1. Introduction

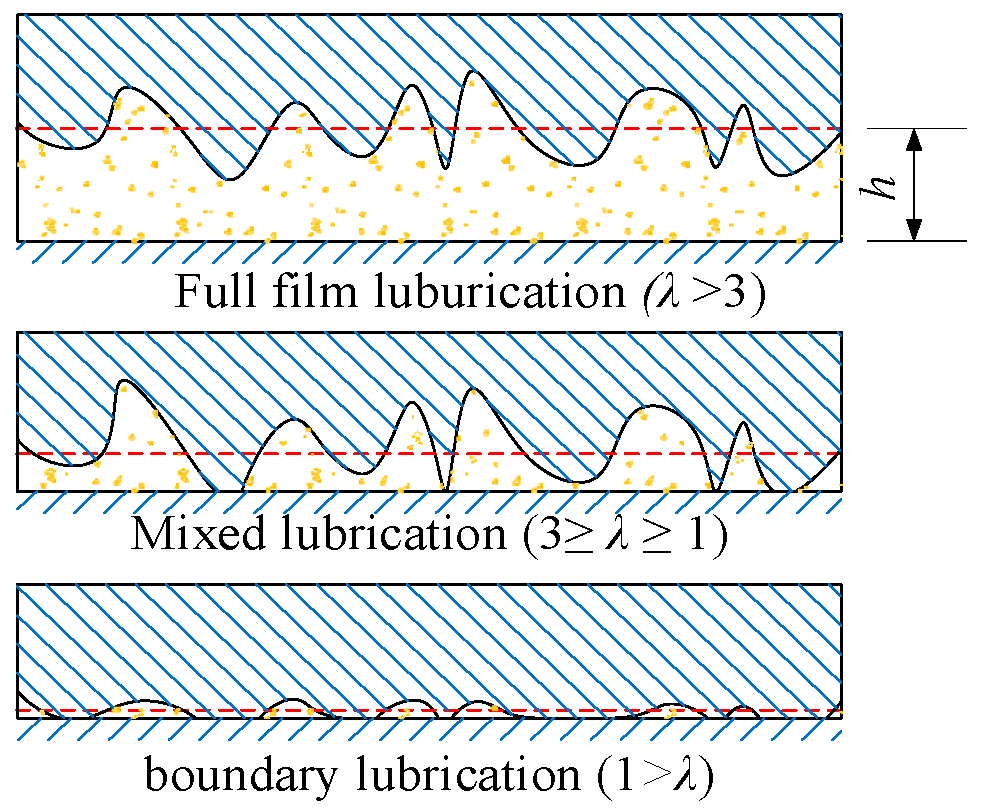

Gear drives are widely utilized in aerospace, robotics, and construction machinery due to their high transmission efficiency, precision, and reliability. High reliability constitutes the principal characteristic of gears and represents an important area of gear research. In engineering practice, gear failures primarily manifest as pitting, scuffing, and other surface defects, with inadequate lubrication being the predominant cause. Therefore, the gear lubrication has being garnered significant attention. However, most studies have relied on deterministic models and theories, which are inadequate for analyzing lubrication performance gearsets with random parameters.

With the continuous improvement of lubrication theory, the research in gear lubrication has gradually matured. The properties of lubricants [

1,

2,

3,

4], thermal effect [

5,

6,

7], transient effect [

8,

9,

10], and rough surface effect [

11,

12] have been comprehensive studied in the field of gear lubrication. However, existing studies on gear lubrication is mainly based on deterministic models and theories, assuming that the gear has deterministic material and dimensional parameters, as well as deterministic loads and velocities. In engineering practice, the parameters of gear transmission system and external excitation are inevitably random. These uncertainties stem from the variations in material properties due to the production environment and technical conditions, as well as the geometric deviations caused by machining, installation, and measurement errors. Additionally, the random external incentives further complicate the problem. The coupling propagation of these various uncertainties makes it challenging to accurately predict the gear lubrication state.

Recently, the influence of randomness on gear lubrication behaviors has gained attention. The lubrication characteristics of a gear system were investigated under stochastic load through modeling the load as a combination of a constant component and random noise [

13]. The numerical characteristics of the minimum film thickness (MFT) was successfully captured. A random tribodynamic model of a gear pair was proposed to study the effect of uncertainty rotation speed on the lubrication behaviors [

14]. The pinion rotation speed was supposed to obey Gaussian distribution. The MFT was selected to indicate the lubrication performance. The results revealed that the MFT was no longer obey Gaussian distribution, and the uncertainty can be suppressed by increasing the lubricant viscosity. Although some progress has been made in studying the effects of random external excitations on gear lubrication, the impact of uncertainties in material and dimensional parameters has received insufficient attention.

As the principal characteristic of gear transmission, the reliability of gear system has been studied from different perspectives. For example, an innovative method was proposed to evaluate the reliability of the motion accuracy of gear systems [

15]. The probability density function (PDF) and its cumulative distribution function of the transmission error were obtained by the saddle point approximation. The response surface method and artificial neural network were used to capture the fatigue reliability of involute gear under elastohydrodynamic lubrication [

16,

17]. The fatigue reliability of aero-engine gear was studied using an active learning Kriging-based method, the analysis efficiency of fatigue reliability was significantly improved [

18]. A reliability prediction model was built for the helicopter planetary gear drive and the impact of load distribution uniformity on the overall reliability was studied [

19]. Different from the reliability of gear structural strength mentioned above, the time-dependent kinematic reliability model of gear system was established [

20]. The impact of meshing stiffness, manufacturing errors uncertainty, and material characteristics of gear system on the kenimatic reliability were studied. Furthermore, some scholars started to focus on the lubrication reliability of gear system in recent years. The lubrication reliability of gear system under stochastic load was investigated [

13]. The lubrication reliability model was proposed based on the stress-strength interference model. It was revealed that the failure probability of lubrication at the dedendum of the pinion was higher than the other regions. To evaluate the lubrication reliability of rolling bearing [

21], a model on grounds of a probability box model was proposed with considering the uncertainty of lubricant material, load, and raceway structure. In summary, while the lubrication reliability has attracted increasing attention, existing models and methods remains un-developed, especially for gear lubrication reliability analysis considering the uncertainty of material and dimensional parameters.

