Microstructure and Strengthening/Toughening Mechanisms of Heavy Gauge Pipeline Steel Processed by Ultrafast Cooling

Abstract

:1. Introduction

2. Materials and Methods

3. Results

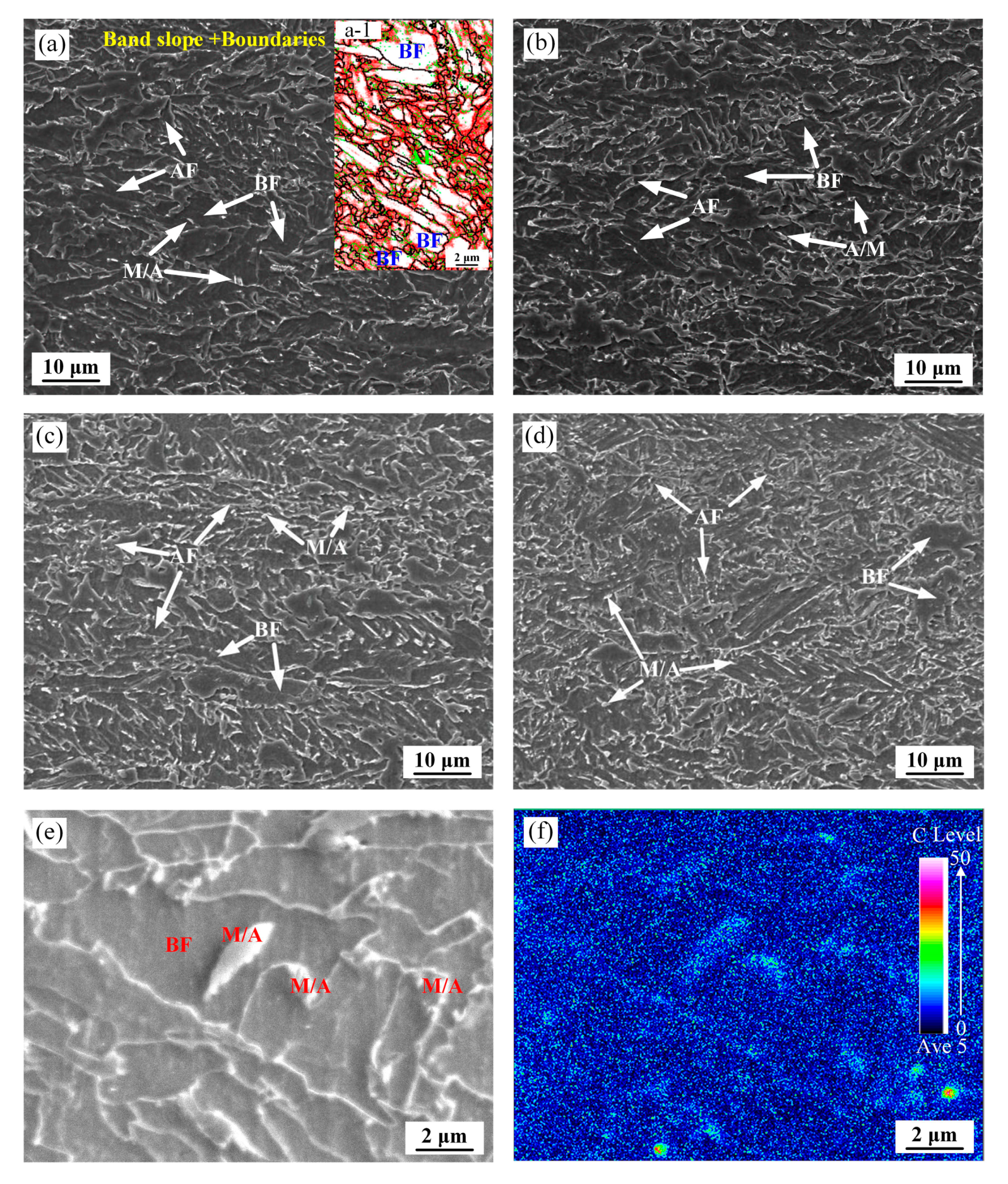

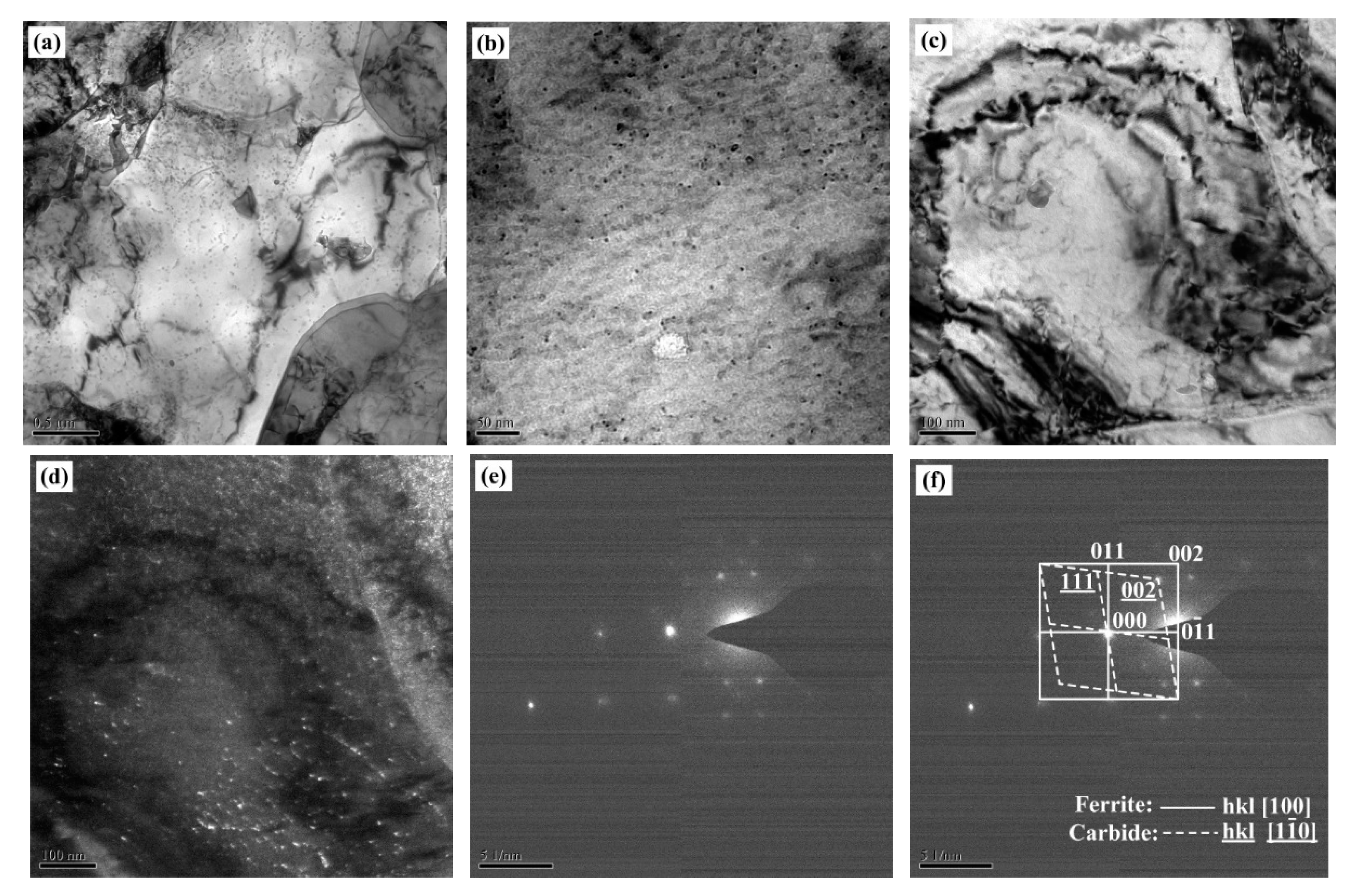

