Research of Tribological Properties of 34CrNiMo6 Steel in the Production of a Newly Designed Self-Equalizing Thrust Bearing

Abstract

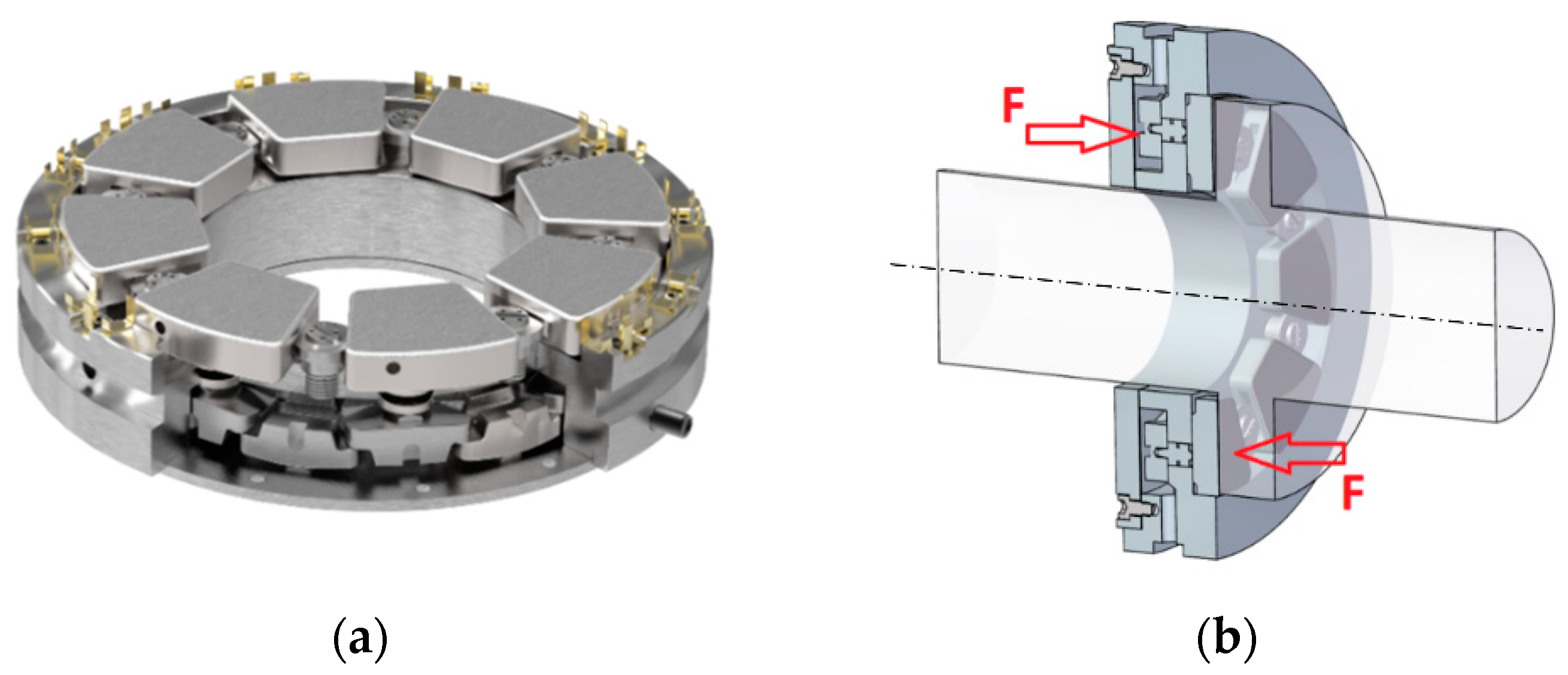

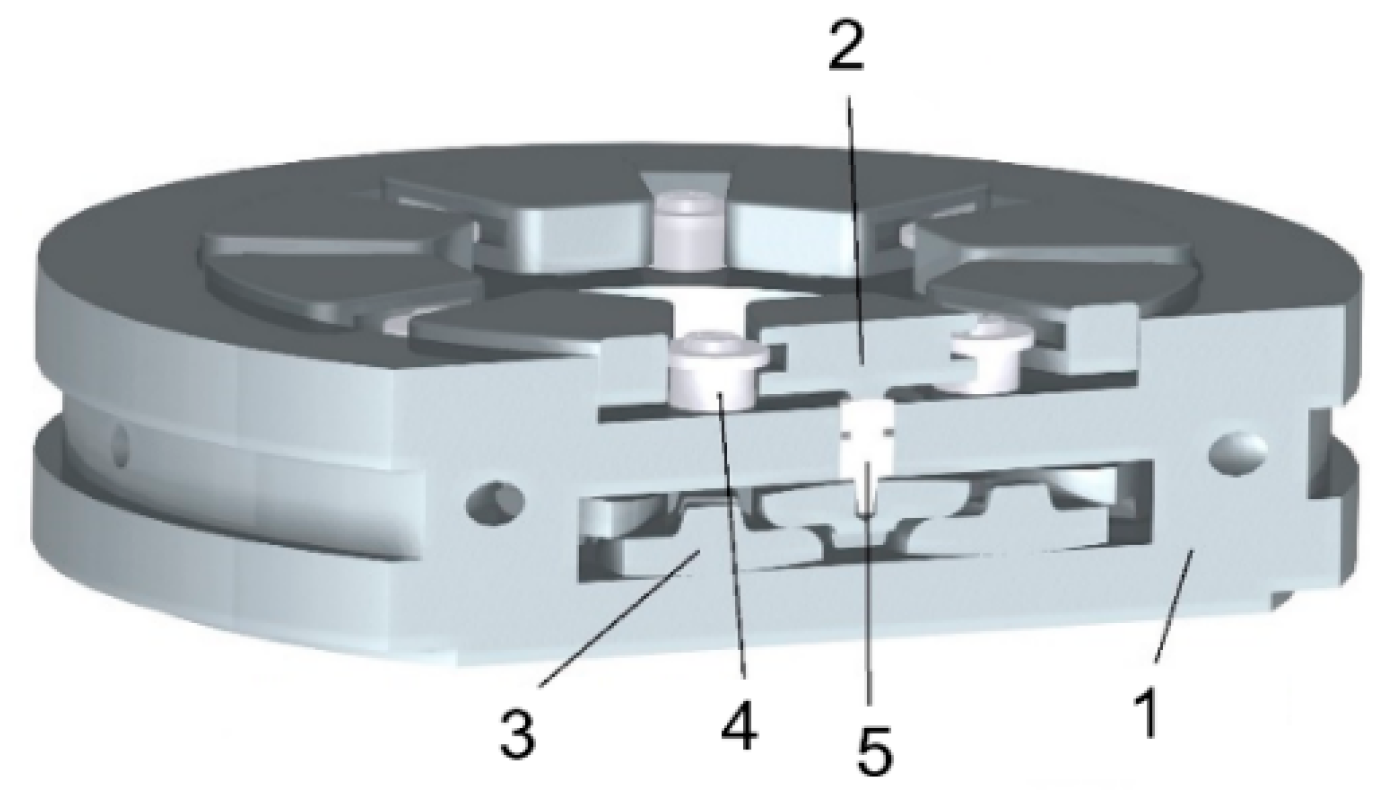

1. Introduction

2. State of the Art

3. Experimental Samples Design

3.1. Geometry of Samples

3.2. Material of Samples

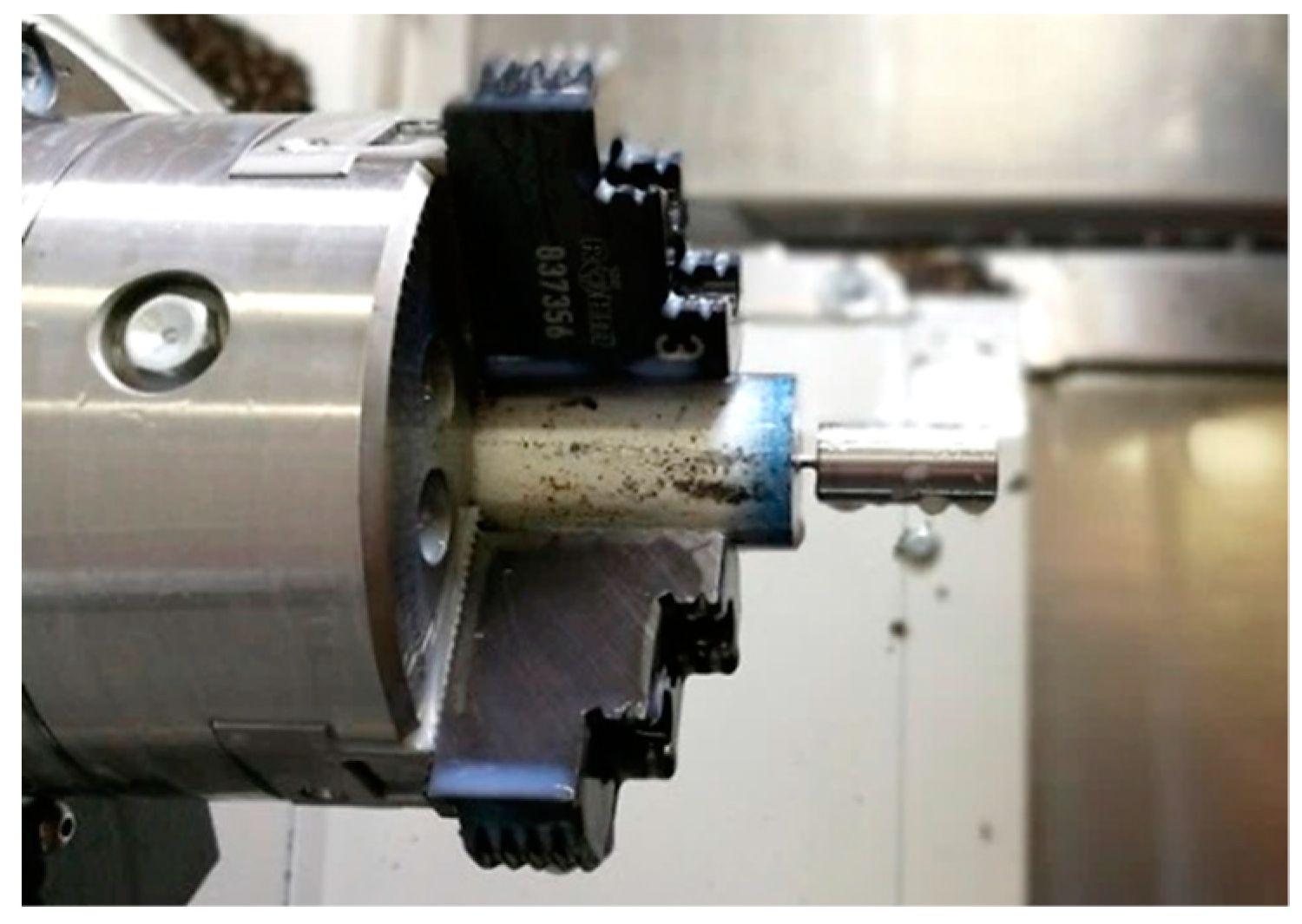

3.3. Technological Conditions of Samples Production

- cutting speed: vc = 120 m·min−1;

- cutting depth: ap = 0.5 mm;

- Coolant: Blasocut BC35 Kombi −5% + 95% water;

