Evaluation of Long-Term Skid Resistance in Granite Manufactured Sand Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- (1)

- Cement

- (2)

- Fine aggregates

- (3)

- Coarse aggregates

- (4)

- Stone powder

- (5)

- Admixtures

- (6)

- Fly ash

- (7)

- Water

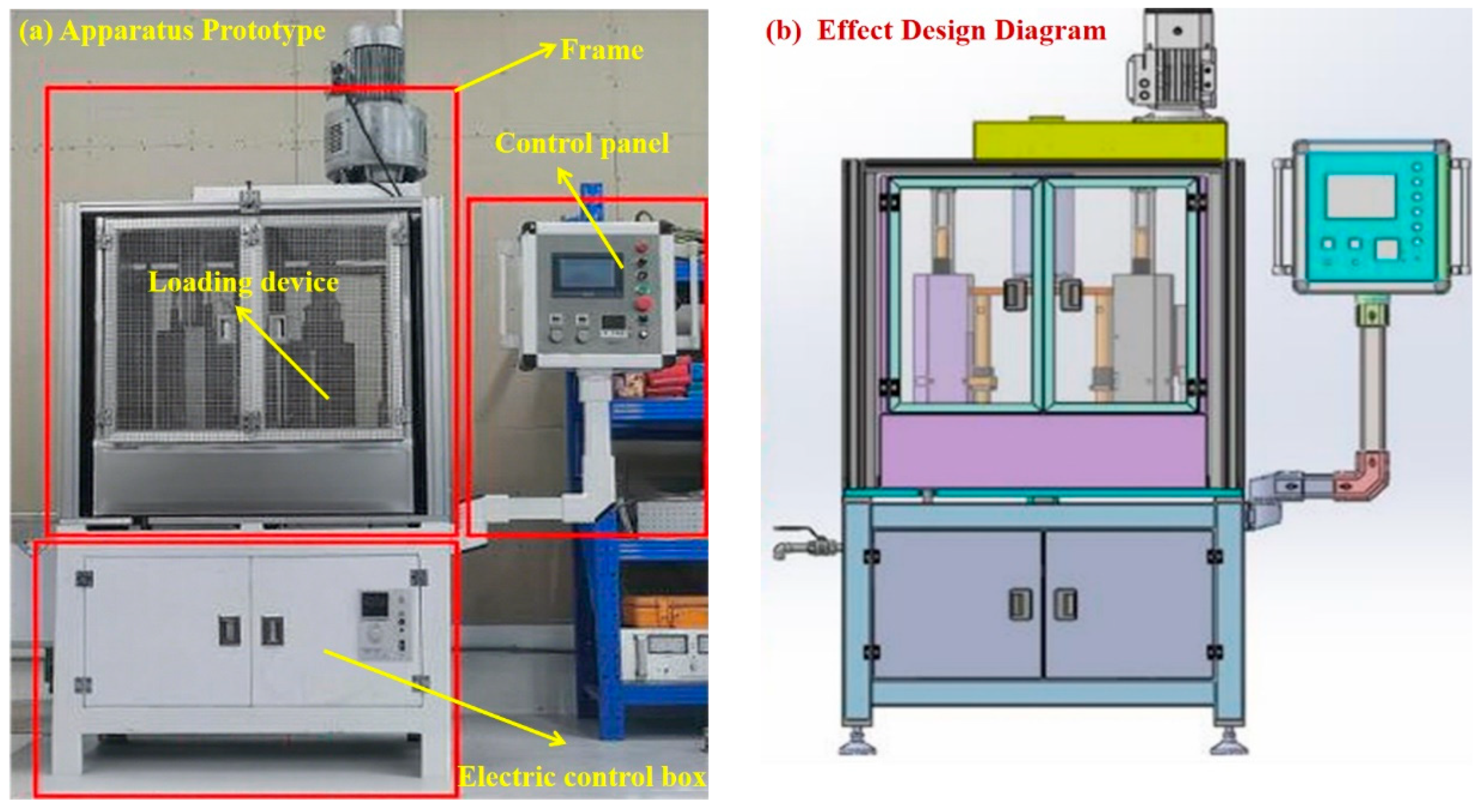

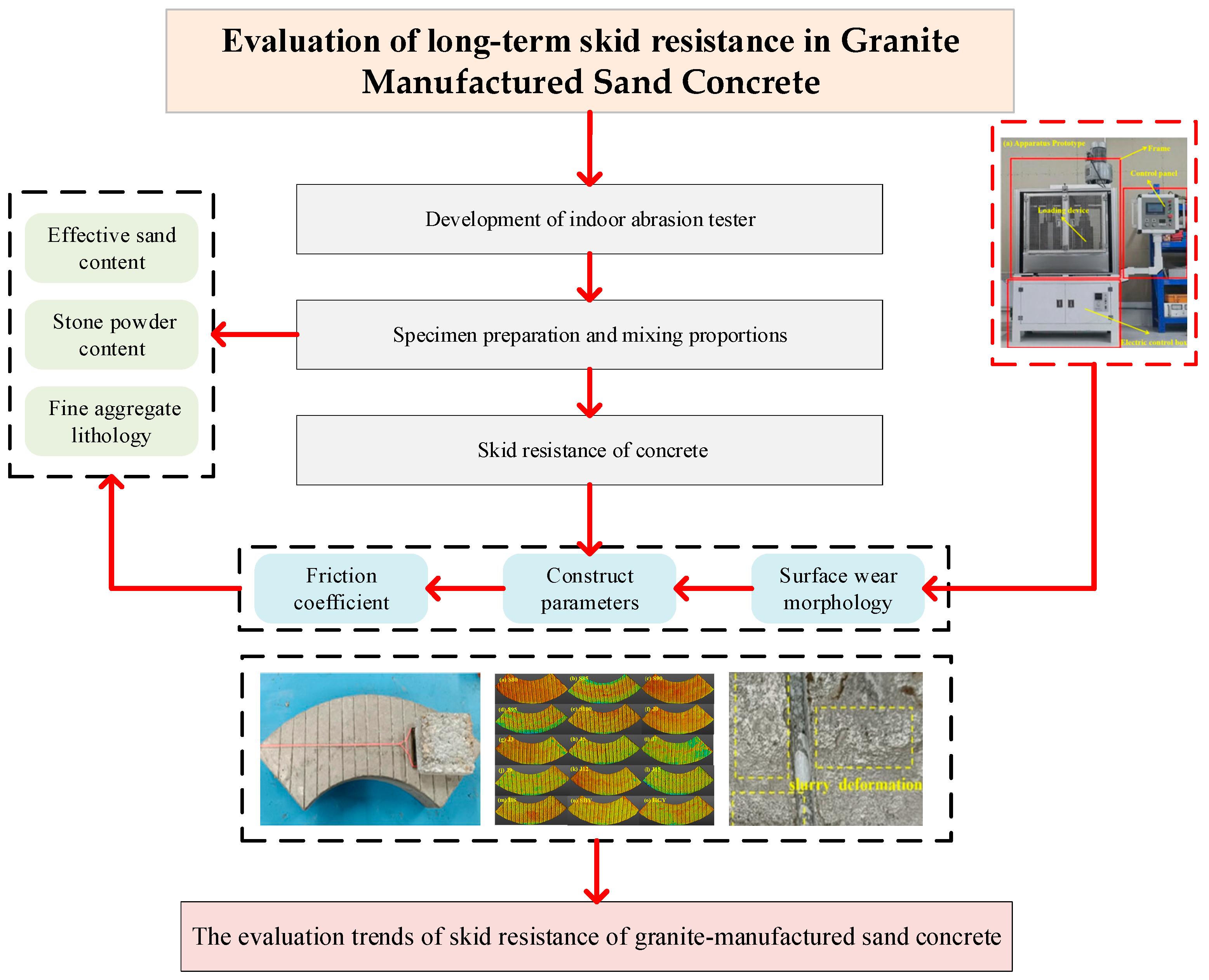