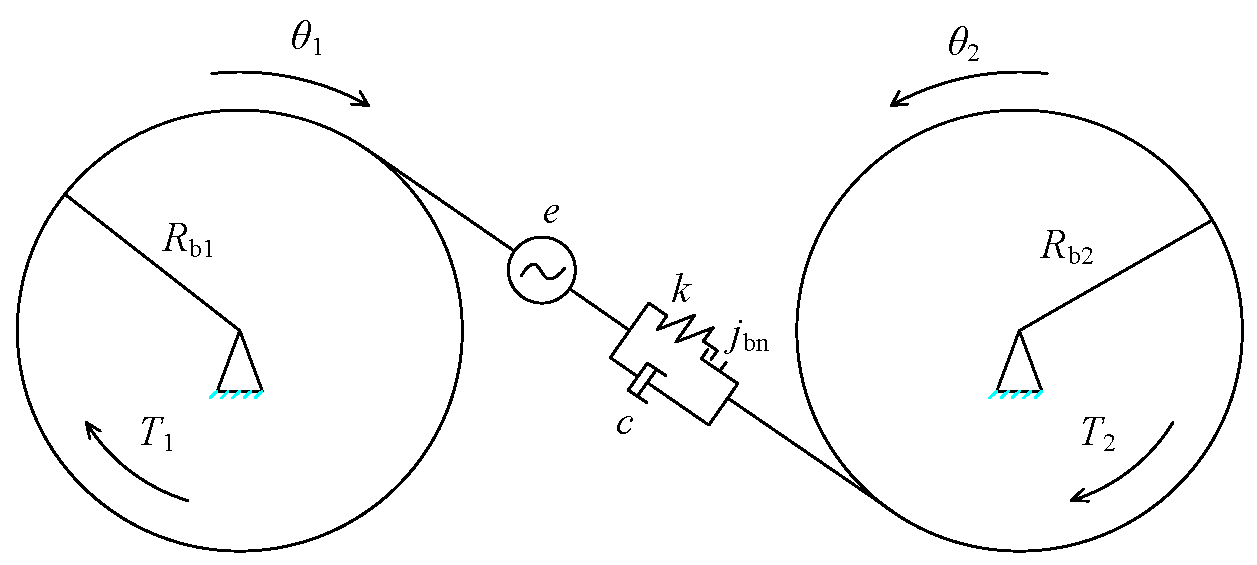

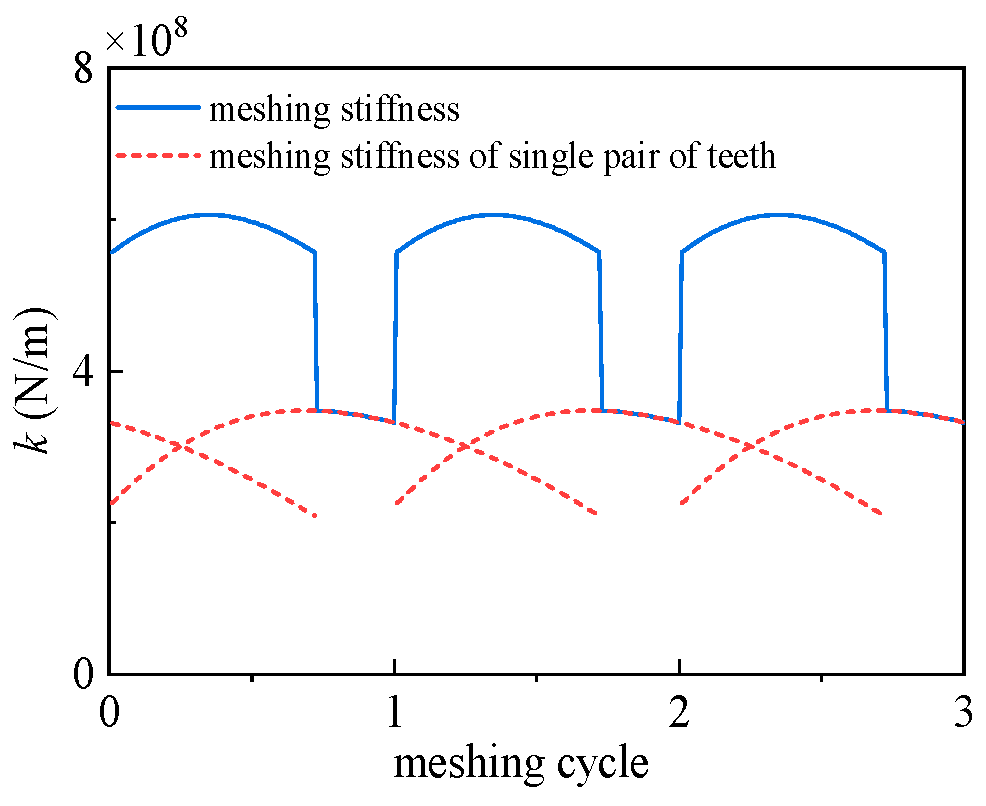

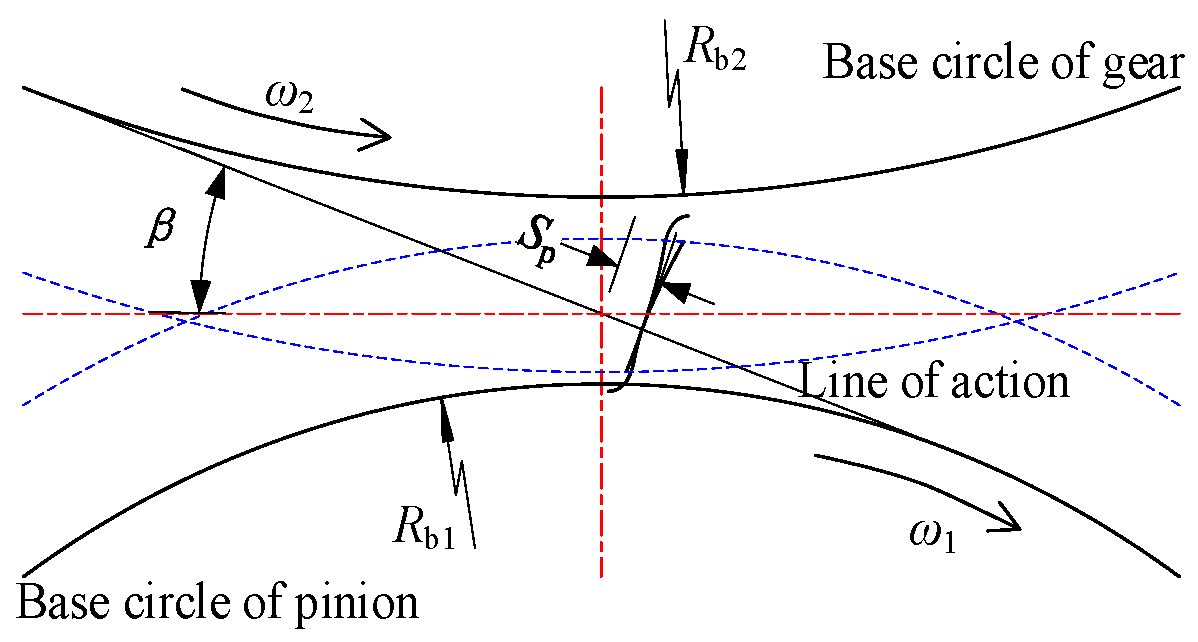

Reliable lubrication reduces direct contact between rough peaks, reducing wear, improving transmission efficiency, and extending the service life and reliability of gears. The lubrication state of gears demonstrates significant randomness under the action of uncertain parameters and external excitation. However, the model and approach considering the randomness of gear system remains undeveloped. To address this, a gear dynamic model was established that considers the time-variant meshing stiffness, side backlash, and static transmission error to calculate the dynamic meshing force of the gear pair. The geometric and kinematic analyses of the gear pair were carried out to obtain the equivalent curvature radius and entrainment velocity. Finally, a gear lubrication reliability model was constructed based on the film thickness ratio, and the failure probability of the gear lubrication system is accurately calculated by the Monte Carlo simulation (MCS) method. The remainder of this paper can be summarized as follows. In

Section 2, gear lubrication reliability model is established. In

Section 3, lubrication reliability analysis and its numerical procedure is provided. Results and discussion are exposited in

Section 4. Finally, conclusions for the current study are drawn in

Section 5.

3. Lubrication Reliability Analysis and Its Numerical Procedure

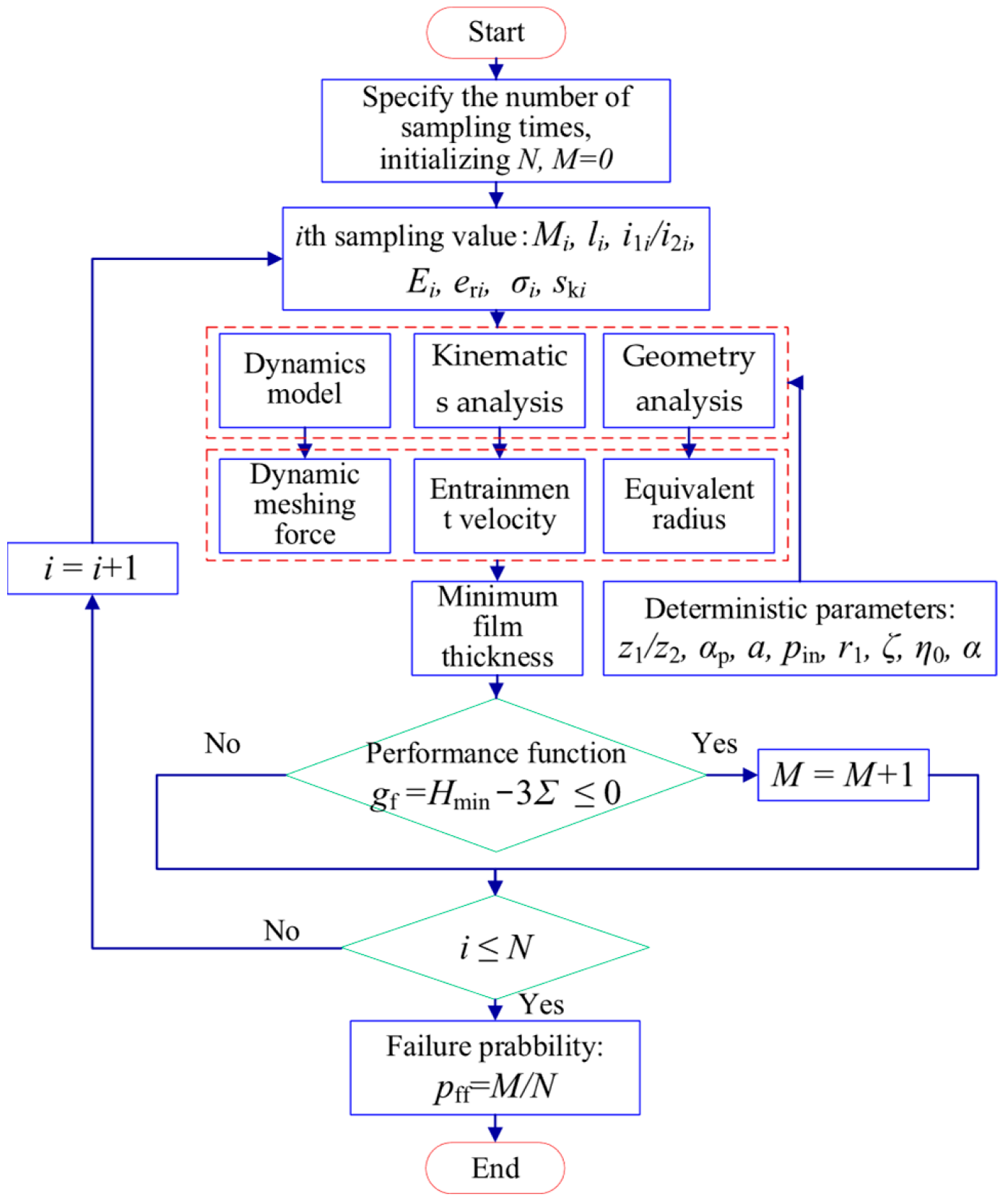

The lubrication reliability analysis process is shown in

Figure 6. The main lubrication reliability analysis methods include first-order second moment method [

28], surrogate model method [

29,

30], Monte Carlo method [

31], interval analysis method [

32], etc. Due to the advantage of high computational accuracy of the Monte Carlo method (MCS) with direct sampling, it is adopted to implement precise reliability analysis in this paper, whose mathematical model is as follows:

where

Pf is the lubrication failure probability.

