Mixed Fretting Regime

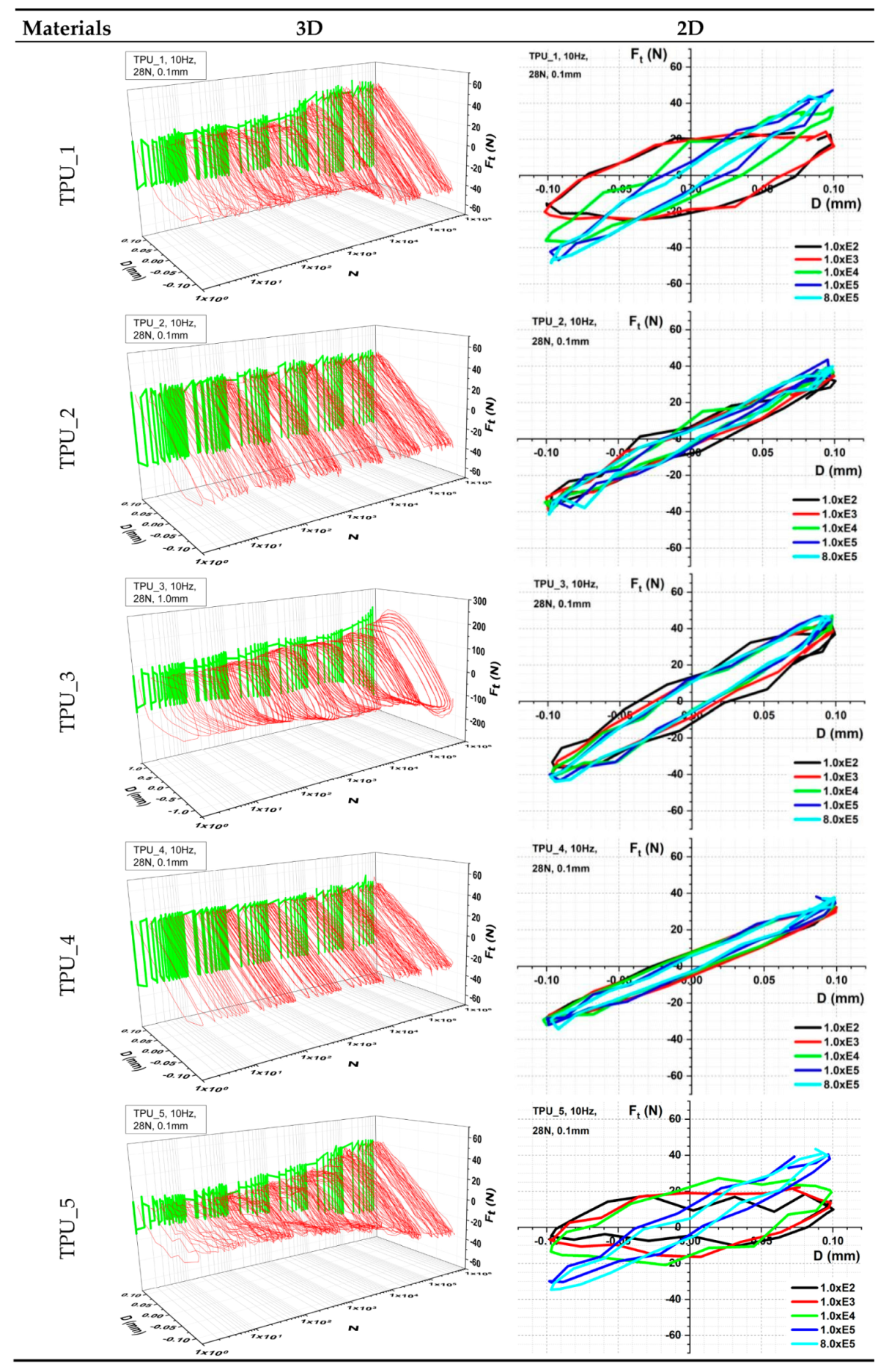

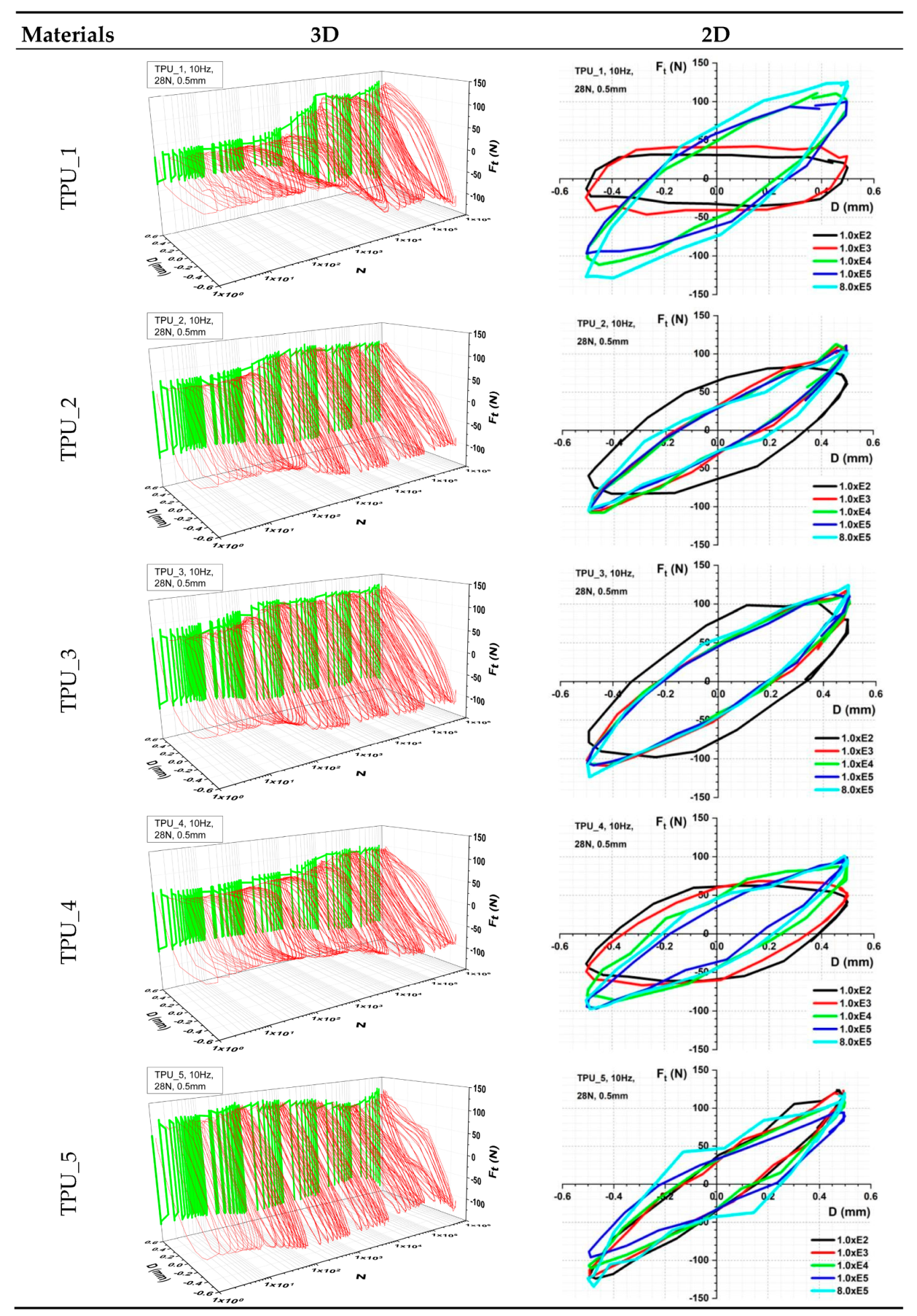

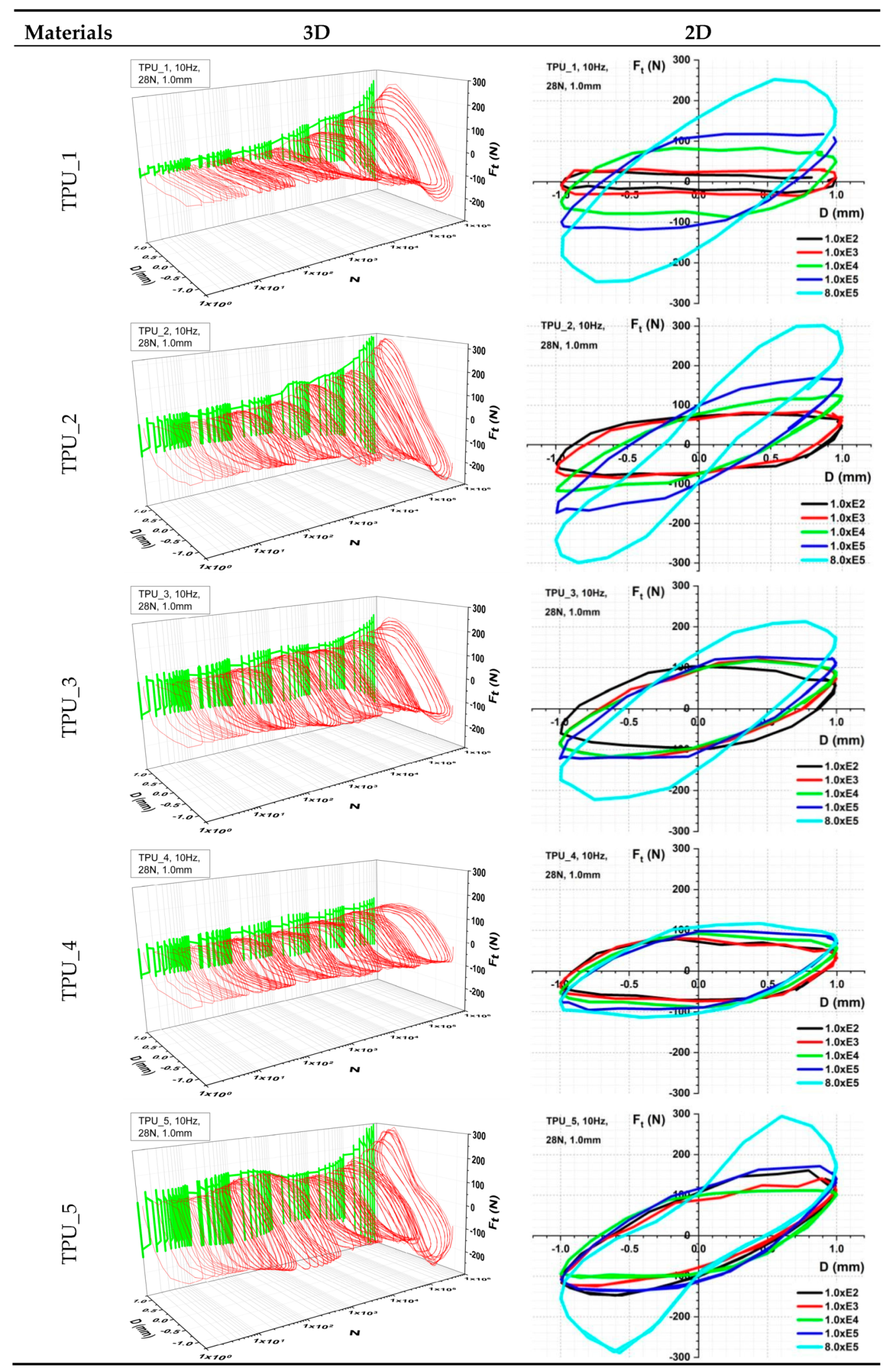

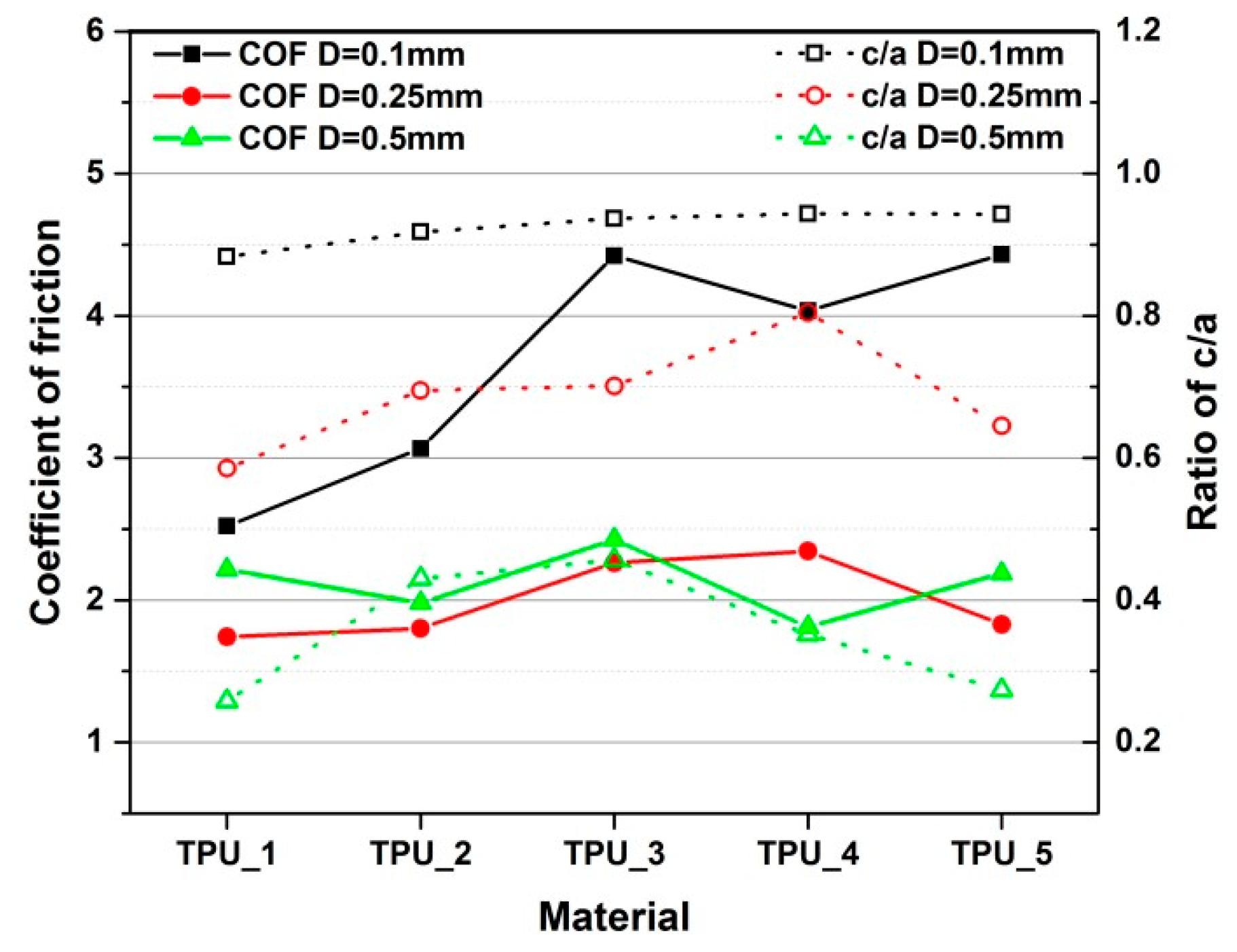

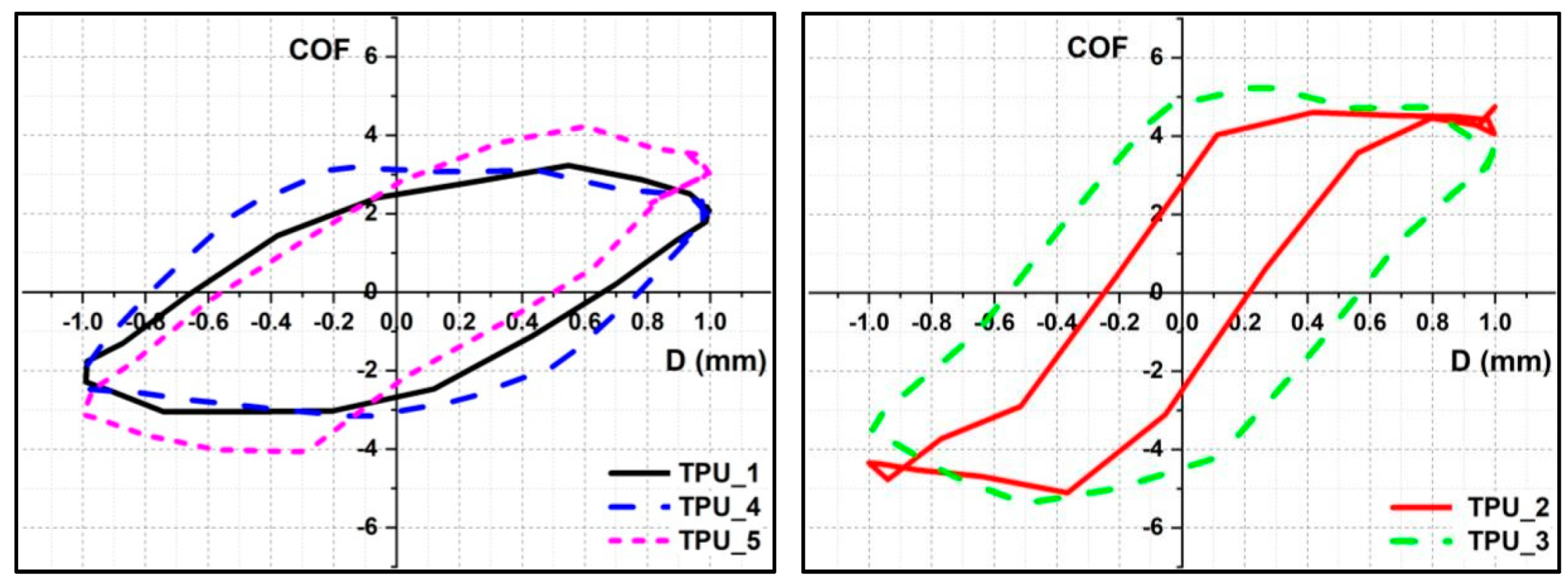

Compared to the hystereses in the partial slip regime, more alterations of the hystereses can be observed in the mixed fretting regime (

Figure 9). Among the five TPUs, the hysteresis of TPU_1 changed differently, while the other TPUs behaved similarly in the mixed fretting regime. For TPU_1, the tangential force remained almost constant in the first 10

3 cycles when the samples were between −0.3 mm and +0.3 mm. As can be seen from the hysteresis, after approximately 10

3 cycles, its form began to change. The tangential force became larger with the increased displacement. It should be mentioned that the tangential force at the displacement (D) = ±0.5 mm reduced at first and then increased again when the cycle number increased from 10

4 to 10

6, whereas it increased continually at D = 0 mm. This phenomenon can be attributed to the wear generating process. As examined in [

12], delamination wear and cracks can be found in the stick region after the test. After approximately 10

3 cycles, the damage began to appear on the edge of the ring. More wear debris was generated with increasing cycles because of the partial slip between the sample and the counterpart. Hence, the stick region became smaller and the tangential force at the maximum displacement decreased slightly. Due to the repeated shear stress, delamination and cracks can occur in the stick region. As a consequence, the tangential force can be altered.