2.2. Indoor Abrasion Tester

2.2.1. Device Design and Structure

2.2.2. Device Test Steps

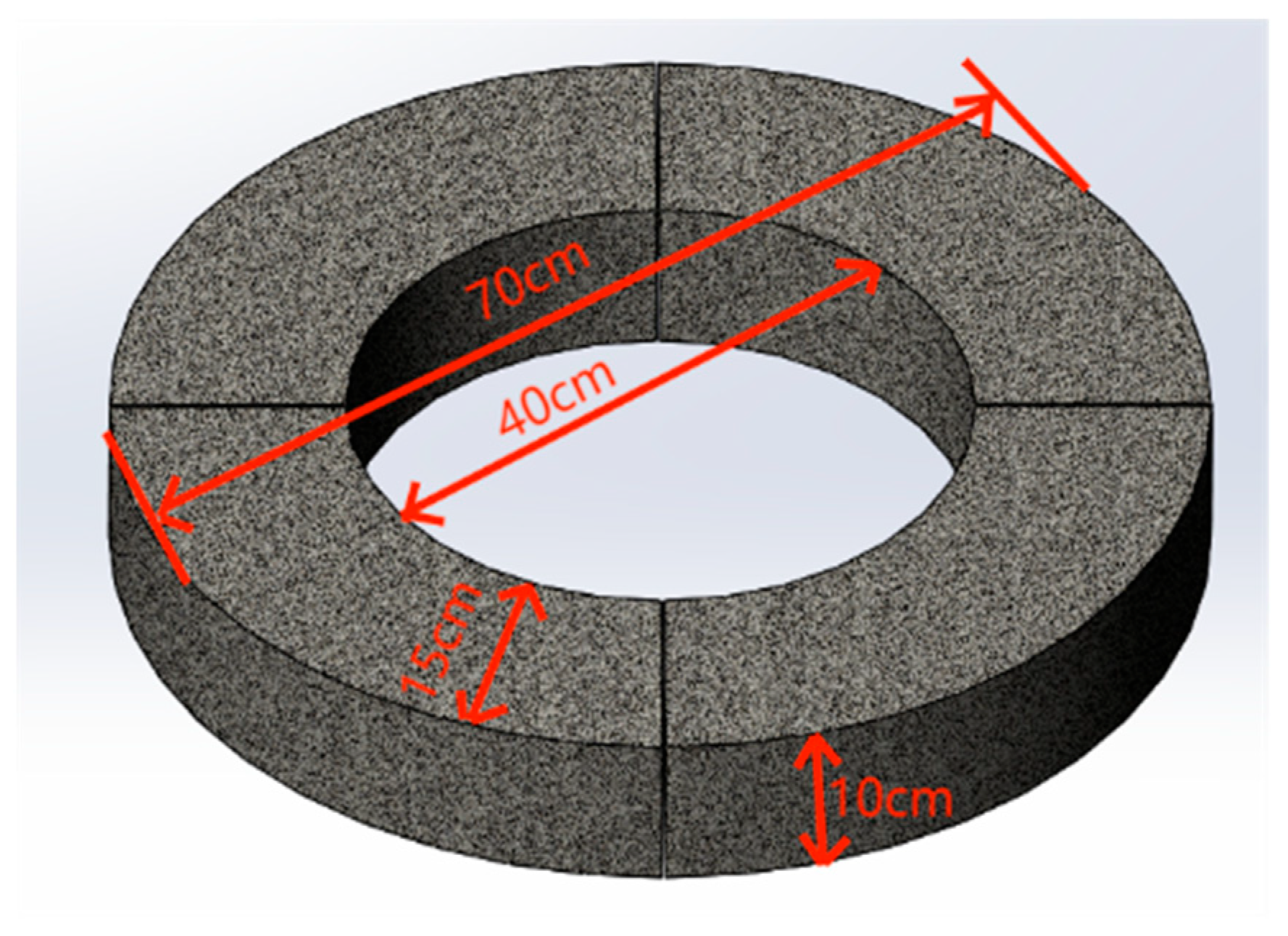

2.3. Specimen Preparation and Mixing Proportions

2.3.1. Mixing Proportions and Testing Program

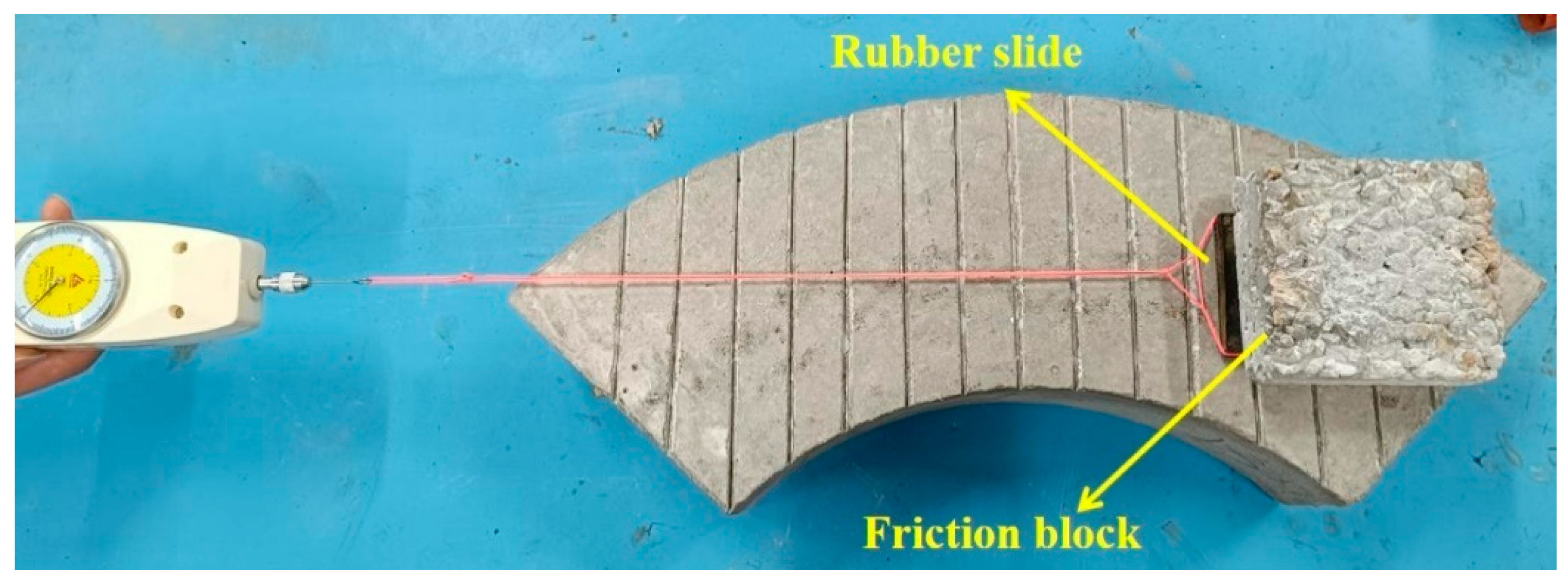

2.3.2. Test Methods

- (1)

- Skid resistance test of concrete

- (2)

