Effects of Solution Treatment on Laser Welding of Ti–6Al–4V Alloy Plate Produced through Wire Arc Additive Manufacturing

Abstract

1. Introduction

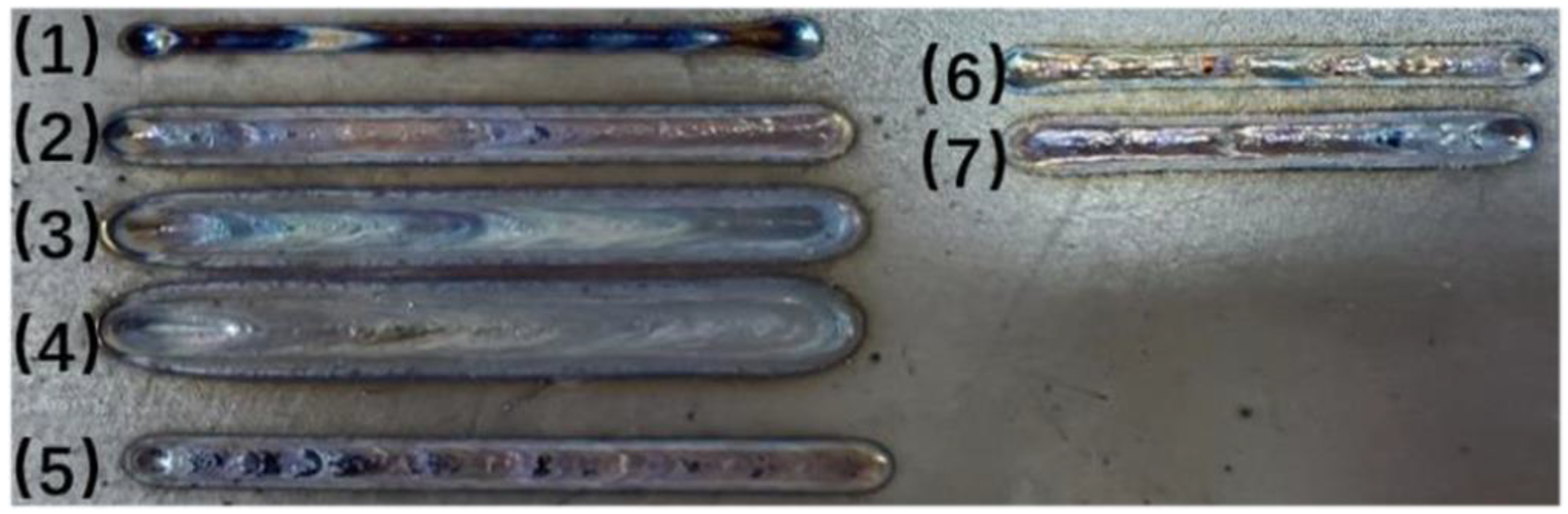

2. Materials and Methods

3. Results and Discussion

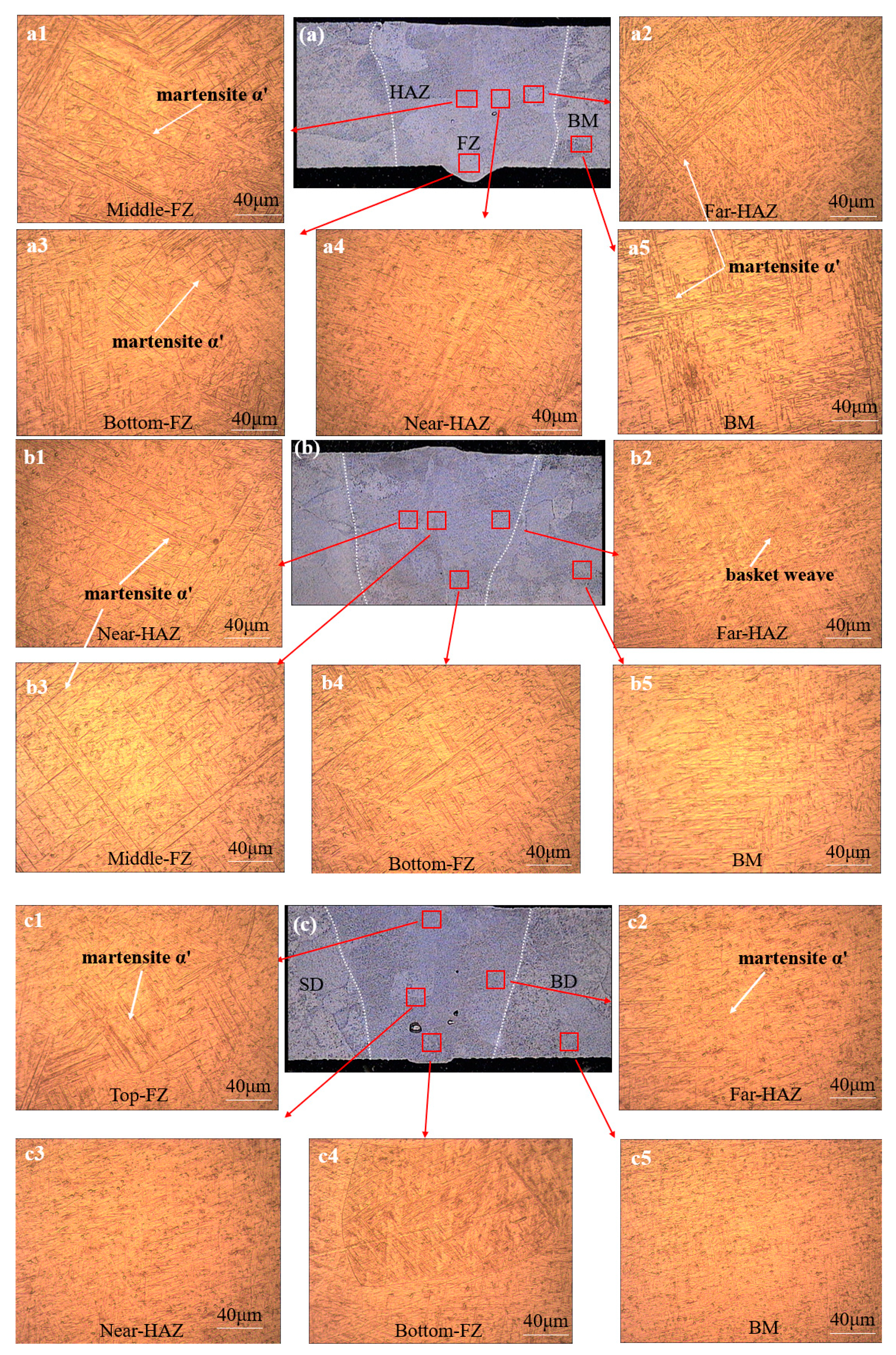

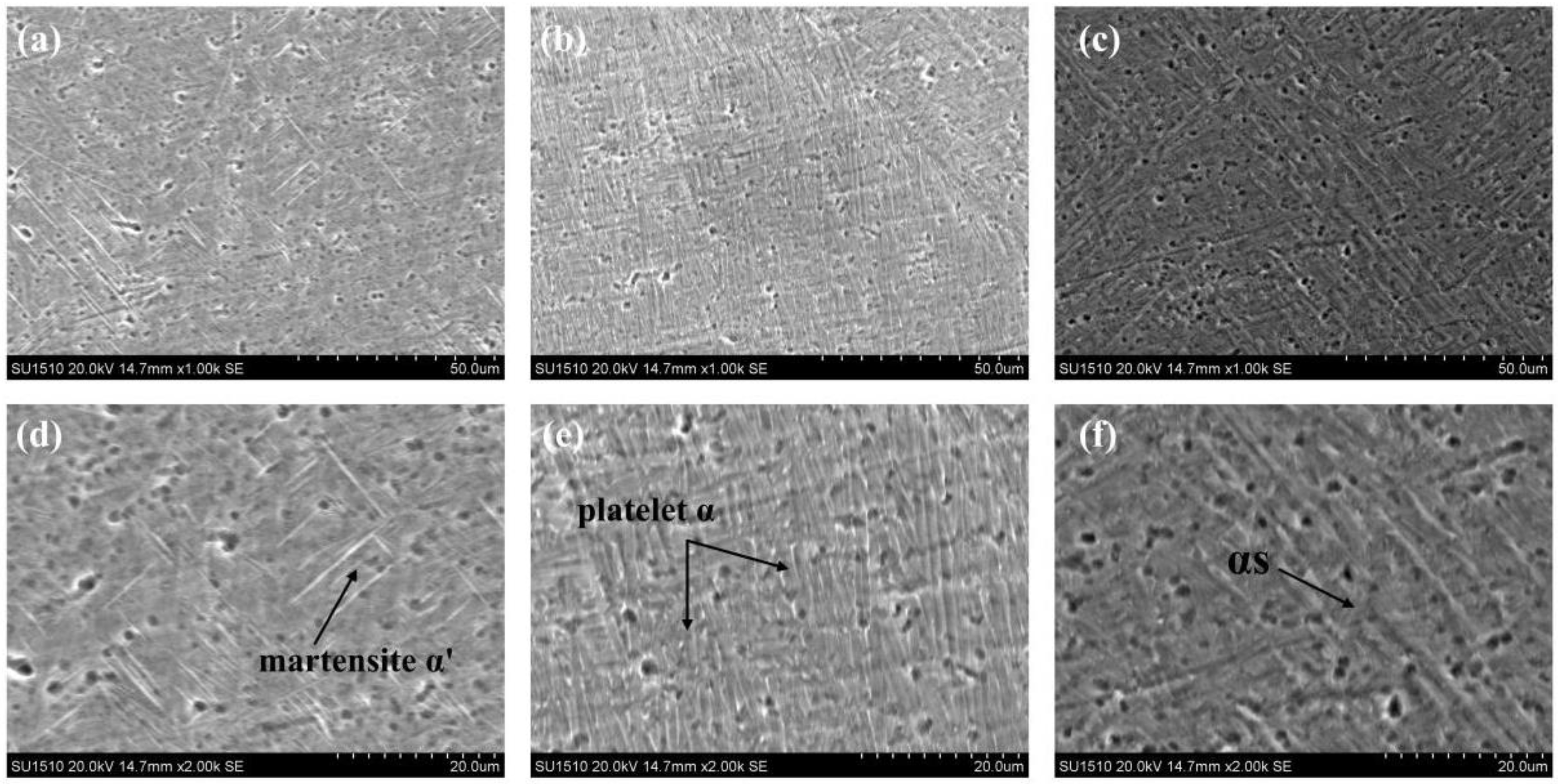

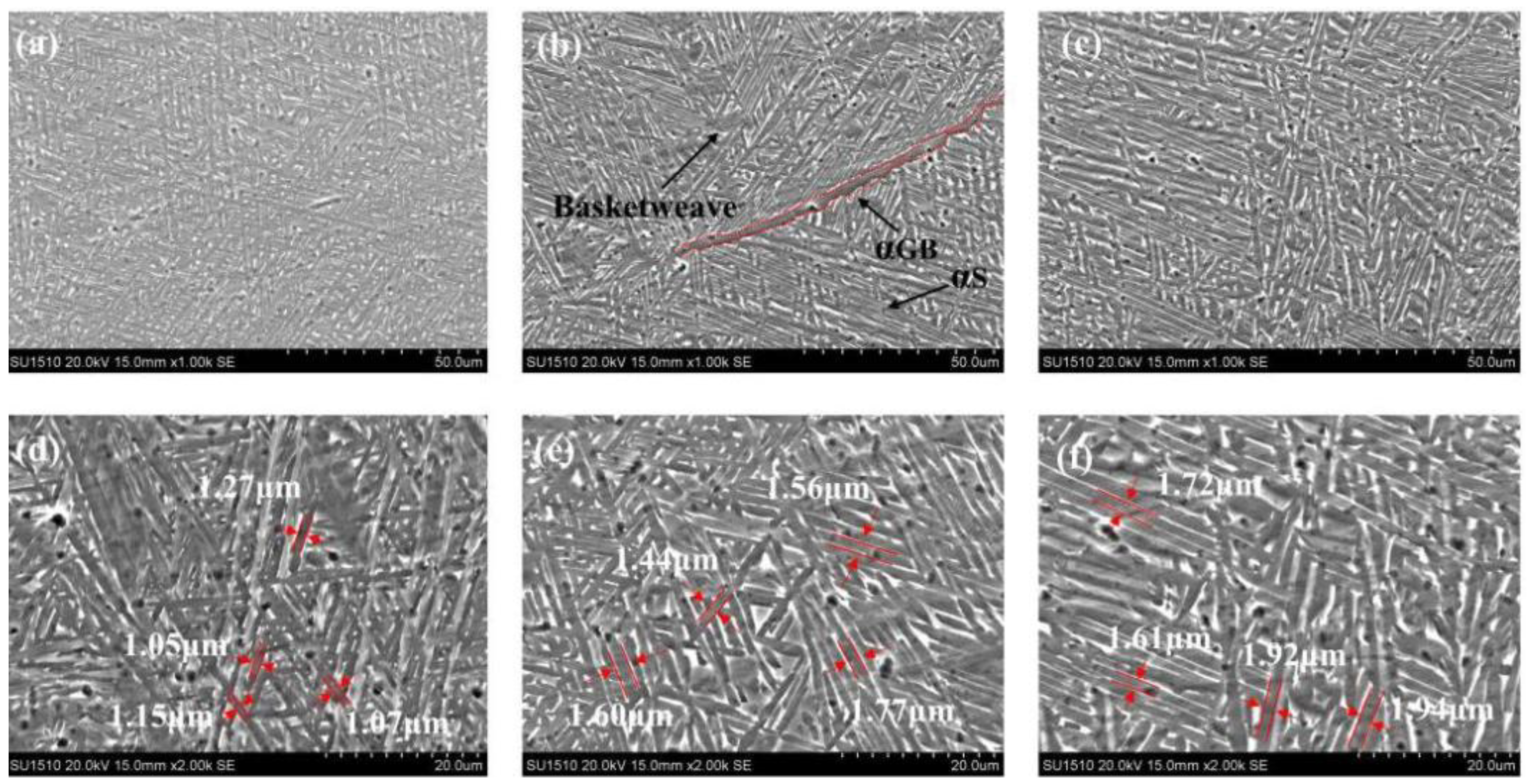

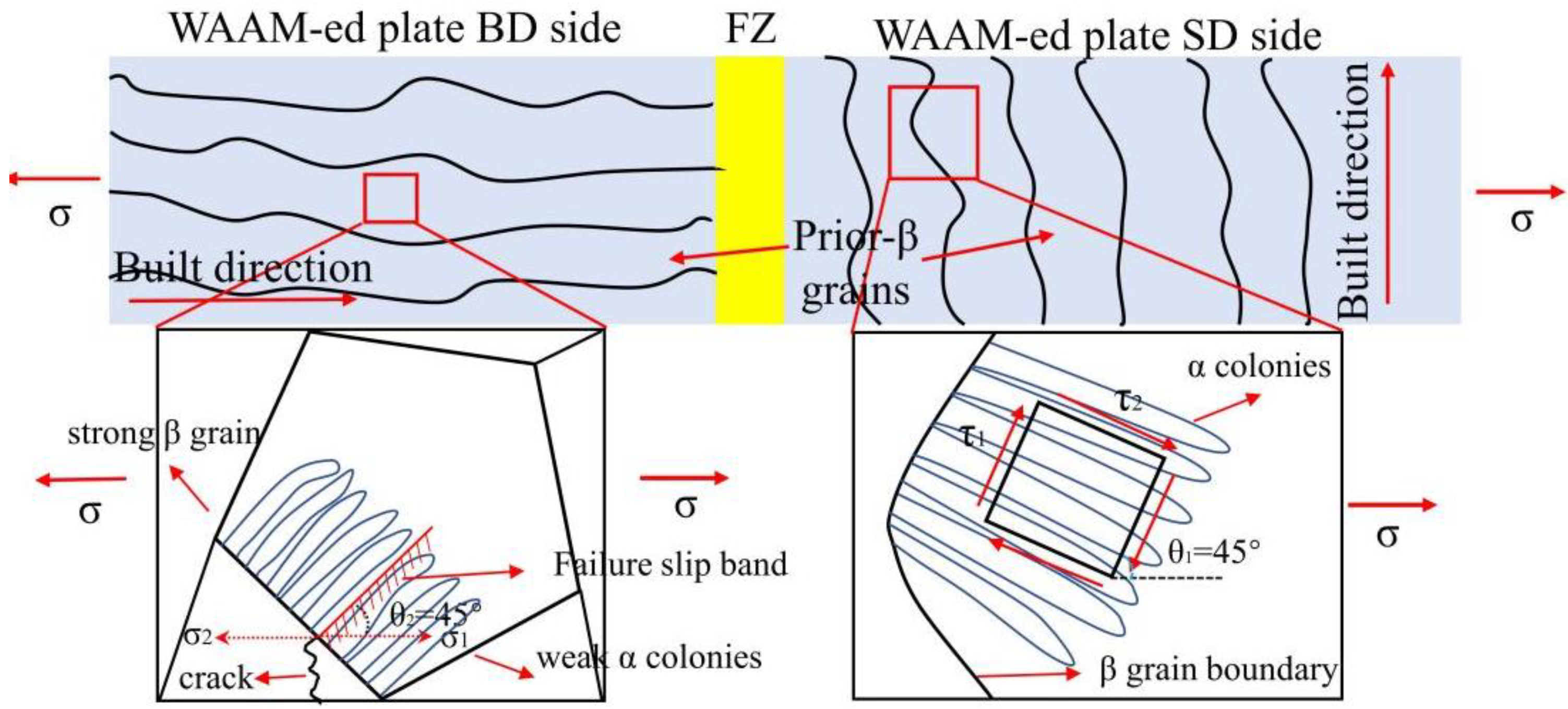

3.1. Micro and Macrostructure of Weld

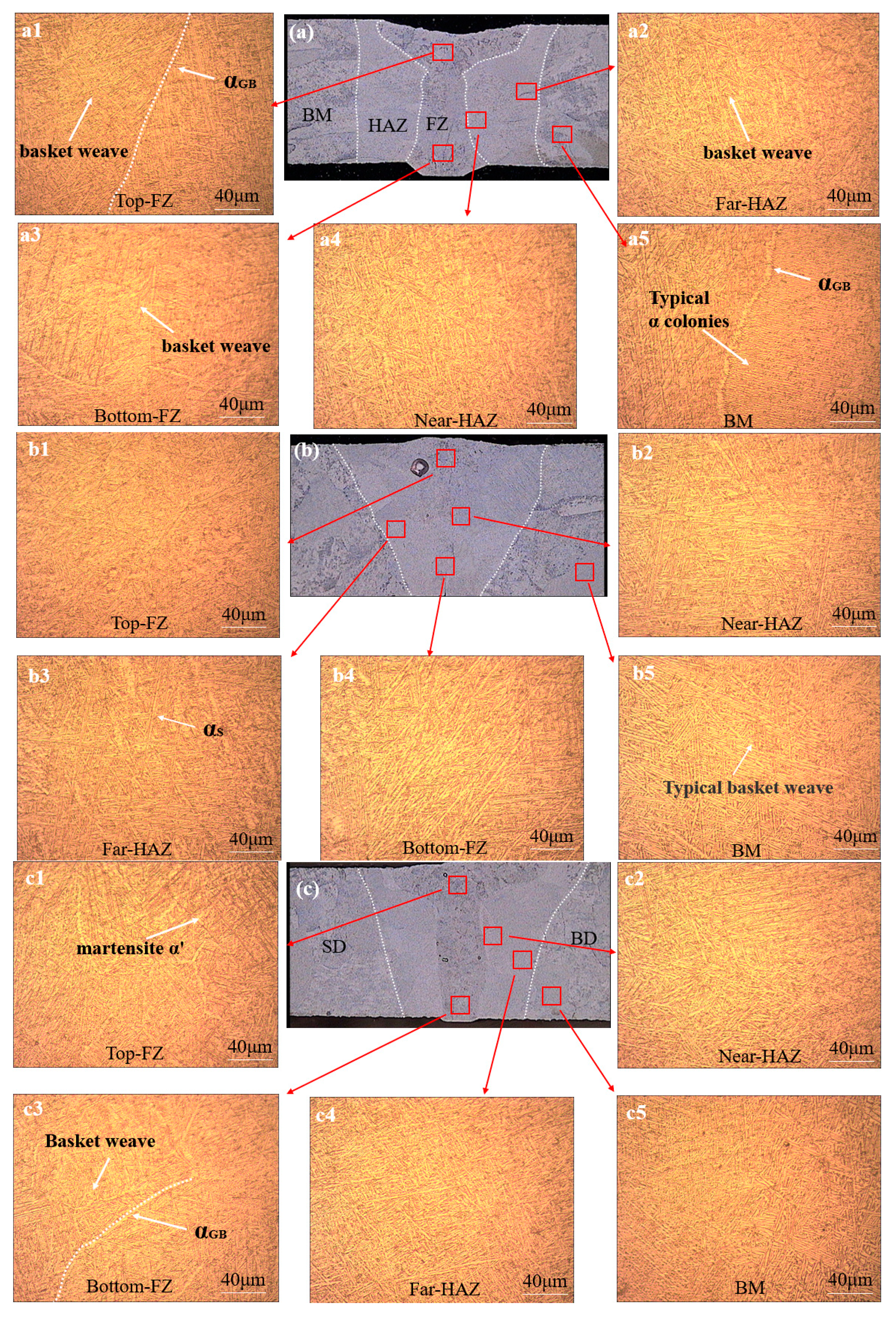

