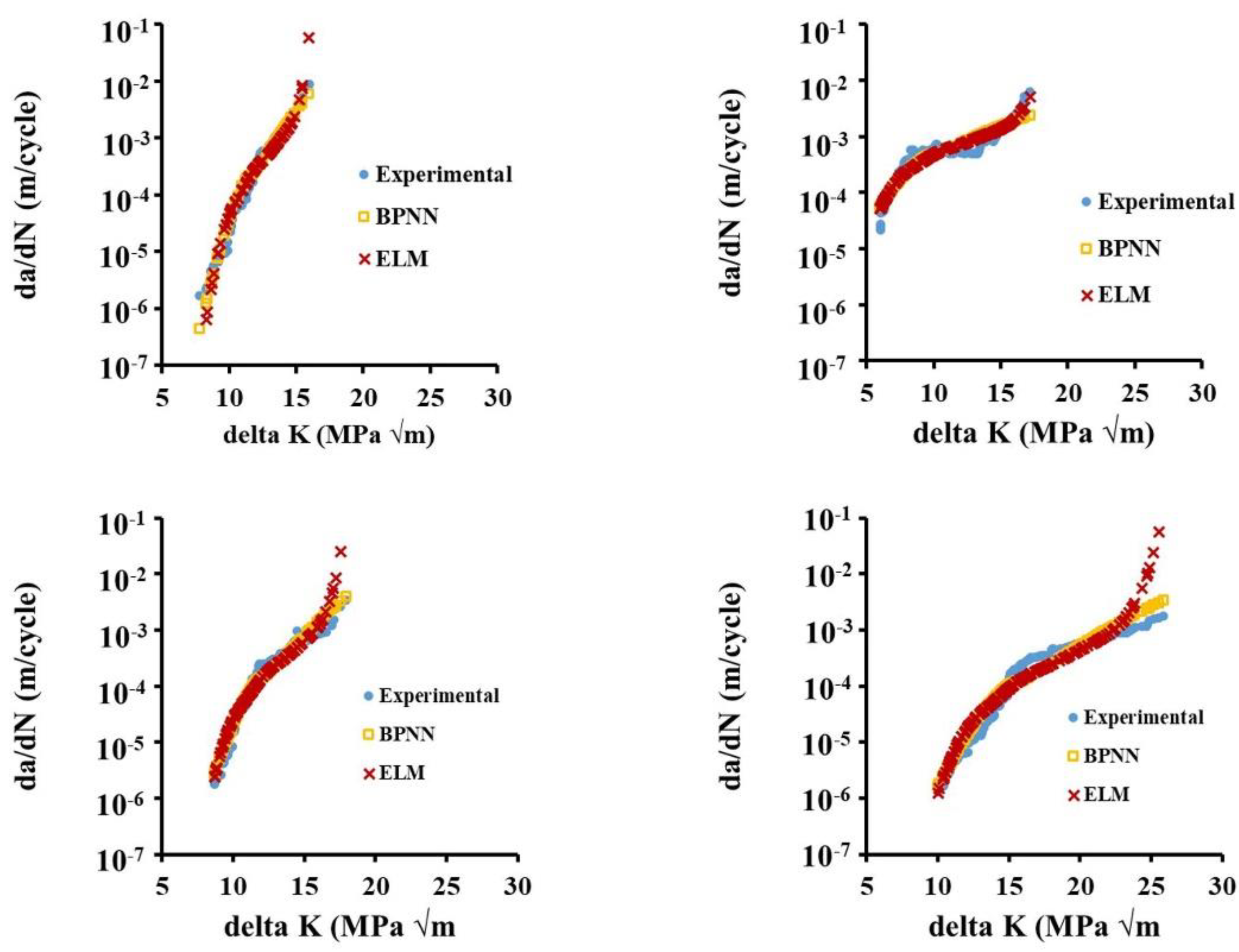

Back Propagation Neural Networks

4. Conclusions

- Machine learning techniques are way too easy and flexible as compared to designing numerical equations because of their non-linear activation functions.

- In back propagation, accuracy increases till certain number of epochs and starts decreasing after that, hence optimum number of epochs is determined by experimentation.

- In ELM model, optimum number of neurons in hidden layer affects the accuracy and is found by experimenting.

- Activation functions in both the above neural networks play a critical role as they are prominent in explaining non-linearity.

- Curve fitting model requires initial assumption about the type of function to be used and also fails if model fits other than polynomial functions as they are difficult to assume, for example log function. ELM is the best model followed by back propagation neural networks because of its ability to model non-linearity.