- Acquisition and calculation of construct parameters

3. Results and Discussion

3.1. Evaluation Trends of Friction Coefficient of Concrete

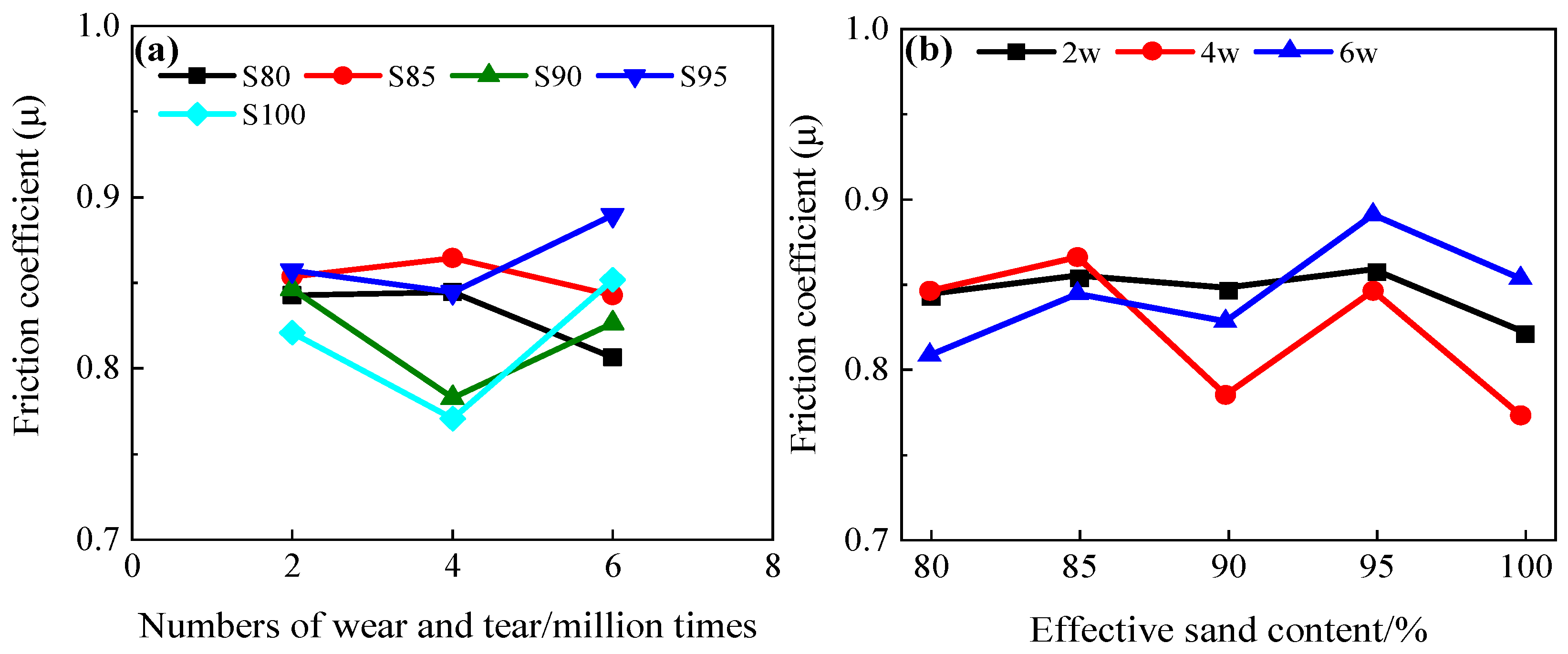

3.1.1. Evaluation Trends of Friction Coefficient of GS Concrete with Different Effective Sand Content

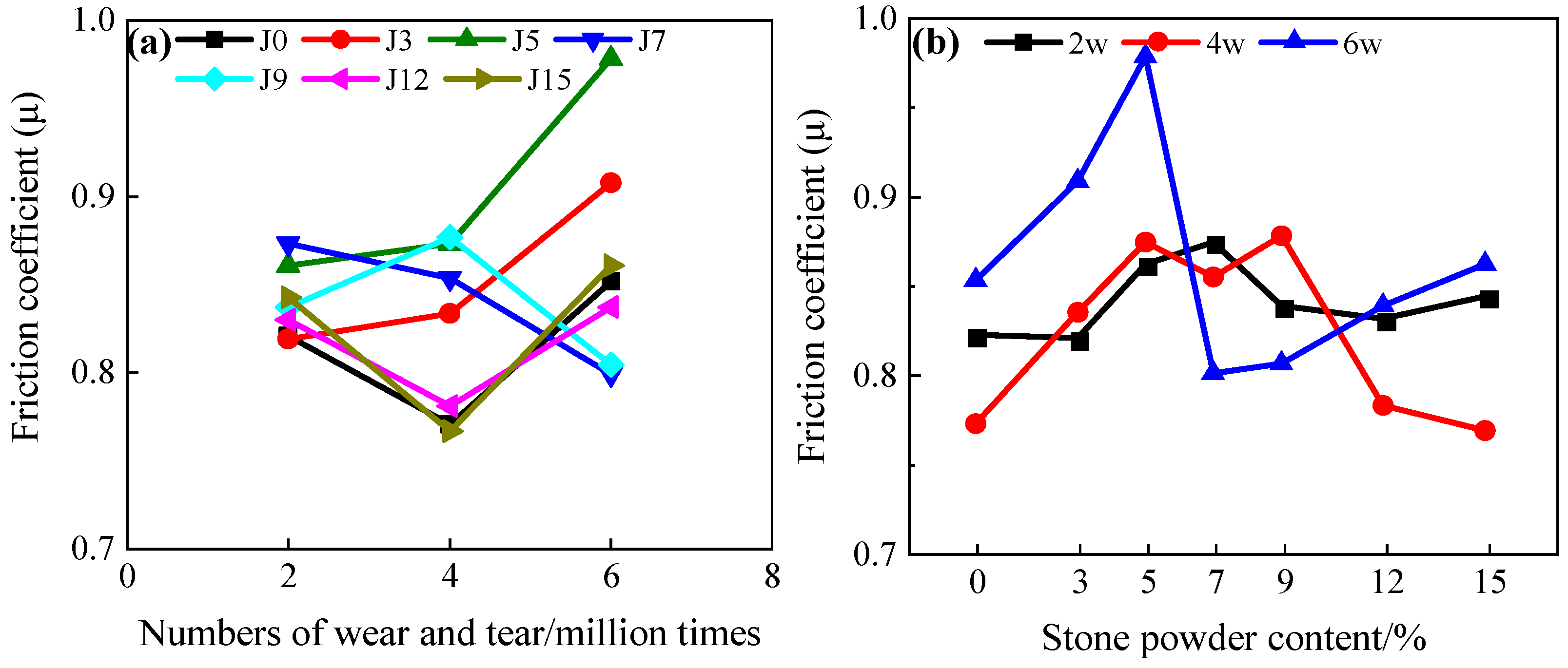

3.1.2. Evaluation Trends of Friction Coefficient of GS Concrete with Different Stone Powder

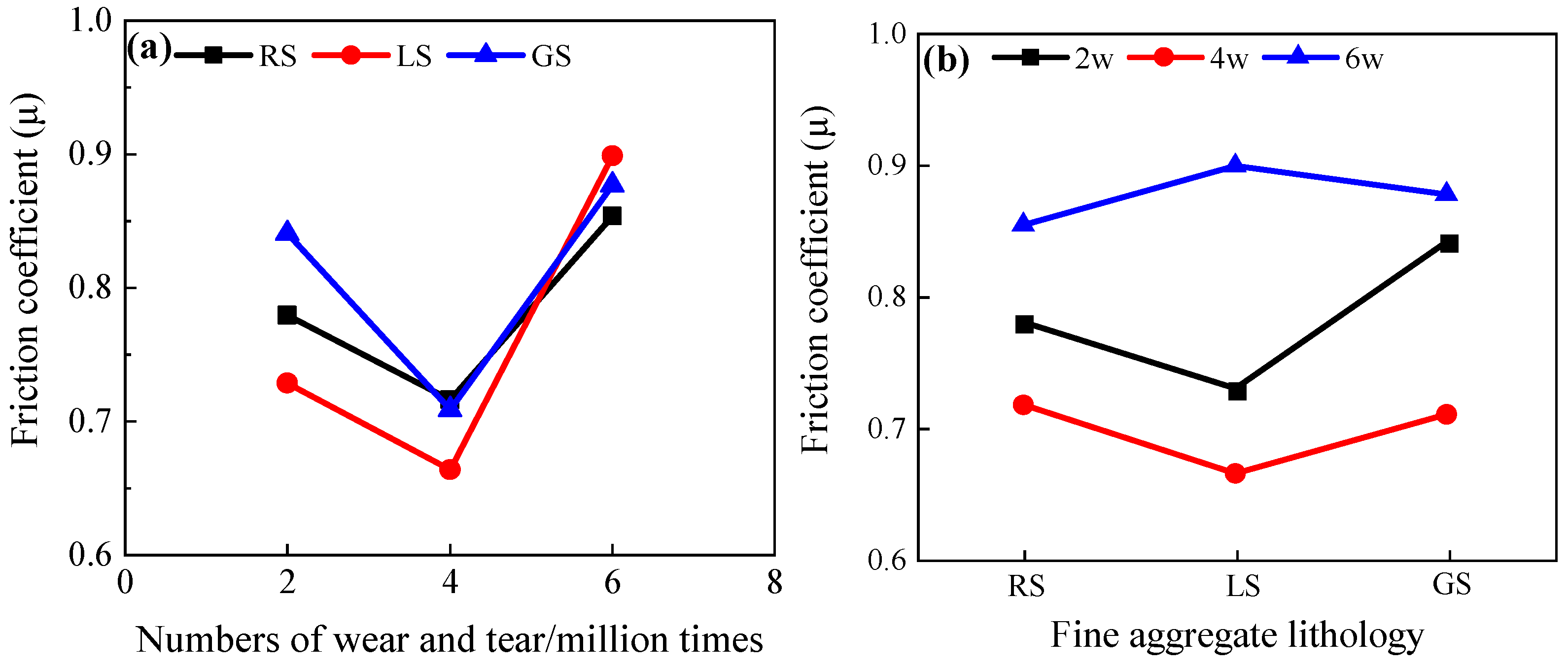

3.1.3. Evaluation Trends of Friction Coefficient of Concrete with Different Aggregate Lithology

3.2. Study of the Construct Parameters of Concrete

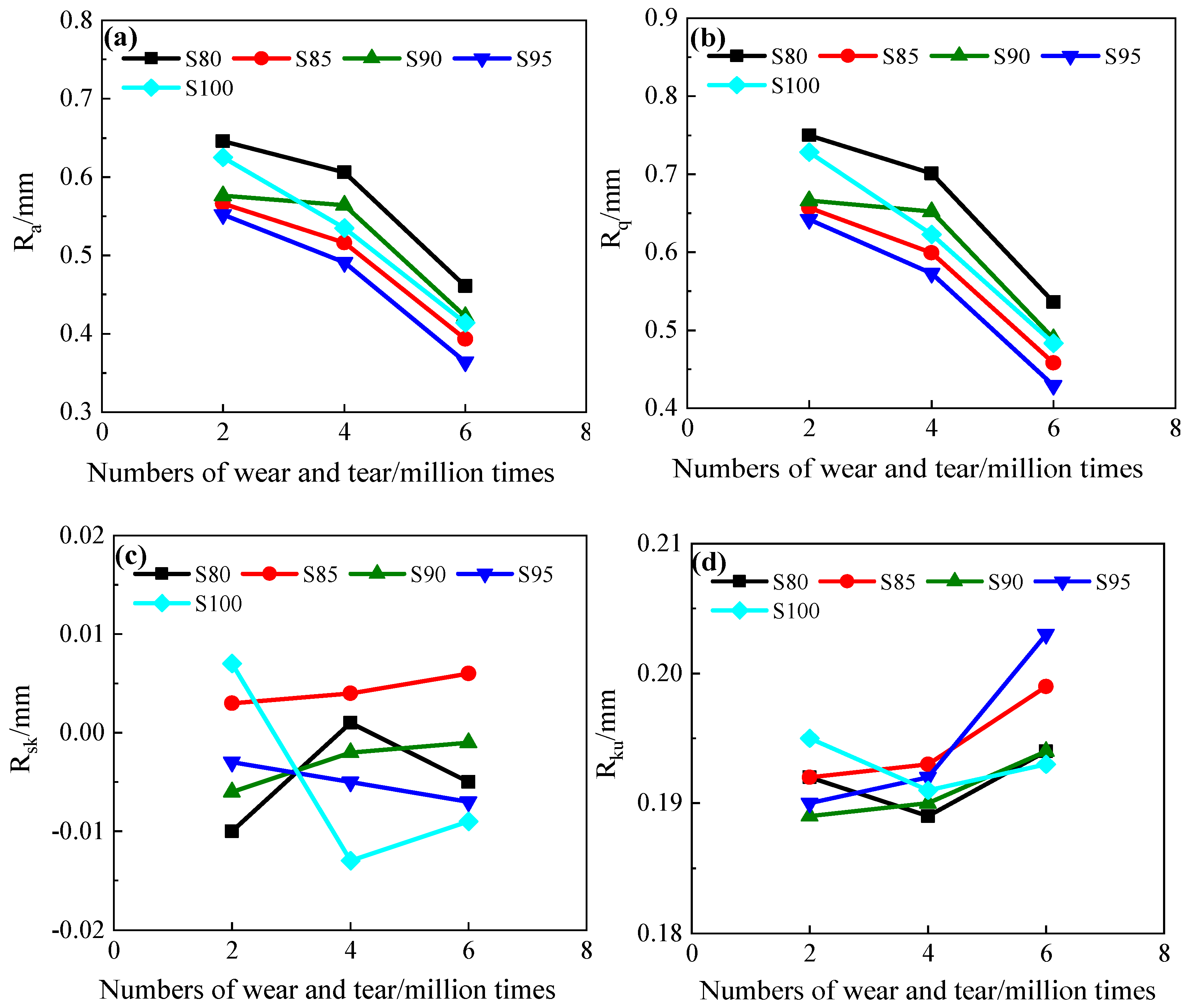

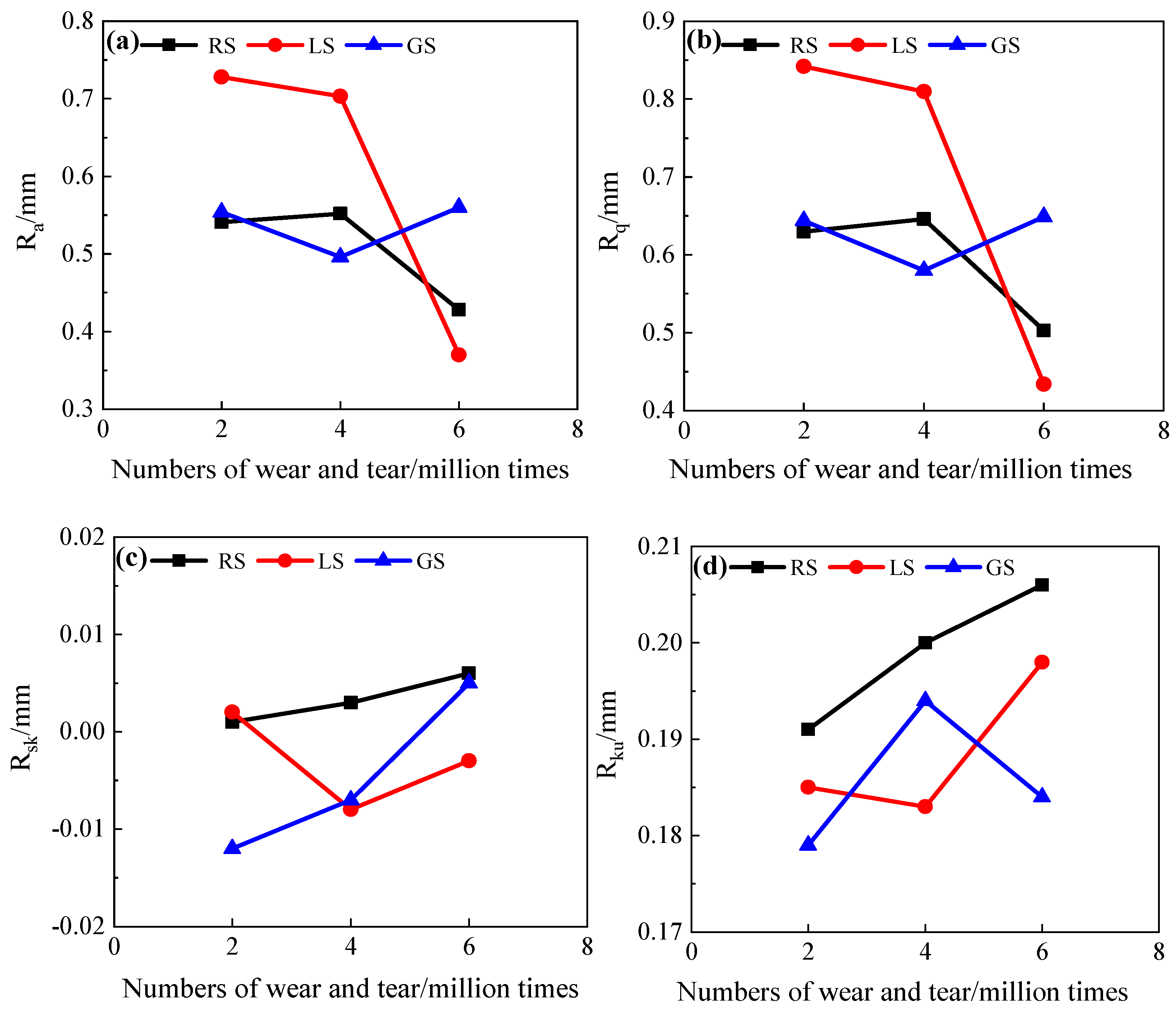

3.2.1. Effect of Effective Sand Content on the Construct Parameters of GS Concrete

3.2.2. Effect of Stone Powder on the Construct Parameters of GS Concrete

3.2.3. Effect of Fine Aggregate Lithology on the Construct Parameters of Concrete

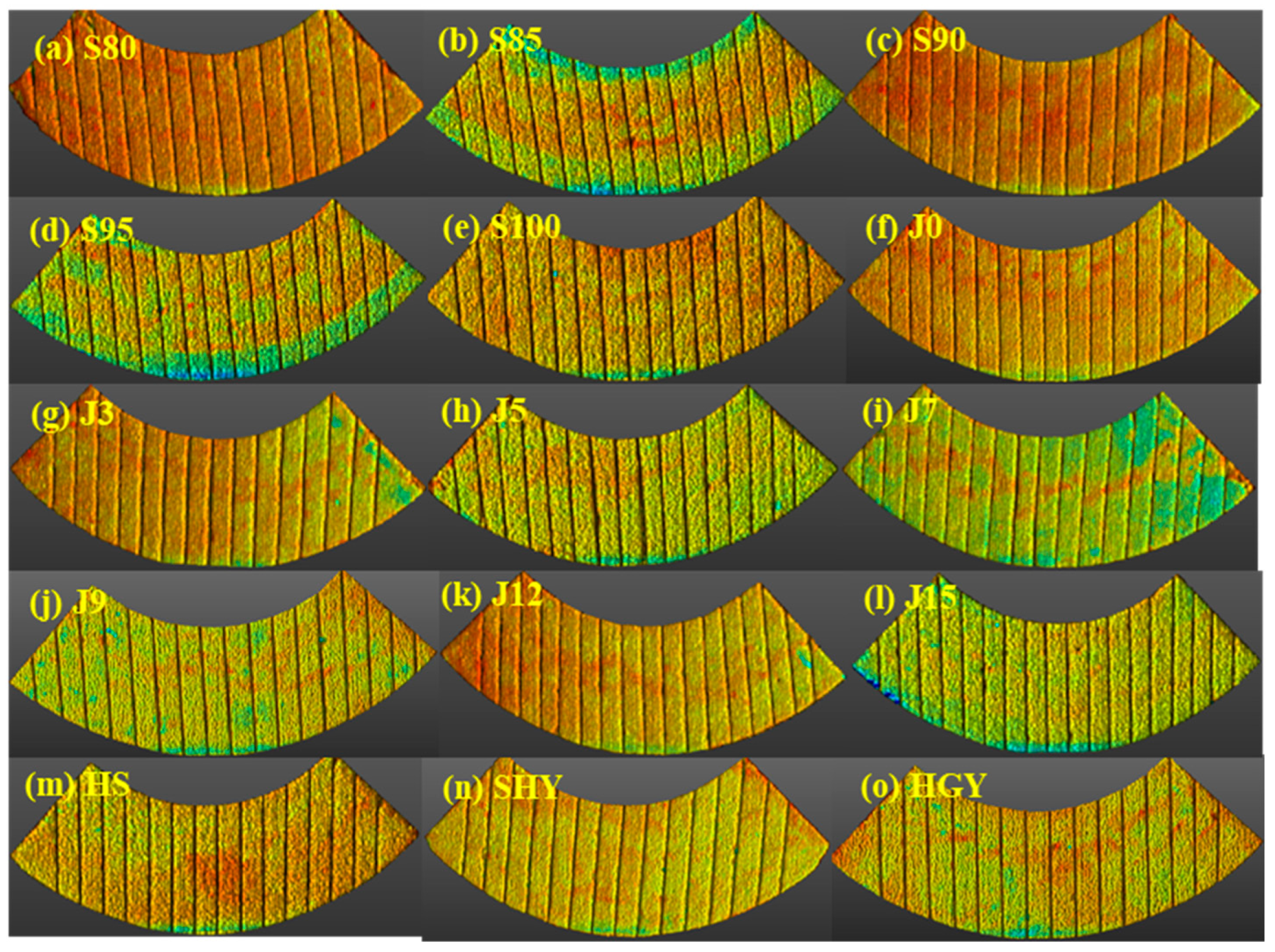

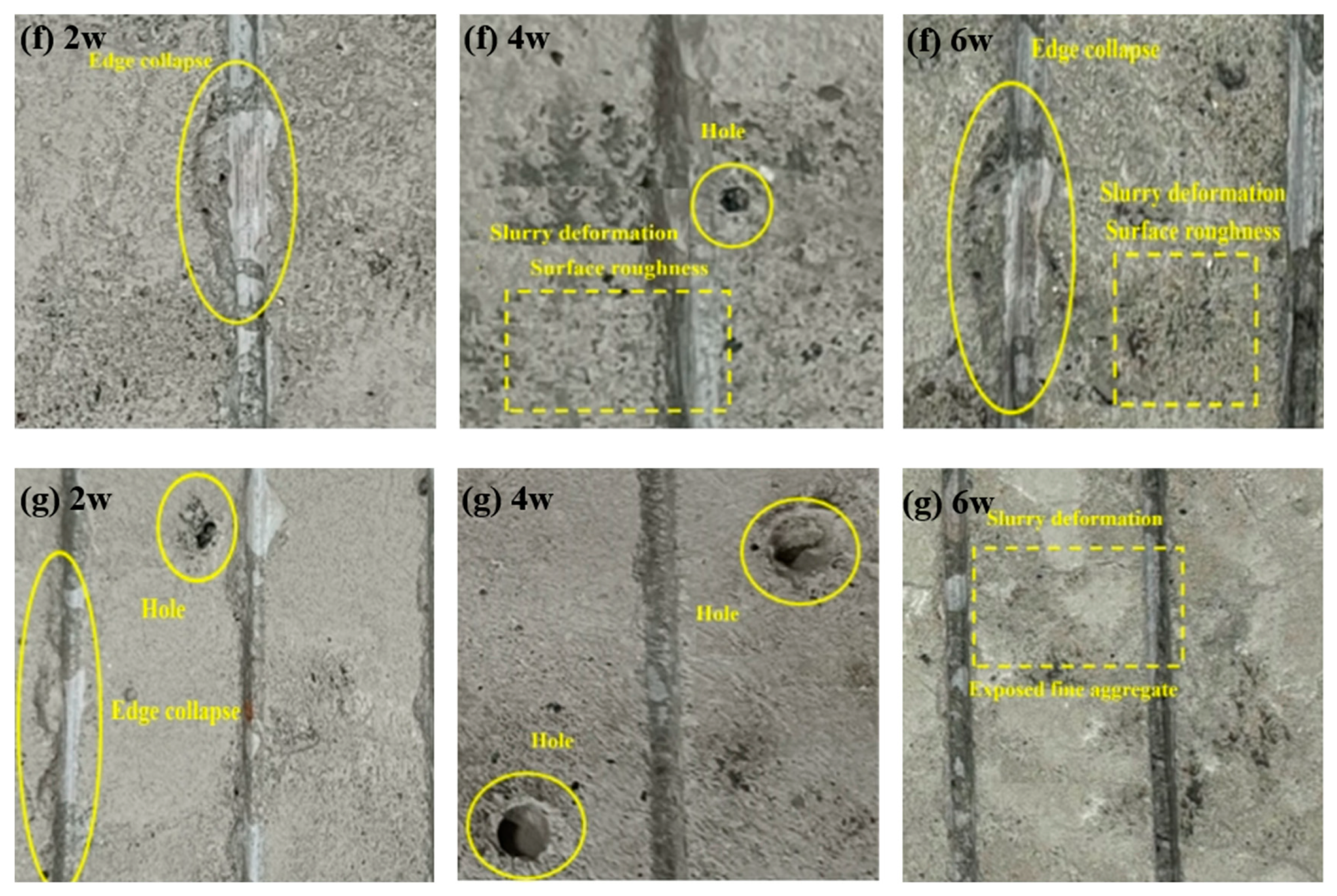

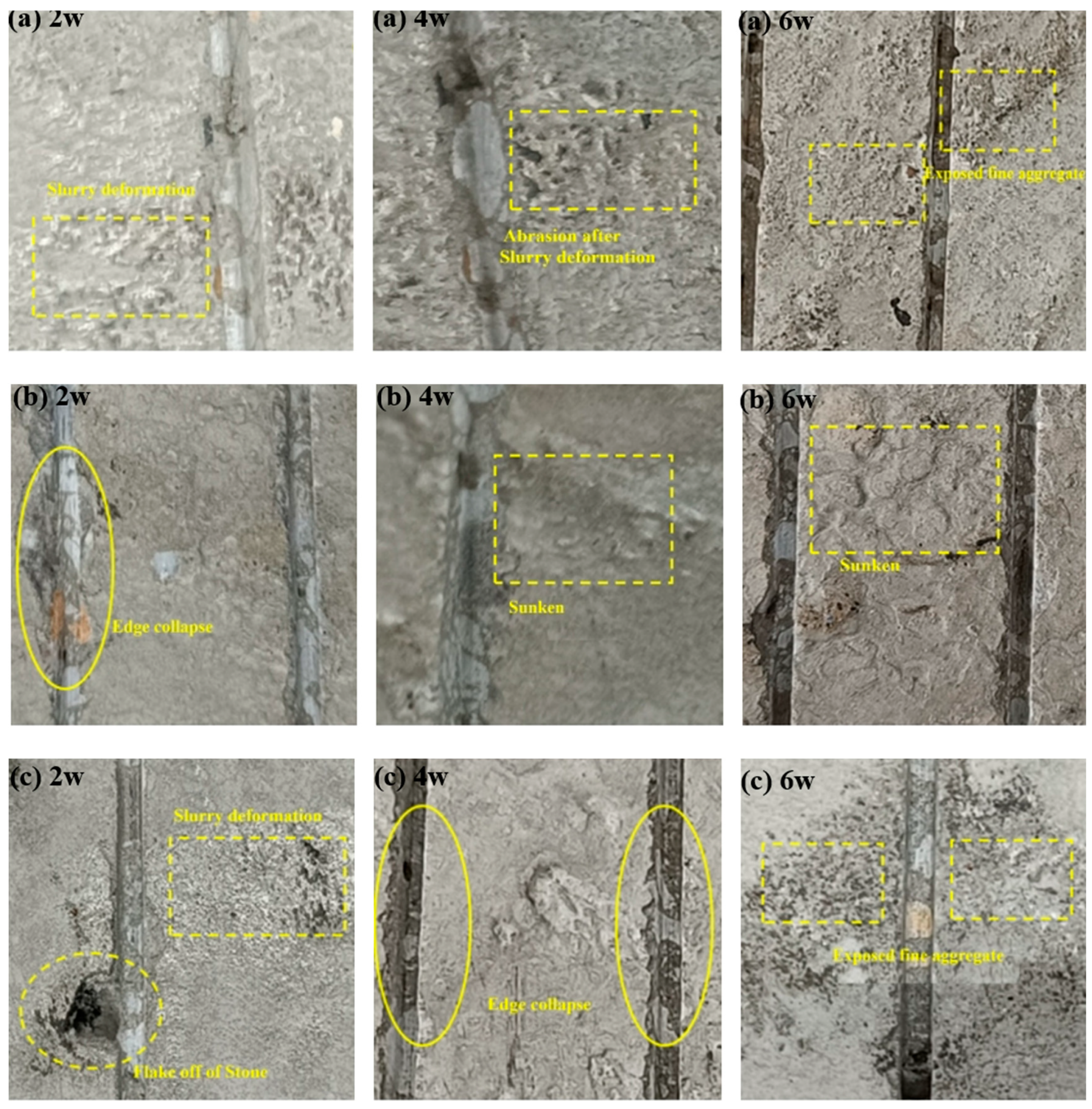

3.3. Evolution Trends of Surface Wear Morphology of Concrete

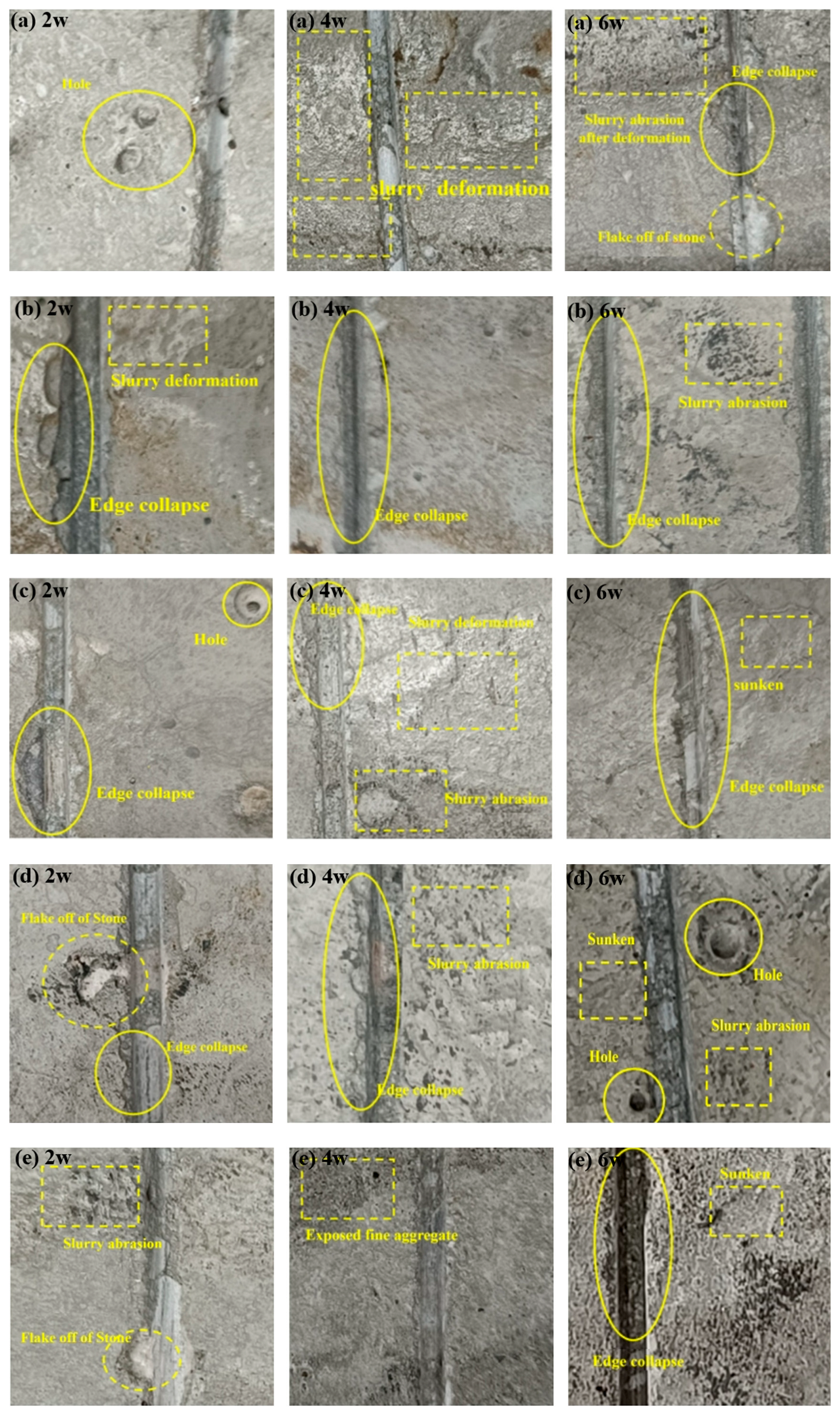

3.3.1. Evolution Trends of Surface Wear Morphology of GS Concrete with Different Effective Sand Content

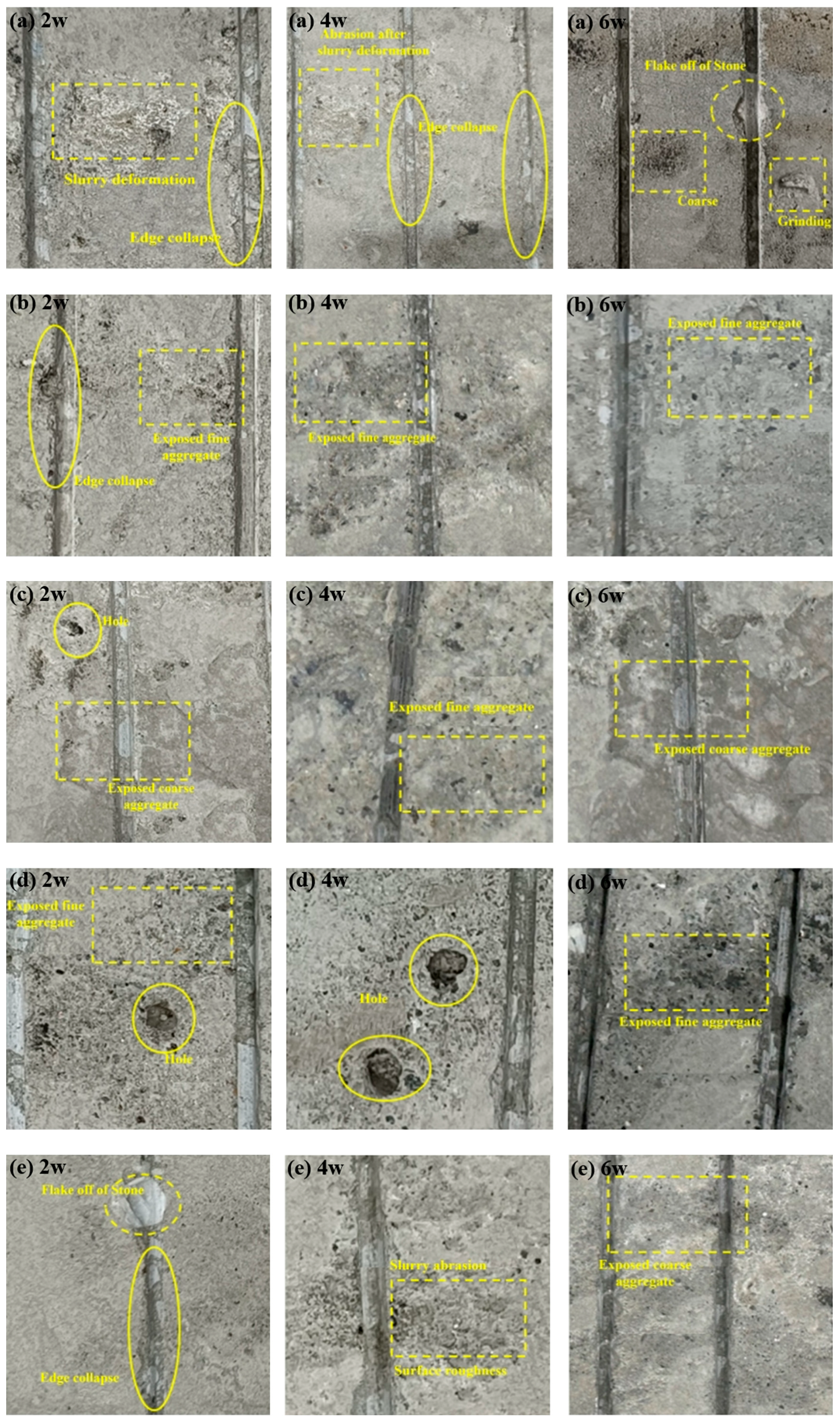