3.2. Post Welding Solution Treatment

3.3. Tensile Properties

3.4. Microhardness

4. Conclusions

- (1)

- Rapid cooling caused shear deformation of the β phase and formed a large number of acicular martensite α′. As the FZ depth increased, acicular α′ became finer and denser due to the increased cooling rate.

- (2)

- The post welding solution treatment promoted the decomposition of the metastable phase produced, and a large martensite α′ phase transformed into platelet α. The decreased martensite α′ content led to a slight decrease in tensile strength and microhardness, but elongation was significantly improved.

- (3)

- The welds of samples without solution treatment were filled with a large amount of martensite α′. Solution treatment made the structure uniform, and the outline of weld clear. FZ, HAZ, and BM were composed of platelet α with different aspect ratios, which all showed a typical basket-weave structure morphology.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, X.; Li, L.; Lei, Z.; Chen, Y. Study on welding characteristics of combining laser welding and resistance seam welding joined Ti-6Al-4V lap joints. Pac. Int. Conf. Appl. Lasers Opt. 2008, 2008, 341. [Google Scholar]

- Fomin, F.; Froend, M.; Ventzke, V.; Alvarez, P.; Bauer, S.; Kashaev, N. Correction to: Metallurgical aspects of joining commercially pure titanium to Ti-6Al-4V alloy in a T-joint configuration by laser beam welding. Int. J. Adv. Manuf. Technol. 2018, 97, 2019–2031. [Google Scholar] [CrossRef]

- Mcandrew, A.R.; Rosales, M.A.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of ti-6al-4v wire+arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Lei, R.; Xiao, W.; Ma, C.; Zheng, R.; Zhou, L. Development of a high strength and high ductility near β-ti alloy with twinning induced plasticity effect. Scr. Mater. 2018, 156, 47–50. [Google Scholar]

- Wang, W.; Huang, R.; Zhao, Y.; Liu, H.; Huang, C.; Yang, X.; Shan, Y.; Zhao, X.Q.; Li, L. Adjustable zero thermal expansion in Ti alloys at cryogenic temperature. J. Alloys Compd. 2018, 740, 47–51. [Google Scholar] [CrossRef]

- Tsai, T.J.; Wang, L.M. Improved mechanical properties of Ti–6Al–4V alloy by electron beam welding process plus annealing treatments and its microstructural evolution. Mater. Des. 2014, 60, 587–598. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; DLR: Dresden, Germany, 2003. [Google Scholar]