- The non-linearity, even in the Paris region of fatigue crack growth of the materials can be better predicted using ML algorithms rather than using Paris law or polynomial curve fitting techniques.

- The ELM model, the quickest of the two ML models used, predicts the unstable crack growth region more accurately when compared to BPNN and polynomial curve fitting techniques.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kardomateas, G.A.; Geubelle, P.H. Fatigue and Fracture Mechanics in Aerospace Structures. In Encyclopedia of Aerospace Engineering; Blockley, R., Shyy, W., Eds.; Wiley: Chichester, UK, 2010. [Google Scholar]

- Stanzl-Tschegg, S.E. When do small fatigue cracks propagate and when are they arrested? Corros. Rev. 2019, 37, 397–418. [Google Scholar] [CrossRef]

- Schütz, W. Fatigue life prediction of aircraft structures—Past, present and future. Eng. Fract. Mech. 1974, 6, 745–762. [Google Scholar] [CrossRef]

- Bock, F.E.; Aydin, R.C.; Cyron, C.J.; Huber, N.; Kalidindi, S.R.; Klusemann, B. A Review of the Application of Machine Learning and Data Mining Approaches in Continuum Materials Mechanics. Front. Mater. 2019, 6, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Versino, D.; Tonda, A.; Bronkhorst, C.A. Data driven modeling of plastic deformation. Comput. Methods Appl. Mech. Eng. 2017, 318, 981–1004. [Google Scholar] [CrossRef] [Green Version]

- Dimiduk, D.M.; Holm, E.; Niezgoda, S.R. Perspectives on the Impact of Machine Learning, Deep Learning, and Artificial Intelligence on Materials, Processes, and Structures Engineering. Integr. Mater. Manuf. Innov. 2018, 7, 157–172. [Google Scholar] [CrossRef] [Green Version]

- Haynes, R.; Joshi, G.; Bradley, N. Machine learning-based prognostics of fatigue crack growth in notch pre-cracked aluminum 7075-T6 rivet hole. Proc. Annu. Conf. PHM Soc. 2018, 10, 1–8. [Google Scholar]

- An, D.; Choi, J.-H.; Kim, N.H.; Pattabhiraman, S. Fatigue life prediction based on Bayesian approach to incorporate field data into probability model. Struct. Eng. Mech. 2011, 37, 427–442. [Google Scholar] [CrossRef] [Green Version]

- Doh, J.; Lee, J. Bayesian estimation of the lethargy coefficient for probabilistic fatigue life model. J. Comput. Des. Eng. 2017, 5, 191–197. [Google Scholar] [CrossRef]

- Rovinelli, A.; Sangid, M.D.; Proudhon, H.; Ludwig, W. Using machine learning and a data-driven approach to identify the small fatigue crack driving force in polycrystalline materials. NPJ Comput. Mater. 2018, 4, 35. [Google Scholar] [CrossRef] [Green Version]

- Castillo, E.F.; Muñiz-Calvente, M.; Canteli, A.F.; Blasón, S. Fatigue Assessment Strategy Using Bayesian Techniques. Materials 2019, 12, 3239. [Google Scholar] [CrossRef] [Green Version]

- Ali, H. Accelerated Fatigue Reliability Analysis of Stiffened Sections Using Deep Learning. Master’s Thesis, National University of Sciences and Technology, Islamabad, Pakistan, 2018; pp. 1–53. Available online: https://hdl.handle.net/11244/320947 (accessed on 16 July 2020).

- Pujol, J.C.F.; Pinto, J.M.A. A neural network approach to fatigue life prediction. Int. J. Fatigue 2011, 33, 313–322. [Google Scholar] [CrossRef]

- Schwarzer, M.; Rogan, B.; Ruan, Y.; Song, Z.; Lee, D.Y.; Percus, A.; Chau, V.T.; Moore, B.A.; Rougier, E.; Viswanathan, H.S.; et al. Learning to fail: Predicting fracture evolution in brittle material models using recurrent graph convolutional neural networks. Comput. Mater. Sci. 2019, 162, 322–332. [Google Scholar] [CrossRef] [Green Version]

- Pierson, K.; Rahman, A.; Spear, A.D. Predicting Microstructure-Sensitive Fatigue-Crack Path in 3D Using a Machine Learning Framework. JOM 2019, 71, 2680–2694. [Google Scholar] [CrossRef] [Green Version]

- Ch, S.R.; Raja, A.; Jayaganthan, R.; Vasa, N.; Raghunandan, M. Study on the fatigue behaviour of selective laser melted AlSi10Mg alloy. Mater. Sci. Eng. A 2020, 781, 139180. [Google Scholar] [CrossRef]

