A New Electron Backscatter Diffraction-Based Method to Study the Role of Crystallographic Orientation in Ductile Damage Initiation †

Abstract

1. Introduction

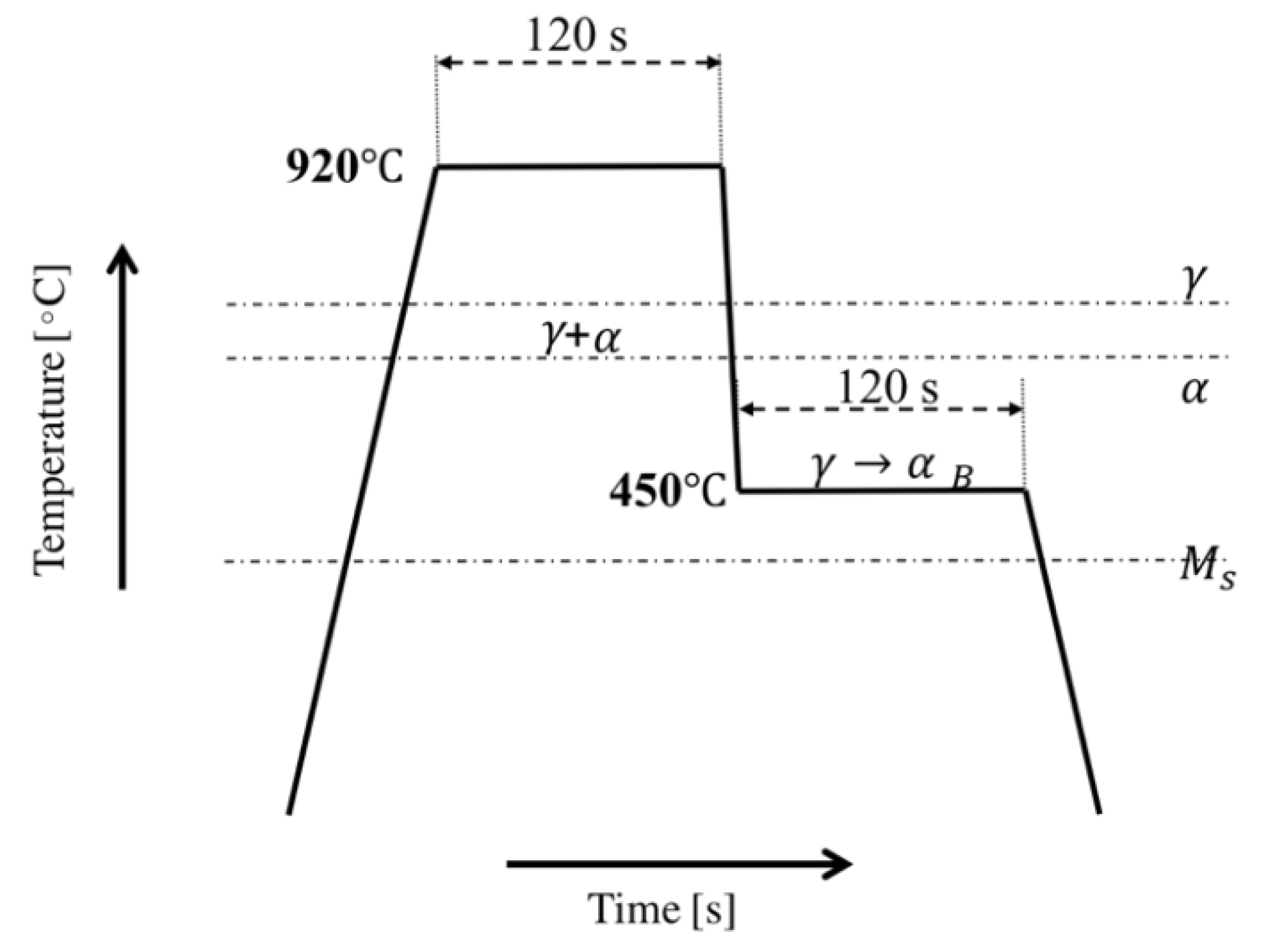

2. Materials and Methods

3. Results and Discussion

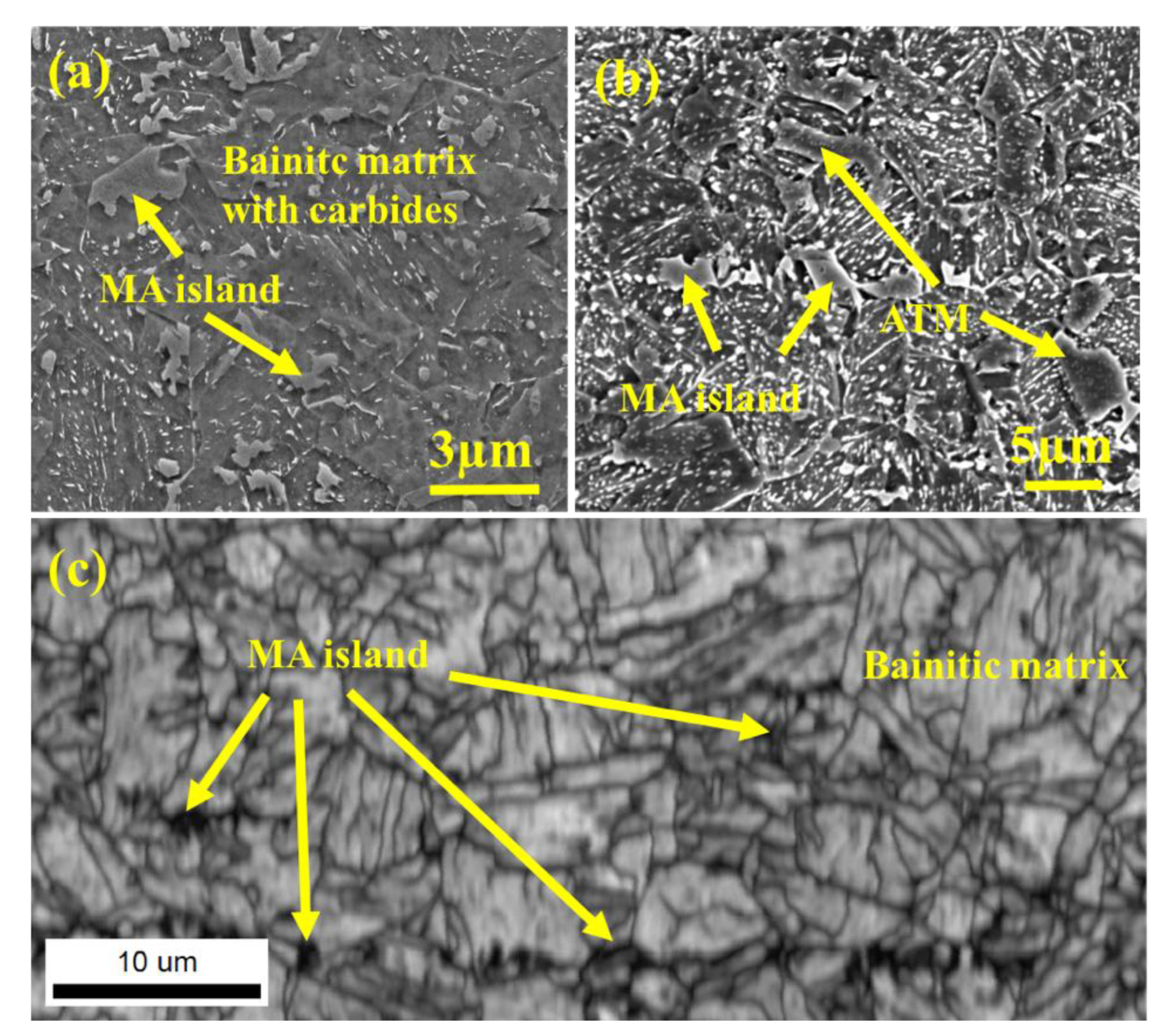

3.1. Microstructure Characterization

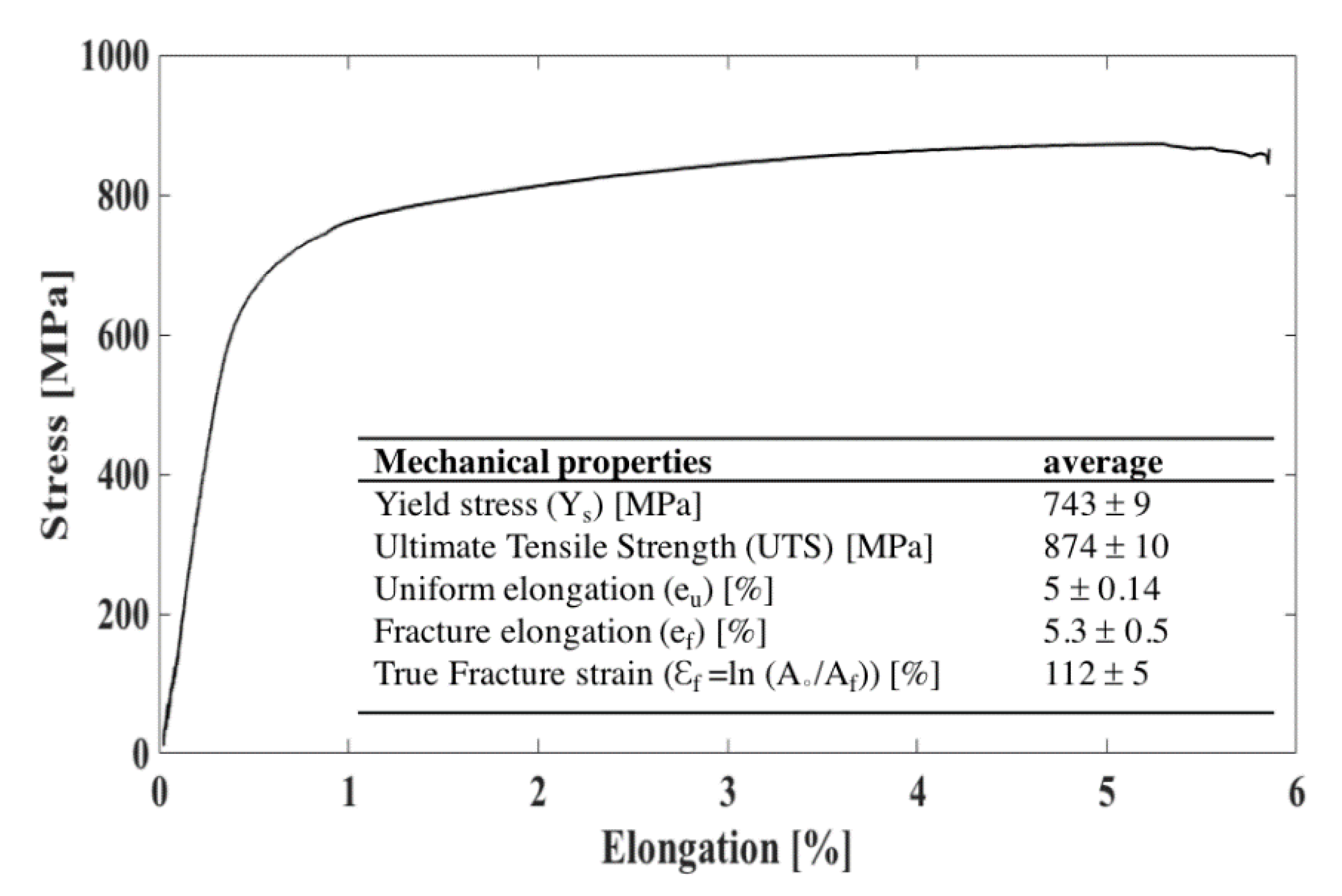

3.2. Tensile Test

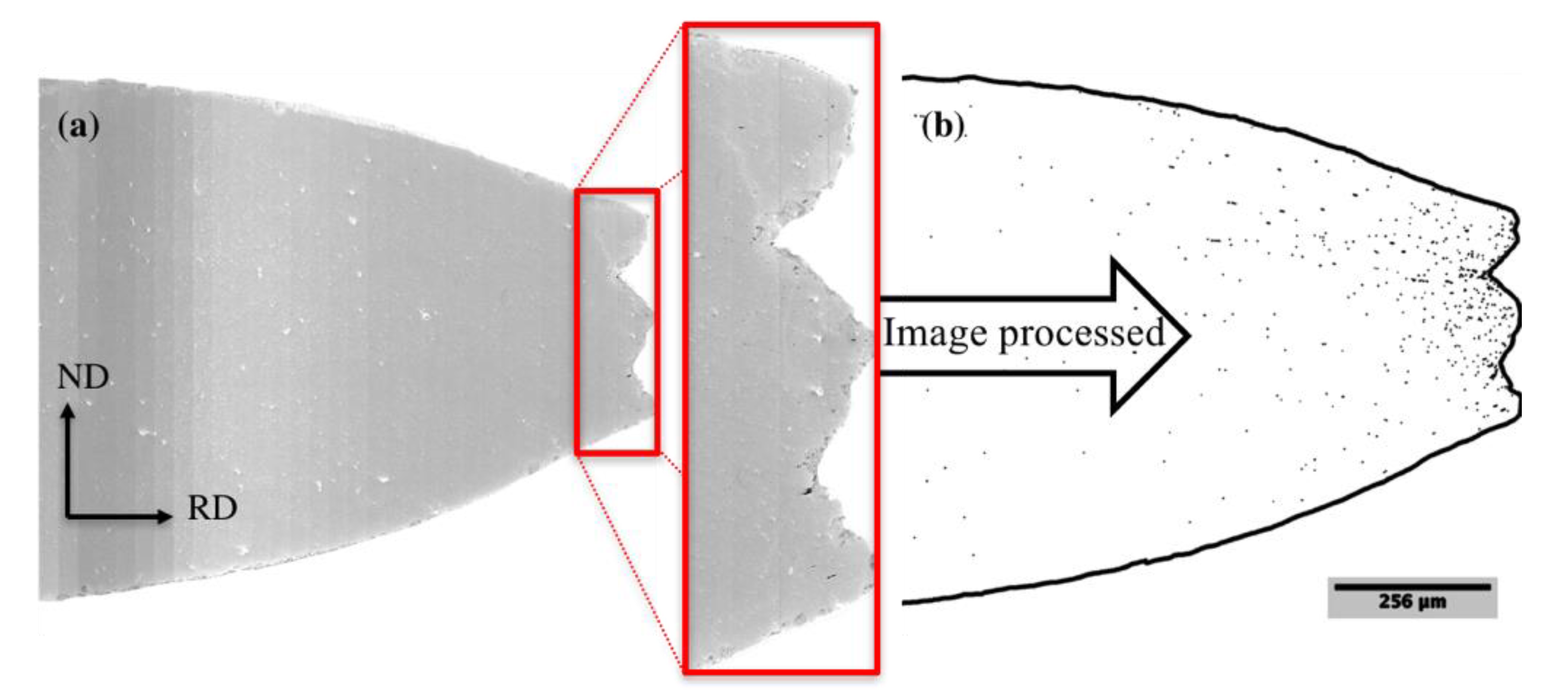

3.3. Damage Analysis

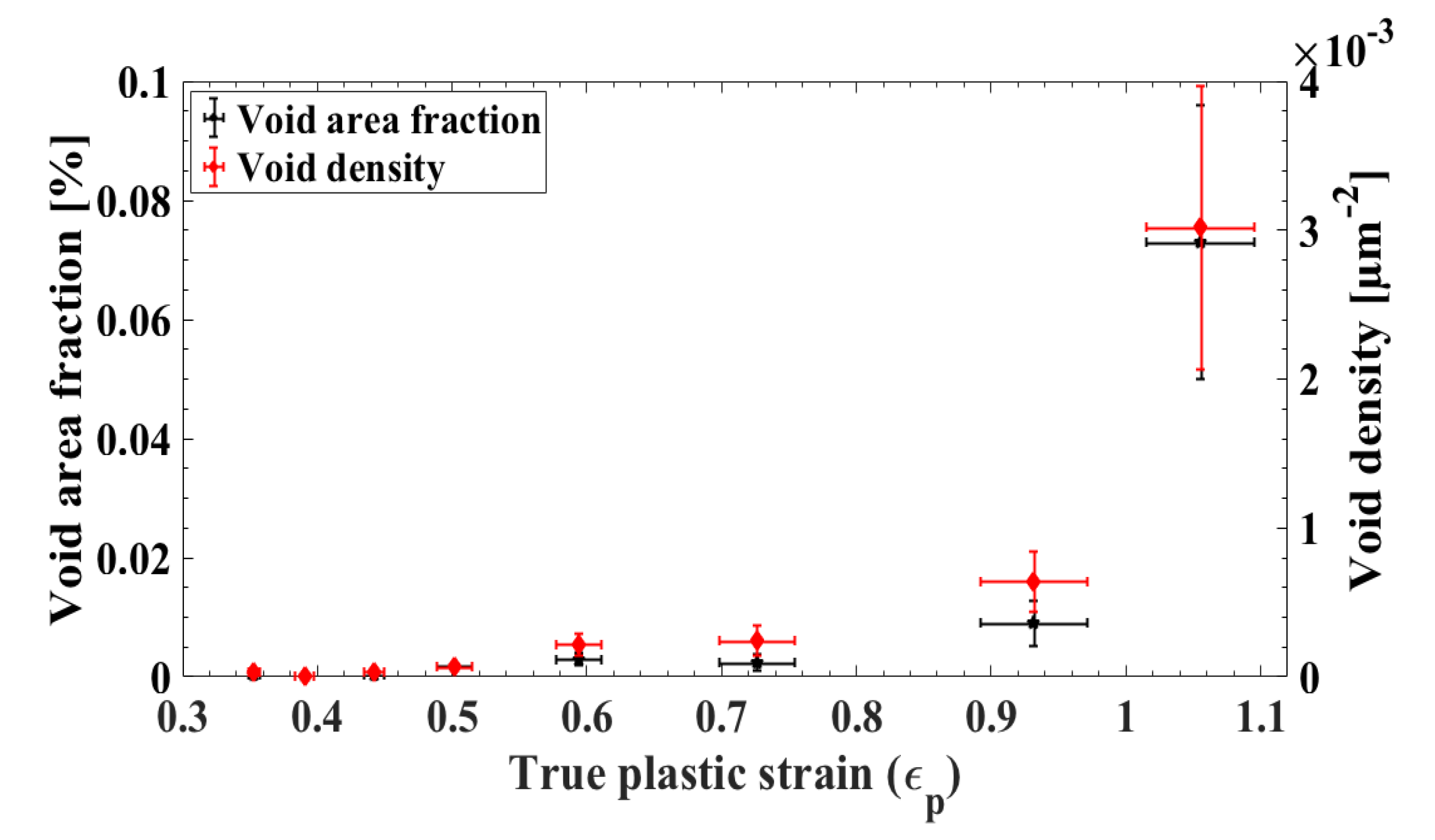

3.3.1. Quantitative Analysis of Voids’ Evolution

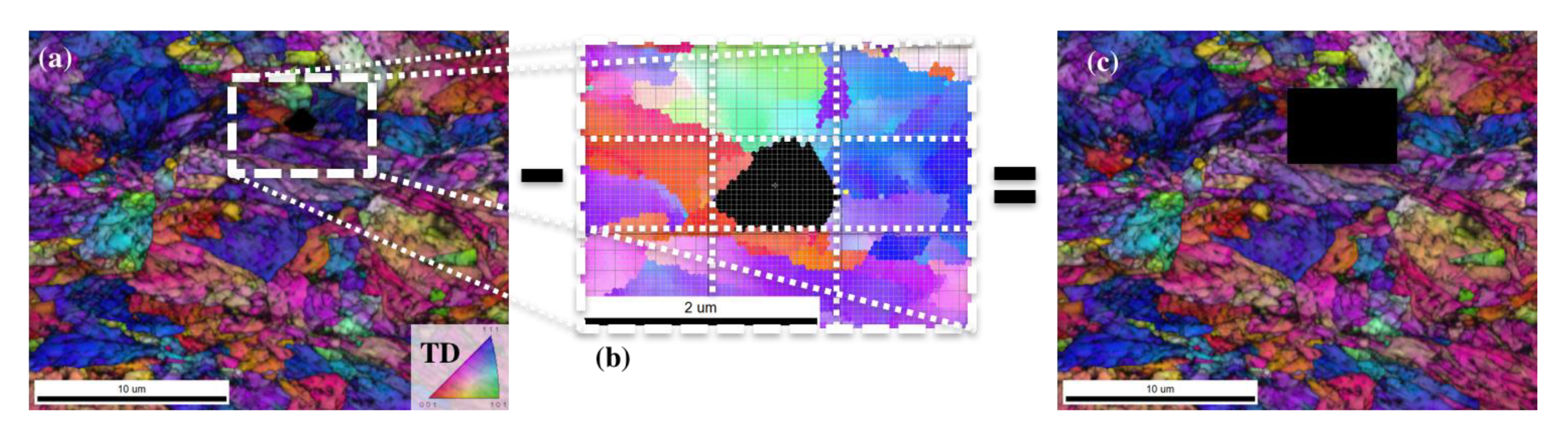

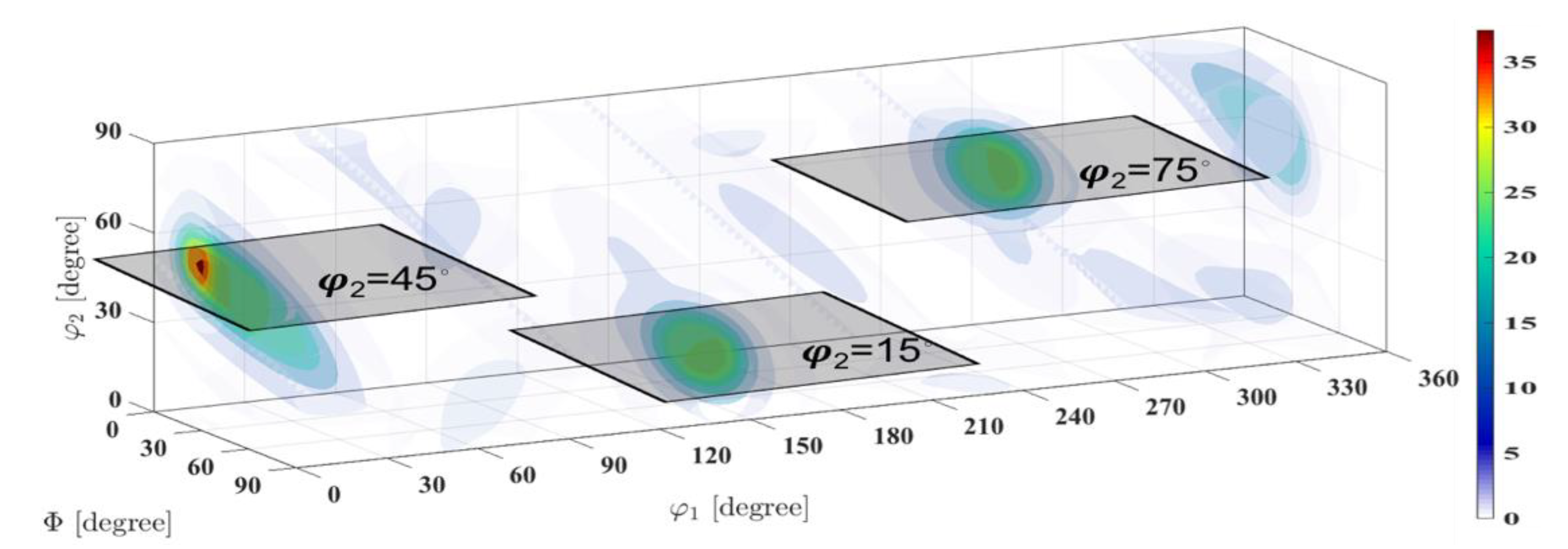

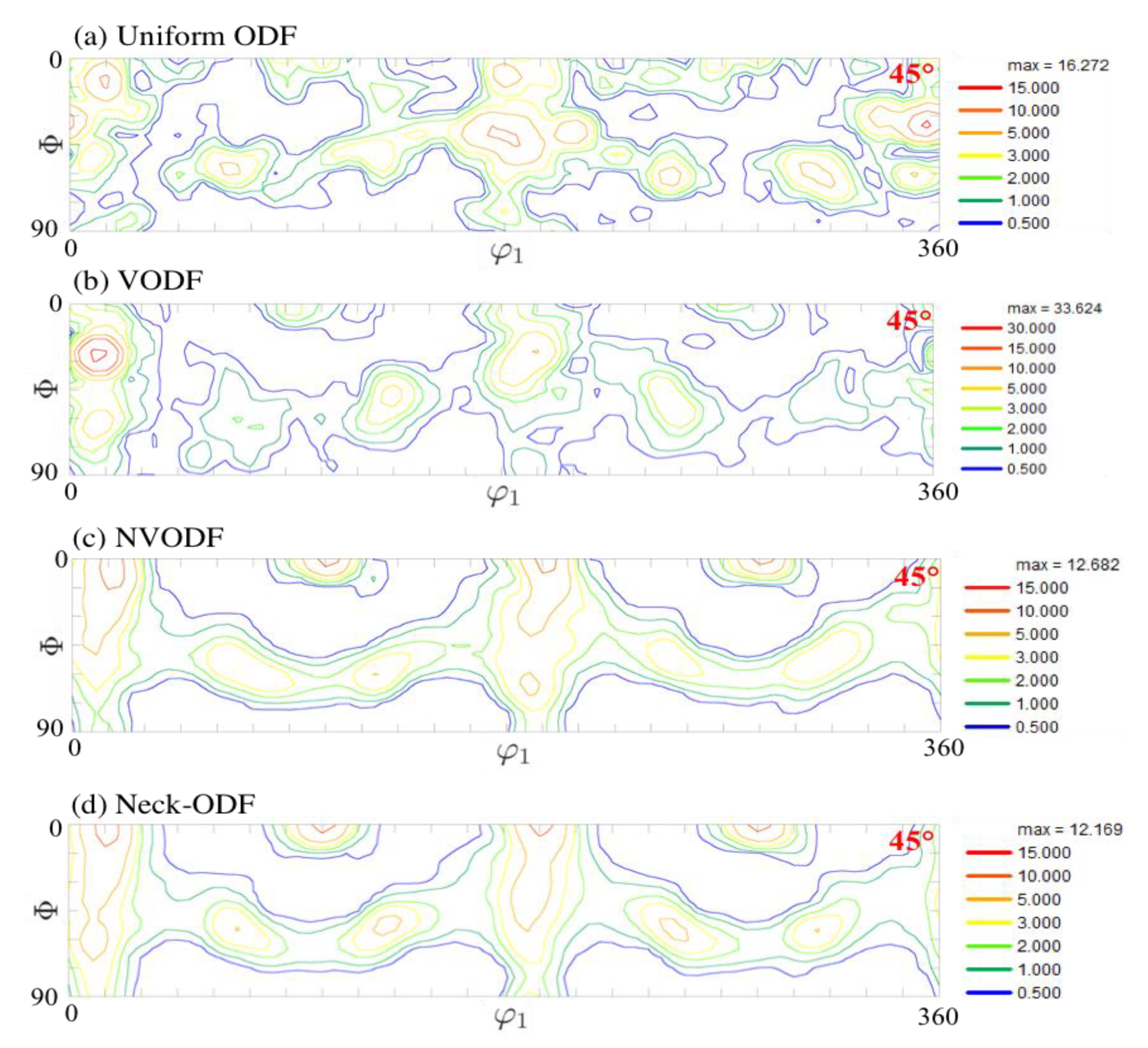