3.3.2. Evolution Trends of Surface Wear Morphology of GS Concrete with Different Stone Powder

3.3.3. Evolution Trends of Surface Wear Morphology of Concrete with Different Fine Aggregate Lithology

4. Conclusions

- Within the tested sand content range (80–100%), we observed that the friction coefficient increased first and then decreased with the wear cycles with a lower effective sand content. With a higher effective sand content, the friction coefficient decreases first and then increases. The 95% sand content maintains a relatively high friction coefficient throughout the test cycle. These trends indicate that there is a potential link between sand content and friction behavior related to the wear stage, but generalization is required to expand the data range.

- Within the tested stone powder content range (0–15%), we observed that the influence of stone powder content on the friction coefficient as the number of wear cycles increases manifests in three distinct patterns: For 0%, 12%, and 15% stone powder content, the friction coefficient initially decreases and then increases; for 3% and 5% content, it consistently increases; and for 7% and 9% content, it eventually decreases. Under the same number of wear cycles, the differences in friction coefficients among different stone powder contents progressively increase with additional wear cycles. However, specimens with 5% stone powder content maintain a high friction coefficient across various wear cycles, exhibiting the best skid resistance, suggesting potential optimization value within this experimental scope.

- For the fine aggregate lithologies examined (LS/RS/GS), the friction coefficient generally decreases then increases with wear cycles. GS yields higher friction values than RS in the tested samples, while LS exhibits greater variability. This implies lithology-dependent wear mechanisms, but geological diversity (e.g., mineral composition variations within lithologies) necessitates broader sampling for conclusive claims.

- Combined with wear morphology analysis, groove edge collapse progressively occurs as the number of wear cycles increases. However, we speculate that the addition of stone powder can significantly enhance the paste strength and delay the onset of groove edge collapse. Paste deformation primarily results from the low-strength cement paste formed due to surface bleeding, which is associated with the fine aggregate grading. Higher effective sand content and the addition of stone powder can effectively reduce the bleeding phenomenon.