TPU_2 and TPU_3 show similar hystereses. From 10

2 to 10

3 cycles, the hysteresis narrows, which means the tangential force reduces at D = 0 mm and increases at D = ±0.5 mm. For TPU_4 this change occurred later, after 10

3 cycles. However, for TPU_5 the maximum tangential force becomes slightly smaller with the increasing number of cycles. From the 2 × 10

5 cycle, it begins to increase. It is also noticeable that the tangential force does not change linearly, but rather with an inflection point at approximately D = +0.15 mm for the movement from D = +0.5 to −0.5 mm, and vice versa. Due to the repeated shear stress, the left and right sides of the stick region can be folded (

Figure 9). This can lead to an inflection in the tangential force.

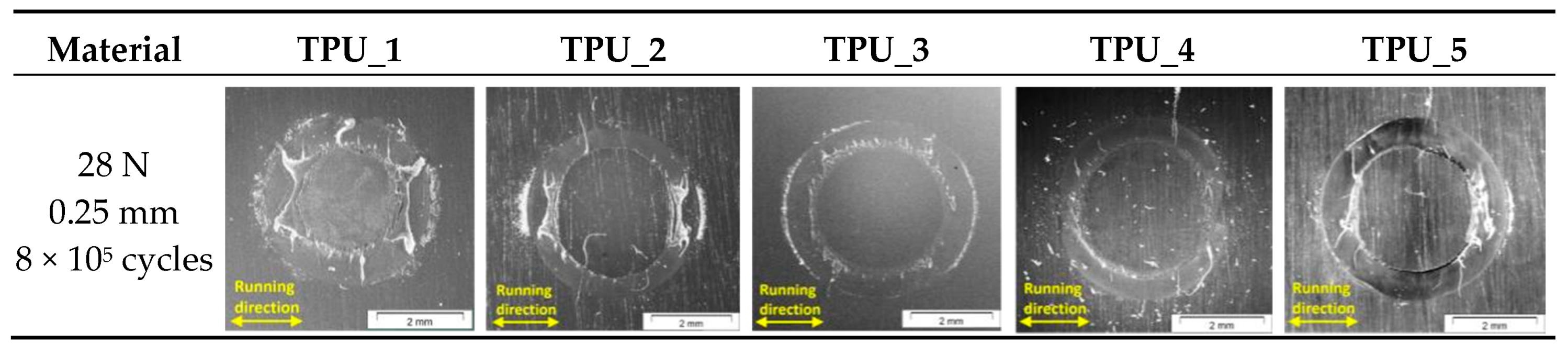

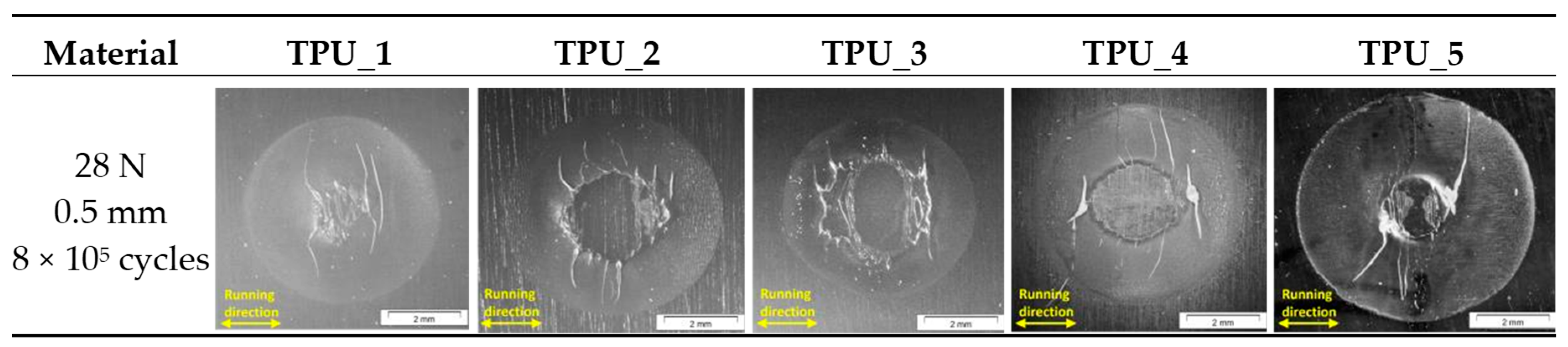

The mixed fretting regime, as its name suggests, is the transition field between the partial slip and gross slip regimes. As seen in

Figure 9, the stick regions are much smaller than those in the partial slip regimes. Due to its larger amplitude, the stick region becomes smaller with increasing cycle numbers. Butterfly-like wear scars can be identified distinctly on TPU_3. On both sides of the stick regions, folds can be observed on TPUs_2, 3, 4, and 5. As explained in [

12], repeated normal and shear stresses induce cracks and delamination wear on TPU_1.