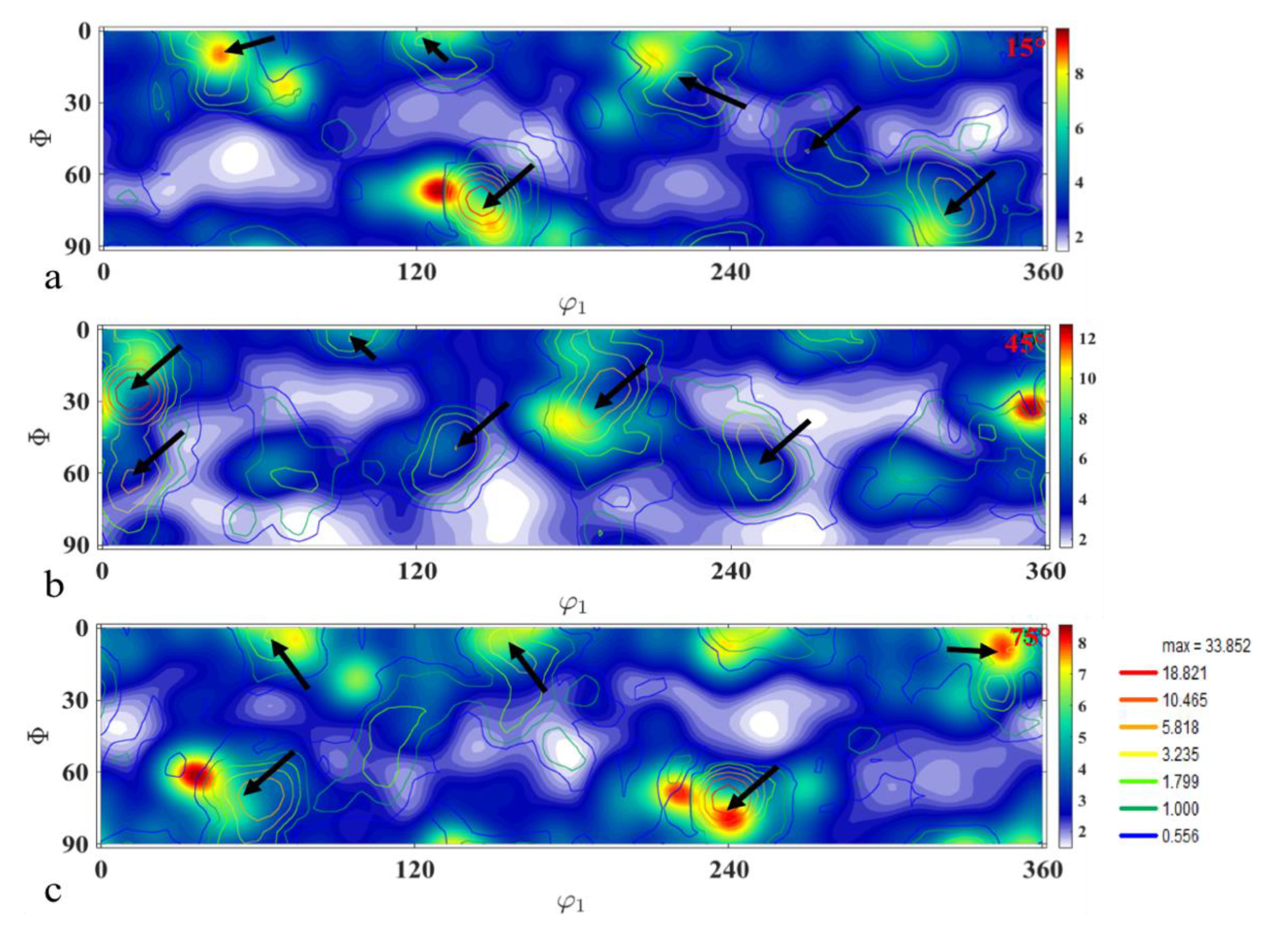

3.3.2. Crystallographic Orientation Aspect of Void Initiation

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matlock, D.; Speer, J.G.; de Moor, E.; Gibbs, P.J. Recent developments in Advanced High Strength Sheet Steels for automotive applications—An Overview. JESTECH 2012, 15, 1–12. [Google Scholar]

- Bouaziz, O.; Zurob, H.; Huang, M. Driving force and logic of development of advanced high strength steels for automotive applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Caballero, F.G.; Allain, S.; Cornide, J.; Velásquez, J.D.P.; Garcia-Mateo, C.; Miller, M.K. Design of cold rolled and continuous annealed carbide-free bainitic steels for automotive application. Mater. Des. 2013, 49, 667–680. