An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications

Abstract

1. Introduction

2. Wear Behavior of Ti Alloys (Without Surface Modifications)

3. Surface Modification Methods

3.1. Surface Texturing

3.2. Surface Grafting

3.3. Surface Coatings

4. Wear Behavior of Modified Ti Alloys

5. Summary

- Surface coatings have resolved the issues related to the negative effects of metal bearings. They can improve wear resistance, wettability, and the mechanical properties of the modified surface.

- Surface texturing techniques decrease the friction coefficient between the contacting surfaces substantially by generating hydrodynamic pressure.

- Both coating techniques and surface texturing can decrease wear and friction initially.

- Remarkably, it is concluded that the PMPC-grafted surface layer can act as a suitable lubricant to mimic the articular cartilage physiologically. It shows an important decrease in friction coefficient than that of the coated and textured surfaces. Clinical success of PMPC grafted surface has been also proved in some recent studies.

- Titanium alloys show unsuitable wear resistance and tribological properties because of their low surface oxides and plastic shearing.

- The porosity of the material should be considered for the selection of a proper processing technique.

- Surface modification methods can be used to make an improvement in the tribological properties of titanium alloys.

Author Contributions

Funding

Conflicts of Interest

References

- Affatato, S.; Ruggiero, A. Surface analysis on revised hip implants with stem taper for wear and failure incidence evaluation: A first investigation. Meas. J. Int. Meas. Confed. 2019, 145, 38–44. [Google Scholar] [CrossRef]

- Affatato, S.; Brando, D. Introduction to wear phenomena of orthopaedic implants. Wear Orthop. Implant. Artif. Jt. 2013, 3–26. [Google Scholar] [CrossRef]

- Ruggiero, A.; Merola, M.; Affatato, S. On the biotribology of total knee replacement: A new roughness measurements protocol on In Vivo condyles considering the dynamic loading from musculoskeletal multibody model. Measurement 2017, 112, 22–28. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Park, C.H.; Park, J.-W.; Yeom, J.-T.; Chun, Y.S.; Lee, C.S. Enhanced mechanical compatibility of submicrocrystalline Ti-13Nb-13Zr alloy. Mater. Sci. Eng. A 2010, 527, 4914–4919. [Google Scholar] [CrossRef]

- Gibson, L.J. The mechanical behavior of cancellous bone. J. Biomech. 1985, 18, 317. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Sumner, D.R.; Galante, J.O. Determinants of stress shielding. Clin. Orthop. Relat. Res. 1992, 274, 203–212. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, Z.; Li, L. Corrosion fatigue resistances of surgical implant stainless steels and titanium alloy. Corros. Sci. 1993, 35, 587–597. [Google Scholar] [CrossRef]

- Okazaki, Y.; Ito, Y.; Kyo, K.; Tateishi, T. Corrosion resistance and corrosion fatigue strength of new titanium alloys for medical implants without V and Al. Mater. Sci. Eng. A 1996, 213, 138–147. [Google Scholar] [CrossRef]

- Ikeda, M.; Komatsu, S.-Y.; Sowa, I.; Niinomi, M. Aging behavior of the Ti-29Nb-13Ta-4.6Zr new beta alloy for medical implants. Met. Mater. Trans. A 2002, 33, 487–493. [Google Scholar] [CrossRef]

- Shukla, A.; Balasubramaniam, R.; Bhargava, S.; Shukla, A. Effect of replacement of V by Fe and Nb on passive film behavior of Ti–6Al–4V in simulated body fluid conditions. J. Alloys Compd. 2005, 389, 144–152. [Google Scholar] [CrossRef]

- Niinomi, M.; Hattori, T.; Morikawa, K.; Kasuga, T.; Suzuki, A.; Fukui, H.; Niwa, S. Development of low rigidity β-type titanium alloy for biomedical applications. Mater. Trans. 2002, 43, 2970–2977. [Google Scholar] [CrossRef]

- Tkachenko, S.; Datskevich, O.; Kulak, L.; Jacobson, S.; Engqvist, H.; Persson, C. Wear and friction properties of experimental Ti-Si-Zr alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2014, 39, 61–72. [Google Scholar] [CrossRef]

- Duisabeau, L.; Combrade, P.; Forest, B. Environmental effect on fretting of metallic materials for orthopaedic implants. Wear 2004, 256, 805–816. [Google Scholar] [CrossRef]

- Virtanen, S.; Milosev, I.; Gomez-Barrena, E.; Trebše, R.; Salo, J.; Konttinen, Y. Special modes of corrosion under physiological and simulated physiological conditions. Acta Biomater. 2008, 4, 468–476. [Google Scholar] [CrossRef]

