On the Role of a ZDDP in the Tribological Performance of Femtosecond Laser-Induced Periodic Surface Structures on Titanium Alloy against Different Counterbody Materials

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

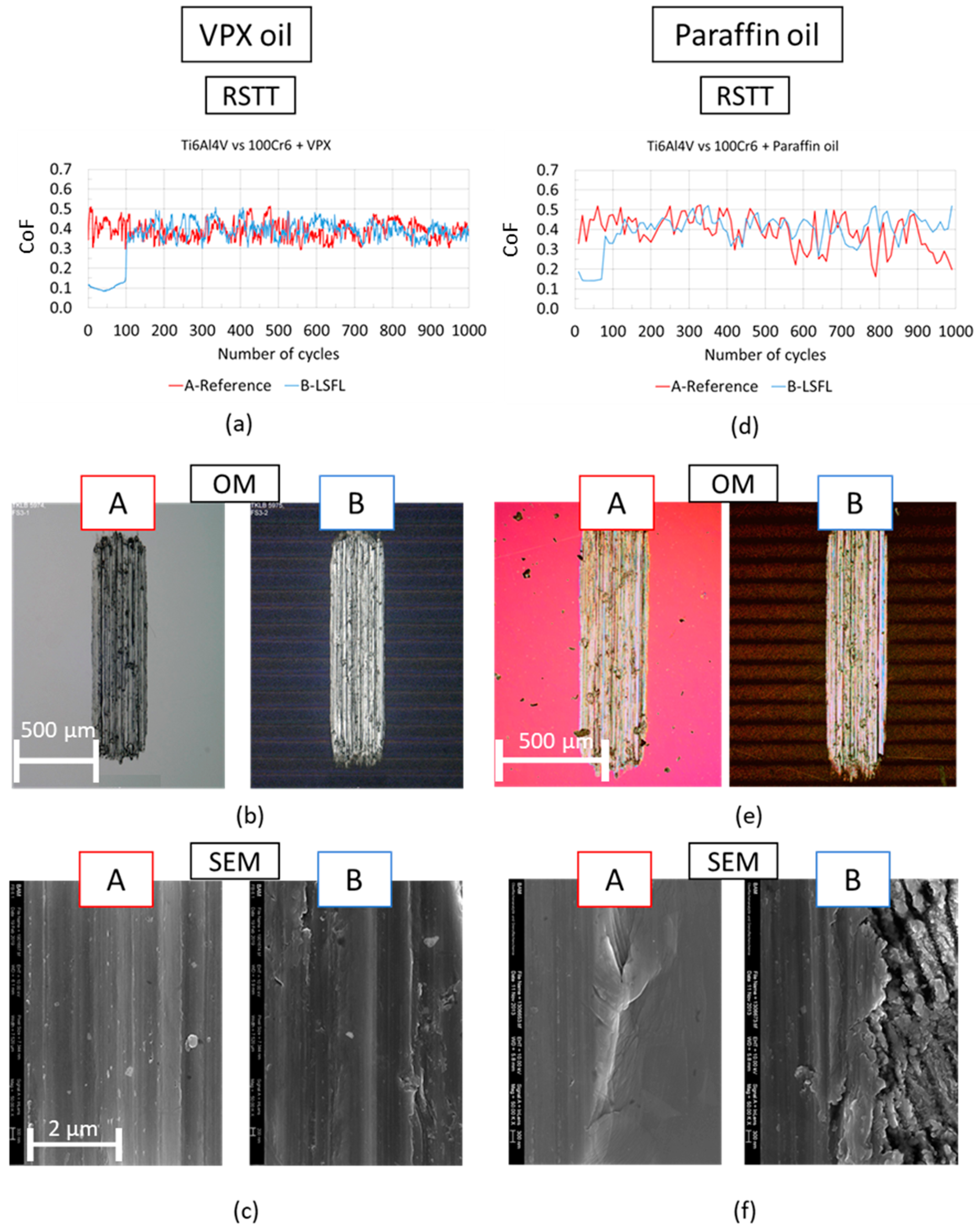