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Design of novel high-strength bainitic steels. Thermec. Mater. Sci. Forum 2003, 426–432, 1337–1342. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 1. Mater. Sci. Technol.-Lond. 2001, 17, 512–516. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 2. Mater. Sci. Technol.-Lond. 2001, 17, 517–522. [Google Scholar] [CrossRef]

- Caballero, F.G.; Garcia-Mateo, C.; Chao, J.; Santofimia, M.J.; Capdevila, C.; de Andres, C.G. Effects of morphology and stability of retained austenite on the ductility of TRIP-aided bainitic steels. ISIJ Int. 2008, 48, 1256–1262. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, K.; Guo, Z.; Chen, N.; Rong, Y. A new effect of retained austenite on ductility enhancement in high strength bainitic steel. Mater. Sci. Eng. A-Struct. 2012, 552, 288–294. [Google Scholar] [CrossRef]

- Shakerifard, B.; Lopez, J.G.; Legaza, M.C.T.; Verleysen, P.; Kestens, L.A.I. Strain rate dependent dynamic mechanical response of bainitic multiphase steels. Mater. Sci. Eng. A-Struct. 2019, 745, 279–290. [Google Scholar] [CrossRef]

- Ahmad, E.; Manzoor, T.; Ali, K.L.; Akhter, J.I. Effect of microvoid formation on the tensile properties of dual-phase steel. J. Mater. Eng. Perform. 2000, 9, 306–310. [Google Scholar] [CrossRef]

