Abstract

The need for metallic biomaterials will always remain high with their growing demand in joint replacement in the aging population. This creates need for the market and researchers to focus on the development and advancement of the biometals. Desirable characteristics such as excellent biocompatibility, high strength, comparable elastic modulus with bones, good corrosion resistance, and high wear resistance are the significant issues to address for medical implants, particularly load-bearing orthopedic implants. The widespread use of titanium alloys in biomedical implants create a big demand to identify and assess the behavior and performance of these alloys when used in the human body. Being the most commonly used metal alloy in the fabrication of medical implants, mainly because of its good biocompatibility and corrosion resistance together with its high strength to weight ratio, the tribological behavior of these alloys have always been an important subject for study. Titanium alloys with improved wear resistance will of course enhance the longevity of implants in the body. In this paper, tribological performance of titanium alloys (medical grades) is reviewed. Various methods of surface modifications employed for titanium alloys are also discussed in the context of wear behavior.

1. Introduction

The growth of aging population has caused an increasing demand for using metallic biomaterials in the manufacturing process of medical implants (e.g., hip [1,2] and knee [2,3] implants). Metals (and metal alloys) including stainless steels, Co-Cr-Mo, and titanium alloys are most commonly used in load-bearing implants because of their favorable features such as high strength, stiffness, and toughness. Specifically, titanium alloys are more commonly used owing to their better biocompatibility and mechanical strength characteristics [4]. For instance, the lower wear rate was reported as a reason for the popularity of Ti-6Al-4V alloy although its high Young’s modulus may lead to stress shielding, incompatibility with the host bone, and bone resorption [5,6,7]. Increasing the risk of loosening at the implant-bone interference contributes to the growth of revision surgeries [8].

Presence of vanadium as a toxic threat for human tissues influences the activity of inflammatory response cells. In addition, the risk of developing Alzheimer’s disease may enhance with aluminum [9,10,11]. Replacing vanadium (V) by non-toxic elements such as niobium (Nb) and iron (Fe) in Ti-6Al-4Fe and Ti-6Al-4Nb resulted in improved corrosion resistance [12]. Some features of newly developed β-type titanium alloys have been reported in several studies including better mechanical strength, greater biocompatibility, low stiffness, and non-allergic characteristic in comparison with conventional Ti alloys [13]. However, low wear resistance and high friction coefficients were noted as the major issues of these alloys in implants’ design and manufacture [14,15,16]. To overcome these shortcomings some surface engineering techniques have been performed, such as nano-grained surface, laser surface texturing, coatings, and oxidation, as solutions [17]. This paper aims to review the literature on the tribological behavior of Ti alloys including new generation ones, and the effect of surface modification methods on the friction and wear resistance of these alloys.

2. Wear Behavior of Ti Alloys (Without Surface Modifications)

Generally, a poor tribological performance with low surface hardness has been reported for titanium alloys that are used in biomedical implants [18,19,20]. High coefficients of friction (COF), intense adhesive wear, and low abrasion resistance are regarded as the adverse effects of their tribological behavior [21]. Mechanical sliding between titanium alloys (or a titanium alloy and another material) may lead to wear damage over the surface by disrupting the protective oxide layer, mainly in the presence of a third body at the interface [22].

High reactivity of titanium alloys causes a rapid change of the oxide surface layer to oxidative environment; consequently, it may lead to a removal during the sliding of the two contacting surfaces [22]. After investigation of wear behavior by ball-on-disc and pin-on-disc tribometers, it was reported that the volume loss of titanium alloys increases with rising sliding speed. Higher wear resistance of Ti-6Al-4V alloy was also compared with Ti-6Al-7Nb alloy. This study listed Ti-6Al-7Nb and Ti-6Al-4V in a decreasing order based on their estimated wear values at any specific sliding speed [22].

The results of a study performed by De Viteri and Fuentes [23] showed that the protective oxide layer can be removed from the surface of metals. This phenomenon occurs by applying contact loads which allows metals to have interaction with the surrounding environment (or the adjacent material). It can cause adverse effects including high friction and corrosion, and also premature failure of implants [23]. Narayanana and Rajamanickamb [24] reviewed the mechanical and tribological behavior of titanium alloys. Poor tribological properties of titanium alloys were concluded in this study due to low plastic strain and unsuited surface reaction of titanium alloys to form oxides. Geetha et al. [25] found that the wear resistance of Ti-6Al-4V is lower than that of Co-Cr-Mo alloy and 316L stainless steel. In addition, higher metal concentrations were reported in the tissue that was removed from the area around the Ti-alloy prosthesis when compared with the Co-Cr alloy and stainless-steel prostheses.

Long et al. [26] described the process of wear by performing wear and fretting wear investigations on Ti-35Nb-6Zr-5Ta alloy. A correlation was found between the wear mechanism and both the plastic deformation and tribological transformation of surface (TTS) layers which included α-Ti grains (free from β phases). The fretting studies on two α+β alloys (Ti-6Al-4V and Ti-5V-3Al-3Cr-3Sn), and β alloy (Ti-15V-3Al-3Cr) in air showed the formation of TTS layers. The resulting wear particles caused third body abrasive wear. The lowest COF was reported for Ti-5Al-2.5Fe and the highest for commercially pure (CP) titanium, according to the investigations on the fretting wear rate of CP titanium, Ti-6Al-4V, Ti-5Al-2.5Fe, Ti-13Nb-13Zr, and Co-28Cr-6Mo alloys against a steel ball in Hank’s solution [27].

Yoneyama et al. [28] demonstrated a correlation between wear rate and hardness; when the hardness increases, the wear rate decreases. It was also pointed out that the wear rate of Ti-6Al-4V alloy was significantly less than that of Ti-6Al-7Nb alloy because of the higher hardness of Ti-6Al-4V. Higher hardness and the friction coefficient of Ti-6Al-4V caused reduced material removal specifically in higher sliding speeds. However, no significant change of material removal was identified for Ti-6Al-7Nb [28].

Titanium alloys have an adhesion ability because they are chemically active and ductile [29]. The large wear loss or removal of material is contributed by adhesion; therefore, the wear rate is found out by adding the adhesive wear to the total wear. The differences between the wear rates that were investigated in the body fluid environment and under normal atmosphere were reported by Ganesh et al. and Ren et al. [30,31]. Higher wear rates and material losses were shown in the body fluid environment compared to the normal atmospheric condition which may be due to the corrosive nature of the body fluid environment [30,31].

