1. Introduction

Sliding bearings are machine elements that enable the transmission of power and torque; they serve to carry loads with minimal friction. Tribological mechanisms have a significant influence on the efficiency and service life of machines, primarily through the coefficient of friction (COF), surface morphology change, wear and contact temperature [

1]. Conventional, usually metal, sliding bearings rely on an external lubricant supply and operate in a hydrodynamic lubrication system. These systems require additional equipment for the lubricant supply, so their maintenance as well as the management of their use, most commonly mineral oils, increases operating costs and represents a potential environmental hazard. In the context of sustainable mechanical engineering, there is a need for the development of sliding bearings that operate in lubrication-free conditions, with appropriate load-carrying capacity and service life [

1,

2].

Polymer-based bearings and their composites show significant potential for successful operation as a self-lubricating and maintenance-free solution. Compared to metals, polymers are characterized by low mass and corrosion resistance and can operate in lubrication-free conditions, thus eliminating lubricant supply subsystems and reducing the risk of environmental contamination with mineral oils [

3,

4]. By using polymers with solid lubricants and composites reinforced with graphite, graphene, molybdenum disulfide, polytetrafluoroethylene (PTFE), glass fibers, glass beads, or ceramic particles, it is possible to significantly reduce the coefficient of friction and specific wear while maintaining the necessary elasticity and load-carrying capacity [

3,

5,

6,

7,

8]. Research shows that carefully engineered polymer composites can match and even exceed the friction and wear performance of metal bearings, especially in aggressive environments, oscillatory regimes, and conditions with limited lubrication, corrosion risk, and critical requirements [

3,

4,

8].

The development of additive manufacturing (AM), a paradigm based on the addition of material, opened up a space for utilizing new materials and improving the design of sliding bearings. Among the AM processes, selective laser sintering (SLS) stood out as particularly favorable for the production of functional, end-use, load-carrying machine parts since it enables the creation of complex geometries directly from polymer powder [

9]. A key advantage of the SLS process is that it does not require support structures; enables efficient use of powder; and offers the possibility of adjusting production parameters such as laser power, hatching space, powder bed temperature, and build orientation to obtain high-quality parts [

9,

10,

11]. These parameters influence the porosity, microstructure, and mechanical properties of the manufactured part [

10,

11,

12,

13]. For tribological applications, SLS enables the use of high-performance materials, including polyamide 12 (PA12) and its composites reinforced with glass beads, glass fibers, carbon fibers, and solid lubricants, which can be optimized to improve tribological characteristics under lubrication-free conditions [

6,

10,

14,

15,

16,

17].

Polyamide 12 is one of the most commonly used thermoplastics due to its favorable processability, dimensional stability, and balanced mechanical properties. By adding glass beads to the PA12 matrix, a glass bead-filled composite, also known as PA 3200 GF, is obtained. This material was developed for making stiff, dimensionally stable parts under load, such as sliding bearings. Experimental tests show that reinforcement with glass beads increases the modulus of elasticity and stiffness of pure PA12, while the mechanical response still exhibits a certain sensitivity to powder bed temperature and build orientation [

11,

13,

18,

19]. The interaction between the glass reinforcement and the polymer matrix can lead to a decrease in fracture toughness, tensile strength, and fatigue life, as well as to decreased ductility compared to neat PA12 or short-fiber-reinforced grades [

12,

18,

19,

20]. These tests indicate that both the material formula and the production parameters must be carefully optimized in order to achieve a balance between stiffness, strength, and damage tolerance for demanding operating conditions [

12,

13,

19,

20].

Tribological tests of SLS-produced PA12 and their composites are usually conducted using standardized methods such as pin-on-disc or block-on-disc. For short glass fiber-reinforced PA12 in conditions of sliding on steel, it was shown that the amount of fibers and the applied load have a key effect on friction and wear, while the fiber orientation itself had a relatively small effect [

5]. Orientation-dependent tests on SLS-manufactured PA 3200 GF showed marked anisotropy in wear: specimens with layers perpendicular to the sliding plane showed more adhesive wear but significantly lower COF and material loss [

14]. Other studies have shown that the addition of solid lubricants such as MoS

2, PTFE, and graphite can significantly reduce friction and specific wear, in some cases by more than 50%, as well as change the dominant wear mechanism [

6,

15]. PA12 composites made by SLS, reinforced with carbon fiber and graphite, show reduced friction, increased resistance to wear, and, in certain cases, almost complete tribological independence from the orientation of production [

7,

16,

17]. The literature indicates that SLS-produced PA 12 composites, including PA 3200 GF, are a reliable choice for applications in dry-sliding conditions, provided careful selection of composition and manufacturing parameters [

6,

7,

8,

10,

14,

15,

16].

In contrast to extensive tests of tribological samples, a relatively small number of studies dealt with additively manufactured sliding bearings with real geometries and real operating conditions. Research on textured journal bearings made by fused deposition modeling (FDM) with acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and nylon showed that nylon-based bearings show the best combination of low friction and low wear rate among the tested materials [

21]. The authors in [

22] compared SLS and FDM methods for manufacturing bearings based on aluminum and nylon and showed that SLS nylon bearings have low friction in a certain range of loads and speeds. By examining MultiJet-printed bearing sleeves, the authors showed in [

23] that internal fit and applied load have the greatest impact on performance at low speeds. In the previous work [

24] in which we examined SLS-made PA12 bearings, it was shown that for the corresponding pressure–velocity (PV) regimes, we have a low and stable coefficient of friction, while the contact temperature remains in the safe zone, thus confirming the feasibility of additively manufactured bearings in real operating conditions.

Despite the progress mentioned, there is still a significant gap in research. Most tribological studies of SLS-fabricated PA12 and PA 3200 GF are based on simple sample geometries, short-term tests, or a single test regime, which makes it difficult to directly apply the results to real sliding bearings. For PA 3200 GF, experimental data on the influence of the PV regime on the running-in process, stabilization of the tribological response, and accompanying changes in topographic parameters relevant to load-carrying capacity remain very limited. A clearer understanding of these relationships is key to defining PV limits, avoiding deformation due to overheating, and achieving stable long-term operation.

Based on existing knowledge of PA 3200 GF and tests of additively manufactured bearings, this paper examines SLS-manufactured PA 3200 GF sliding bearings under realistic operating conditions. The aim of this study is to quantify the evolution of the friction coefficient and contact temperature in several different PV regimes and to characterize changes in surface morphology based on pre- and post-test data. Moreover, the specific wear rate is determined and the main wear mechanisms are identified based on experimental examination of the worn bearing surfaces. Evaluation of long-term durability is not the focus of this study and will be explored in future research. Based on these findings, this study presents experimentally supported knowledge of how different loading regimes affect the tribological properties of SLS-fabricated sliding bearings under dry-sliding conditions, thus providing a clearer understanding relevant to environmentally oriented machine design.

2. Materials and Methods

In this section, a detailed overview of the material used, the manufacturing procedure, the experimental setup, the measurement techniques, and the test conditions will be specified. The aim of this chapter is to define how the PA 3200 GF bearings were made, the way in which the tribological measurements were performed, and the PV regimes under which the tests were performed, ensuring full transparency and reproducibility of the experiment methodology.

2.1. Material Description

The sample bearings were produced from PA 3200 GF (EOS GmbH, Krailling, Germany), a polyamide 12 matrix reinforced with 40 wt% glass beads. This composite material is characterized by increased stiffness while maintaining sufficient elasticity to ensure stable performance at elevated temperatures. Due to its improved mechanical properties and wear resistance, PA 3200 GF is successfully applied for machine parts under higher loads, making it a suitable choice for the plain bearings tested in this work. The material properties [

25] are summarized in

Table 1.