- Revathi, A.; Magesh, S.; Balla, V.K.; Das, M.; Manivasagam, G. Current advances in enhancement of wear and corrosion resistance of titanium alloys–A review. Mater. Technol. 2016, 31, 696–704. [Google Scholar]

- Frączek, T.; Olejnik, M.; Tokarz, A. Evaluation of plasma nitriding efficiency of titanium alloys for medical applications. Metalurgija 2009, 48, 83–86. [Google Scholar]

- Kustas, F.M.; Misra, M.S. Friction and wear of titanium alloys. In ASM Handbook, Friction, Lubrication, and Wear Technology; Blau, P.J., Ed.; ASM International: Geauga County, OH, USA, 1992; Volume 18, pp. 778–784. [Google Scholar]

- Textor, M.; Sittig, C.; Frauchiger, V.; Tosatti, S.; Brunette, D.M.; Tengvall, P.; Thomsen, P. Properties and Biological Significance of Natural Oxide Films on Titanium and Its Alloys. In The Effect of Hydrogen and Hydrides on the Integrity of Zirconium Alloy Components; Springer Science and Business Media LLC: Berlin, Germany, 2001; pp. 171–230. [Google Scholar]

- Yerokhin, A.L.; Niea, X.; Leyland, A.; Matthews, A. Characterization of oxide films produced by plasma electrolytic oxidation of a Ti-6Al-4V alloy. Surf. Coat. Technol. 2000, 130, 195–206. [Google Scholar] [CrossRef]

- Fellah, M.; Labaiz, M.; Assala, O.; Dekhil, L.; Taleb, A.; Rezag, H.; Iost, A.; Labaï, Z.M. Tribological behavior of Ti-6Al-4V and Ti-6Al-7Nb Alloys for Total Hip Prosthesis. Adv. Tribol. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- De Viteri, V.S.; Fuentes, E. Titanium and Titanium Alloys as Biomaterials. In Tribology-Fundamentals and Advancements; IntechOpen: Rijeka, Croatia, 2013; pp. 155–181. [Google Scholar]

- Narayanana, B.; Rajamanickamb, A. A Review on Tribological Behaviour of Titanium Alloys. Int. J. Pure Appl. Math. 2018, 119, 2225–2229. [Google Scholar]

- Geetha, M.; Singh, A.; Asokamani, R.; Gogia, A. Ti based biomaterials, the ultimate choice for orthopaedic implants–A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Friction and surface behaviour of selected titanium alloys during reciprocating sliding motion. Wear 2001, 249, 158–168. [Google Scholar] [CrossRef]

- Choubey, A.; Basu, B.; Balasubramaniam, R. Tribological behaviour of Ti-based alloys in simulated body fluid solution at fretting contacts. Mater. Sci. Eng. A 2004, 379, 234–239. [Google Scholar] [CrossRef]

- Yoneyama, T.; Doi, H.; Kobayashi, E.; Nakano, T.; Hamanaka, H. Deformation property of titanium and dental alloys in an indentation test. Dent. Jpn. 1997, 33, 92–96. [Google Scholar]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Ganesh, B.K.C.; Ramanaih, N.; Bhuvaneswari, N.; Pammi, S.V.N. Effect of Hank’s solution and shot blasting on the tribological behavior of titanium implant alloys. Int. J. Mater. Biomater. Appl. 2012, 2, 5–11. [Google Scholar]

- Ren, G.; Zhang, Z.; Zhu, X.; Men, X.; Jiang, W.; Liu, W. Sliding wear behaviors of Nomex fabric/phenolic composite under dry and water-bathed sliding conditions. Friction 2014, 2, 264–271. [Google Scholar] [CrossRef]

- Dursun, Ö.; Tansel, T.; Hatice, E.; Ibrahim, Ç. Synthesis, characterization and Dry Sliding Wear Behavior of In-situ Formed TiAl3 Precipitate Reinforced A356 Alloy Produced by Mechanical Alloying Method. Mater. Res. 2015, 18, 813–820. [Google Scholar] [CrossRef]

- Mehdi, M.; Farokhzadeh, K.; Edrisy, A. Dry sliding wear behavior of superelastic Ti-10V-2Fe-3Al β-titanium alloy. Wear 2016, 350, 10–20. [Google Scholar] [CrossRef]

- Yildiz, F.; Yetim, A.; Alsaran, A.; Efeoglu, I. Wear and corrosion behaviour of various surface treated medical grade titanium alloy in bio-simulated environment. Wear 2009, 267, 695–701. [Google Scholar] [CrossRef]

- Li, S.J.; Yang, R.; Li, S.; Hao, Y.L.; Cui, Y.Y.; Niinomi, M.; Guo, Z.X. Wear characteristics of Ti-Nb-Ta-Zr and Ti-6Al-4V alloys for biomedical applications. Wear 2004, 257, 869–876. [Google Scholar] [CrossRef]

