Measured and Predicted Operating Characteristics of a Tilting-Pad Journal Bearing with Jacking-Oil Device at Hydrostatic, Hybrid, and Hydrodynamic Operation

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Model

2.1.1. Governing Equations

2.1.2. Oil Inlet Boundary Conditions

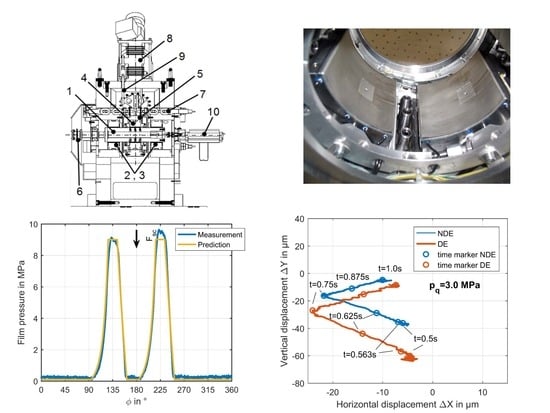

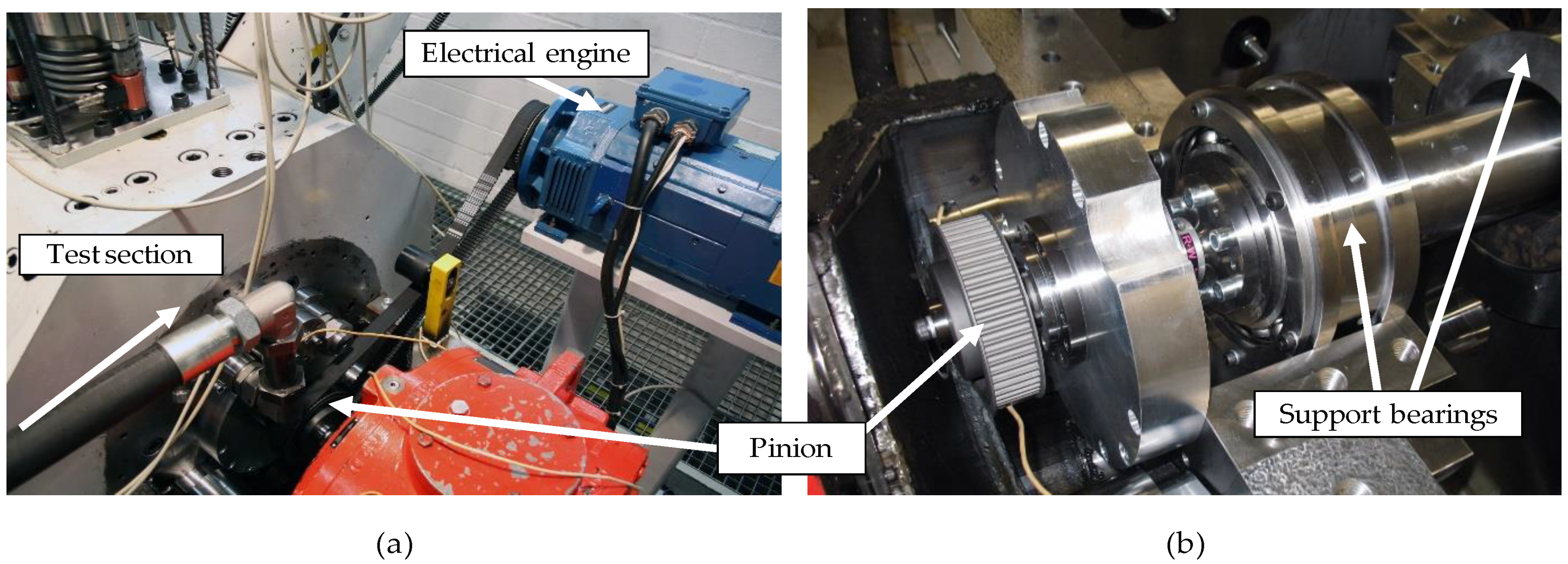

2.2. Test Rig

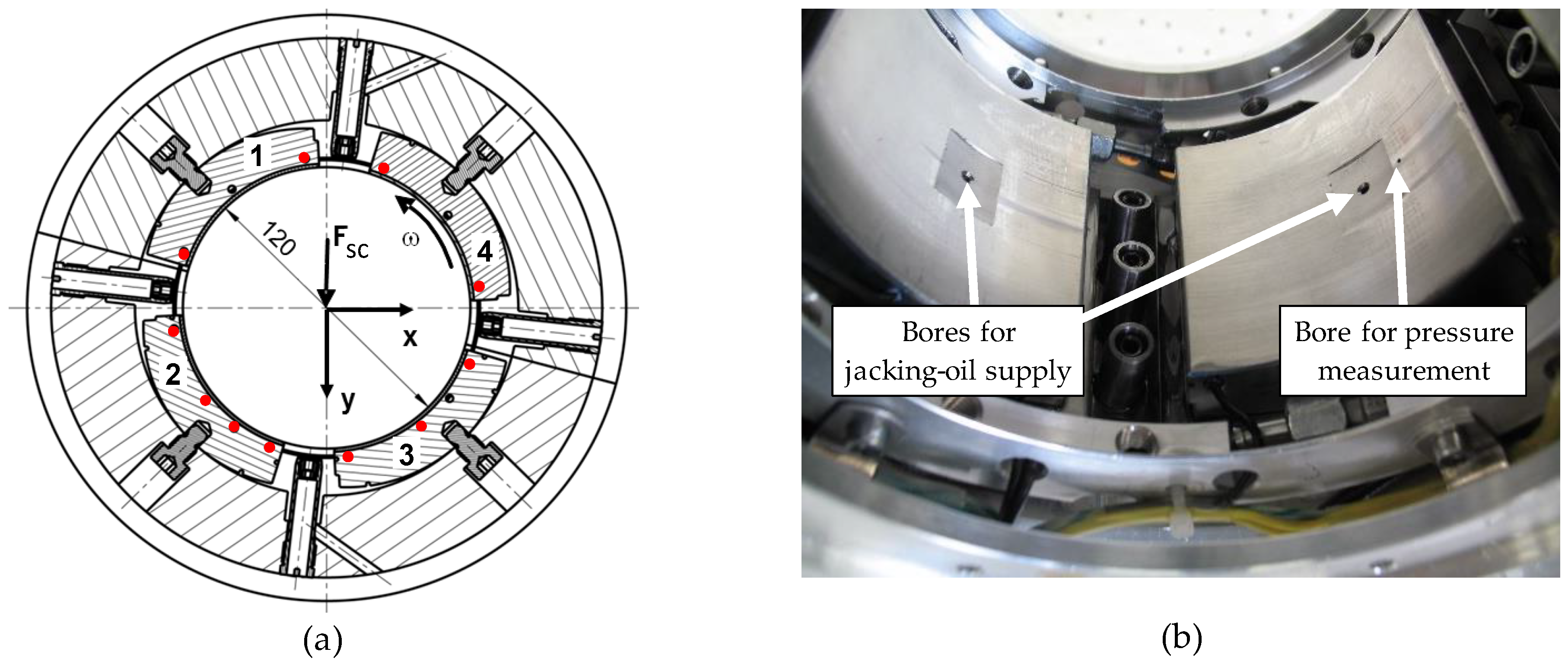

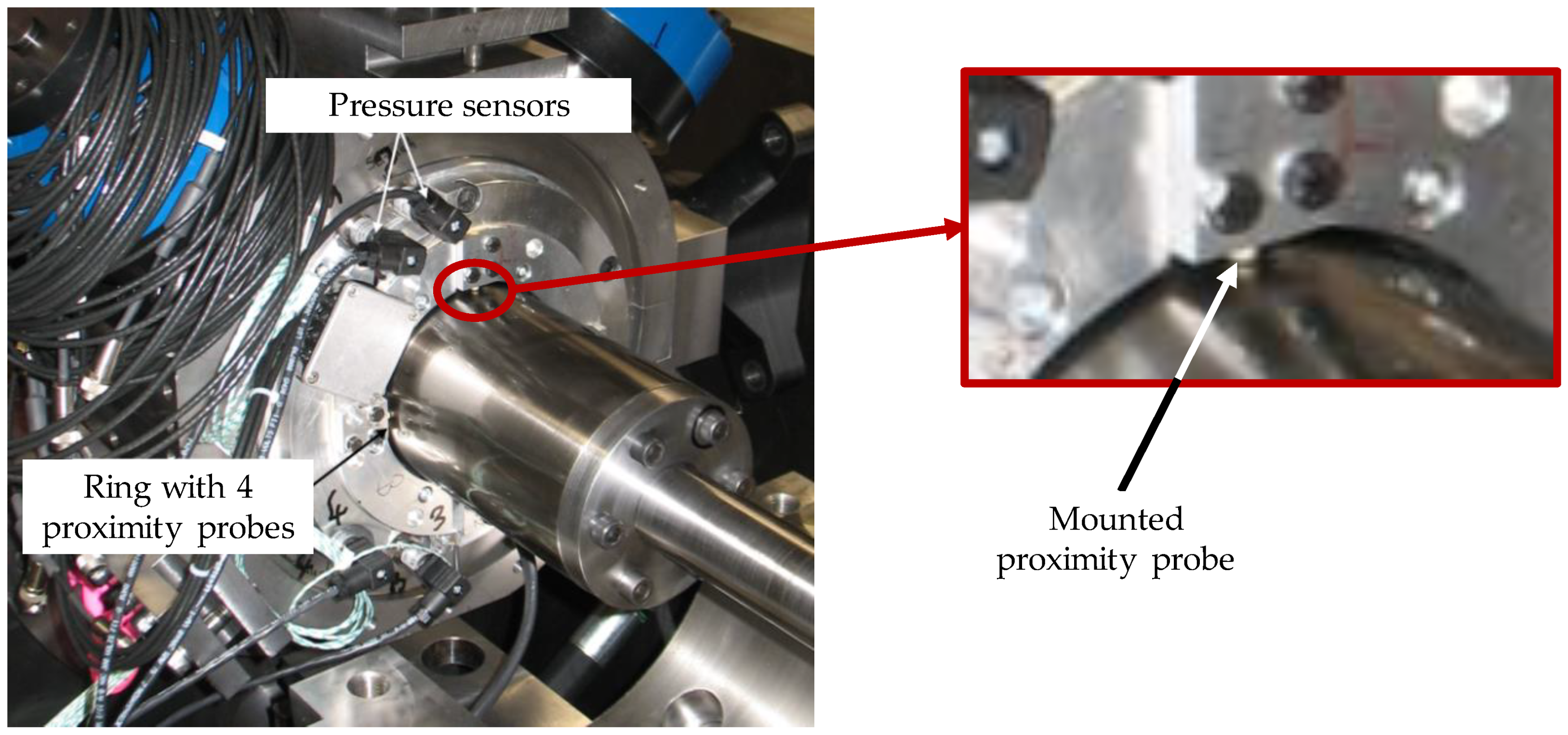

2.3. Test Bearing and Instrumentation

3. Results