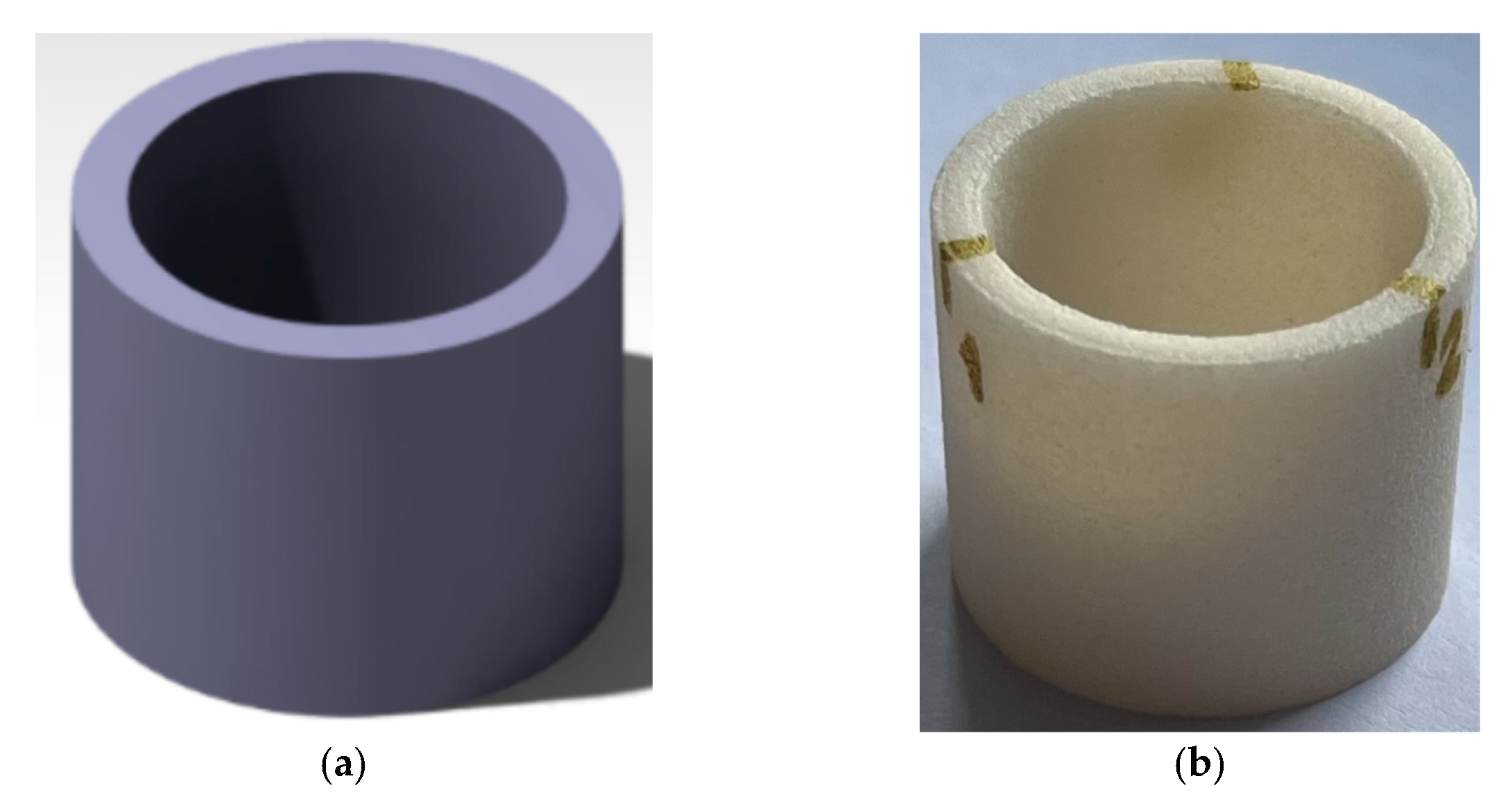

The investigated bearings have a nominal inner diameter of 20 mm, an outer diameter of 30 mm, and a length of 20 mm. These dimensions enable easy assembly while guaranteeing constant fit and uniform distribution of load throughout operation. All samples were printed along the

Z-axis, selected due to the known influence of the print orientation on the mechanical and tribological properties of SLS-manufactured components. Measurements taken at three axial locations yielded an average inner diameter of

d = 20.18 ± 0.034 mm, which indicates adequate process repeatability and narrow tolerance distribution.

Figure 1 shows the CAD model from which the STL file was used for the sample’s SLS production.

The tested bearings are mounted on a sleeve made of stainless steel, with a mean diameter of 19.877 mm and a length of 37.25 mm, which achieved a loose fit with a mean value of clearance of 0.304 mm. The stainless-steel sleeve was polished to a smooth finish suitable for sliding bearing application and testing. The goal of the chosen geometry is to simulate realistic operating conditions.

2.2. Selective Laser Sintering of Sliding Bearings

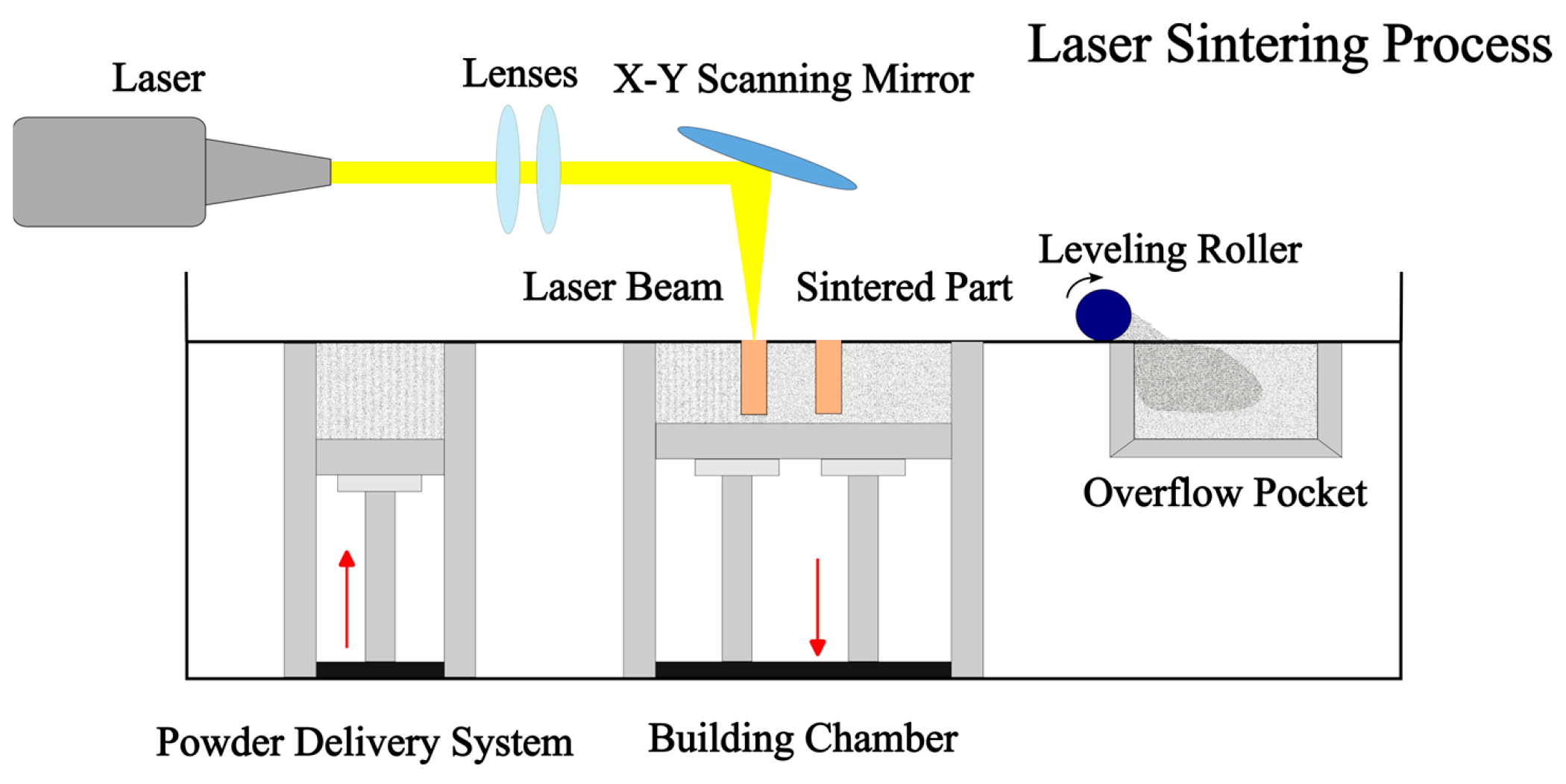

The SLS technology, shown in

Figure 2, was used for the production of parts, as it is one of the most reliable additive technologies for producing components with complex geometries. The powder sintering process uses a laser as an energy source to selectively melt material in accordance with a digital 3D model in STL format. After the completion of the melting of an individual layer, the building chamber is lowered by a predefined value, which enables the formation of the next layer. This process is repeated until the part is completely fabricated. SLS technology supports a broad range of polymer materials, including PA12, polyamide 11 (PA11), polypropylene (PP), thermoplastic polyurethane (TPU), and polyether ether ketone (PEEK), among others. The key advantages compared to other additive techniques are the possibilities of making parts of complex geometries without the need for additional support structures and the reusage of powder, which reduces material consumption and shortens post-processing time [

29].

We fabricated the samples using the Formiga P100 SLS system (EOS GmbH). Manufacturer-recommended process settings were applied during the fabrication process, ensuring the highest quality and reliability of the resulting parts. All samples were fabricated in a single batch, ensuring uniform sintering conditions and thus uniformity of the properties of all tested bearings. The powder used as the material was 70% new and 30% used powder, in accordance with EOS recommendations for achieving optimal mechanical and tribological performance. The process parameters for SLS fabrication are shown in

Table 2.