- Alam, M.; Haseeb, A. Response of Ti-6Al-4V and Ti-24Al-11Nb alloys to dry sliding wear against hardened steel. Tribol. Int. 2002, 35, 357–362. [Google Scholar] [CrossRef]

- Rigney, D.A. Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 1987, 119, 369–390. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.; Chakraborty, M. Wear response of heat-treated Ti-13Zr-13Nb alloy in dry condition and simulated body fluid. Wear 2008, 264, 1015–1025. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Cvijović, Z.; Mitrović, S.; Rakin, M.; Veljović, Đ.; Babić, M. Tribological behaviour of orthopaedic Ti-13Nb-13Zr and Ti-6Al-4V alloys. Tribol. Lett. 2010, 40, 59–70. [Google Scholar] [CrossRef]

- Ghosh, S.; Abanteriba, S. Status of surface modification techniques for artificial hip implants. Sci. Technol. Adv. Mater. 2016, 17, 715–735. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K. Improving the anti-seizure ability of SiC seal in water with RIE texturing. Tribol. Lett. 2003, 14, 275–280. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Suh, N.P.; Mosleh, M.; Howard, P.S. Control of friction. Wear 1994, 175, 51–158. [Google Scholar] [CrossRef]

- Ranjan, R.; Lambeth, D.N.; Trömel, M.; Goglia, P.; Li, Y. Laser texturing for low-flying-height media. J. Appl. Phys. 1991, 69, 5745–5747. [Google Scholar] [CrossRef]

- Ghosh, S.; Choudhury, D.; Das, N.S.; Pingguan-Murphy, B.; Pingguan-Murphy, B. Tribological role of synovial fluid compositions on artificial joints-a systematic review of the last 10 years. Lubr. Sci. 2014, 26, 387–410. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X. Biomimetic design of elastomer surface pattern for friction control under wet conditions. Bioinspir. Biomim. 2013, 8, 046001. [Google Scholar] [CrossRef]

- Ghosh, S.; Choudhury, D.; Roy, T.; Bin Mamat, A.; Masjuki, H.H.; Pingguan-Murphy, B. Tribological investigation of diamond-like carbon coated micro-dimpled surface under bovine serum and osteoarthritis oriented synovial fluid. Sci. Technol. Adv. Mater. 2015, 16, 35002. [Google Scholar] [CrossRef]

- Pratap, T.; Patra, K. Mechanical micro-texturing of Ti-6Al-4V surfaces for improved wettability and bio-tribological performances. Surf. Coat. Technol. 2018, 349, 71–81. [Google Scholar] [CrossRef]

- Wright, V.; Dowson, D. Lubrication and cartilage. J. Anat. 1976, 121, 107–118. [Google Scholar]

- Edmondson, S.; Osborne, V.L.; Huck, W.T. Polymer brushes via surface-initiated polymerizations. Chem. Soc. Rev. 2004, 33, 14–22. [Google Scholar] [CrossRef]

- Takatori, Y.; Moro, T.; Ishihara, K.; Kamogawa, M.; Oda, H.; Umeyama, T.; Kim, Y.T.; Ito, H.; Kyomoto, M.; Tanaka, T.; et al. Clinical and radiographic outcomes of total hip replacement with poly (2-methacryloyloxyethyl phosphorylcholine)-grafted highly cross-linked polyethylene liners: Three-year results of a prospective consecutive series. Mod. Rheumatol. 2015, 25, 286–291. [Google Scholar] [CrossRef]

- Klein, J. Hydration lubrication. Friction 2013, 1, 1–23. [Google Scholar] [CrossRef]

- Qin, L.; Feng, X.; Hafezi, M.; Zhang, Y.; Guo, J.; Dong, G.; Qin, Y. Investigating the tribological and biological performance of covalently grafted chitosan coatings on Co-Cr-Mo alloy. Tribol. Int. 2018, 127, 302–312. [Google Scholar] [CrossRef]

- Antunes, R.A.; De Oliveira, M.C.L. Corrosion processes of physical vapor deposition-coated metallic implants. Crit. Rev. Biomed. Eng. 2009, 37, 425–460. [Google Scholar] [CrossRef]

- Ching, H.A.; Choudhury, D.; Nine, M.J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 14402. [Google Scholar] [CrossRef]

- Ghosh, S.; Choudhury, D.; Pingguan-Murphy, B. Lubricating ability of albumin and globulin on artificial joint implants: A tribological perspective. Int. J. Surface Sci. Eng. 2016, 10, 193–206. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Bai, W.; Zhao, X.; Wang, T.; Tu, J. Bias-graded deposition and tribological properties of Ti-contained a-C gradient composite film on Ti6Al4V alloy. Appl. Surf. Sci. 2013, 279, 450–457. [Google Scholar] [CrossRef]