- Saresh, N.; Pillai, M.G.; Mathew, J. Investigations into the effects of electron beam welding on thick Ti–6Al–4V titanium alloy. J. Mater. Process. Technol. 2007, 192–193, 83–88. [Google Scholar] [CrossRef]

- Meshram, S.D.; Mohandas, T. A comparative evaluation of friction and electron beam welds of near-α titanium alloy. Mater. Des. 2010, 31, 2245–2252. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P.A. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.W.; Colegrove, P.A.; Antonysamy, A.A. Microstructure and Mechanical Properties of Wire and Arc Additive Manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.W.; Rush, M.T. Morphology investigation on direct current pulsed gas tungsten arc welded additive layer manufactured Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2011, 57, 597–603. [Google Scholar] [CrossRef]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–784. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Gulizia, S.; Fraser, D.; Oh, C.H.; Lu, S.L.; Qian, M. Layer Additive Production or Manufacturing of Thick Sections of Ti-6Al-4V by Selective Electron Beam Melting (SEBM). JOM 2017, 69, 1836–1843. [Google Scholar] [CrossRef]

- Albermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Wang, P.; Tan, X.; Nai, M.L.S.; Tor, S.B.; Wei, J. Spatial and geometrical-based characterization of microstructure and microhardness for an electron beam melted Ti–6Al–4V component. Mater. Des. 2016, 95, 287–295. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Wang, X. Progress and Challenges of Laser Direct Manufacturing of Large Titanium Structural Components (Invited Paper). Chin. J. Lasers 2009, 36, 3204–3209. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Wang, P.; Lu, S.L.; Li, L.Q.; Nai, M.L.S.; Wei, J. Laser welding of electron beam melted Ti-6Al-4V to wrought Ti-6Al-4V: Effect of welding angle on microstructure and mechanical properties. J. Alloys Compd. 2019, 782, 967–972. [Google Scholar] [CrossRef]

- Wang, P.; Nai, M.L.S.; Lu, S.; Bai, J.; Zhang, B.; Wei, J. Study of Direct Fabrication of a Ti-6Al-4V Impeller on a Wrought Ti-6Al-4V Plate by Electron Beam Melting. JOM 2017, 69, 2738–2744. [Google Scholar] [CrossRef]

- Chen, X.H.; Zhang, J.; Chen, X.; Cheng, X.; Huang, Z. Electron beam welding of laser additive manufacturing Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy thick plate. Vacuum 2018, 151, 116–121. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Stjohn, D.H.; Krynen, J.; Tedman, J.S.; Dargusch, M.S. Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing. Acta Mater. 2019, 168, 261–274. [Google Scholar] [CrossRef]

- Bu, H.; Gao, Q.; Li, Y.; Wang, F.Y.; Zhan, X.H. Comparative Study on Microstructure and Aluminum Distribution Between Laser Beam Welding and Electron Beam Welding of Ti–6Al–4V Alloy Plates. Met. Mater. Int. 2020, 26, 1–13. [Google Scholar] [CrossRef]

- Gioacchino, F.D.; Fonseca, J.A. An experimental study of the polycrystalline plasticity of austenitic stainless steel. Int. J. Plast. 2015, 74, 92–109. [Google Scholar] [CrossRef]

- Lu, W.; Shi, Y.; Lei, Y.; Li, X. Effect of electron beam welding on the microstructures and mechanical properties of thick TC4-DT alloy. Mater. Des. 2012, 34, 509–515. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Jones, P.; Pleydellpearce, C.; Rugg, D.; Williams, S. The effect of prestrain on low and high temperature creep in Ti834. Mater. Sci. Eng. A 2010, 527, 6683–6689. [Google Scholar] [CrossRef]

- Whittaker, M.T. Considerations in fatigue lifing of stress concentrations in textured titanium 6-4. Int. J. Fatigue 2011, 33, 1384–1391. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.; Cuiuri, D.; Dong, B.; Li, H. In-depth study of the mechanical properties for Fe3Al based iron aluminide fabricated using the wire-arc additive manufacturing process. Mater. Sci. Eng. A 2016, 669, 118–126. [Google Scholar] [CrossRef]