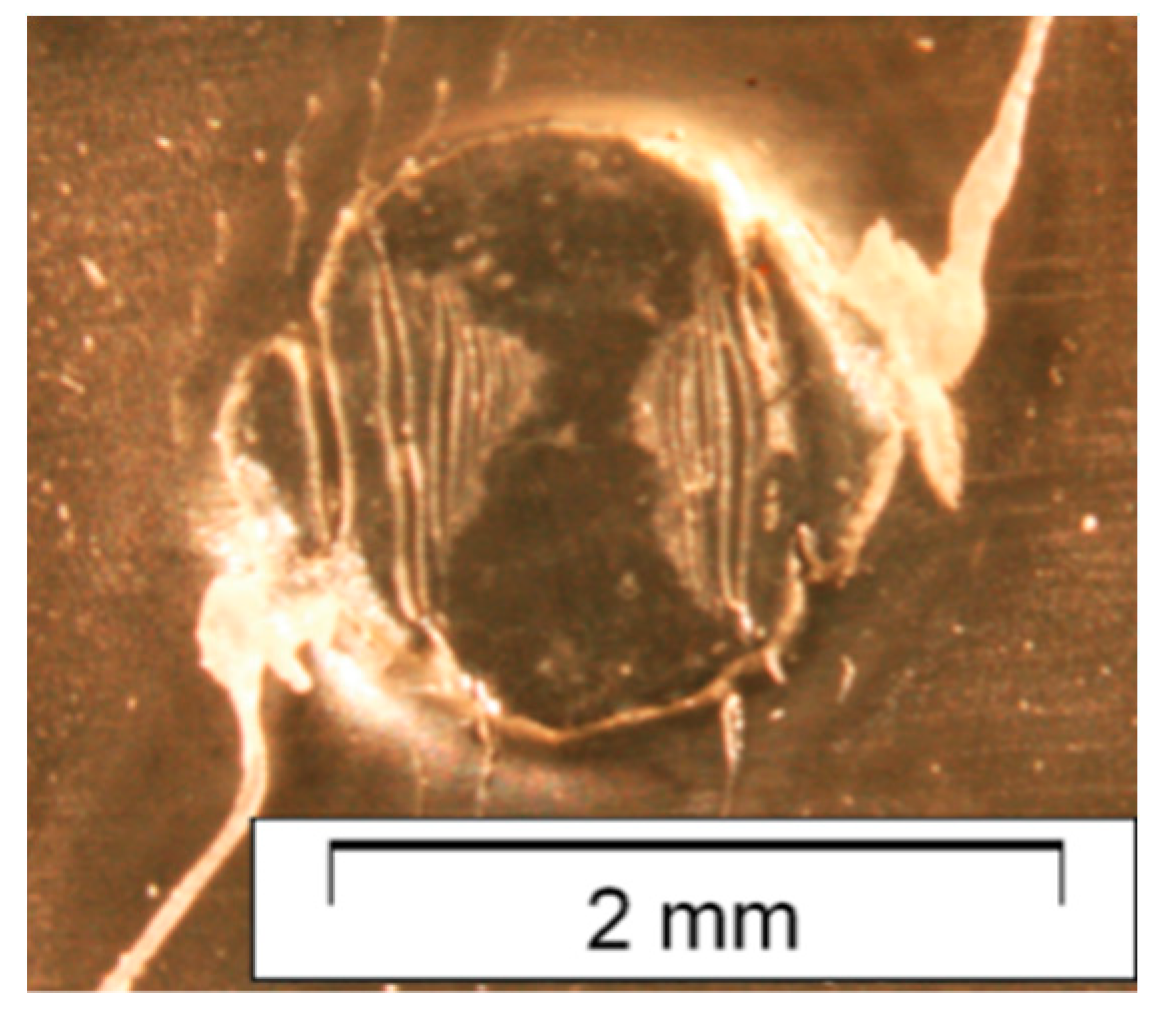

Figure 10 shows the profiles of the wear scars. TPUs_1 and 5 have the smallest stick regions and the deepest scars in the slip regions. In the stick regions of TPU_2 and TPU_5, slight surface alteration can be observed on the edges. Especially on TPU_5, the deformation of the surface decreases from the edge to the middle (

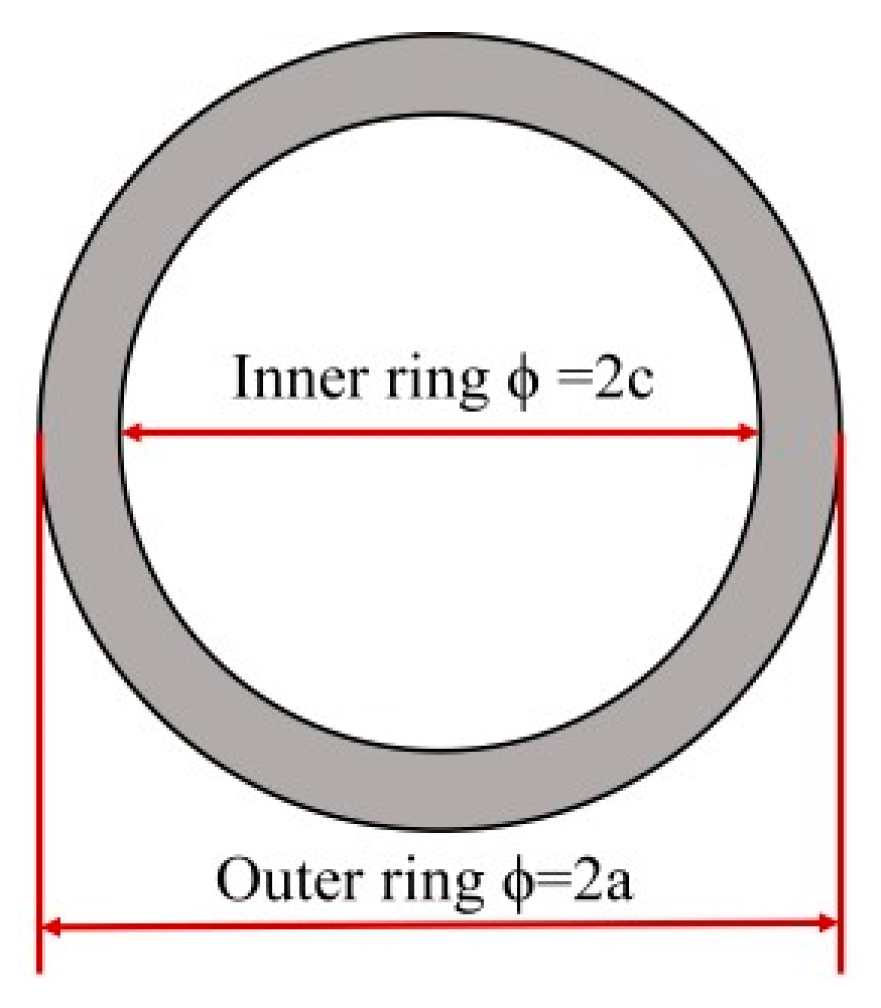

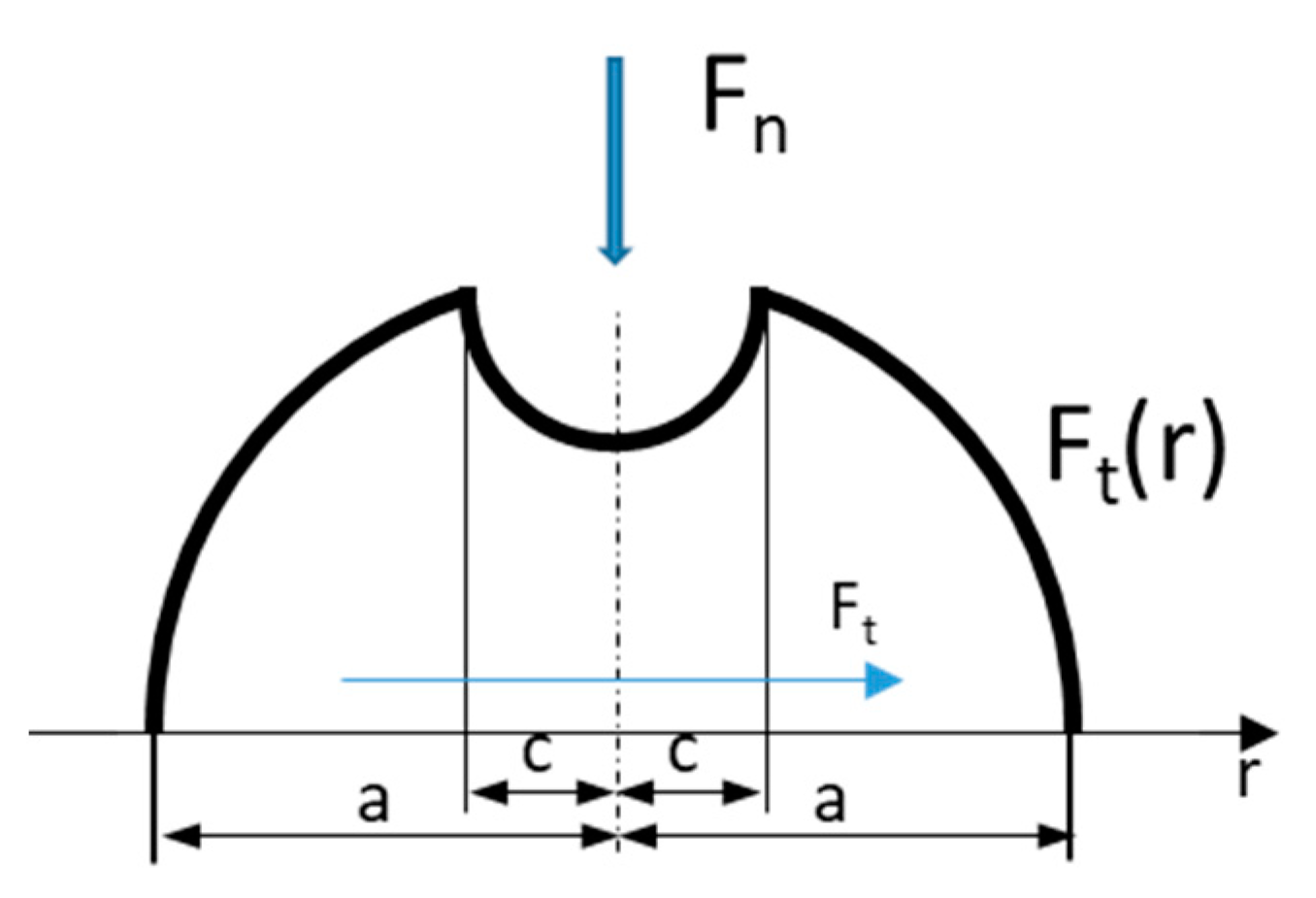

Figure 11). This can be explained by the shear stress distribution. For this circular contact under a steady normal force and an oscillating tangential load, the maximum shear stress is located at the edge of the stick region (

Figure 12) [

18].

The hysteresis of TPU_1 shows a distinct transitional phase by approximately 5 × 10

