Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly

Abstract

:1. Introduction

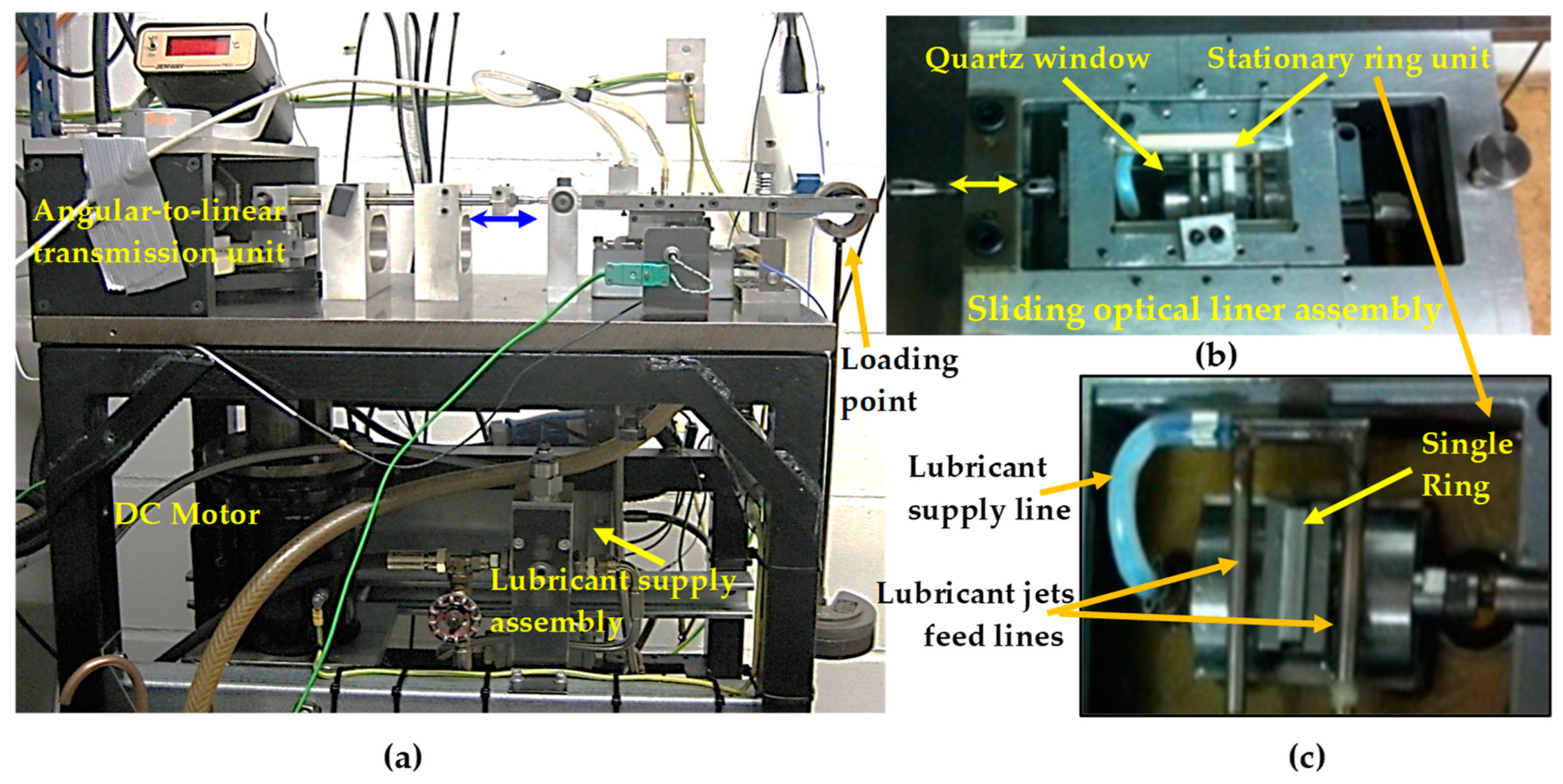

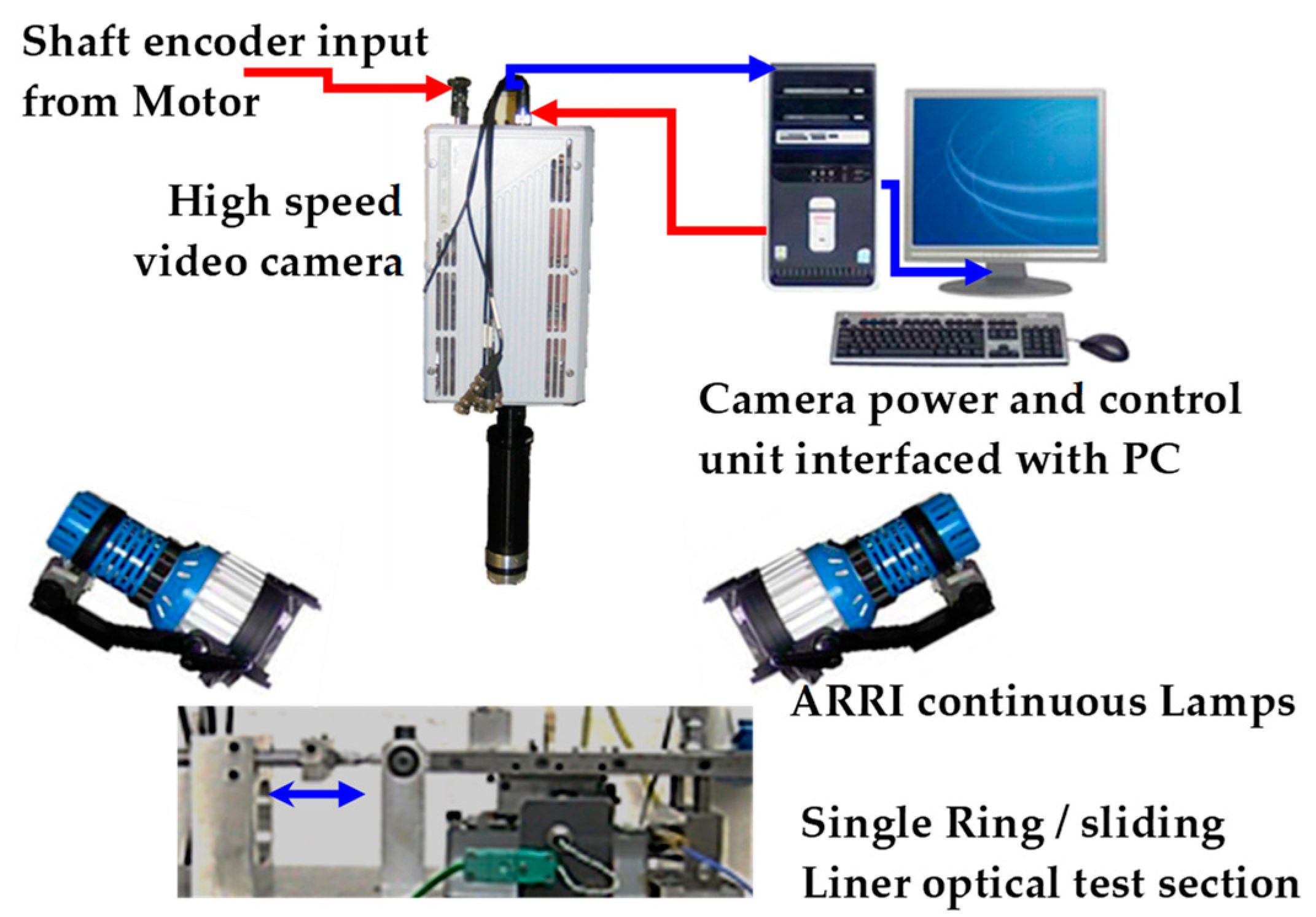

2. Experimental Set up and Instrumentation

3. Results and Discussions

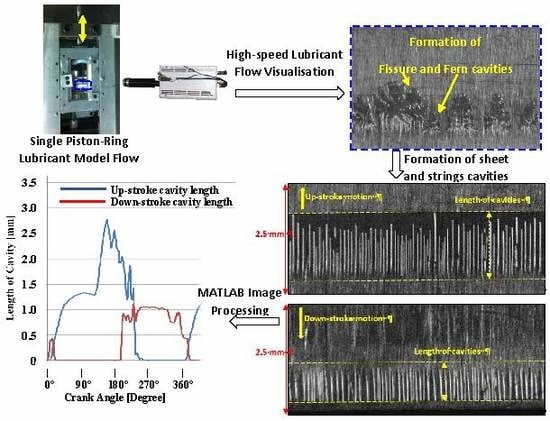

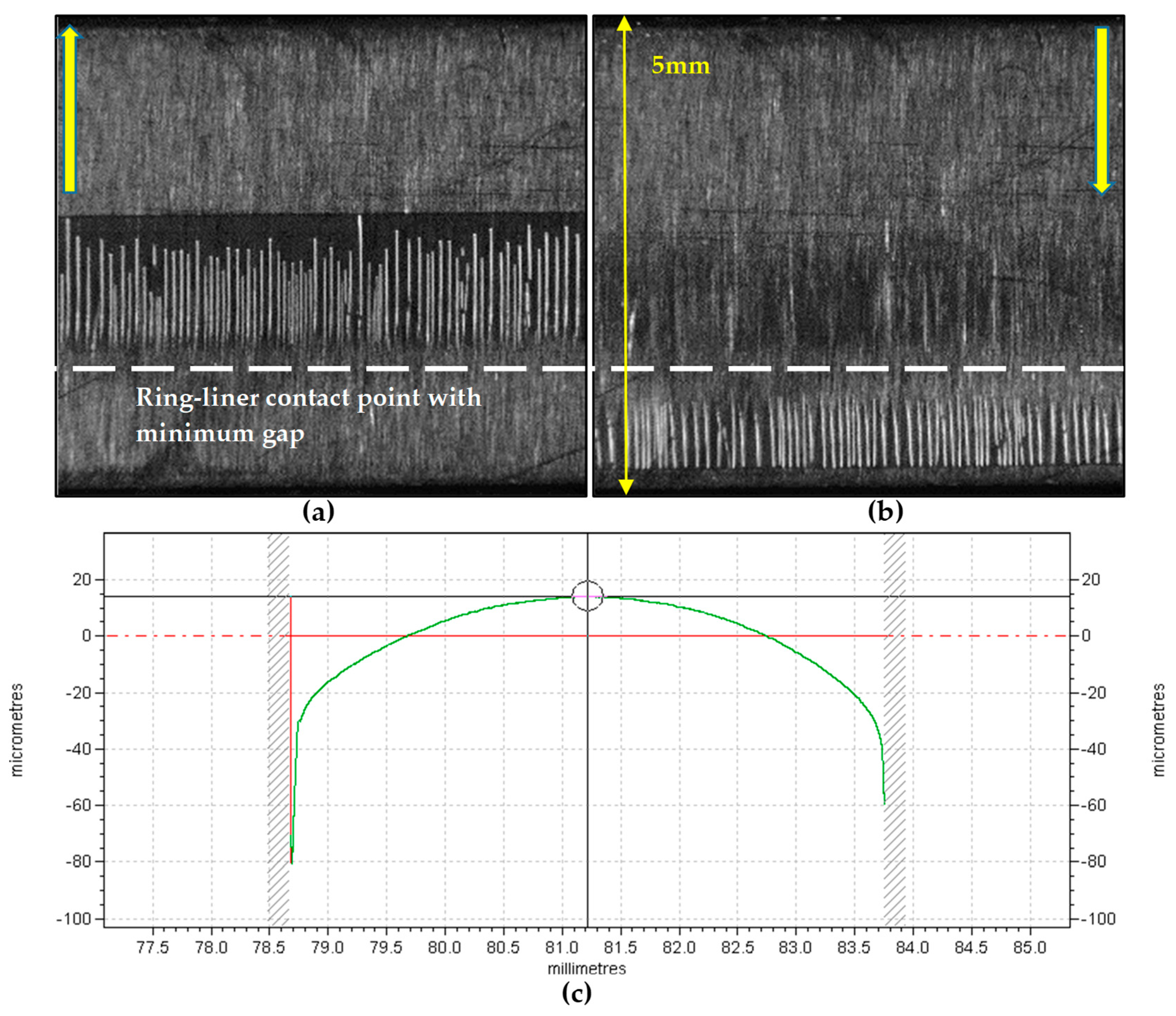

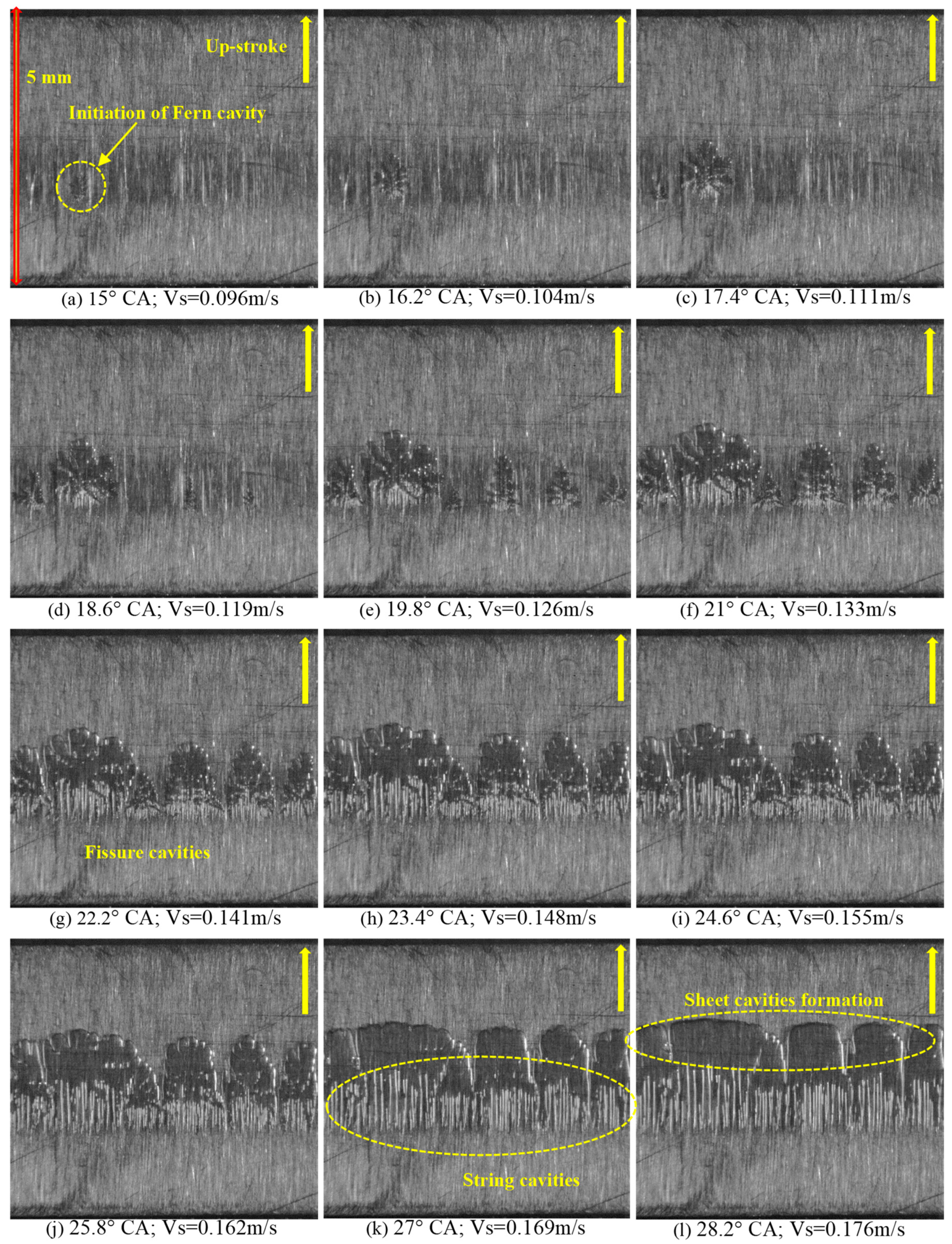

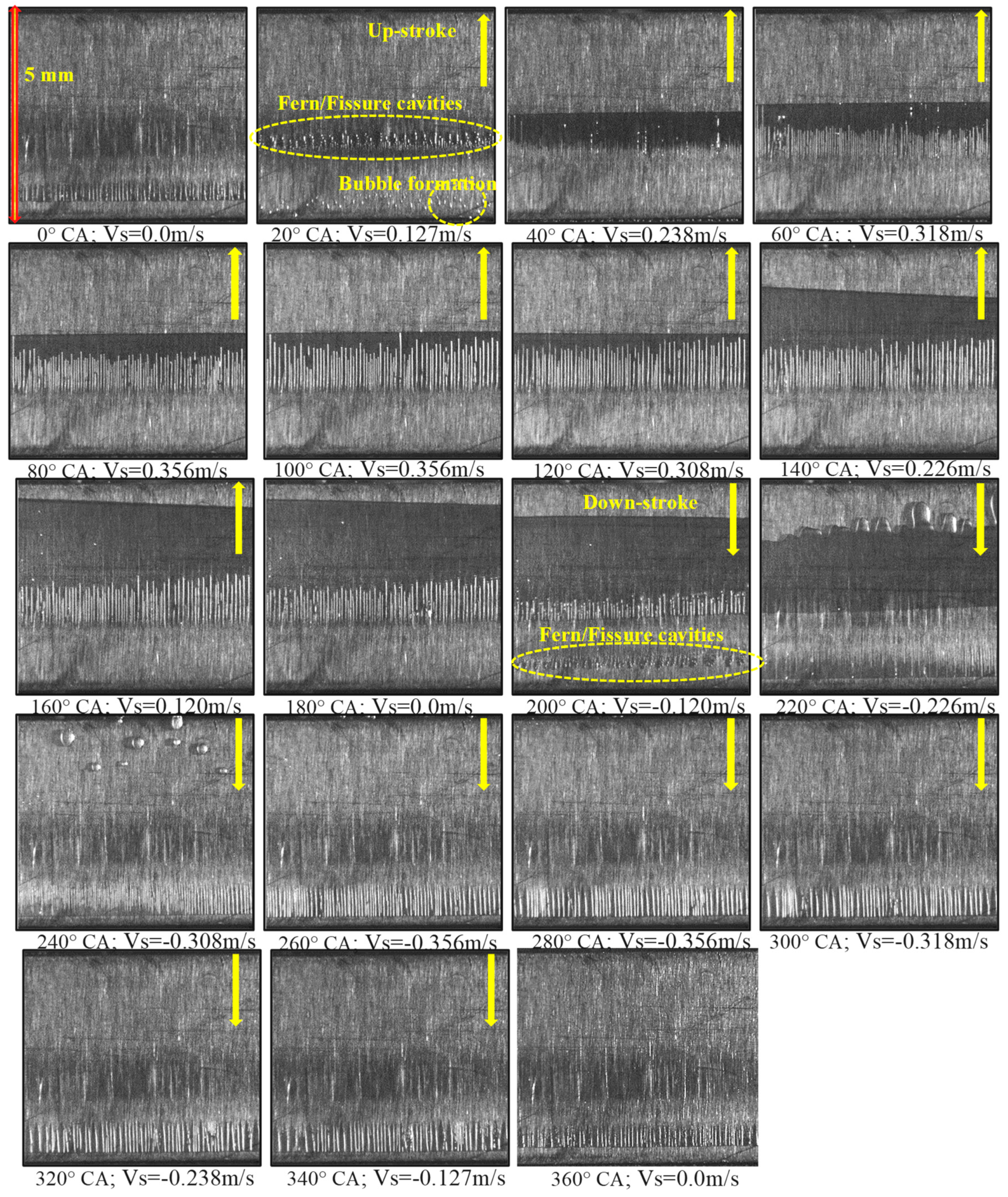

3.1. Visualisation Results