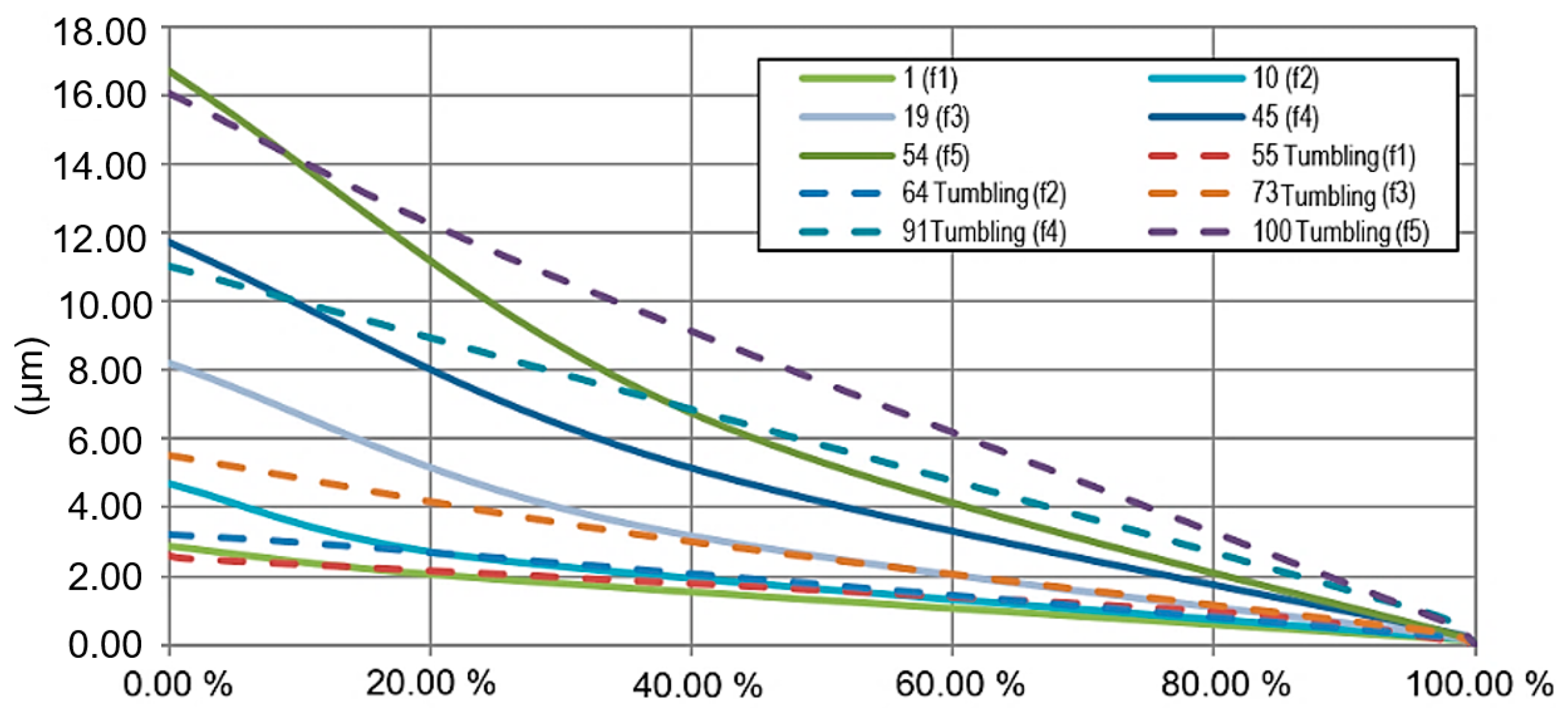

- feed per revolution: f = 0.08; 0.12; 0.16; 0.2; 0.24 mm.

| Tumbling type | Towed; |

| Rotor speed | 40 rpm; |

| Rotation bracket | 90 rpm; |

| Immersion depth | 420 mm; |

| Lift | Not used; |

| Medium | H4/400; |

| Clockwise tumbling time | 3 min; |

| Counterclockwise tumbling time | 3 min; |

| Total time | 6 min. |

3.4. Number of Experimental Samples

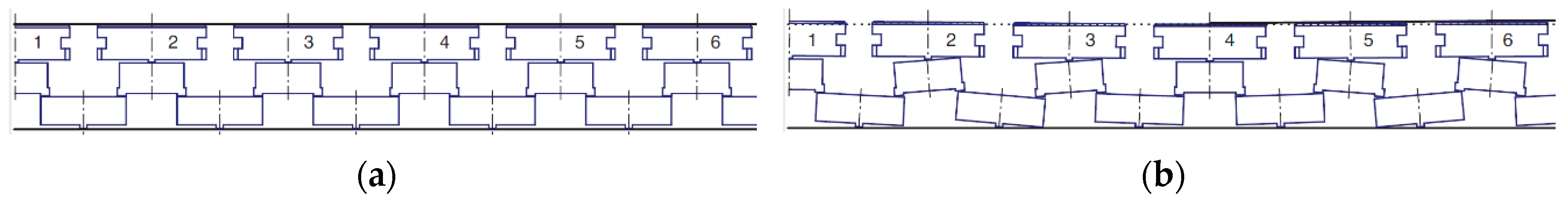

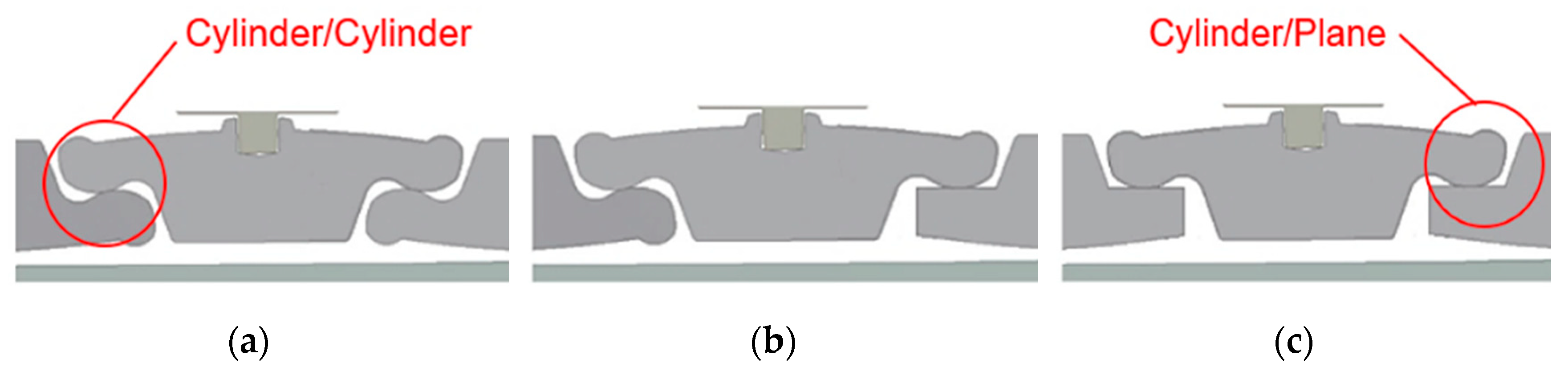

- (a)

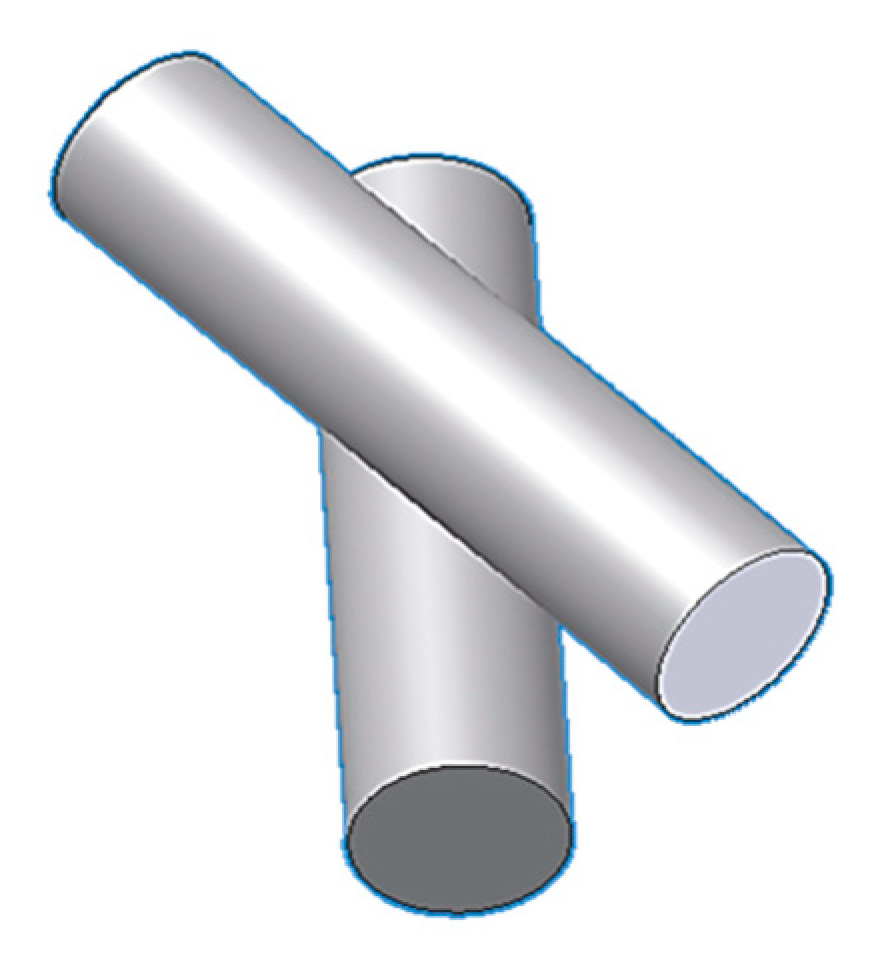

- Load contact pairs “Cylinder/Cylinder = C/C” and “Cylinder/Plane = C/P”.