2.3. Experimental Setup

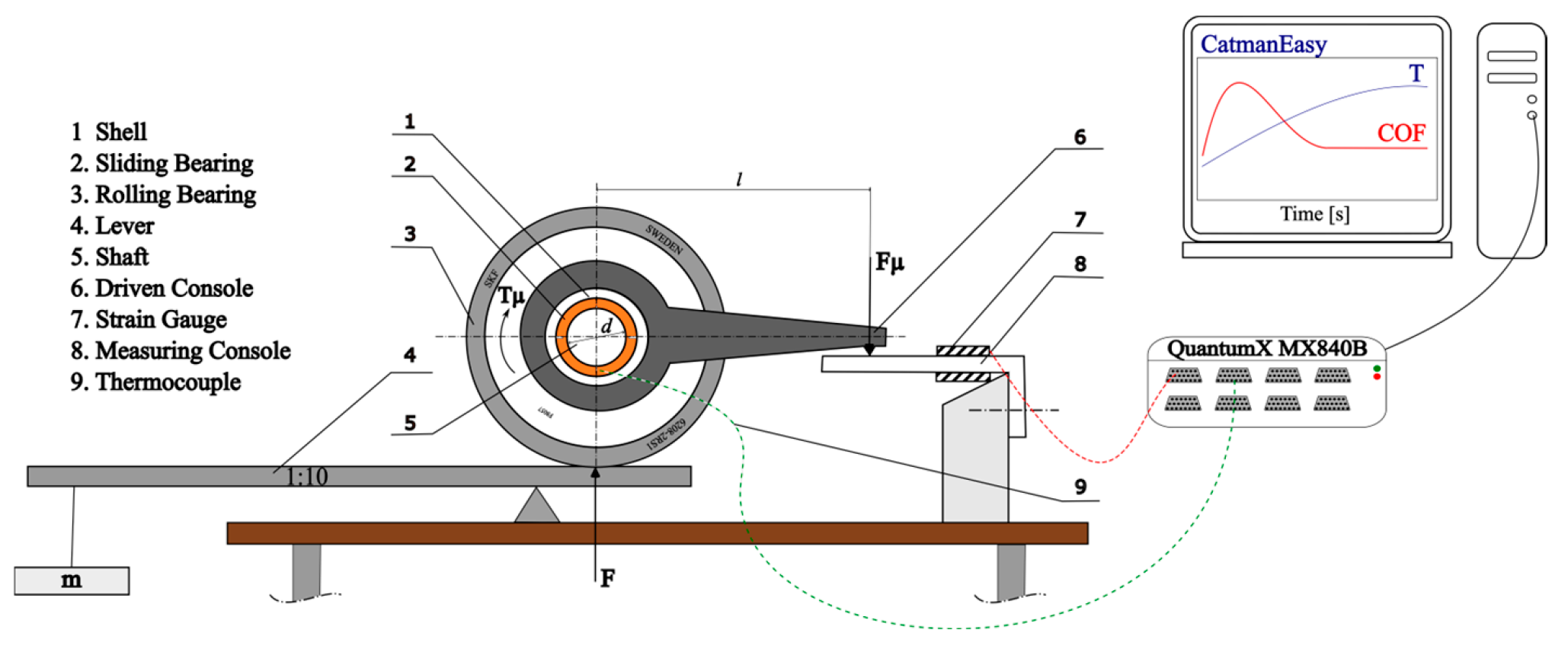

The tribological characteristics of sliding bearings were investigated on the USL 5-30 device,

Figure 3, developed at the Faculty of Mechanical Engineering, University of Belgrade. The tested bearing was installed in a subassembly consisting of a sleeve, a rolling bearing, and a driven console. The rotation is provided by an electric motor connected by a belt transmission to the sleeve on which the sleeves are located. The friction-generated torque was transferred to a driven console resting on a measuring console with built-in strain gauges, arranged in Wheatstone’s bridge, which allows registration of the friction torque. The angular speed of the sleeve is regulated by a frequency regulator (AEG Microverter D 2.8/230 V), while the radial load is introduced by a lever system. Weights are placed on the free end of the lever, which generates a radial force on the subassembly with a sliding bearing in a lever ratio of 1:10.

Unlike conventional tribological tests, such as pin-on-disc or block-on-disc tests, this procedure analyzes real machine parts instead of pin or disc specimens. Consequently, the actual contact between the inner and outer cylinders is taken into account, as well as the characteristic pressure distribution on the side where the radial force acts.

2.4. Experimental Measurements

The tests were performed to determine the coefficient of friction, contact temperature, wear rate, and surface evolution of the sliding bearing during interaction with a sleeve made of stainless steel.

The coefficient of friction was determined indirectly, through the frictional moment transformed from the moving console to the measuring console. Four strain gauges, CLY41–6/120ZE (HBM), each with a nominal resistance of 120 Ω, connected in a full Wheatstone bridge, are placed on the measuring console. This configuration enables maximum sensitivity in the measuring system and simultaneous temperature compensation, because all four branches actively participate in the registration of the resistance change caused by the friction moment.

Contact temperature was measured using a K-type thermocouple, TF-50 (PeakTech Prüf- und Messtechnik GmbH, Ahrensburg, Germany), embedded in the sliding bearing. The sensor allows a measurement range from −40 to 204 °C, with an accuracy of ± 0.5% of the reading value. A blind hole with a diameter and depth of the tip of the thermocouple is positioned at a distance of 1–1.5 mm from the sleeve-bearing contact surface. The hole, where the embedded tip is located, is at the mid-width of the front outer bearing surface. This configuration enables stable mechanical fixation and excellent temperature contact between the sensor and the tested bearing. The measured temperature represents the bearing temperature close to the sleeve-bearing sliding interface, which reliably reflects the thermomechanical response of the bearing in dry sliding conditions.

The mass of the samples was determined on a Mettler B6 mechanical analytical balance (Mettler-Toledo International Inc., Greifensee, Switzerland), with a resolution of 0.1 mg and a maximum capacity of 100 g. The average measured mass of the PA 3200 GF sliding bearing was m = 4.1404 ± 0.1303 g. The analytical balance’s high resolution allowed for the precise measurement of mass loss of the samples after tribological testing.

Surface roughness was measured using a MarSurf SD26 (Mahr GmbH, Göttingen, Germany) contact profilometer at three characteristic measuring points on the inner bearing surface, evenly distributed at an angle of 120°. The traversing length was 5.6 mm, with a sampling length of 2.5 mm and a cutoff of 0.8 mm, resulting in a total of 11199 measuring points per measuring line according to the ISO 21920-3 standard [

30]. The parameters

,

,

, and

were determined on each measuring trace based on the ISO 21920-2 [

31] standard, which allows a detailed assessment of the condition of the bearing surface before and after testing.

The QuantumX MX840B (Hottinger Baldwin Messtechnik, Darmstadt, Germany) module was used for data acquisition, enabling simultaneous recording of signals from eight different sensors. In this study, strain gauge and thermocouple signals were acquired in parallel. Data acquisition was carried out with a sampling frequency of 1 Hz, while the signal was processed through a built-in active low-pass filter automatically adapted to the sampling frequency. The obtained signals are monitored and stored in real time using the software package catmanEasy/AP (version 4.1.1.17, Hottinger Baldwin Messtechnik GmbH, Darmstadt, Germany), which provides visualization, calibration of the measuring channels, and data export for further analysis. This system enabled reliable detection of both short-term oscillations and long-term trends during the entire duration of the tribological tests.

Before SEM imaging using Tescan MIRA3 (TESCAN Group a.s., Brno, Czech Republic), the selected representative samples were sputter-coated with a thin gold layer using a Polaron SC503 (Fisons Instruments, Ipswich, UK) sputter coater to minimize electrostatic charging during SEM analysis. SEM analysis offers a more detailed look at the surface morphology, wear mechanism and manufacturing quality of the SLS-fabricated bearings.

2.5. Experimental Conditions

The experimentally obtained results provide insight into the tribological characteristics of the SLS-fabricated composite PA 3200 GF bearing. The tests were carried out under dry-sliding conditions, in contact with a stainless-steel sleeve.

Three pressure (P) and velocity (V) regimes, given in

Table 3, were applied to enable an analysis of bearing behavior under varying PV conditions. The selected regimes are defined based on literature precedent for SLS composites made with PA12 base tested in dry-sliding condition. Previous studies show a PV value of 1 MPa·ms

−1 as heavily loaded operating conditions [

14,

16]. Accordingly, this regime is defined as a high PV regime, while the other regimes are chosen proportionally and relatively in relation to this one and classified as medium and low PV. For each PV regime, three independent tests were conducted using new samples. To minimize potential bias associated with the order of performance, the order of tests was randomized. The complete PV characteristic of the bearing was beyond the scope of this research and remains the focus of future investigations.

All tests were performed under laboratory conditions at a typical indoor relative humidity of 30%. Before and after testing, all samples were cleaned in an ultrasonic bath (ASonic Ultrasonic Cleaner PRO90) using petroleum ether as a medium for 30 min at a temperature of 45 °C to remove residual dust and potential contaminants. After cleaning, the samples were air-dried at a temperature of 25 °C and 30% relative humidity. To remove moisture from the surface pores, it was dried in a dryer for 2 h at a temperature of 40 °C without affecting mechanical properties.