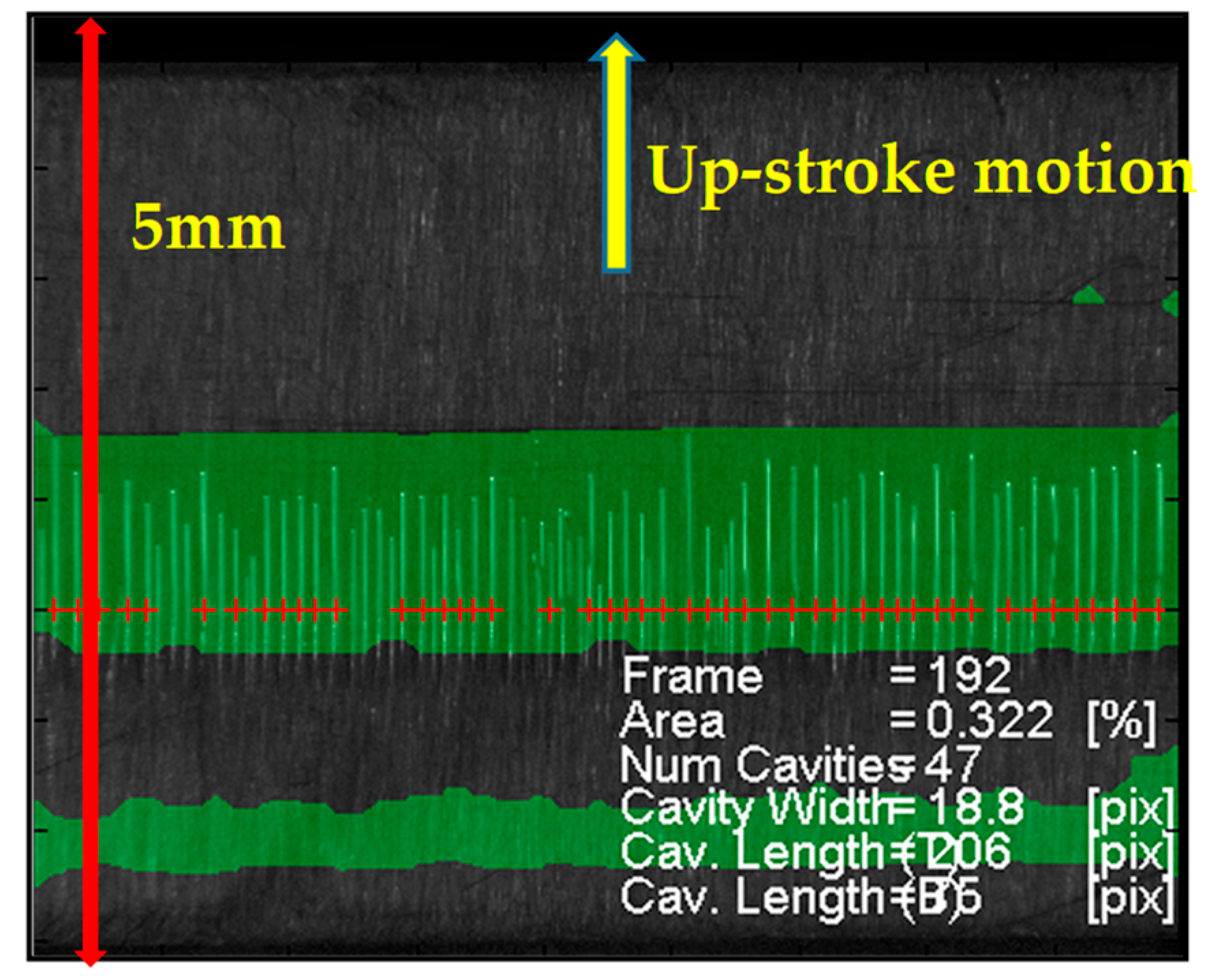

3.2. Processed Results

4. Conclusions

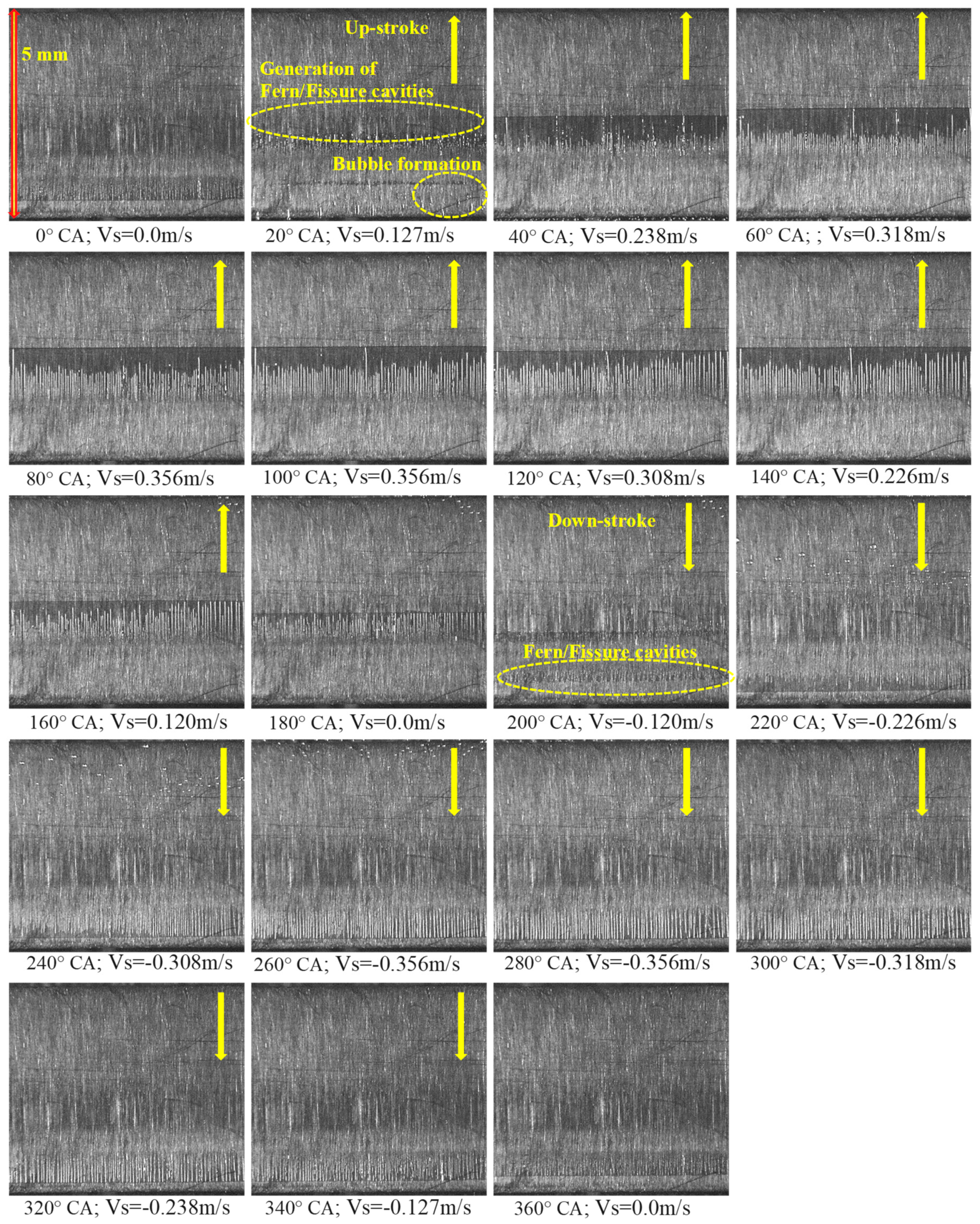

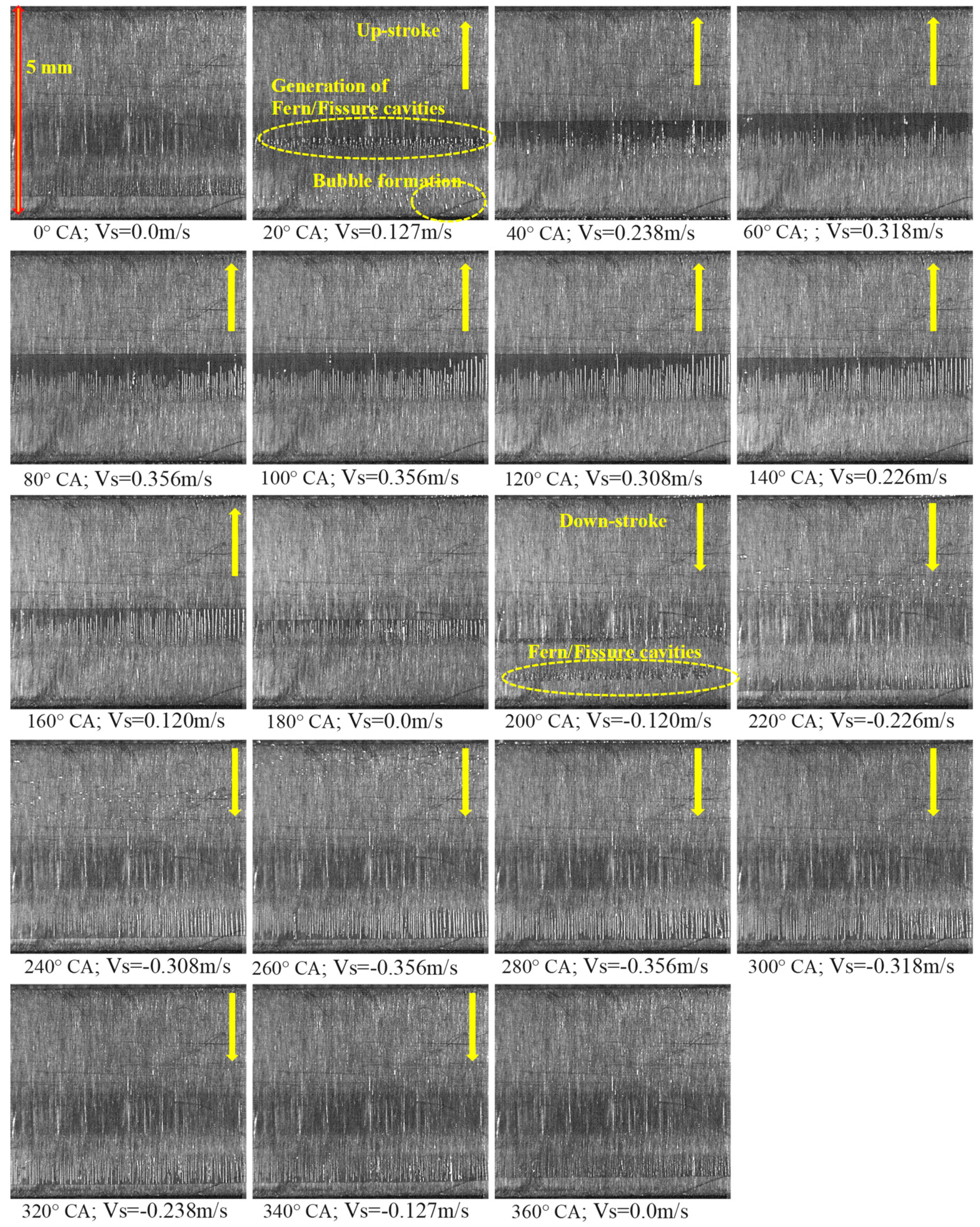

- The visualisation images, during the up-stroke motion, showed that a small fern cavity is initiated at a nucleation site at around 15° CA, which grows and spread quickly with time during which other ferns start to appear. As they grow, they start to coalesce and form the fissure type