- (b)

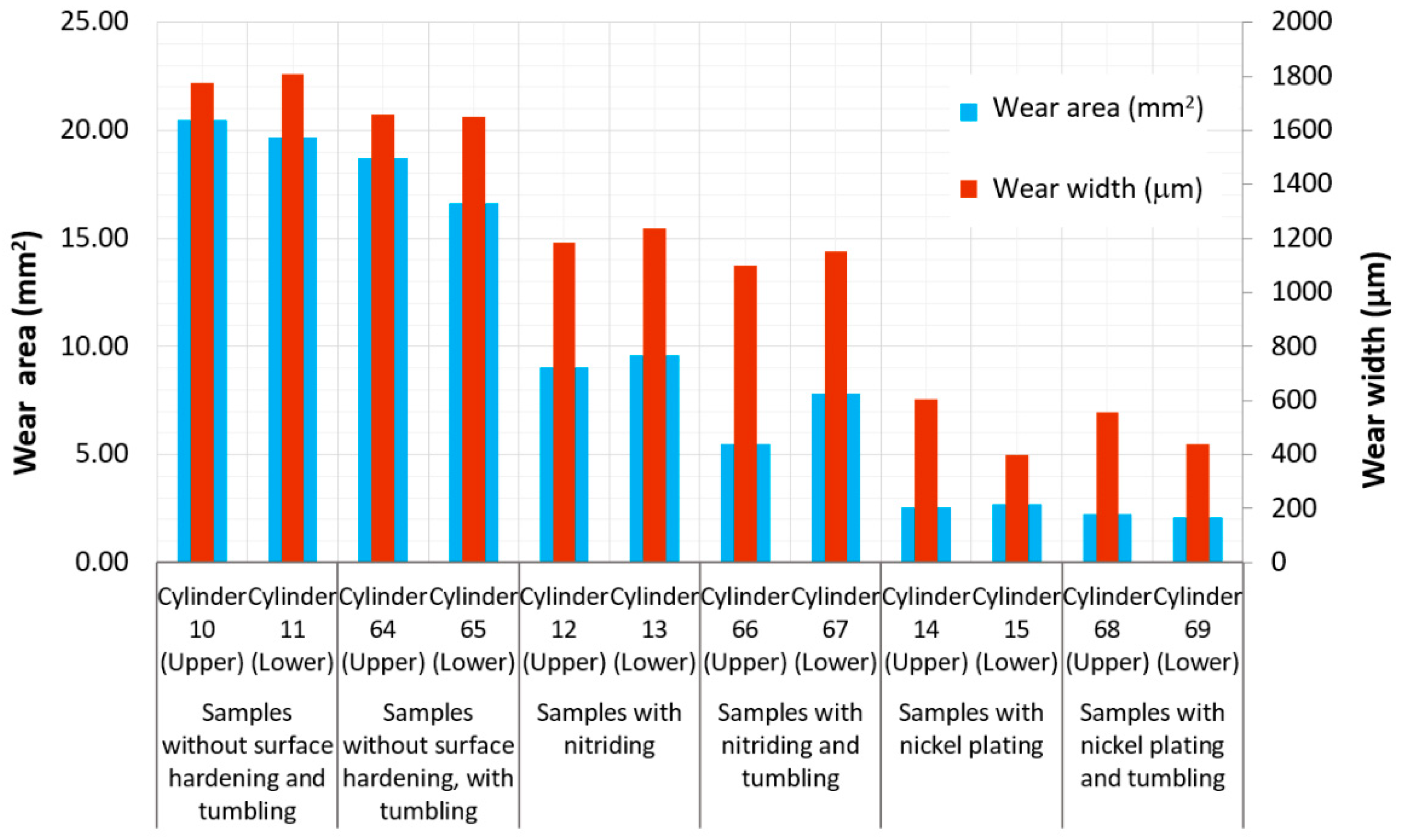

- Parameter x1—feed per revolution: f1 = 0.08 mm; f2 = 0.12 mm; f3 = 0.16 mm; f4 = 0.2 mm; f5 = 0.24 mm.

- (c)

- Parameter x2—surface hardening: with or without tumbling, nitriding or electroless nickel plating.