- Bai, W.; Cai, J.; Wang, X.; Wang, D.; Gu, C.; Tu, J. Mechanical and tribological properties of a-C/a-C:Ti multilayer films with various bilayer periods. Thin Solid Film. 2014, 558, 176–183. [Google Scholar] [CrossRef]

- Hsu, C.-S.; Li, Q. Surface modification of Ti64 through hydrothermal treatment in urea solutions. Mater. Lett. 2018, 216, 299–302. [Google Scholar] [CrossRef]

- Datta, S.; Das, M.; Balla, V.K.; Bodhak, S.; Murugesan, V. Mechanical, wear, corrosion and biological properties of arc deposited titanium nitride coatings. Surf. Coat. Technol. 2018, 344, 214–222. [Google Scholar] [CrossRef]

- Danışman, Ş.; Odabas, D.; Teber, M. The effect of coatings on the wear behavior of Ti6Al4V alloy used in biomedical applications. Mater. Sci. Eng. 2018, 295, 012044. [Google Scholar] [CrossRef]

- Waghmare, D.T.; Padhee, C.K.; Prasad, R.; Masanta, M. NiTi coating on Ti-6Al-4V alloy by TIG cladding process for improvement of wear resistance: Microstructure evolution and mechanical performances. J. Mater. Process. Technol. 2018, 262, 551–561. [Google Scholar] [CrossRef]