3 cycles (

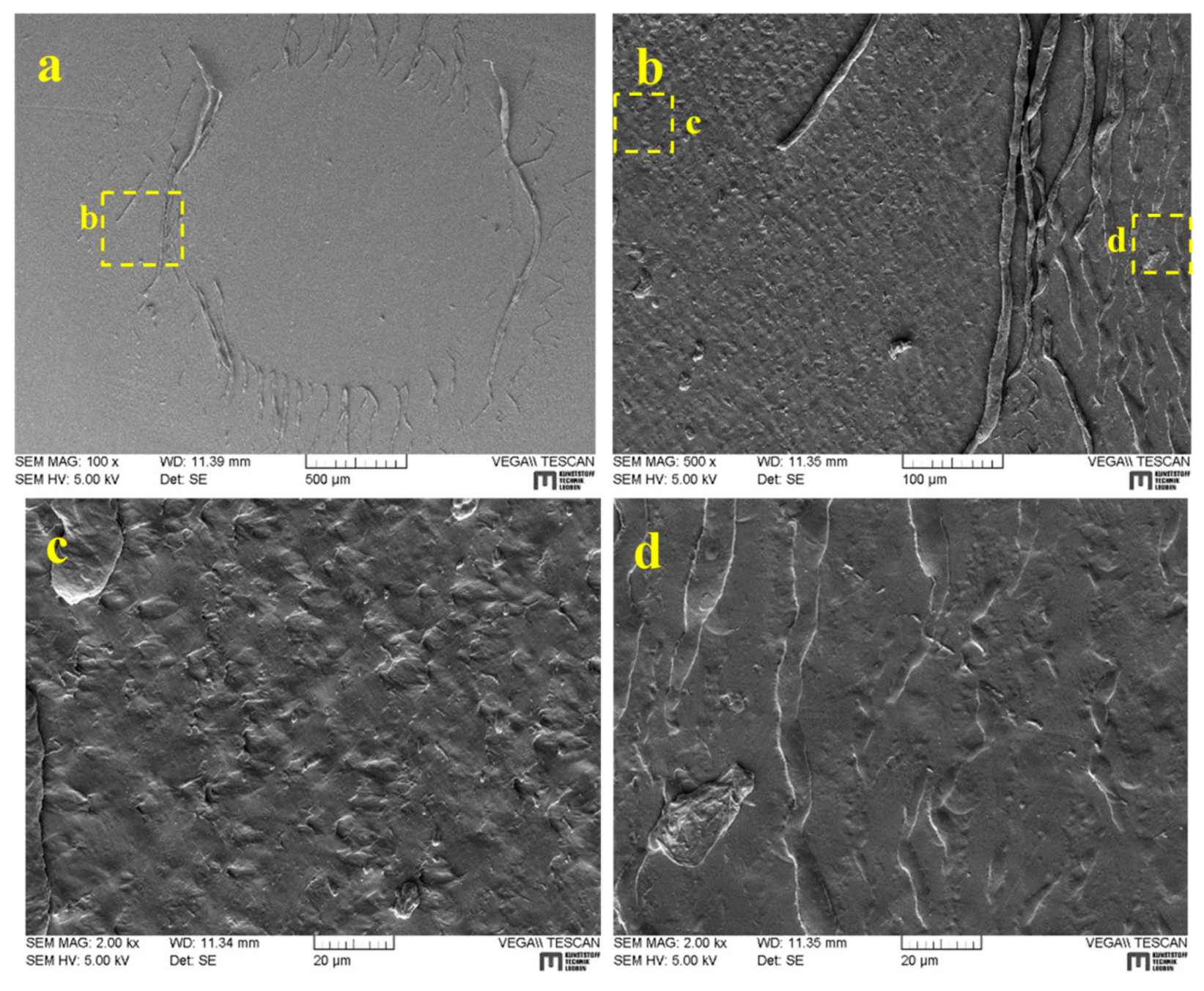

Figure 9). The wear scar after 5 × 10

3 cycles is shown in

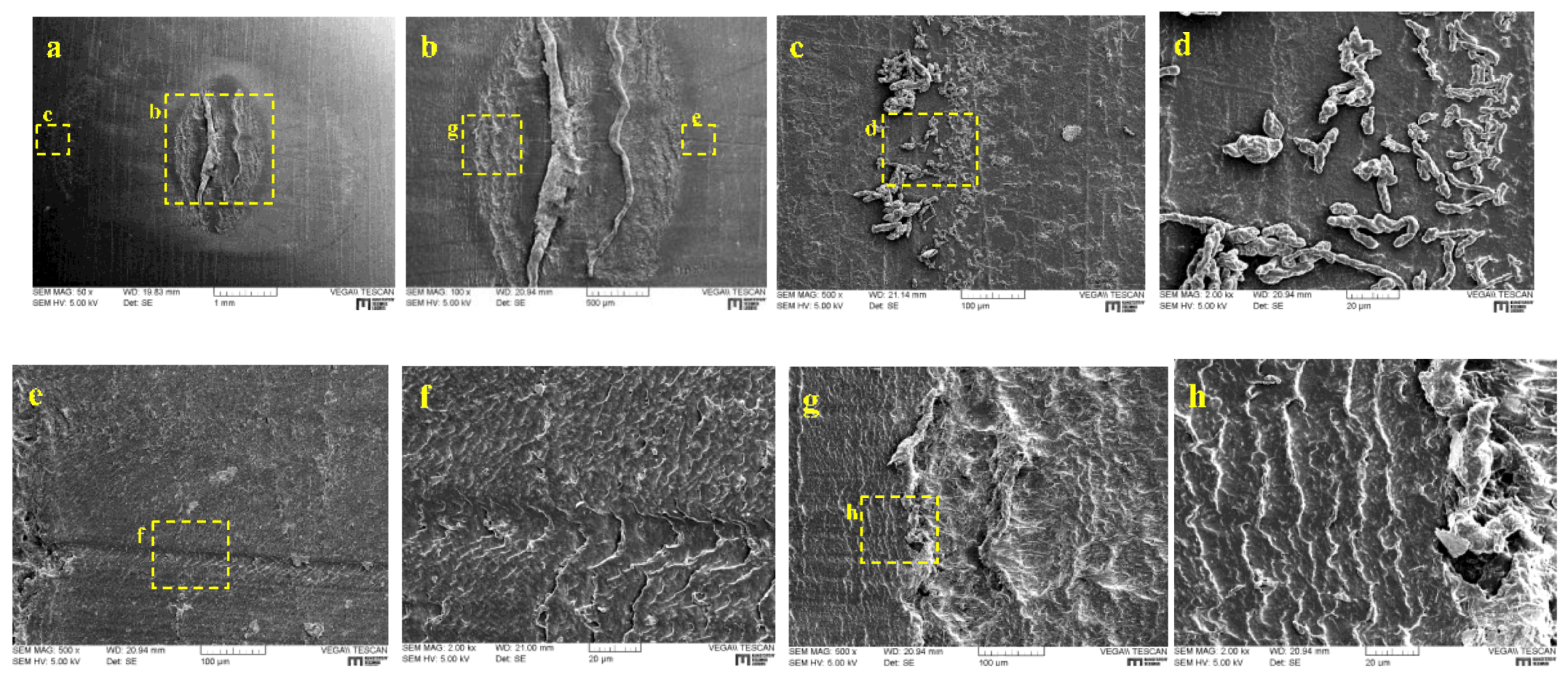

Figure 13. Rolled stripe-like debris can be observed around the stick region (

Figure 13a). Similar but much smaller debris can also be found in the partial slip regions. Additionally, micro pitting is identified at the edge of the outer ring. Due to surface fatigue, micro pitting can occur after the incubation period in fretting tests [

19,

20]. At the edge of the inner ring, the rolled debris was pressed into the surface and flattened due to plastic deformation. The contact was changed to three-body contact, which can lead to debris formation, and hence an alteration in the hysteresis form. Due to the debris between the contact surfaces, the tangential force was reduced slightly. The alteration in the hysteresis form is in good agreement with the previous studies [

21]. However, a similar steady phase after the alteration cannot be identified, similar to in Godet’s experiments with steel alloys [

21]. After a short steady phase, the tangential force began to increase because the surface morphology changed with the increasing number of cycles. Though the hardness of the debris is similar to the substrate, it can also affect the contact situation. The real contact area decreases, which leads to higher local contact stress and contact temperatures [

22,

23]. For polymers, all of these changes can affect the contact states, and thus accelerate the wear process. The profiles of wear scars show the depth of each scars (

Figure 14).

Compared to TPU_1, no apparent debris can be observed on TPU_4 after 5 × 10

3 cycles (

Figure 15). However, delamination wear, which is attributed to cyclic shear and normal stresses [

24,

25], can be found in particular in the region where the maximum shear stress occurred, according to the hystereses in

Figure 9.

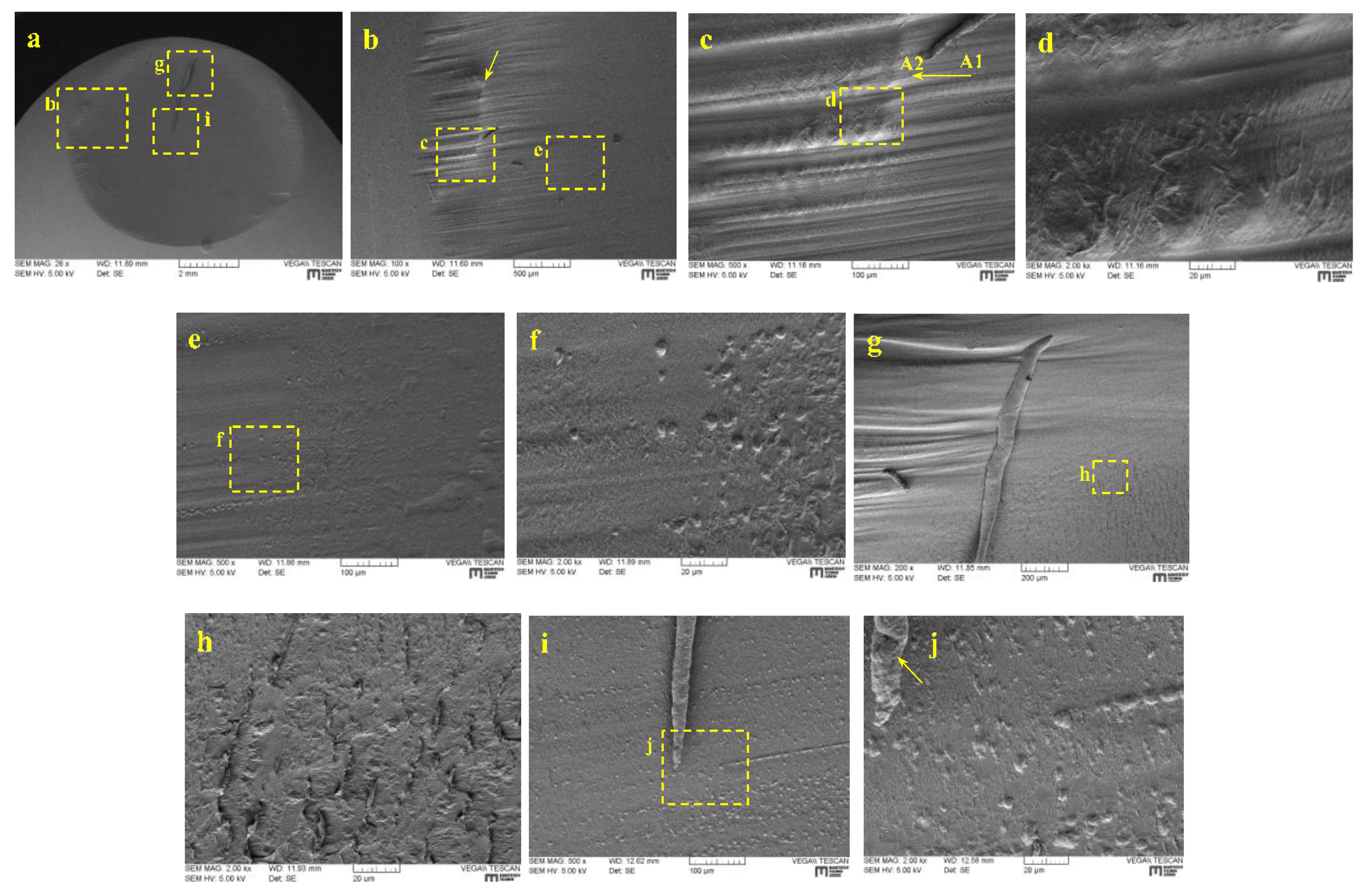

According to the hystereses, the transitional phase occurred slightly later. Its wear scar after 5 × 10

4 cycles is shown in

Figure 16. Various kinds of wear debris can be identified on the surface. On the whole, its debris is considerably larger than that of other materials. Larger block-like debris can be found on both sides, while stripe-like debris can be seen in the top and bottom regions. The stripe-like debris was rolled together due to the repeated movement, which was also observed using the in situ method [

26]. Small stripe-like debris can be found in the middle area (

Figure 16b,c), which was partially pressed into the surface (

Figure 16d). Due to the larger block-like debris, the tangential force changed continuously. At the edge of the ring, layer-like debris can be found, which can be attributed to repeated stresses. Meanwhile, debris particles were observed at the edge of the outer ring, where according to the microstructures of the substrate, no contact occurs (

Figure 16g,h). Therefore, the wear particles could be generated in the early phase and were removed at that point.