4. Preliminary Tests

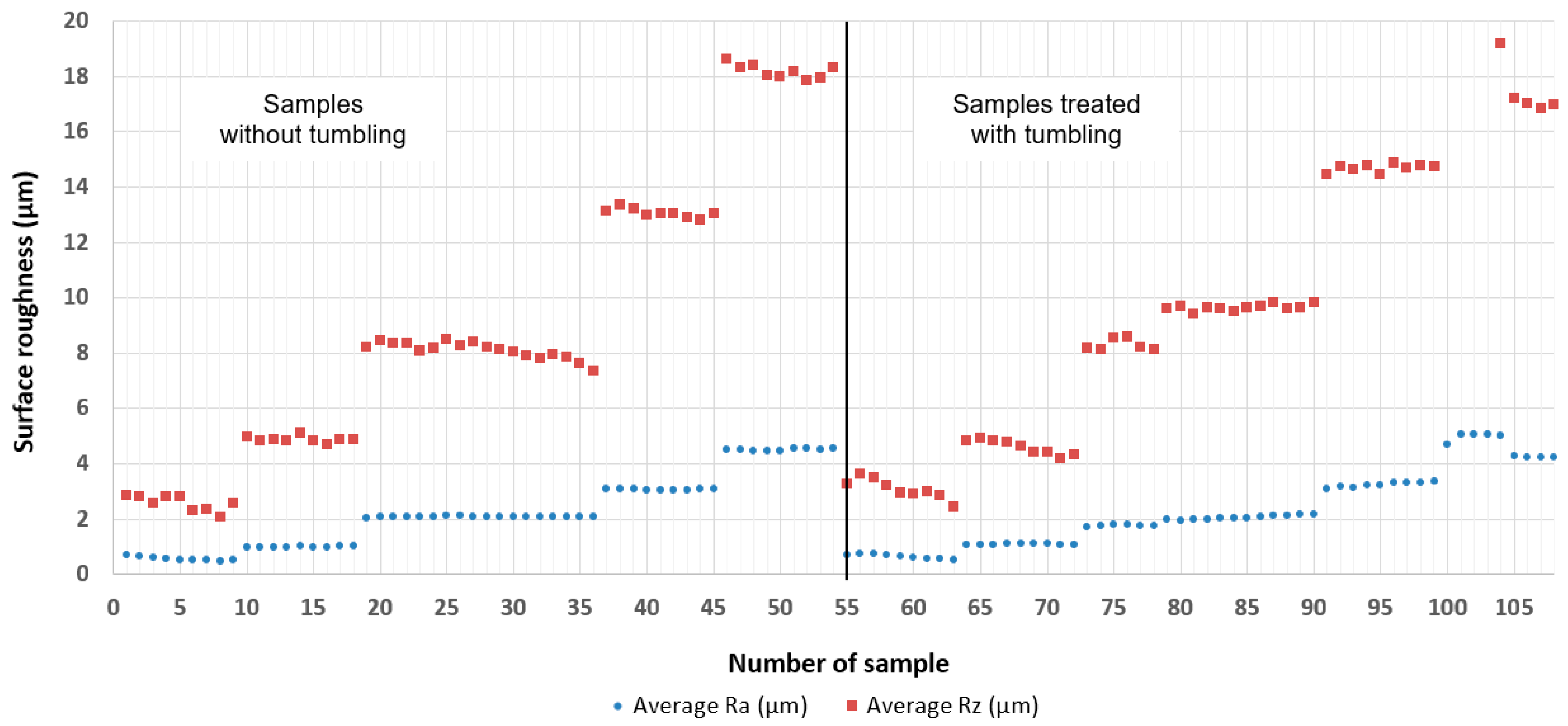

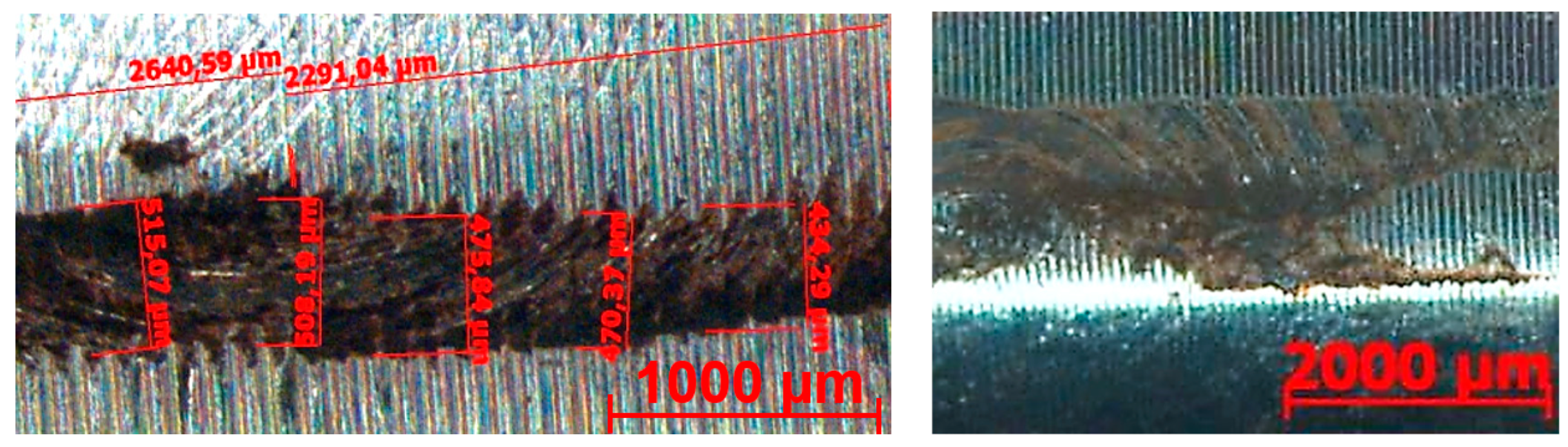

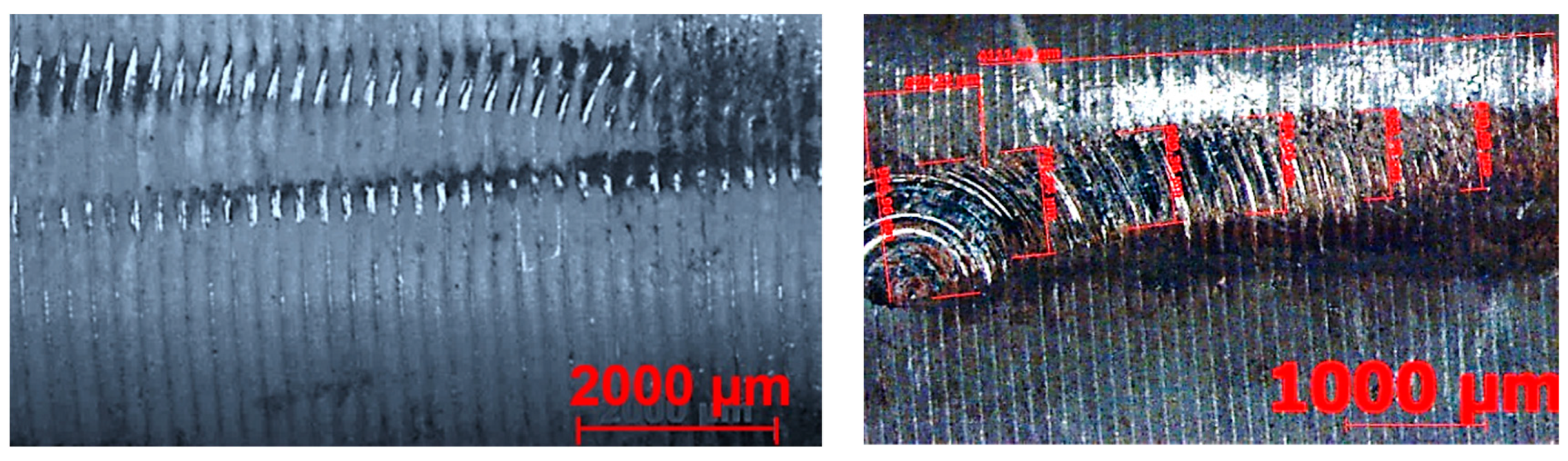

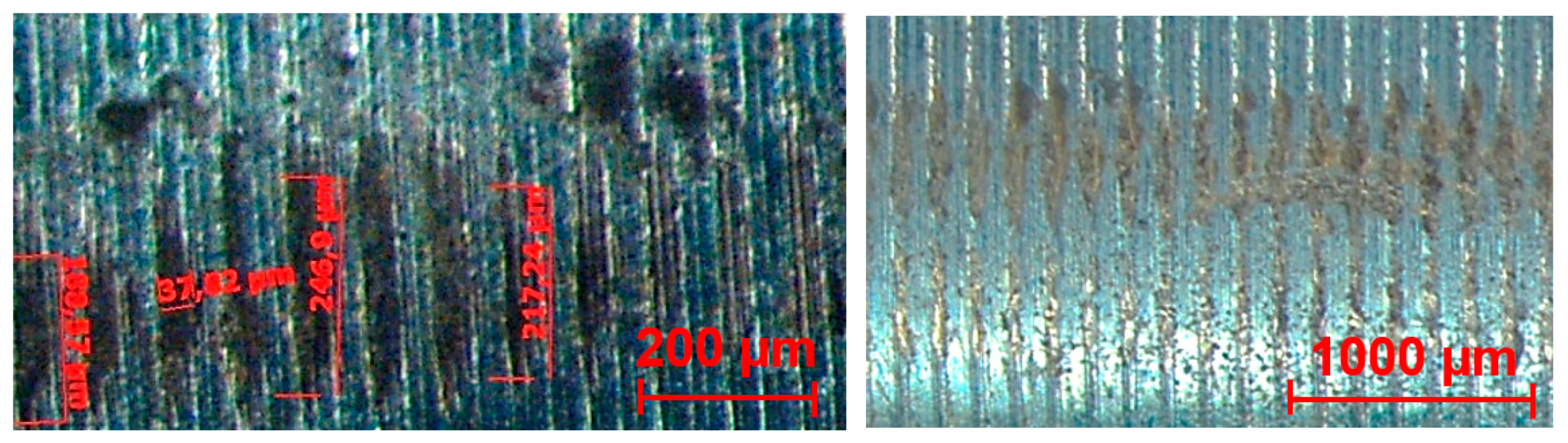

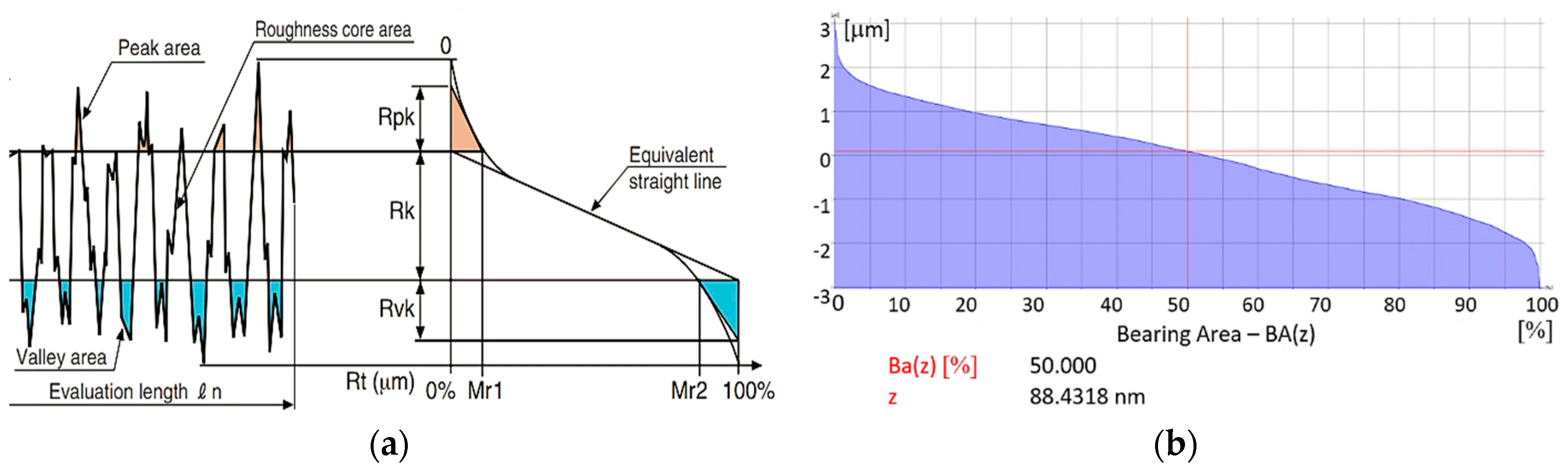

4.1. Surface Roughness Investigation

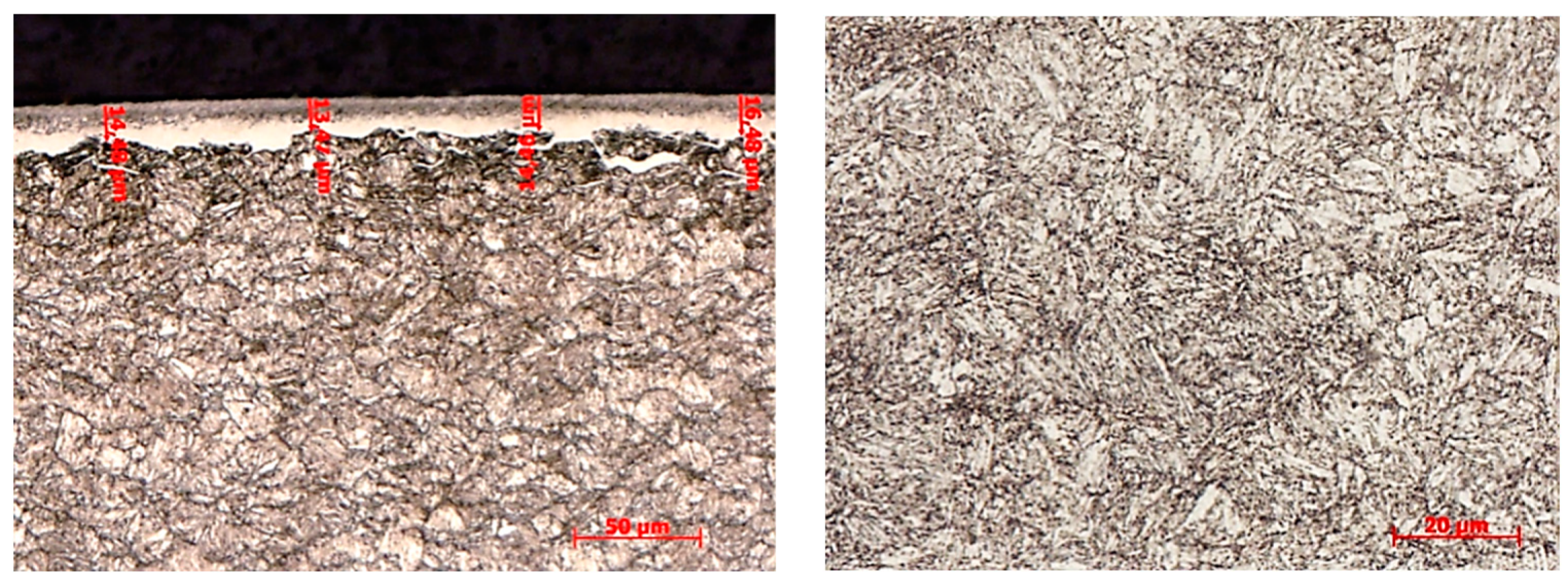

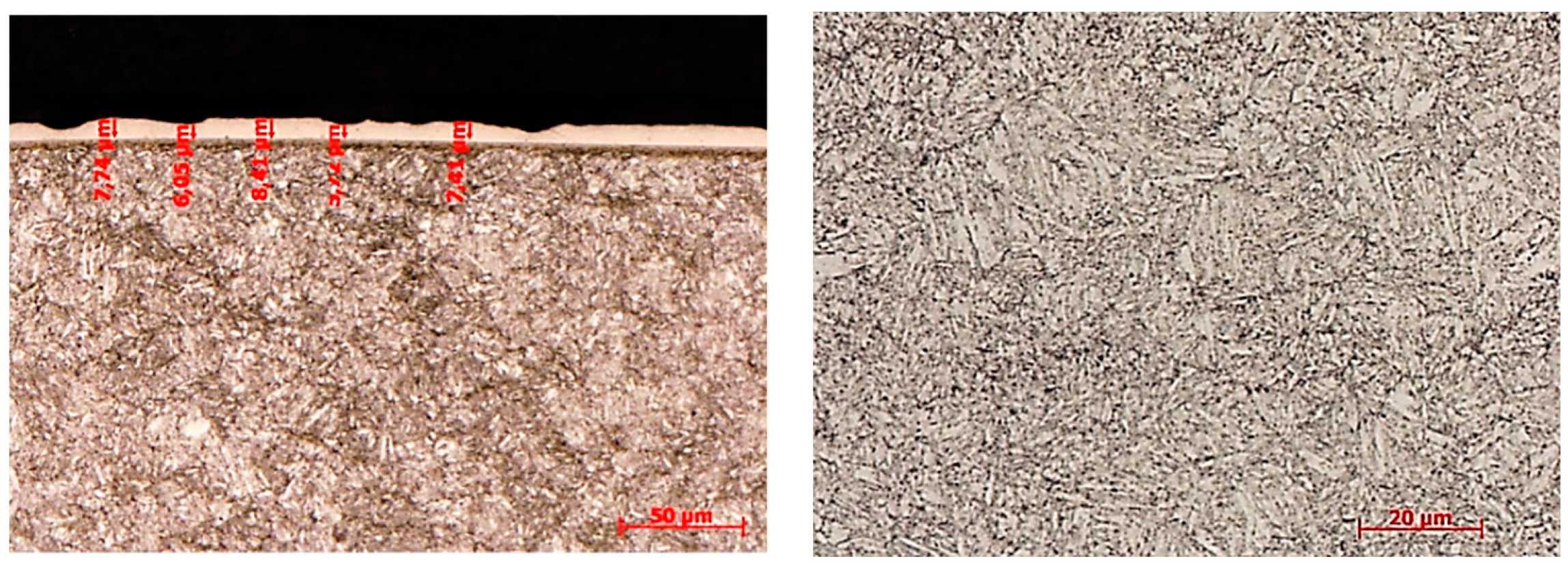

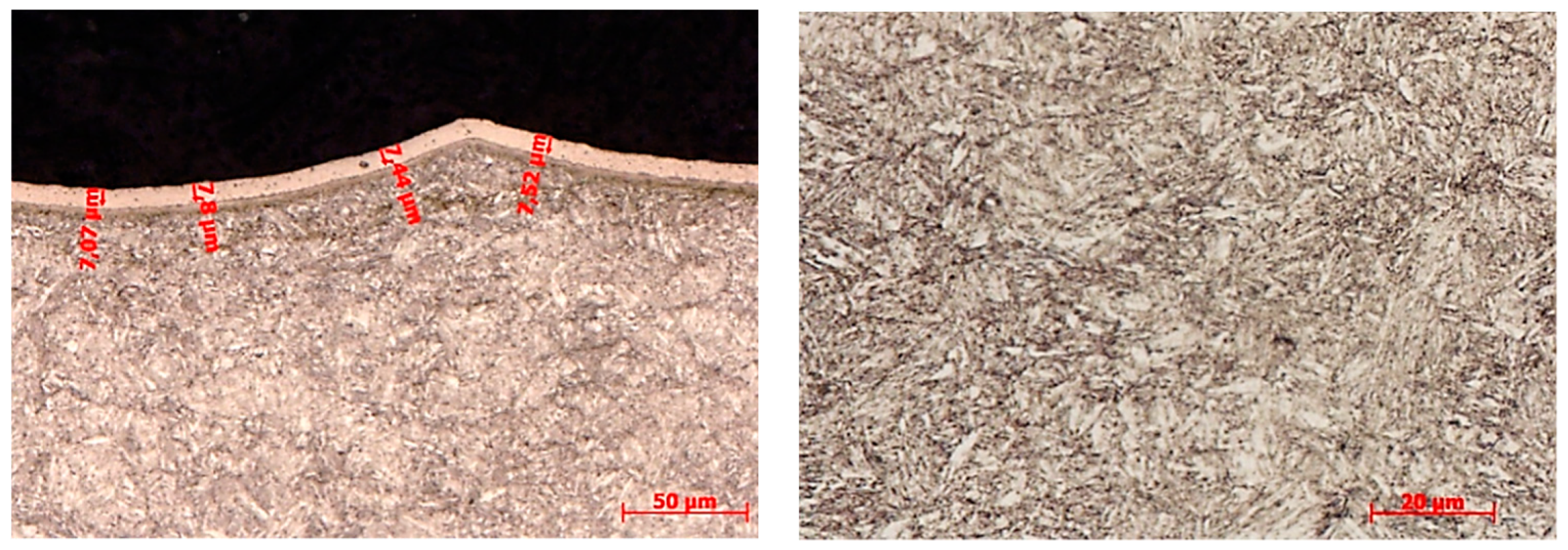

4.2. Microhardness and Metallographic Analysis

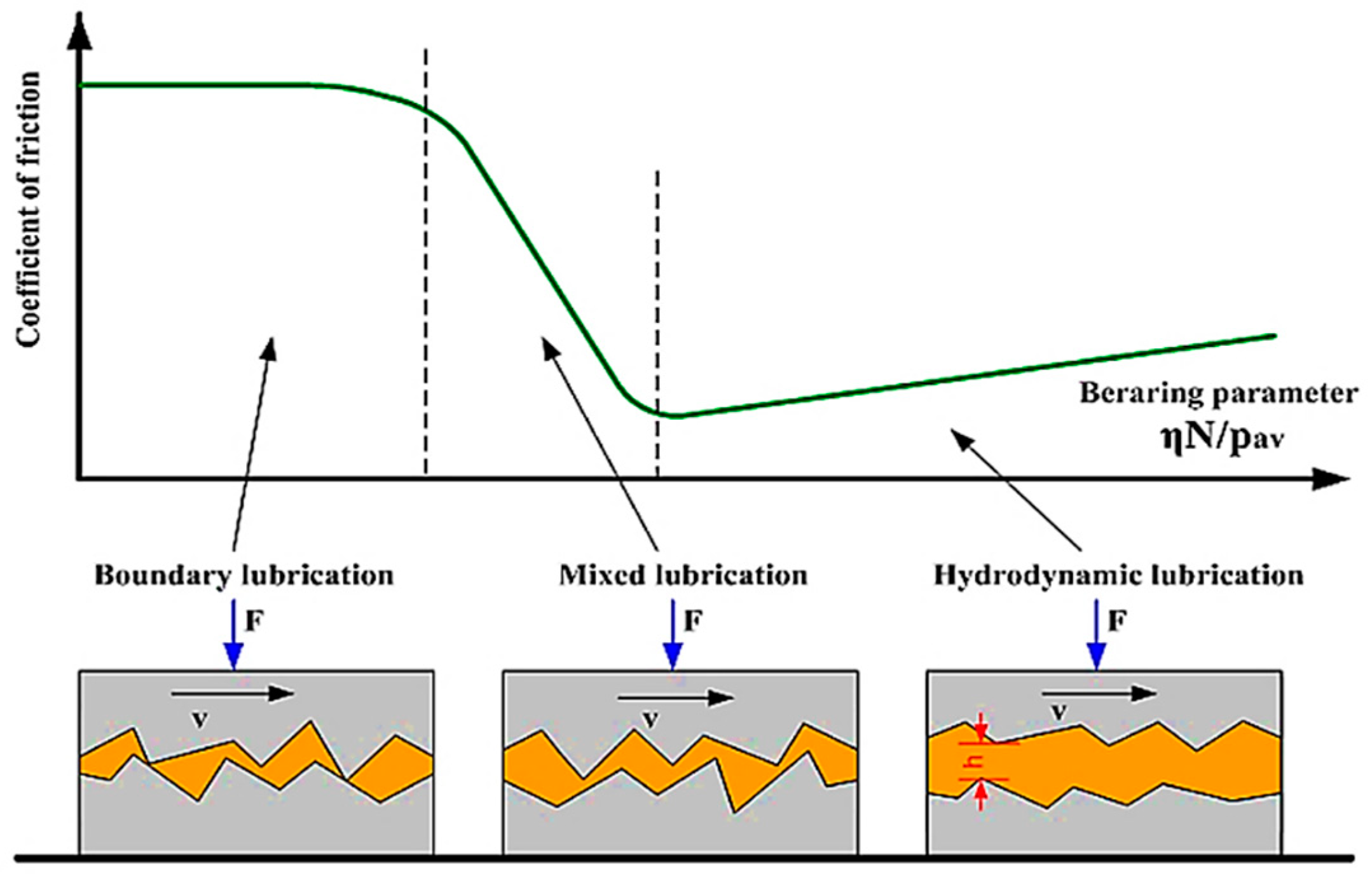

5. Tribological Behaviour of 34CrNiMo6 Steel

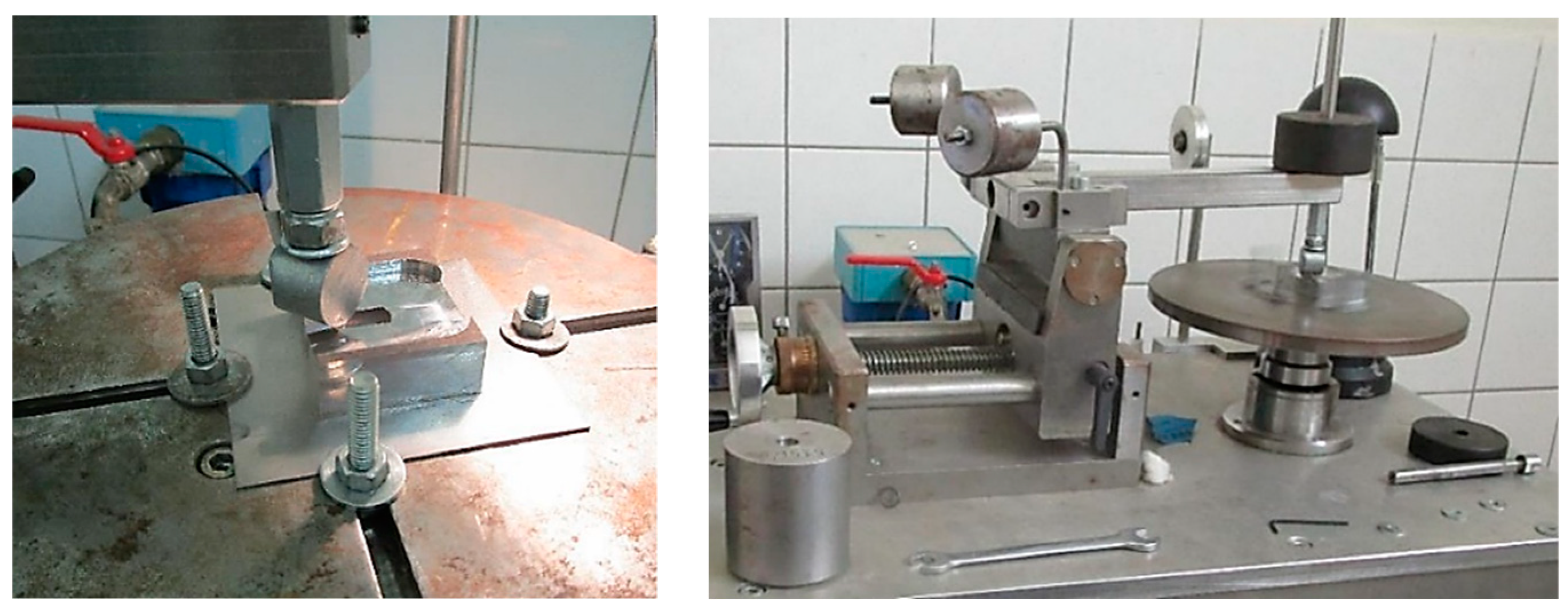

5.1. Pin-on-Disk Test

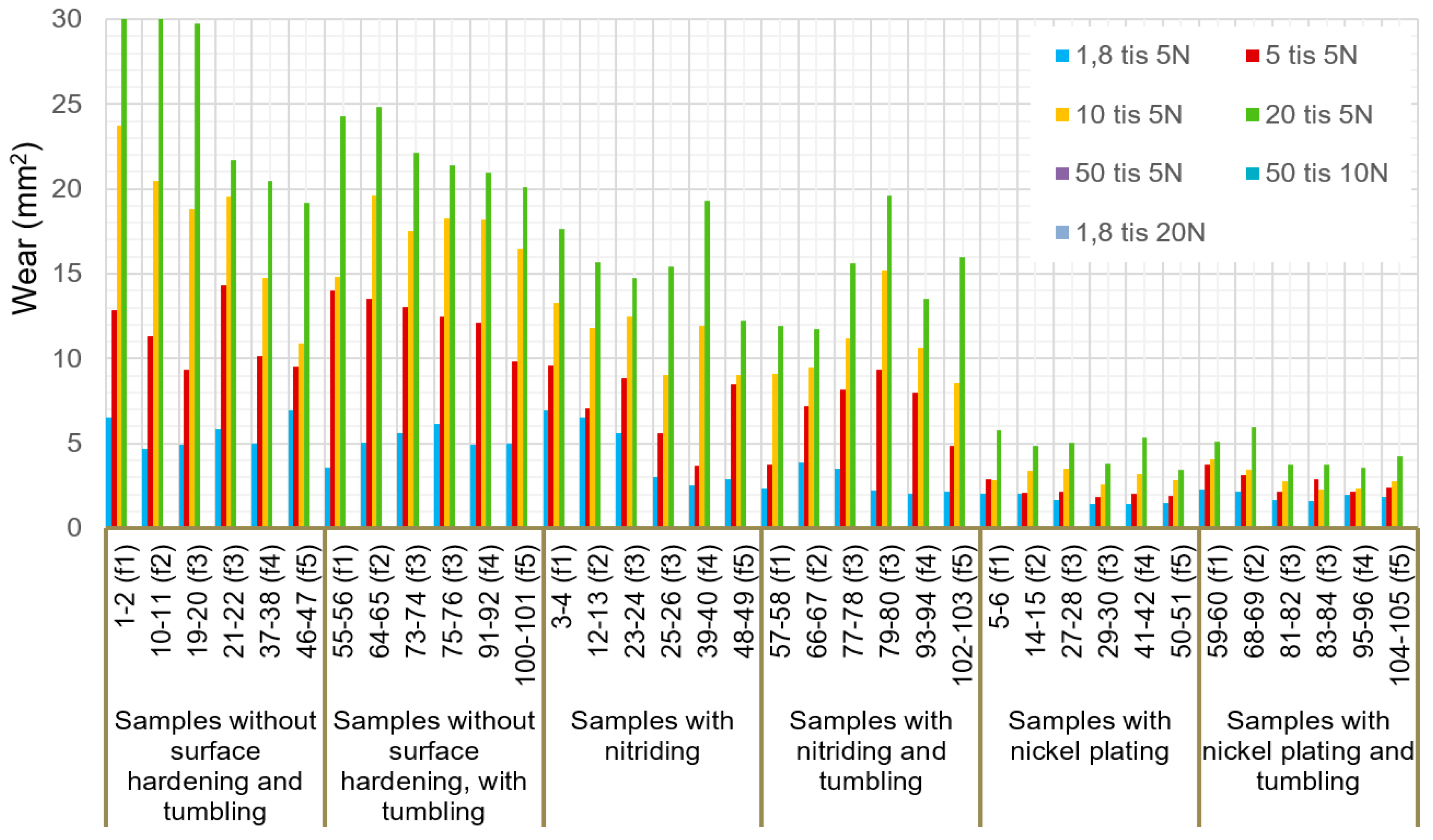

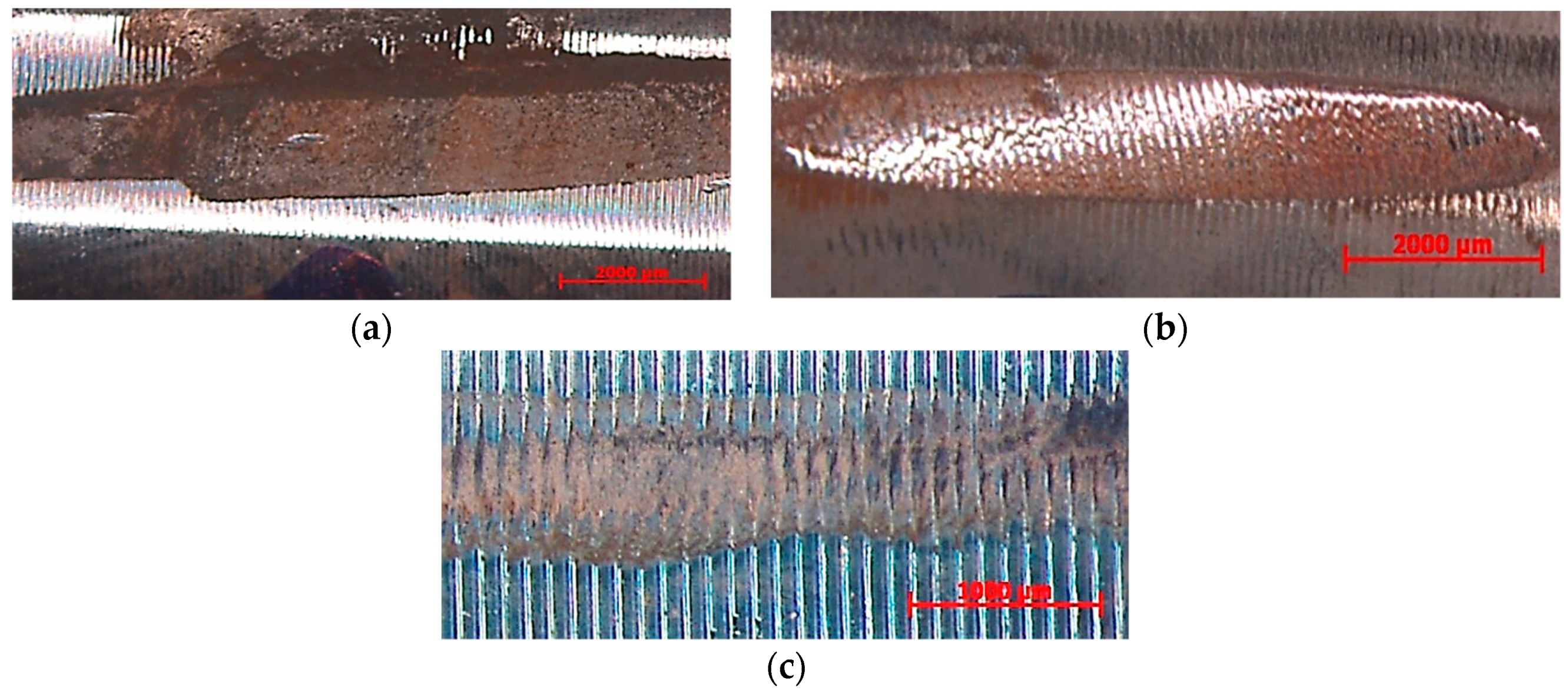

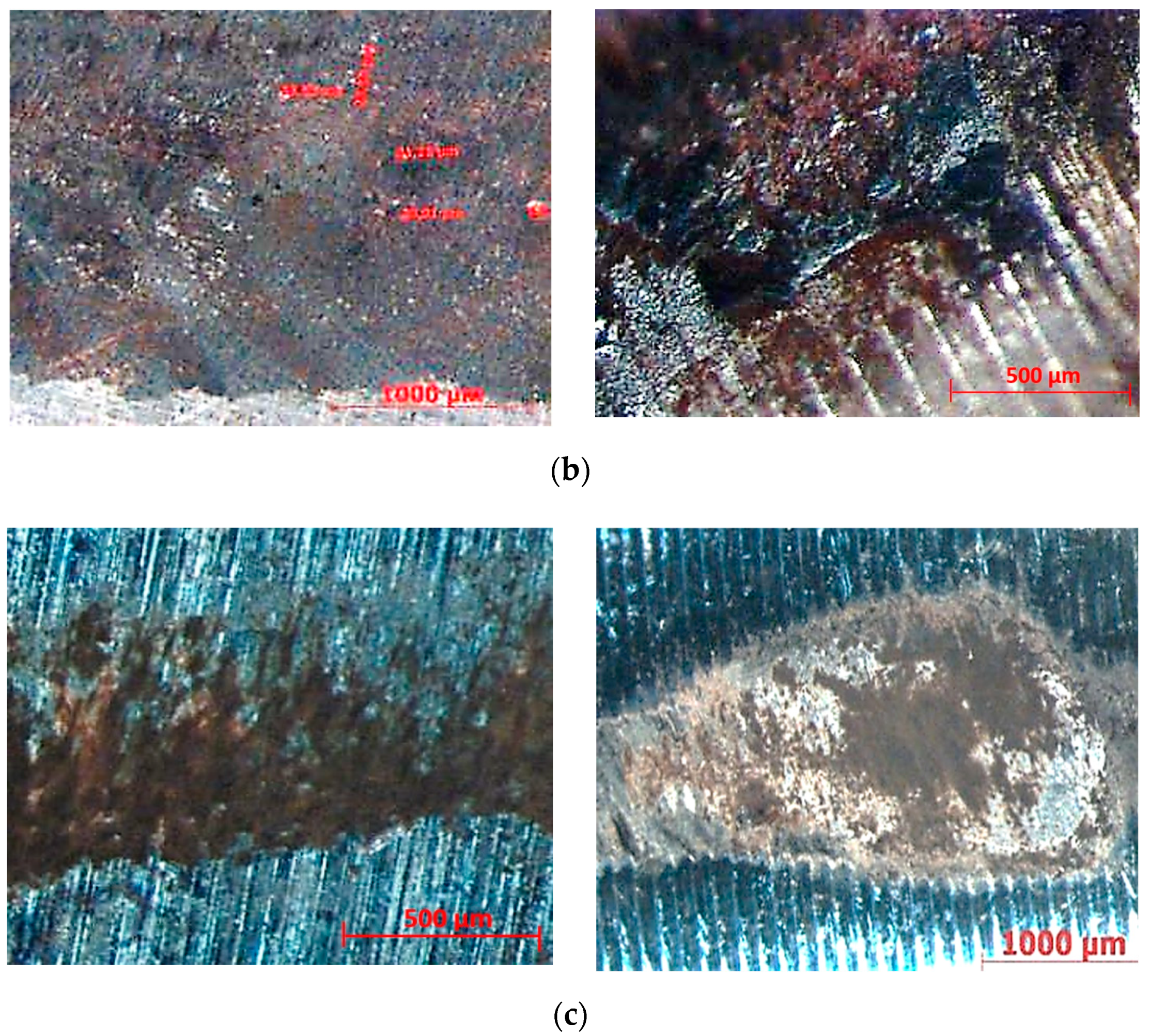

5.1.1. Wear Measuring and Observation

5.1.2. Discussions

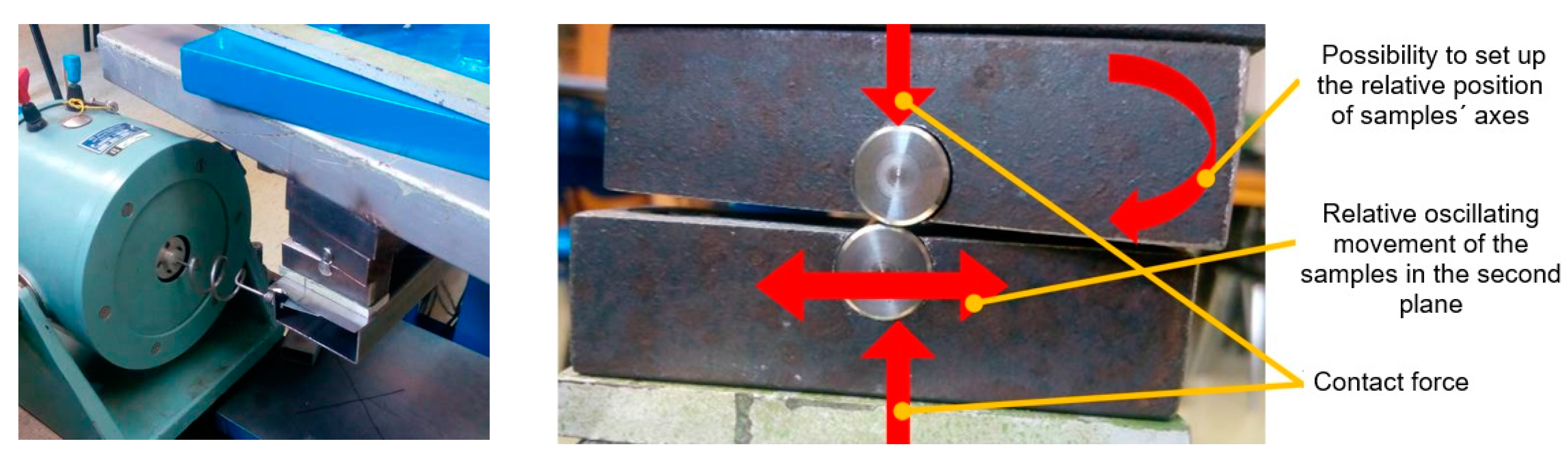

5.2. Frequency Tribological Test

| contact force: | 15 N; |

| feed: | ±0.2 mm; |

| oscillation speed: | 50 Hz; |

| a number of oscillations: | 1 × 106. |

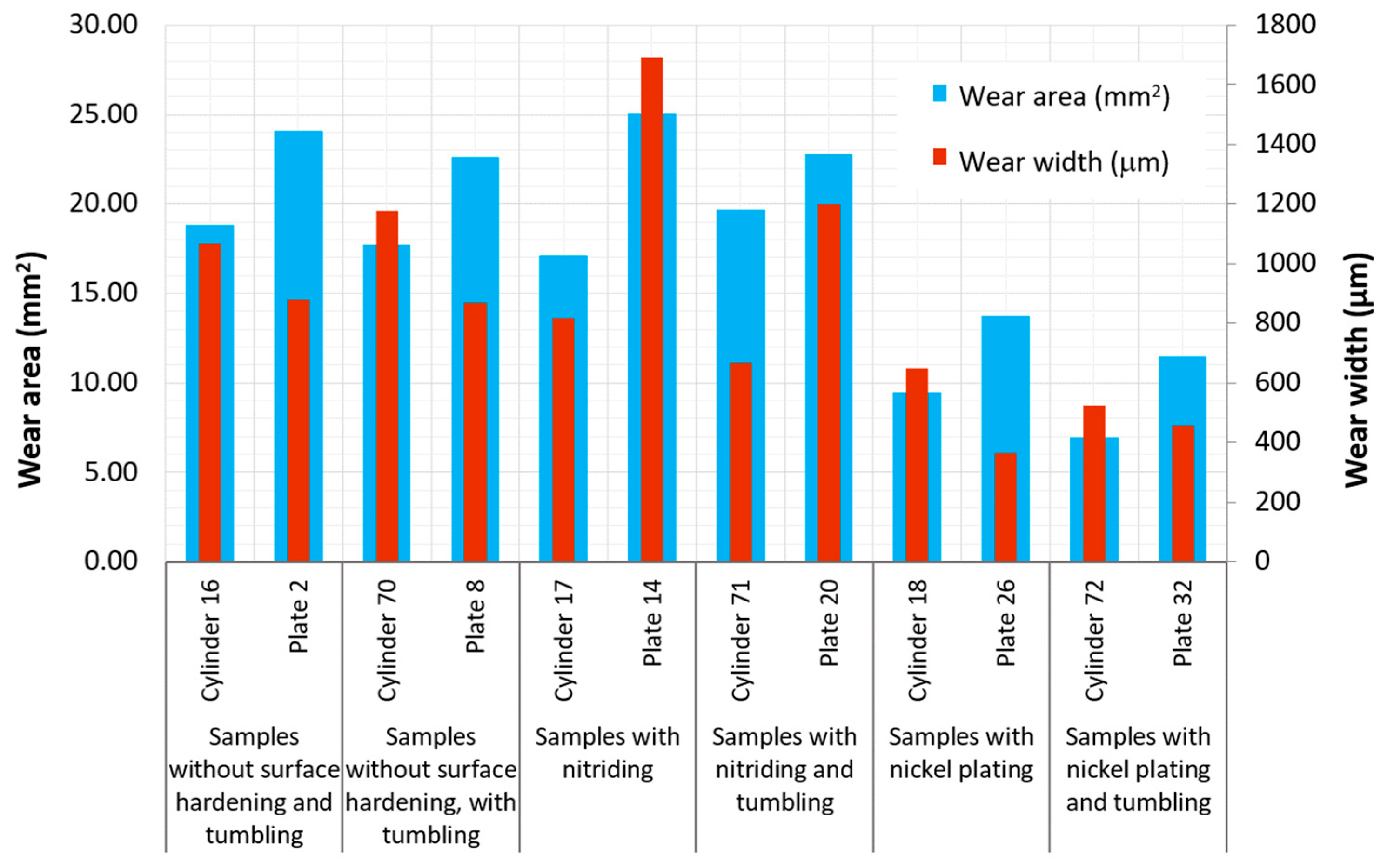

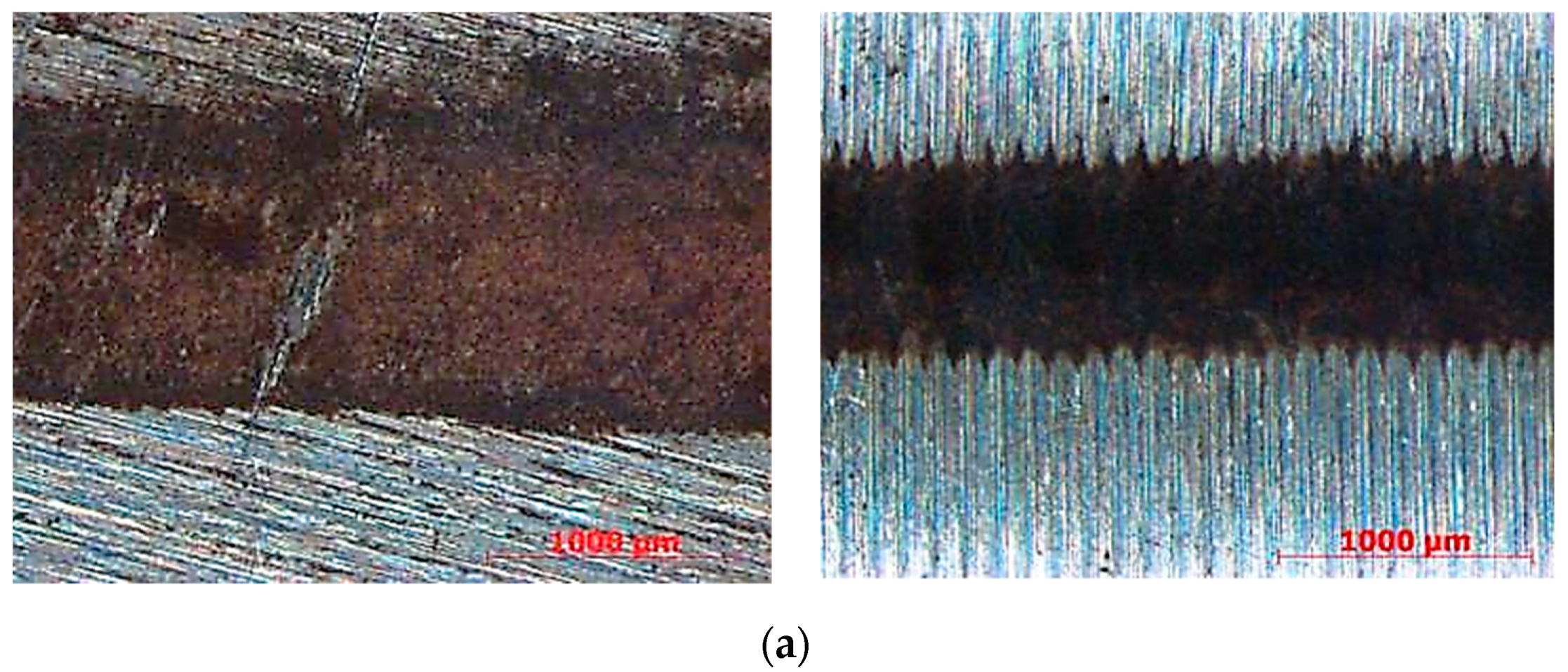

5.2.1. Configuration “Cylinder/Cylinder”

5.2.2. Configuration “Cylinder/Plate”

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ap | depth of cut (mm) |

| vc | cutting speed (mmin−1) |

| f | feed per revolution (mm) |