Fx(

x) denotes the joint probability density function of uncertainty parameters.

E(⸳) refers to expectation operator.

I(⸳) is the failure indicator function and it can be expressed as

Based on the above formula, lubrication reliability analysis using MCS method can be used to calculate the failure probability through the following three steps:

Firstly, the gear modulus, tooth width, static transmission error amplitude, elastic model of material, and rotary inertia of the pinion and gear are defined as random variable. The sampling values of those parameters are obtained on the basis of their probability density function.

Then, with the samples of those parameters, the dynamic mesh-force was captured by the gear dynamics model. The time-variant entrainment velocity and equivalent curvature radius can be obtained through the gear kinematics and geometric analysis, and the MFT of the gear lubrication was further obtained.

Finally, the dynamic meshing force, time-variant entrainment velocity, and time-variant equivalent curvature radius are substituted into functional functions to determine whether the gear lubrication failure occurs. After N times of sampling, the failure frequency is counted to estimate the failure probability of gear lubrication. In this paper, the sampling number N is set to 100,000 times, and the kinetic equation is calculated using the Runge-Kutta numerical integration method with fourth-order constant step size. The Monte Carlo simulation 105 times needs about 4 h On a personal computer with an i7-6700 CPU Intel Core i7-6700 Santa Clara, California, USA and a 3.4 GHz processor.

4. Results and Discussions

To investigated the lubrication reliability of the gear system, the stochastic geometric parameters and material characteristics are considered in this paper. The modulus of the gear, tooth width, moment of inertia of the pinion and gear, elastic modulus of the material, and amplitude of static transmission error are all obey Gaussian distribution, and these random variables are independent of each other [

33,

34]. The statistics law of these parameters can be obtained by measuring and statistical analyzing large number of samples. If the sample satisfies other distributions, the method still applies. The mean value and coefficient of variation are shown in

Table 1, and the other parameters are constant.

4.1. Statistical Characteristics of the Dynamic Response of Gear System

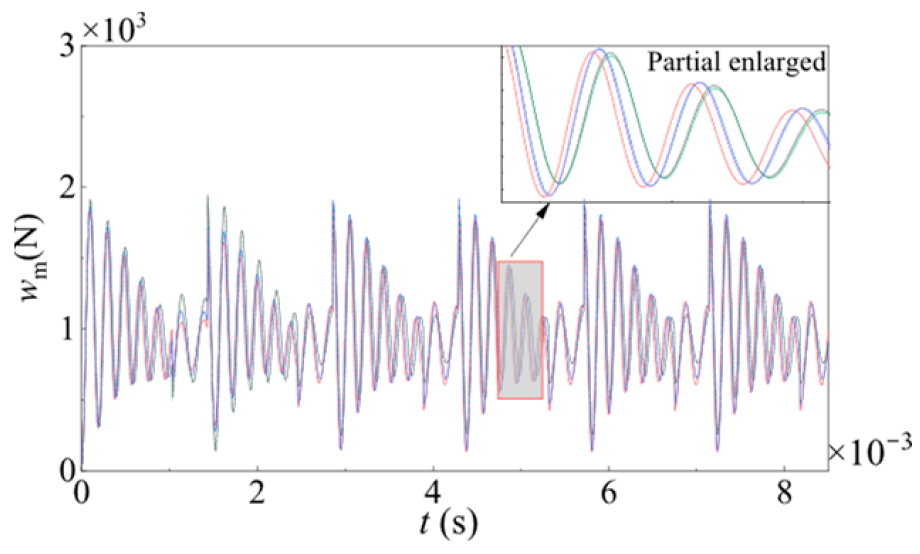

The dynamic response and meshing force of gear pair are no longer deterministic time function due to the randomness of gear parameters.

Figure 7 depicts the samples meshing force. As can be seen, the meshing force on a single tooth region is larger than that of double teeth regions. It increases from the approach point to the lowest point of single tooth contact and decreases from the highest point of single tooth contact to the recession point. A single sample curve fluctuates due to single and double teeth transformation. The values of each meshing force sample are different at the same time, which is caused by the randomness of gear parameters. The sample of meshing force on a single tooth is illustrated in

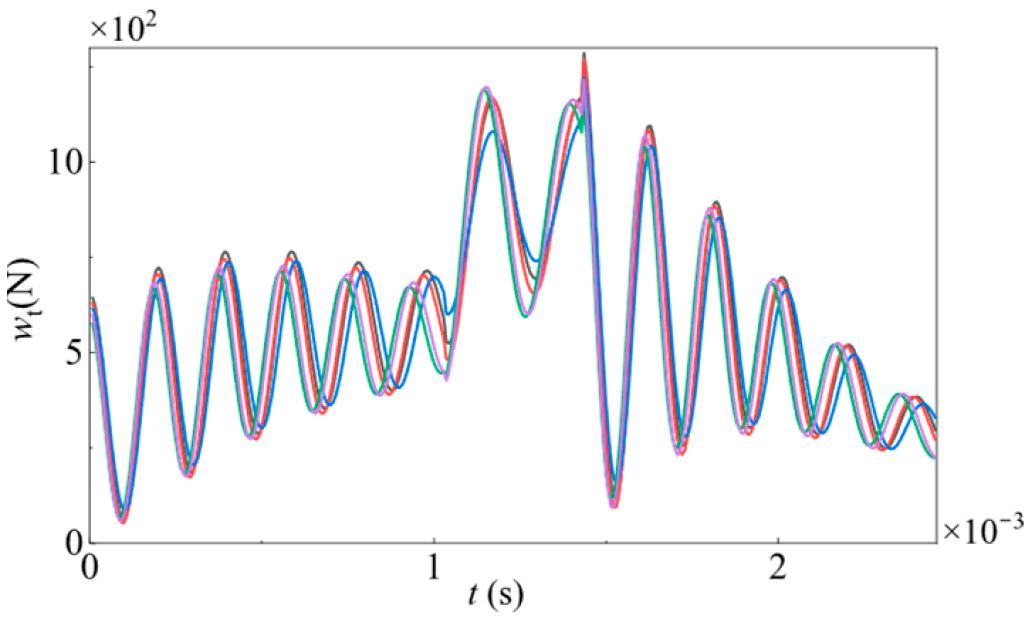

Figure 8.

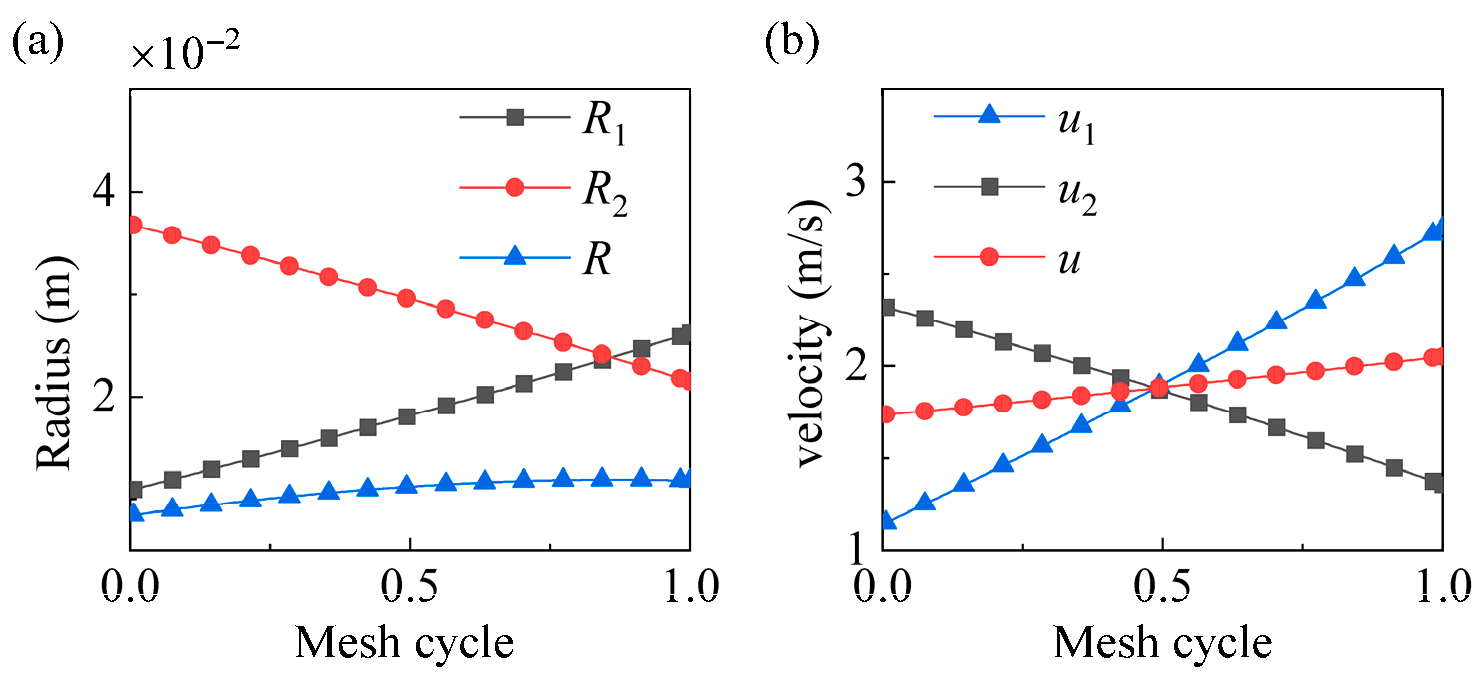

Figure 9 show samples of the equivalent radius of curvature and the entrainment velocity from mesh-in to mesh-out of the teeth. The meshing force, radius of curvature, entrainment velocity are not strictly stochastic process but random variable, the values at different time point are complete correlation.