Gross Slip Regime

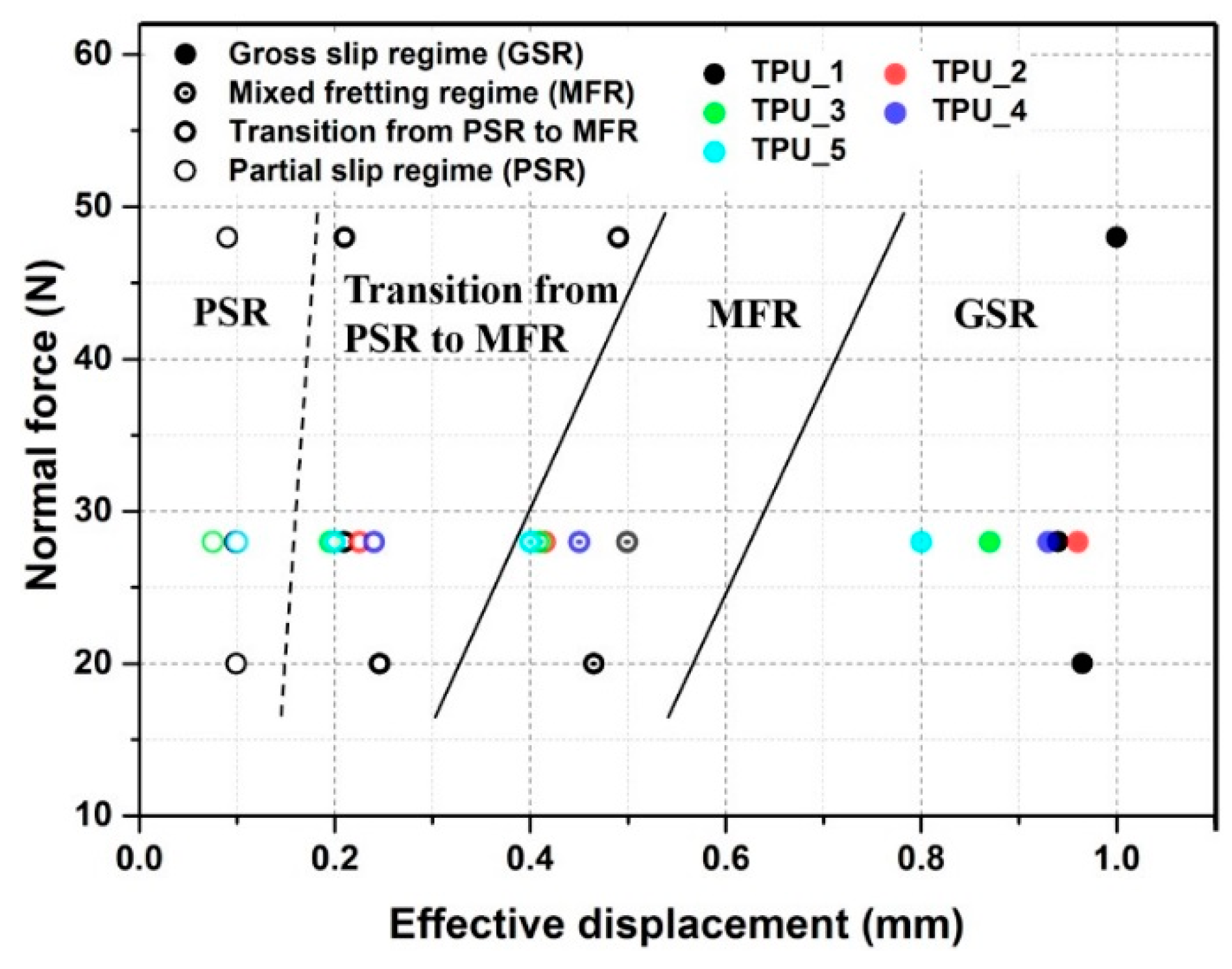

For the behaviors in the gross slip regime, each material shows its differences (

Figure 17). For TPU_1, in the first 10

3 cycles, its tangential force remained almost constant with a slight increase during the movements, but still at a very low level of approximately 30 N, which is much smaller than other materials. The beginning behavior depends very much on the TPU surface. All surfaces were cleaned before the tests, even though their surfaces were slightly different. After 10

3 cycles its form began to change. When the sample moved from the furthest point (D = ±1.0 mm) to the central position (D = 0 mm), the tangential force reduced at first and then increased. After reaching the middle point, the tangential force remained almost constant until the furthest point. After approximately 2 × 10

5 cycles, the hysteresis form changed again. This was caused by severe wear, which altered the geometry of the sample.

TPU_2’s tangential force increased gradually with the number of cycles and stayed in a similar form. From approximately 10

5 cycles, server wear was generated on both sides of the contact area (

Figure 18). This explains the hysteresis form in the 8 × 10

5 cycle. In the middle area, the surface is much smoother than other regions, so the tangential force changed when the sample moved in the central area.

For TPU_3, its tangential force increases slowly with the number of cycles until 105 cycles. Similar hysteresis to TPU_1 can be observed after 105 cycles. However, its maximum tangential force is slightly smaller than that of TPU_1.

The hysteresis of TPU_4 can be described with three parallelograms, the first of which describes the first 103 cycles. The second one shows the hysteresis from 105 cycles. Between 103 and 105, the hysteresis is illustrated with the third parallelogram, which can be treated as a transition phase. Both its height and width are between the first two parallelograms.

For TPU_5, its hysteresis looks very similar to the first 105 cycles. However, the maximum tangential force was not constant. It increased for the first 100 cycles and then decreased. From 5 × 103 cycles, it increased again. After 4 × 105 cycles, the tangential force grew faster after passing over the middle point.