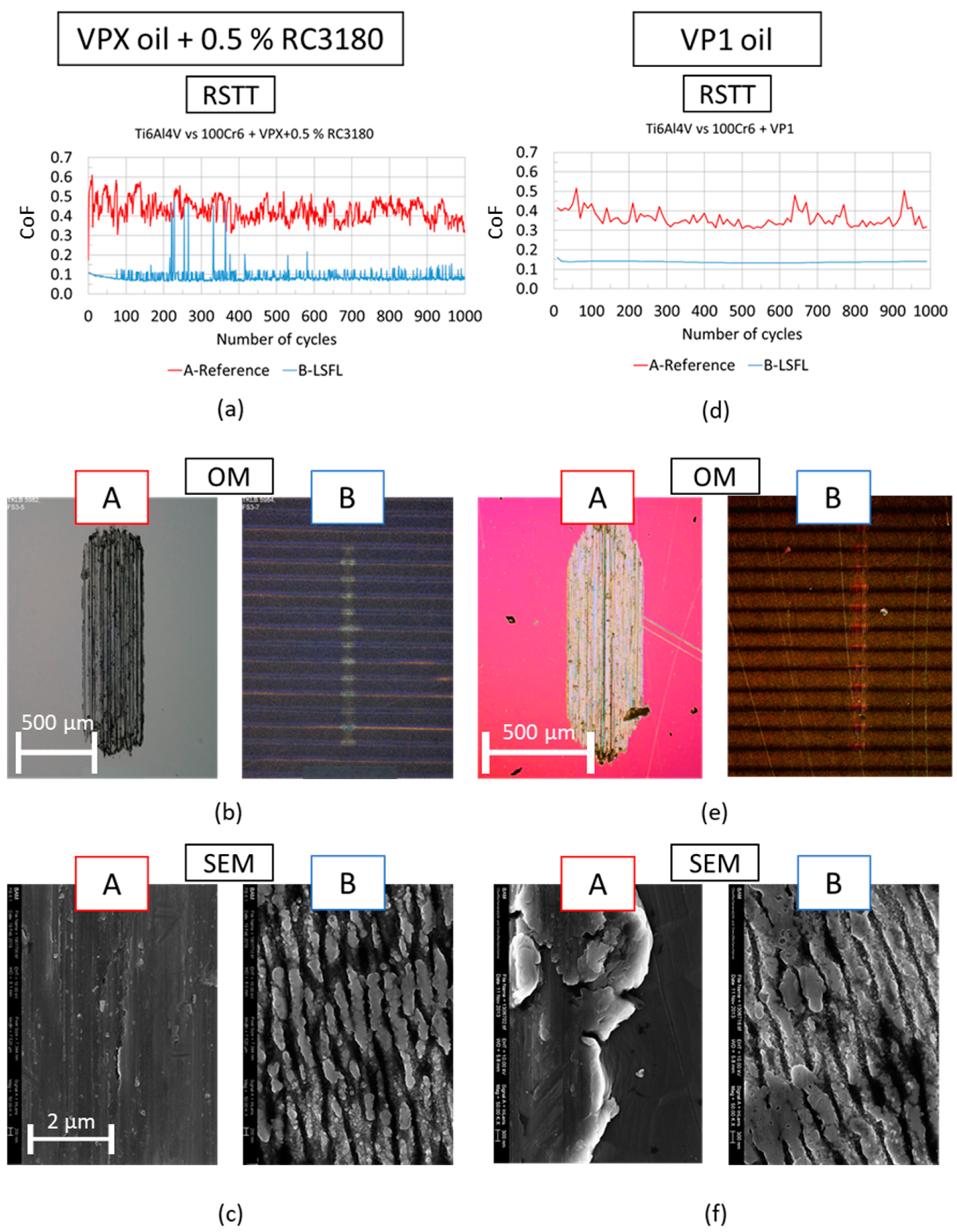

3.1. Reciprocating Sliding Tribological Tests (RSTT) against 100Cr6 in Different Lubricants

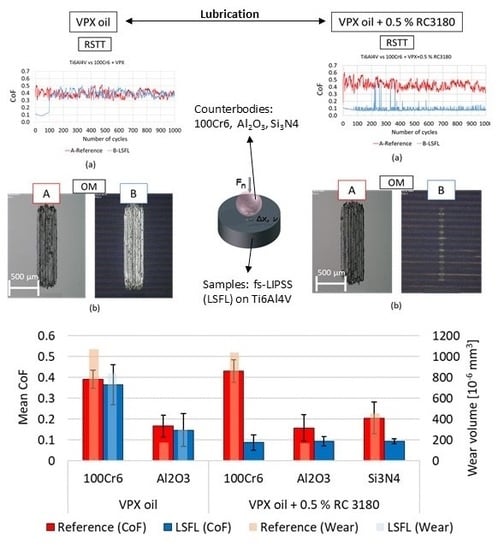

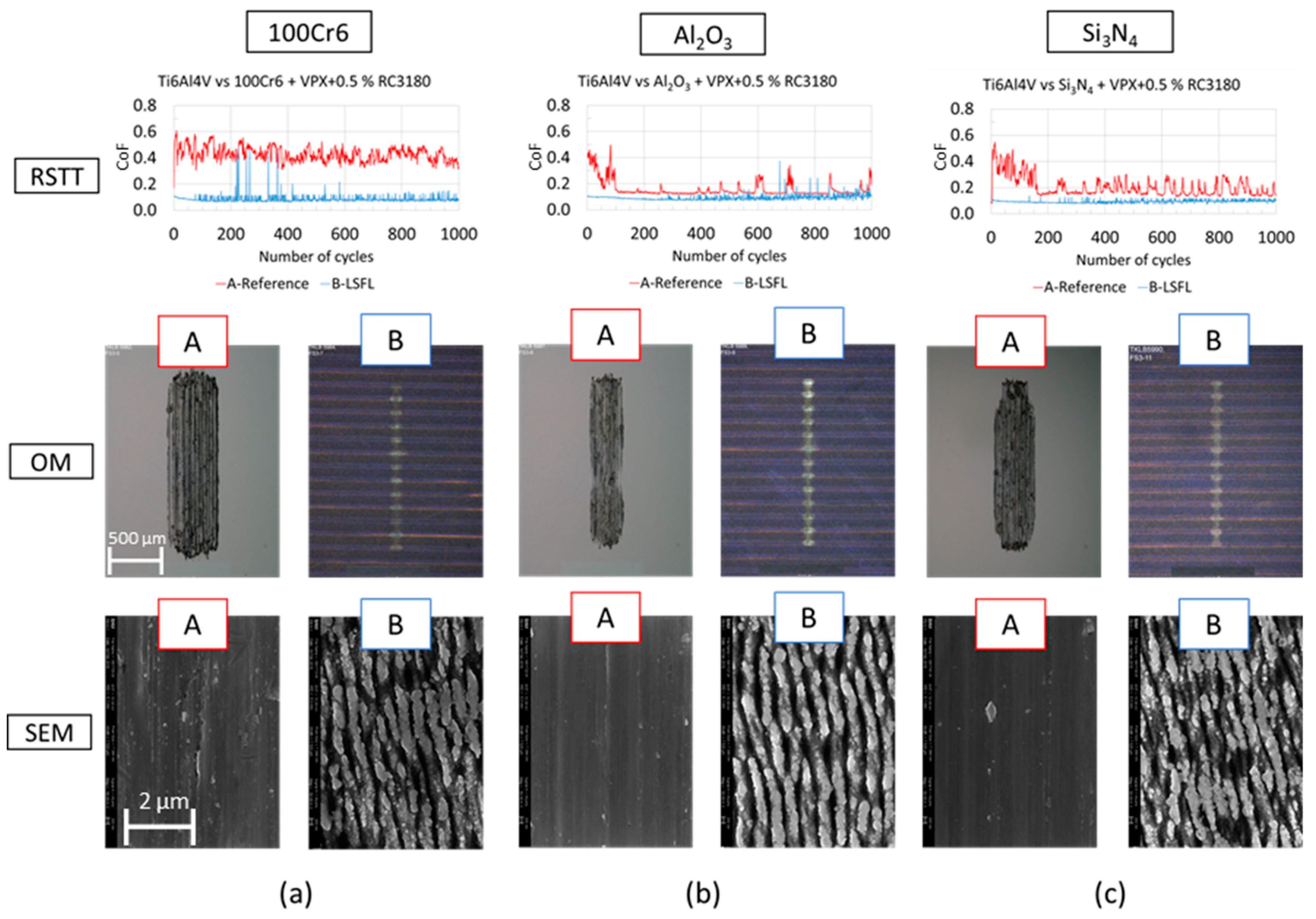

3.2. RSTT against Different Counterbody Materials

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abere, M.; Zhong, M.; Krüger, J.; Bonse, J. Ultrafast laser-induced morphological transformations. MRS Bull. 2016, 41, 969–974. [Google Scholar] [CrossRef]