cavities, which are unstable and spread rapidly in all direction and after joining the neighbouring fissures they form a stable sheet cavitation at their forefront while at their tails they breakup into stable strings type cavitation. Similar patterns have been observed during down-stroke motion.

- It was observed that the onset of cavitation happens almost at the same time for all lubricants and at both speeds with little dependency on either viscosity or speed.

- Visualisation results over the whole cycle showed the step by step changes in the sheet/strings cavities with CA and, in general, they grow and develop into their full status when the liner reaches its maximum velocity and then the start to collapse during the liner deceleration.

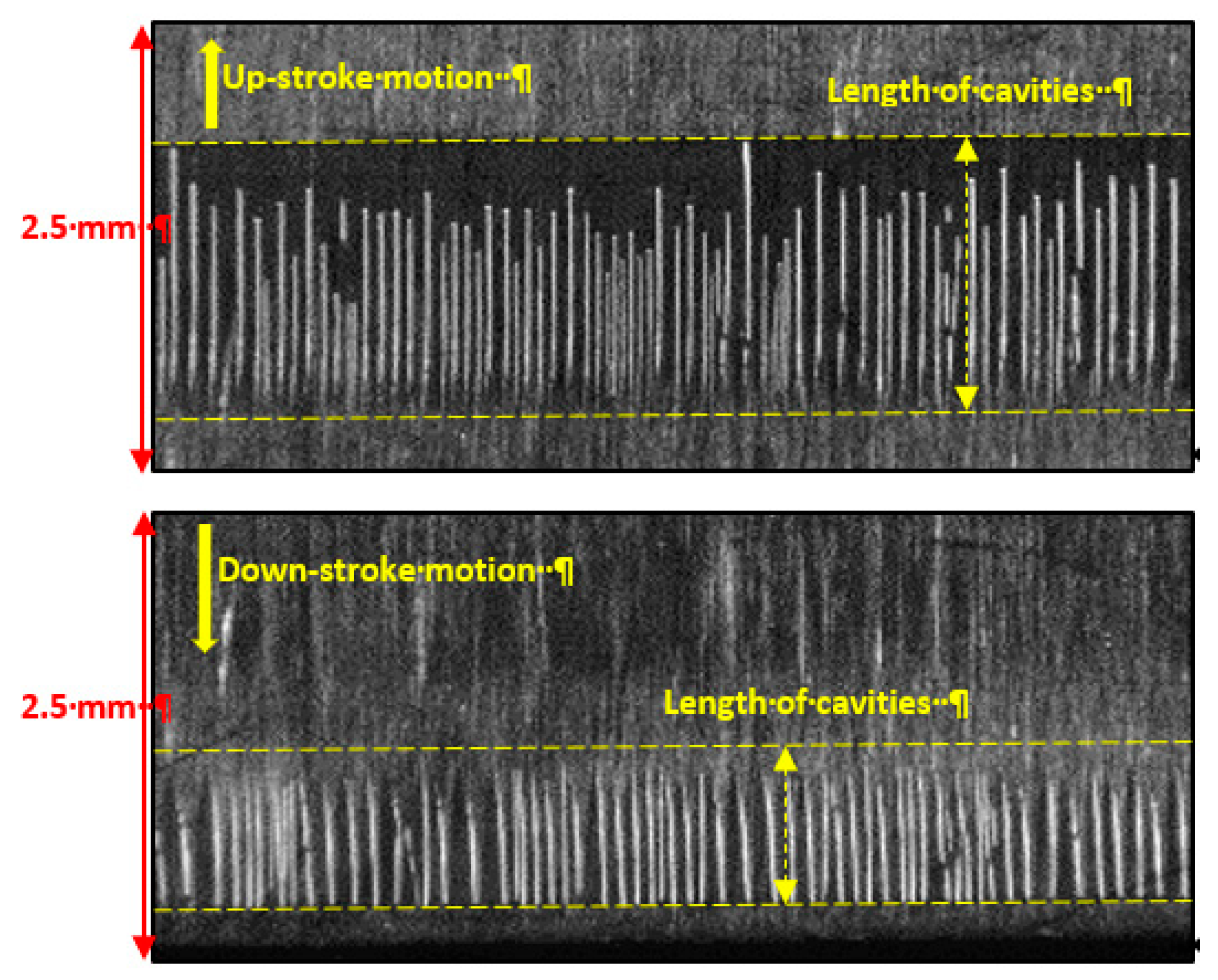

- In up-stroke motion, at fully developed state, the length of cavities measurements from images were 1.36 mm, 1.2 mm and 0.95 mm for Lubricant A, B and C, respectively, giving a reduction of about 12% and 30% for Lubricants B and C when compared to Lubricant A. the corresponding values for down-stroke were 0.91 mm, 0.74 mm and 0.59 mm giving a reduction of 18.7% and 35% for Lubricants B and C when compared to Lubricant A. This is expected as lowering the lubricant viscosity results in a reduction of negative pressure and therefore less cavities.