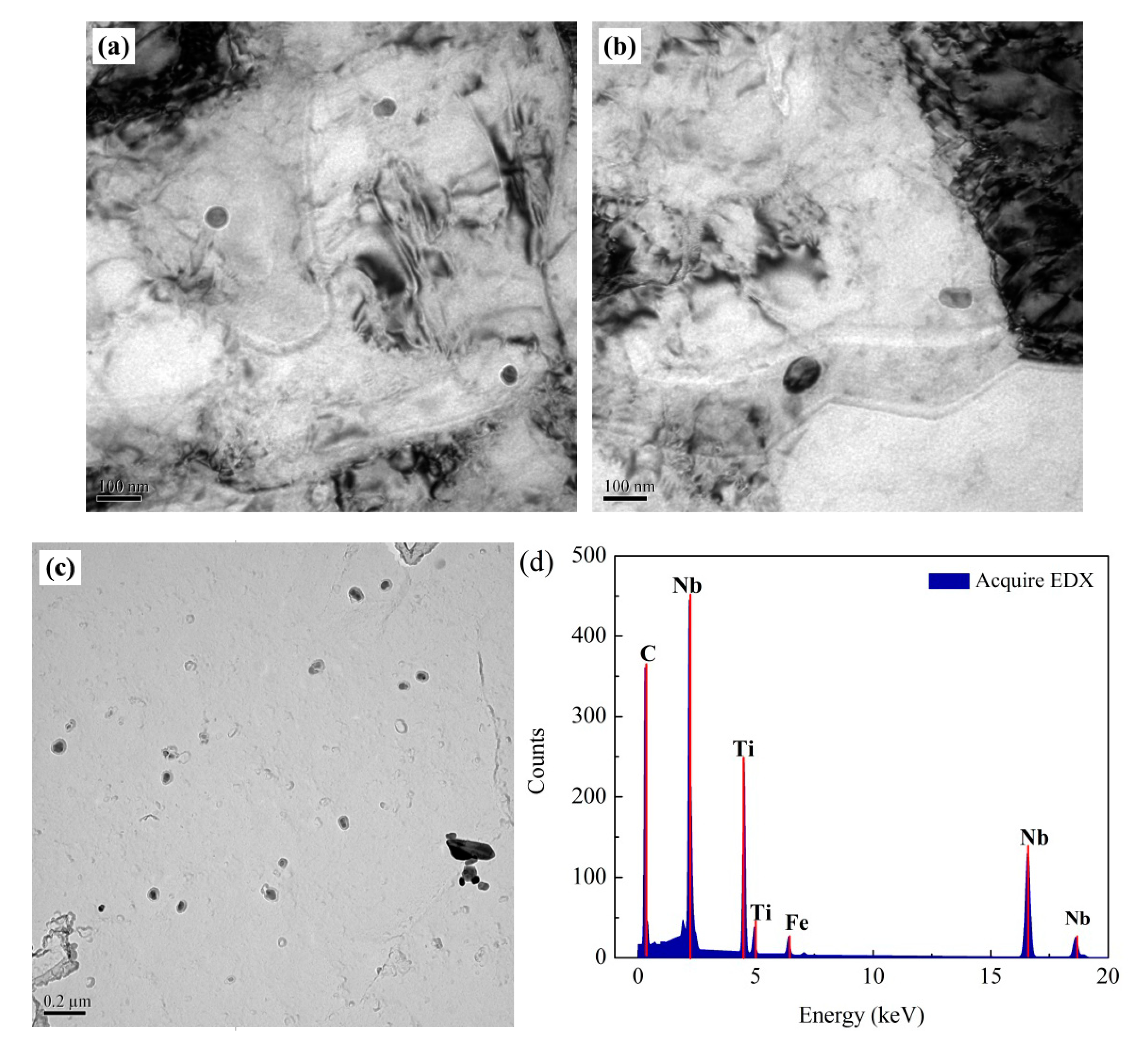

3.1. Microstructural Evolution

3.2. Mechanical Propertiesres

4. Discussion

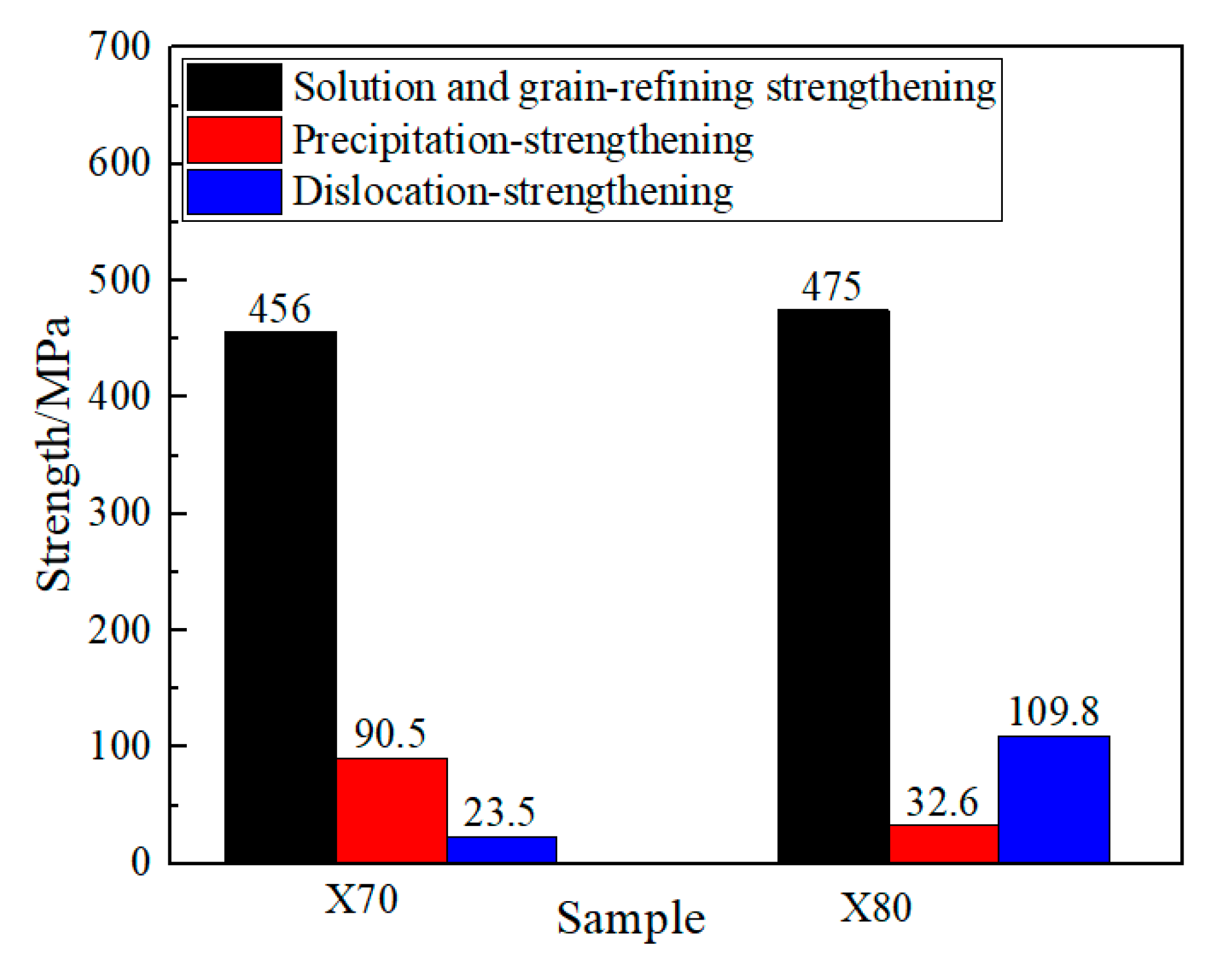

4.1. Strengthening Mechanisms of X70/X80 Pipeline Steels under UFC

4.2. Effect of TMCP Process on Microstructure and Toughening Mechanism

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, X.G.; Zeng, C.Y.; Yang, H.; Ma, L.Y.; Liu, Z.Y.; Wu, D.; Wang, G.D. Effect of cooling process on microstructure and mechanical properties of X100 pipeline steel. Steel Res. Int. 2016, 87, 1366–1375. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, Q.; Cui, Z.Y.; Wu, W.; Li, Z.; Du, C.W.; Li, X.G. Field experiment of stress corrosion cracking behavior of high strength pipeline steels in typical soil environments. Constr. Build. Mater. 2017, 148, 131–139. [Google Scholar] [CrossRef]