3. Results and Discussion

The results presented in this section show the tribological response of SLS-manufactured PA 3200 GF sliding bearings, with a focus on the effect of different PV regimes on COF, temperature, wear behavior, and surface change in dry-sliding conditions.

3.1. Time Evolution of COF and Temperature

The aim of this section is to present time-dependent coefficients of friction and temperature for examined PV regimes in order to understand their mutual dependence. After acquisition, the data were analyzed using the MATLAB (version 2024b, The MathWorks, Inc., Natick, MA, USA) software package.

Before processing, the signals obtained from the sensors were filtered using an active low-pass filter to remove noise and ensure the actual measured values.

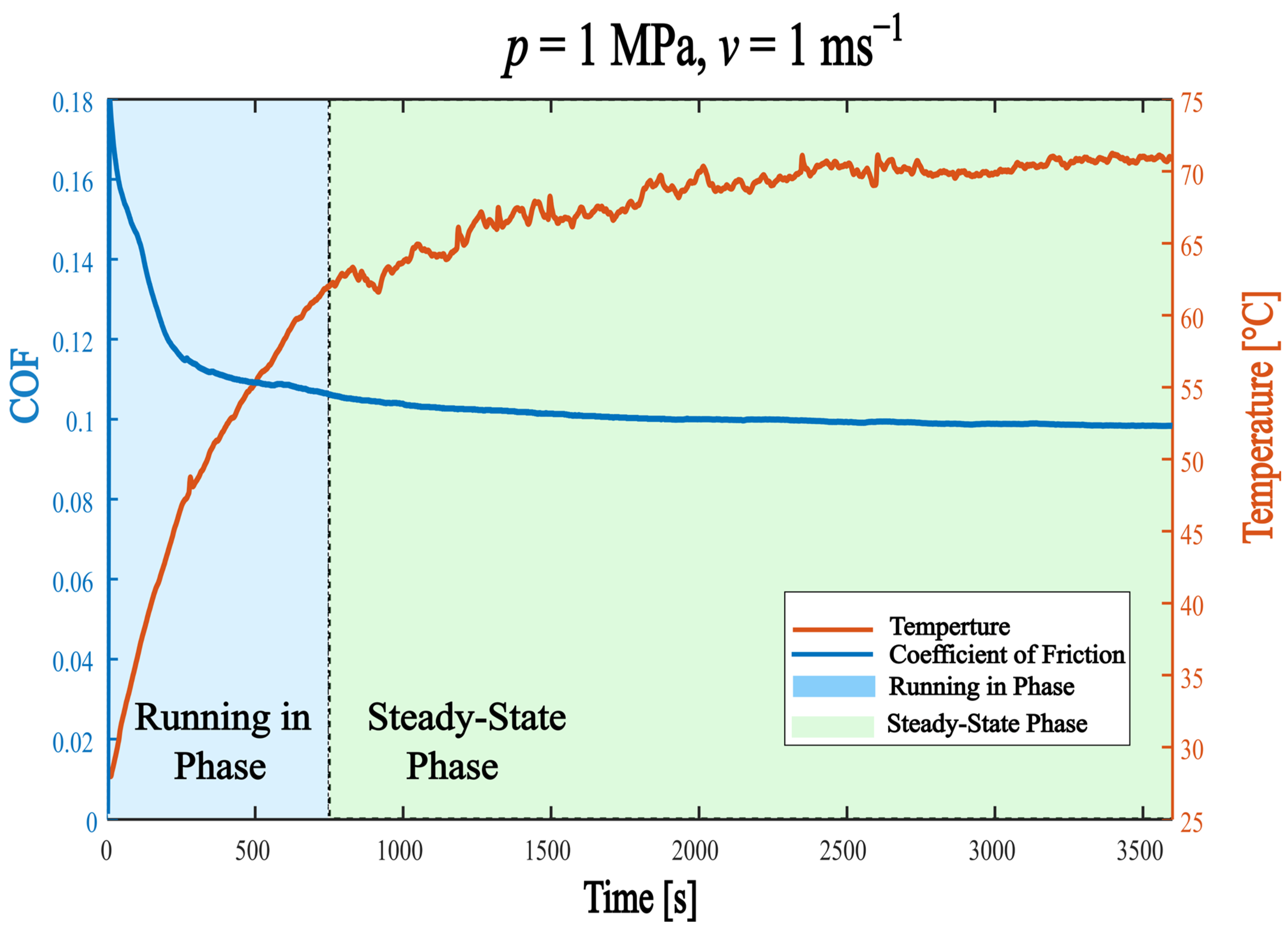

Figure 4,

Figure 5 and

Figure 6 show the experimentally measured trends of the coefficient of friction and temperature as a function of time. The total duration of each test was 3600 s, which was enough to reach the steady-state of the system. Tests for all regimes were performed in triplicate. All graphs clearly show the characteristic two phases of tribological behavior:

- •

the running-in phase, during which adaptation and alignment of the surfaces in contact occur,

- •

steady-state phase, in which the contact reaches mechanical and thermal equilibrium.

- •

At the beginning of sliding, the bearing surface of the polymer bearing is relatively rough with pronounced asperities, which leads to discontinuity in the contact between the bearing and the sleeve. In this phase, there is an increased share of mechanical interlocking, when material irregularities remain trapped within each other, resulting in increased friction and pronounced oscillations. Therefore, the actual contact surface is initially significantly smaller than the nominally calculated one, because the contact is made on the tops of the asperities. As the test continues, under the influence of radial load and speed designated as the PV regime, the asperities are mechanically cut off, deformed, and worn, which increases the effective area in contact. This process of smoothing the surface leads to a gradual decrease and stabilization of the friction coefficient, which is clearly observed in the COF and T trend diagrams.

Figure 4 shows a representative graph of COF and T evolution for Regime I (

p = 1 MPa,

v = 1 m∙s

−1) which represents the most heavily loaded regime. In the initial phase of the test, there is a sudden increase in COF to a maximum value of 0.1798, after which the coefficient of friction starts to decrease. This sudden increase and drop in the coefficient of friction indicates the running-in phase. In Regime I, the running-in phase takes ≈960 s, after which the COF settles at ≈0.09. The temperature has an amplitude of change of 43.23 °C, from an initial temperature of 27.99 °C to a maximum temperature of 71.22 °C.

