The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel

Abstract

1. Introduction

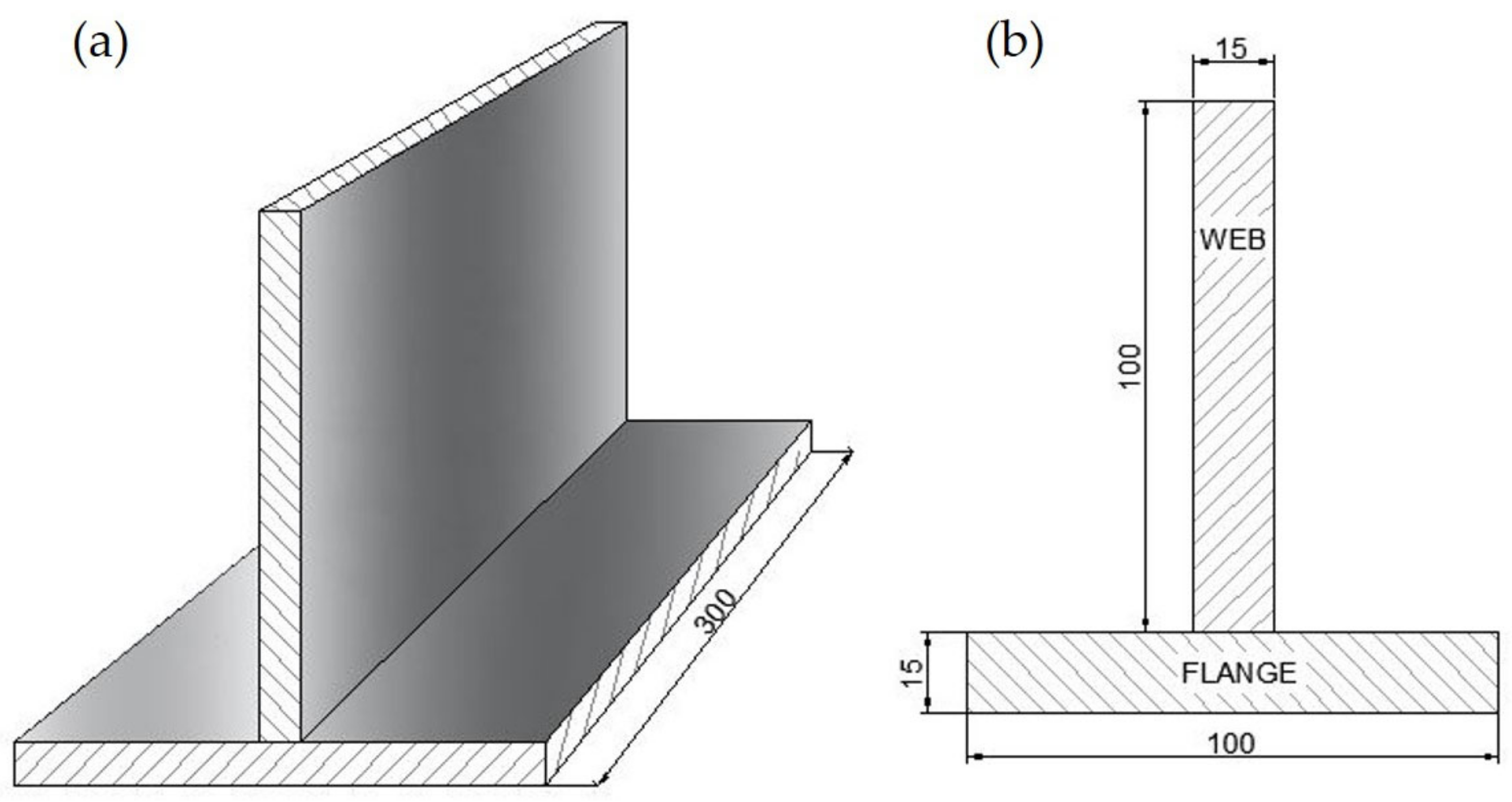

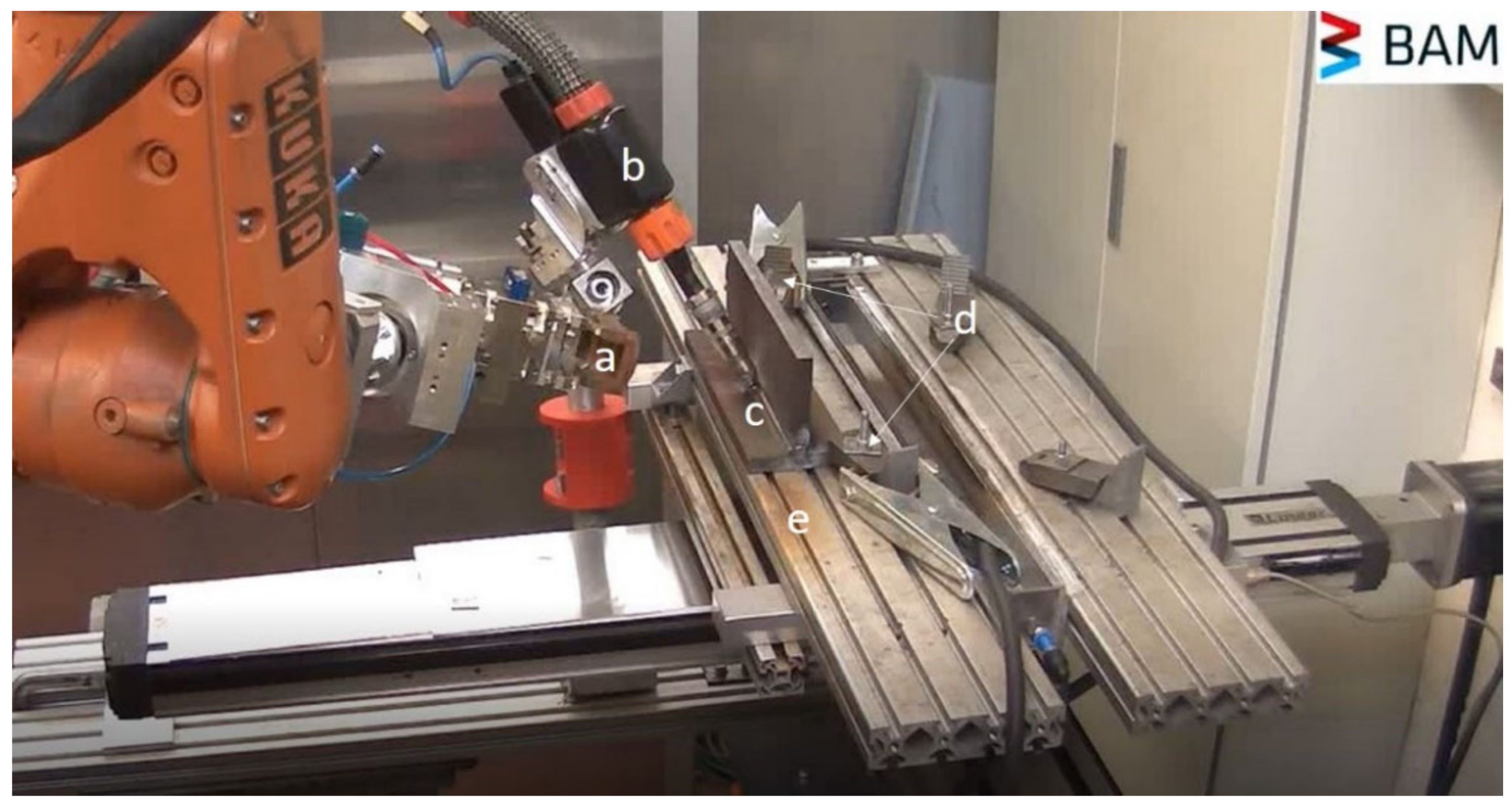

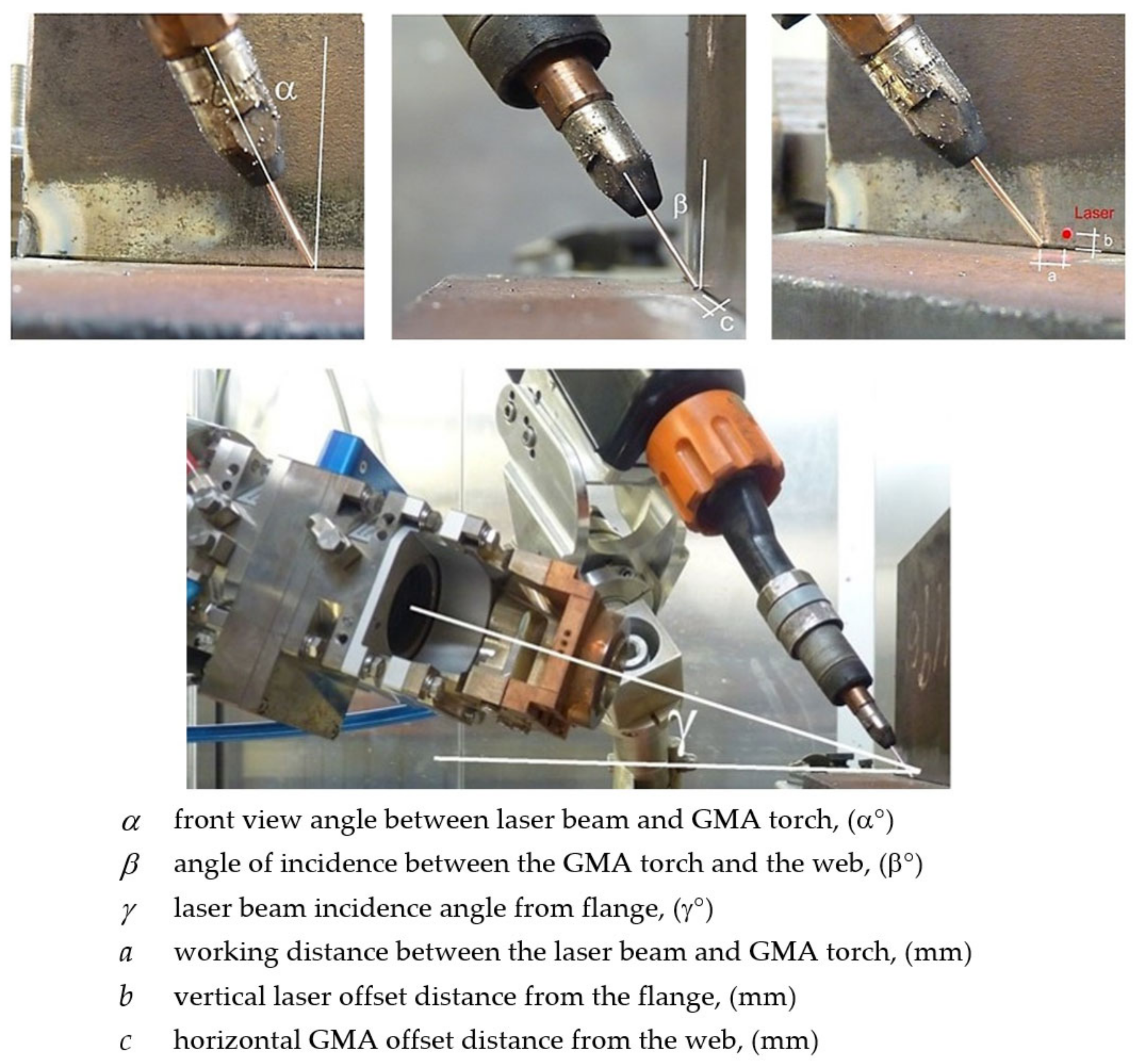

2. Materials and Methods

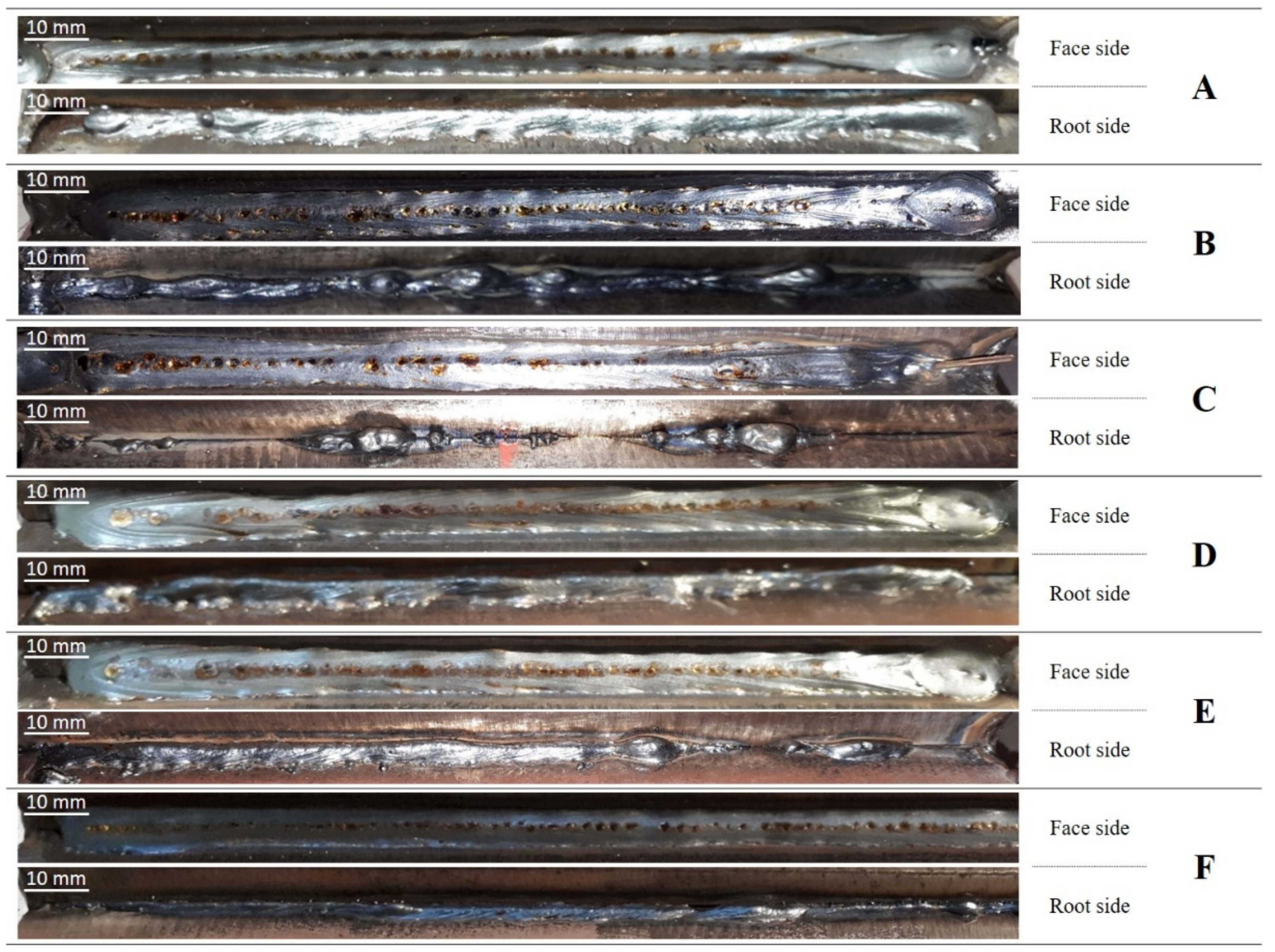

3. Results and Discussion

3.1. Effect of Process Parameters

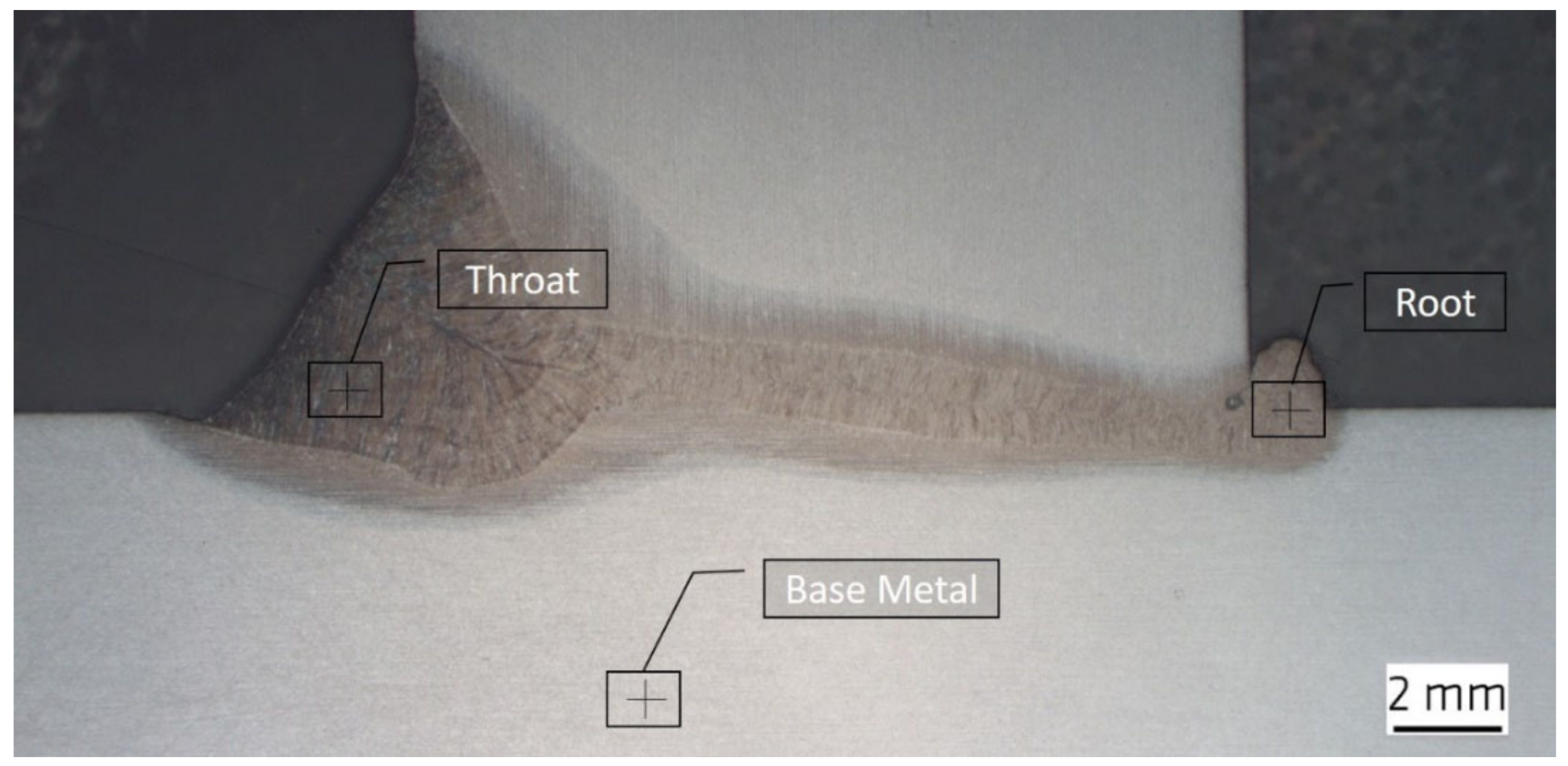

3.2. Quality Verification and Deep Analysis of Best Weld (F)

3.2.1. Evaluation of Imperfections

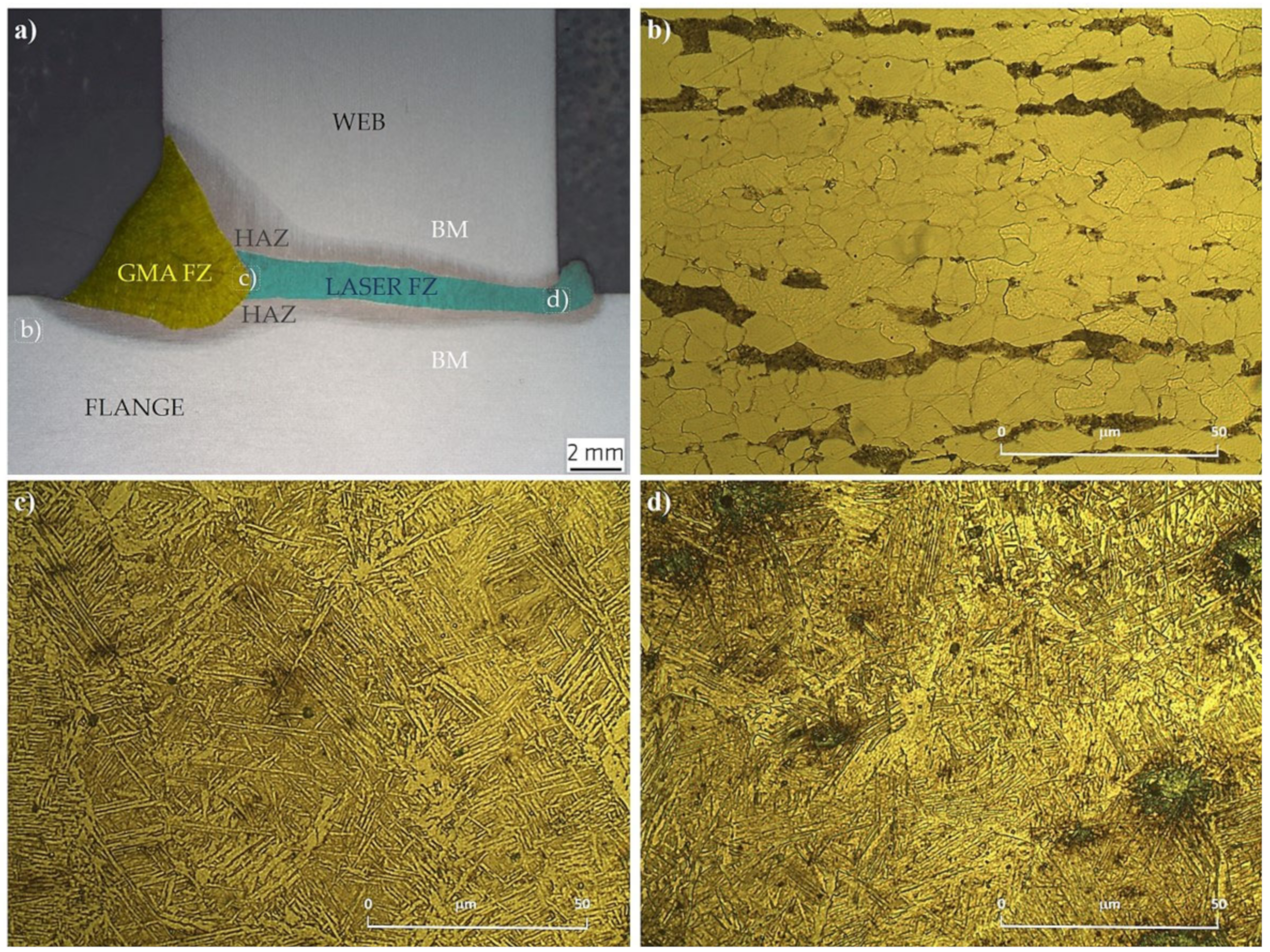

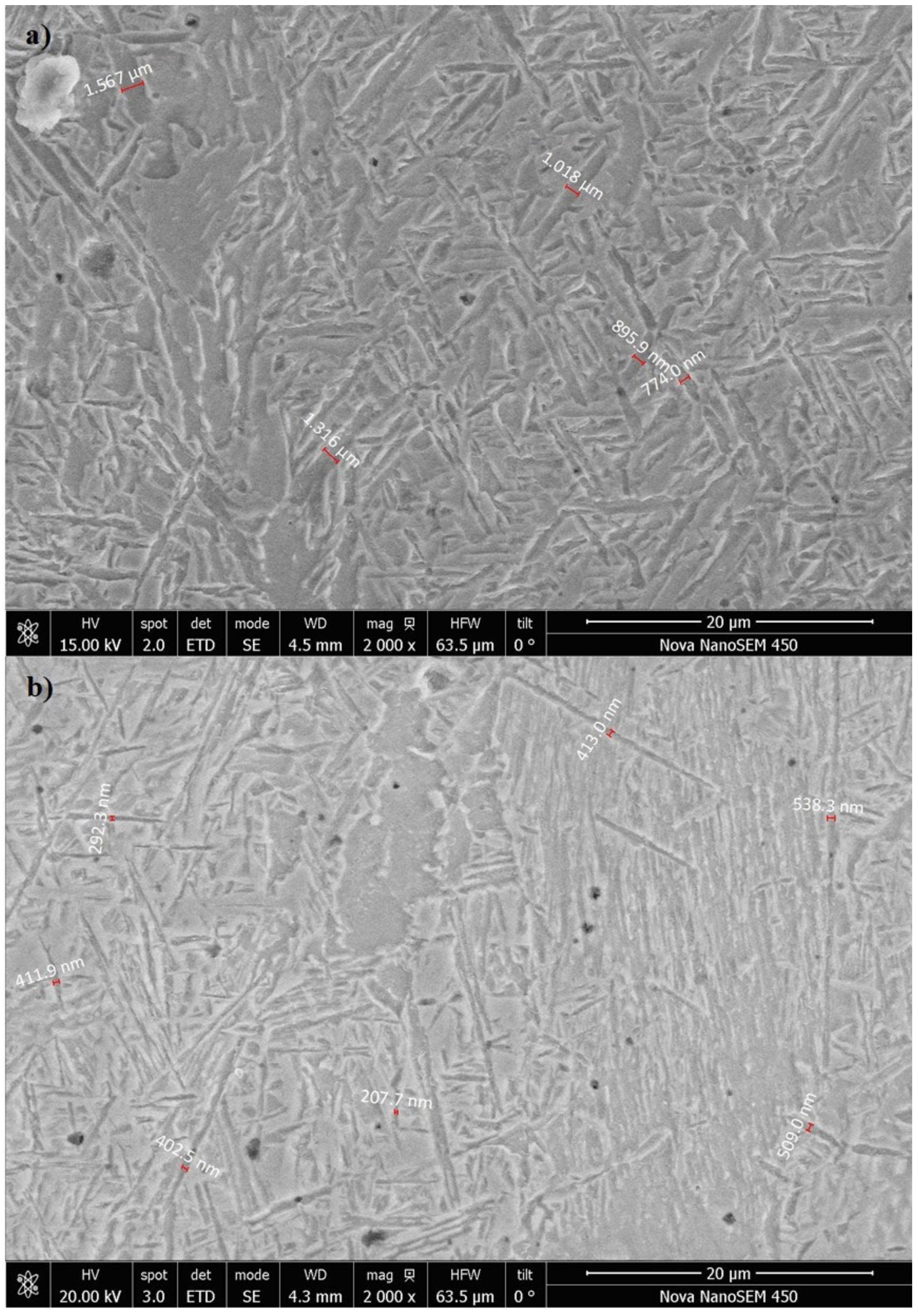

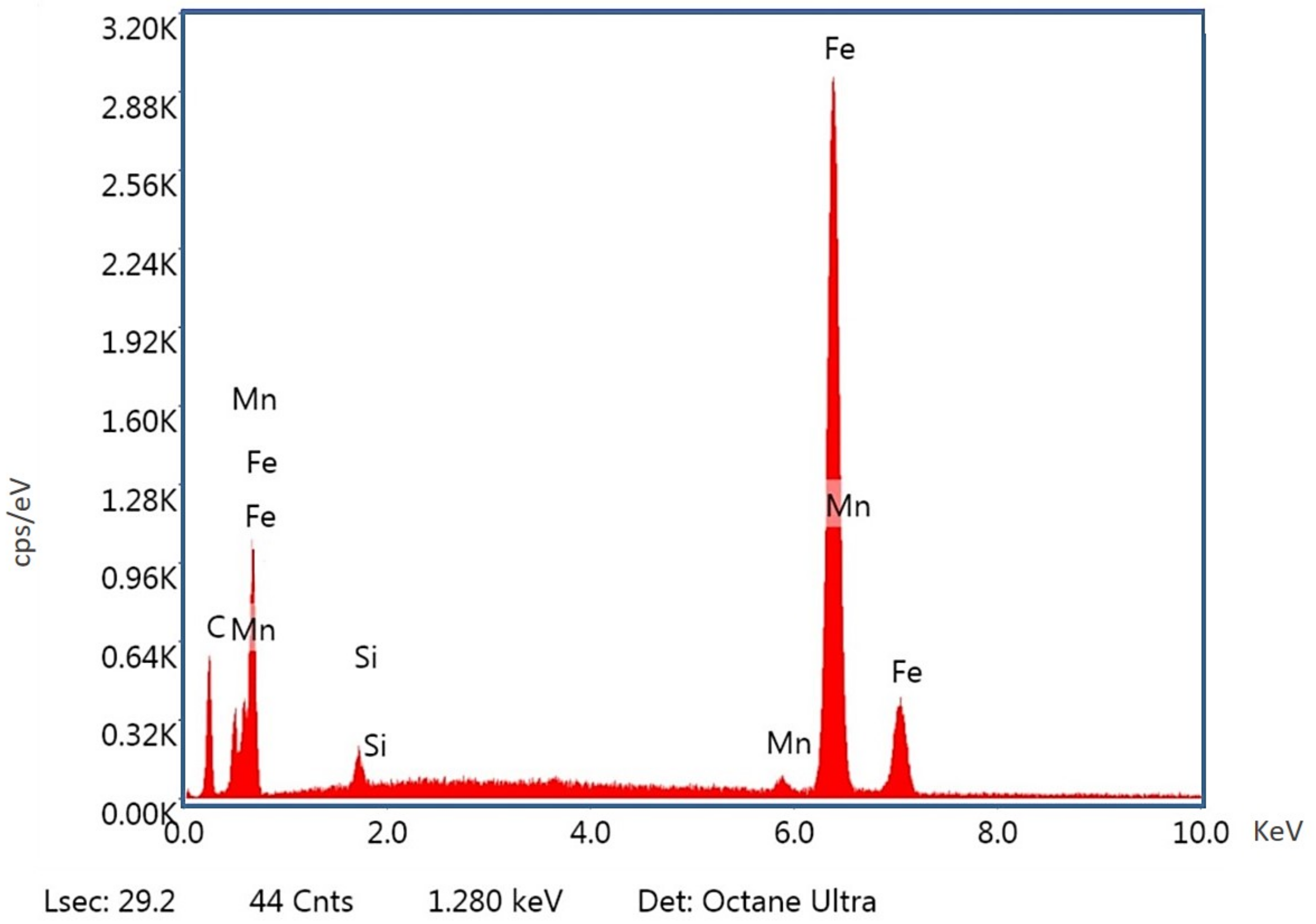

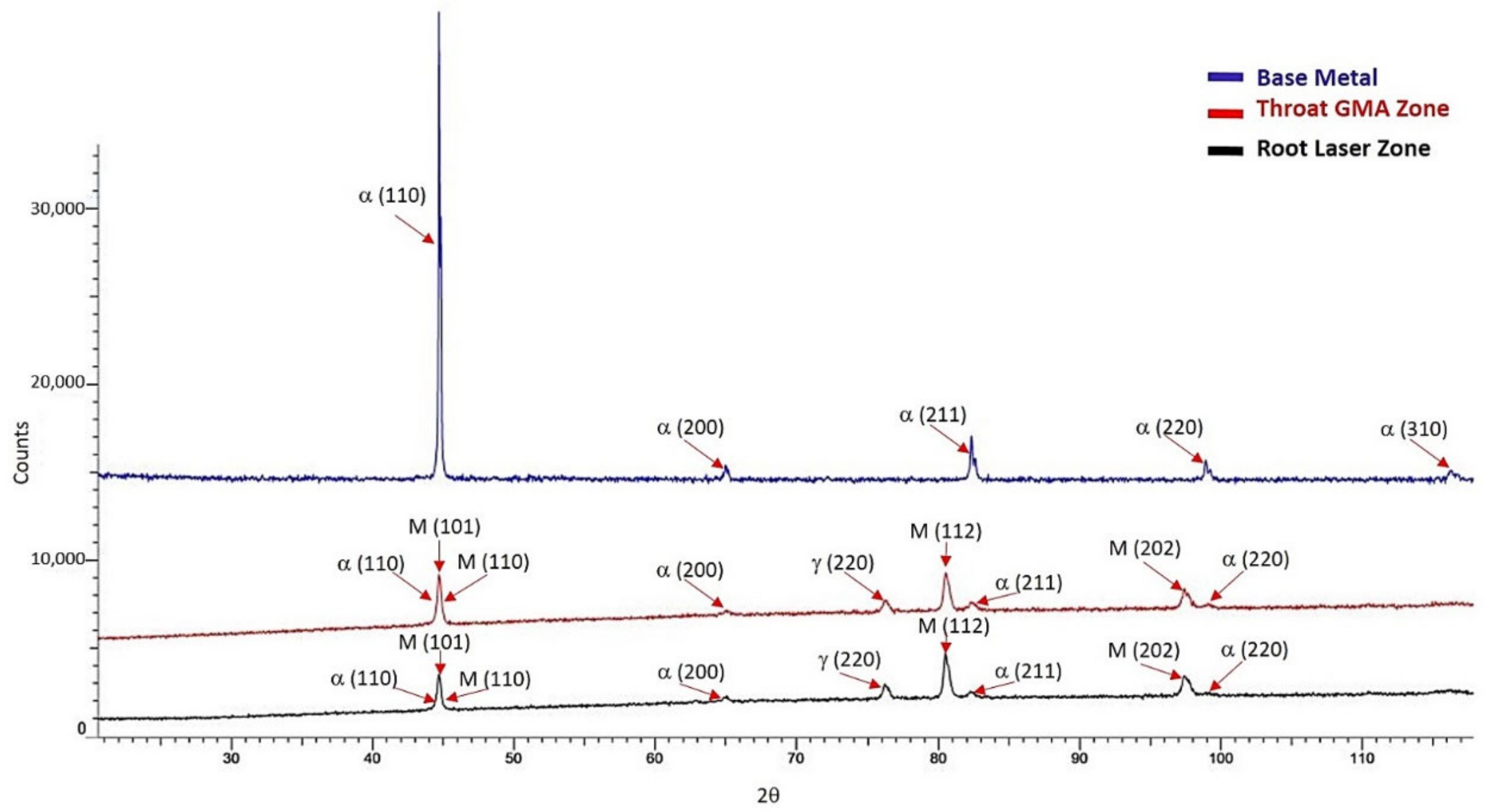

3.2.2. Microstructural Analysis at Fusion Zone

3.2.3. Hardness

4. Conclusions

5. Future Research

- -