- Shim, D.J.; Uddin, M.; Wilkowski, G. Comparison between standard and modified back-slotted DWTT specimens. In Proceedings of the 2014 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014. [Google Scholar]

- Yu, P.S.; Ru, C.Q. Analysis of energy absorptions in drop-weight tear tests of pipeline steel. Eng. Fract. Mech. 2016, 160, 138–146. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.Q.; Kang, J.; Yuan, G.; Di, H.S. Crack propagation behavior during DWTT for X80 pipeline steel processed via ultra-fast cooling technique. Chin. J. Mater. Res. 2017, 31, 728–736. [Google Scholar] [CrossRef]

- Kang, M.; Kim, H.; Lee, S.; Shin, S.Y. Effects of Dynamic Strain Hardening Exponent on Abnormal Cleavage Fracture Occurring During Drop Weight Tear Test of API X70 and X80 Linepipe Steels. Metall. Mater. Trans. A 2013, 45, 682–697. [Google Scholar] [CrossRef] [Green Version]

- Yuan, G.; Hu, W.L.; Wang, X.Q.; Kang, J.; Zhao, J.H.; Di, H.S.; Wang, G.D. The relationship between microstructure, crystallographic orientation, and fracture behavior in a high strength ferrous alloy. J. Alloys Compd. 2017, 695, 526–539. [Google Scholar] [CrossRef]

- Costin, W.L.; Lavigne, O.; Kotousov, A.; Ghomashchi, R.; Linton, V. Investigation of hydrogen assisted cracking in acicular ferrite using site-specific micro-fracture tests. Mater. Sci. Eng. A 2016, 651, 859–868. [Google Scholar] [CrossRef] [Green Version]

- Xiong, Z.; Liu, S.; Wang, X.; Shang, C.; Li, X.; Misra, R.D.K. The contribution of intragranular acicular ferrite microstructural constituent on impact toughness and impeding crack initiation and propagation in the heat-affected zone (HAZ) of low-carbon steels. Mater. Sci. Eng. A 2015, 636, 117–123. [Google Scholar] [CrossRef]

- Zhou, M.W.; Yu, H. Influences of Microstructure and Texture on Toughness of Acicular Ferrite Pipeline Steel. Adv. Mater. Res. 2011, 399–401, 245–249. [Google Scholar] [CrossRef]

- Yamamoto, S.; Yokoyama, H.; Yamada, K.; Niikura, M. Effects of the Austenite Grain Size and Deformation in the Unrecrystallized Austenite Region on Bainite Transformation Behavior and Microstructure. ISIJ Int. 1995, 35, 1020–1026. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Lee, H.; Kim, N. Transformation behavior and microstructural characteristics of acicular ferrite in linepipe steels. Mater. Sci. Eng. A 2008, 478, 361–370. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, J.; Ye, Z.; Hong, X.; Huang, H.; Xu, W. Effect of grain size and misorientation angle on fatigue crack growth of nanocrystalline materials. Mater. Sci. Eng. A 2016, 663, 1–7. [Google Scholar] [CrossRef]

- Kim, Y.W.; Song, S.W.; Seo, S.J.; Hong, S.-G.; Lee, C.S. Development of Ti and Mo micro-alloyed hot-rolled high strength sheet steel by controlling thermomechanical controlled processing schedule. Mater. Sci. Eng. A 2013, 565, 430–438. [Google Scholar] [CrossRef]