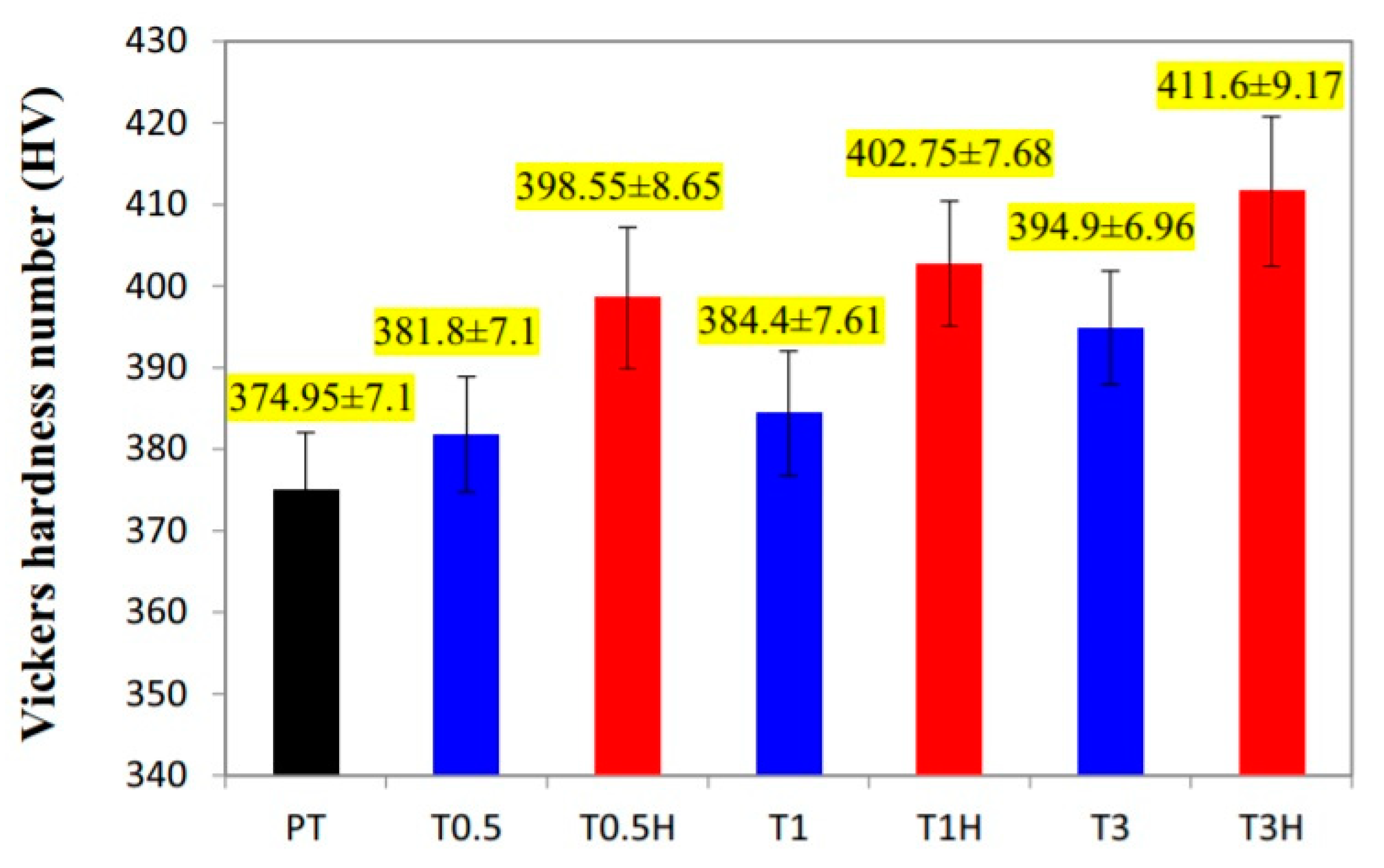

- Samanta, A.; Bhattacharya, M.; Ratha, I.; Chakraborty, H.; Datta, S.; Ghosh, J.; Bysakh, S.; Sreemany, M.; Rane, R.; Joseph, A.; et al. Nano- and micro-tribological behaviours of plasma nitrided Ti6Al4V alloys. J. Mech. Behav. Biomed. Mater. 2018, 77, 267–294. [Google Scholar] [CrossRef]

- Ng, C.; Chan, O.; Man, H. Formation of TiN Grid on NiTi by Laser Gas Nitriding for Improving Wear Resistance in Hanks’ Solution. J. Mater. Sci. Technol. 2016, 32, 459–464. [Google Scholar] [CrossRef]