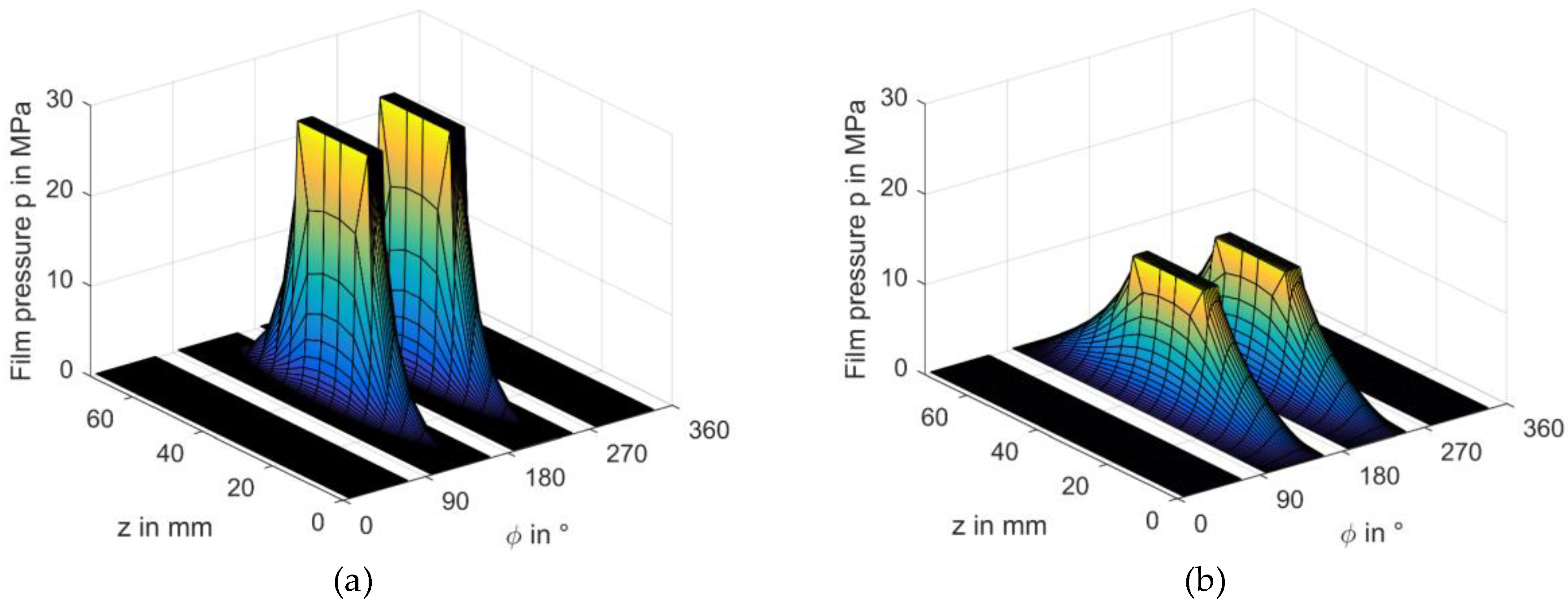

3.1. Lift Procedure at Zero Journal Rotation

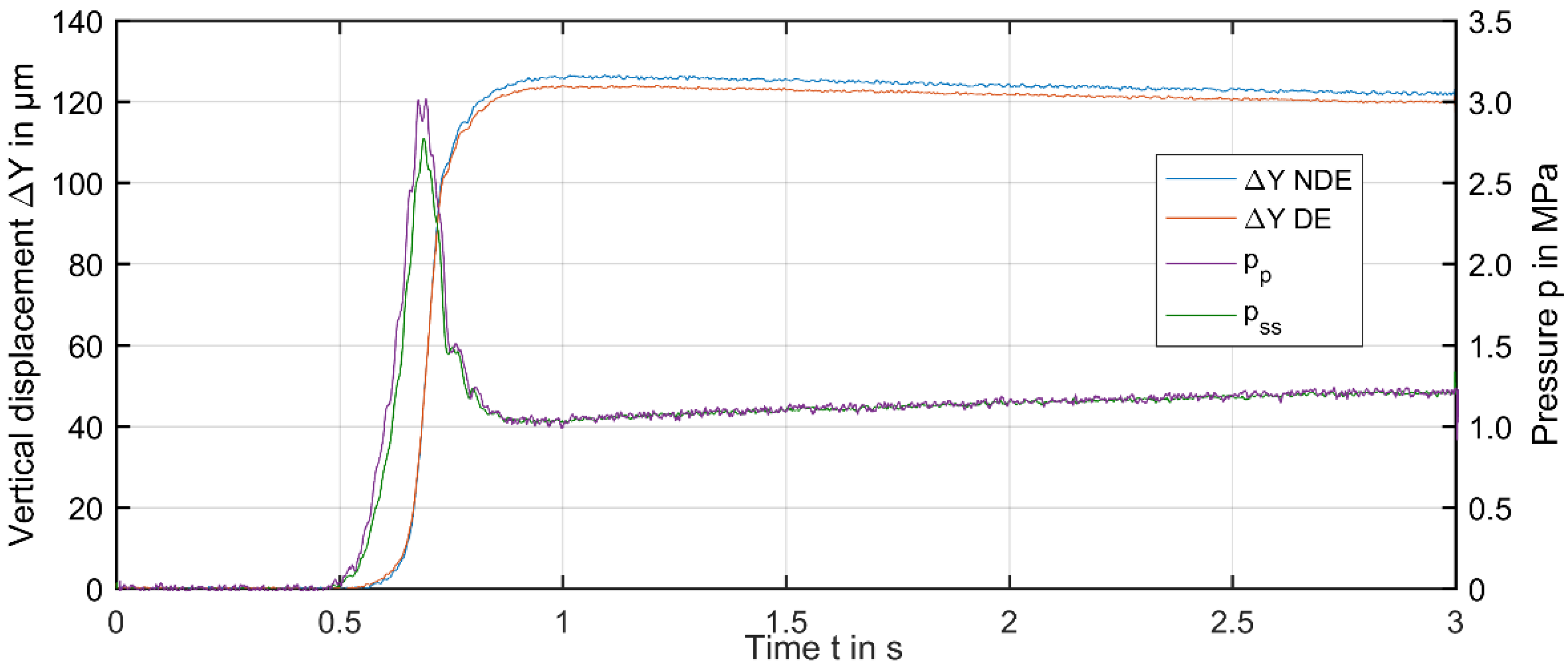

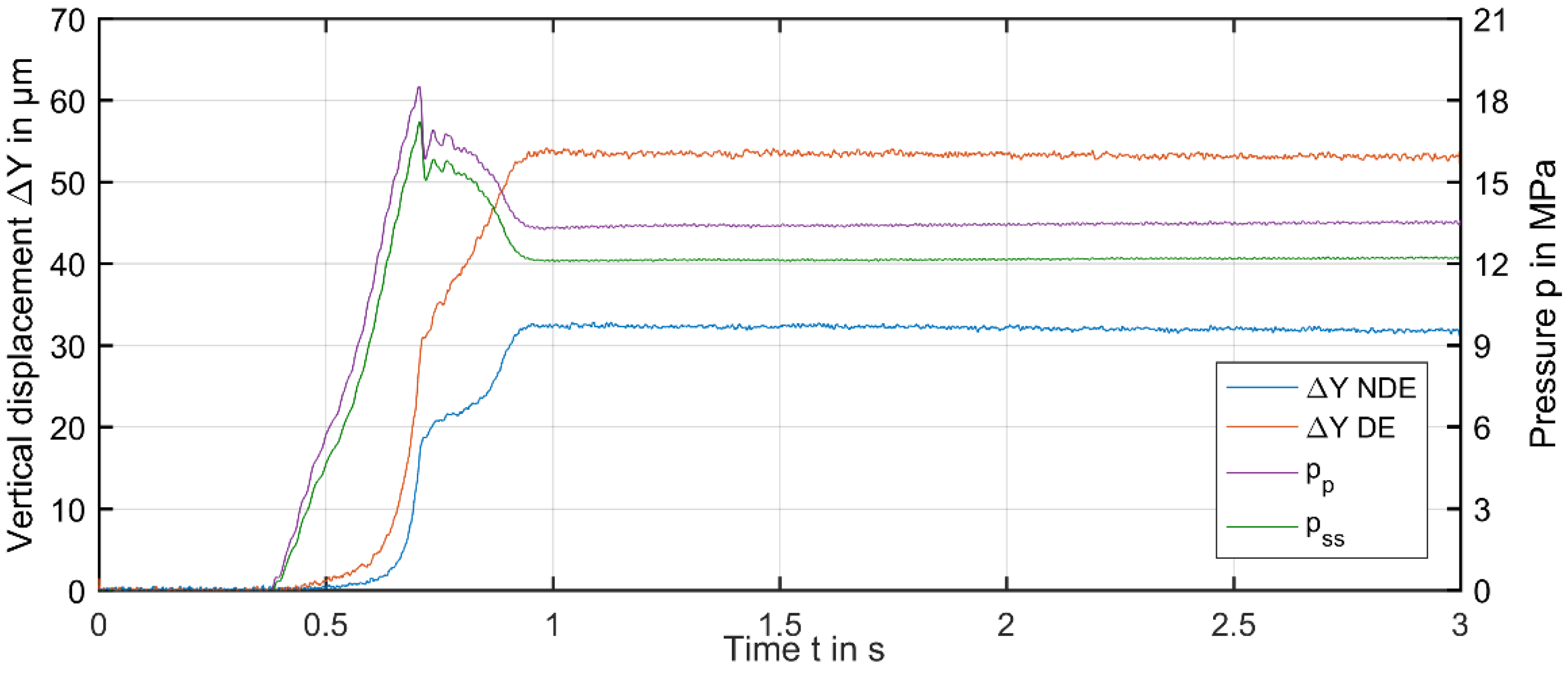

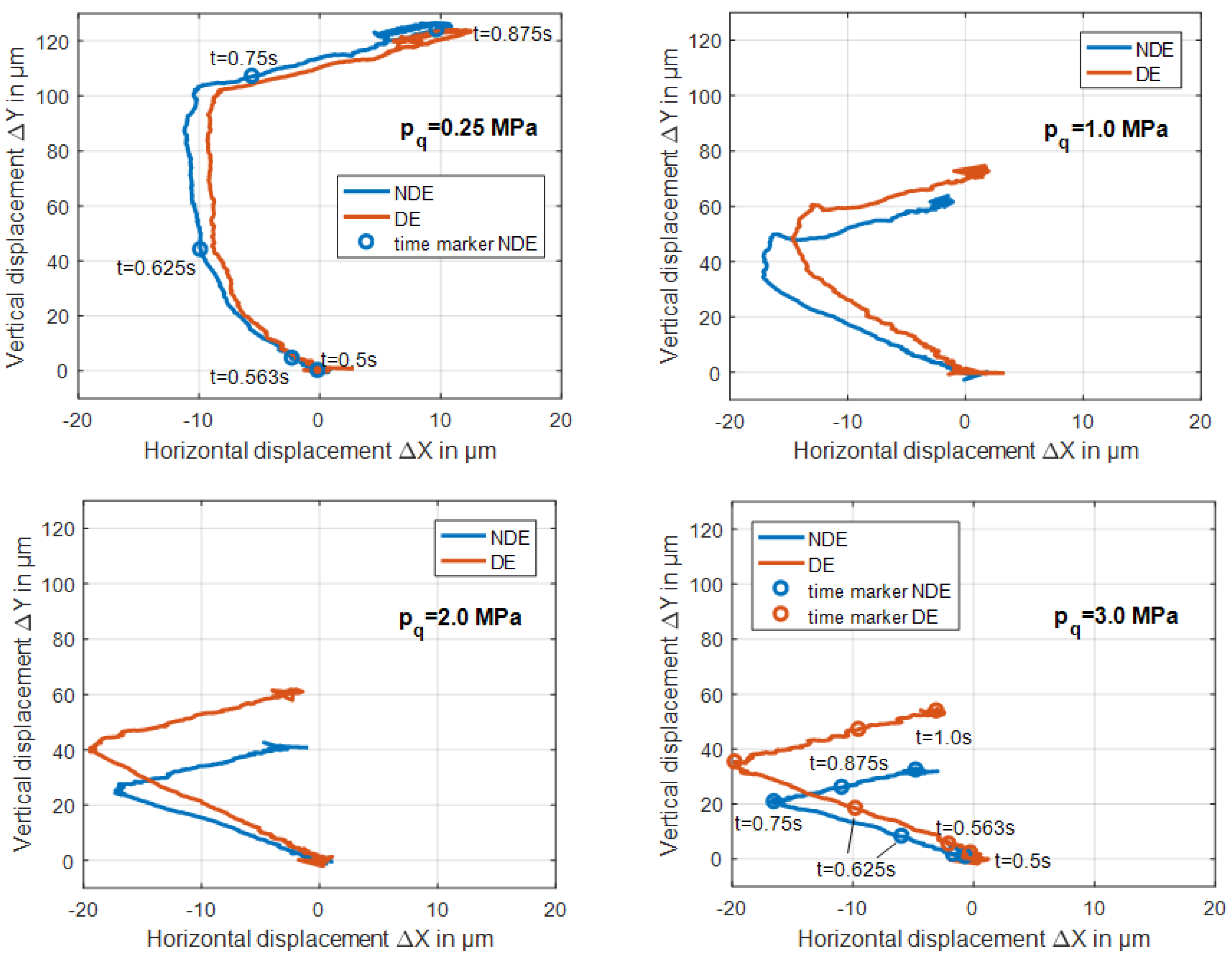

3.1.1. Dynamic Lift Procedure

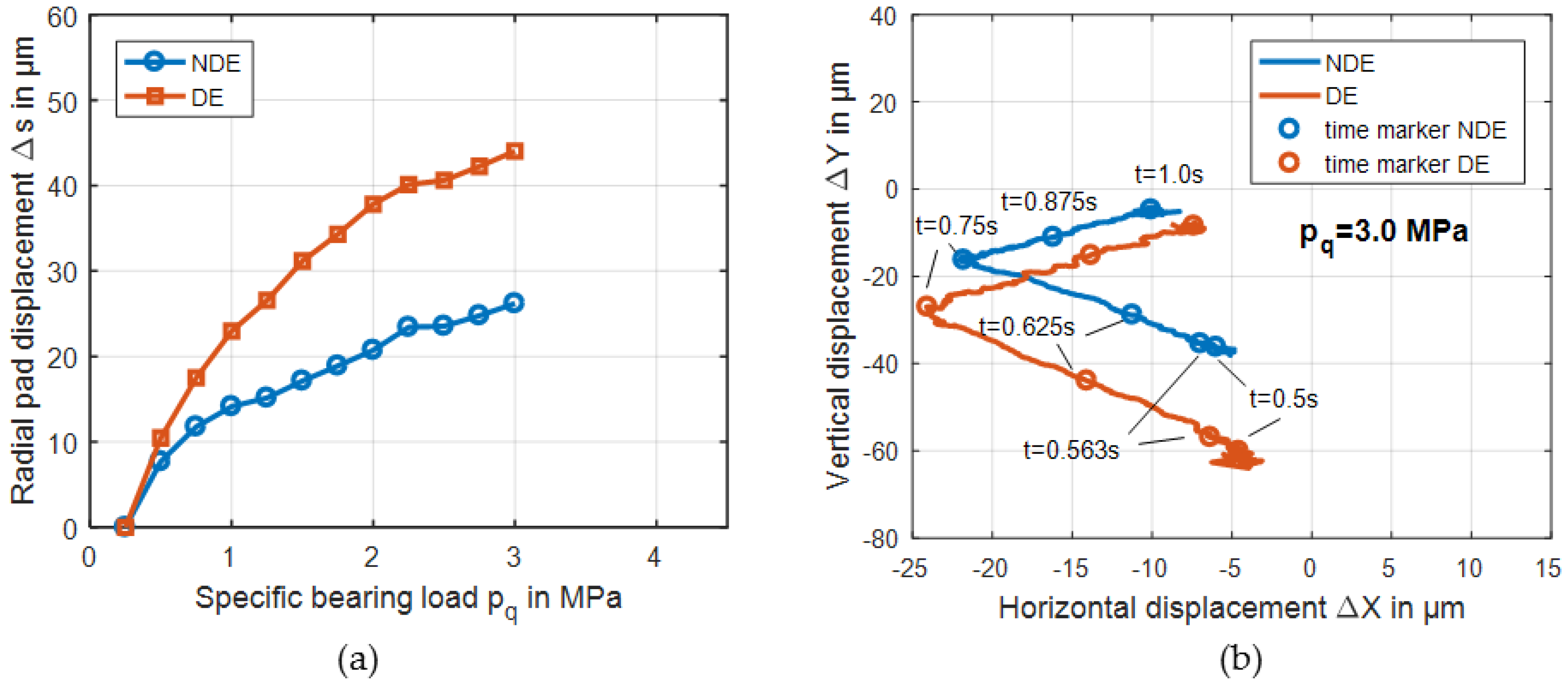

- With increasing load, the bearing housing moves close to the curve of maximum eccentricity among pad number 2 during the start of the lift-off procedure

- The misalignment between bearing housing and journal changes its direction during the lift-off procedure