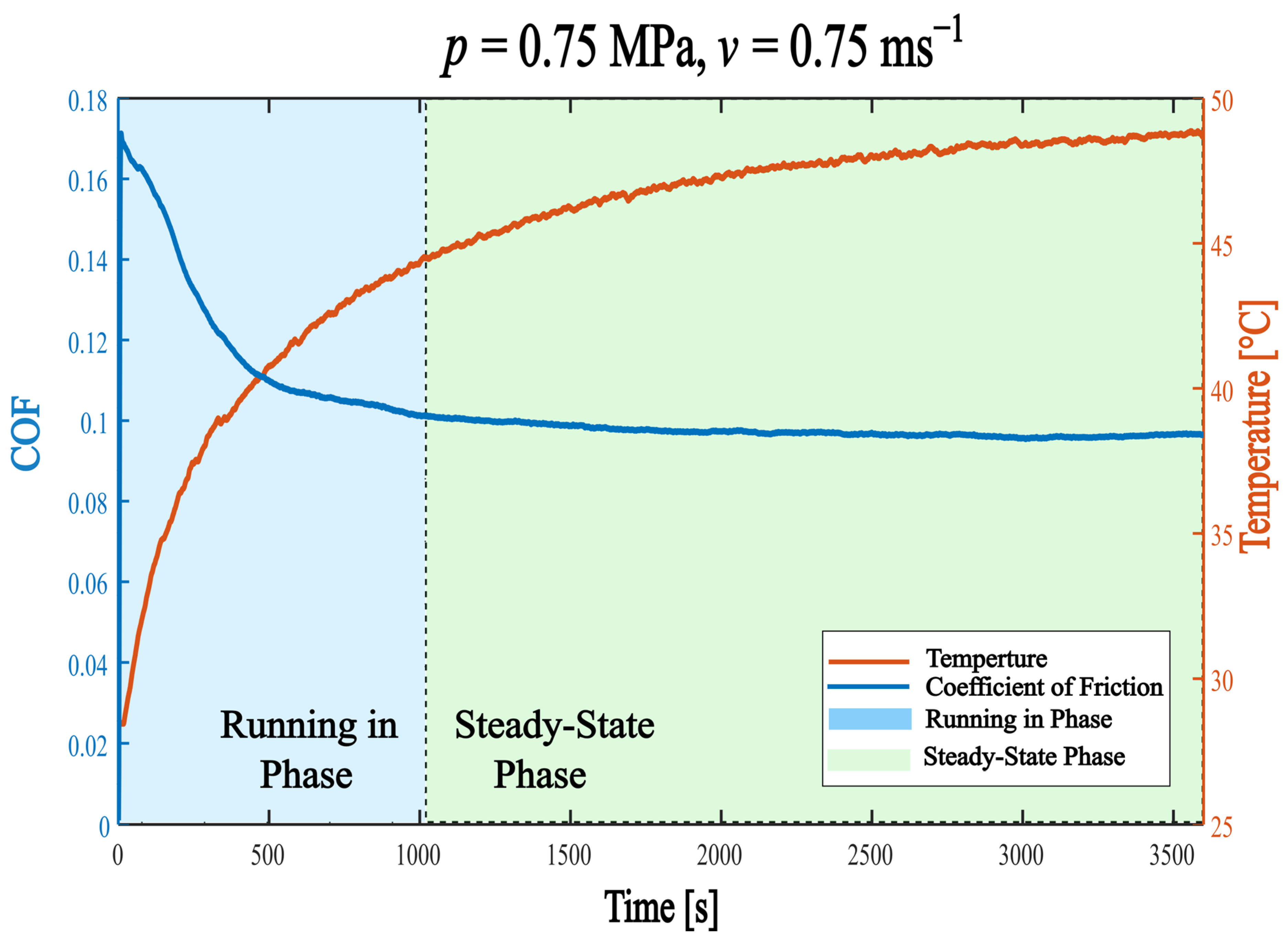

The evolution of friction and temperature for moderately loaded Regime II (

p = 0.75 MPa,

v = 0.75 m∙s

−1) is shown in

Figure 5. During the running-in period, which lasts ≈ 1080 s, the COF reaches a maximum value of 0.1712 before gradually decreasing to a stable value of ≈0.09. This reduction in COF indicates progressive surface polishing and real contact stabilization between the bearing and sleeve. During the test, the contact temperature increases from 28.46 °C to 48.86 °C, which represents a moderate increase corresponding to the medium PV regime. Stable COF and moderate temperature oscillations confirm balanced heat generation and dissipation during steady operation.

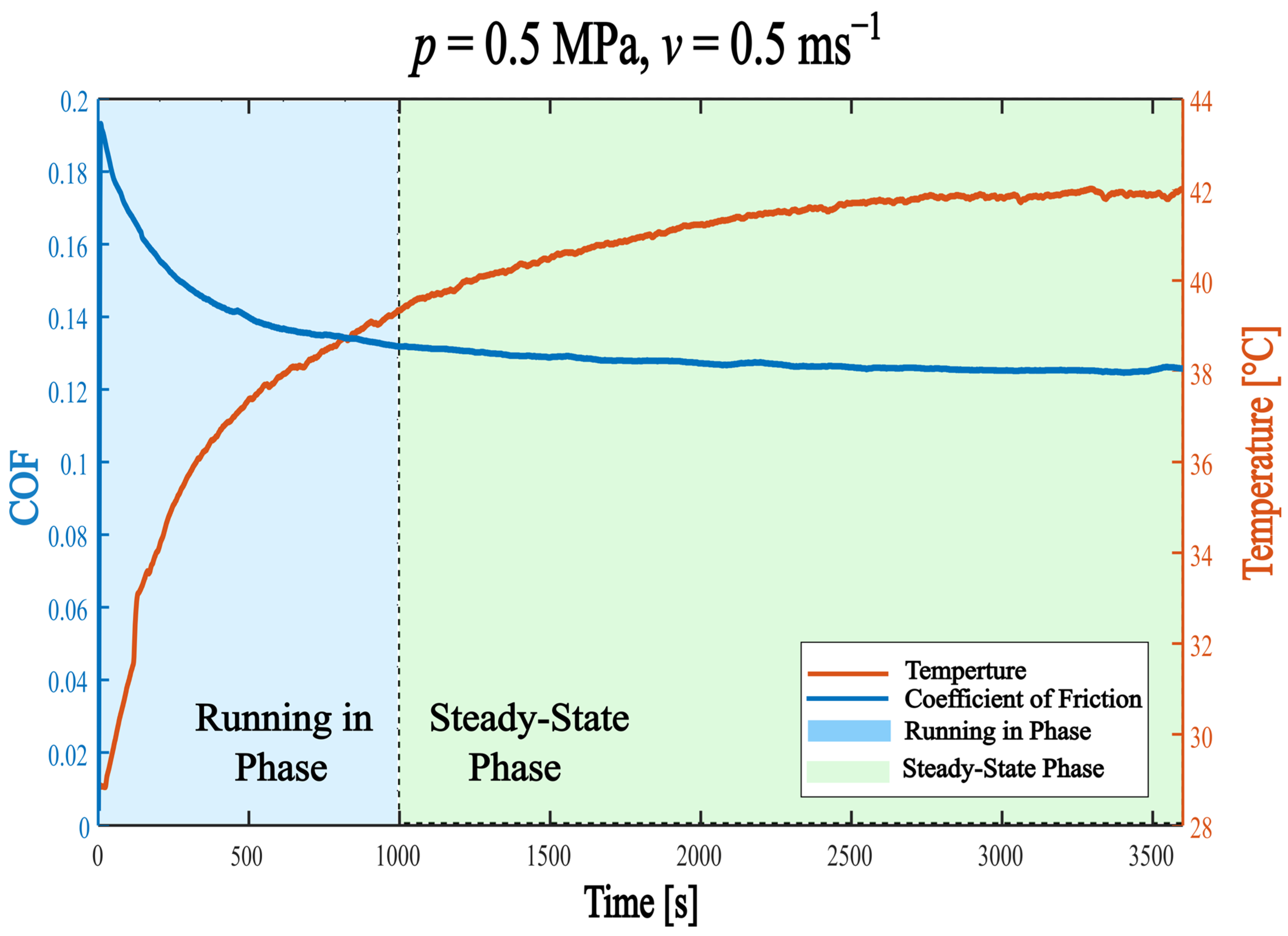

Figure 6 shows the time-dependent change in COF and T for the least loaded Regime III (

p = 0.5 MPa,

v = 0.5 m∙s

−1). The COF initially increases to a value of 0.1931 and subsequently decreases to a steady-state level of approximately 0.12 after a running-in period of ≈1000 s. The observed behavior shows slower surface adaptation due to lower contact pressure and speed. During this interval, the temperature rises moderately from 28.85 °C to 42.02 °C, maintaining good thermal stability and confirming the mild friction conditions typical for low PV regimes.

Throughout the duration of the test, COF and T show mutual dependence. The drop in COF during the running-in period coincides with a sharp increase in temperature, after which both parameters reach stable values. This phenomenon indicates the formation of a stable zone of contact between the bearing and sleeve, in which the processes of heat generation and dissipation are balanced. In all tested regimes, the COF stabilization moment corresponds to the temperature stabilization, which confirms that the friction and the temperature of the PA 3200 GF bearing are interrelated.

A comparative analysis of the three PV regimes indicates a clear pattern of tribological behavior. Higher PV values lead to a shorter running-in period, a lower stable COF, and a higher contact temperature as a consequence of increased heat generation by limited dissipation. Conversely, lower PV values result in a longer period of adaptation of the contact surfaces, as well as a higher stable COF, but with less temperature rise and thermally more stable behavior in the steady-state. The intermediate regime shows the most favorable relationship between the coefficient of friction and thermal stability, which can be considered the favorable operating condition for PA 3200 GF bearings in dry-sliding conditions.