- Banumathy, S.; Mandal, R.K.; Singh, A.K. Texture and anisotropy of a hot rolled Ti-16Nb alloy. J. Alloys Compd. 2010, 500, 325–338. [Google Scholar] [CrossRef]

- Zeng, L.; Bieler, T.R. Effects of working, heat treatment, and aging on microstructural evolution and crystallographic texture of α, α′ α″ and β phases inTi-6Al-4V wire. Mater. Sci. Eng. A 2015, 392, 403–414. [Google Scholar] [CrossRef]

- Yu, H.C.; Li, F.Z.; Yang, J.J.; Shao, J.J.; Wang, Z.M.; Zeng, X.Y. Investigation on laser welding of selective laser melted Ti-6Al-4V parts: Weldability, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 712, 20–27. [Google Scholar] [CrossRef]

- Kumar, C.; Das, M.; Paul, C.P.; Singh, B. Experimental investigation and metallo-graphic characterization of fiber laser beam welding of Ti-6Al-4V alloy using re-sponse surface method. Opt. Lasers Eng. 2017, 95, 52–68. [Google Scholar] [CrossRef]

| Category | Al | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| Wire | 6.05 | 4.00 | 0.15 | 0.02 | 0.01 | 0.003 | 0.018 | Bal. |

| Substrate | 6.10 | 3.90 | 0.15 | 0.08 | 0.05 | 0.015 | 0.02 | Bal. |

| Group | Defocus Distance Δf/mm | Laser Power P/kW | Welding Speed V/(m/min) | Argon Shielded Q/(L/min) |

|---|---|---|---|---|

| 1 | 0 | 2.5 | 2 | 15 |

| 2 | 0 | 2 | 2 | 15 |

| 3 | 0 | 1.5 | 2 | 15 |

| 4 | 0 | 1 | 2 | 15 |

| 5 | 0 | 1 | 1.5 | 15 |

| 6 | 0 | 1 | 1 | 15 |

| 7 | 0 | 1.5 | 1 | 15 |

| Before Solution Treatment | Tensile Strength (MPA) | Elongation (%) | After Solution Treatment | Tensile Strength (MPA) | Elongation (%) |

|---|---|---|---|---|---|

| SD + SD | 970.2 ± 5 | 5.13 ± 0.82 | SD + SD | 948.9 ± 4 | 10.07 ± 0.77 |

| SD + BD | 966.8 ± 3 | 6.07 ± 0.75 | SD + BD | 924.8 ± 6 | 11.03 ± 2.62 |

| BD + BD | 933.6 ± 4 | 6.98 ± 0.83 | BD + BD | 911.6 ± 8 | 12.23 ± 1.22 |

| ASTM B381-13 | ≥895 | ≥10 | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Chen, Y.; Zhang, T.; Deng, H.; Ji, D. Effects of Solution Treatment on Laser Welding of Ti–6Al–4V Alloy Plate Produced through Wire Arc Additive Manufacturing. Metals 2020, 10, 1310. https://doi.org/10.3390/met10101310

Xu M, Chen Y, Zhang T, Deng H, Ji D. Effects of Solution Treatment on Laser Welding of Ti–6Al–4V Alloy Plate Produced through Wire Arc Additive Manufacturing. Metals. 2020; 10(10):1310. https://doi.org/10.3390/met10101310

Chicago/Turabian StyleXu, Mingfang, Yuhua Chen, Timing Zhang, Huaibo Deng, and Di Ji. 2020. "Effects of Solution Treatment on Laser Welding of Ti–6Al–4V Alloy Plate Produced through Wire Arc Additive Manufacturing" Metals 10, no. 10: 1310. https://doi.org/10.3390/met10101310

APA StyleXu, M., Chen, Y., Zhang, T., Deng, H., & Ji, D. (2020). Effects of Solution Treatment on Laser Welding of Ti–6Al–4V Alloy Plate Produced through Wire Arc Additive Manufacturing. Metals, 10(10), 1310. https://doi.org/10.3390/met10101310