- The shorter length of the cavities in down-stroke, around 35% for all lubricants, compare to those in the up-stroke motion is related to the ring profile which is not symmetrical with a contact point at an offset from the centerline towards the lower edge of the ring with much smaller diverging area during the down-stroke motion.

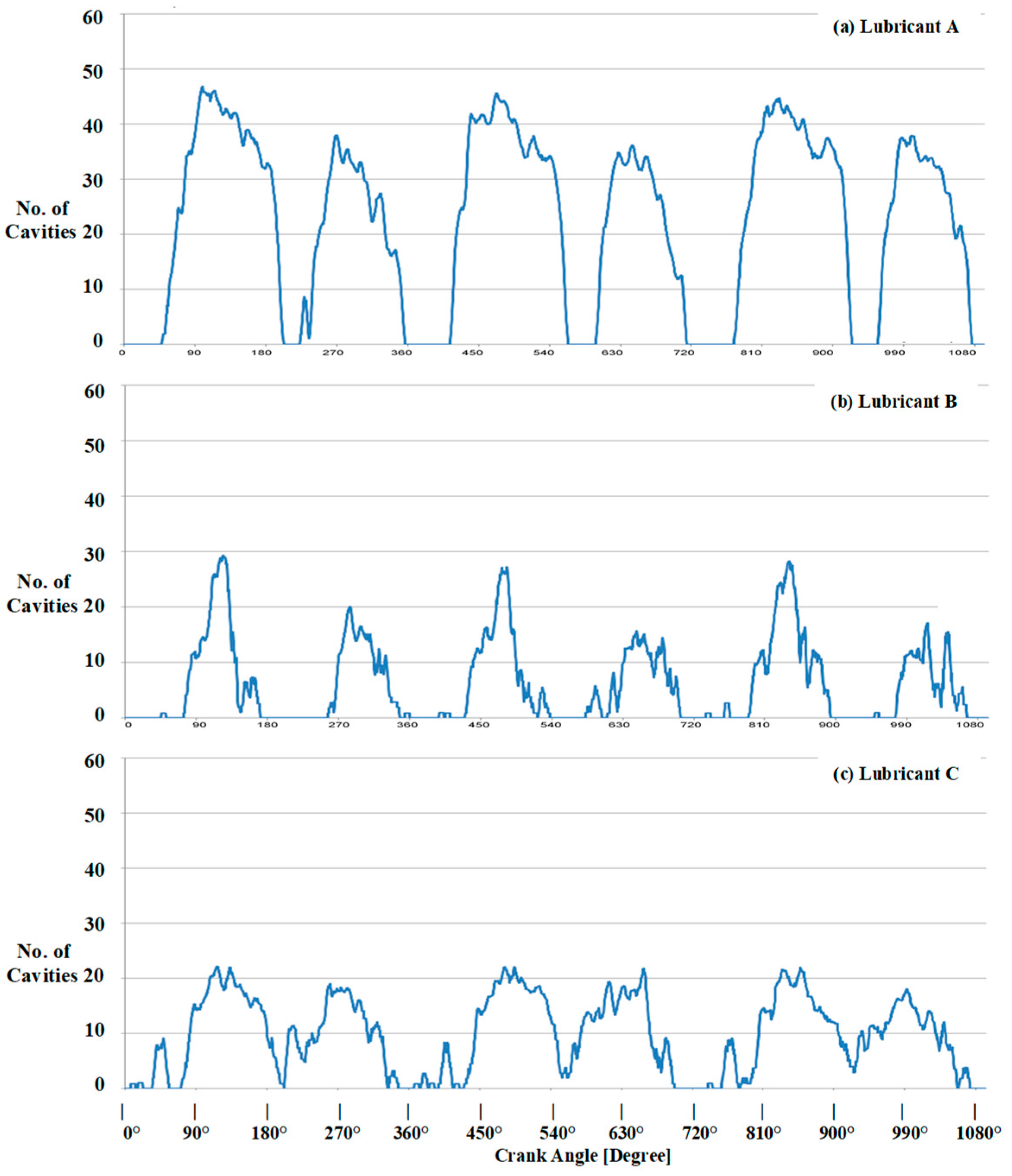

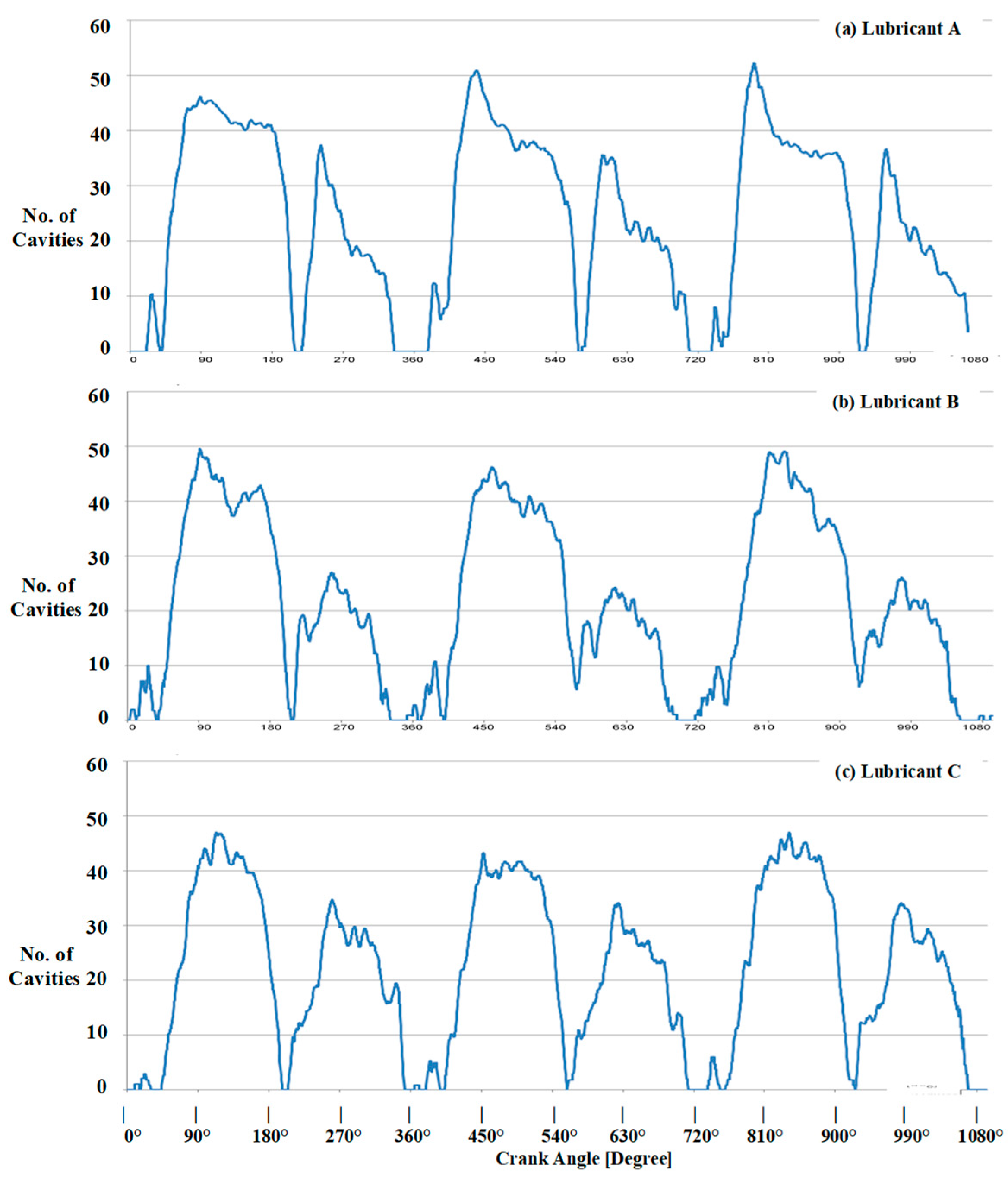

- The processed data by MATLAB for number and length of cavities presented a good degree of repeatability over different cycles for all lubricants and that they showed much higher number of string cavities with Lubricant A (of highest viscosity) than Lubricants B and C at 300 rpm. However, at higher speed of 600 rpm the number of string cavities of all lubricants become similar, which may well be due to increase in oil film thickness at higher speed.

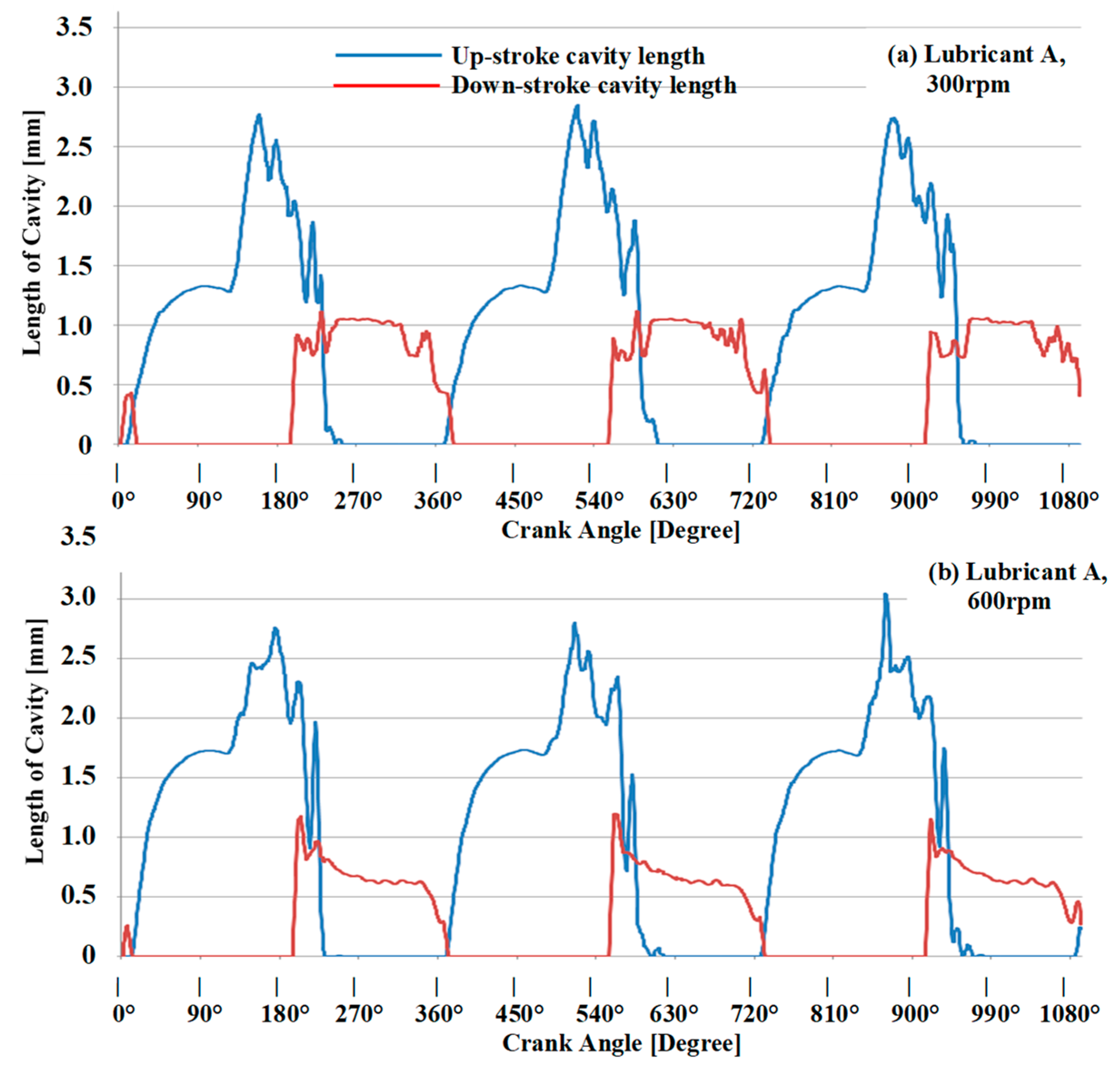

- The extracted processed data of length of cavities for Lubricant A at both speeds showed a very good agreement with those obtained from images directly and it confirmed as the speed increased from 300 rpm to 600 rpm the length of cavities, at fully developed state, also increased from 1.3 mm to 1.7 mm; an increase of 30% at 600 rpm and again it can be attributed to the increase in oil film thickness as mentioned above.

- Although the overall agreement between the processed data by MATLAB and visualisation measurements, it failed to calculate accurately the length of cavities for Lubricants B and C due to background noise. This suggests that more refinement is required in setting the thresholds and more importantly that the extracted data should always be checked with images to be sure of the data accuracy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Voss, K.E.; Lampert, J.K.; Farrauto, R.J.; Rice, G.W.; Punke, A.; Krohn, R. Catalytic Oxidation of Diesel Particulates with Base Metal Oxides. In Catalysis and Automotive Pollution Control III; Frennet, A., Bastin, J.M., Eds.; Elsevier: Amsterdam, The Netherlands, 1995; Volume 96, pp. 499–515. [Google Scholar]

- Kittelson, D.B.; Watts, W.F.; Johnson, J. Diesel Aerosol Sampling Methodology - CRC E-43, Final Report 2002. University of Minnesota, Report for the Coordinating Research Council. Available online: http://www.crcao.com/reports/recentstudies00-02/E-43%20Final%20Report.pdf (accessed on 9 October 2019).