Figure 10 shows the meshing force distribution histogram of the first six meshing cycles at the same time point (each time point is separated by one meshing cycle). It can be seen that the histograms of the first three cycles differ significantly, while the histograms become more identical from the 3rd to the 6th cycles.

Table 2 shows the first four statistical moments of meshing forces at the six moments in

Figure 10. It can be observed that the numerical characteristics barely change after the 5th meshing cycle. Therefore, it can be concluded that the statistical characteristics of the meshing force tend to be stable after the 5th meshing cycle. If the degradation of gear parameters due to wear is not considered, any cycle after the 5th engagement cycle can be selected to study the lubrication reliability of gear.

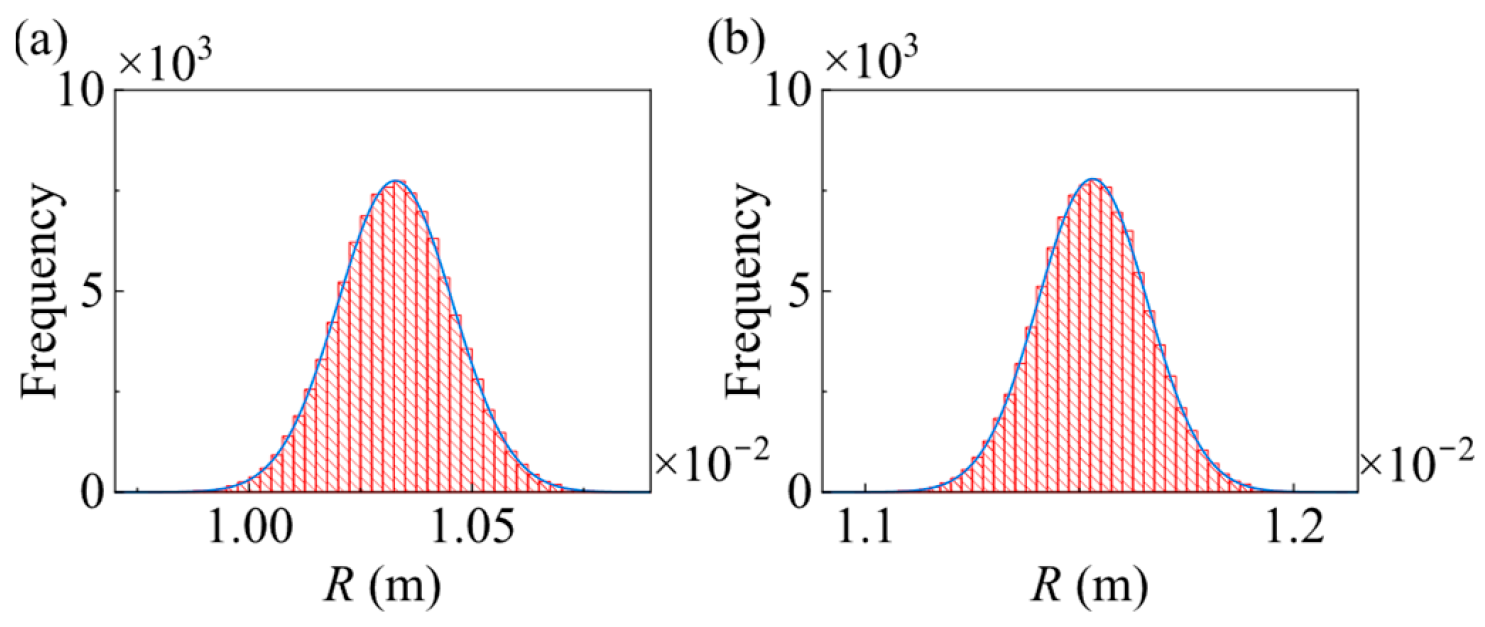

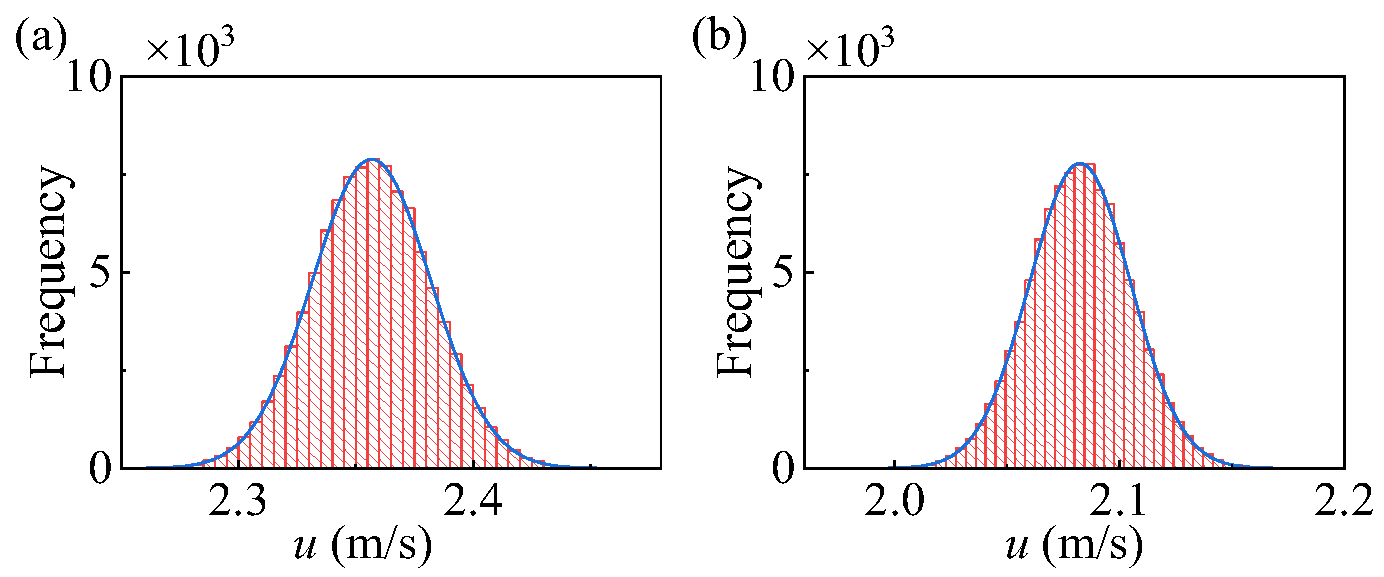

Figure 11 and

Figure 12 are the distribution histograms of the equivalent curvature radius and entrainment velocity at two different time points, and the corresponding first four-order statistical moments are shown in

Table 3 and

Table 4. It can be seen that the variation coefficients of the equivalent curvature radius and the entrainment velocity at different moment virtually identical, and are close to 0.01 which is the variability coefficient of the gear parameters. The skewness approaches 0, and the kurtosis approaches 3. Conclusion can be drowned that the distribution of curvature radius and entrainment velocity obey Gaussian. The uncertainty from gear parameters to equivalent curvature radius and entrainment velocity does not change significantly.