- Application of this technology to weld panels of larger dimensions than those of the laboratory, including both semi-industrial (1–2 m long welds) and industrial scales (10–20 m long welds). The analyses of welding distortion and residual stresses of these industrial T-joints are of great interest.

- -

- Analyses of the fatigue behavior and resistance of the structure on a semi-industrial scale. These mechanical studies are missing at the reported literature. The lack of knowledge regarding fatigue behavior of HLAW joints is especially relevant.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Egerland, S.; Staufer, H.; Ruehrnoessl, M.; Schorn, M. Investigation of advanced laser-MAG tandem hybrid welding for joining gap-flawed thin sheet metal parts. Weld. World 2018, 62, 95–104. [Google Scholar] [CrossRef]

- Üstündaǧ, O.; Gook, S.; Gumenyuk, A.; Rethmeier, M. Mechanical properties of single-pass hybrid laser arc welded 25 mm thick-walled structures made of fine-grained structural steel. Procedia Manuf. 2019, 36, 112–120. [Google Scholar] [CrossRef]

- Ustündag, O.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Full penetration hybrid laser arc welding of up to 28 mm thick S355 plates using electromagnetic weld pool support. J. Phys. 2018, 1109, 12015. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetwov, M.; Tsibulskiy, I.; Firsova, A. Hybrid Laser-Arc Welding of the High-Strength Shipbuilding Steels: Equipment and Technology. Phys. Procedia 2017, 89, 156–163. [Google Scholar] [CrossRef]