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Zhang, X.; Jin, F.; Zhao, X. Impact of Stone Powder Content on Corrosion Resistance in Reinforced Concrete under Stray Current and Chloride Interactions. Materials 2024, 17, 196. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Wang, Y.; Liang, G.; Yang, X. A Review of Long-Term Skid Resistance of Asphalt Pavement. Appl. Sci. 2025, 15, 1895. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, W.; Liu, D.; Zhang, W.; Zhang, R. Experimental Study on the Properties of Mortar and Concrete Made with Tunnel Slag Machine-Made Sand. Materials 2022, 15, 4817. [Google Scholar] [CrossRef]

- Wu, H.; Liu, K.; Yang, F.; Shen, B.; Ma, K.; Zhang, J.; Liu, B. Experimental Mechanical Properties and Numerical Simulation of C80 Concrete with Different Contents of Stone Powder. Materials 2022, 15, 3282. [Google Scholar] [CrossRef]

- Xue, H.; Chen, M.; Tang, Z.; Fan, G.; Zhou, J. Macro and Micro Impact Mechanisms of Stone Powder in Manufactured Sand on Physical and Mechanical Properties of Concrete. Adv. Eng. Sci. 2023, 55, 151–160. [Google Scholar]

- Tsivilis, S.; Batis, G.; Chaniotakis, E.; Grigoriadis, G.; Theodossis, D. Properties and Behavior of Limestone Cement Concrete and Mortar. Cem. Concr. Res. 2000, 30, 1679–1683. [Google Scholar] [CrossRef]