Dursun et al. [32] pointed out some information about the plastic deformation occurring during the initial phases of wear; and found that there is a positive correlation between this level of wear and the sliding distance. In another study, Choubey et al. [27] performed the tribological testing in Hank’s solution and reported that the cracks were created on all Ti alloy samples (e.g., Ti-6Al-4V and Ti-5Al-2.5Fe) because of abrasive wear. A liquid environment was also considered in this wear test to investigate the lubricant effect in reducing the friction; and the temperature remained the same at the contact area of the samples.

A comparative study between untreated and β-annealed Ti-10V-2Fe-3Al alloy by Mehdi et al. [33] showed that the β-annealed alloy has a higher wear resistance at loads ≤2 N because of the super-elasticity effect. Besides, a significant transition of the wear rates was seen in the loads over 2 N. Adhesion phenomenon and material transferring from Ti-alloy to steel were listed as the important reasons of these changes. The super-elasticity effect did not make any increase in the wear resistance level because of the changes in the adhesion behavior of the Ti-alloy.

Some other studies reported that there are several wear mechanisms while only a few of them can occur simultaneously. The basic wear mechanism in Ti alloys is abrasion followed by adhesion and transfer layer. The transfer of material is found important in case of tribology [34,35,36,37]. Alam and Haseeb [36] simulated the Ti-alloy pin-on-disc (steel) wear test and acknowledged that the adhesion occurs based on the transferred layer effect. But if no transfer layer exists, it means abrasive wear is dominant. Likewise, Majumdar et al. [38] found that the dominant wear is abrasive in Ti-13Zr-13Nb alloy by performing the wear test in Hank’s solution and Bovine serum. Cvijović-Alagić et al. [39] found that Ti-6Al-4V has a higher wear resistance than Ti-Nb-Zr alloy in Ringer’s solution, independent of the microstructure [39]. It was concluded that the wear decreases when the hardness increases. More wear loss also occurred in Ti-13Nb-13Zr. The amount of wear was lower in case of Ti-6Al-4V.

3. Surface Modification Methods

Surface modification is a solution to improve the properties of materials (and biomaterials that are relevant to this paper) such as tribological and mechanical properties. It can also improve the biocompatibility of medical devices. These methods can modify the surface properties (e.g., surface charge, surface composition, and surface energy). There is an increasing trend of using surface modifications in the manufacturing process of implants. However, more advancement is still needed in this specific field to minimize the wear rate of biomedical implants [40]. The surface modification methods can be mainly divided into three main categories, which are described below.

3.1. Surface Texturing

This method of surface modification can provide a lubricating effect to reduce the wear of implant surfaces [37]. This method is used to enhance the frictional and tribological performance of materials by producing micro-textures as lubricant storage on the material surface [41]. Besides, the hydrodynamic pressure increases during sliding [42] which can trap the wear debris in dimples [43], and reduce the contact area [44], the friction coefficient, and then the wear rate [45].

Improved lubricating effect of the small size dimple was explained by Huang and Wang [46] and an equal distribution of lubricant was reported because of high pore density. The dimples can store and release the lubricant under the loading conditions which lead to a decrease in the sliding contact and wear rate. By contrast, Ghosh et al. [47] found that textured surfaces cannot create a suitable wear resistance under high loads. An improved tribological behavior was seen in a simulated body fluid than in water even at higher loads. Totally, wear mechanism was explained as a cause of creating textured surface (a third body) and generating wear particles. A study by Pratap and Patra [48] showed that the mechanical surface modification enhanced the surface wettability and tribological properties of Ti-6Al-4V alloy. This comparative study of three different micro-tools (micro ball-end mill, micro flat-end mill, and micro drill) targeted to produce circular micro dimples on the surface with semi-hemispherical, flat, and conical end geometries, respectively. It was concluded that micro ball-end textured semi-hemispherical end micro-dimpled surface has a lower COF because of the highest aspect ratio (0.159) which improved the surface wettability. It caused a reduction in the wear rate by trapping the wear debris into the micro dimples. The enhancement of wettability by surface texturing may depend on some other factors such as primary surface conditions and textured geometry. Texturing with micro-dimples can also be a suitable option to improve the hydrophilicity [48].

3.2. Surface Grafting

Grafting is a way to improve surface hydrophilicity by increasing the wettability. The grafted surfaces possess a brush-like hydrophilic structure which seems similar to articular cartilage. This method protects the surface from biofouling by resisting the biofilm formation. The presence of water-soluble macromolecules is responsible for the hydrophilic nature of the cartilage. The fluid film formation, generated by the hydrophilic macromolecules, decrease the friction in the joints [45,46,47,48,49]. There are two general grafting methods: “grafting to” and “grafting from”. “Grafting to” is used in some polymer coatings such as spin and dip coatings. It provides low adhesion by using biological fluid as a suitable solvent for coated polymers. Thus, the coated material can be removed in a biological environment. “Grafting from” produces polymer brushes with high density that conform to solvents by changing the graft density [50].

Takatori et al. [51] focused on the development of poly (2-methacryloyloxyethyl phosphorylcholine) (PMPC) grafting onto cross-linked polyethylene (CLPE) in order to create more surface biocompatibility and hydrophilic in nanometer range. It showed a significant decrease in the magnitude of friction (μ = 0.0004) by using the hydration lubrication mechanism which was provided by trapping water molecules in PMPC-grafted surface [52]. With this study, the preventative role of bone-resorption in producing wear particles was identified by considering the point that the PMPC-grafted surface is biologically inert in nature. Qin et al. [53] reported grafting chitosan on Co-Cr-Mo alloy by applying the layer-by-layer deposition technique. As a result, a significant increase (about seven times) in the wear resistance level was found after investigating its tribological behavior under simulated conditions.

3.3. Surface Coatings

Surface coatings are applied to provide a layer onto the material surface with the purpose of improving the surface properties, and reducing the friction and wear rates [40]. Surface coatings can prevent the production of wear particles and improve the lifetime of medical implants [40]. There are various coating methods as wear resistant coatings such as metal nitriding, plasma nitriding, laser gas alloying, laser treatments, laser cladding, and sputtering. These coating methods are introduced to improve the physical and mechanical properties of the surface (e.g., hardness and hydrophilicity) and reduce the friction and wear rate of the material. Coatings can also prevent the tribo-corrosion of the bulk material [54,55]. Choosing a suitable coating deposition method plays a significant role in achieving a better performance of the coated surface. A high-quality surface such as dense, homogeneous with excellent adhesion to the substrate can only be obtained by using a suitable deposition method.