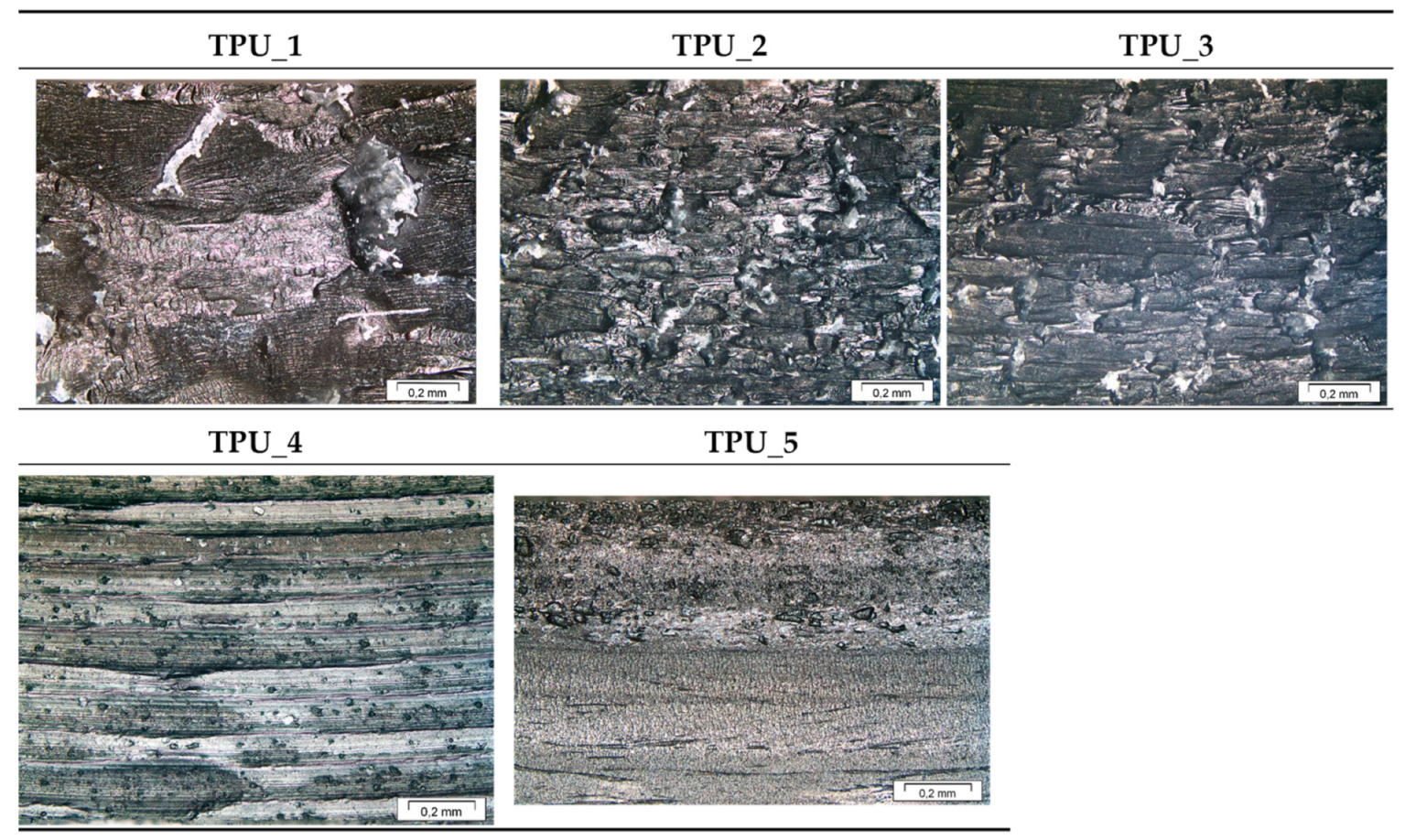

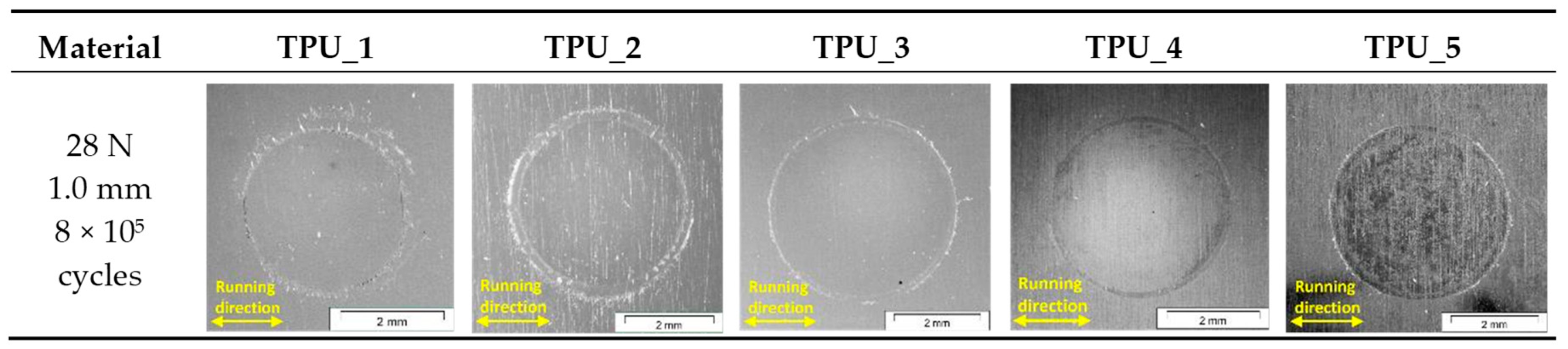

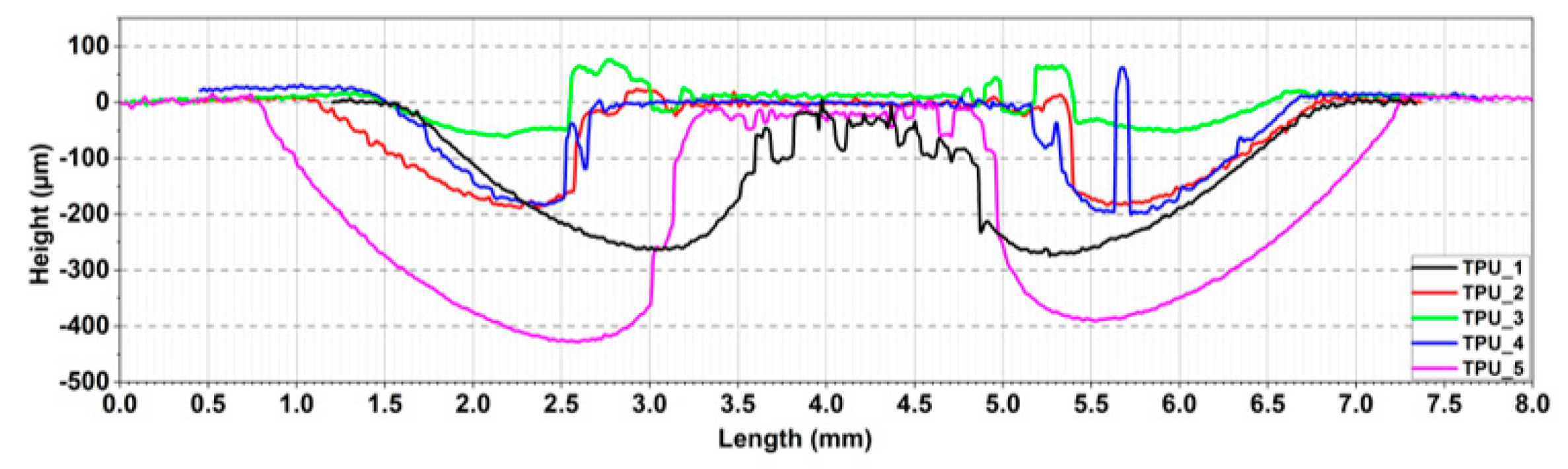

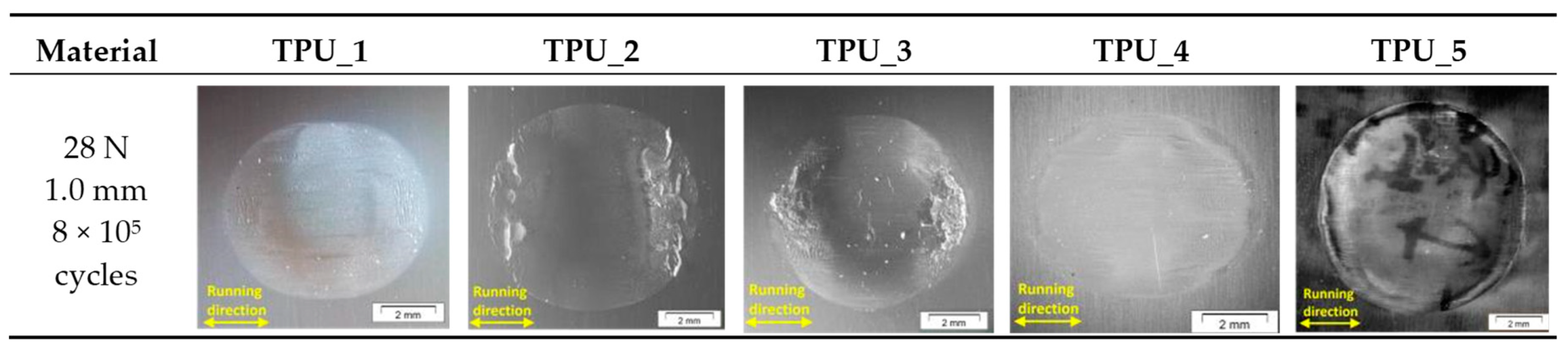

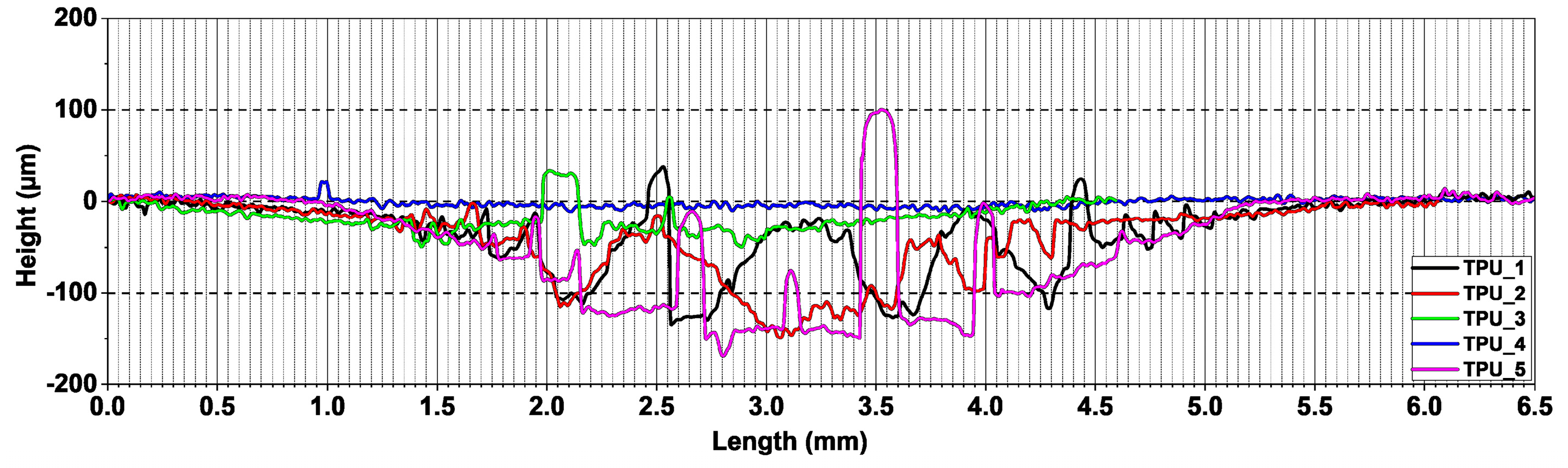

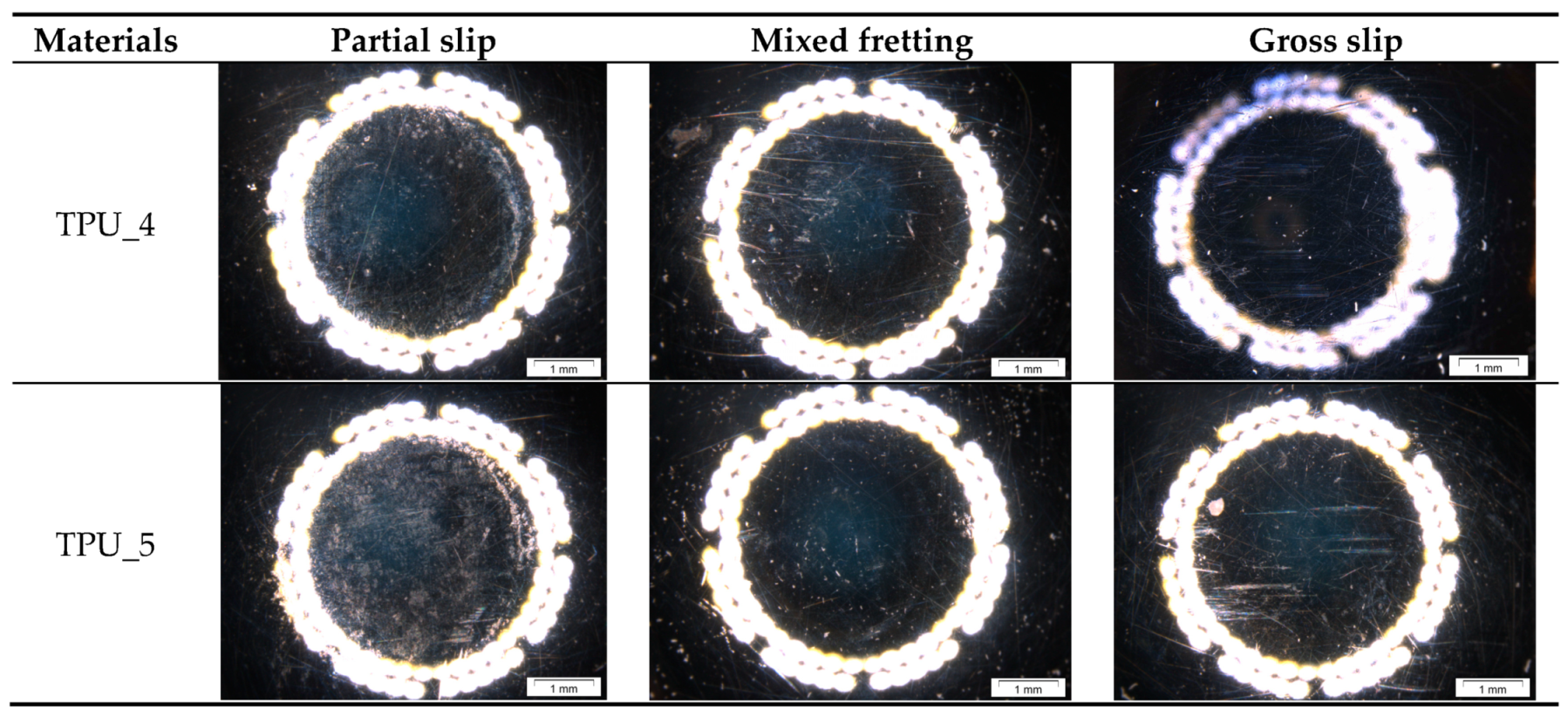

In the gross slip regime, the counterpart slips over the contact area. As can be observed in

Figure 18, the wear scars of TPU_1, 4, and 5 show a definite similarity, and materials were removed because of the slip movements. However, severe wear can be seen on both sides of the scars in TPUs_2 and 3. This phenomenon can also be identified in the hysteresis. The evidence points to the substantial likelihood that these two materials behaved differently under cyclic normal and shear stresses, in particular at a relatively high temperature, which is related to fatigue mechanisms. Additionally, this can also be initiated by third body wear; the liberated debris stays in the contact zone and acts as a third body, which can lead to an acceleration of the wear process.

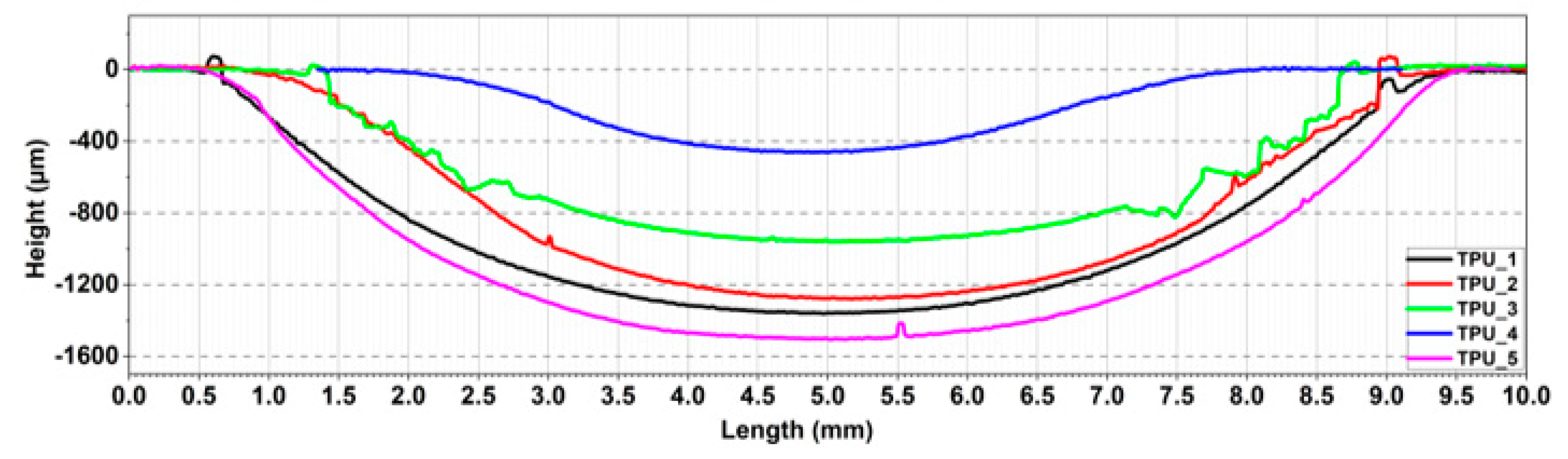

In comparison to the mixed fretting regime, wear scars in the gross slip regime are considerably broader and deeper. Among the five materials, the most severe wear was identified in TPU_5, which corresponds to the mixed fretting regime. For TPU_5, rolled debris on the bottom of the wear scar facilitated the slip movement of the counterpart, which resulted in a reduction of tangential force in the middle area (

Figure 17). TPU_4 shows the best wear resistance, which is consistent with the results in tribological tests. The scar depth of TPU_4 is about 500 µm, which is only one-third of the depth in TPU_5 and half of that in TPU_3 (

Figure 19).