- Liu, H.; Lin, W.; Hong, M. Surface coloring by laser irradiation of solid substrates. APL Photonics 2019, 4, 051101. [Google Scholar] [CrossRef]

- Kirner, S.V.; Hermens, U.; Mimidis, A.; Skoulas, E.; Florian, C.; Hischen, F.; Plamadeala, C.; Baumgartner, W.; Winands, K.; Mescheder, H.; et al. Mimicking bug-like surface structures and their fluid transport produced by ultrashort laser pulse irradiation of steel. Appl. Phys. A 2017, 123, 754. [Google Scholar] [CrossRef]

- Epperlein, N.; Menzel, F.; Schwibbert, K.; Koter, R.; Bonse, J.; Sameith, J.; Krüger, J.; Toepel, J. Influence of femtosecond laser produced nanostructures on biofilm growth on steel. Appl. Surf. Sci. 2017, 418, 420–424. [Google Scholar] [CrossRef]

- Heitz, J.; Plamadeala, C.; Muck, M.; Armbruster, O.; Baumgartner, W.; Weth, A.; Steinwender, C.; Blessberger, H.; Kellermair, J.; Kirner, S.V.; et al. Femtosecond laser-induced microstructures on Ti substrates for reduced cell adhesion. Appl. Phys. A 2017, 123, 734. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Griepentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond laser texturing of surfaces for tribological applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef] [PubMed]

- Bäuerle, D. Laser Processing and Chemistry, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Bonse, J.; Höhm, S.; Kirner, S.V.; Rosenfeld, A.; Krüger, J. Laser-induced periodic surface structures—A scientific evergreen. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 9000615. [Google Scholar] [CrossRef]

- Bonse, J.; Höhm, S.; Koter, R.; Hartelt, M.; Spaltmann, D.; Pentzien, S.; Rosenfeld, A.; Krüger, J. Tribological performance of sub-100-nm femtosecond laser-induced periodic surface structures on titanium. Appl. Surf. Sci. 2016, 374, 190–196. [Google Scholar] [CrossRef]

- Bonse, J.; Koter, R.; Hartelt, M.; Spaltmann, D.; Pentzien, S.; Höhm, S.; Rosenfeld, A.; Krüger, J. Femtosecond laser-induced periodic surface structures on steel and titanium alloy for tribological applications. Appl. Phys. A 2014, 117, 103–110. [Google Scholar] [CrossRef]

- Bonse, J.; Koter, R.; Hartelt, M.; Spaltmann, D.; Pentzien, S.; Höhm, S.; Rosenfeld, A.; Krüger, J. Tribological performance of femtosecond laser-induced periodic surface structures on titanium and a high toughness bearing steel. Appl. Surf. Sci. 2015, 336, 21–27. [Google Scholar] [CrossRef]

- Nicholls, M.A.; Do, T.; Norton, P.R.; Kasrai, M.; Bancroft, G.M. Review of the lubrication of metallic surfaces by zinc dialkyl-dithiophosphates. Tribol. Int. 2005, 38, 15–39. [Google Scholar] [CrossRef]