TiN coatings were reported to increase the wear rate at high surface roughness of 169 nm. It means that better surface wettability acts as a lubricant which can only be obtained by reducing the surface roughness; hence, lower surface roughness is required in order to reduce the friction and improve the wear resistance [56]. In some recent studies, magnetron sputtering method was used to improve the tribological behavior of Ti-6Al-4V alloy by creating multilayer films [57,58].

Hsu and Li [59] reported that the hydrothermally treated Ti-6Al-4V surfaces improved the tribological performance. The surface was treated in urea solution with or without the subsequent heat treatment. In another study, the cathodic arc deposition method was considered by Datta et al. [60] to deposit TiN coatings onto Ti-6Al-4V alloy. Better biocompatibility and non-toxicity were reported in the conclusions of this study which resulted in a significant reduction in wear rate. Danisman et al. [61] used magnetron sputtering to form three different coatings of TiN, TiAlN, and TiCN on Ti-6Al-4V. The results showed that TiN is more effective than the other two coating materials in reducing rate of wear.

Another method, tungsten inert gas cladding, was used to coat Ti-6Al-4V alloy with thick layers of NiTi and NiTi2. The thick layers were prepared using ball-mill route from the mixture of Ni and Ti powder [62]. The pin-on-disc wear test showed a significant reduction of wear in sliding abrasive wear of the coated sample [62]. Plasma nitriding of Ti-6Al-4V alloy as the other coating method was carried out in a plasma reactor with a hot wall vacuum chamber. The results showed that the wear rate of plasma nitrided Ti alloy was about 99% lower than that of the untreated Ti alloy [63].

Ng, Chan, and Man [64] worked on the surface of nickel-titanium (NiTi) and fabricated a grid network of titanium nitride using laser gas nitriding (LGN). Both hard-TiN grid and soft-NiTi substrate contributed to reducing the wear rate of the surface. Laser gas alloying treatment causes a substantial improvement in the surface properties of TNZT (Ti-Nb-Zr-Ta) alloy. The results of this method showed an improved sliding wear resistance against ultra-high-molecular-weight polyethylene (UHMWPE) in Hanks’ solution [65]. Direct laser nitriding technique associated with continuous-wave fiber also showed a suitable performance to modify the surfaces of commercially pure titanium and Ti-6Al-4V alloy. The increased wear resistance of Ti surfaces was proved using pin-on-disk wear tests and friction tests [66].

In summary, surface modification techniques are used for modifying the material surface to offer specific characteristics in different applications such as biomedical devices and implants. This paper reviews some relevant research papers, although there are many others which were excluded because their scope was not in tribology. Some derivations in parameters selection and experimental set-ups were seen in the studies. Furthermore, wide-ranging comparisons among the three surface modification techniques were not simple. Friction coefficient and wear rate are the evaluation criteria (two major factors) in most studies for assessing the tribological performance.

Overall, surface texturing techniques show an important decrease in friction coefficient for biomedical implants such as implant surfaces, although the wear rate of textured surface is still meaningfully high. Coatings and surface texturing techniques are investigated to enhance the wear performance of biomedical implant materials. The PMPC-grafted layer has accomplished an important goal simulating articular cartilage, which is very effective in lubrication and has resulted highly desirable tribological results and wear resistant properties. Its high oxidation stability causes excellent mechanical properties for long-term hip bearings. As a result, PMPC-grafted liner/head is ongoing in the long-term clinical usages. Recently, a successful clinical performance of PMPC grafter liner was reported by Moro et al. [67] after seven years’ post-surgery. No adverse effects and no revision surgery and no osteolysis were informed and observed. However, cobalt-chromium-molybdenum (Co-Cr-Mo) and cobalt-chromium (Co-Cr) alloys were used in recent studies as the head material against PMPC-grafted CLPE liner [67,68,69,70,71].

4. Wear Behavior of Modified Ti Alloys

Metal alloys including titanium alloys can be modified by surface modification techniques to improve the material properties and tribological performance [72,73]. In a study [57], amorphous carbon (a-C) gradient composite film with a 1.5 μm thickness was deposited on Ti-6Al-4V alloy using a bias-graded magnetron sputtering method. This method resulted in an increase in the adhesion strength, and a decrease in both friction coefficient (0.08) and wear rate (4.63 × 10−17 m3/Nm) in Hank’s solution. Bai et al. [58] modified Ti-6Al-4V using magnetron sputtering and created a-C/a-C:Ti multilayer film with a 3 μm thickness. It resulted in the lowest average COF of 0.09 and low wear rate of 8.06 × 10−17 m3/Nm. They also found the cracks-free wear track and no breakage of the film.

Titanium contained carbon-based nano-multilayer film was also developed on Ti-6Al-4V alloy with 2.1 μm thickness using closed field magnetron sputtering [74]. Lower wear rate (1.95 × 10−16 m3/Nm) in Hank’s solution was concluded in comparison with the normal atmospheric condition (4.25 × 10−17 m3/Nm). The energy-dispersive X-ray spectroscopy (EDX) outcomes showed a narrow track without wear debris with no breakage of film proved by the peaks of Ti and C.

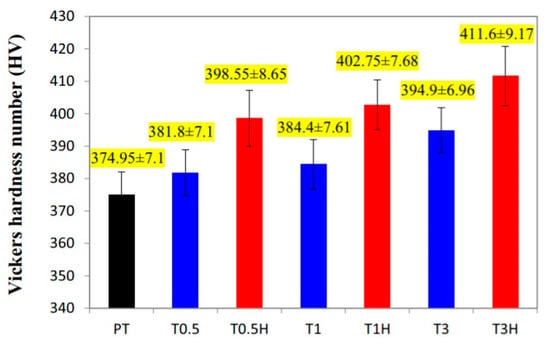

Based on a study on hydrothermal treatments [59], the polished Ti-6Al-4V surfaces were treated in urea solution with or without subsequent heating at 400 °C for 1 h. It reduced the surface roughness because of the formation of anatase TiO2 and increased the Vickers hardness with the increase in urea concentration from 0.5 M to 3 M as shown in Figure 1. Also, the contact angle increased, and hydrophilicity decreased with the increase in urea concentration and heat treatment.

Figure 1.

Variation in hardness with increase in urea concentration (H = heat treated, PT = polished/untreated) [59].

