Hot Compression Deformation and Activation Energy of Nanohybrid-Reinforced AZ80 Magnesium Matrix Composite

Abstract

1. Introduction

2. Experiment Procedure

2.1. Materials and Preparation

2.2. Hot Compression Test

2.3. Microstructure Characterization

3. Results and Discussion

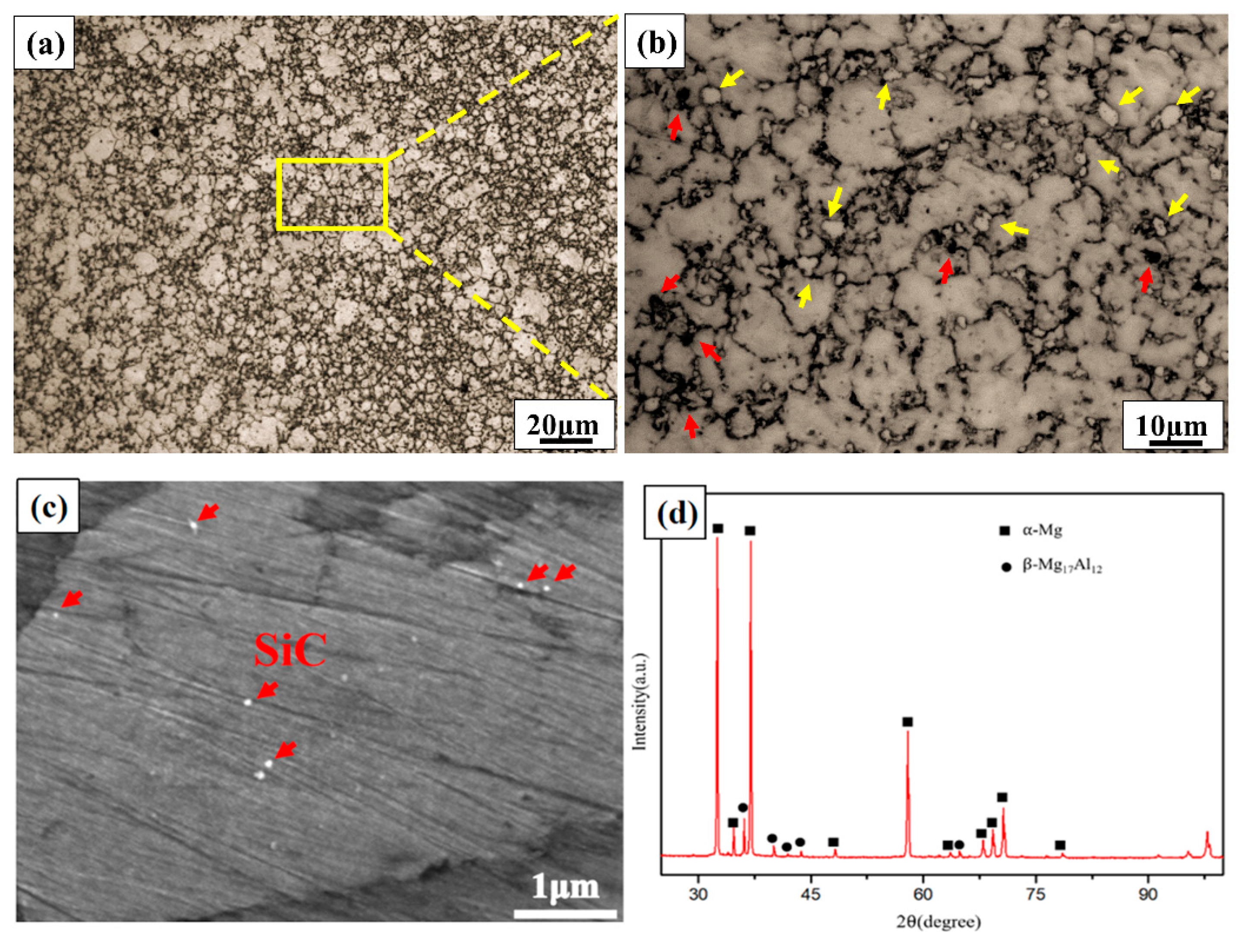

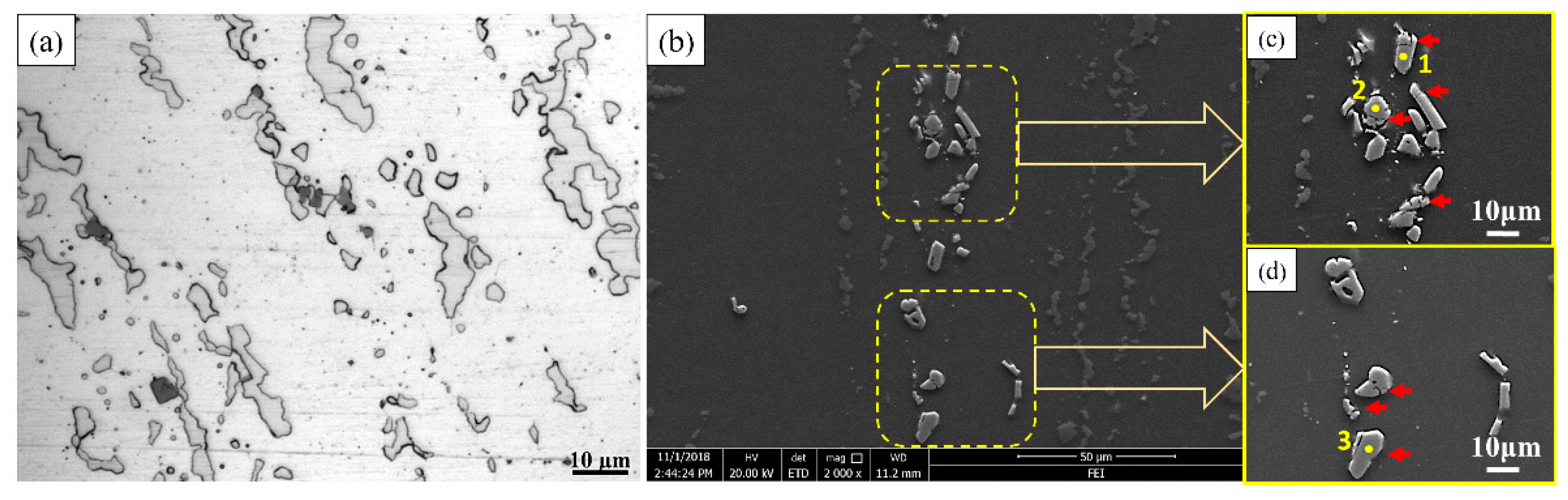

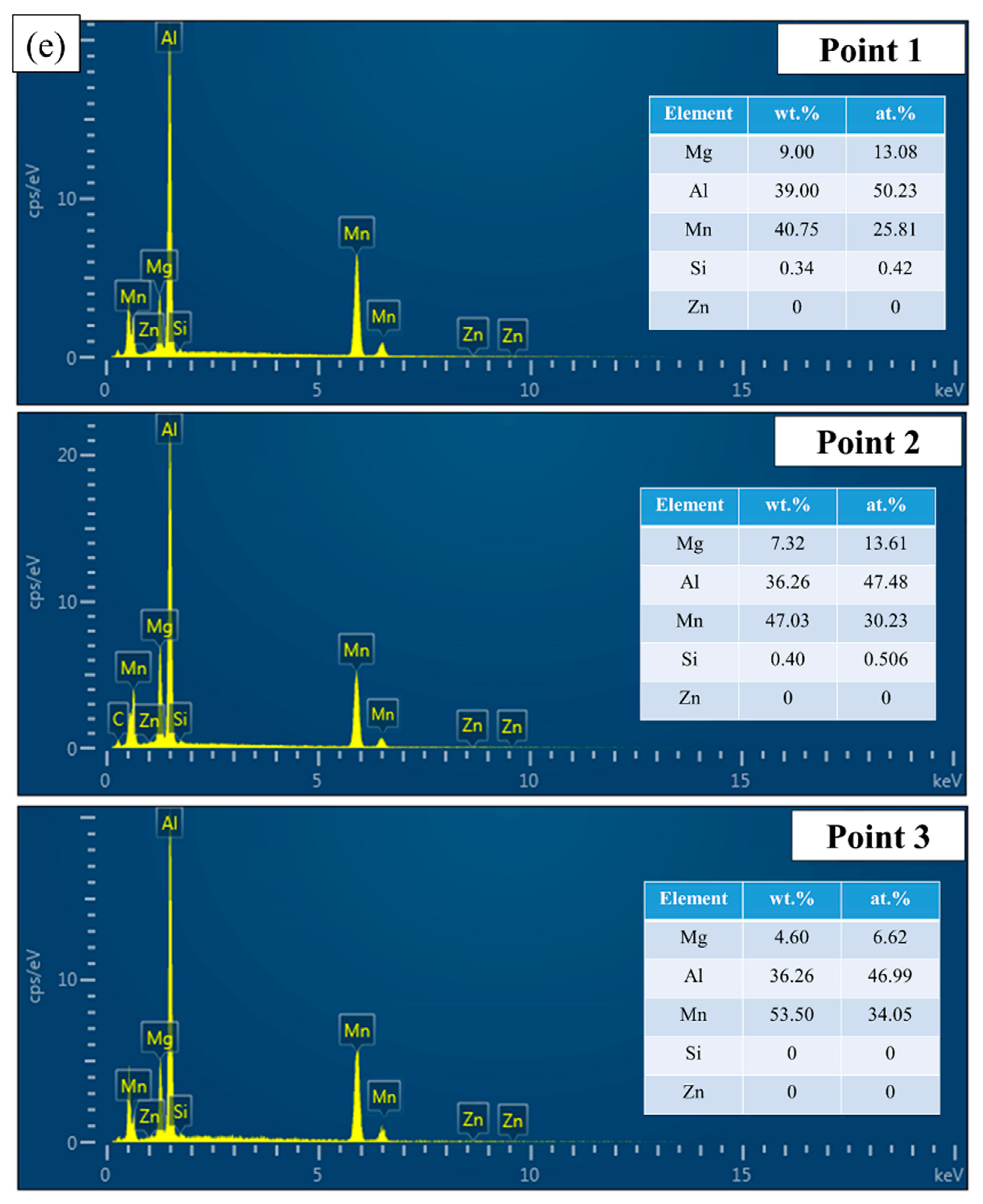

3.1. Extruded Microstructure Analysis

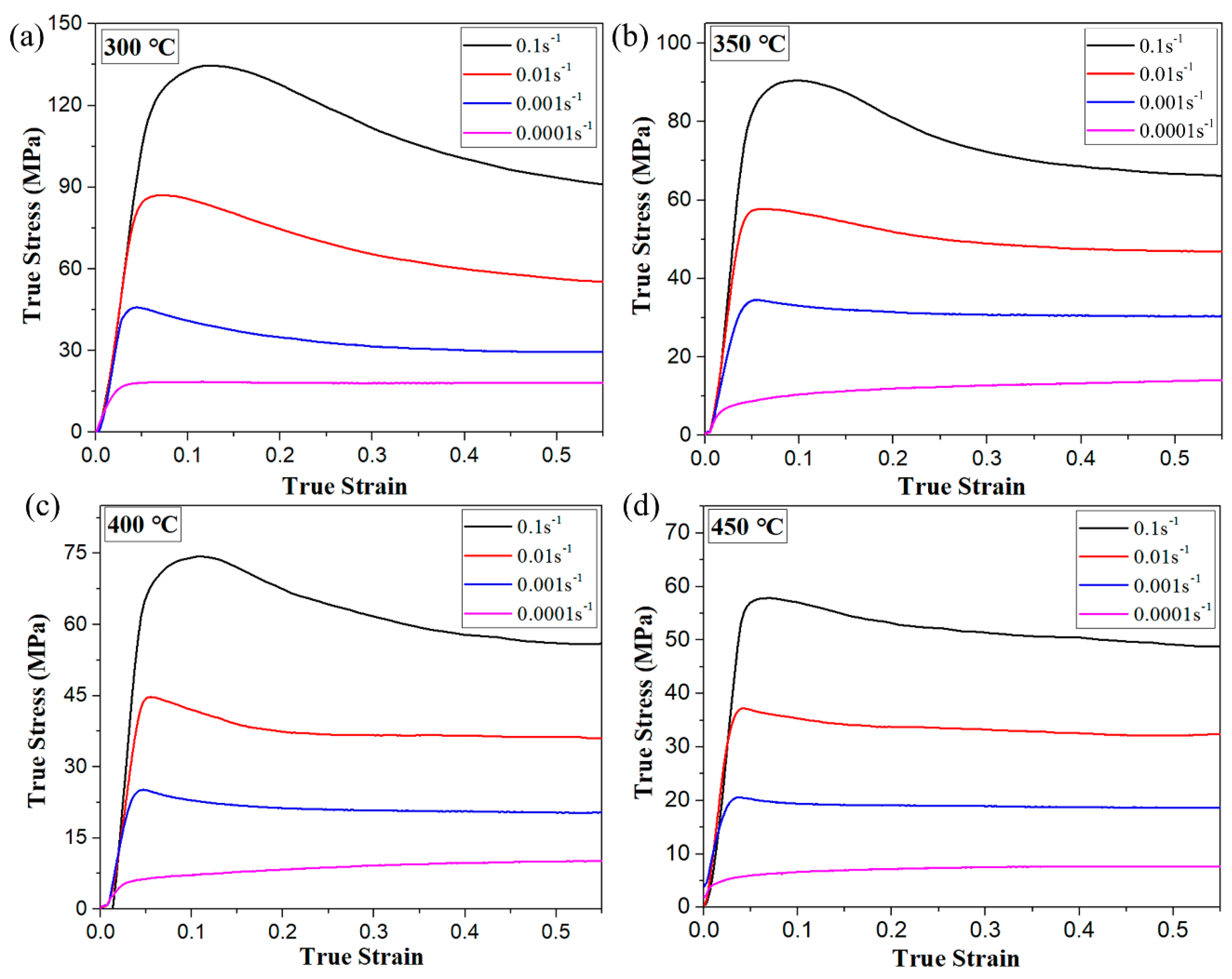

3.2. Flow Stress–Strain Curve Analysis

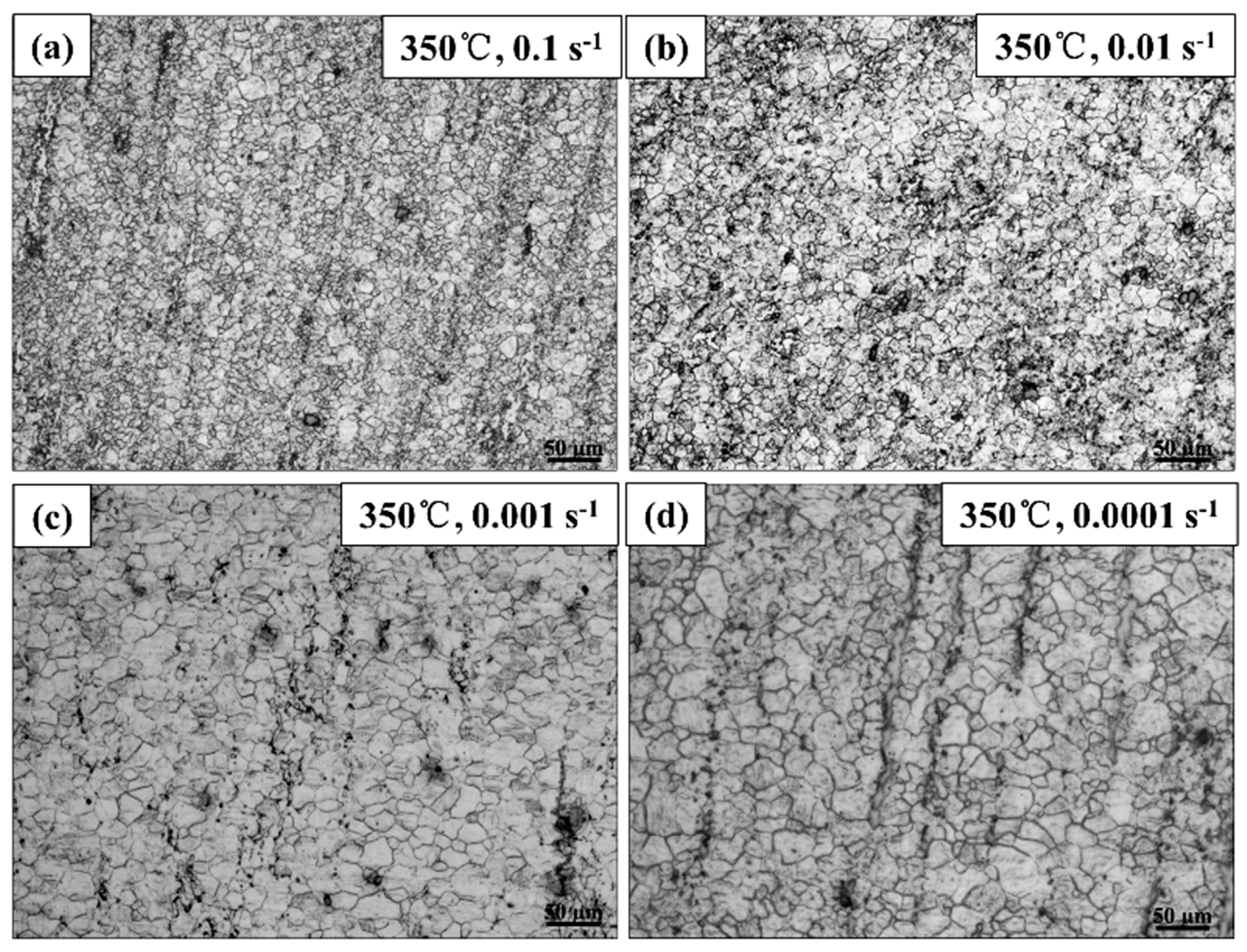