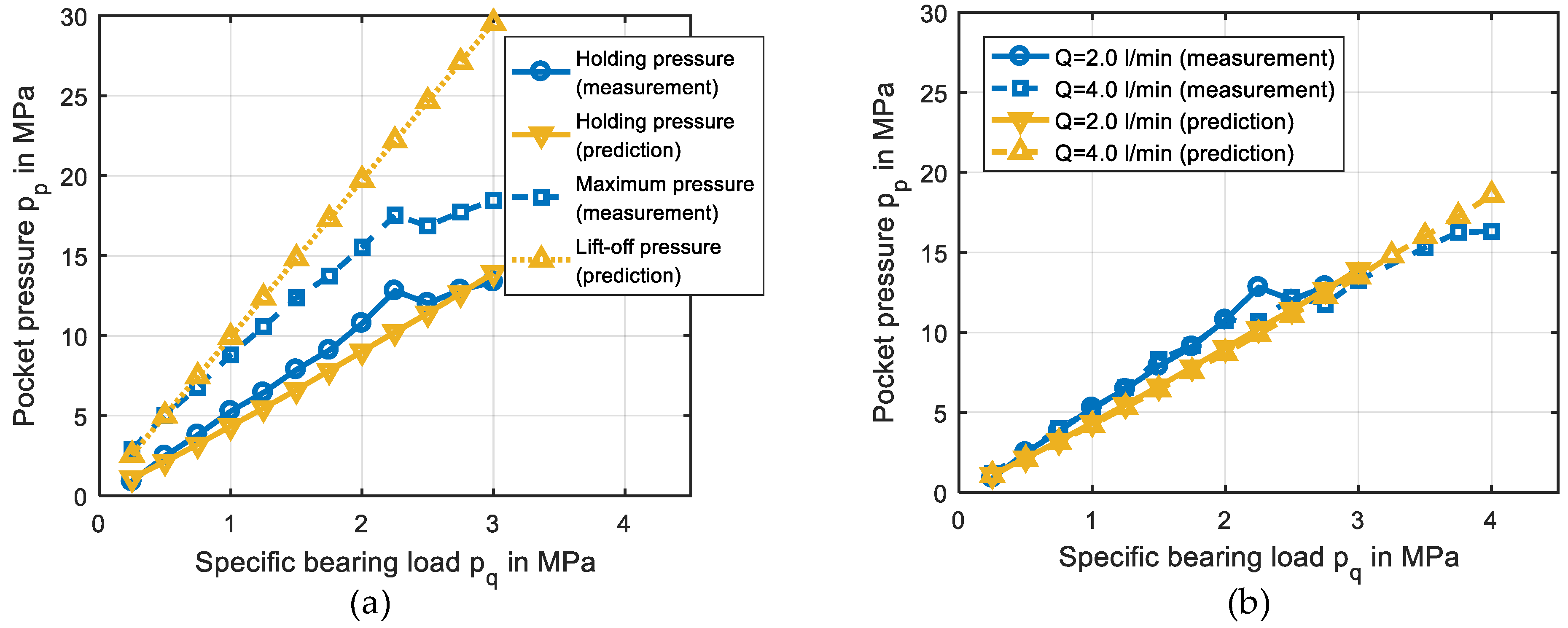

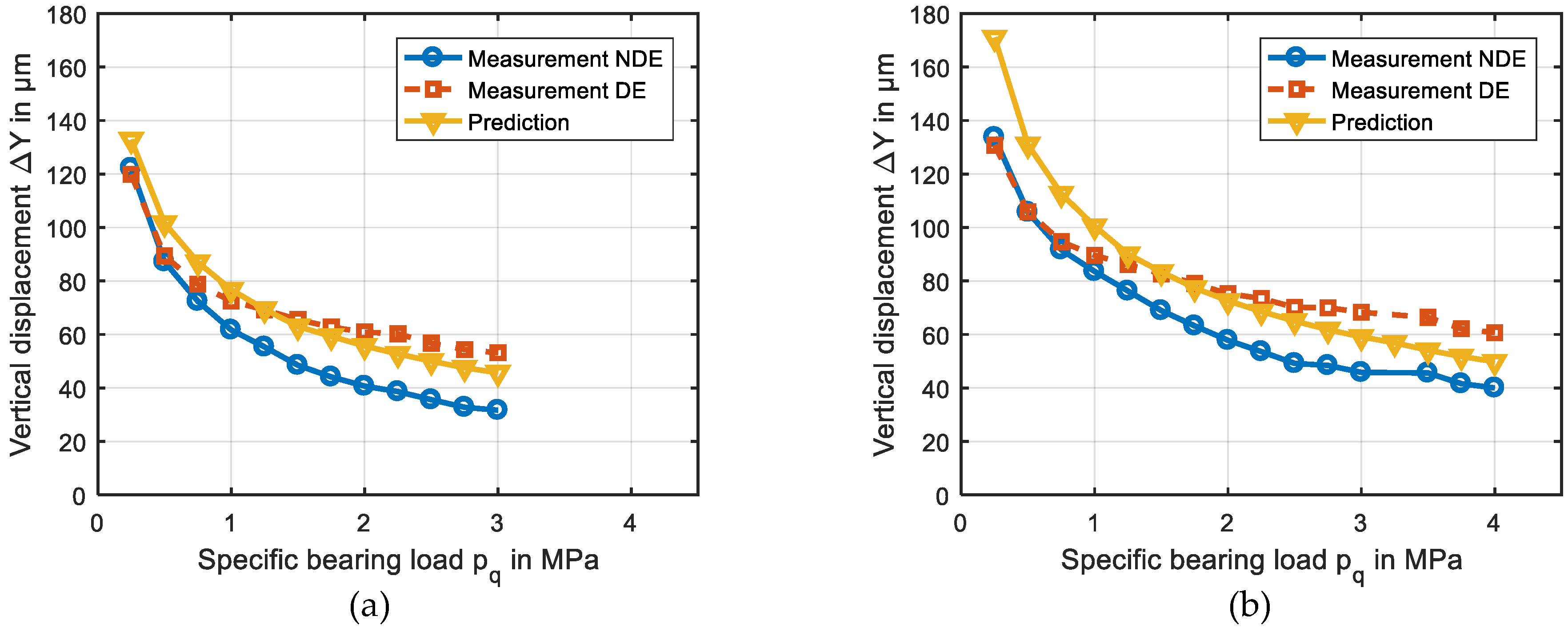

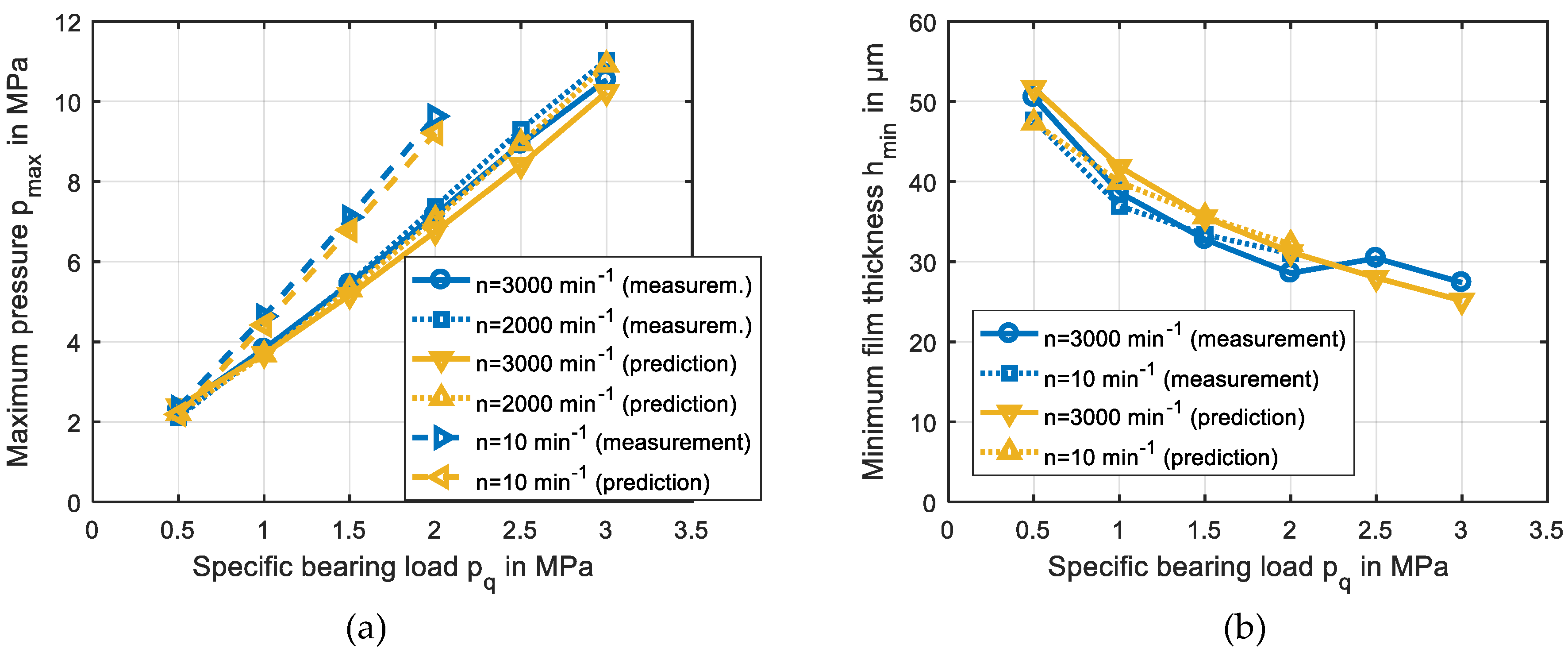

3.1.2. Stationary Characteristic Parameters of the Lift Procedure

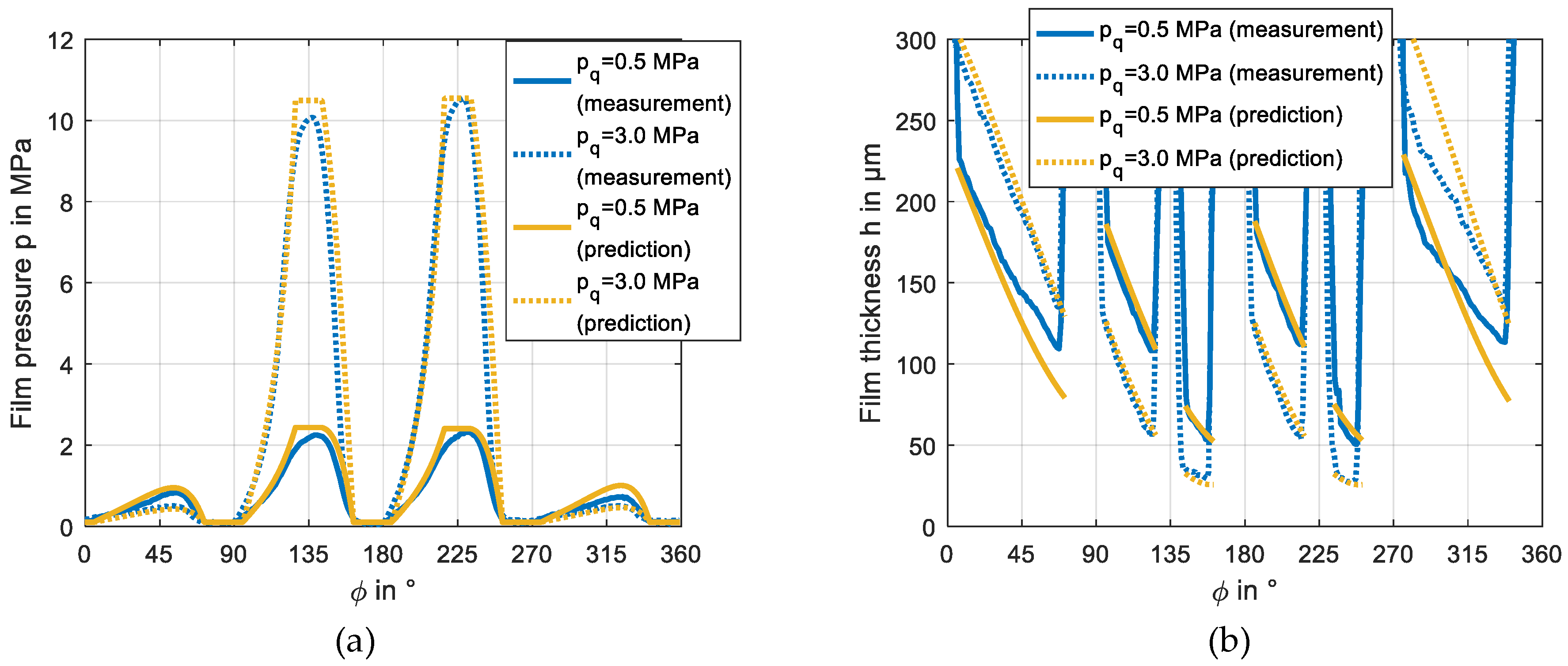

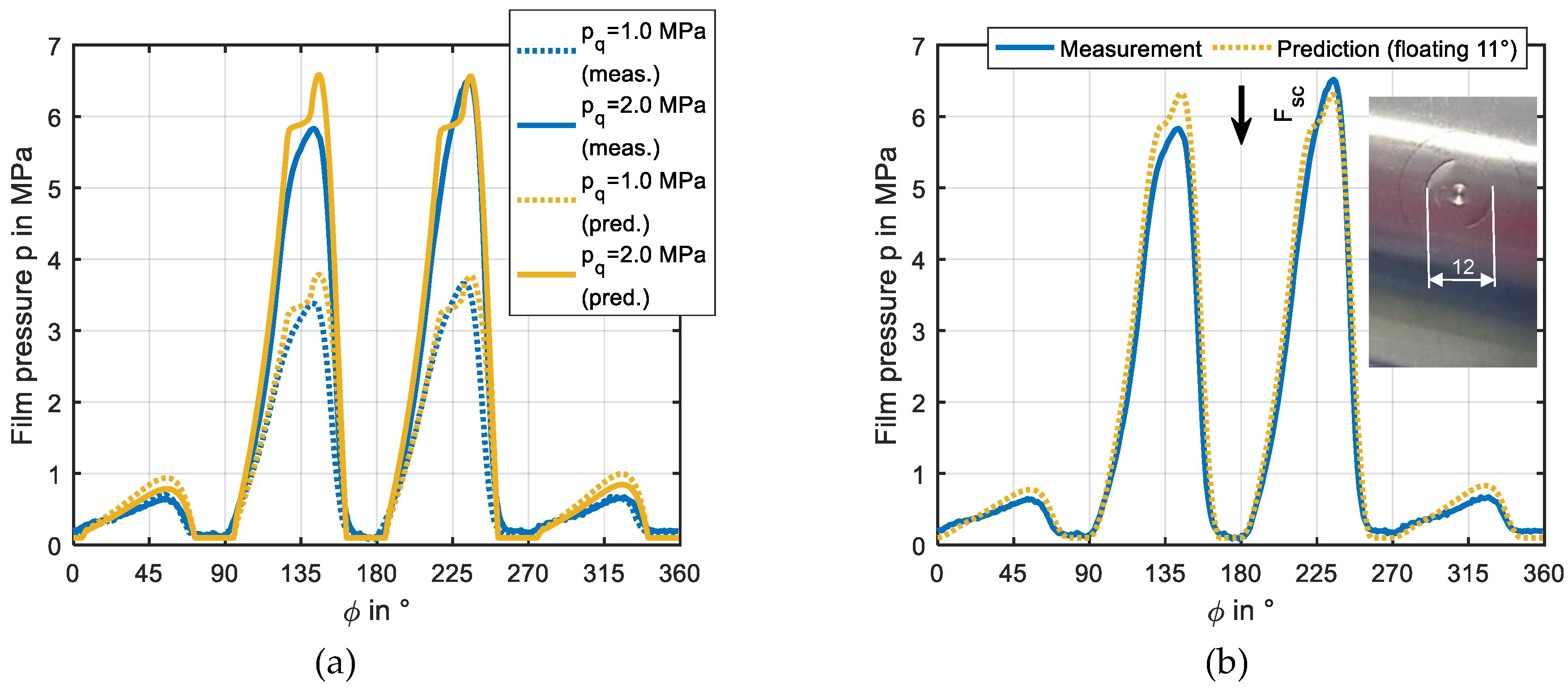

3.2. Hybrid Lubrication

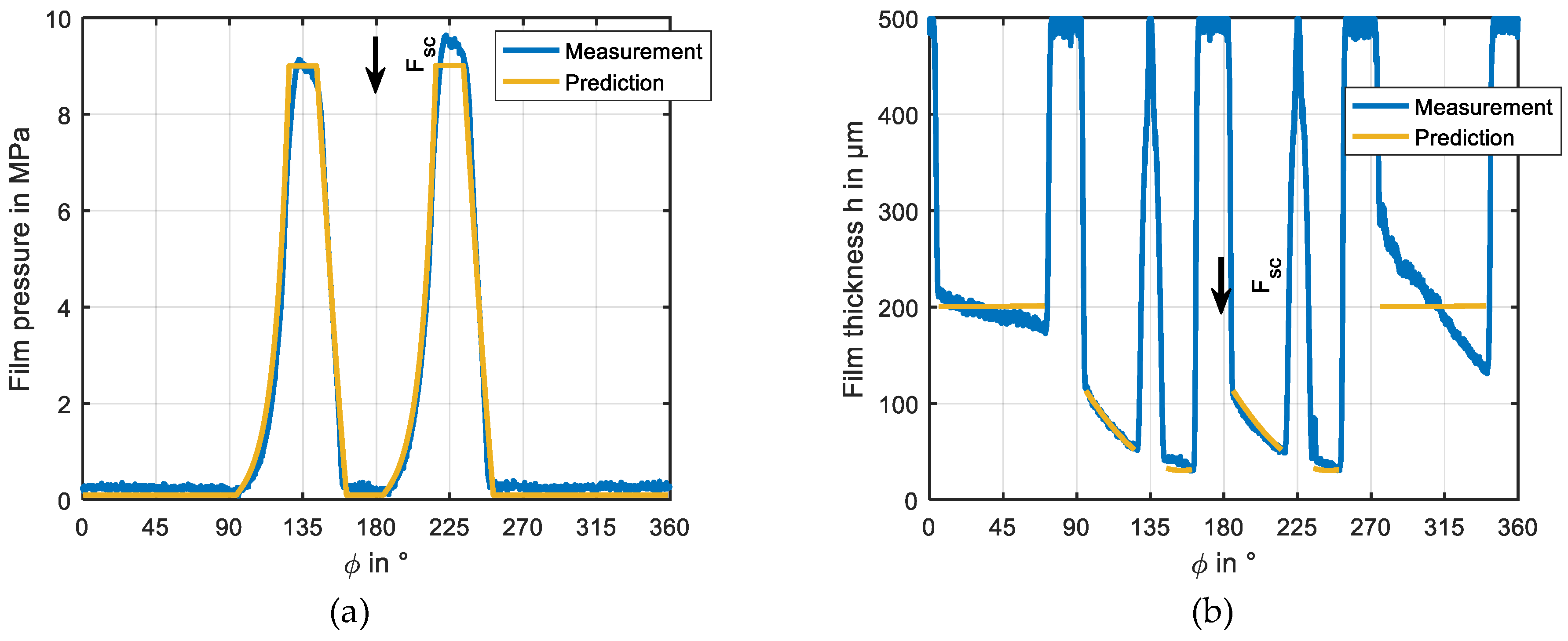

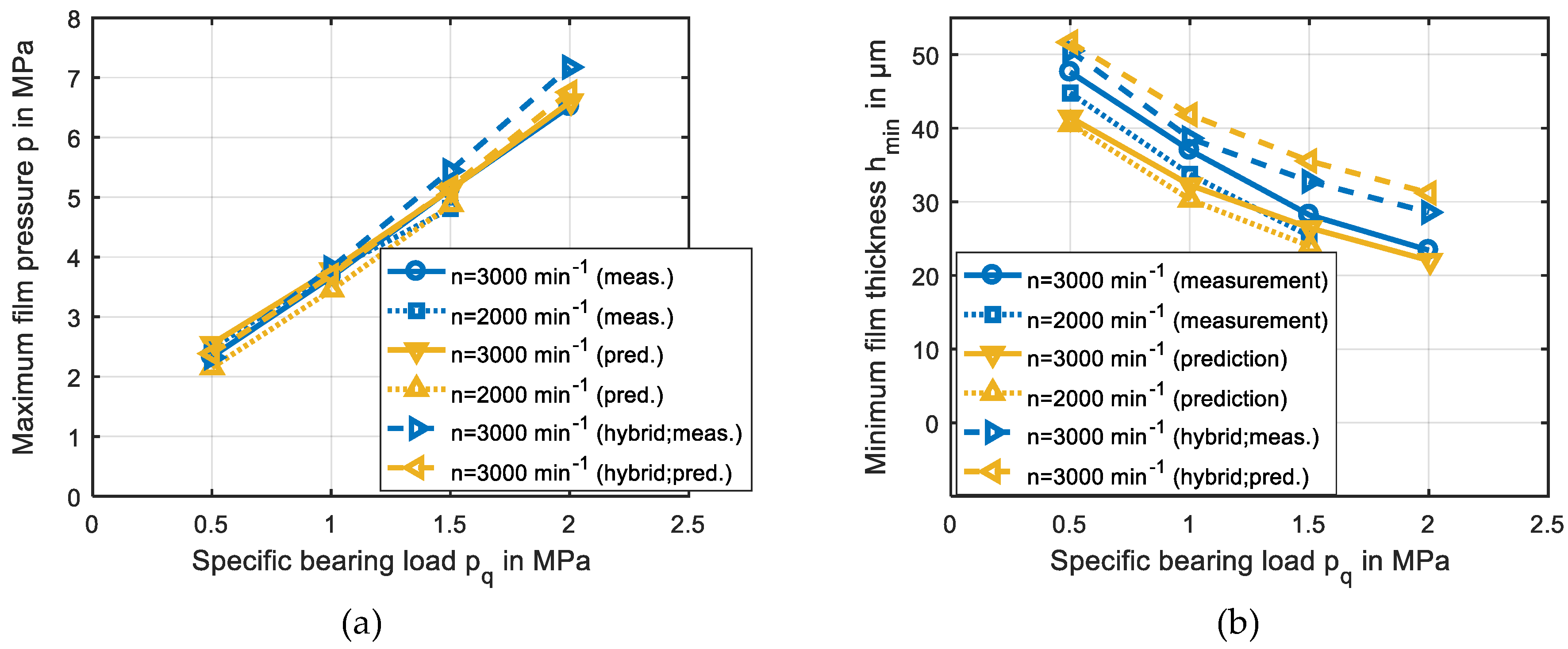

3.3. Operation in the Hydrodynamic Regime with Deactivated Jacking-Oil Pockets

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| B | bearing length |

| c | lubricant specific heat |

| D | nominal bearing diameter |

| F0, F1, F2 | viscosity factors |

| Fsc | static bearing load |

| h | film thickness |

| n | rotor speed |

| p | pressure |

| pp | pocket pressure |

| specific bearing load | |

| pss | pressure on sliding surface at sensor position |

| Qjo | jacking-oil flow rate |

| u, v, w | flow velocities |

| x, y, z | cartesian coordinates |

| Θ | lubricant density ratio |

| η | lubricant dynamic viscosity |

| λ | lubricant conductivity |

| ρ | lubricant density |

| φ | angular coordinate |

| Φ | dissipation |

References

- Neale, M.J. The Tribology Handbook; Butterworth-Heinemann: Oxford, UK, 1995. [Google Scholar]