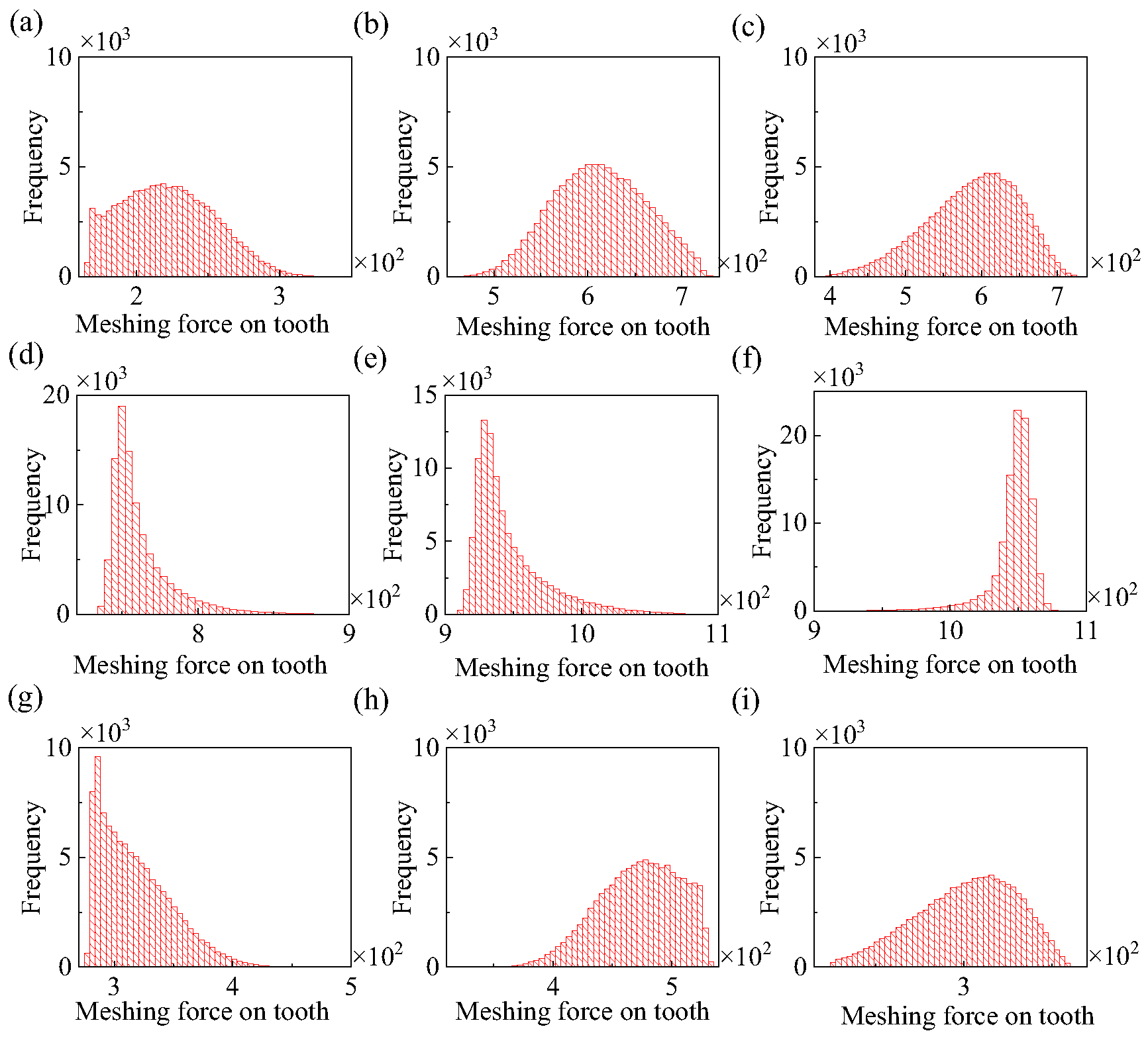

For the purpose of investigating the meshing force distribution on a single tooth, the 10th meshing cycle is chosen. The meshing cycle of a single tooth is segmented into 9 equal time intervals. The meshing force distribution histogram corresponding to each time point is presented in

Figure 13. Evidently, the meshing forces at every time do not conform to the Gaussian distribution any longer, and the disparities are quite substantial. This phenomenon can be accounted for by the pronounced nonlinear characteristics inherent in the gear system.

Table 5 shows the first four order statistical moments and the variation coefficients of the meshing force corresponding to

Figure 13. As is shown, the meshing force of single tooth exhibits stronger non-Gaussian characteristics, and the coefficient of variation at each time point is greater than the gear parameter. The non-Gaussian characteristics of the single tooth mesh force stems from the nonlinearity of the gear dynamics system. It can be seen that the uncertainty of gear parameters is increased by the action of the dynamic system.

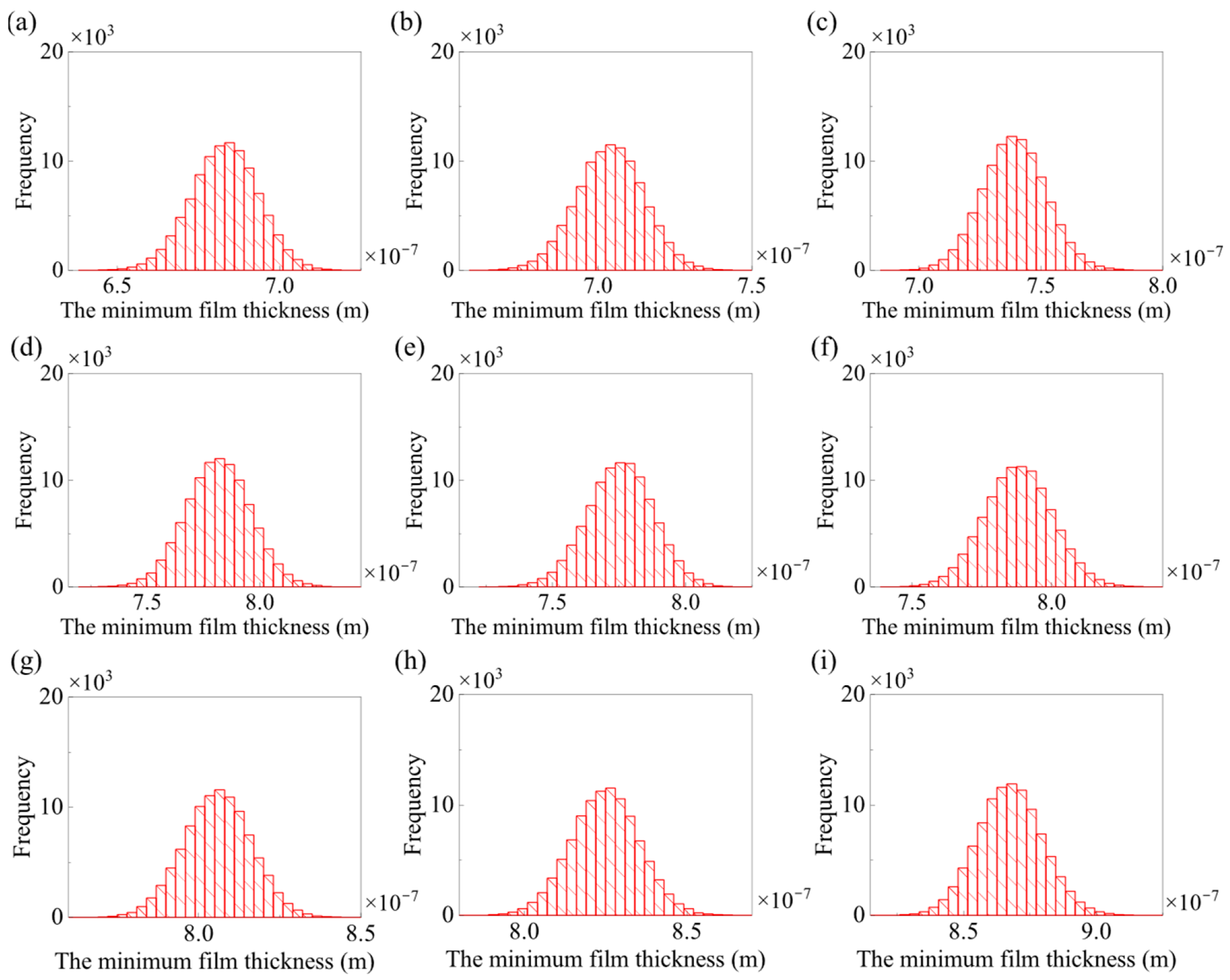

4.2. Lubrication Reliability Analysis of Gear System

Before the gear lubrication reliability analysis, the MFT probability histogram of 9 moments corresponding to

Figure 13 was obtained, and are shown in

Figure 14. At the same time, the first four order statistical moments and variation coefficient of the MFT at the 9 moments are obtained in

Table 6. The parameters selected in this section are as follow: the driving gear speed

n1 = 1500 r/min, RMS roughness

σ = 0.1 μm, skewness

sk = 0, the variation coefficient of RMS roughness is 0.1, and the standard deviation of skewness is 0.2. As can be observed from

Table 6 and

Figure 14, the probability distribution of the MFT approximates the Gaussian distribution. This is due to the fact that both the equivalent curvature radius and the entrainment velocity are close to the Gaussian distribution. Consequently, it can be deduced that the impact of these two factors on the randomness of the MFT is more significant than that of the meshing force. Despite the coefficient of variation being larger than that of the gear parameter, no evident variation pattern is manifested. Thus, the uncertainty is augmented during the transmission from gear parameters to the MFT, yet the extent of amplification is not pronounced.