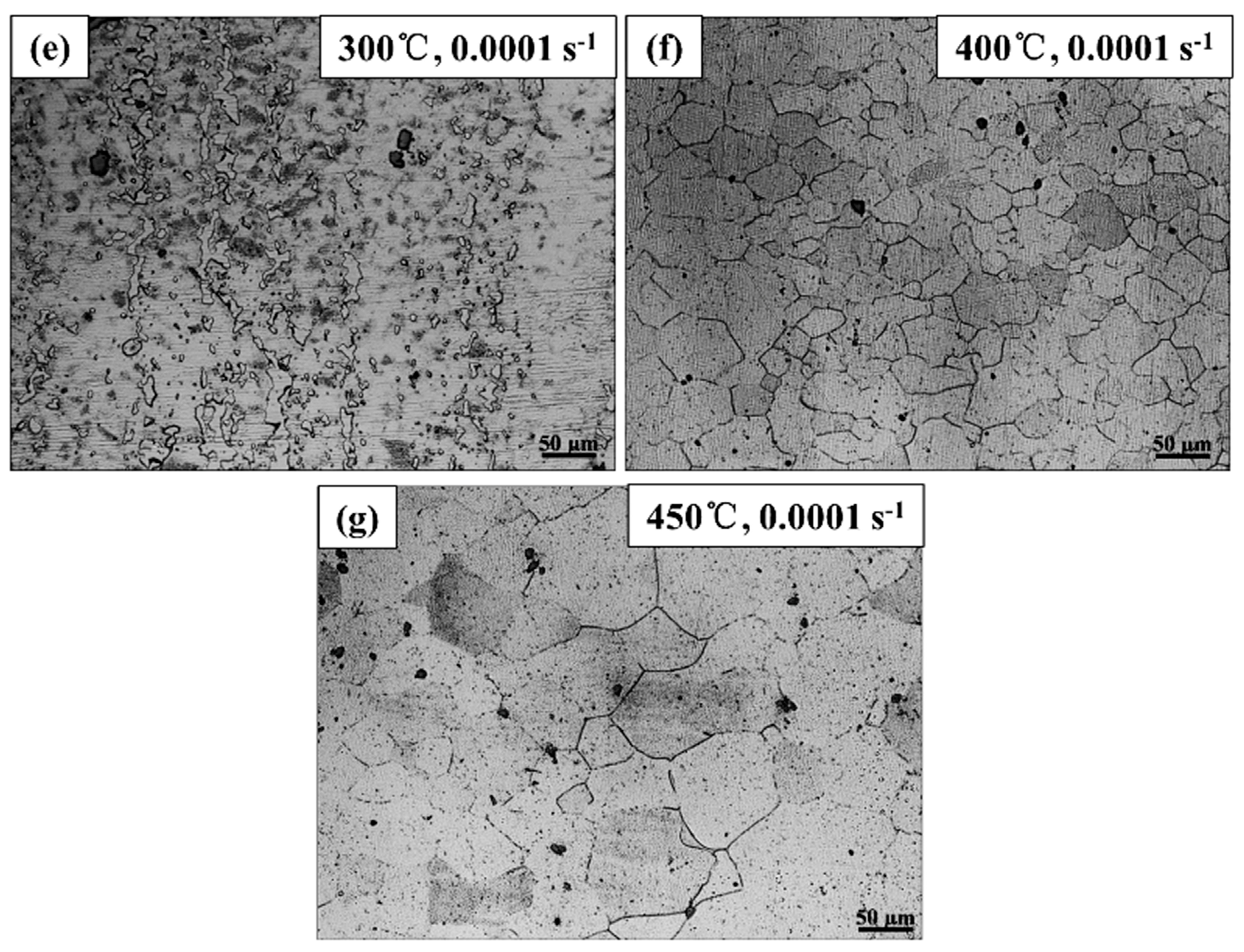

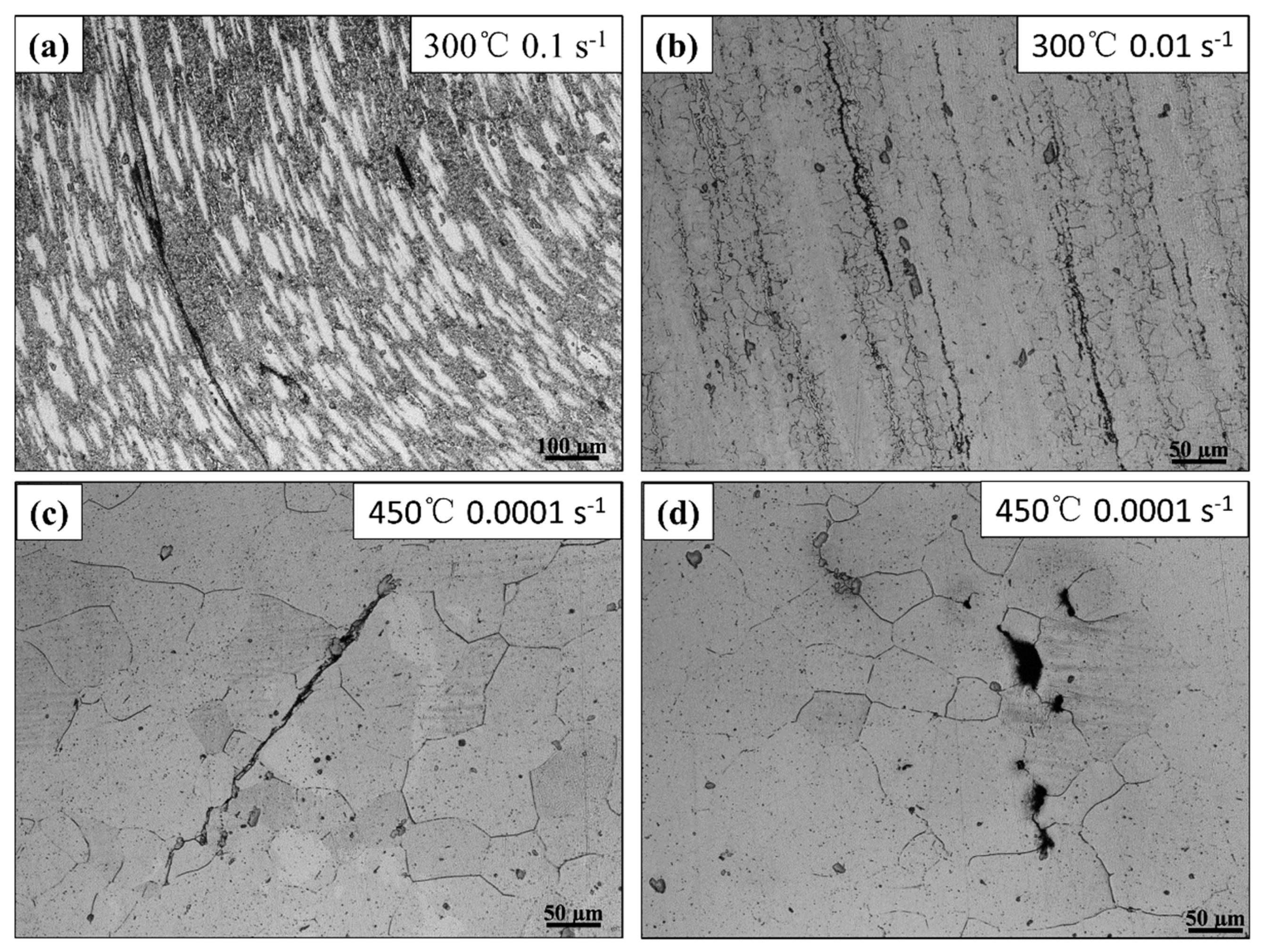

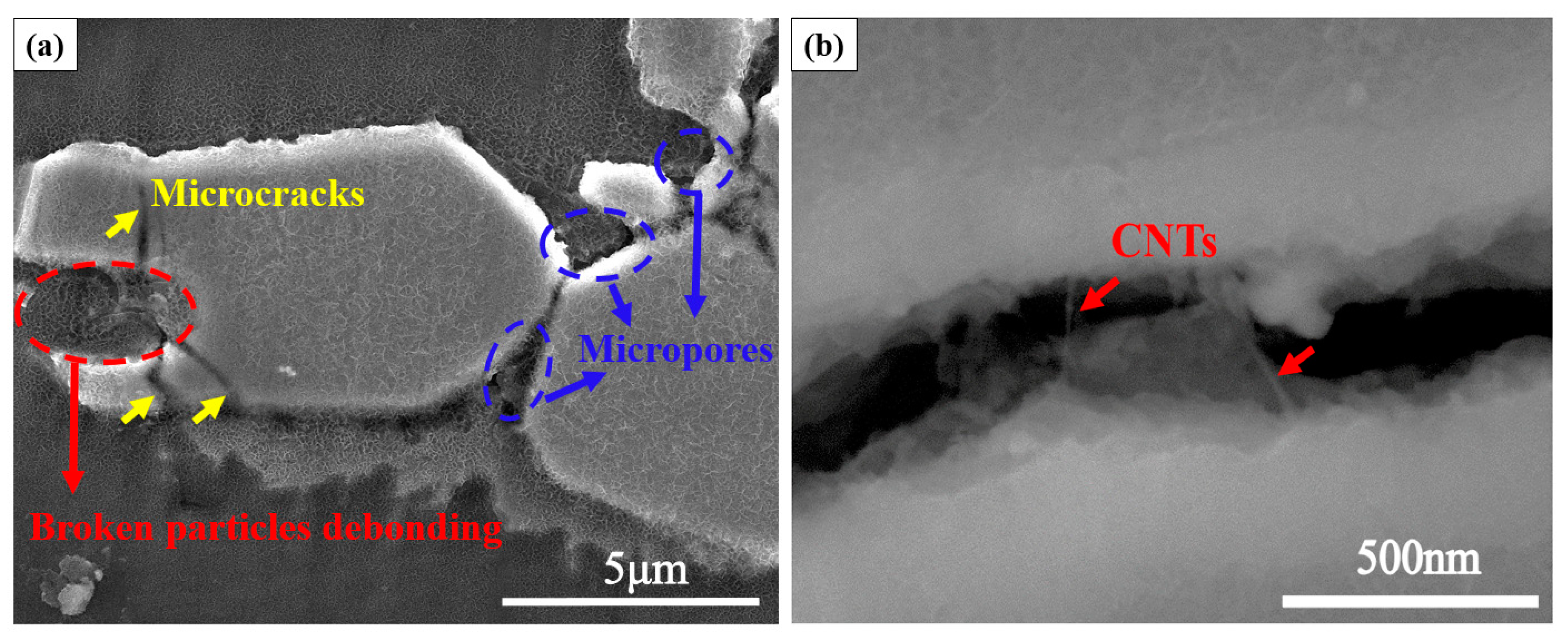

3.3. Deformation Microstructure Analysis

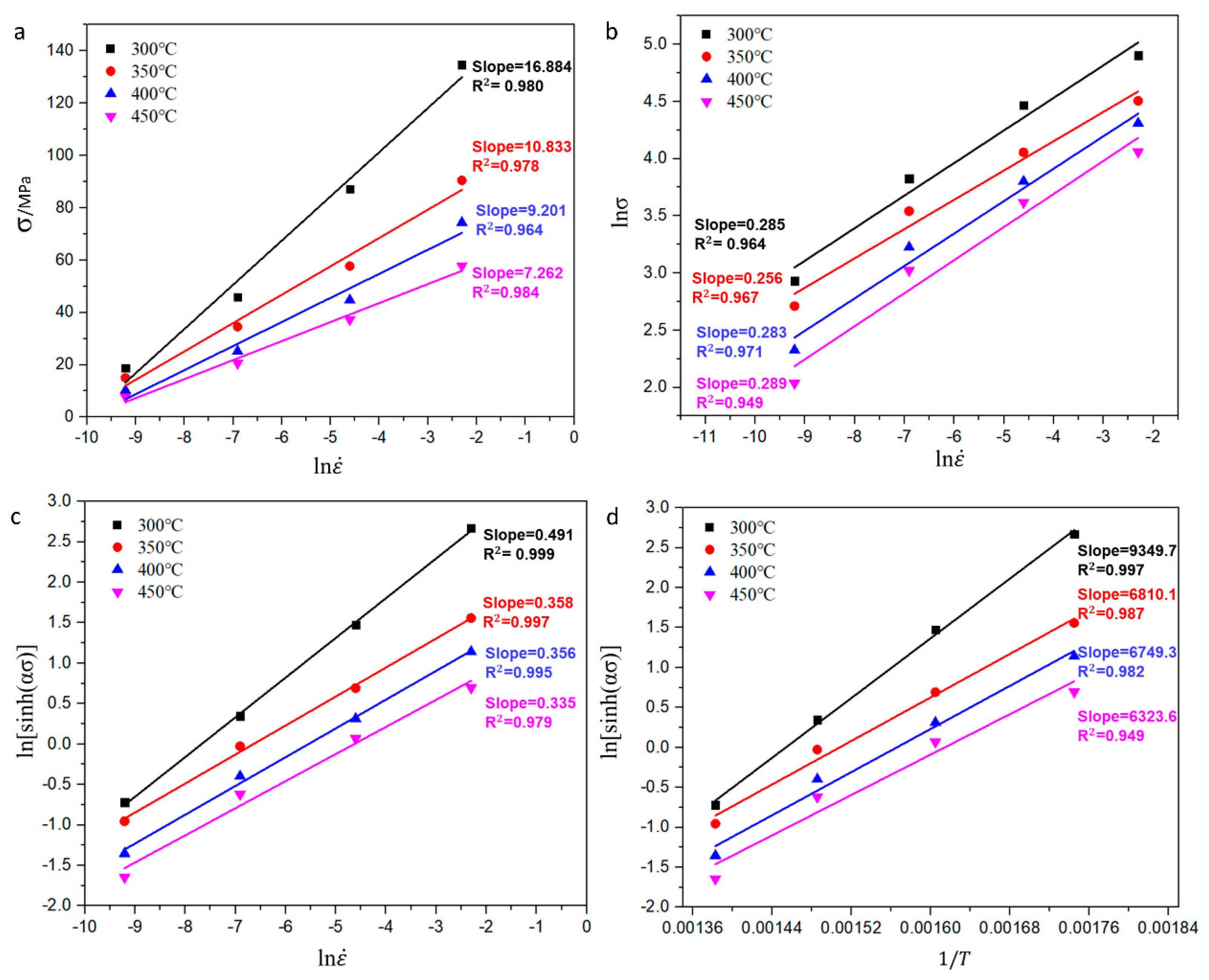

3.4. Constitutive Modeling

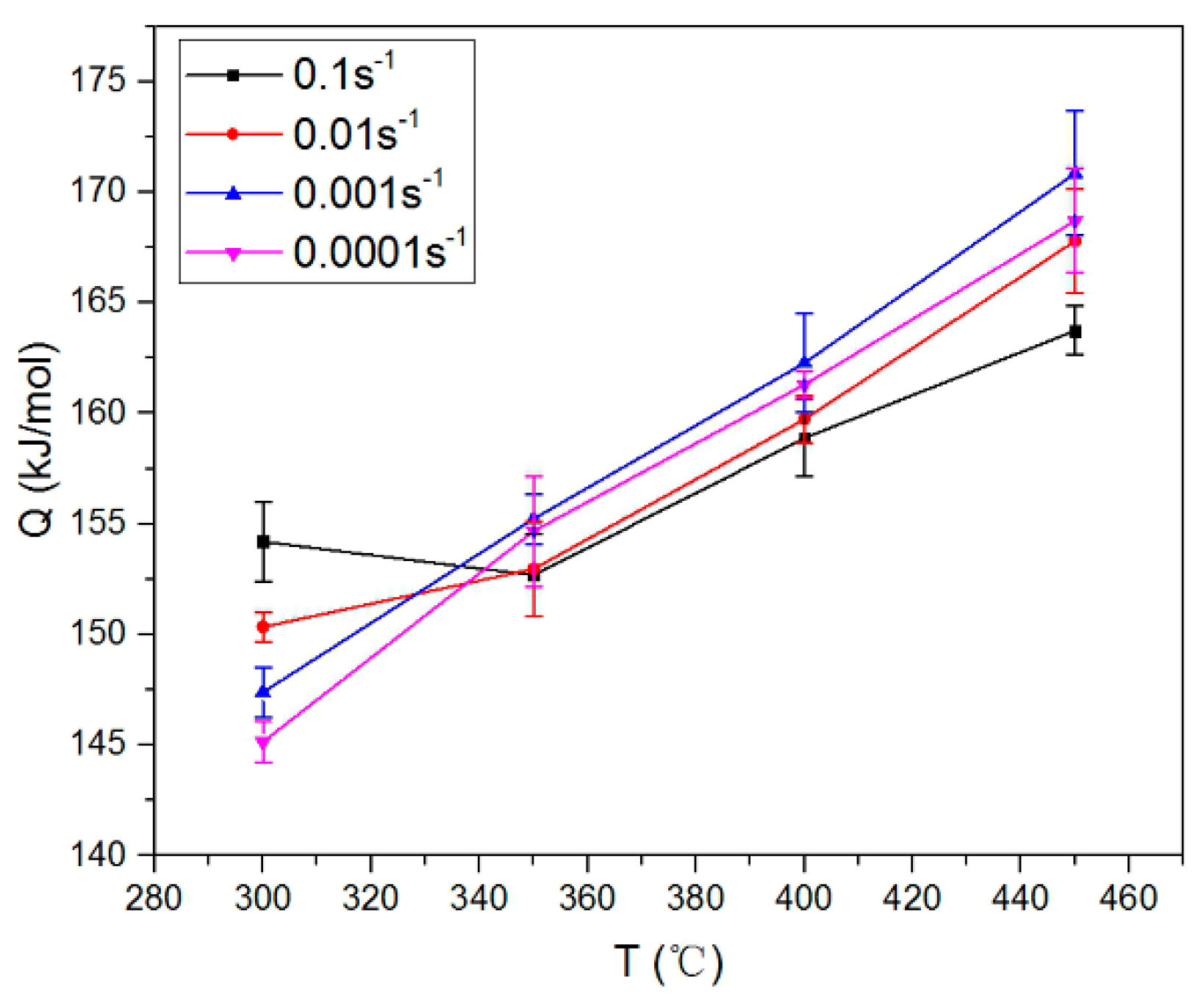

3.5. Hot Deformation Activation Energy

3.5.1. Effect of Adding Reinforcement on Activation Energy

3.5.2. Influence of Hot Deformation Conditions on Activation Energy

3.5.3. Microstructural Analysis of Instability

4. Conclusions

- (1)

- Deformation temperature and strain rate had significant influence on the flow stress of the nanocomposite. The true stress of the composite rapidly improved with the rise of the true strain in the initial period of deformation; once true stress reached peak stress, it presented a trend of slow decline before gradually stabilizing at strain rates of 0.001–1 s−1. When the composite was hot compressed at strain rates of 0.0001 s−1, true stress first increased and then directly presented a stable state due to no peak stress existing. In addition, the flow stress of the nanocomposite improved with the reduction of deformation temperature and the increase of strain rate.