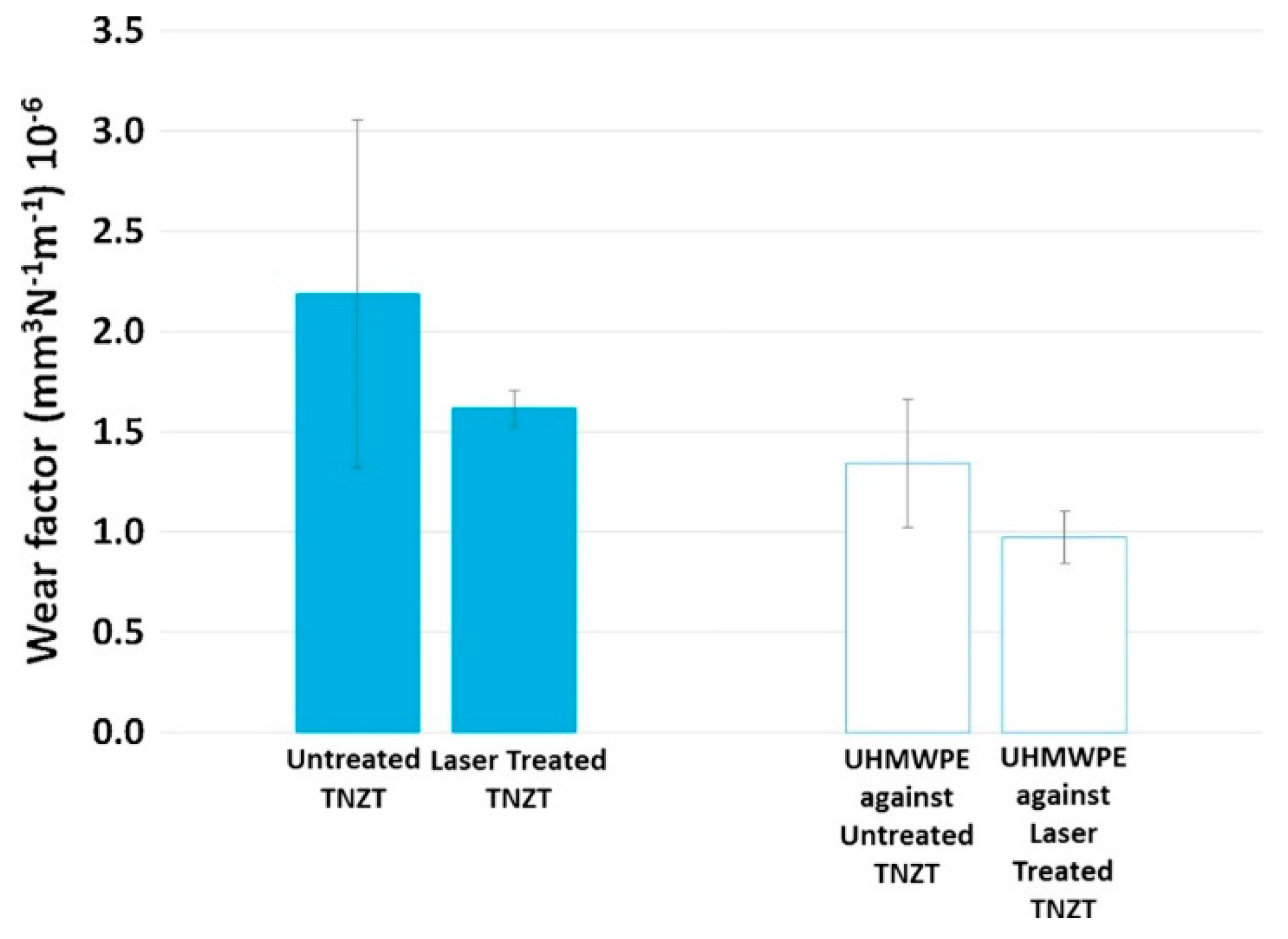

- Chan, C.-W.; Lee, S.; Smith, G.; Sarri, G.; Ng, C.-H.; Sharba, A.; Man, H.-C. Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl. Surf. Sci. 2016, 367, 80–90. [Google Scholar] [CrossRef]

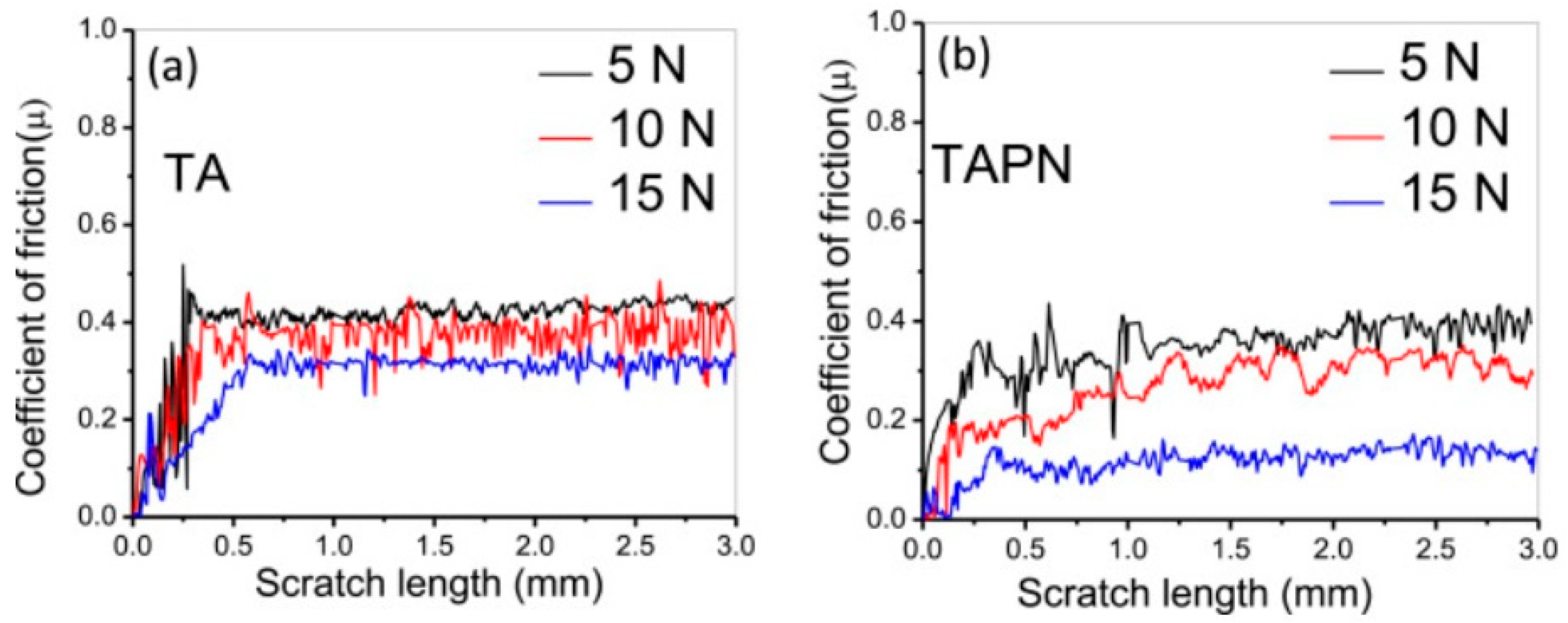

- Chan, C.-W.; Lee, S.; Smith, G.C.; Donaghy, C. Fibre laser nitriding of titanium and its alloy in open atmosphere for orthopaedic implant applications: Investigations on surface quality, microstructure and tribological properties. Surf. Coat. Technol. 2017, 309, 628–640. [Google Scholar] [CrossRef]