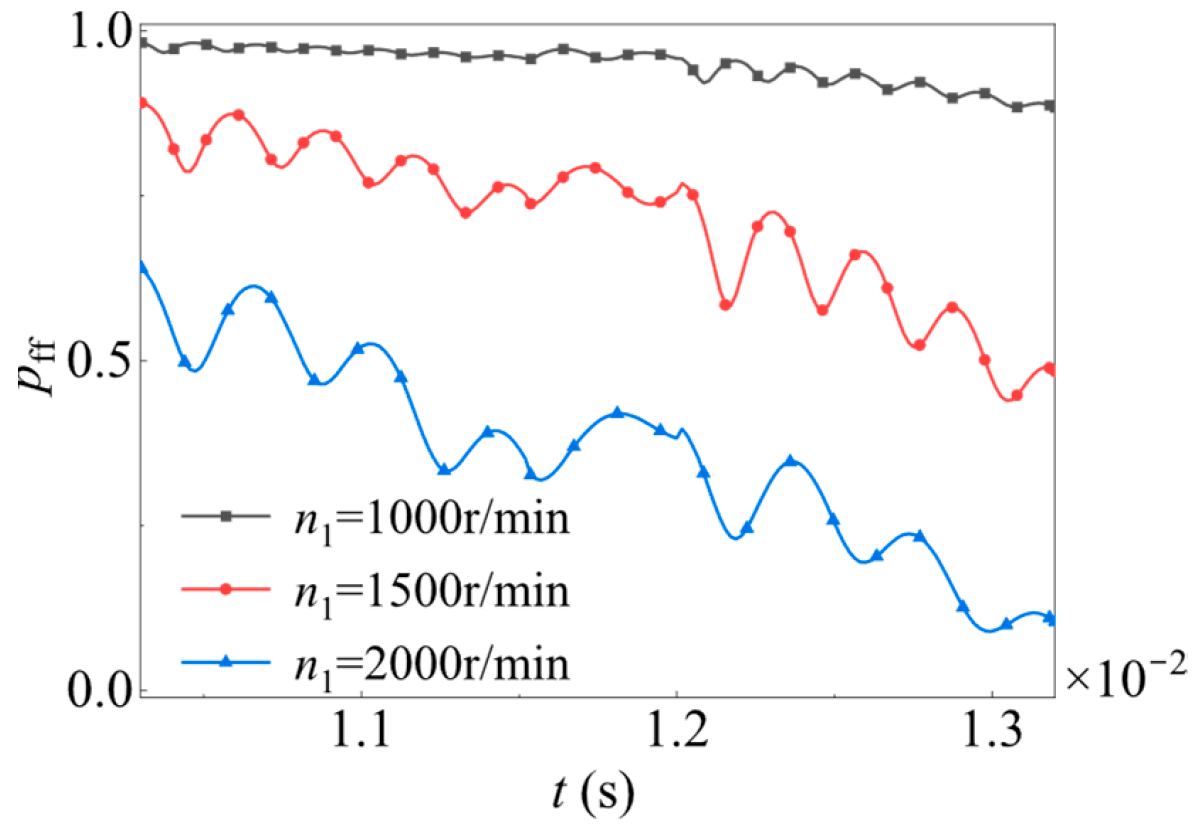

Figure 15 illustrates the probability of lubrication failure of a gear tooth from approach point to recession point at different gear speeds. The speed of the driving gear are set as

n1 = 1000 r/min,

n1 = 1500 r/min, and

n1 = 2000 r/min respectively. The ordinate

pff denotes the failure probability of lubrication. The mean of RMS roughness and skewness of rough surfaces are

σm = 0.1 μm and

skm = 0, respectively. Set the variation coefficient of RMS roughness to 0.2, and the standard deviation of skewness to 0.2 and keeps constant. The results indicate that the rotational speed has a substantial impact on the reliability of gear lubrication. When the speed is lower than a specific value, a complete oil film fails to be formed. However, when the speed exceeds a certain value, full film lubrication can always be ensured.

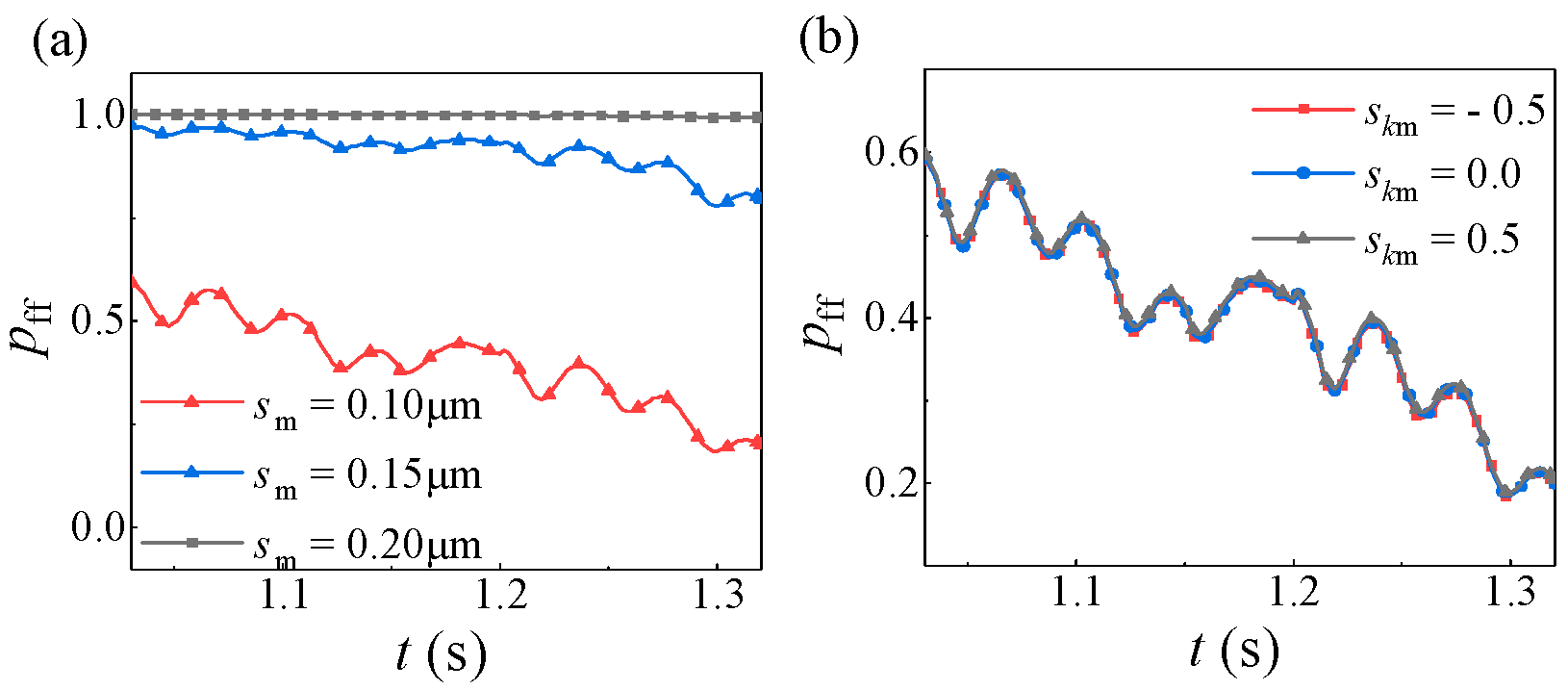

The lubrication failure probability of gear system with different comprehensive RMS roughness and skewness in the meshing cycle of single tooth is shown in

Figure 16. The driving gear speed is

n1 = 2000 r/min. In

Figure 16a, the mean roughness of the comprehensive RMS is set as

σm = 0.10 μm,

σm = 0.15 μm,

σm = 0.20 μm, respectively, their standard deviations are set as 0.03 μm, the mean skewness is

skm = 0, and the standard deviations of skewness are all 0.3. In

Figure 16b, the comprehensive RMS roughness is

σm = 0.10 μm, the standard deviation is 0.03 μm. Skewness is set to

skm = −0.5,

skm = 0,

skm = 0.5 respectively, and their standard deviations are set to 0.3. Based on the results, conclusions are drawn that the root RMS roughness exerts a significant influence on the lubrication reliability of gears. Specifically, the probability of lubrication failure tends to decrease as the roughness value decreases. Nevertheless, when the roughness drops below a certain value, the improvement effect brought about by further reducing it on the lubrication reliability becomes no longer evident. In contrast, the impact of skewness on the probability of lubrication failure is relatively minor. As the skewness increases, the probability of lubrication failure only experiences a slight increase.

4.3. Degradation Law of Gear Surface Roughness and Lubrication Reliability

In the process of service, with the increase of wear, the shape of the tooth surface also changes. From the preceding analysis, it is evident that the shape parameters of the tooth surface have a substantial influence on the lubrication reliability. Consequently, a gear wear test was devised to explore the patterns in which tooth surface roughness parameters such as Ra, Rq, Sk, and Ku vary with the degree of wear.