3.2. Steady-State Comparison

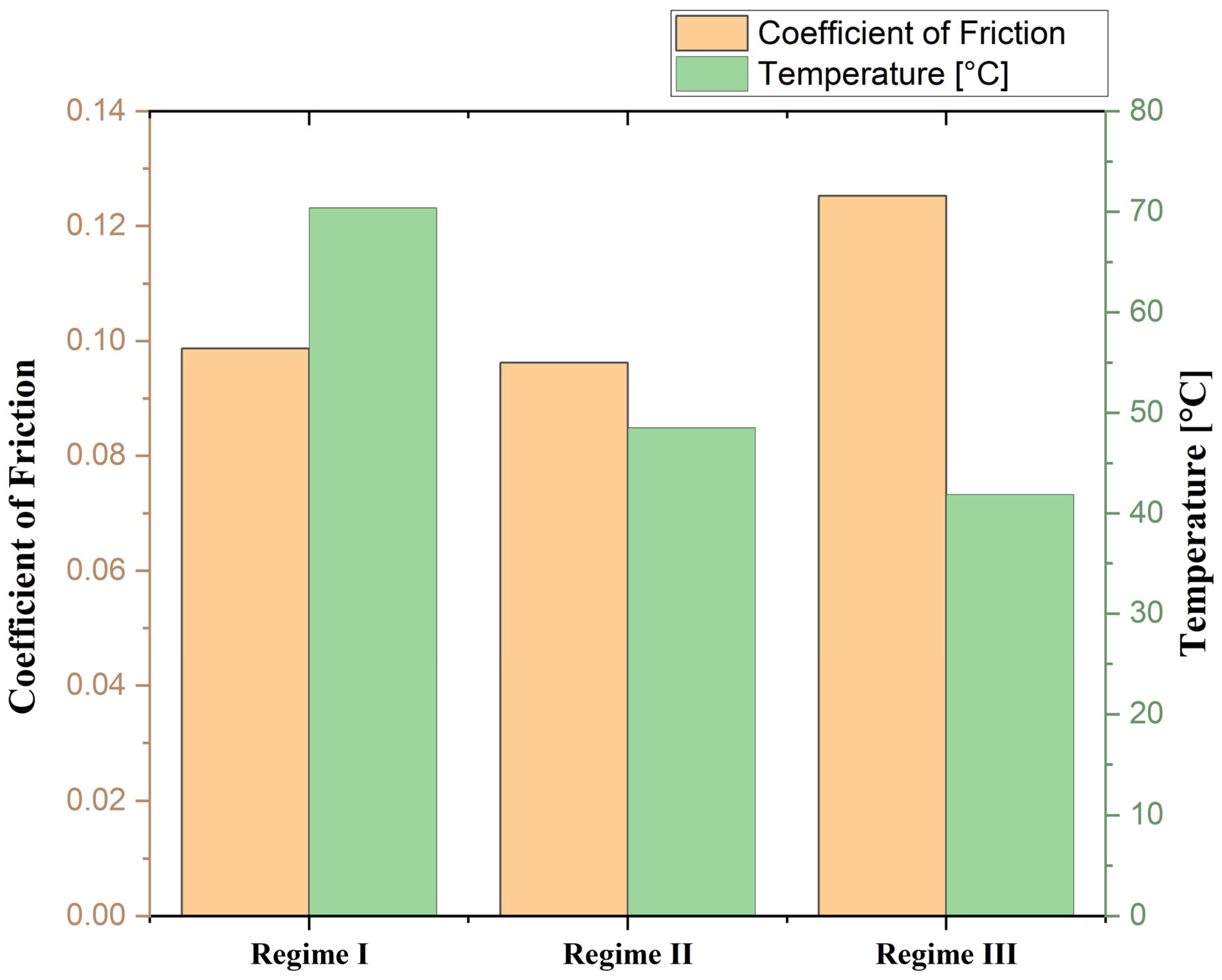

Steady-state values of friction coefficient and contact temperature were determined in triplicate for all regimes, given in

Figure 7. The steady-state interval was defined in the last quarter of each test (900 data points), in which the system reached thermal and mechanical equilibrium, to avoid the effects of the transition phase. Mean values of COF and T were calculated for each test separately.

Table 4 summarizes the results of the tribological test. Among the tested conditions, Regime II shows the best balance between friction and thermal stability, with the lowest mean COF and mean temperature increase. Regime I, with the highest level of PV, shows a comparative COF but with a significantly higher mean temperature increase, which may be a consequence of limited heat dissipation. Regime III, at the lowest PV values, shows a slightly higher COF followed by the lowest contact temperature, which indicates a reduction in frictional energy generation but with insufficient load that leads to incomplete surface conformity. In all PV regimes, the measured temperatures during operation remain below the critical thermal limits determined for PA 3200 GF material, i.e., below ≈96 °C and ≈157 °C [

25], at which softening, stiffness decrease, and unwanted changes in bearing geometry may occur. As sliding continues, local temperature rise becomes an important factor that can significantly affect system performance. Polymers are generally more thermomechanically sensitive than metals, and elevated temperatures can lead to softening if the Vicat softening temperature is exceeded, which can result in an increase in the actual contact area and even local melting and adhesive wear. Studies of polymer materials [

32] show that if the temperature limits are moderate, this process can contribute to stabilization friction through the creation of a homogeneous transfer film.

The standard deviations of the COF, and temperature within the steady-state interval were less than 0.0003 and less than 0.5 °C, respectively, indicating minimal oscillations and stable contact conditions. These values represent the within-run standard deviation and confirm that the PA 3200 GF plain bearings achieve a very consistent tribological response after establishing a stable operating regime. Variations in mean steady-state values of COF and T for three repetitions per regime are small compared to differences between regimes, which indicates satisfactory reproducibility of tribological performance.

Overall, the comparison of steady-state values confirms that the tribological behavior of the PA 3200 GF bearing is stable and predictable under dry-sliding conditions. Considering only friction and temperature, Regime II was the most favorable. However, according to the results of the surface morphology analysis shown in

Section 3.3, this regime results in the largest increase in the peak and core parameters. Therefore, the suitable PV regime depends on the balance of low friction, temperature stability, and surface integrity required for a particular application. Comparing the results with PA12 [

24], PA 3200 GF bearings shows a negligibly higher COF in the most loaded regime but with significantly better thermal stability during all regimes and a more favorable COF-T balance.

3.3. Wear Behavior and Wear Mechanism of PA 3200 GF Sliding Bearings

Wear behavior of SLS-manufactured PA 3200 GF sliding bearings is quantified by determining the specific wear rate by measuring the mass loss after tribological testing. This approach was chosen as an already widely accepted standard in polymer tribology, where the absolute change in volume is often tiny and difficult to measure with adequate accuracy due to the pronounced elasticity of the material, surface irregularity, and the formation of wear products. Therefore, the method based on mass loss represents a reliable and reproducible way for comparative wear analysis under controlled conditions.

Specific wear rate

is determined as [

33]:

where

is the mass loss,

is the material density,

is the applied radial force, and

is the total sliding length. The specific wear rate was determined based on the mass loss after 2 hours of the experiment. The extended duration of the test was applied to increase the measurement reliability of the wear rate, since there will be a cumulative increase in mass loss, and the coefficient of friction and the temperature remain unchanged compared to the stationary state achieved in the first hour.

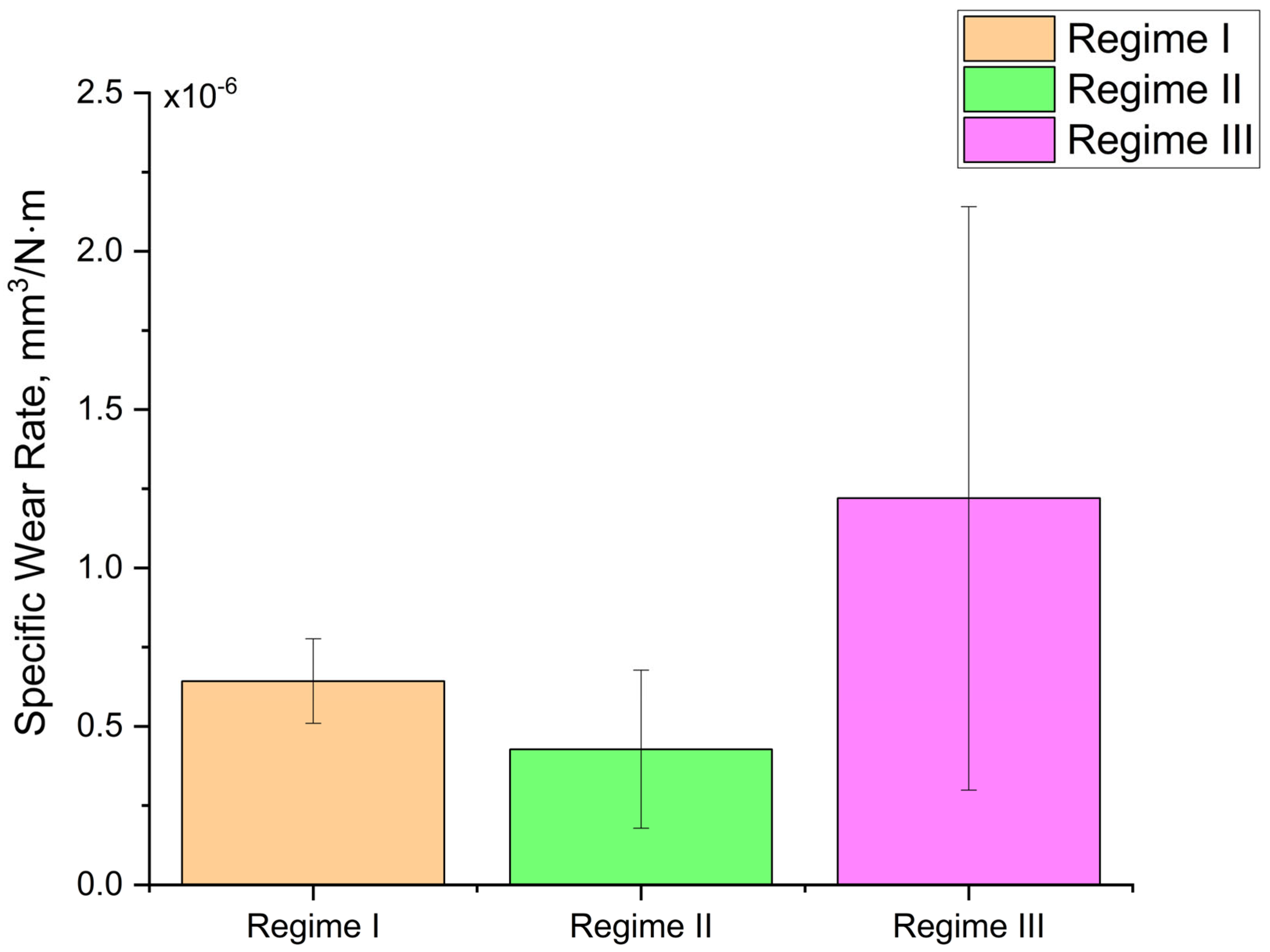

The specific wear rate results for different PV regimes are given in

Figure 8.