- Churiaque, C.; Chludzinski, M.; Porrua-Lara, M.; Dominguez-Abecia, A.; Abad-Fraga, F.; Sánchez-Amaya, J.M. Laser Hybrid Butt Welding of Large Thickness Naval Steel. Metals 2019, 9, 100. [Google Scholar] [CrossRef]

- Churiaque, C.; Chludzinski, M.; Dos Santos, R.E.; Sánchez-Amaya, J.M.; Porrua-Lara, M.; Abad-Fraga, F. Laser hybrid welding in shipbuilding. In Proceedings of the RINA (Royal Institution of Naval Architects) International Conference Marine Design, Cádiz, Spain, 15–16 January 2020; pp. 65–73. [Google Scholar]

- Gao, M.; Zeng, X.Y.; Hu, Q.W. Effects of welding parameters on melting energy of CO2 laser-GMA hybrid welding. Sci. Technol. Weld. Join. 2006, 11, 517–522. [Google Scholar] [CrossRef]

- Üstündağ, Ö.; Gook, S.; Gumenyuk, A.; Rethmeier, M. Hybrid laser arc welding of thick high-strength pipeline steels of grade X120 with adapted heat input. J. Mater. Process. Technol. 2020, 275, 116358. [Google Scholar] [CrossRef]

- Cerwenka, G.; Steinmeier, O.; Petronis, E.; Keßler, T.; Fisher, H.W.A.; Fiedler, W.; Schulze, F.; Emmelmann, C. Development of a flexible low laser power hybrid (LLPH) technology for shipbuilding including additive manufactured semi-automated hand-held unit. Procedia CIRP 2018, 74, 770–774. [Google Scholar] [CrossRef]

- Yoo, W.-S.; Kim, J.-D.; Na, S.-J. Study of a mobile platform-manipulator welding system for horizontal fillet joints. Mechatronics 2001, 11, 853–868. [Google Scholar] [CrossRef]

- Udin, I.N.; Voropaev, A.A.; Unt, A. Application Development for the Evaluation of Penetration in Laser and Laser-Arc Hybrid Welding of Tee and Corner Joints. Key Eng. Mater. 2019, 822, 381–388. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Ma, N. Predicting welding deformation in thin plate panel structure by means of inherent strain and interface element. Sci. Technol. Weld. Join. 2012, 17, 13–21. [Google Scholar] [CrossRef]

- Hammad, A.; Churiaque, C.; Sánchez-Amaya, J.M.; Abdel-Nasser, Y. Experimental and numerical investigation of hybrid laser arc welding process and the influence of welding sequence on the manufacture of stiffened flat panels. J. Manuf. Process. 2021, 61, 527–538. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, H.; Ren, L.; Quan, G. An investigation on plasma-MIG hybrid welding of 5083 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 98, 1433–1440. [Google Scholar] [CrossRef]