4.3.1. Design of Test Device

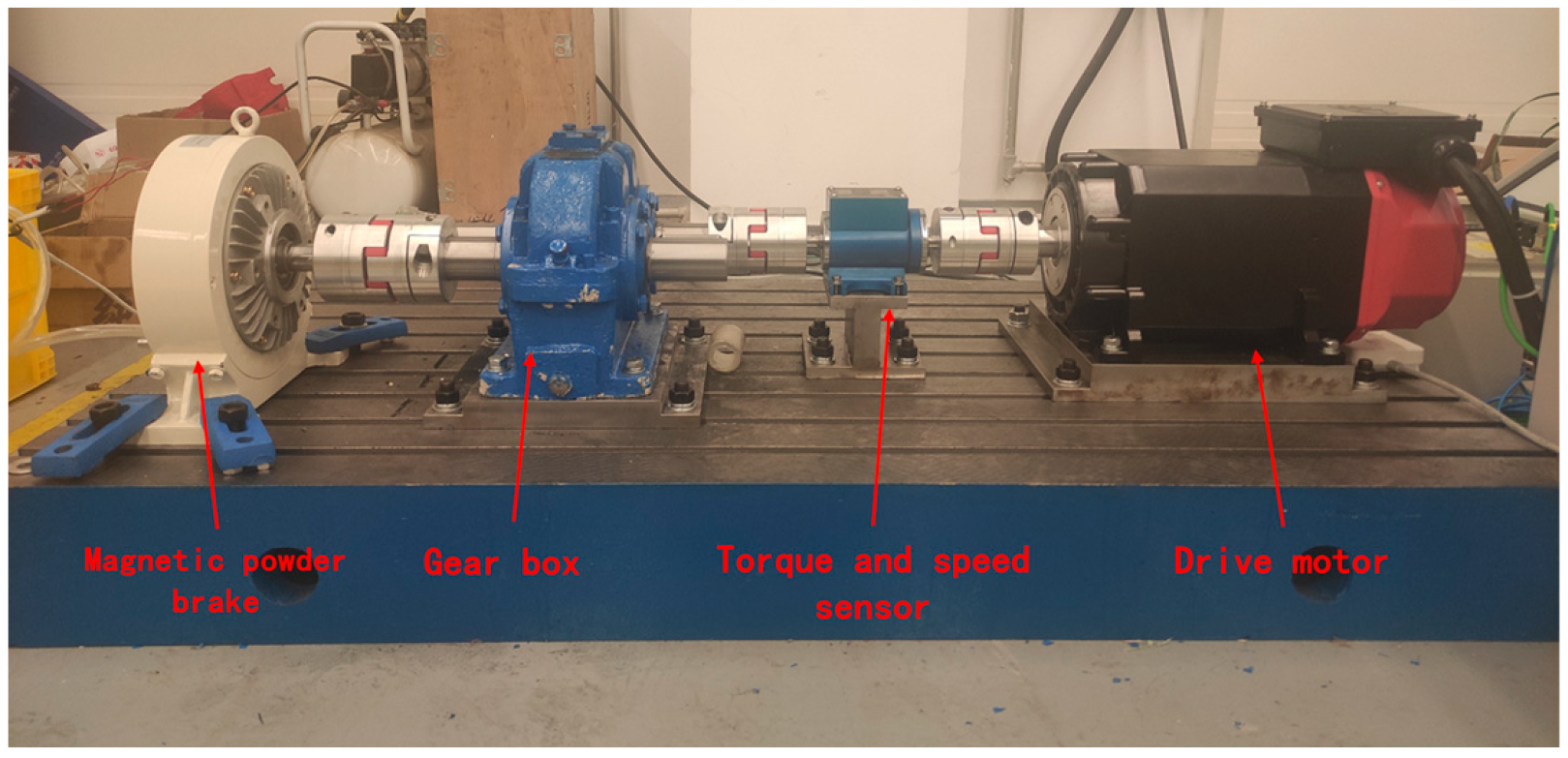

As illustrated in

Figure 17, the gear test device consists of an AC servo motor, torque speed sensor, gearbox, magnetic powder brake, acceleration sensor, etc.

The control interface of the experimental device is shown in

Figure 18. There are two control modes: torque and speed. The output torque and speed of the motor in real-time can be recorded. The test gear depicted in

Figure 19 is an involute spur gear with a modulus of 2.75. The number of teeth on the driving wheel is 24, while that on the driven wheel is 49, and the machining accuracy is at level 6. During the experiment, the output torque of the driving motor was 50 N⸱m, and the output speed was 500 r/min.

4.3.2. Tooth Surface Roughness Experiment

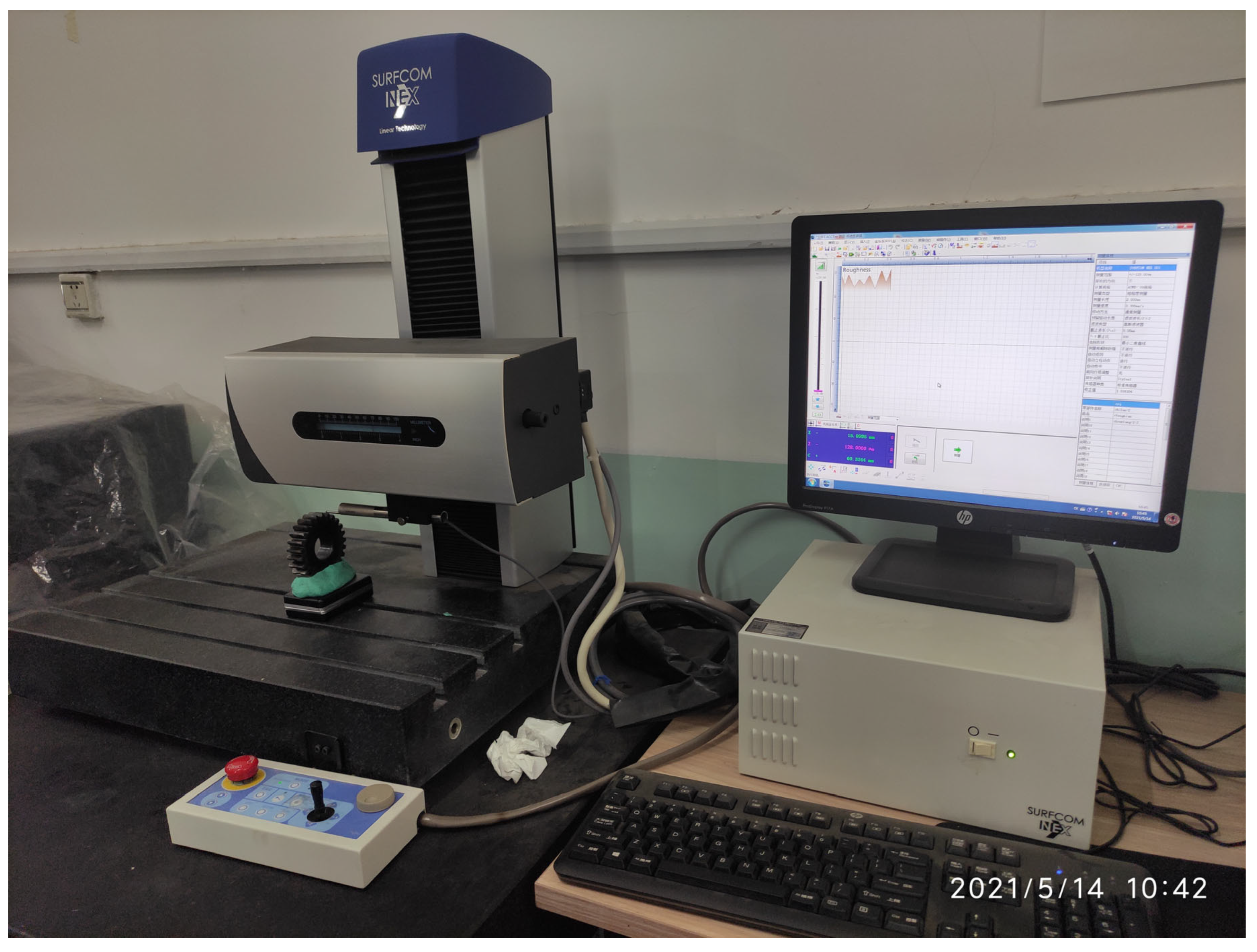

In this article, the roughness measurement of gears is conducted by utilizing the SURFCOM NEX 001SD-12 manufacted by Tokyo Seimitsu Co., LTD., Tokyo, Japan surface roughness measuring instrument manufactured by Tokyo Precision (as illustrated in

Figure 20). This measuring instrument is applicable for measuring flat surfaces, inclined surfaces, outer cylindrical surfaces, inner hole surfaces and so on. It can readily acquire rough surface parameters such as Ra, Rq, Rz, Sk, Ku and others.

The data obtained by the roughness measuring instrument reflect the statistical characteristics of the surface height over the test length, and it is usually assumed that the surface height is stable in the measurement direction. Therefore, Rq, Sk, and Ku can be used to replace RMS roughness, sk, and ku in lubrication analysis.