Datta et al. [60] studied cathodic arc deposit TiN coatings on Ti-6Al-4V alloy. The wear rate against the Al2O3 ball in Hank’s balanced salt solution (HBSS) was only one-fourth (6.8 ± 1.7 × 10−7 mm3/Nm) of the uncoated alloy. The hardness also increased seven times after TiN coatings. The biocompatibility and non-toxicity of TiN coatings were proved by in vitro cell viability assays in this paper. A thick layer of NiTi and NiTi2 was deposited on Ti-6Al-4V alloy using a tungsten inert gas cladding technique [62]. A pin-on-disc wear test showed a significant reduction in the wear rate of the coated sample which was 9.5 times less than the uncoated one as measured by the pin height loss.

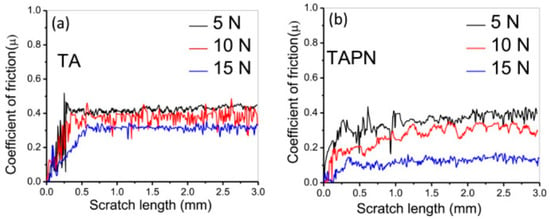

Plasma nitriding is another modification method that is used to reduce the wear rate in Ti alloys. This is performed in plasma reactor in a hot wall vacuum chamber. A study showed that the wear rate of plasma nitrided Ti alloy samples was 99% less than that of the uncoated ones. The COF of the plasma treated samples reduced 52%, and the wear track was much thinner compared with the untreated alloy, as shown in Figure 2. The average COF for plasma nitrided Ti alloy was reduced to 0.23 which was 0.35 before treatment. The wear rate at 15 N load was 7.66 × 10−12 m3/Nm of plasma treated alloy and 1.27 × 10−11 m3/Nm of the untreated one [63].

Figure 2.

The coefficients of friction (COF) as a function of scratch length for: (a) Ti-6Al-4V alloy (TA), and (b) plasma nitrided Ti-6Al-4V alloy (TAPN); under different loads [63].

Ghosh et al. [47] grafted poly (2-methacryloyloxyethyl phosphorylcholine) (PMPC) on Ti-6Al-4V alloy by selective laser melting. Three different techniques (ultraviolet (UV) irradiation, thermal heating, and UV irradiation by N2 gas) were applied during the tests and the results showed a great performance for N2 gas because of existing oxygen in the atmosphere which prevented the polymerization. Improvements in the wear resistance of the treated surface were obtained (by scratch test). The improved wear resistance of the treated surface was proved by scratch test; the scratch depth was of ~50 nm on the untreated sample while there was almost no scratch (~5 nm) on the grafted sample under 0.5 mN load.

Danisman et al. [61] deposited three different coatings of TiN, TiAlN, and TiCN with an average thickness of 2 μm on Ti-6Al-4V using the magnetron sputtering method. The results demonstrated lower wear rates for TiN coated alloy. The average weight loss of 0.38 mg, wear track width of 0.87 mm, and average COF value of 0.45 were also found. The nickel titanium (NiTi) was modified by fabricating the titanium nitride (TiN) grid network which was performed using laser gas nitriding [64]. The wear rate of the treated sample reduced because of the lubrication effect supported by the hydrophilic (nitrided NiTi)/hydrophobic (UHMWPE) friction coupling. The reduction in wear rate was contributed by both a hard-TiN grid and a soft-NiTi substrate. Also, the hardness of the sample improved about four times and Young’s Modulus reduced about two times after the treatment. The HN/Er ratio of NiTi substrate (0.066) was about half of the nitride layer (0.136). This method resulted in a lower COF in the range of 0.04–0.07 as compared to the untreated surface of 0.14. It was also found that the wear factor decreases with an increase in the nitride coverage area.

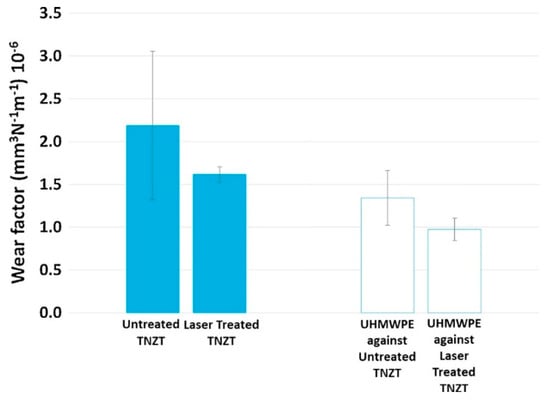

Chan et al. [65] treated the TNZT alloy to improve its surface properties by laser gas alloying treatment. The performance was investigated in Hank’s solution when TNZT was sliding against UHMWPE. The pin-on-plate sliding test showed that the wear resistance was improved only because of small amounts of material loss. The wear factor (1.7 × 10−6 mm3/Nm) was reduced 26% after the treatment [65]. Figure 3 shows the wear factor of treated and untreated alloys from the sliding test.

Figure 3.

Wear factor of Ti-Nb-Zr-Ta (TNZT) with and without laser treatment from ultra-high-molecular-weight polyethylene (UHMWPE) pin/TNZT plate sliding test [65].

In another study [63], the direct laser nitriding was applied on commercially pure titanium and also Ti-6Al-4V alloy in an open atmosphere using continuous-wave (CW) fiber laser. Investigation of friction and wear rate in fetal bovine serum (FBS) associated with pin-on-disk test results showed that the mass loss in the treated pure titanium pair (0.02 mg) and Ti alloy pair (0.06 mg) was lower than that of in the untreated pure titanium (34.14 mg) and Ti alloy pairs (9.23 mg) [66]. Many researchers have investigated the tribological behavior of titanium alloys that are used in many applications in various fields. Several papers have been published on the dry sliding wear behavior of titanium alloys under various conditions.