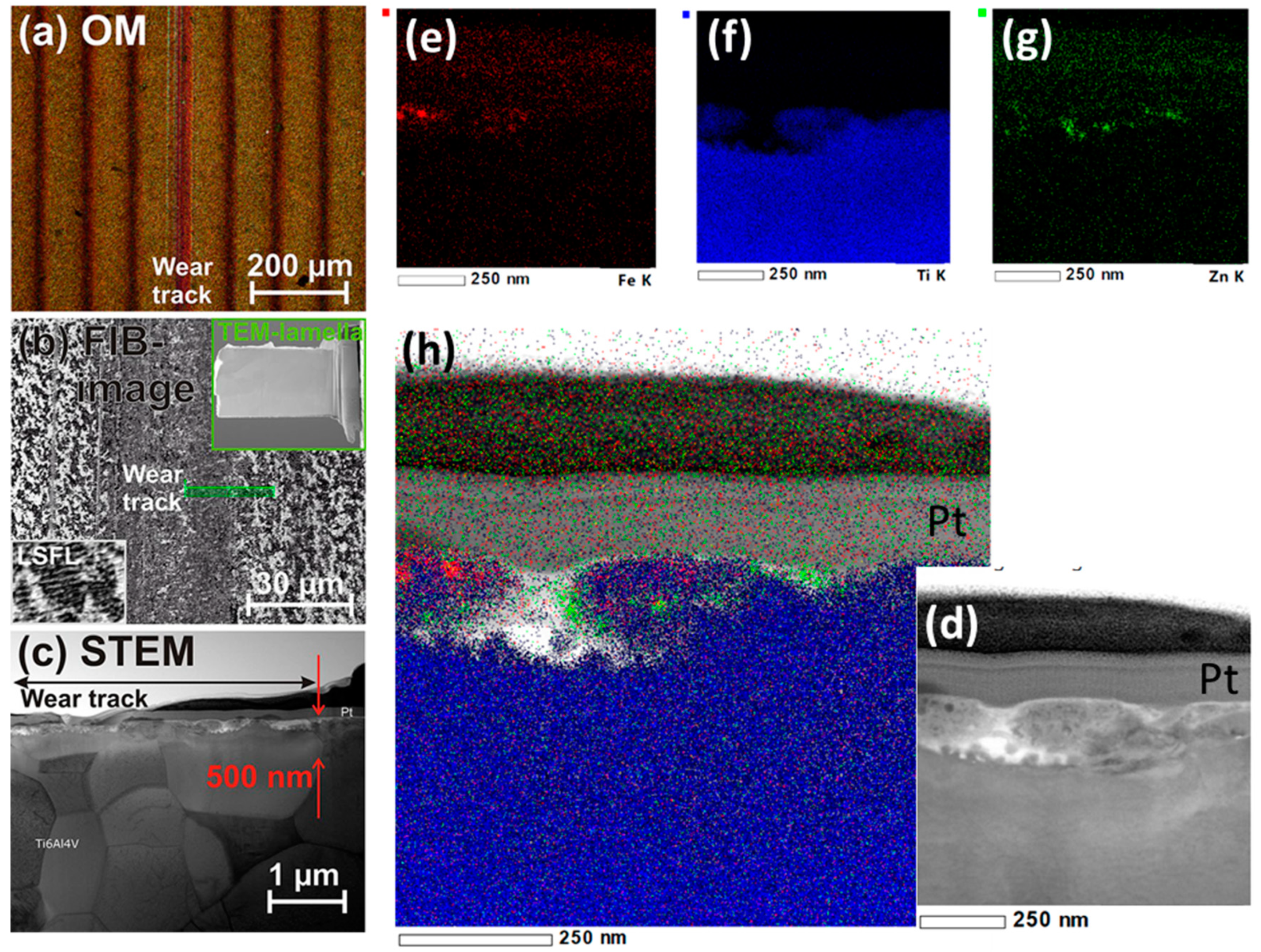

- Kirner, S.V.; Wirth, T.; Sturm, H.; Krüger, J.; Bonse, J. Nanometer-resolved chemical analyses of femtosecond laser-induced periodic surface structures on titanium. J. Appl. Phys. 2017, 122, 104901. [Google Scholar] [CrossRef]

- Kirner, S.V.; Slachciak, N.; Elert, A.M.; Griepentrog, M.; Fischer, D.; Hertwig, A.; Sahre, M.; Dörfel, I.; Sturm, H.; Pentzien, S.; et al. Tribological performance of titanium samples oxidized by fs-laser radiation, thermal heating, or electrochemical anodization. Appl. Phys. A 2018, 124, 326. [Google Scholar] [CrossRef]

- Klaffke, D.; Hartelt, M. Tribological characterization of thin hard coatings by reciprocating sliding tests. Tribol. Lett. 1995, 1, 265–276. [Google Scholar] [CrossRef]

- ASTM D7755-11 2017. Standard Practice for Determining the Wear Volume on Standard Test Pieces Used by High-Frequency, Linear-Oscillation (SRV) Test Machine; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Itoa, K.; Martin, J.M.; Minfray, C.; Katoa, K. Low-friction tribofilm formed by the reaction of ZDDP on iron oxide. Tribol. Int. 2006, 39, 1538–1544. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Howe, J.Y.; Meyer, H.M. Oxygen diffusion enables anti-wear boundary film formation on titanium surfaces in zinc-dialkyl-dithiophosphate (ZDDP)-containing lubricants. Scipta Mater. 2009, 60, 886–889. [Google Scholar] [CrossRef]