| rpm | revolution per minute (min−1) |

| Ra | arithmetical average deviation from a mean line (μm) |

| Rz | ten-point height of irregularities (μm) |

| C/C | Cylinder/Cylinder contact surfaces |

| C/P | Cylinder/Plate contact surfaces |

| R | refinement |

| N | nitriding |

| ENP | Electroless Nickel Plating |

| Rk | core roughness depth: Depth of the roughness core profile |

| Rpk | reduced peak height Average height of protruding peaks above the roughness core profile |

| Rvk | reduced valley depths: Average depth of valleys projecting through roughness core profile |

| Mr1 | material portion 1: Level in (%): determined for the intersection line which separates the protruding peaks from the roughness core profile |

| Mr2 | material portion 2: Level in (%), determined for the intersection line which separates the deep valleys from the roughness core profile. |

| A1 | Peak area |

| A2 | Valley area |

References

- DeCamillo, S. Current issues regarding unusual conditions in high-Speed turbomachinery. In 5th EDF/LMS Poitiers Workshop Proceedings; Université de Poitiers: Paris, France, 2006; pp. A1–A10. [Google Scholar]

- Kumar, D.A.; Manisha, D.; Shailendra, J. Study of shaft voltage & bearing currents in electrical machines. In Proceedings of the IEEE Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), Bhopal, India, 1–2 March 2012; pp. 1–4. [Google Scholar]

- Tanaka, T. Approaches to the safer operation of thrust and journal bearings used in turbomachinery. In 10th EDF/Pprime Poitiers Workshop; Université de Poitiers: Paris, France, 2011; pp. A1–A22. [Google Scholar]

- Wodtke, M.; Schubert, A.; Fillon, M.; Wasilczuk, M.; Pajączkowski, P. Large hydrodynamic thrust bearing—Comparison of the theoretical prediction and measurements. In 9th EDF/LMS Poitiers Workshop Proceedings; Université de Poitiers: Paris, France, 2010; pp. M1–M8. [Google Scholar]

- Gregory, R.S. Factors Influencing Power Loss of Tilting-Pad Thrust Bearings. J. Lubr. Technol. 1979, 101, 154–160. [Google Scholar] [CrossRef]

- Zhu, S.; Huang, P. Influence mechanism of morphological parameters on tribological behaviors based on bearing ratio curve. Tribol. Int. 2017, 10, 10–18. [Google Scholar] [CrossRef]

- Malotová, Š.; Čep, R.; Kratochvíl, J.; Šajgalík, M.; Czán, A. Dependence of the Resistance of the Integrated Layers on the Wear of Ceramic Cutting Tool. Manuf. Technol. 2018, 18, 444–448. [Google Scholar] [CrossRef]