- Böhm, M.; Kowalski, M. Fatigue life estimation of explosive cladded transition joints with the use of the spectral method for the case of a random sea state. Mar. Struct. 2020, 71, 102739. [Google Scholar] [CrossRef]

- Ragu Nathan, S.; Balasubramanian, V.; Malarvizhi, S.; Rao, A.G. Effect of welding processes on mechanical and microstructural characteristics of high strength low alloy naval grade steel joints. Def. Technol. 2015, 11, 308–317. [Google Scholar] [CrossRef]

- Mazar Atabaki, J.; Ma, W.; Kovacevic, L.R. Hybrid laser/arc welding of advanced high strength steel to aluminum alloy by using structural transition insert. Mat. Des. 2015, 75, 120–135. [Google Scholar] [CrossRef]

- Kowalski, M. Identification of fatigue and mechanical characteristics of explosively welded steel—Titanium composite. Frattura ed Integrità Strutturale 2017, 11, 85–92. [Google Scholar] [CrossRef]

- Erny, C.; Thevenet, D.; Cognard, J.-Y.; Korner, M. Fatigue life prediction of welded ship details. Mar. Struct. 2012, 251, 13–32. [Google Scholar] [CrossRef]

- Xing, S.; Dong, P.; Threstha, A. Analysis of fatigue failure mode transition in load-carrying fillet-welded connections. Mar. Struct. 2016, 46, 102–126. [Google Scholar] [CrossRef]

- Üstündaǧ, O.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Improvement of Filler Wire Dilution Using External Oscillating Magnetic Field at Full Penetration Hybrid Laser-Arc Welding of Thick Materials. Metals 2019, 9, 594. [Google Scholar] [CrossRef]

- Mazar Atabaki, M.; Yazdian, N.; Kovacevic, R. Hybrid laser/arc welding of thick high-strength steel in different configurations. Adv. Manuf. 2018, 6, 176–188. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Yang, G.; Kovacevic, R. Hybrid laser-arc welding of advanced high-strength steel. J. Mater. Process. Technol. 2014, 214, 2823–2833. [Google Scholar] [CrossRef]

- Unt, A.; Lappalainen, E.; Salminen, A. Autogeneous laser and hybrid laser arc welding of T-joint low alloy steel with fiber laser systems. Phys. Procedia 2013, 41, 140–143. [Google Scholar] [CrossRef][Green Version]

- Tsibulskiy, I.A.; Akhmetov, A.D.; Korsmik, R.S.; Voropaev, A.A.; Mendagaliyev, R.V.; Eremeev, A.D. The influence of the gap size on the formation of a welded joint in hybrid laser-arc welding of angular joints and T-joints. J. Phys. Conf. Ser. 2018, 1109, 12033. [Google Scholar] [CrossRef]

- Bunaziv, I.; Dørum, C.; Ren, X.; Eriksson, M.; Akselsen, O.M. Application of LBW and LAHW for fillet welds of 12 and 15 mm structural steel. Procedia Manuf. 2019, 36, 121–130. [Google Scholar] [CrossRef]

- Olschok, S. Laserstrahl-Lichtbogen Hybridschweißen von Stahl im Dickblechbereich; Shaker Verlag: Aachen, Germany, 2008. [Google Scholar]

- UNE-EN ISO 15614-14. Specification and Qualification of Welding Procedures for Metallic Materials—Welding Procedure Test—Part 14: Laser-Arc Hybrid Welding of Steels, Nickel and Nickel Alloys; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- BV NR 216 DT R07 E. BV Rules on Materials and Welding for the Classification of Marine Units; Bureau Veritas: Paris, France, 2018; Volume 33. [Google Scholar]

- Lloyd’s Register Group. Rules for the Manufacture, Testing and Certification of Materials; Lloyd’s Register: London, UK, 2017. [Google Scholar]

- DNVGL-CG-0287. Hybrid Laser-Arc Welding; DNVGL: Oslo, Norway, 2015. [Google Scholar]

- UNE-EN ISO 17637. Non-Destructive Testing of Welds—Visual Testing of Fusion-Welded Joints; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- UNE-EN ISO 12932. Welding—Laser-Arc Hybrid Welding of Steels, Nickel and Nickel Alloys—Quality Levels for Imperfections; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- UNE-EN ISO 5817. Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- UNE EN ISO 13919-1. Electron and Laser-Beam Welded Joints—Requirements and Recommendations on Quality Levels for Imperfections—Part 1: Steel, Nickel, Titanium and Their Alloys; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- UNE-EN ISO 17639. Destructive Tests on Welds in Metallic Materials—Macroscopic and Microscopic Examination of Welds; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- UNE-EN ISO 17638. Non-Destructive Testing of Welds—Magnetic Particle Testing; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- UNE-EN ISO 3452-1. Non-Destructive Testing—Penetrant Testing—Part 1: General Principles; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- UNE-EN ISO 17636-2. Non-Destructive Testing of Welds—Radiographic Testing—Part 2: X- and γ-Ray Techniques with Digital Detectors; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- UNE EN ISO 17640. Non-Destructive Testing of Welds—Ultrasonic Testing—Techniques, Testing Levels, and Assessment; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- UNE-EN ISO 9015-1. Destructive Tests on Welds in Metallic Materials—Hardness Testing—Part 1: Hardness Test on Arc Welded Joints; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- UNE-EN ISO 6947. Welding and Allied Processes—Welding Positions; ISO: Geneva, Switzerland, 2020. [Google Scholar]

- AWS A3.0M /A3.0. Standard Welding Terms and Definitions; American Welding Society: Miami, FL, USA, 2020. [Google Scholar]

- Tang, G.; Zhao, X.; Li, R.; Liang, Y.; Jiang, Y.; Chen, H. The effect of arc position on laser-arc hybrid welding of 12-mm-thick high strength bainitic steel. Optics Laser Technol. 2020, 121, 105780. [Google Scholar] [CrossRef]

- Üstündağ, Ö.; Bakir, N.; Gumenyuk, A.; Rethmeier, M. Influence of oscillating magnetic field on the keyhole stability in deep penetration laser beam welding. Optics Laser Technol. 2021, 135, 106715. [Google Scholar] [CrossRef]

- McPherson, N.A.; Suarez-Fernandez, N.; Moon, D.W.; Tan, C.P.H.; Lee, C.K.; Baker, T.N. Laser and laser assisted arc welding processes for DH 36 microalloyed steel ship plate. Sci. Technol. Weld. Join. 2005, 10, 460–467. [Google Scholar] [CrossRef]

- Thewlis, G. Materials perspective: Classification and quantification of microstructures in steels. Mater. Sci. Technol. 2004, 20, 143–160. [Google Scholar] [CrossRef]