Miller et al. [75] reported that galling occurs on the bare titanium and it stops working when it is in sliding contact with itself and most other metals. Rigney et al. [76] reported that the abrasive wear condition may arise when system shifts toward transition as sliding wear proceeds. In case of ductile materials, sliding wear processes are accompanied by severe plastic deformation. In 1999, Molinari et al. [77] assessed the wear mechanisms of titanium alloys under various loads and sliding speeds. In 2002, the response of different titanium alloys to dry sliding wear against hardened steel was studied by Alam and Haseeb [36]. In 2003, Young et al. [78] studied the dry sliding wear behavior of titanium alloys both in atmospheric and vacuum conditions. Guleryuz and Cimenoglu [79] studied the wear behavior of titanium alloys by adopting surface modification techniques. In 2007, Ming et al. [80] studied the dry friction characteristics of titanium alloy under high sliding velocity. Majumdar et al. [38] studied the wear response of heat-treated titanium alloys under dry and simulated body fluid conditions. In 2009, Cvijovic-alagic et al. [81] studied the effect of heat treatment and the tribological properties of titanium alloys. In 2010, El-tyeb et al. [82] reported the sliding wear characteristics of titanium alloys with the purpose of using in cryogenic sliding applications. The high-temperature galling characteristics of titanium alloys were studied by Blau et al. [83] in two separate conditions (with and without surface treatments). Cui et al. [84] studied the wear characteristics of titanium alloys at various temperatures. In 2012, Sharma et al. [85] studied the dry sliding wear behavior of titanium alloy (Ti-6Al-4V). Chen et al. [86] studied the wear behavior of selected titanium alloys and compared with AISI H13 steel as a function of load and temperature. In 2013, Chauhan et al. [87] used the response surface methodology to study the dry sliding wear behavior of titanium alloys. Sahoo et al. [88] studied the effect of microstructure on the dry sliding wear behavior of titanium alloys. In 2015, Sharma et al. [89] studied the tribological behavior of Ti-3Al-2.5V alloy sliding against EN32 steel disc of hardness 62HRC, in the dry sliding condition. Sharma et al. [90] studied the optimization of wear and friction characteristics of Ti-3Al-2.5 V alloy sliding against EN32 steel disc of hardness 62HRC in the dry sliding condition. Generally, the mechanical and tribological properties of titanium alloys can be greatly controlled by the resistance to plastic shearing, micro cracking tendency, and thermal stability of the material.

5. Summary

There is a never-ending demand for Ti-based alloys in biomedical applications owing to their good physical, mechanical, and biological performance. Presently, significant improvements on the low modulus β-type Ti-based alloys are being achieved as these alloys appear to be a promising replacement for the conventional Ti alloys. This paper presented an overview on the recent developments of biomedical Ti-based alloys and specifically their wear resistance behavior. Various surface modification methods are discussed and their effect on the wear resistance of the alloys are presented in Table 1. This paper also shows the importance of investigating surface modification methods to support further improvements in titanium alloys in medical implant applications.

Table 1.

Summary of surface modification methods.

It is obvious that surface modifications have important positive effects on the tribological performance. In recent decades, considerable progress has been made in the basic understanding of better surface designing for both in vitro and in vivo applications. The study summarizes the following points:

- Surface coatings have resolved the issues related to the negative effects of metal bearings. They can improve wear resistance, wettability, and the mechanical properties of the modified surface.

- Surface texturing techniques decrease the friction coefficient between the contacting surfaces substantially by generating hydrodynamic pressure.

- Both coating techniques and surface texturing can decrease wear and friction initially.

- Remarkably, it is concluded that the PMPC-grafted surface layer can act as a suitable lubricant to mimic the articular cartilage physiologically. It shows an important decrease in friction coefficient than that of the coated and textured surfaces. Clinical success of PMPC grafted surface has been also proved in some recent studies.

In addition, this review extracts the following points about the mechanical and tribological behavior of titanium alloys:

- Titanium alloys show unsuitable wear resistance and tribological properties because of their low surface oxides and plastic shearing.

- The porosity of the material should be considered for the selection of a proper processing technique.

- Surface modification methods can be used to make an improvement in the tribological properties of titanium alloys.

Author Contributions

S.K. and K.G. contributed to the literature review, structure and writing of the manuscript. R.H.O. supervised and contributed to the structure and writing of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Affatato, S.; Ruggiero, A. Surface analysis on revised hip implants with stem taper for wear and failure incidence evaluation: A first investigation. Meas. J. Int. Meas. Confed. 2019, 145, 38–44. [Google Scholar] [CrossRef]

- Affatato, S.; Brando, D. Introduction to wear phenomena of orthopaedic implants. Wear Orthop. Implant. Artif. Jt. 2013, 3–26. [Google Scholar] [CrossRef]

- Ruggiero, A.; Merola, M.; Affatato, S. On the biotribology of total knee replacement: A new roughness measurements protocol on In Vivo condyles considering the dynamic loading from musculoskeletal multibody model. Measurement 2017, 112, 22–28. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Park, C.H.; Park, J.-W.; Yeom, J.-T.; Chun, Y.S.; Lee, C.S. Enhanced mechanical compatibility of submicrocrystalline Ti-13Nb-13Zr alloy. Mater. Sci. Eng. A 2010, 527, 4914–4919. [Google Scholar] [CrossRef]

- Gibson, L.J. The mechanical behavior of cancellous bone. J. Biomech. 1985, 18, 317. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Sumner, D.R.; Galante, J.O. Determinants of stress shielding. Clin. Orthop. Relat. Res. 1992, 274, 203–212. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, Z.; Li, L. Corrosion fatigue resistances of surgical implant stainless steels and titanium alloy. Corros. Sci. 1993, 35, 587–597. [Google Scholar] [CrossRef]

- Okazaki, Y.; Ito, Y.; Kyo, K.; Tateishi, T. Corrosion resistance and corrosion fatigue strength of new titanium alloys for medical implants without V and Al. Mater. Sci. Eng. A 1996, 213, 138–147. [Google Scholar] [CrossRef]

- Ikeda, M.; Komatsu, S.-Y.; Sowa, I.; Niinomi, M. Aging behavior of the Ti-29Nb-13Ta-4.6Zr new beta alloy for medical implants. Met. Mater. Trans. A 2002, 33, 487–493. [Google Scholar] [CrossRef]

- Shukla, A.; Balasubramaniam, R.; Bhargava, S.; Shukla, A. Effect of replacement of V by Fe and Nb on passive film behavior of Ti–6Al–4V in simulated body fluid conditions. J. Alloys Compd. 2005, 389, 144–152. [Google Scholar] [CrossRef]

- Niinomi, M.; Hattori, T.; Morikawa, K.; Kasuga, T.; Suzuki, A.; Fukui, H.; Niwa, S. Development of low rigidity β-type titanium alloy for biomedical applications. Mater. Trans. 2002, 43, 2970–2977. [Google Scholar] [CrossRef]

- Tkachenko, S.; Datskevich, O.; Kulak, L.; Jacobson, S.; Engqvist, H.; Persson, C. Wear and friction properties of experimental Ti-Si-Zr alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2014, 39, 61–72. [Google Scholar] [CrossRef]

- Duisabeau, L.; Combrade, P.; Forest, B. Environmental effect on fretting of metallic materials for orthopaedic implants. Wear 2004, 256, 805–816. [Google Scholar] [CrossRef]

- Virtanen, S.; Milosev, I.; Gomez-Barrena, E.; Trebše, R.; Salo, J.; Konttinen, Y. Special modes of corrosion under physiological and simulated physiological conditions. Acta Biomater. 2008, 4, 468–476. [Google Scholar] [CrossRef]