- Straton, J.T.; Willermet, P.A. An Analysis of Valve Train Friction in Terms of Lubrication Principles; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 1983; p. 830165. [Google Scholar]

- Uras, H.; Patterson, D. Measurement of Piston Ring Assembly Friction in Reciprocating Machines. ASME 1987, 87-ICE-55. [Google Scholar]

- Rezeka, S.; Henein, N. A New Approach to Evaluate Instantaneous Friction and Its Components in Internal Combustion Engines; No. 840179. SAE Technical Paper; SAE International: Warrendale, PA, USA, 1984; p. 840719. [Google Scholar]

- Taraza, D.; Henein, N.; Bryzik, W. Friction Losses in Multi-Cylinder Diesel Engines. In SAE Transactions; SAE International: Warrendale, PA, USA, 2000; pp. 874–884. [Google Scholar]

- Ostovar, P. Fluid Aspects of Piston-Ring Lubrication. Ph.D. Thesis, Department of Mechanical Engineering, Imperial College London, London, UK, 1996. [Google Scholar]

- Dellis, P. Aspects of Lubrication in Piston Cylinder Assemblies. Ph.D. Thesis, Department of Mechanical Engineering, Imperial College London, London, UK, 2005. [Google Scholar]

- Dhunput, A. Oil Transport in Piston Ring Assemblies. Ph.D. Thesis, Department of Mechanical Engineering and Aeronautics, University of London, London, UK, 2009. [Google Scholar]

- Vasilakos, I. Cavitation in the Cylinder-Liner and Piston-Ring in a New Designed Optical IC Engine. Ph.D. Thesis, Department of Mechanical Engineering and Aeronautics, University of London, London, UK, 2017. [Google Scholar]

- Priest, M.; Dowson, D.; Taylor, C.M. Theoretical modelling of cavitation in piston-ring lubrication. Proc. IMechE Part C J. Mech. Eng. Sci. 2000, 214, 435–447. [Google Scholar] [CrossRef]

- Mortier, R.M.; Orszulik, S.T. Chemistry and technology of lubricants. In Chapman & Hall, 2nd ed.; Springer: Dordrecht, The Netherlands, 1997. [Google Scholar]

- Arcoumanis, C.; Duszynski, M.; Flora, H.; Ostovar, P. Development of a piston-ring lubrication test-rig and investigation of boundary condition for modelling lubricant film properties. SAE Trans. 1995, 104, 1433–1451. [Google Scholar]

- Dhunput, A.; Teodorescu, M.; Arcoumanis, C. Investigation of cavitation development in the lubricant film of piston-ring assemblies. J. Phys. Conf. Ser. 2007, 85, 012005. [Google Scholar] [CrossRef]

- Dells, P. An attempt to calibrate the laser induced fluorescence (LIF) signal used for oil film thickness (OFT) measurements in simulating test rigs. Tribol. Ind. 2015, 38, 525–538. [Google Scholar]

- Dellis, P. Laser-induced fluorescence measurements in a single-ring test rig: Evidence of cavitation and the effect of different operating conditions and lubricants in cavitation patterns and initiation. Int. J. Engine Res. 2019. Article first published online on January 14th, 1–15. [Google Scholar] [CrossRef]

- Tian, T.; Morris, N.J.; Coupland, J.M.; Arevalo, L. Cavitation bubble measurement in tribology contacts using digital holographic microscopy. Tribol. Lett. 2015, 58, 1–10. [Google Scholar]

- Sherrington, I.; Smith, E.H. Experimental methods for measuring the oil-film thickness between the piston-rings and cylinder-wall of internal combustion engines. Tribol. Int. 1985, 18, 315–320. [Google Scholar] [CrossRef]

- Sherrington, I.; Söchting, S. An experimental study of variability in the thickness of the hydrodynamic lubricant film between the piston-rings and cylinder bore of an internal combustion engine under steady operating conditions. In Tribology 2006-Surface Engineering and Tribology for Future Engines and Drivelines; IMechE: London, UK, 2006. [Google Scholar]

- Greene, A.B. Initial visual studies of piston-cylinder dynamic oil film behaviour. Wear 1969, 13, 345–360. [Google Scholar] [CrossRef]

- Sanda, S.; Saito, A.; Konomi, T.; Nohira, H. Development of Scanning Laser-Induced-Fluorescence Method for Analyzing Piston Oil Film Behaviour; IMechE Paper C; IMechE: London, UK, 1993; Volume 465, pp. 155–164. [Google Scholar]

- Nakashima, K.; Ishihara, S.; Urano, K. Influence of Piston Ring-Gaps on Lubricating Oil Flow into the Combustion Chamber; Paper 952546; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Kim, S.; Azetsu, A.; Yamauchi, M.; Someya, T. Dynamic Behaviour of Oil Film between Piston-ring and Cylinder Liner: Visualization of Oil Film Rupture and Measurement of Oil Film Pressure Using Simulating Rig. JSME 1995, 38, 783–789. [Google Scholar]

- Thirouard, B.P.; Tian, T.; Hart, D.P. Investigation of Oil Transport Mechanisms in the Piston-ring-pack of a Single-Cylinder Diesel Engine, Using Two-Dimensional, Laser-Induced Fluorescence. In SAE Transactions; Paper 982658; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Thirouard, B.P. Characterization and Modelling of the Fundamental Aspects of oil Transport in the Piston-Ring-Pack of Internal Combustion Engines. Ph.D. Thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, MA, USA, 2001. [Google Scholar]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Gamer, C.P.; King, P.D. Thermo-mixed hydrodynamics of piston compression ring conjunction. Tribol. Lett. 2013, 51, 323–340. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Fang, Z. Effects of nozzle inner surface roughness on the performance of self-resonating cavitating waterjets under different ambient pressures. J. Mech. Eng. 2017, 63, 92–102. [Google Scholar] [CrossRef]

- Delprete, C.; Razavykia, A.; Baldissera, P. Detailed analysis of piston secondary motion and tribological performance. Int. J. Engine Res. 2019. Article first published online on February 28th, 1–15. [Google Scholar] [CrossRef]

| Lubricants | Flow Rate [L/min] | Temperature [°C] | Kinematic Viscosity [cSt] | Speed [rpm] |

|---|---|---|---|---|

| A | 0.05 | 70 | 45.6 | 300 and 600 |

| B | 0.05 | 70 | 30.9 | 300 and 600 |

| C | 0.05 | 70 | 20.2 | 300 and 600 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nouri, J.M.; Vasilakos, I.; Yan, Y.; Reyes-Aldasoro, C.-C. Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly. Lubricants 2019, 7, 88. https://doi.org/10.3390/lubricants7100088

Nouri JM, Vasilakos I, Yan Y, Reyes-Aldasoro C-C. Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly. Lubricants. 2019; 7(10):88. https://doi.org/10.3390/lubricants7100088

Chicago/Turabian StyleNouri, Jamshid M., Ioannis Vasilakos, Youyou Yan, and Constantino-Carlos Reyes-Aldasoro. 2019. "Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly" Lubricants 7, no. 10: 88. https://doi.org/10.3390/lubricants7100088

APA StyleNouri, J. M., Vasilakos, I., Yan, Y., & Reyes-Aldasoro, C.-C. (2019). Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly. Lubricants, 7(10), 88. https://doi.org/10.3390/lubricants7100088