- (2)

- The constitutive equation of the nanocomposite could be described by a sine-hyperbolic Arrhenius equation, which can be expressed as:

- (3)

- The activation energy of the nanohybrid/AZ80 composite was estimated in this study as 157.8 KJ/mol, which is higher than that for unreinforced extruded AZ80 alloys. The high Q value of the composite was mainly attributed to the addition of nano-reinforcements, which acted as barriers to effectively restrict dislocation motion.

- (4)

- Under the deformation conditions of low temperature with high strain rate (300 °C, 0.1–0.01 s−1) and high temperature with low strain rate (450 °C, 0.0001 s−1), it was easy for the phenomenon of local instability to occur at the compression specimen of the nanohybrid/AZ80 composite.

Author Contributions

Funding

Conflicts of Interest

References

- Fan, L.; Zhou, M.; Zhang, Y.; Tang, Q.; Quan, G.; Liu, B. The semi-solid microstructural evolution and coarsening kinetics of AZ80-0.2Y-0.15Ca magnesium alloy. Mater. Charact. 2019, 154, 116–126. [Google Scholar] [CrossRef]

- Cai, Z.; Chen, F.; Ma, F.; Guo, J. Dynamic recrystallization behavior and hot workability of AZ41M magnesium alloy during hot deformation. J. Alloys Compd. 2016, 670, 55–63. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, M.; Lu, T.; Fan, L.; Guo, Y.; Zhang, Y.; Boehlert, C.J.; Quan, G. Eutectic phase strengthening and strain rate sensitivity behavior of AZ80 magnesium alloy. Mater. Sci. Eng. A 2020, 770. [Google Scholar] [CrossRef]

- Matin, A.; Saniee, F.F.; Abedi, H.R. Microstructure and mechanical properties of Mg/SiC and AZ80/SiC nano-composites fabricated through stir casting method. Mater. Sci. Eng. A 2015, 625, 81–88. [Google Scholar] [CrossRef]

- Parizi, M.T.; Ebrahimi, G.R.; Ezatpour, H.R.; Paidar, M. The structure effect of carbonaceous reinforcement on the microstructural characterization and mechanical behavior of AZ80 magnesium alloy. J. Alloys Compd. 2019, 809, 151682. [Google Scholar] [CrossRef]

- Parizi, M.T.; Habibolahzadeh, A.; Ebrahimi, G.R. Microstructure evaluations and mechanical properties of rheo-cast AZ80/Ca/Al2O3 nanocomposite after extrusion process. Mater. Sci. Eng. A 2017, 693, 33–41. [Google Scholar] [CrossRef]

- Deng, K.-K.; Li, J.-C.; Xu, F.-J.; Nie, K.-B.; Liang, W. Hot deformation behavior and processing maps of fine-grained SiCp/AZ91 composite. Mater. Des. 2015, 67, 72–81. [Google Scholar] [CrossRef]

- Mulyadi, M.; Rist, M.; Edwards, L.; Brooks, J. Parameter optimization in constitutive equations for hot forging. J. Mater. Process. Technol. 2006, 177, 311–314. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Li, Q.; Shu, G.; Tang, G. Hot deformation behavior and microstructural evolution of particulate-reinforced AA6061/B4C composite during compression at elevated temperature. Mater. Sci. Eng. A 2017, 696, 248–256. [Google Scholar] [CrossRef]

- Zhou, S.S.; Deng, K.K.; Li, J.C.; Nie, K.B.; Xu, F.J.; Zhou, H.F.; Fan, J.F. Hot deformation behavior and workability characteristics of bimodal size SiCp/AZ91 magnesium matrix composite with processing map. Mater. Des. 2014, 64, 177–184. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Liu, G.; Guo, W.; Jiang, H.; Ding, W. Effect of SiC particles and the particulate size on the hot deformation and processing map of AZ91 magnesium matrix composites. Mater. Sci. Eng. A 2017, 707, 315–324. [Google Scholar] [CrossRef]

- Tan, T.X.; Zhang, B.; Liu, K.; Yan, X.; Han, J.; Liu, X.; Yang, W.; Zhou, C.; Yu, Z.; Shao, P.; et al. Microstructure and mechanical property of the 2024Al matrix hybrid composite reinforced with recycled SiCp/2024Al composite particles. J. Alloys Compd. 2020, 815. [Google Scholar] [CrossRef]

- Sahoo, B.N.; Panigrahi, S.K. Deformation behavior and processing map development of AZ91 Mg alloy with and without addition of hybrid in-situ TiC+TiB2 reinforcement. J. Alloys Compd. 2019, 776, 865–882. [Google Scholar] [CrossRef]

- Chen, X.; Fu, D.; Teng, J.; Zhang, H. Hot deformation behavior and mechanism of hybrid aluminum-matrix composites reinforced with micro-SiC and nano-TiB2. J. Alloys Compd. 2018, 753, 566–575. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Liao, W.; Guo, W.; Ye, B.; Li, W.; Jiang, H.; Ding, W. Effects of cyclic extrusion and compression on the microstructure and mechanical properties of AZ91D magnesium composites reinforced by SiC nanoparticles. Mater. Charact. 2017, 126, 17–27. [Google Scholar] [CrossRef]

- Zhang, B.L.; Maclean, M.S.; Baker, T.N. Hot deformation behaviour of aluminium alloy 6061/SiCp MMCs made by powder metallurgy route. Mater. Sci. Technol. 2013, 16, 897–902. [Google Scholar] [CrossRef]

- Saravanan, L.; Senthilvelan, T. Investigations on the hot workability characteristics and deformation mechanisms of aluminium alloy-Al2O3 nanocomposite. Mater. Des. 2015, 79, 6–14. [Google Scholar] [CrossRef]

- Lingbao, R.; Gaofeng, Q.; Boehlert, C.J.; Zhou, M.; Guo, Y.; Fan, L. The Microstructure Evolution and Deformation Behavior of AZ80 during Gradient Increment Cyclic Loading. Metall. Mater. Trans. A 2018, 49, 3692–3702. [Google Scholar]

- Sellars, C.M.; Mctegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Taleghani, M.A.J.; Navas, E.M.R.; Salehi, M.; Torralba, J.M. Hot deformation behaviour and flow stress prediction of 7075 aluminium alloy powder compacts during compression at elevated temperatures. Mater. Sci. Eng. A 2012, 534, 624–631. [Google Scholar] [CrossRef]