- Nguyen, D.L.H.; Do, D.T.T.; Lee, J.; Rabczuk, T.; Nguyen-Xuan, H. Forecasting Damage Mechanics by Deep Learning. Comput. Mater. Contin. 2019, 61, 951–977. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, W.; Du, Y.; Zhang, G.; Yang, Y. Prediction of fatigue stress concentration factor using extreme learning machine. Comput. Mater. Sci. 2016, 125, 136–145. [Google Scholar] [CrossRef]

- Zio, E.; Di Maio, F. Fatigue crack growth estimation by relevance vector machine. Expert Syst. Appl. 2012, 39, 10681–10692. [Google Scholar] [CrossRef]

- Mohanty, J.; Mahanta, T.; Mohanty, A.; Thatoi, D. Prediction of constant amplitude fatigue crack growth life of 2024 T3 Al alloy with R-ratio effect by GP. Appl. Soft Comput. 2015, 26, 428–434. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Sun, F.; Zhang, W. A Comparison Study of Machine Learning Based Algorithms for Fatigue Crack Growth Calculation. Materials 2017, 10, 543. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Bao, Z.; Jiang, S.; He, J. An Artificial Neural Network-Based Algorithm for Evaluation of Fatigue Crack Propagation Considering Nonlinear Damage Accumulation. Materials 2016, 9, 483. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.-B.; Zhou, H.; Ding, X.; Zhang, R. Extreme Learning Machine for Regression and Multiclass Classification. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2011, 42, 513–529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, G.-B. An Insight into Extreme Learning Machines: Random Neurons, Random Features and Kernels. Cogn. Comput. 2014, 6, 376–390. [Google Scholar] [CrossRef]

- Huang, G.-B.; Chen, L.; Siew, C.-K. Universal Approximation Using Incremental Constructive Feedforward Networks With Random Hidden Nodes. IEEE Trans. Neural Netw. 2006, 17, 879–892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, G.-B.; Chen, L. Convex incremental extreme learning machine. Neurocomputing 2007, 70, 3056–3062. [Google Scholar] [CrossRef]

- Joshi, A.; Yogesha, K.K.; Raja, A.; Owalabi, G.; Jayaganthan, R. Effects of Cryorolling followed by Annealing on the Fatigue Crack Propagation behavior of Ultrafine grained Al 2014 Alloy. (To be communicated).

- Joshi, A.; Yogesha, K.K.; Jayaganthan, R. Influence of cryorolling and followed by annealing on high cycle fatigue behavior of ultrafine grained Al 2014 alloy. Mater. Charact. 2017, 127, 253–271. [Google Scholar] [CrossRef]

- Yogesha, K.K.; Joshi, A.; Jayaganthan, R. Fatigue Behavior of Ultrafine-Grained 5052 Al Alloy Processed Through Different Rolling Methods. J. Mater. Eng. Perform. 2017, 31, 1476–2836. [Google Scholar] [CrossRef]

- Yogesha, K.K.; Joshi, A.; Raja, A.; Jayaganthan, R. High-Cycle Fatigue Behaviour of Ultrafine Grained 5052 Al Alloy. Processed Through Cryo-Forging; Springer Science and Business Media LLC: Cham, Switzerland, 2019; pp. 153–161. [Google Scholar]

| Model Name | MSE |

|---|---|

| BPNN | 1.89 |

| ELM | 1.84 |

| Curve fitting | 0.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raja, A.; Chukka, S.T.; Jayaganthan, R. Prediction of Fatigue Crack Growth Behaviour in Ultrafine Grained Al 2014 Alloy Using Machine Learning. Metals 2020, 10, 1349. https://doi.org/10.3390/met10101349

Raja A, Chukka ST, Jayaganthan R. Prediction of Fatigue Crack Growth Behaviour in Ultrafine Grained Al 2014 Alloy Using Machine Learning. Metals. 2020; 10(10):1349. https://doi.org/10.3390/met10101349

Chicago/Turabian StyleRaja, Allavikutty, Sai Teja Chukka, and Rengaswamy Jayaganthan. 2020. "Prediction of Fatigue Crack Growth Behaviour in Ultrafine Grained Al 2014 Alloy Using Machine Learning" Metals 10, no. 10: 1349. https://doi.org/10.3390/met10101349

APA StyleRaja, A., Chukka, S. T., & Jayaganthan, R. (2020). Prediction of Fatigue Crack Growth Behaviour in Ultrafine Grained Al 2014 Alloy Using Machine Learning. Metals, 10(10), 1349. https://doi.org/10.3390/met10101349