- Moro, T.; Takatori, Y.; Kyomoto, M.; Ishihara, K.; Kawaguchi, H.; Hashimoto, M.; Tanaka, T.; Oshima, H.; Tanaka, S. Wear resistance of the biocompatible phospholipid polymer-grafted highly cross-linked polyethylene liner against larger femoral head. J. Orthop. Res. 2015, 33, 1103–1110. [Google Scholar] [CrossRef]

- Kyomoto, M.; Moro, T.; Saiga, K.; Hashimoto, M.; Ito, H.; Kawaguchi, H.; Takatori, Y.; Ishihara, K. Biomimetic hydration lubrication with various polyelectrolyte layers on cross-linked polyethylene orthopedic bearing materials. Biomaterials 2012, 33, 4451–4459. [Google Scholar] [CrossRef]

- Yamane, S.; Kyomoto, M.; Moro, T.; Watanabe, K.; Hashimoto, M.; Takatori, Y.; Tanaka, S.; Ishihara, K. Effects of extra irradiation on surface and bulk properties of PMPC-grafted cross-linked polyethylene. J. Biomed. Mater. Res. Part A 2016, 104, 37–47. [Google Scholar] [CrossRef]

- Moro, T.; Kawaguchi, H.; Ishihara, K.; Kyomoto, M.; Karita, T.; Ito, H.; Nakamura, K.; Takatori, Y. Wear resistance of artificial hip joints with poly (2-methacryloyloxyethyl phosphorylcholine) grafted polyethylene: Comparisons with the effect of polyethylene cross-linking and ceramic femoral heads. Biomaterials 2009, 30, 2995–3001. [Google Scholar] [CrossRef]

- Kyomoto, M.; Moro, T.; Takatori, Y.; Tanaka, S.; Ishihara, K. Multidirectional wear and impact-to-wear tests of phospholipid-polymer-grafted and vitamin E-blended crosslinked polyethylene: A pilot study. Clin. Orthop. Relat. Res. 2015, 473, 942–951. [Google Scholar] [CrossRef][Green Version]

- Affatato, S.; Ruggiero, A.; Merola, M.; Logozzo, S. Does metal transfer differ on retrieved Biolox® Delta composites femoral heads? Surface investigation on three Biolox® generations from a biotribological point of view. Compos. Part B Eng. 2017, 113, 164–173. [Google Scholar] [CrossRef]

- Affatato, S.; Ruggiero, A.; De Mattia, J.S.; Taddei, P. Does metal transfer affect the tribological behaviour of femoral heads? Roughness and phase transformation analyses on retrieved zirconia and Biolox® Delta composites. Compos. Part B Eng. 2016, 92, 290–298. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Bai, W.; Wang, D.; Gu, C.; Tu, J. Microstructure, mechanical and tribological properties of a-C/a-C:Ti nanomultilayer film. Surf. Coat. Technol. 2013, 232, 403–411. [Google Scholar] [CrossRef]

- Miller, P.; Holladay, J. Friction and wear properties of titanium. Wear 1958, 2, 133–140. [Google Scholar] [CrossRef]

- Rigney, D. Comments on the sliding wear of metals. Tribol. Int. 1997, 30, 361–367. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Tesi, B.; Bacci, T. Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 1997, 208, 105–112. [Google Scholar] [CrossRef]

- Young, L.; Dezhuang, Y.; Shiyu, H.E.; Wanliang, W.U. Dry Sliding Wear of Ti-6Al-4V Alloy in Air and Vaccum. Trans. Nonferrous Soc. China 2003, 13, 1137–1140. [Google Scholar]

- Guleryuz, H.; Cimenoglu, H. Surface modification of a Ti–6Al–4V alloy by thermal oxidation. Surf. Coat. Technol. 2005, 192, 164–170. [Google Scholar] [CrossRef]

- Qiu, M.; Zhang, Y.; Zhu, J.; Yang, J. Dry friction characteristics of Ti-6Al-4V alloy under high sliding velocity. J. Wuhan Univ. Technol. Sci. Ed. 2007, 22, 582–585. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Mitrović, S.; Cvijović, Z.; Veljović, Đ.; Babić, M.; Rakin, M. Influence of the heat treatment on the tribological characteristics of the Ti-based alloy for biomedical applications. Tribol. Ind. 2009, 31, 17–22. [Google Scholar]

- El-Tayeb, N.; Yap, T.; Brevern, P. Wear characteristics of titanium alloy Ti54 for cryogenic sliding applications. Tribol. Int. 2010, 43, 2345–2354. [Google Scholar] [CrossRef]

- Blau, P.J.; Erdman, D.L., III; Ohriner, E.; Jolly, B.C. High-Temperature Galling Characteristics of TI-6AL-4V With and Without Surface Treatments. Tribol. Trans. 2011, 54, 192–200. [Google Scholar] [CrossRef]