- Avramovic-Cingara, G.; Ososkov, Y.; Jain, M.K.; Wilkinson, D.S. Effect of martensite distribution on damage behaviour in DP600 dual phase steels. Mater. Sci. Eng. A-Struct. 2009, 516, 7–16. [Google Scholar] [CrossRef]

- He, X.J.; Terao, N.; Berghezan, A. Influence of Martensite Morphology and Its Dispersion on Mechanical-Properties and Fracture Mechanisms of Fe-Mn-C Dual Phase Steels. Meter. Sci. 1984, 18, 367–373. [Google Scholar] [CrossRef]

- Steinbrunner, D.L.; Matlock, D.K.; Krauss, G. Void Formation during Tensile Testing of Dual Phase Steels. Metall. Trans. A 1988, 19, 579–589. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Zambaldi, C.; Shanthraj, P.; Roters, F.; Raabe, D. Integrated experimental-simulation analysis of stress and strain partitioning in multiphase alloys. Acta Mater. 2014, 81, 386–400. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Diehl, M.; Yan, D.; Roters, F.; Raabe, D. Strain localization and damage in dual phase steels investigated by coupled in-situ deformation experiments and crystal plasticity simulations. Int. J. Plast. 2014, 63, 198–210. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Geers, M.G.D. Identification of the continuum damage parameter: An experimental challenge in modeling damage evolution. Acta Mater. 2012, 60, 3581–3589. [Google Scholar] [CrossRef]

- Yan, D.S.; Tasan, C.C.; Raabe, D. High resolution in situ mapping of microstrain and microstructure evolution reveals damage resistance criteria in dual phase steels. Acta Mater. 2015, 96, 399–409. [Google Scholar] [CrossRef]

- Shakerifard, B.; Lopez, J.G.; Hisker, F.; Kestens, L.A.I. Effect of banding on micro-mechanisms of damage initiation in bainitic/martensitic steels. Mater. Sci. Eng. A-Struct. 2018, 735, 324–335. [Google Scholar] [CrossRef]

- Jia, N.; Peng, R.L.; Wang, Y.D.; Chai, G.C.; Johansson, S.; Wang, G.; Liaw, P.K. Interactions between the phase stress and the grain-orientation-dependent stress in duplex stainless steel during deformation. Acta Mater. 2006, 54, 3907–3916. [Google Scholar] [CrossRef]