- Revathi, A.; Magesh, S.; Balla, V.K.; Das, M.; Manivasagam, G. Current advances in enhancement of wear and corrosion resistance of titanium alloys–A review. Mater. Technol. 2016, 31, 696–704. [Google Scholar]

- Frączek, T.; Olejnik, M.; Tokarz, A. Evaluation of plasma nitriding efficiency of titanium alloys for medical applications. Metalurgija 2009, 48, 83–86. [Google Scholar]

- Kustas, F.M.; Misra, M.S. Friction and wear of titanium alloys. In ASM Handbook, Friction, Lubrication, and Wear Technology; Blau, P.J., Ed.; ASM International: Geauga County, OH, USA, 1992; Volume 18, pp. 778–784. [Google Scholar]

- Textor, M.; Sittig, C.; Frauchiger, V.; Tosatti, S.; Brunette, D.M.; Tengvall, P.; Thomsen, P. Properties and Biological Significance of Natural Oxide Films on Titanium and Its Alloys. In The Effect of Hydrogen and Hydrides on the Integrity of Zirconium Alloy Components; Springer Science and Business Media LLC: Berlin, Germany, 2001; pp. 171–230. [Google Scholar]

- Yerokhin, A.L.; Niea, X.; Leyland, A.; Matthews, A. Characterization of oxide films produced by plasma electrolytic oxidation of a Ti-6Al-4V alloy. Surf. Coat. Technol. 2000, 130, 195–206. [Google Scholar] [CrossRef]

- Fellah, M.; Labaiz, M.; Assala, O.; Dekhil, L.; Taleb, A.; Rezag, H.; Iost, A.; Labaï, Z.M. Tribological behavior of Ti-6Al-4V and Ti-6Al-7Nb Alloys for Total Hip Prosthesis. Adv. Tribol. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- De Viteri, V.S.; Fuentes, E. Titanium and Titanium Alloys as Biomaterials. In Tribology-Fundamentals and Advancements; IntechOpen: Rijeka, Croatia, 2013; pp. 155–181. [Google Scholar]

- Narayanana, B.; Rajamanickamb, A. A Review on Tribological Behaviour of Titanium Alloys. Int. J. Pure Appl. Math. 2018, 119, 2225–2229. [Google Scholar]

- Geetha, M.; Singh, A.; Asokamani, R.; Gogia, A. Ti based biomaterials, the ultimate choice for orthopaedic implants–A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Friction and surface behaviour of selected titanium alloys during reciprocating sliding motion. Wear 2001, 249, 158–168. [Google Scholar] [CrossRef]

- Choubey, A.; Basu, B.; Balasubramaniam, R. Tribological behaviour of Ti-based alloys in simulated body fluid solution at fretting contacts. Mater. Sci. Eng. A 2004, 379, 234–239. [Google Scholar] [CrossRef]

- Yoneyama, T.; Doi, H.; Kobayashi, E.; Nakano, T.; Hamanaka, H. Deformation property of titanium and dental alloys in an indentation test. Dent. Jpn. 1997, 33, 92–96. [Google Scholar]

- Dong, H.; Bell, T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear 2000, 238, 131–137. [Google Scholar] [CrossRef]

- Ganesh, B.K.C.; Ramanaih, N.; Bhuvaneswari, N.; Pammi, S.V.N. Effect of Hank’s solution and shot blasting on the tribological behavior of titanium implant alloys. Int. J. Mater. Biomater. Appl. 2012, 2, 5–11. [Google Scholar]

- Ren, G.; Zhang, Z.; Zhu, X.; Men, X.; Jiang, W.; Liu, W. Sliding wear behaviors of Nomex fabric/phenolic composite under dry and water-bathed sliding conditions. Friction 2014, 2, 264–271. [Google Scholar] [CrossRef]

- Dursun, Ö.; Tansel, T.; Hatice, E.; Ibrahim, Ç. Synthesis, characterization and Dry Sliding Wear Behavior of In-situ Formed TiAl3 Precipitate Reinforced A356 Alloy Produced by Mechanical Alloying Method. Mater. Res. 2015, 18, 813–820. [Google Scholar] [CrossRef]

- Mehdi, M.; Farokhzadeh, K.; Edrisy, A. Dry sliding wear behavior of superelastic Ti-10V-2Fe-3Al β-titanium alloy. Wear 2016, 350, 10–20. [Google Scholar] [CrossRef]

- Yildiz, F.; Yetim, A.; Alsaran, A.; Efeoglu, I. Wear and corrosion behaviour of various surface treated medical grade titanium alloy in bio-simulated environment. Wear 2009, 267, 695–701. [Google Scholar] [CrossRef]

- Li, S.J.; Yang, R.; Li, S.; Hao, Y.L.; Cui, Y.Y.; Niinomi, M.; Guo, Z.X. Wear characteristics of Ti-Nb-Ta-Zr and Ti-6Al-4V alloys for biomedical applications. Wear 2004, 257, 869–876. [Google Scholar] [CrossRef]

- Alam, M.; Haseeb, A. Response of Ti-6Al-4V and Ti-24Al-11Nb alloys to dry sliding wear against hardened steel. Tribol. Int. 2002, 35, 357–362. [Google Scholar] [CrossRef]

- Rigney, D.A. Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 1987, 119, 369–390. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.; Chakraborty, M. Wear response of heat-treated Ti-13Zr-13Nb alloy in dry condition and simulated body fluid. Wear 2008, 264, 1015–1025. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Cvijović, Z.; Mitrović, S.; Rakin, M.; Veljović, Đ.; Babić, M. Tribological behaviour of orthopaedic Ti-13Nb-13Zr and Ti-6Al-4V alloys. Tribol. Lett. 2010, 40, 59–70. [Google Scholar] [CrossRef]

- Ghosh, S.; Abanteriba, S. Status of surface modification techniques for artificial hip implants. Sci. Technol. Adv. Mater. 2016, 17, 715–735. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K. Improving the anti-seizure ability of SiC seal in water with RIE texturing. Tribol. Lett. 2003, 14, 275–280. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Suh, N.P.; Mosleh, M.; Howard, P.S. Control of friction. Wear 1994, 175, 51–158. [Google Scholar] [CrossRef]

- Ranjan, R.; Lambeth, D.N.; Trömel, M.; Goglia, P.; Li, Y. Laser texturing for low-flying-height media. J. Appl. Phys. 1991, 69, 5745–5747. [Google Scholar] [CrossRef]