- Kim, B.; Boucard, E.; Sourmail, T.; San Martín, D.; Gey, N.; Rivera-Díaz-del-Castillo, P.E.J. The influence of silicon in tempered martensite: Understanding the microstructure–properties relationship in 0.5–0.6 wt.% C steels. Acta Mater. 2014, 68, 169–178. [Google Scholar] [CrossRef]

- Pickering, F.B. Physical Metallurgy and the Design of Steels; Applied Science Publishers Ltd.: London, UK, 1978. [Google Scholar]

- Gladman, T. Precipitation hardening in metals. Mater. Sci. Technol. 1999, 15, 30–36. [Google Scholar] [CrossRef]

- Li, Z.L.; Chen, D.; Li, Y.J.; Wang, X.Q.; Kang, J.; Yuan, G. A novel process involving multiple strengthening mechanisms for production of low-residual stress X80 pipe steel based on ultra-fast cooling. Mater. Lett. 2019, 257, 126767. [Google Scholar] [CrossRef]

| Steel | C | P | S | Mn | Si | Nb + V + Ti | Cu + Ni + Mo | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| X70 | 0.044 | 0.012 | 0.001 | 1.60 | 0.19 | 0.12 | 0.62 | 0.16 | Bal. |

| X80 | 0.061 | 0.013 | 0.001 | 1.75 | 0.11 | 0.11 | 0.52 | 0.27 | Bal. |

| No. | AF | BF + M/A | Observed Position |

|---|---|---|---|

| X70-UFC | 90 | 10 | Quarter-thickness |

| 85 | 15 | Mid-thickness | |

| X80-UFC | 92 | 8 | Quarter-thickness |

| 88 | 12 | Mid-thickness |

| No. | Tensile Property | DWTT/% | ||||

|---|---|---|---|---|---|---|

| Rt0.5 /MPa | Rm /MPa | Elongation /% | Specimen 1 | Specimen 2 | Average | |

| 25.4 mm X70 | 549.5 | 687 | 21 | 90 | 95 | 92.5 |

| API SPEC X70 | 500–625 | 570–700 | ≥16 | –15°C, single ≥ 80%, average ≥ 85% | ||

| 22 mm X80 | 589.5 | 710.2 | 23 | 90 | 100 | 95 |

| API SPEC X80 | 555–690 | 625–825 | ≥16 | –15°C, single ≥ 80%, average ≥ 85% | ||

| No. | –20 °C | –40 °C | –60 °C | –80 ℃ | –120 °C |

|---|---|---|---|---|---|

| 25.4 mm X70 | 413 ± 7 J | 387 ± 12 J | 311 ± 10 J | 200 ± 12 | 20 ± 4 |

| 22 mm X80 | 305 ± 3 J | 300 ± 5 J | 279 ± 15 J | 125 ± 14 | 11 ± 3 |

| API SPEC 5L | –20 °C, single ≥ 160 J, average ≥ 200 J | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.-q.; Yuan, G.; Zhao, J.-h.; Wang, G.-d. Microstructure and Strengthening/Toughening Mechanisms of Heavy Gauge Pipeline Steel Processed by Ultrafast Cooling. Metals 2020, 10, 1323. https://doi.org/10.3390/met10101323

Wang X-q, Yuan G, Zhao J-h, Wang G-d. Microstructure and Strengthening/Toughening Mechanisms of Heavy Gauge Pipeline Steel Processed by Ultrafast Cooling. Metals. 2020; 10(10):1323. https://doi.org/10.3390/met10101323

Chicago/Turabian StyleWang, Xue-qiang, Guo Yuan, Jin-hua Zhao, and Guo-dong Wang. 2020. "Microstructure and Strengthening/Toughening Mechanisms of Heavy Gauge Pipeline Steel Processed by Ultrafast Cooling" Metals 10, no. 10: 1323. https://doi.org/10.3390/met10101323

APA StyleWang, X.-q., Yuan, G., Zhao, J.-h., & Wang, G.-d. (2020). Microstructure and Strengthening/Toughening Mechanisms of Heavy Gauge Pipeline Steel Processed by Ultrafast Cooling. Metals, 10(10), 1323. https://doi.org/10.3390/met10101323