- Ettles, C.M.; Knox, R.T.; Ferguson, J.H.; Horner, D. Test Results for PTFE-Faced Thrust Pads, With Direct Comparison Against Babbitt-Faced Pads and Correlation with Analysis. J. Tribol. 2003, 125, 814–823. [Google Scholar] [CrossRef]

- Martsinkovsky, V.; Yurko, V.; Tarelnik, V.; Filonenko, Y. Designing Thrust Sliding Bearings of High Bearing Capacity. Procedia Eng. 2012, 39, 148–156. [Google Scholar] [CrossRef]

- Mikula, A.M. The Leading-Edge-Groove Tilting-Pad Thrust Bearing: Recent Developments. J. Tribol. 1985, 107, 423–428. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Tabandeh-Khorshid, M.; Omrani, E.; Lovell, M.R.; Menezes, P.L. Tribology for Scientists and Engineers; Springer: New York, NY, USA, 2013; pp. 233–268. [Google Scholar]

- Straka, F. Static Analysis of Self-Equalizing System in Tilting Pad Thrust Bearing; Pilsen Doosan Skoda Power: Pilsen, Czech Republic, 2013. [Google Scholar]

- Pitel, J.; Matiskova, D.; Marasova, D. A new approach to evaluation of the material cutting using the artificial neural networks. TEM J. 2019, 8, 325–332. [Google Scholar]

- Branagan, L.A. Survey of Damage Investigation of Babbitted Industrial Bearings. Lubricants 2015, 3, 91–112. [Google Scholar] [CrossRef]

- Ferroudji, F. Static Strength Analysis of a Full-scale 850 kW wind Turbine Steel Tower. Int. J. Eng. Adv. Technol. 2019, 8, 403–406. [Google Scholar]