- Ghosh, S.; Choudhury, D.; Das, N.S.; Pingguan-Murphy, B.; Pingguan-Murphy, B. Tribological role of synovial fluid compositions on artificial joints-a systematic review of the last 10 years. Lubr. Sci. 2014, 26, 387–410. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X. Biomimetic design of elastomer surface pattern for friction control under wet conditions. Bioinspir. Biomim. 2013, 8, 046001. [Google Scholar] [CrossRef]

- Ghosh, S.; Choudhury, D.; Roy, T.; Bin Mamat, A.; Masjuki, H.H.; Pingguan-Murphy, B. Tribological investigation of diamond-like carbon coated micro-dimpled surface under bovine serum and osteoarthritis oriented synovial fluid. Sci. Technol. Adv. Mater. 2015, 16, 35002. [Google Scholar] [CrossRef]

- Pratap, T.; Patra, K. Mechanical micro-texturing of Ti-6Al-4V surfaces for improved wettability and bio-tribological performances. Surf. Coat. Technol. 2018, 349, 71–81. [Google Scholar] [CrossRef]

- Wright, V.; Dowson, D. Lubrication and cartilage. J. Anat. 1976, 121, 107–118. [Google Scholar]

- Edmondson, S.; Osborne, V.L.; Huck, W.T. Polymer brushes via surface-initiated polymerizations. Chem. Soc. Rev. 2004, 33, 14–22. [Google Scholar] [CrossRef]

- Takatori, Y.; Moro, T.; Ishihara, K.; Kamogawa, M.; Oda, H.; Umeyama, T.; Kim, Y.T.; Ito, H.; Kyomoto, M.; Tanaka, T.; et al. Clinical and radiographic outcomes of total hip replacement with poly (2-methacryloyloxyethyl phosphorylcholine)-grafted highly cross-linked polyethylene liners: Three-year results of a prospective consecutive series. Mod. Rheumatol. 2015, 25, 286–291. [Google Scholar] [CrossRef]

- Klein, J. Hydration lubrication. Friction 2013, 1, 1–23. [Google Scholar] [CrossRef]

- Qin, L.; Feng, X.; Hafezi, M.; Zhang, Y.; Guo, J.; Dong, G.; Qin, Y. Investigating the tribological and biological performance of covalently grafted chitosan coatings on Co-Cr-Mo alloy. Tribol. Int. 2018, 127, 302–312. [Google Scholar] [CrossRef]

- Antunes, R.A.; De Oliveira, M.C.L. Corrosion processes of physical vapor deposition-coated metallic implants. Crit. Rev. Biomed. Eng. 2009, 37, 425–460. [Google Scholar] [CrossRef]

- Ching, H.A.; Choudhury, D.; Nine, M.J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 14402. [Google Scholar] [CrossRef]

- Ghosh, S.; Choudhury, D.; Pingguan-Murphy, B. Lubricating ability of albumin and globulin on artificial joint implants: A tribological perspective. Int. J. Surface Sci. Eng. 2016, 10, 193–206. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Bai, W.; Zhao, X.; Wang, T.; Tu, J. Bias-graded deposition and tribological properties of Ti-contained a-C gradient composite film on Ti6Al4V alloy. Appl. Surf. Sci. 2013, 279, 450–457. [Google Scholar] [CrossRef]

- Bai, W.; Cai, J.; Wang, X.; Wang, D.; Gu, C.; Tu, J. Mechanical and tribological properties of a-C/a-C:Ti multilayer films with various bilayer periods. Thin Solid Film. 2014, 558, 176–183. [Google Scholar] [CrossRef]

- Hsu, C.-S.; Li, Q. Surface modification of Ti64 through hydrothermal treatment in urea solutions. Mater. Lett. 2018, 216, 299–302. [Google Scholar] [CrossRef]

- Datta, S.; Das, M.; Balla, V.K.; Bodhak, S.; Murugesan, V. Mechanical, wear, corrosion and biological properties of arc deposited titanium nitride coatings. Surf. Coat. Technol. 2018, 344, 214–222. [Google Scholar] [CrossRef]

- Danışman, Ş.; Odabas, D.; Teber, M. The effect of coatings on the wear behavior of Ti6Al4V alloy used in biomedical applications. Mater. Sci. Eng. 2018, 295, 012044. [Google Scholar] [CrossRef]

- Waghmare, D.T.; Padhee, C.K.; Prasad, R.; Masanta, M. NiTi coating on Ti-6Al-4V alloy by TIG cladding process for improvement of wear resistance: Microstructure evolution and mechanical performances. J. Mater. Process. Technol. 2018, 262, 551–561. [Google Scholar] [CrossRef]

- Samanta, A.; Bhattacharya, M.; Ratha, I.; Chakraborty, H.; Datta, S.; Ghosh, J.; Bysakh, S.; Sreemany, M.; Rane, R.; Joseph, A.; et al. Nano- and micro-tribological behaviours of plasma nitrided Ti6Al4V alloys. J. Mech. Behav. Biomed. Mater. 2018, 77, 267–294. [Google Scholar] [CrossRef]

- Ng, C.; Chan, O.; Man, H. Formation of TiN Grid on NiTi by Laser Gas Nitriding for Improving Wear Resistance in Hanks’ Solution. J. Mater. Sci. Technol. 2016, 32, 459–464. [Google Scholar] [CrossRef]

- Chan, C.-W.; Lee, S.; Smith, G.; Sarri, G.; Ng, C.-H.; Sharba, A.; Man, H.-C. Enhancement of wear and corrosion resistance of beta titanium alloy by laser gas alloying with nitrogen. Appl. Surf. Sci. 2016, 367, 80–90. [Google Scholar] [CrossRef]

- Chan, C.-W.; Lee, S.; Smith, G.C.; Donaghy, C. Fibre laser nitriding of titanium and its alloy in open atmosphere for orthopaedic implant applications: Investigations on surface quality, microstructure and tribological properties. Surf. Coat. Technol. 2017, 309, 628–640. [Google Scholar] [CrossRef]

- Moro, T.; Takatori, Y.; Kyomoto, M.; Ishihara, K.; Kawaguchi, H.; Hashimoto, M.; Tanaka, T.; Oshima, H.; Tanaka, S. Wear resistance of the biocompatible phospholipid polymer-grafted highly cross-linked polyethylene liner against larger femoral head. J. Orthop. Res. 2015, 33, 1103–1110. [Google Scholar] [CrossRef]