- Ismaeel, N.S.; Khalaf, M.A. Properties of High Strength Concrete Containing StonePowder as Natural Pozzolanic Materials. J. Univ. Anbar Pure Sci. 2014, 7, 1–7. [Google Scholar] [CrossRef]

- Craeye, B.; De Schutter, G.; Desmet, B.; Vantomme, J.; Heirman, G.; Vandewalle, L.; Cizer, Ö.; Aggoun, S.; Kadri, E. Effect of Mineral Filler Type on Autogenous Shrinkage of Self-Compacting Concrete. Cem. Concr. Res. 2010, 40, 908–913. [Google Scholar] [CrossRef]

- Li, H.; Huang, F.; Cheng, G.; Xie, Y.; Tan, Y.; Li, L.; Yi, Z. Effect of Granite Dust on Mechanical and Some Durability Properties of Manufactured Sand Concrete. Constr. Build. Mater. 2016, 109, 41–46. [Google Scholar] [CrossRef]

- Lu, L.; Yang, Z.; Lin, Y.; Dong, S. Partial Replacement of Manufactured Sand with Homologous Granite Powder in Mortar: The Effect on Porosity and Capillary Water Absorption. Constr. Build. Mater. 2023, 376, 131031. [Google Scholar] [CrossRef]

- Rao, K.; Desai, V.; Mohan, D. Experimental Investigations on Mode II Fracture of Concrete with Crushed Granite Stone Fine Aggregate Replacing Sand. Mater. Res.-Ibero-Am. J. Mater. 2012, 15, 41–50. [Google Scholar] [CrossRef]

- Singh, S.; Nande, N.; Bansal, P.; Nagar, R. Experimental Investigation of Sustainable Concrete Made with Granite Industry By-Product. J. Mater. Civ. Eng. 2017, 29, e017559. [Google Scholar] [CrossRef]