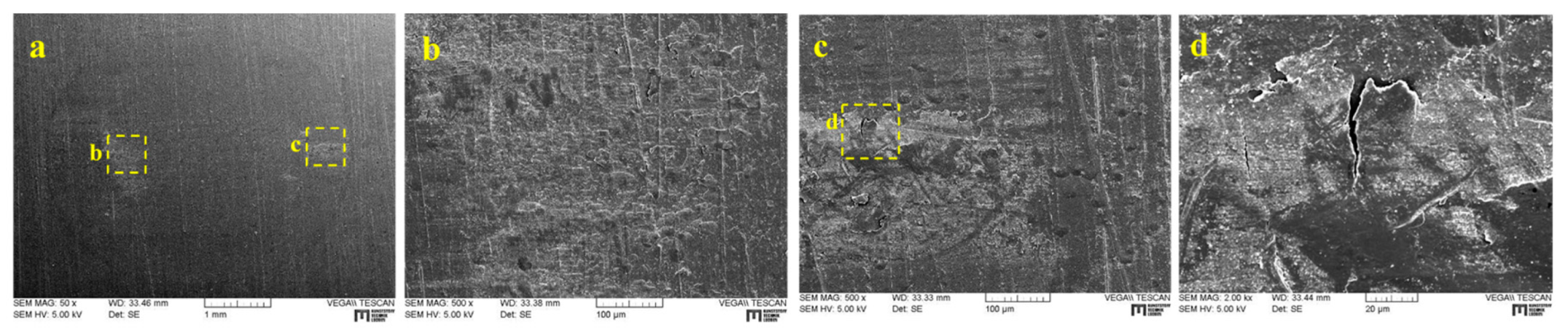

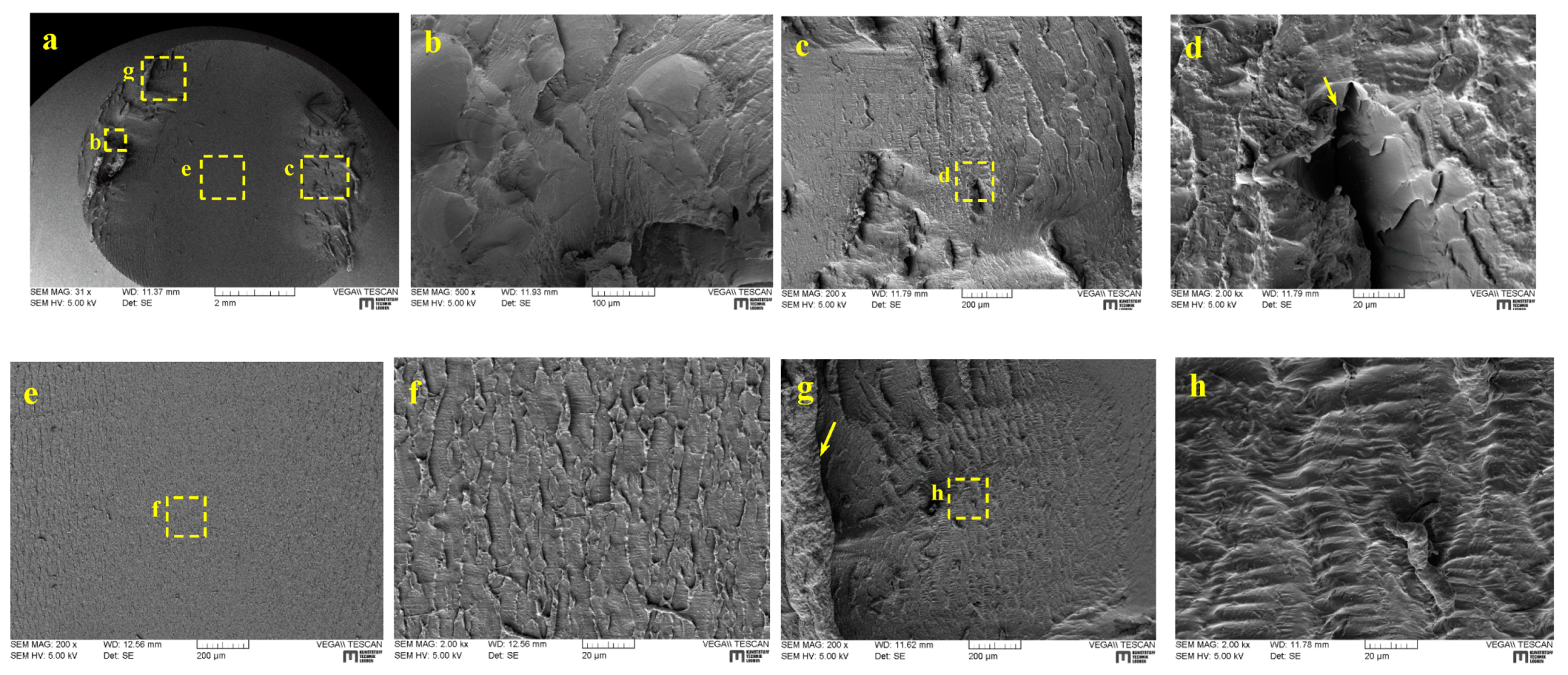

On both sides of the contact area, severe wear can be found on TPUs_2 and 3 after 8 × 10

5 cycles. Larger cracks can be observed in

Figure 20d. At the end of the test, its tangential force increased to over 300N on both sides (

Figure 17). Flake-like sections can be identified in

Figure 20b,d. On the one hand, the glass transition temperature increases with increasing frequency. Thus, the material becomes slightly more brittle under 10 Hz than in a static situation. On the other hand, due to the large amplitude, debris can be easily torn away from the surface. Small wave-like debris was found in the middle area, which was generated as a result of repeated shear stress (

Figure 20e,f). This kind of debris was also found in TPU_1 [

12]. Moreover, the smooth wave surface was observed in the topside region (

Figure 20h), which looks different to

Figure 20b. This can be ascribed to the contact state. In

Figure 20a, due to the spherical counterpart, the normal and shear stresses in region g are considerably smaller than those in region b. Hence, cracks in region g are smaller. Small wave-like debris was rolled together into larger debris (

Figure 20g) when the ball slid over the region. After this process, the surface, which was full of small wave-like debris, looked smooth. Microcracks are generated with further movement.

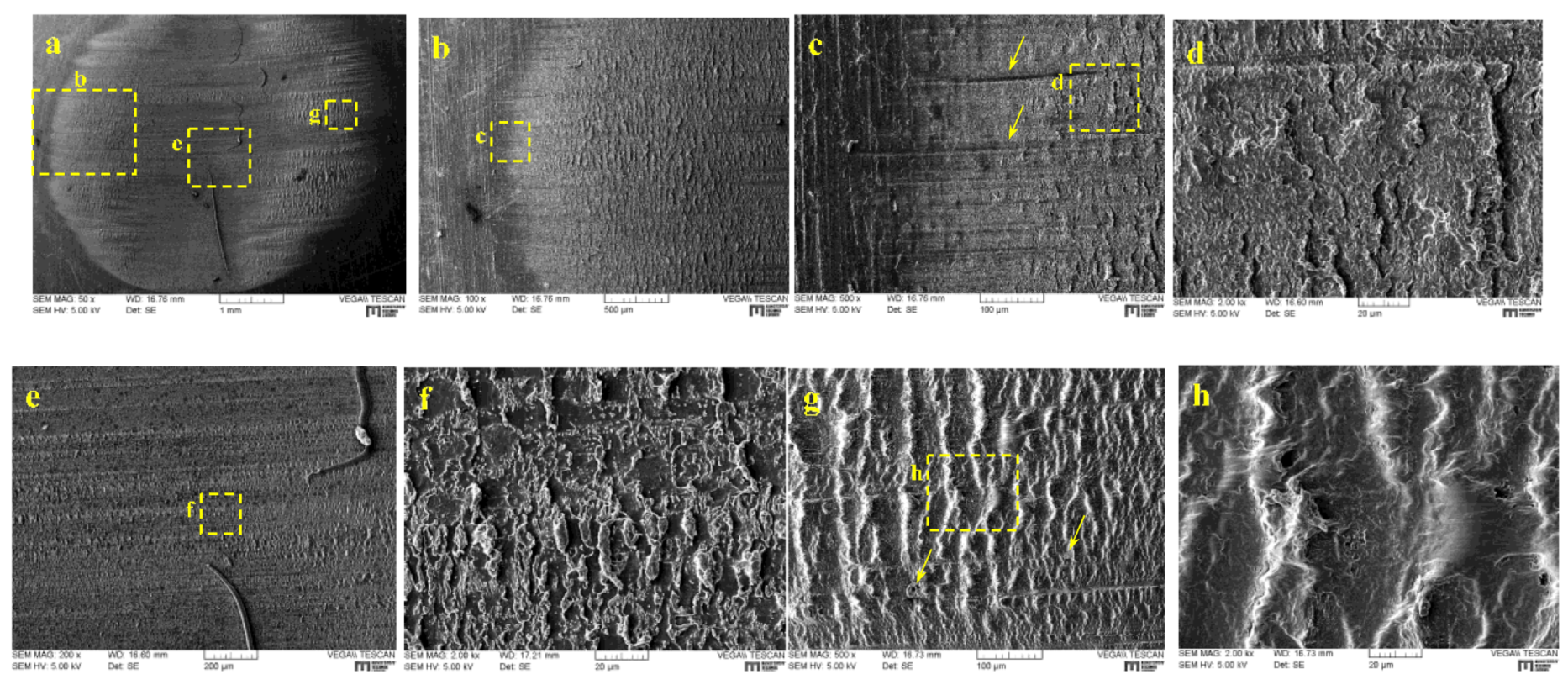

Compared with TPU_2, the wear on TPU_4 is not as severe. The tangential force of its last cycle, approximately 120N, is significantly smaller than that of the other materials. On the one hand, it is the softest material in both static and dynamic states (

Table 1). On the other hand, no severe wear, such as was seen for TPU_2, can be found for TPU_4 (

Figure 19). As shown in

Figure 21a, wave-like debris can be found on both sides, whereas the middle region is relatively smooth but with a lot of stripe-like debris. As evident in

Figure 21c,g, several grooves are visible, which can be attributed to third-body abrasive wear. Particles can also be found in

Figure 21g. Generally, the abrasive material must be harder than the surface [

27]. These particles can be wear particles from the counterpart or external contamination. Both matter types are harder than the substrate. The particles might be tiny at the beginning, however they can be wrapped up in TPU debris. Compared to the other materials, except for TPU_5, the height of the wave-like debris is much smaller, so the sides are smoother. In addition, due to its lower hardness, the waves seem to be flattened when the counterpart slides over them. Both of these phenomena facilitate the moment of the counterpart.

Consequently, the tangential force of TPU_4 remains almost constant or even reduces with the counterpart’s movement from the middle to the side (

Figure 17). The wear debris at the edge of the contact area and in the middle of the area is shown in

Figure 21d,f, respectively. They look different from TPU_1 [

12] and TPU_2. As shown in

Figure 21d, owing to surface fatigue, the wear debris seems to be either delaminated from the surface or pressed into the surface. The debris clearly appears to be looser. The wear scars of the middle region can be affected by the interfacial debris, making the rolled wear debris look less neat than TPUs_1 and 2.