- Kyomoto, M.; Moro, T.; Saiga, K.; Hashimoto, M.; Ito, H.; Kawaguchi, H.; Takatori, Y.; Ishihara, K. Biomimetic hydration lubrication with various polyelectrolyte layers on cross-linked polyethylene orthopedic bearing materials. Biomaterials 2012, 33, 4451–4459. [Google Scholar] [CrossRef]

- Yamane, S.; Kyomoto, M.; Moro, T.; Watanabe, K.; Hashimoto, M.; Takatori, Y.; Tanaka, S.; Ishihara, K. Effects of extra irradiation on surface and bulk properties of PMPC-grafted cross-linked polyethylene. J. Biomed. Mater. Res. Part A 2016, 104, 37–47. [Google Scholar] [CrossRef]

- Moro, T.; Kawaguchi, H.; Ishihara, K.; Kyomoto, M.; Karita, T.; Ito, H.; Nakamura, K.; Takatori, Y. Wear resistance of artificial hip joints with poly (2-methacryloyloxyethyl phosphorylcholine) grafted polyethylene: Comparisons with the effect of polyethylene cross-linking and ceramic femoral heads. Biomaterials 2009, 30, 2995–3001. [Google Scholar] [CrossRef]

- Kyomoto, M.; Moro, T.; Takatori, Y.; Tanaka, S.; Ishihara, K. Multidirectional wear and impact-to-wear tests of phospholipid-polymer-grafted and vitamin E-blended crosslinked polyethylene: A pilot study. Clin. Orthop. Relat. Res. 2015, 473, 942–951. [Google Scholar] [CrossRef][Green Version]

- Affatato, S.; Ruggiero, A.; Merola, M.; Logozzo, S. Does metal transfer differ on retrieved Biolox® Delta composites femoral heads? Surface investigation on three Biolox® generations from a biotribological point of view. Compos. Part B Eng. 2017, 113, 164–173. [Google Scholar] [CrossRef]

- Affatato, S.; Ruggiero, A.; De Mattia, J.S.; Taddei, P. Does metal transfer affect the tribological behaviour of femoral heads? Roughness and phase transformation analyses on retrieved zirconia and Biolox® Delta composites. Compos. Part B Eng. 2016, 92, 290–298. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Bai, W.; Wang, D.; Gu, C.; Tu, J. Microstructure, mechanical and tribological properties of a-C/a-C:Ti nanomultilayer film. Surf. Coat. Technol. 2013, 232, 403–411. [Google Scholar] [CrossRef]

- Miller, P.; Holladay, J. Friction and wear properties of titanium. Wear 1958, 2, 133–140. [Google Scholar] [CrossRef]

- Rigney, D. Comments on the sliding wear of metals. Tribol. Int. 1997, 30, 361–367. [Google Scholar] [CrossRef]

- Molinari, A.; Straffelini, G.; Tesi, B.; Bacci, T. Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 1997, 208, 105–112. [Google Scholar] [CrossRef]

- Young, L.; Dezhuang, Y.; Shiyu, H.E.; Wanliang, W.U. Dry Sliding Wear of Ti-6Al-4V Alloy in Air and Vaccum. Trans. Nonferrous Soc. China 2003, 13, 1137–1140. [Google Scholar]

- Guleryuz, H.; Cimenoglu, H. Surface modification of a Ti–6Al–4V alloy by thermal oxidation. Surf. Coat. Technol. 2005, 192, 164–170. [Google Scholar] [CrossRef]

- Qiu, M.; Zhang, Y.; Zhu, J.; Yang, J. Dry friction characteristics of Ti-6Al-4V alloy under high sliding velocity. J. Wuhan Univ. Technol. Sci. Ed. 2007, 22, 582–585. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Mitrović, S.; Cvijović, Z.; Veljović, Đ.; Babić, M.; Rakin, M. Influence of the heat treatment on the tribological characteristics of the Ti-based alloy for biomedical applications. Tribol. Ind. 2009, 31, 17–22. [Google Scholar]

- El-Tayeb, N.; Yap, T.; Brevern, P. Wear characteristics of titanium alloy Ti54 for cryogenic sliding applications. Tribol. Int. 2010, 43, 2345–2354. [Google Scholar] [CrossRef]

- Blau, P.J.; Erdman, D.L., III; Ohriner, E.; Jolly, B.C. High-Temperature Galling Characteristics of TI-6AL-4V With and Without Surface Treatments. Tribol. Trans. 2011, 54, 192–200. [Google Scholar] [CrossRef]

- Cui, X.H.; Mao, Y.S.; Wei, M.X.; Wang, S.Q. Wear Characteristics of Ti-6Al-4V Alloy at 20–400 °C. Tribol. Trans. 2012, 55, 185–190. [Google Scholar] [CrossRef]

- Sharma, M.D.; Sehgal, R. Dry Sliding Friction and Wear Behaviour of Titanium Alloy (Ti-6Al-4V). Tribol. Online 2012, 7, 87–95. [Google Scholar] [CrossRef]

- Chen, K.M.; Zhang, Q.Y.; Li, X.X.; Wang, L.; Cui, X.H.; Wang, S.Q. Comparative Study of Wear Behaviors of a Selected Titanium Alloy and AISI H13 Steel as a Function of Temperature and Load. Tribol. Trans. 2014, 57, 838–845. [Google Scholar] [CrossRef]

- Chauhan, S.R.; Dass, K. Dry Sliding Wear Behaviour of Titanium (Grade 5) Alloy by Using Response Surface Methodology. Adv. Tribol. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Sahoo, R.; Jha, B.B.; Sahoo, T.K. Experimental Study on the Effect of Microstructure on Dry Sliding Wear Behavior of Titanium Alloy Using Taguchi Experimental Design. Tribol. Trans. 2014, 57, 216–224. [Google Scholar] [CrossRef]

- Sharma, M.D.; Sehgal, R.; Pant, M. Tribological behavior of Ti3Al2.5V alloy sliding against EN-31 steel under dry condition. Tribol. Trans. 2016, 59, 451–461. [Google Scholar] [CrossRef]

- Sharma, M.D.; Sehgal, R.; Pant, M. Modeling and Optimization of Friction and Wear Characteristics of Ti3Al2.5V Alloy Under Dry Sliding Condition. J. Tribol. 2016, 138, 031603. [Google Scholar] [CrossRef]

- Ghosh, S.; Abanteriba, S.; Wong, S.; Houshyar, S. Selective laser melted titanium alloys for hip implant applications: Surface modification with new method of polymer grafting. J. Mech. Behav. Biomed. Mater. 2018, 87, 312–324. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).