- Fillon, M.; Wodtke, M.; Wasilczuk, M. Effect of presence of lifting pocket on the THD performance of a large tilting-pad thrust bearing. Friction 2015, 3, 266–274. [Google Scholar] [CrossRef]

- Chaomleffel, J.P.; Nicolas, D. Experimental investigation of hybrid journal bearings. Tribol. Int. 1986, 19, 253–259. [Google Scholar] [CrossRef]

- Varela, A.C.; Santos, I.F. Performance improvement of tilting-pad journal bearings by means of controllable lubrication. Mech. Ind. 2012, 13, 17–32. [Google Scholar] [CrossRef]

- Varela, A.C.; Santos, I.F. Dynamic coefficients of a tilting pad with active lubrication: Comparison between theoretical and experimental results. ASME J. Tribol. 2015. [CrossRef]

- Elwell, R.C. Hydrostatic lubrication. In Handbook of Tribology; Booser, E.R., Ed.; CRC Press: Boca Raton, FL, USA, 1984. [Google Scholar]

- Raud, X.; Fillon, M.; Helene, M. Numerical modelling of hydrostatic lift pockets in hydrodynamic journal bearings–Application to low speed working conditions of highly loaded tilting pad journal bearings. Mech. Ind. 2013, 14, 327–334. [Google Scholar] [CrossRef]

- Buchhorn, N.; Kukla, S.; Bender, B.; Neumann, M. Tilting-pad journal bearing in hybrid operation: A numerical and experimental investigation. In Proceedings of the 63rd ASME Turbo Expo, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Kluitenberg, M.; Childs, D. Measuring the impact of jacking-oil ports on the rotordynamic characteristics of a four-pad, LBP, tilting-pad journal bearing. In Proceedings of the 1st Global Power and Propulsion Forum, Zurich, Switzerland, 16–18 January 2017. No. GPPF-2017-175. [Google Scholar]

- Tschoepe, D.P.; Childs, D.W. Measurements versus predictions for the static and dynamic characteristics of a four-pad, rocker-pivot, tilting-pad journal bearing. ASME J. Eng. Gas Turb. Power 2014. [Google Scholar] [CrossRef]

- Hagemann, T.; Kukla, S.; Schwarze, H. Measurement and prediction of the static operating conditions of a large turbine tilting-pad bearing under high circumferential speeds and heavy loads. In Proceedings of the 58th ASME Turbo Expo, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Kukla, S.; Hagemann, T.; Schwarze, H. Measurement and prediction of the dynamic characteristics of a large turbine tilting-pad bearing under high circumferential speeds. In Proceedings of the 58th ASME Turbo Expo, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Hagemann, T. Ölzuführungseinfluss Bei Schnell Laufenden und Hoch Belasteten Radialgleitlagern unter Berücksichtigung des Lagerdeformationsverhaltens. Ph.D. Thesis, Clausthal University of Technology, Clausthal-Zellerfeld, Germany, 2011. [Google Scholar]

- Hagemann, T.; Schwarze, H. A model for oil flow and fluid temperature inlet mixing in hydrodynamic journal bearings. ASME J. Tribol. 2018. [Google Scholar] [CrossRef]

- Dowson, D. A Generalized Reynolds Equation for Fluid Film Lubrication. Int. J. Mech. Sci. 1962, 4, 159–170. [Google Scholar] [CrossRef]

- Hagemann, T.; Blumenthal, H.; Kraft, C.; Schwarze, H. A study on energetic and hydraulic interaction of combined journal and thrust bearings. In Proceedings of the 60th ASME Turbo Expo, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Hagemann, T.; Schwarze, H. Theoretical and experimental analyses of directly lubricated tilting-pad journal bearings with leading edge groove. ASME J. Eng. Gas Turb. Power 2018. [Google Scholar] [CrossRef]

- Hagemann, T.; Zeh, C.; Prölß, M.; Schwarze, H. The impact of convective fluid inertia forces on operation of tilting-pad journal bearings. Int. J. Rotat. Mach. 2017. [Google Scholar] [CrossRef]

- Bou-Said, B.; Chaomleffel, J.P. Hybrid Journal Bearings: Theoretical and Experimental Results. ASME J. Tribol. 1989, 111, 265–269. [Google Scholar] [CrossRef]

- Hagemann, T.; Kraft, C.; Pfeiffer, P.; Schwarze, H. Erhöhung der Betriebssicherheit von Rotierenden Maschinen deren Hydrodynamische Radial- und Axiallager Zusätzlich mit einer Hydrostatischen Laufhilfe Ausgestattet sind; Technical Report 1135; FVV: Frankfurt am Main, Germany, August 2017. [Google Scholar]

| Parameter | Value |

|---|---|

| Geometrical Properties | |

| Number of tilting-pads | 4 |

| Nominal diameter, mm | 120 |

| Tilting-pad thickness, mm | 20 |

| Bearing width, mm | 72 |

| Angular length of tilting-pads, degrees | 70 |

| Relative position of tilting-pad support | 0.6 |

| Radial clearance (assembled), µm | 108 |

| Preload (assembled) | 0.50 |

| Angular length of jacking-oil pockets, degree | 16 |

| Width of jacking-oil pockets, mm | 20 |

| Maximum depth of jacking-oil pockets, mm | 0.4 |

| Static Analysis Parameters | |

| Bearing load, kN | 2.2–34.6 |

| Rotational speed, rpm | 0–3000 |

| Lubricant supply temperature, °C | 50 |

| Lube oil flow rate, l/s | 1.0 |

| Lubricant Properties | |

| Lubricant | ISO VG 32 |

| Lubricant density kg/m³ | 865 @ 40 °C |

| Lubricant specific heat capacity kJ/(kg·K) | 2.0 @ 20 °C |

| Thermal Boundaries and Material Properties | |

| Lubricant thermal conductivity, W/(m·K) | 0.13 |

| Pad and journal thermal conductivity, W/(m·K) | 45 |

| Pad ambient temperature, °C | 60 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hagemann, T.; Pfeiffer, P.; Schwarze, H. Measured and Predicted Operating Characteristics of a Tilting-Pad Journal Bearing with Jacking-Oil Device at Hydrostatic, Hybrid, and Hydrodynamic Operation. Lubricants 2018, 6, 81. https://doi.org/10.3390/lubricants6030081

Hagemann T, Pfeiffer P, Schwarze H. Measured and Predicted Operating Characteristics of a Tilting-Pad Journal Bearing with Jacking-Oil Device at Hydrostatic, Hybrid, and Hydrodynamic Operation. Lubricants. 2018; 6(3):81. https://doi.org/10.3390/lubricants6030081

Chicago/Turabian StyleHagemann, Thomas, Peter Pfeiffer, and Hubert Schwarze. 2018. "Measured and Predicted Operating Characteristics of a Tilting-Pad Journal Bearing with Jacking-Oil Device at Hydrostatic, Hybrid, and Hydrodynamic Operation" Lubricants 6, no. 3: 81. https://doi.org/10.3390/lubricants6030081

APA StyleHagemann, T., Pfeiffer, P., & Schwarze, H. (2018). Measured and Predicted Operating Characteristics of a Tilting-Pad Journal Bearing with Jacking-Oil Device at Hydrostatic, Hybrid, and Hydrodynamic Operation. Lubricants, 6(3), 81. https://doi.org/10.3390/lubricants6030081