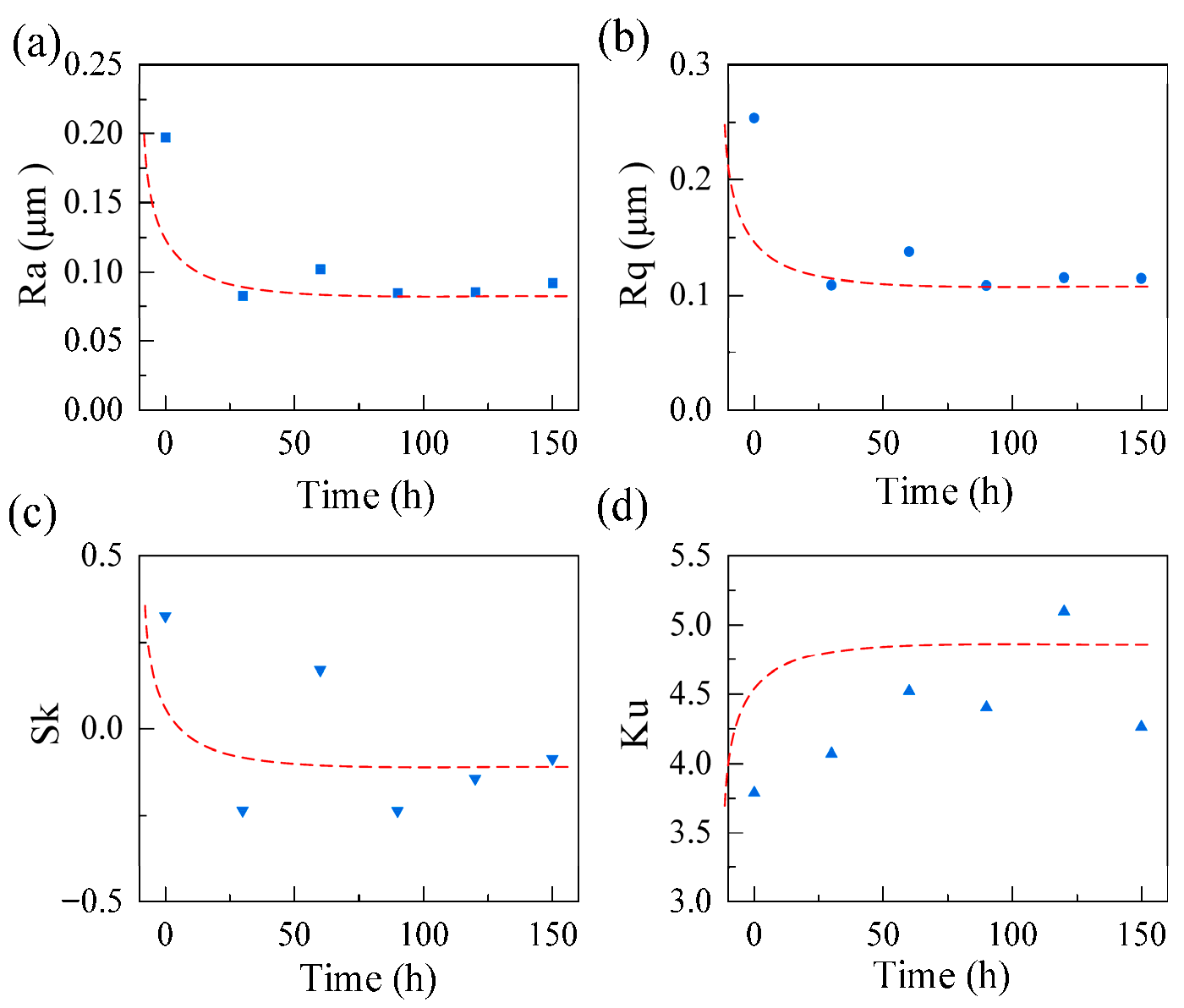

The test lasted for 150 h, and the radial roughness of 3 specific teeth of the driving gear was measured every 30 h, and the meshing surface of each tooth was measured 5 times. Then 15 groups of measurement results were statistically processed. In 5 measurements from 30 h to 150 h, the mean value, standard deviation, and coefficient of variation of Ra, Rq, Sk, and Ku are shown in

Table 7,

Table 8,

Table 9,

Table 10,

Table 11 and

Table 12. The profiles of three gear teeth on the driving wheel are shown in

Figure 21. (a–c) are the shapes of the three tooth profiles after 150 h, with the left side being the non-contact surface and the right side being the contact surface. It can be seen that the wear is greater in the root and top areas of the teeth, and the wear is the smallest near the nodes.

Figure 22 presents the variations in the mean values of the four roughness parameters within the time range from 0 to 150 h. The line represents the change trend of the roughness surface. It can be observed that the mean values of Ra and Rq initially decline rapidly as wear occurs and then gradually stabilize. The mean value of Sk demonstrates a downward trend, whereas the mean value of Ku increases first and then stabilizes. The randomness of Sk and Ku are greater than Ra and Rq. The variation patterns of these four parameters over time all display the characteristics of a bathtub curve, featuring a sharp change at first and then reaching a relatively stable plateau stage.

Figure 22.

Variation process of gear surface roughness parameters with wear (a) average Ra; (b) average Rq; (c) average Sk; (d) average Ku.

Figure 22.

Variation process of gear surface roughness parameters with wear (a) average Ra; (b) average Rq; (c) average Sk; (d) average Ku.

4.3.3. Evolution of Gear Lubrication Reliability

In order to investigate the alterations in the lubrication reliability of gears during the service period, this section selects three wear stages within the tooth surface wear process to simulate the three moments ranging from the running-in wear stage to the stable wear stage. Based on the previous experiment, it can be noticed that as the wear progresses, the RMS roughness and skewness gradually decrease, while the degree of dispersion gradually increases. The surface roughness parameters of these three stages are presented in

Table 13.

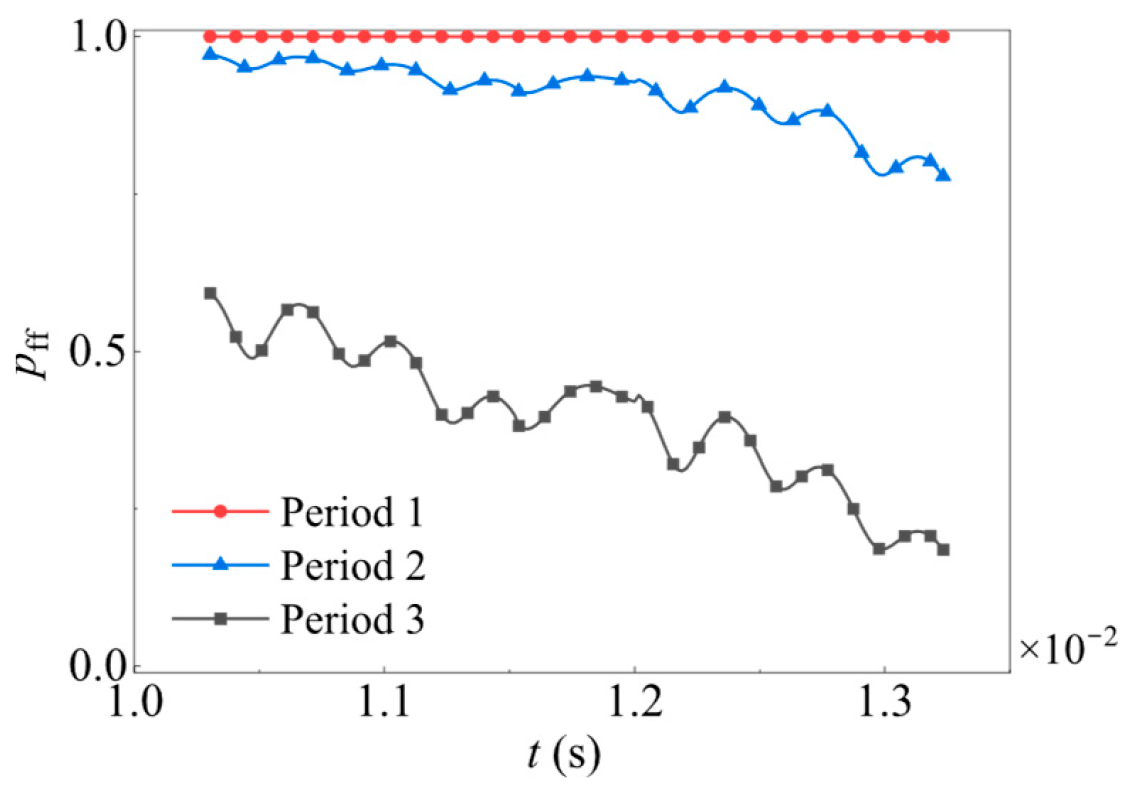

The values of mean and standard deviation of RMS roughness and skewness in the three stages are shown in

Table 13. The driving gear speed is taken as n1 = 2000 r/min.

Figure 23 illustrates the probability of lubrication failure during a single tooth meshing cycle across three stages. It can be readily concluded that the probability of lubrication failure is relatively higher in the early stage of gear service (stage one). As the wear progresses, the lubrication reliability of the gear improves. Since this article only focuses on the running-in and stable wear stages, the lubrication performance gradually gets better over the service time. However, when the service time increases further, the roughness will increase sharply and enter the stage of severe wear. It can thus be easily predicted that the lubrication reliability will decline at that time as well.

Figure 23.

Lubrication failure probability of a single tooth meshing cycle at different service stages.

Figure 23.

Lubrication failure probability of a single tooth meshing cycle at different service stages.

5. Conclusions

To address the challenge of lubrication state reliability arising from gear parameter uncertainty, a gear lubrication reliability analysis method considering gear parameter uncertainty is proposed in the present work. A gear dynamics model was established to obtained the meshing force. The geometric and kinematic analyses of the gear pair were carried out to obtain the equivalent curvature radius and entrainment velocity. Finally, a gear lubrication reliability model was established, and the effects of rotational speed, surface roughness, and other parameters on gear lubrication reliability were systematically analyzed using MSC. The following conclusions were drawn:

The dynamic meshing force no longer follows a Gaussian distribution, whereas the equivalent curvature radius and entrainment velocity remain Gaussian-distributed. While the MFT does not obey the Gaussian distribution, its non-Gaussian property is weaker than the meshing force. Additionally, the uncertainties from gear parameters to meshing forces and MFT are increased.

- 2.

The lubrication failure probability of the gear pair is higher in the root area compared to other areas. The result indicates that the gear speed and RMS roughness have a significant effect on the lubrication reliability of the gear, while the skewness of the gear tooth surface has a relatively small effect.

- 3.

The tooth surface roughness parameters change drastically in the early stage of service and then tend to be stable. However, its randomness continues to increase with the increase of wear, and the lubrication reliability of the gear improves with the increase of wear in the early stage.

In summary, the present work highlights the significant influence of gear parameter uncertainties on lubrication reliability, providing deeper insights into the interactions between gear dynamics, wear behavior, and lubrication performance. These findings contribute valuable guidance for the design and maintenance of reliable gear systems under uncertain operating conditions.