- Pantazopoulos, G.; Toulfatzis, A.; Vazdirvanidis, A.; Rikos, A. Analysis of the Degradation Process of Structural Steel Component Subjected to Prolonged Thermal Exposure. Met. Microstruct. Anal. 2016, 5, 149–156. [Google Scholar] [CrossRef]

- Glavatskih, S.B. Tilting Pad Thrust Bearings. In Tribological Research and Design for Engineering Systems; Elsevier: Amsterdam, The Netherlands, 2003; pp. 379–390. [Google Scholar]

- Noda, S.; Zenitani, S.; Yamada, Y.; Sasaki, T. Improved Technologies of Steam Turbine for Long Term Continuous Operation. Mitsubishi JUKO GIHO 2004, 41, 161–165. [Google Scholar]

- Urban, M.; Skopeček, T.; Dolejš, J. Measurement of axial bearings with self-equalized elements and the fixture design for the measuring their maximal misalignement. Proc. Mech. Eng. Technol. 2015, 1, 263–270. [Google Scholar]

- Pantazopoulos, G.A. A Short Review on Fracture Mechanisms of Mechanical Components Operated under Industrial Process Conditions: Fractographic Analysis and Selected Prevention Strategies. Metals 2019, 9, 148. [Google Scholar] [CrossRef]

- Lehocká, D.; Simkulet, V.; Klich, J.; Štorkan, Z.; Krejčí, L.; Kepič, J.; Birčák, J. Evaluation of possibility of AISI 304 stainless steel mechanical surface treatment with ultrasonically enhanced pulsating water jet. In Lecture Notes in Mechanical Engineering; Springer Nature: Basel, Switzerland, 2019; pp. 163–172. [Google Scholar]

- Battez, A.H.; González, R.; Felgueroso, D.; Fernández, J.; Fernández, M.D.R.; García, M.; Peñuelas, I.; Fernandez, R. Wear prevention behaviour of nanoparticle suspension under extreme pressure conditions. Wear 2007, 263, 1568–1574. [Google Scholar] [CrossRef]

- Popescu, N.; Cojocaru, M.; Mihailov, V. Experimental studies on bulk tempering of 34CrNiMo6 steel. Surf. Eng. Appl. Electrochem. 2012, 48, 28–34. [Google Scholar] [CrossRef]

- Cochet, J.; Thuillier, S.; Loulou, T.; Decultot, N.; Carré, P.; Manach, P.Y. Heat treatment of 34CrNiMo6 steel used for mooringshackles. Int. J. Adv. Manuf. Technol. 2017, 91, 2329–2346. [Google Scholar] [CrossRef]

- Ge, Y.; Wang, K. Effect of tempering temperature on precipitate evolution and mechanical properties of 34CrNiMo6 steel. Mater. Tehnol. 2019, 53, 527–534. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.; Antunes, F. Low-cycle fatigue behaviour of 34CrNiMo6 high strength steel. Theor. Appl. Fract. Mech. 2012, 58, 28–34. [Google Scholar] [CrossRef]

- Li, Y.; Fang, W.; Lu, C.; Gao, Z.; Ma, X.; Jin, W.; Ye, Y.; Wang, F. Microstructure and Mechanical Properties of 34CrMo4 Steel for Gas Cylinders Formed by Hot Drawing and Flow Forming. Materials 2019, 12, 1351. [Google Scholar] [CrossRef]

- Maniee, A.; Mahboubi, F.; Soleimani, R. The study of tribological and corrosion behaviour of plasma nitrided 34CrNiMo6 steel under hot and cold wall conditions. Mater. Des. 2014, 60, 599–604. [Google Scholar] [CrossRef]

- Huang, C.; Lin, X.; Yang, H.; Liu, F.; Huang, W. Microstructure and Tribological Properties of Laser Forming Repaired 34CrNiMo6 Steel. Materials 2018, 11, 1722. [Google Scholar] [CrossRef] [PubMed]

- Abd El-Azim, M.E.; Ghoneim, M.M.; Nasreldin, A.M.; Soliman, S. Effect of various heat treatments on microstructure and mechanical properties of 34CrNiMo6 steel. Z. Metallkd 1997, 88, 502–507. [Google Scholar]

- Costa, J.; Ferreira, J.; Ramalho, A. Fatigue and fretting fatigue of ion-nitrided 34CrNiMo6 steel. Theor. Appl. Fract. Mech. 2001, 35, 69–79. [Google Scholar] [CrossRef]

- Selmy, A.I.; El-Sonbaty, I.; Shehata, F.; Khashaba, U.A. Some factors affecting the accuracy of turned parts. Sci. Bull. Fac. Eng. 1989, 24, 356–368. [Google Scholar]

- Baron, P.; Dobránsky, J.; Pollák, M.; Kočiško, M.; Cmorej, T. The Parameter Correlation of Acoustic Emission and High-Frequency Vibrations in the Assessment Process of the Operating State of the Technical System. Acta Mech. Autom. 2016, 10, 112–116. [Google Scholar] [CrossRef]

- Xiao, L.; Rosen, B.G.; Amini, N.; Nilsson, P.H. A study on the effect of surface topography on rough friction in roller contact. J. Wear 2003, 254, 1162–1169. [Google Scholar] [CrossRef]

- Borghi, A.; Gualtieri, E.; Marchetto, D.; Moretti, L.; Valeri, S. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 2008, 265, 1046–1051. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Q.; Qin, Z.; Luo, Q.; Wu, Z.; Liu, L. Tribological performance of surfaces enhanced by texturing and nitrogen implantation. Appl. Surf. Sci. 2016, 363, 161–167. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vizintin, J. Influence of surface preparation on roughness parameters, friction and wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Polcar, T.; Parreira, N.; Novak, R. Friction and wear behaviour of CrN coating at temperatures up to 500 °C. Surf. Coat. Technol. 2007, 201, 5228–5235. [Google Scholar] [CrossRef]

- Kuduzović, A.; Poletti, M.C.; Sommitsch, C.; Dománková, M.; Mitsche, S.; Kienreich, R. Investigations into the delayed fracture susceptibility of 34CrNiMo6 steel, and the opportunities for its application in ultra-high-strength bolts and fasteners. Mater. Sci. Eng. A 2014, 590, 66–73. [Google Scholar] [CrossRef]

- Bayes, D.M. The Physical Properties of Electroless Nickel Coatings. In Proceedings of the EN 95 Conference, Singapore, 21–23 November 1995. [Google Scholar]

- Kiran, K.; Manohar, B.; Divakar, S. A central composite rotatable design analysis of lipase catalyzed synthesis of lauroyl lactic acid at bench-scale level. Enzym. Microb. Technol. 2001, 29, 122–128. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.J.; Lin, C.; Shi, F. Development of a Set of Stribeck Curves for Conformal Contacts of Rough Surfaces. Tribol. Trans. 2006, 49, 526–535. [Google Scholar] [CrossRef]

- Filippov, A.; Nikonov, A.; Rubtsov, V.; Dmitriev, A.; Tarasov, S. Vibration and acoustic emission monitoring the stability of peakless tool turning: Experiment and modeling. J. Mater. Process. Technol. 2017, 246, 224–234. [Google Scholar] [CrossRef]

- Panda, A.; Dobransky, J.; Jančik, M.; Pandova, I.; Kačalova, M. Advantages and effectiveness of the powder metallurgy in manufacturing technologies. Metalurgija 2018, 57, 353–356. [Google Scholar]

| Component | C | Mn | Si | P | S | Cr | Ni | Mo | V | Cu | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (wt.%) | 0.34 | 0.793 | 0.282 | 0.0196 | 0.0052 | 1.72 | 1.55 | 0.221 | 0.0092 | 0.193 | 0.0194 |

| Without Tumbling | With Tumbling | Feed | Type of Surface | Heat Treatment | Without Tumbling | With Tumbling | Feed | Type of Surface | Heat Treatment | Without Tumbling | With Tumbling | Feed | Type of Surface | Heat Treatment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample (Cylinder) Number | Sample (Cylinder) Number | Sample (Cylinder) Number | ||||||||||||

| 1 | 55 | f1 | C/C | R | 19 | 73 | f3 | C/C | R | 37 | 91 | f4 | C/C | R |

| 2 | 56 | R | 20 | 74 | R | 38 | 92 | R | ||||||

| 3 | 57 | R + N | 21 | 75 | R | 39 | 93 | R + N | ||||||

| 4 | 58 | R + N | 22 | 76 | R | 40 | 94 | R + N | ||||||

| 5 | 59 | R + ENP | 23 | 77 | R + N | 41 | 95 | R + ENP | ||||||

| 6 | 60 | R + ENP | 24 | 78 | R + N | 42 | 96 | R + ENP | ||||||

| 7 | 61 | C/P | R | 25 | 79 | R + N | 43 | 97 | C/P | R | ||||

| 8 | 62 | R + N | 26 | 80 | R + N | 44 | 98 | R + N | ||||||

| 9 | 63 | R + ENP | 27 | 81 | R + ENP | 45 | 99 | R + ENP | ||||||

| 10 | 64 | f2 | C/C | R | 28 | 82 | R + ENP | 46 | 100 | f5 | C/C | R | ||

| 11 | 65 | R | 29 | 83 | R + ENP | 47 | 101 | R | ||||||

| 12 | 66 | R + N | 30 | 84 | R + ENP | 48 | 102 | R + N | ||||||

| 13 | 67 | R + N | 31 | 85 | C/P | R | 49 | 103 | R + N | |||||

| 14 | 68 | R + ENP | 32 | 86 | R | 50 | 104 | R + ENP | ||||||

| 15 | 69 | R + ENP | 33 | 87 | R + N | 51 | 105 | R + ENP | ||||||

| 16 | 70 | C/P | R | 34 | 88 | R + N | 52 | 106 | C/P | R | ||||

| 17 | 71 | R + N | 35 | 89 | R + EN | 53 | 107 | R + N | ||||||

| 18 | 72 | R + ENP | 36 | 90 | R + ENP | 54 | 108 | R + ENP | ||||||

| HV 0.025 | f1 = 0.08 mm | f1 = 0.24 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| Cross-Cut | Longitudinal Cut | Cross-Cut | Longitudinal Cut | |||||

| Surface | Core | Surface | Core | Surface | Core | Surface | Core | |

| Average Value | 621 | 392 | 225 | 382 | 451 | 375 | 671 | 386 |

| Deviation | 18 | 19 | 23 | 13 | 108 | 17 | 11 | 26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urban, M.; Monkova, K. Research of Tribological Properties of 34CrNiMo6 Steel in the Production of a Newly Designed Self-Equalizing Thrust Bearing. Metals 2020, 10, 84. https://doi.org/10.3390/met10010084

Urban M, Monkova K. Research of Tribological Properties of 34CrNiMo6 Steel in the Production of a Newly Designed Self-Equalizing Thrust Bearing. Metals. 2020; 10(1):84. https://doi.org/10.3390/met10010084

Chicago/Turabian StyleUrban, Marek, and Katarina Monkova. 2020. "Research of Tribological Properties of 34CrNiMo6 Steel in the Production of a Newly Designed Self-Equalizing Thrust Bearing" Metals 10, no. 1: 84. https://doi.org/10.3390/met10010084

APA StyleUrban, M., & Monkova, K. (2020). Research of Tribological Properties of 34CrNiMo6 Steel in the Production of a Newly Designed Self-Equalizing Thrust Bearing. Metals, 10(1), 84. https://doi.org/10.3390/met10010084