- Cui, X.H.; Mao, Y.S.; Wei, M.X.; Wang, S.Q. Wear Characteristics of Ti-6Al-4V Alloy at 20–400 °C. Tribol. Trans. 2012, 55, 185–190. [Google Scholar] [CrossRef]

- Sharma, M.D.; Sehgal, R. Dry Sliding Friction and Wear Behaviour of Titanium Alloy (Ti-6Al-4V). Tribol. Online 2012, 7, 87–95. [Google Scholar] [CrossRef]

- Chen, K.M.; Zhang, Q.Y.; Li, X.X.; Wang, L.; Cui, X.H.; Wang, S.Q. Comparative Study of Wear Behaviors of a Selected Titanium Alloy and AISI H13 Steel as a Function of Temperature and Load. Tribol. Trans. 2014, 57, 838–845. [Google Scholar] [CrossRef]

- Chauhan, S.R.; Dass, K. Dry Sliding Wear Behaviour of Titanium (Grade 5) Alloy by Using Response Surface Methodology. Adv. Tribol. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Sahoo, R.; Jha, B.B.; Sahoo, T.K. Experimental Study on the Effect of Microstructure on Dry Sliding Wear Behavior of Titanium Alloy Using Taguchi Experimental Design. Tribol. Trans. 2014, 57, 216–224. [Google Scholar] [CrossRef]

- Sharma, M.D.; Sehgal, R.; Pant, M. Tribological behavior of Ti3Al2.5V alloy sliding against EN-31 steel under dry condition. Tribol. Trans. 2016, 59, 451–461. [Google Scholar] [CrossRef]

- Sharma, M.D.; Sehgal, R.; Pant, M. Modeling and Optimization of Friction and Wear Characteristics of Ti3Al2.5V Alloy Under Dry Sliding Condition. J. Tribol. 2016, 138, 031603. [Google Scholar] [CrossRef]

- Ghosh, S.; Abanteriba, S.; Wong, S.; Houshyar, S. Selective laser melted titanium alloys for hip implant applications: Surface modification with new method of polymer grafting. J. Mech. Behav. Biomed. Mater. 2018, 87, 312–324. [Google Scholar] [CrossRef]

| Method | Coating | Thickness | Substrate | Results | Reference |

|---|---|---|---|---|---|

| Hydrothermal treatment in urea solution | Ti-oxide formation | 0.87–1.52 μm | Ti-6Al-4V |

| [59] |

| Magnetron sputtering | a-C/a-C-Ti multilayer film | 3 μm | Ti-6Al-4V |

| [58] |

| Bias—graded magnetron sputtering | Ti contained a-C gradient composite film | 1.5 μm | Ti-6Al-4V |

| [57] |

| Covalently graft or layer by layer deposition | chitosan | 4–8 nm (dried) 0–0.38 nm (wet condition) | Co-Cr-Mo |

| [53] |

| Cathodic arc deposition | TiN | 3.0 ± 0.1 μm | Ti-6Al-4V |

| [60] |

| Micro-texturing | Micro-dimple | Ti-6Al-4V |

| [48] | |

| Tungsten inert gas cladding | NiTi Coating | Ti-6Al-4V |

| [62] | |

| Plasma nitriding | Ti-6Al-4V |

| [63] | ||

| Grafting of selective laser melted alloy in N2 gas | poly (2-methacryloyloxyethyl phosphorylcholine) (PMPC) | 221 ± 80 nm | Ti-6Al-4V |

| [91] |

| Magnetron sputtering | TiN, TiAlN, TiCN | Average 2 μm | Ti-6Al-4V |

| [61] |

| Laser gas nitriding | TiN grid | 1.76 μm | NiTi alloy |

| [64] |

| Laser treatment (laser gas alloying with nitrogen) | 500 nm to 1 μm | Ti-35.3Nb-7.3Zr-5.7Ta |

| [65] | |

| Fiber laser nitriding in open atmosphere | Pure Ti & Ti-6Al-4V |

| [66] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaur, S.; Ghadirinejad, K.; H. Oskouei, R. An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications. Lubricants 2019, 7, 65. https://doi.org/10.3390/lubricants7080065

Kaur S, Ghadirinejad K, H. Oskouei R. An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications. Lubricants. 2019; 7(8):65. https://doi.org/10.3390/lubricants7080065

Chicago/Turabian StyleKaur, Sukhpreet, Khashayar Ghadirinejad, and Reza H. Oskouei. 2019. "An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications" Lubricants 7, no. 8: 65. https://doi.org/10.3390/lubricants7080065

APA StyleKaur, S., Ghadirinejad, K., & H. Oskouei, R. (2019). An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications. Lubricants, 7(8), 65. https://doi.org/10.3390/lubricants7080065