The results show that the medium Regime II has the lowest specific wear rate, which shows that it best balances the applied load and speed. Conversely, the least loaded regime has the highest specific wear rate, despite the reduced load, indicating that wear is not only influenced by pressure and speed. Relatively large scatter in Regime III shows that there is reduced wear stability, likely caused by intermittent micro-contact, heterogeneous pressure distribution between polymer and glass balls, local stress concentrations, and the sintering process itself, which is heterogeneous on the surface, and therefore balls that are not completely solidified by polymer may fall off. The highest PV regime shows the most repeatable behavior due to wear, which is characterized by a smaller scatter, which may be a consequence of achieving a better and more stable contact. The results show that for SLS-manufactured PA 3200 GF sliding bearings operating in dry sliding conditions, wear behavior is a consequence of contact stability and tribological adaptation of the bearing surface, rather than the load itself. The wear trend is consistent with the friction coefficient trend, and low values indicate stable sliding and controlled material removal. The presented results are limited to the number of samples, investigated PV regimes, and dry sliding conditions. Extrapolation of these tests to other working conditions should be done with extreme caution and be supported by additional experimental tests.

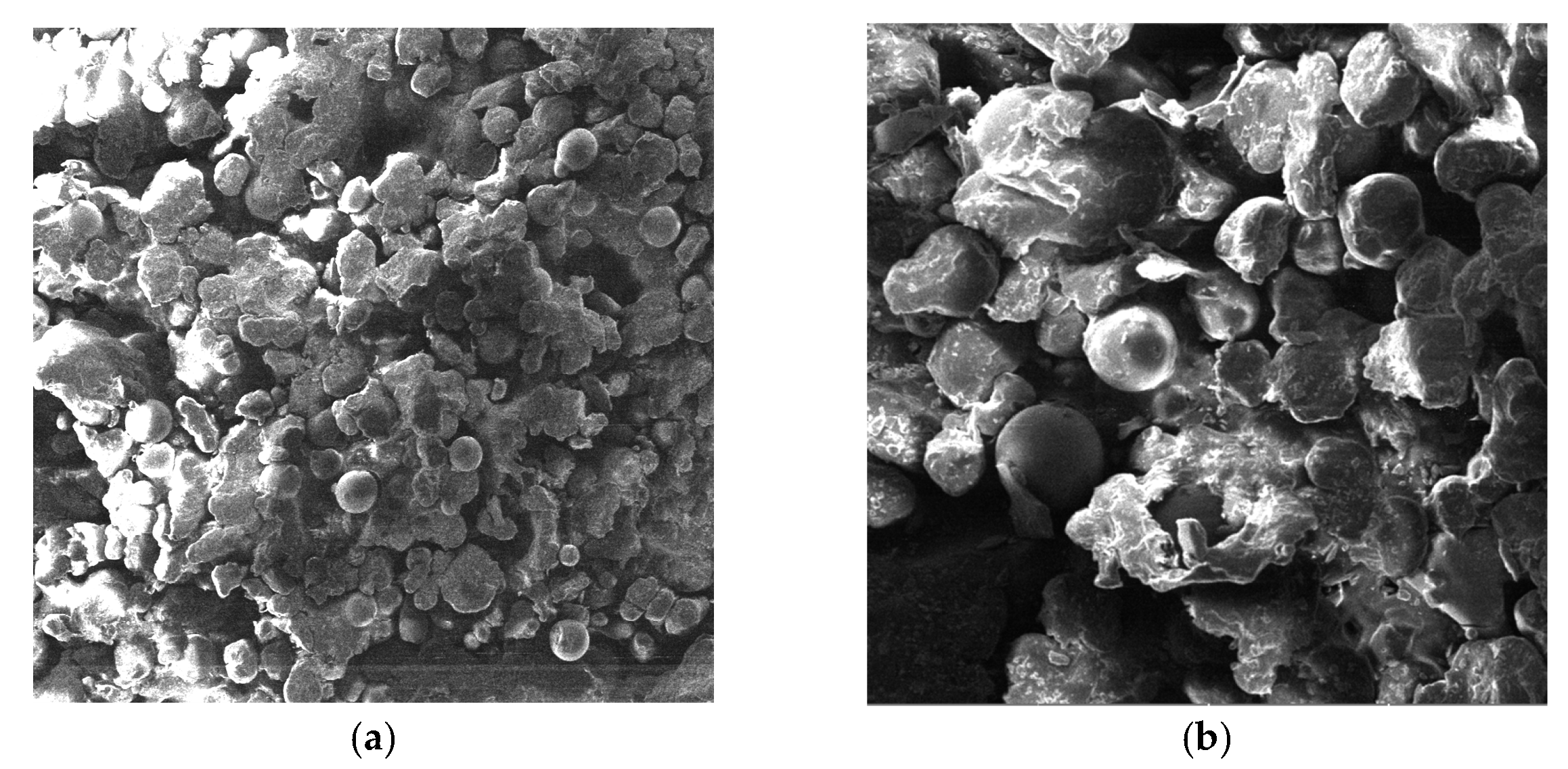

Figure 9 shows SEM images exhibiting the characteristic microstructure of the SLS-manufactured PA 3200 GF sliding bearing after sintering. SEM was used to determine the quality of sintering and to see the surface morphology of the bearing. Both enlargements show that the surface is formed by agglomerates of partially coalesced powder particles, connected by sintered necks, with a pronounced presence of interparticle pores and cavities. At higher magnification (500×), flattened zones of melted powder can be observed, in which almost intact spherical particles of the glass ball are trapped. Such a porous and granular surface morphology directly explains the high initial values of roughness parameters.

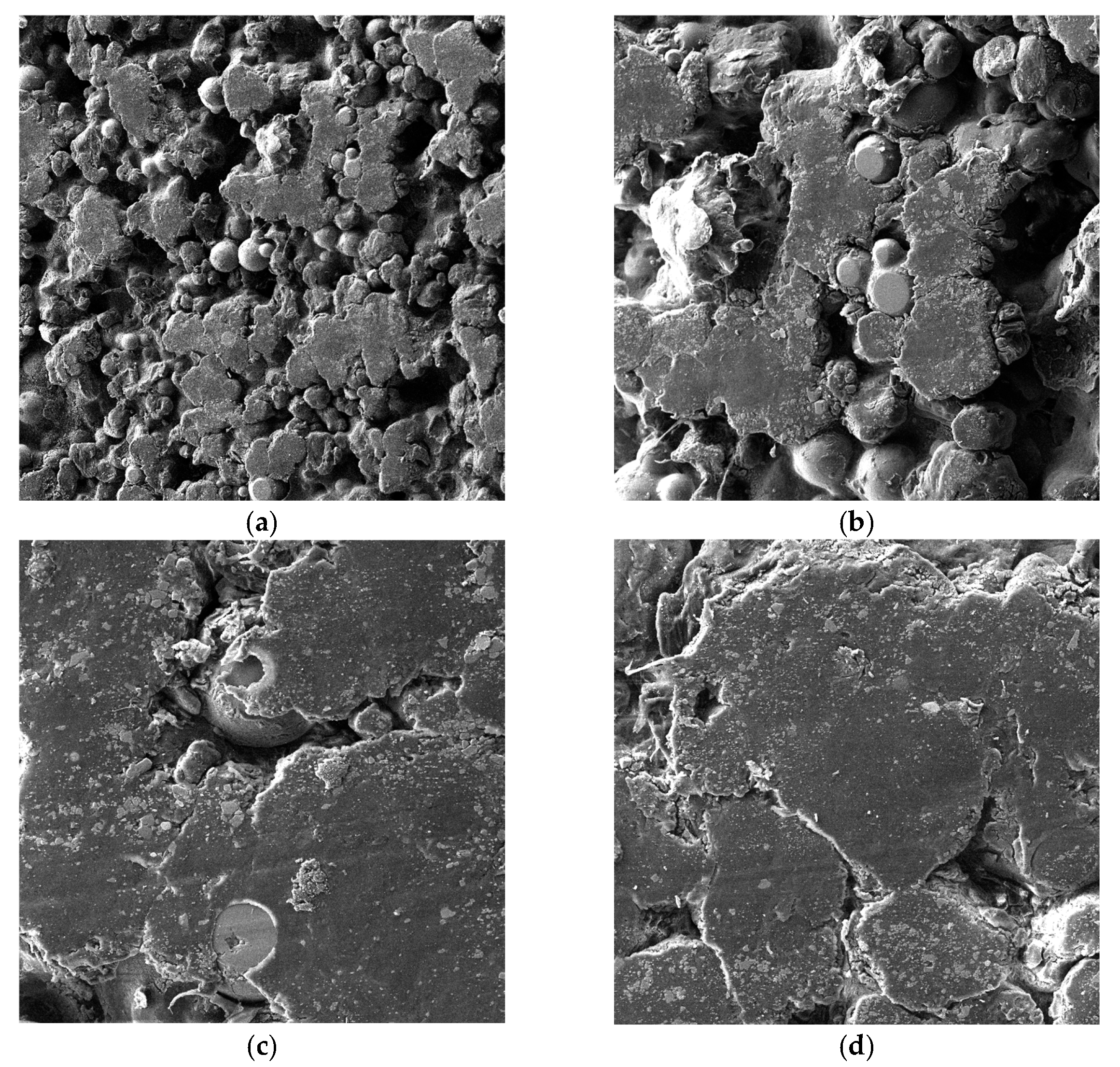

A wear mechanism on the bearing surface was analyzed using SEM.