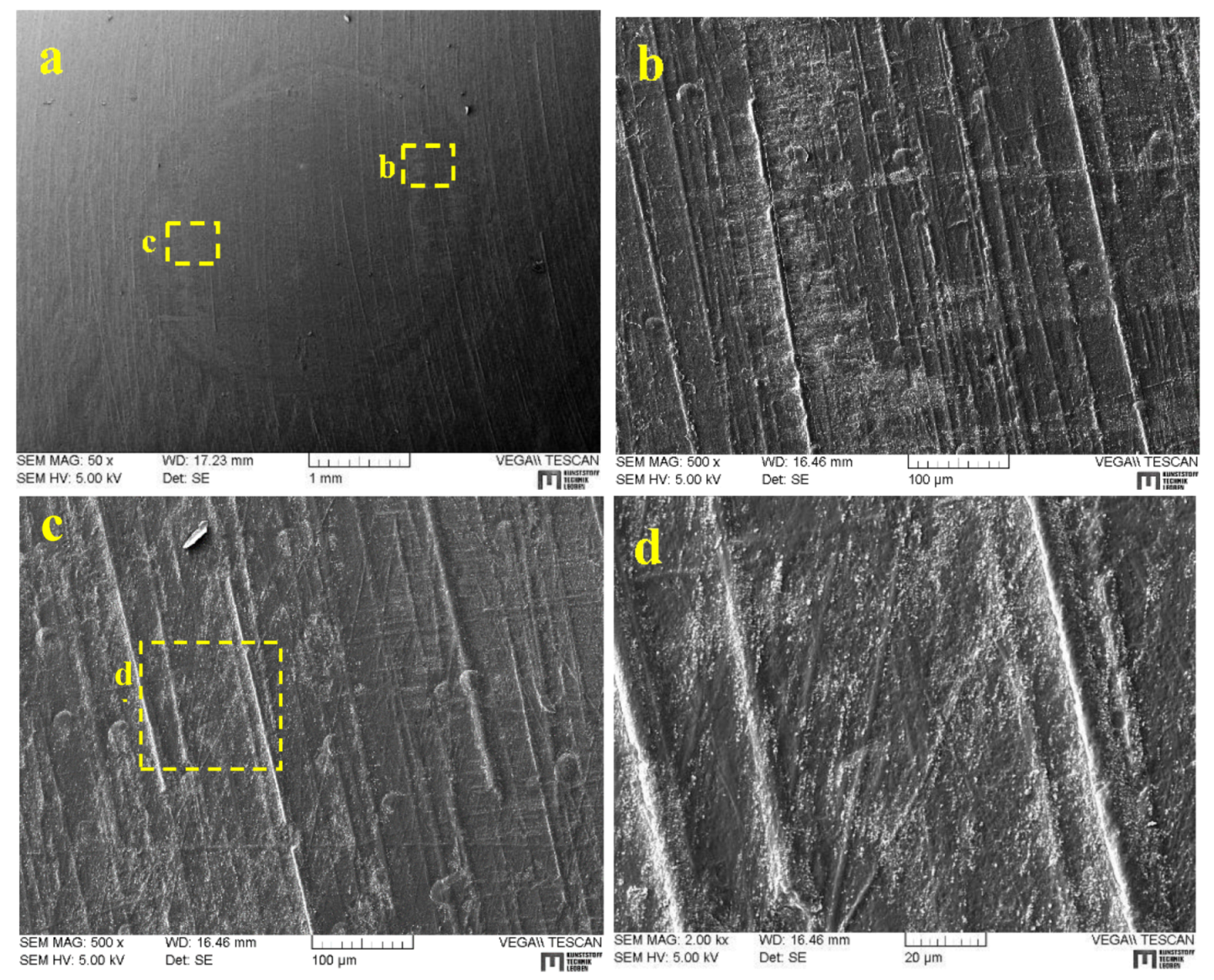

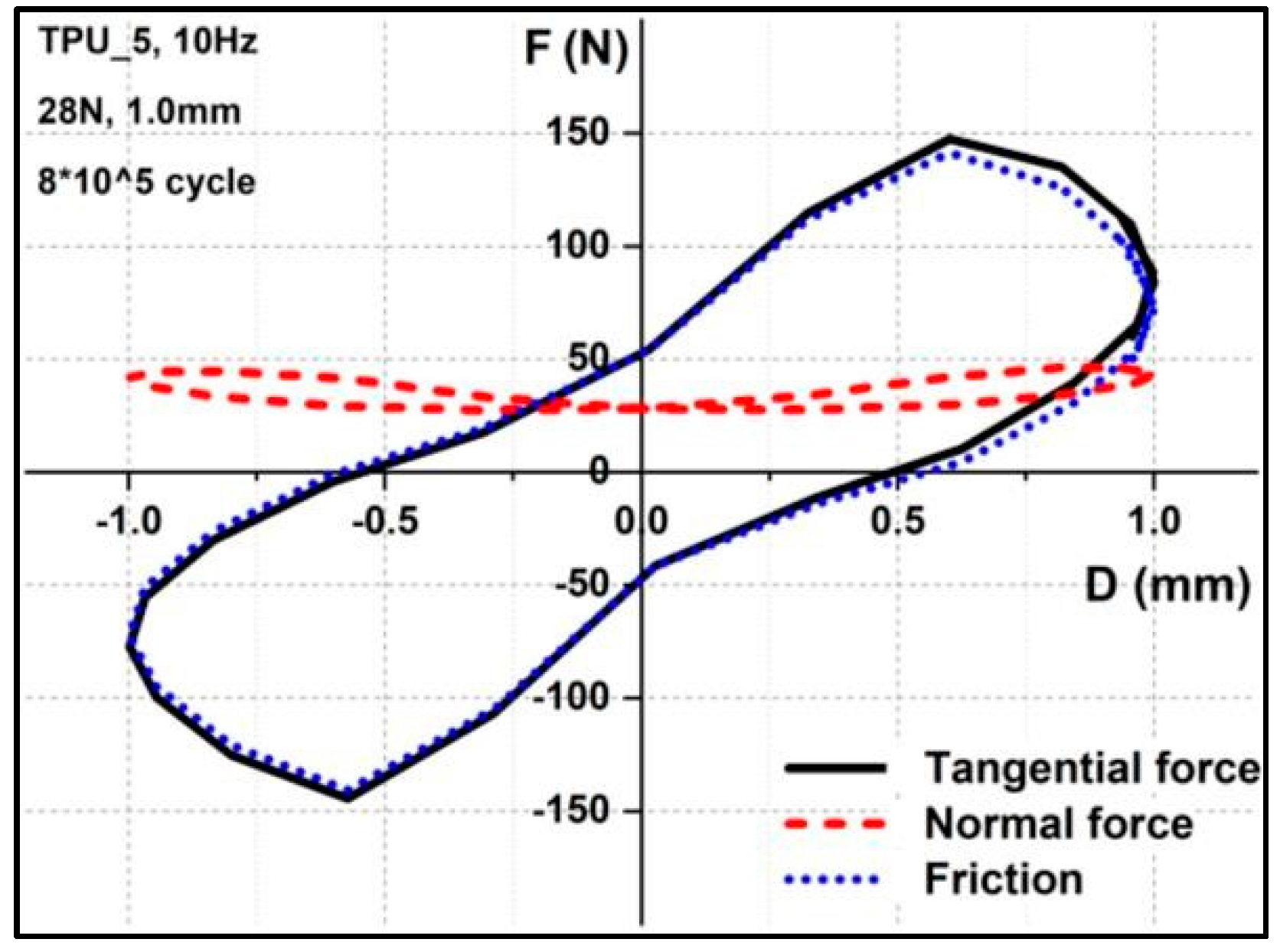

The wear scars of TPU_4 seem to be smoother than those of TPU_5. As shown in

Figure 22b, a slight trough can be found on the surface. Images with high magnification for the trough are shown in

Figure 22c,d. By using the method from our previous work [

12], the friction force and normal force were calculated and are shown in

Figure 23 with tangential force. As can be observed, the friction force is slightly smaller than the tangential force. The normal force is 28 N at D = 0 mm and increases with displacement. The maximal normal force reaches approximately 46 N at approximately D = 0.8–0.9 mm. In the reverse direction, the normal force decreases to 28 N. The trough could be the result of the coaction of small debris with large stripe-like debris under high normal load.

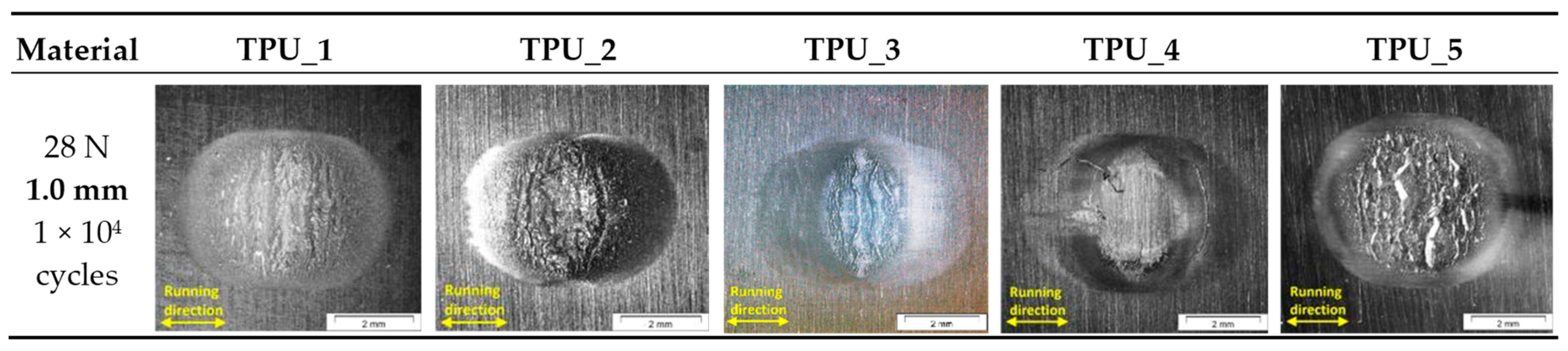

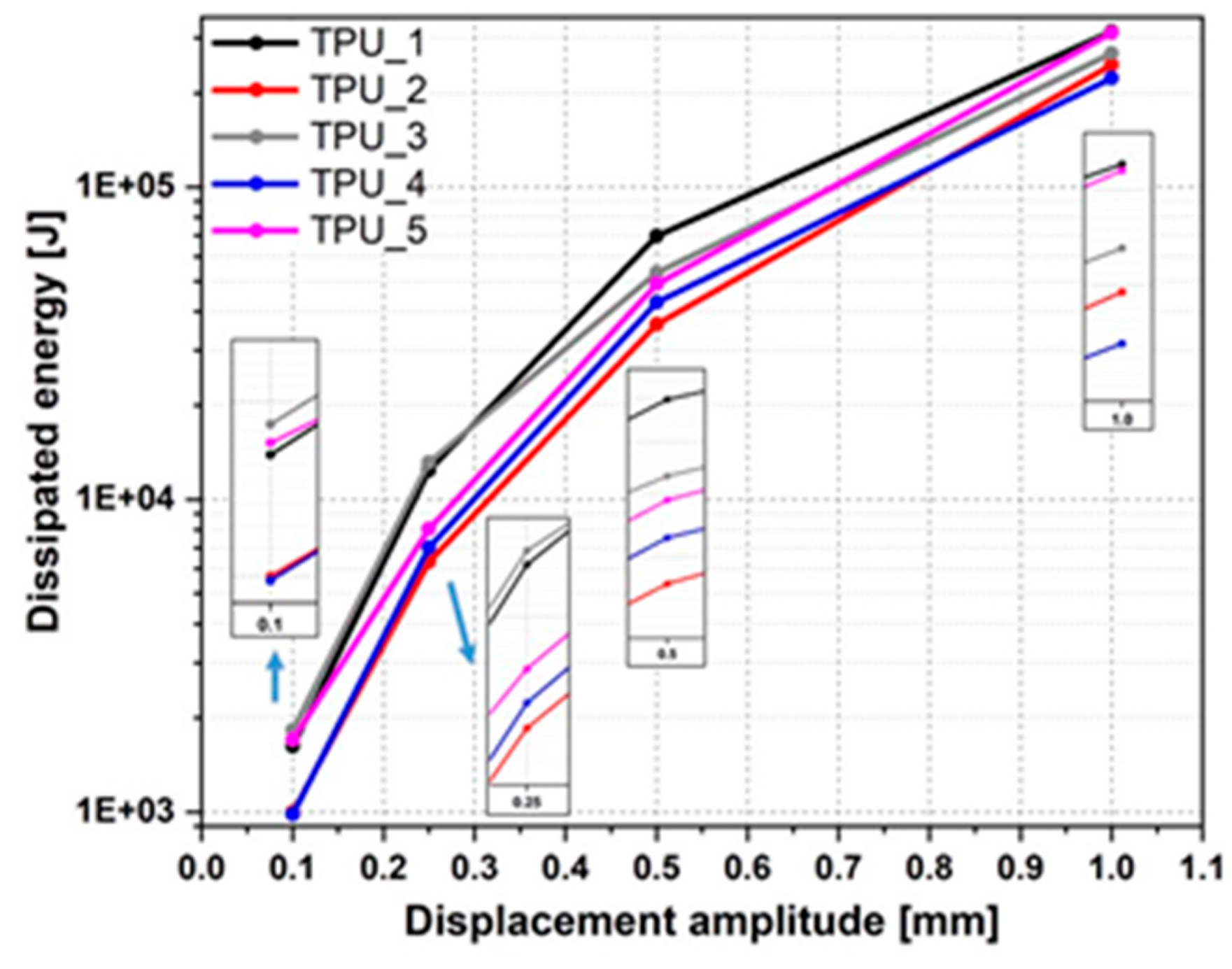

As shown in

Figure 17 and discussed previously, the 10

4 cycle is the approximate transition field for all five TPUs in hysteresis. In order to investigate the alteration process of the wear scars and correlate the hysteresis with the wear scars, tests were conducted until 10

4 cycles.

Figure 24 shows the micrographs of the wear scars. In TPUs_1, 2, and 5, similar wear scars can be observed on the surface after 10

4 cycles. Large cracks were nucleated and propagated perpendicular to the sliding direction, while on TPU_3 the cracks are focused in the middle area and both sides are relatively smooth. For TPU_4, its wear scars after 10

4 cycles look similar to those seen after 8 × 10

5 cycles in the mixed fretting regime. The middle area seems to be stuck on the counterpart. This can be ascribed to its distinctly lower storage modulus under 10 Hz load compared with the other materials. For this reason, TPU_4 can deform even under 1.0 mm displacement amplitude, so that no slip can occur between the middle area of the sample and the counterpart. Stripe-like wear debris can be seen on the surface, which was rolled because of the slip movements on both sides.

Figure 25 shows the profiles of the wear scars after 10

4 cycles. Almost no change can be identified for TPU_4. However, severe wear can be observed in other materials to varying degrees. This reveals the formation process of the wear scars.

After 10

4 cycles, severe wear can be observed in the middle part of the contact area in TPU_3 (

Figure 26a). Sizeable stripe-like debris was generated on both sides, which is perpendicular to the sliding direction. However, small debris can be found at the edge of the sliding area (

Figure 26c,d). This debris was not rolled together as large debris and was partially removed to the edge and partially pressed on the surface (

Figure 26d). In addition, abrasive wear can also be identified (

Figure 26e). Meanwhile, flake-like debris is visible (

Figure 26f), which can be attributed to surface fatigue. At the edge of the middle scar, the embryonic form of the sizeable stripe-like debris can be observed (

Figure 26g). As shown in

Figure 26h, because of the cracks, the debris was separated from the substrate and began to connect to form large pieces of debris. With further cycles, more debris would be rolled together.