- Hsu, C.; Stratmann, A.; Rosenkranz, A.; Gachot, C. Enhanced growth of ZDDP-based tribofilms on laser-interference patterned cylinder roller bearings. Lubricants 2017, 5, 39. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology; Tribology Series 24; Elsevier: Amsterdam, The Netherlands, 1993; p. 349. [Google Scholar]

| Test Parameter [Unit] | Value | ||

|---|---|---|---|

| Tribosystem | Linear reciprocating sliding tribological test (RSTT) | ||

| Samples | fs-LIPSS (LSFL) on Ti6Al4V | ||

| Counterbodies | 100Cr6/Al2O3 /Si3N4 balls of 10 mm diameter | ||

| Young’s Modulus [GPa] | 100Cr6: ~200/Al2O3: ~365/Si3N4: ~300/Ti6Al4V: ~100 | ||

| Hardness [GPa] | 100Cr6: ~7/Al2O3: ~17/Si3N4: ~16/Ti6Al4V: ~1 | ||

| Stroke [µm] | 1000 | ||

| Frequency [Hz] | 1 | ||

| Normal load [N] | 1 | ||

| Number of cycles | 1000 | ||

| Atmosphere | Laboratory air | ||

| Temperature [°C] | ~20–22 | ||

| Relative humidity [%] | ~22–35 | ||

| Lubrication | VPX/VPX + 0.5% RC 3180 | ||

| Hertzian average/maximum contact pressure [MPa] | vs. 100Cr6 | vs. Al2O3 | vs. Si3N4 |

| 242/363 | 272/407 | 263/394 | |

| Hertzian radius of the sample-ball contact [µm] | vs. 100Cr6 | vs. Al2O3 | vs. Si3N4 |