- Cao, X.; Wanjara, P.; Huang, J.; Munro, C.; Nolting, A. Hybrid fiber laser—Arc welding of thick section high strength low alloy steel. Mater. Des. 2011, 32, 3399–3413. [Google Scholar] [CrossRef]

- Gosavi, P.D.; Sarkar, K.K.; Khunte, S.K.; Pawar, V.R.; Basu, B. Microstructure and mechanical properties correlation of the weld joints of a high strength naval grade steel. Struct. Integr. Procedia 2019, 14, 304–313. [Google Scholar] [CrossRef]

- Wang, X.-N.; Zhang, S.-H.; Zhou, J.; Zhang, M.; Chen, C.-J.; Misra, R.D.K. Effect of heat input on microstructure and properties of hybrid fiber laser- arc weld joints of the 800 MPa hot-rolled Nb-Ti-Mo microalloyed steels. Optics Lasers Eng. 2017, 91, 86–96. [Google Scholar] [CrossRef]

- Krauss, G. STEELS: Processing, Structure, and Performance; ASM International: Novelty, OH, USA, 2005. [Google Scholar]

- Campbell, F.C. Elements of Metallurgy and Engineering Alloys; Chapter 10; ASM International: Novelty, OH, USA, 2008; pp. 153–176. [Google Scholar]

- Cao, F.; Zhang, Y.; Shen, Y.; Jinb, Y.; Lia, J.; Hou, W. Effects of beam offset on the macro defects, microstructure and mechanical behaviors in dissimilar laser beam welds of SDSS2507 and Q235. J. Manuf. Process. 2020, 55, 335–347. [Google Scholar] [CrossRef]

- Zhang, X.; Mi, G.; Wang, C. Microstructure and performance of hybrid laser-arc welded high-strength low alloy steel and austenitic stainless steel dissimilar joint. Optics Laser Technol. 2020, 122, 105878. [Google Scholar] [CrossRef]

| STANDARD/TEST | ISO 15614-14 [28] | Bureau Veritas [29] | Lloyd’s Register [30] | Det Norske Veritas Germanischer Lloyd [31] | |

|---|---|---|---|---|---|

| BV NR 216 DT R07 E | Rules Manufacture Testing and Materials Certification | DNVGL-CG-0287 | |||

| Ch.5 Section 4 | Ch. 5 Section 5 | ||||

| Visual | ISO 17637 [32] ISO 12932 [33] | ISO 5817 [34] | ISO 13919-1 [35] | ISO 5817 [34] | ISO 5817 [34] |

| Macro | ISO 17639 [36] ISO 12932 [33] | 1 cross-section | 3 cross-sections | Required | |

| NDT Surface crack detection | MP: ISO 17638 [37] or PL: ISO 3452-1 [38] | PL or MP | - | PL or MP ISO 5817 [34] | |

| NDT Internal discontinuities | X-ray: ISO 17636-2 [39] or UT: ISO 17640 [40] | UT | MP and UT ISO 13919-1 [35] | X-ray or UT | |

| Hardness | ISO 9015 -1 [41] Max. 380 HV | Max. 350 HV | Max. 350 HV | Max. 350 HV | Required |

| Fracture test | - | ISO 5817 [19] | ISO 13919-1 [35] | - | For new welding processes |

| NDT: Non-destructive Tests MP: Magnetic Particles Test PL: Penetrating Liquids Test | X-ray: X-ray Test UT: Ultrasonic Test HV: Hardness Vickers | ||||

| Alloy | C | Si | Mn | Ni | Cr | Cu | Al | P | Mo | S | N | Nb | V | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EH36-TM | 0.110 | 0.210 | 1.210 | 0.010 | 0.030 | 0.010 | 0.033 | 0.017 | 0.001 | 0.005 | 0.005 | 0.003 | 0.071 | 0.017 | Bal. |

| ER70 S-6 | 0.070 | 0.875 | 1.540 | 0.048 | 0.036 | 0.120 | 0.008 | 0.009 | - | - | - | - | - | - | Bal. |

| Material | Charpy 20 °C (J) | Yield Strength (Mpa) | Ultimate Tensile Strength (Mpa) | Elongation (%) |

|---|---|---|---|---|

| EH36-TM | 147 | 503 | 555 | 22 |

| ER70 S-6 | 90–100 | 420–460 | 520–560 | 24–27 |

| Weld Code | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Laser power for welding (kW) | 14.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| Welding speed (m/min) | 1.5 | 1.5 | 1.5 | 1.5 | 1.6 | 1.6 |

| Offset laser, b (mm) | 1 | 1 | 0.7 | 1.3 | 1.3 | 1 |

| Heat input (J/mm) | 909.68 | 851.64 | 864.21 | 856.95 | 811.95 | 805.28 |

| Zone | Sn | Si | P | Mn | Ti | Cr | Cu | Al | S | V | Fe | K | Ca | Mo | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GMA FZ (Throat) | 0.027 | 0.294 | 0.062 | 1.424 | 0.013 | 0.025 | 0.016 | 0.224 | 0.000 | 0.066 | 97.797 | 0.027 | 0.019 | 0.002 | 0.004 |

| Laser FZ (Root) | 0.018 | 0.150 | 0.081 | 1.306 | 0.017 | 0.031 | 0.004 | 0.304 | 0.009 | 0.099 | 97.981 | ||||

| BM | 0.017 | 0.143 | 0.096 | 1.378 | 0.016 | 0.035 | 0.007 | 0.298 | 0.000 | 0.085 | 97.926 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Churiaque, C.; Sánchez-Amaya, J.M.; Porrúa-Lara, M.; Gumenyuk, A.; Rethmeier, M. The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel. Metals 2021, 11, 600. https://doi.org/10.3390/met11040600

Churiaque C, Sánchez-Amaya JM, Porrúa-Lara M, Gumenyuk A, Rethmeier M. The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel. Metals. 2021; 11(4):600. https://doi.org/10.3390/met11040600

Chicago/Turabian StyleChuriaque, Cristina, Jose Maria Sánchez-Amaya, Manuel Porrúa-Lara, Andrey Gumenyuk, and Michael Rethmeier. 2021. "The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel" Metals 11, no. 4: 600. https://doi.org/10.3390/met11040600

APA StyleChuriaque, C., Sánchez-Amaya, J. M., Porrúa-Lara, M., Gumenyuk, A., & Rethmeier, M. (2021). The Effects of HLAW Parameters for One Side T-Joints in 15 mm Thickness Naval Steel. Metals, 11(4), 600. https://doi.org/10.3390/met11040600