Figure 10 clearly shows the change in surface morphology as a consequence of predominantly adhesive wear with plastic deformation and cladding of asperities. Plastic deformation occurred as a result of shear stresses due to sliding, which leads to detachment of wear debris. By increasing the load, adhesion junctions expand, and the dominant wear mechanism does not change, but only morphological intensification does. Therefore, differences between PV regimes are reflected primarily in the intensity and morphology of wear features rather than in a transition of the dominant wear mechanism. Some scratch marks were observed, which may be due to glass debris, which may act as abrasive particles. On the surface of the glass balls, you can see a clear alignment as a result of the wear of the glass balls, which are worn abrasively, which can also be seen by the presence of parallel furrows. Features consistent with accumulated wear debris and smeared polymer layers were observed on the surface.

3.4. Surface Roughness Evolution of PA 3200 GF Bearings

Surface topography is one of the critical factors in the tribology of 3D-printed sliding bearings under dry-sliding conditions, as it has a direct impact on friction, wear, heat generation, and generally on the service life of the bearing. Adjusting these parameters through the printing process itself and post-processing can improve tribological performance.

In dry-sliding conditions, the surface topography goes through a period of adaptation due to removal of peaks, plastic deformation, and filling of micro-bays on the surface.

was used as the basic descriptive parameter of the roughness level, while Abbott-Firestone family () parameters (,

,

) were analyzed as functional parameters relevant for tribological behavior.

describes the peaks of the profile that can be removed during the running-in period and contact stabilization,

represents the load-carrying core of the profile that supports the mechanical load during operation, while

indicates the capacity of the surface to retain worn material. The analysis of these parameters enables the engineering interpretation of running-in, load distribution, and long-term surface resistance during exploitation.

Table 5 shows the average values of roughness parameters. The initial topography of SLS-manufactured bearings is characterized by a rough surface with pronounced cores and moderate peaks. The high load-carrying part of the surface with the presence of valleys indicates that after removing the peak asperities during the running-in phase, the surface can provide stable contact and favorable load-carrying in dry-sliding conditions.

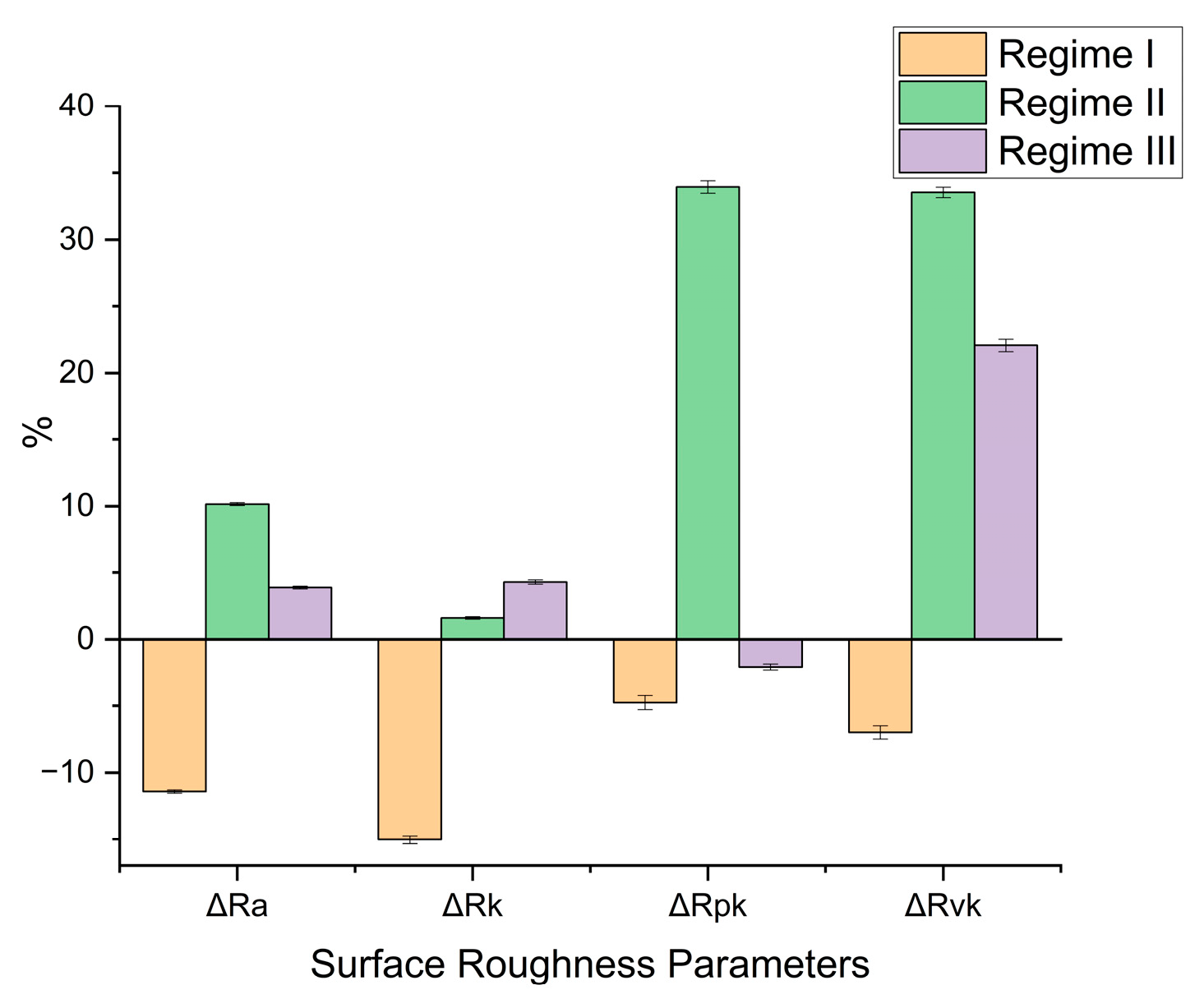

Percentage change in roughness parameters by regime in

Figure 11 offers a more comprehensive understanding of the profile change.

In Regime I, the average negative changes of

and

indicate a general smoothing of the surface and a reduction in the core roughness depth, which shows that the load-carrying backbone of the surface becomes more uniform after operation. A moderate pair of

and

indicates that the peaks of asperities that affect initial wear and the valleys into which wear debris enters are reduced. Taking everything into account, the reduction in all parameters indicates a flatter surface with a narrower roughness amplitude range, which enables a more even load distribution and a reduced risk of local failure.

In Regime II,

and

increase, which indicates a rougher surface with enhanced core roughness compared to the initial state. The reported rise in

and

indicates that both asperity peaks and valleys become more pronounced in relation to the core, indicating greater peak prominence and deeper valleys. The average increase of

,

,

and

indicates a surface topography with a more intensified height contrast, where roughness amplitudes dominate in relation to surface smoothness.

Regime III is characterized by a marginal increase in

and

which indicates that the surface remains relatively rough after work, followed by a small expansion in the core roughness depth. Increased

values indicate that the peaks have partially degraded, followed by an increase in

values, which indicates the formation of deeper valleys. Overall, the combined behavior of the parameters shows an asymmetric surface topography where valleys dominate over peaks, characteristic of lower loads where peak removal occurs without substantial core flattening.

The most favorable behavior is in Regime I, where most of the surface parameters decrease and the supporting surface stabilizes. Regime III, as the least loaded, provides moderate changes without significantly disturbing the profile. The most unfavorable regime from the aspect of the surface roughness is Regime II, where there was the most pronounced deviation of the surface in relation to the initial state.

The coefficient of friction and the temperature increase correlate with the mechanism of change in the surface morphology of the PA 3200 GF bearing during operation. In the most loaded regime, the rapid formation of the steady-state COF corresponds to decreases in

and

which means the effective smoothing of the asperities and the consolidation of the bearing core. At the same time,

and controlled

allow for stable debris accommodation and clarify the elevated but consistent temperature plateau. In the lowest regime, the moderate temperature increase and slower running-in coincide with the moderate changes in roughness, where the peaks are slightly flattened and the valleys are deepened, which leads to a moderately higher COF due to slightly less real contact. The medium PV regime is characterized by the largest increase in

,

, and

despite the low COF. The results indicate that favorable friction alone is not enough; the most suitable bearing performance requires a balanced coevolution of the coefficient of friction, temperature, and roughness parameters within a stable thermomechanical regime.