- Takuda, H.; Fujimoto, H.; Hatta, N. Modelling on flow stress of Mg-Al-Zn alloys at elevated temperatures. J. Mater. Process. Technol. 1998, 80, 513–516. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–46. [Google Scholar] [CrossRef]

- Chen, X.; Liao, Q.; Niu, Y.; Jia, Y.; Le, Q.; Ning, S.; Hu, C.; Hu, K.; Yu, F. Comparison study of hot deformation behavior and processing map of AZ80 magnesium alloy casted with and without ultrasonic vibration. J. Alloys Compd. 2019, 803, 585–596. [Google Scholar] [CrossRef]

- Su, Z.; Wan, L.; Sun, C.; Cai, Y.; Yang, D. Hot deformation behavior of AZ80 magnesium alloy towards optimization of its hot workability. Mater. Charact. 2016, 122, 90–97. [Google Scholar] [CrossRef]

- Lou, Y.; Li, L.; Zhou, J.; Na, L. Deformation behavior of Mg–8Al magnesium alloy compressed at medium and high temperatures. Mater. Charact. 2011, 62, 346–353. [Google Scholar] [CrossRef]

- Vagarali, S.S.; Langdon, T.G. Deformation mechanisms in h.c.p. metals at elevated temperatures—II. Creep behavior of a Mg-0.8% Al solid solution alloy. Acta Metall. 1982, 30, 1157–1170. [Google Scholar] [CrossRef]

- Kaya, A.; Pekgüleryüz, M.; Eliezer, D. 2-High temperature deformation, alloys and processing of magnesium. In The Deformation and Processing of Structural Materials; Guo, Z., Ed.; Woodhead Publishing: Cambridge, UK, 2005; pp. 29–75. [Google Scholar]

- Zheng, H.; Li, Z.; Chen, M.; You, C.; Liu, D. The effect of nano β-TCP on hot compression deformation behavior and microstructure evolution of the biomedical Mg-Zn-Zr alloy. Mater. Sci. Eng. A 2018, 715. [Google Scholar] [CrossRef]

- Mokdad, F.; Chen, D.L.; Liu, Z.Y. Hot deformation and activation energy of a CNT-reinforced aluminum matrix nanocomposite. Mater. Sci. Eng. A 2017, 695, 322–331. [Google Scholar] [CrossRef]

- Zhou, M.; Su, X.; Ren, L.; Yin, D.; Quan, G.; Zhang, Y. Tensile Deformation Behavior of As-extruded Mg-3Al-3Zn-1Ti-0.6RE Magnesium Alloy at Elevated Temperature. Rare Metal Mater. Eng. 2017, 46, 2149–2155. [Google Scholar]

- Wang, C.; Liu, Y.; Lin, T.; Luo, T.; Zhao, Y.; Hou, H.; Yang, Y. Hot compression deformation behavior of Mg-5Zn-3.5Sn-1Mn-0.5Ca-0.5Cu alloy. Mater. Charact. 2019, 157, 109896. [Google Scholar] [CrossRef]

- Fatmi, M.; Djemli, A.; Ouali, A.; Chihi, T.; Ghebouli, M.A.; Belhouchet, H. Heat treatment and kinetics of precipitation of β-Mg17Al12 phase in AZ91 alloy. Results Phys. 2018, 10, 693–698. [Google Scholar] [CrossRef]

- Patel, A.; Das, S.; Prasad, B. Compressive deformation behaviour of Al alloy (2014)–10wt.% SiCp composite: Effects of strain rates and temperatures. Mater. Sci. Eng. A 2011, 530, 225–232. [Google Scholar] [CrossRef]

- Yang, H.; Gao, T.; Liu, G.; Zhao, X.; Chen, H.; Wang, H.; Nie, J.; Liu, X. Simultaneously improving strength and ductility for Al–Cu–Mg alloy via threadiness array of TiC nanoparticles. Materialia 2019, 6. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Bolouri, A.; Kang, C. Correlation between solid fraction and tensile properties of semisolid RAP processed aluminum alloys. J. Alloys Compd. 2012, 516, 192–200. [Google Scholar] [CrossRef]

| Parameter | Q/KJmol−1 | α/Mpa−1 | n | A/s−1 |

|---|---|---|---|---|

| Value | 157.8 | 0.025 | 2.597 | 1.110 × 1010 |

| Strain Rate/s−1 | Q/(kJ·mol−1) | |||

|---|---|---|---|---|

| 300 °C | 350 °C | 400 °C | 450 °C | |

| 0.0001 | 145.143 ± 1.659 | 154.674 ± 3.484 | 158.873 ± 4.212 | 163.740 ± 3.517 |

| 0.001 | 147.389 ± 2.611 | 155.224 ± 1.605 | 159.724 ± 3.373 | 167.789 ± 0.890 |

| 0.01 | 150.347 ± 2.761 | 152.971 ± 3.229 | 162.278 ± 1.691 | 170.850 ± 3.740 |

| 0.1 | 154.193 ± 2.688 | 152.678 ± 1.007 | 161.299 ± 1.702 | 168.702 ± 1.379 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Fan, L.; Zhou, M.; Zhou, Y.; Jiang, K.; Chen, Y. Hot Compression Deformation and Activation Energy of Nanohybrid-Reinforced AZ80 Magnesium Matrix Composite. Metals 2020, 10, 119. https://doi.org/10.3390/met10010119

Li H, Fan L, Zhou M, Zhou Y, Jiang K, Chen Y. Hot Compression Deformation and Activation Energy of Nanohybrid-Reinforced AZ80 Magnesium Matrix Composite. Metals. 2020; 10(1):119. https://doi.org/10.3390/met10010119

Chicago/Turabian StyleLi, Houyi, Lingling Fan, Mingyang Zhou, Youlong Zhou, Kuan Jiang, and Yong Chen. 2020. "Hot Compression Deformation and Activation Energy of Nanohybrid-Reinforced AZ80 Magnesium Matrix Composite" Metals 10, no. 1: 119. https://doi.org/10.3390/met10010119

APA StyleLi, H., Fan, L., Zhou, M., Zhou, Y., Jiang, K., & Chen, Y. (2020). Hot Compression Deformation and Activation Energy of Nanohybrid-Reinforced AZ80 Magnesium Matrix Composite. Metals, 10(1), 119. https://doi.org/10.3390/met10010119