| 36 | 34 | 35 | |

| Hertzian sample-ball deformation [µm] | vs. 100Cr6 | vs. Al2O3 | vs. Si3N4 |

| 0.26 | 0.23 | 0.24 | |

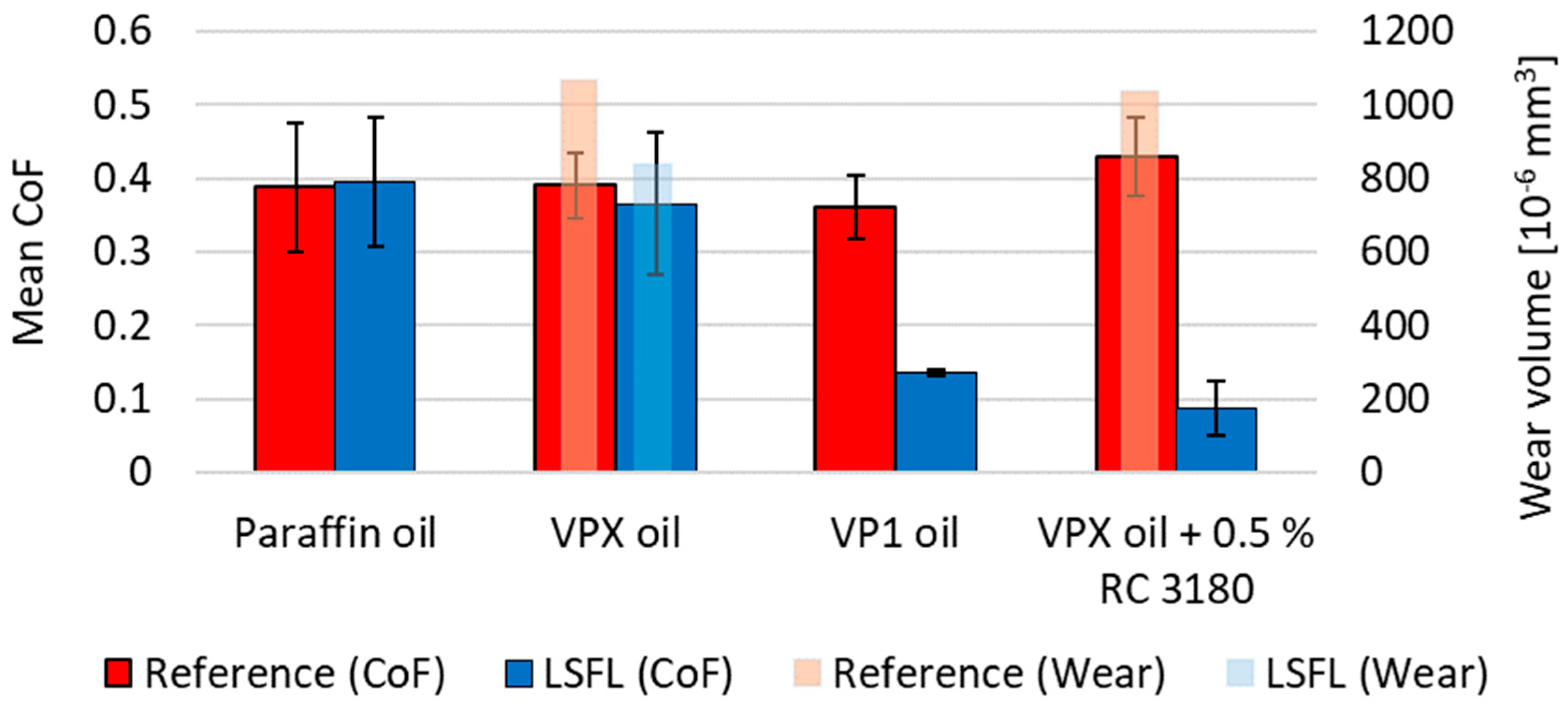

| Lubricant | CoF | Wear Volume [10−6 mm3] | ||

|---|---|---|---|---|

| Reference | LSFL | Reference | LSFL | |

| Paraffin oil | 0.388 ± 0.087 | 0.395 ± 0.087 | n.a. | n.a. |

| VPX oil | 0.391 ± 0.044 | 0.366 ± 0.096 | 1070 | 838 |

| VP1 oil | 0.362 ± 0.043 | 0.137 ± 0.004 | n.a. | n.a. |

| VPX oil + 0.5% RC 3180 | 0.430 ± 0.054 | 0.088 ± 0.036 | 1039 | 0.35 |

| Lubricant | Counterbody | CoF | Wear Volume [10−6 mm3] | ||

|---|---|---|---|---|---|

| Reference | LSFL | Reference | LSFL | ||

| VPX oil | 100Cr6 | 0.391 ± 0.044 | 0.366 ± 0.096 | 1070 | 838 |

| Al2O3 | 0.167 ± 0.053 | 0.148 ± 0.078 | 175 | 295 | |

| VPX oil + 0.5% RC 3180 | 100Cr6 | 0.430 ± 0.054 | 0.088 ± 0.036 | 1039 | 0.35 |

| Al2O3 | 0.158 ± 0.063 | 0.094 ± 0.022 | 169 | 7 | |

| Si3N4 | 0.206 ± 0.077 | 0.094 ± 0.012 | 452 | 4 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayerdi, J.J.; Slachciak, N.; Llavori, I.; Zabala, A.; Aginagalde, A.; Bonse, J.; Spaltmann, D. On the Role of a ZDDP in the Tribological Performance of Femtosecond Laser-Induced Periodic Surface Structures on Titanium Alloy against Different Counterbody Materials. Lubricants 2019, 7, 79. https://doi.org/10.3390/lubricants7090079

Ayerdi JJ, Slachciak N, Llavori I, Zabala A, Aginagalde A, Bonse J, Spaltmann D. On the Role of a ZDDP in the Tribological Performance of Femtosecond Laser-Induced Periodic Surface Structures on Titanium Alloy against Different Counterbody Materials. Lubricants. 2019; 7(9):79. https://doi.org/10.3390/lubricants7090079

Chicago/Turabian StyleAyerdi, Jon Joseba, Nadine Slachciak, Iñigo Llavori, Alaitz Zabala, Andrea Aginagalde, Jörn Bonse, and Dirk Spaltmann. 2019. "On the Role of a ZDDP in the Tribological Performance of Femtosecond Laser-Induced Periodic Surface Structures on Titanium Alloy against Different Counterbody Materials" Lubricants 7, no. 9: 79. https://doi.org/10.3390/lubricants7090079

APA StyleAyerdi, J. J., Slachciak, N., Llavori, I., Zabala, A., Aginagalde, A., Bonse, J., & Spaltmann, D. (2019). On the Role of a ZDDP in the Tribological Performance of Femtosecond Laser-Induced Periodic Surface Structures on Titanium Alloy against Different Counterbody Materials. Lubricants, 7(9), 79. https://doi.org/10.3390/lubricants7090079