- Needleman, A.; Tvergaard, V. Comparison of Crystal Plasticity and Isotropic Hardening Predictions for Metal-Matrix Composites. J. Appl. Mech. Trans. ASME 1993, 60, 70–76. [Google Scholar] [CrossRef]

- Nugent, E.E.; Calhoun, R.B.; Mortensen, A. Experimental investigation of stress and strain fields in a ductile matrix surrounding an elastic inclusion. Acta Mater. 2000, 48, 1451–1467. [Google Scholar] [CrossRef][Green Version]

- Li, R.G.; Xie, Q.G.; Wang, Y.D.; Liu, W.J.; Wang, M.G.; Wu, G.L.; Li, X.W.; Zhang, M.H.; Lu, Z.P.; Geng, C.; et al. Unraveling submicron-scale mechanical heterogeneity by three-dimensional X-ray microdiffraction. Proc. Natl. Acad. Sci. USA 2018, 115, 483–488. [Google Scholar] [CrossRef] [PubMed]

- de Geus, T.W.J.; Maresca, F.; Peerlings, R.H.J.; Geers, M.G.D. Microscopic plasticity and damage in two-phase steels: On the competing role of crystallography and phase contrast. Mech. Mater. 2016, 101, 147–159. [Google Scholar] [CrossRef]

- Shakerifard, B.; Lopez, J.G.; Hisker, F.; Kestens, L.A.I. Crystallographically resolved damage initiation in advanced high strength steel. In Proceedings of the 18th International Conference on Textures of Materials (Icotom-18), St. George, UT, USA, 6–10 November 2017; Volume 375. [Google Scholar]

- Choi, S.H.; Kim, E.Y.; Woo, W.; Han, S.H.; Kwak, J.H. The effect of crystallographic orientation on the micromechanical deformation and failure behaviors of DP980 steel during uniaxial tension. Int. J. Plast. 2013, 45, 85–102. [Google Scholar] [CrossRef]

- Lai, Q.; Bouaziz, O.; Goune, M.; Brassart, L.; Verdier, M.; Parry, G.; Perlade, A.; Brechet, Y.; Pardoen, T. Damage and fracture of dual-phase steels: Influence of martensite volume fraction. Mater. Sci. Eng. A-Struct. 2015, 646, 322–331. [Google Scholar] [CrossRef]

- Landron, C.; Maire, E.; Adrien, J.; Bouaziz, O.; di Michiel, M.; Cloetens, P.; Suhonen, H. Resolution effect on the study of ductile damage using synchrotron X-ray tomography. Nucl. Instrum. Meth. B 2012, 284, 15–18. [Google Scholar] [CrossRef]

- Landron, C.; Maire, E.; Bouaziz, O.; Adrien, J.; Lecarme, L.; Bareggi, A. Validation of void growth models using X-ray microtomography characterization of damage in dual phase steels. Acta Mater. 2011, 59, 7564–7573. [Google Scholar] [CrossRef]

- Han, S.K.; Margolin, H.; Formation, V. Void Growth and Tensile Fracture of Plain Carbon-Steel and a Dual-Phase Steel. Mater. Sci. Eng. A-Struct. 1989, 112, 133–141. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

| Elements | C% | Mn% | Si% | Cr% | Al% | P% | S% | N% |

|---|---|---|---|---|---|---|---|---|

| Steel | 0.215 | 1.96 | 0.10 | 0.61 | 0.020 | 0.007 | 0.0027 | 0.005 |

| Sample | Phases | Grain Size (μm) | Fraction (%) | Block Size (μm) | Cementite Size (μm) |

|---|---|---|---|---|---|

| Bainitic steel | Bainite | 1.44 ± 0.01 | Bal | - | - |

| MA | - | 3.4 ± 1.7 | 0.7 ± 0.35 | - | |

| Cementite | - | 3.6 ± 1.0 | - | 0.07 ± 0.04 | |

| ATM1 | 0.5 ± 0.1 | 4.8 ± 1.8 | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shakerifard, B.; Galan Lopez, J.; Kestens, L.A.I. A New Electron Backscatter Diffraction-Based Method to Study the Role of Crystallographic Orientation in Ductile Damage Initiation. Metals 2020, 10, 113. https://doi.org/10.3390/met10010113

Shakerifard B, Galan Lopez J, Kestens LAI. A New Electron Backscatter Diffraction-Based Method to Study the Role of Crystallographic Orientation in Ductile Damage Initiation. Metals. 2020; 10(1):113. https://doi.org/10.3390/met10010113

Chicago/Turabian StyleShakerifard, Behnam, Jesus Galan Lopez, and Leo A. I. Kestens. 2020. "A New Electron Backscatter Diffraction-Based Method to Study the Role of Crystallographic Orientation in Ductile Damage Initiation" Metals 10, no. 1: 113. https://doi.org/10.3390/met10010113

APA StyleShakerifard, B., Galan Lopez, J., & Kestens, L. A. I. (2020). A New Electron Backscatter Diffraction-Based Method to Study the Role of Crystallographic Orientation in Ductile Damage Initiation. Metals, 10(1), 113. https://doi.org/10.3390/met10010113