- Binici, H.; Shah, T.; Aksogan, O.; Kaplan, H. Durability of Concrete Made with Granite and Marble as Recycle Aggregates. J. Mater. Process. Technol. 2008, 208, 299–308. [Google Scholar] [CrossRef]

- Torgal, F.; Castro-Gomes, J. Influence of Physical and Geometrical Properties of Granite and Limestone Aggregates on the Durability of a C20/25 Strength Class Concrete. Constr. Build. Mater. 2006, 20, 1079–1088. [Google Scholar] [CrossRef]

- Hussin, A.; Poole, C. Petrography Evidence of the Interfacial Transition Zone (ITZ) in the Normal Strength Concrete Containing Granitic and Limestone Aggregates. Constr. Build. Mater. 2011, 25, 2298–2303. [Google Scholar] [CrossRef]

- Sheng, W.; Wang, D.; Cheng, H.; Yang, R.; Wang, Y. Joint Improvements of Skid and Abrasion Resistance of Concrete Pavements through Manufactured Micro- and Macro-Textures. Constr. Build. Mater. 2025, 487, 142033. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, J.; Lai, J.; Shi, X.; Xu, Z. Skid Resistance of Cement Concrete Pavement in Highway Tunnel: A Review. Constr. Build. Mater. 2023, 406, 133235. [Google Scholar] [CrossRef]

- Valença, J.; Puente, I.; Júlio, E.; González-Jorge, H.; Arias-Sánchez, P. Assessment of Cracks on Concrete Bridges Using Image Processing Supported by Laser Scanning Survey. Constr. Build. Mater. 2017, 146, 668–678. [Google Scholar] [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; Li, R.; Zhou, B.; Chen, Z. Study on the Skid Resistance of Asphalt Pavement: A State-of-the-Art Review and Future Prospective. Constr. Build. Mater. 2021, 303, 124411. [Google Scholar] [CrossRef]

- Cui, X.; Chu, L.; Fwa, T.F. Experimental-Cum-Numerical Approach for Directional Skid Resistance Measurement of Grooved Pavements. Measurement 2022, 205, 112129. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Chen, Y.; Zhao, C.; Qiu, J.; Wu, D.; Liu, T.; Fan, H.; Qin, Y.; Tang, K. A State-of-the-Practice Review of Three-Dimensional Laser Scanning Technology for Tunnel Distress Monitoring. J. Perform. Constr. Facil. 2023, 37, 03123001. [Google Scholar] [CrossRef]

- Hanson, D.; Prowell, B. Evaluation of Circular Texture Meter for Measuring Surface Texture of Pavements. Transp. Res. Rec. 2005, 1929, 88–96. [Google Scholar] [CrossRef]

- Mora, C.F.; Kwan, A.K.H. Sphericity, Shape Factor, and Convexity Measurement of Coarse Aggregate for Concrete Using Digital Image Processing. Cem. Concr. Res. 2000, 30, 351–358. [Google Scholar] [CrossRef]

- Adresi, M.; Lacidogna, G. Investigating the Micro/Macro-Texture Performance of Roller-Compacted Concrete Pavement under Simulated Traffic Abrasion. Appl. Sci. 2021, 11, 5704. [Google Scholar] [CrossRef]

- Gierasimiuk, P.; Wasilewska, M.; Gardziejczyk, W. A Comparative Study on Skid Resistance of Concrete Pavements Differing in Texturing Technique. Materials 2021, 14, 178. [Google Scholar] [CrossRef]

- JTG E30-2005; Test Methods of Cement and Concrete for Highway Engineering. China Communications Press: Beijing, China, 2005.

- GB 175-2007; Common Portland Cement. China Standards Press: Beijing, China, 2007.

- GB/T 14684-2022; Sand for Construction. State Administration for Market Regulation: Beijing, China, 2022.

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2011.

- GB 8076-2008; Concrete Admixtures. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2008.

- GB/T 1596-2005; Fly Ash Used for Cement and Concrete. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2005.

- GB 5749-2006; Standards for Drinking Water Quality. Ministry of Health of China: Beijing, China, 2006.

- Li, Z.; Wang, Y.; Yang, X.; Liang, J.; Chen, Y.; Pan, M. Study on Abrasion Resistance of Granite Manufactured Sand Concrete Based on Indoor Abrasion Tester. Coatings 2025, 15, 659. [Google Scholar] [CrossRef]

- Kim, S.H.; Shin, M.C. Steering Pull Model and Its Sensitivity Analysis. Appl. Sci. 2020, 10, 8027. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

- JTG D40-2011; Specifications for Design of Highway Cement Concrete Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- ASTM E1911; Standard Test Method for Measuring the Response of Materials to Thermal and Mechanical Stimuli Using Dynamic Mechan ical Analysis. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E274; Standard Test Method for Skid-Resistance of Paved Surfaces Using a Full-Scale Tire. ASTM International: West Conshohocken, PA, USA, 2018.

- Tian, Y.; Kasyap, S.S.; Senetakis, K. Influence of Loading History and Soil Type on the Normal Contact Behavior of Natural Sand Grain-Elastomer Composite Interfaces. Polymers 2021, 13, 1830. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Mao, J.; Yu, X.; Zhou, B.; Wang, L. Study on the Dynamic Mechanical Properties of Ultrahigh-Performance Concrete under Triaxial Constraints. Materials 2023, 16, 6591. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Wu, R.; Wu, A.; Wang, H.; Wang, S. Analysis of Bleeding of Low Concentration Full Tailings Filling Material and Its Regulate-control. Chin. J. Mater. Res. 2020, 34, 481–488. [Google Scholar]

- Wang, A.; Shi, Y.; Liu, K.; Sun, D.; Lu, B.; Liu, P. Effect of Aircooled Blast Furnace Slag as Fine Aggregate on the Properties of Cement Mortar. Mater. Rep. 2017, 31, 121–125. [Google Scholar]

- Janakiraman, V.; Li, S.; Kahraman, A. An Investigation of the Impacts of Contact Parameters on Wear Coefficient. J. Tribol. 2014, 136, 031602. [Google Scholar] [CrossRef]

- Burdzik, R.; Folega, P.; Lazarz, B.; Stanik, Z.; Warczek, J. Analysis of the impact of surface layer parameters on wear intensity of friction pairs. Arch. Metall. Mater. 2012, 57, 987–993. [Google Scholar] [CrossRef]

- Xin, Y.; Lu, X.; Ji, H.; Hao, H.; Dong, S. Analysis of early damage characteristics and late mechanical behavior of cement specimens. J. China Coal Soc. 2020, 45, 3119–3130. [Google Scholar] [CrossRef]

- Abid, S.R.; Hilo, A.N.; Daek, Y.H. Experimental Tests on the Underwater Abrasion of Engineered Cementitious Composites. Constr. Build. Mater. 2018, 171, 779–792. [Google Scholar] [CrossRef]

- Cheyad, S.M.; Hilo, A.N.; Al-Gasham, T.S. Comparing the Abrasion Resistance of Conventional Concrete and Geopolymer Samples. Mater. Today Proc. 2022, 56, 1832–1839. [Google Scholar] [CrossRef]

- Zhao, M.; Dai, M.; Li, J.; Li, C. Case Study on Performance of Pumping Concrete with Super-Fine River-Sand and Manufactured-Sand. Case Stud. Constr. Mater. 2023, 18, e01850. [Google Scholar] [CrossRef]

- Opara, H.E.; Eziefula, U.G.; Eziefula, B.I. Comparison of Physical and Mechanical Properties of River Sand Concrete with Quarry Dust Concrete. Sel. Sci. Pap.-J. Civ. Eng. 2018, 13, 127–134. [Google Scholar] [CrossRef]

- Xiao, J.; Jin, Y.; Gou, C.; Wang, Y. Effect of ground limestone on hydration characteristics and pore structure of cement pastes. J. Cent. S. Univ. 2010, 41, 2313–2320. [Google Scholar]

- Ding, Z.F. Experimental Study of Crushing and Wear Resistance of Limestone and Basalt Coarse Aggregate Contrast. Highw. Eng. 2014. Available online: https://api.semanticscholar.org/CorpusID:131417272 (accessed on 18 August 2025).

- Najafi Koopas, R.; Rauter, N.; Lammering, R. Two-Dimensional Mesoscale Finite Element Modeling of Concrete Damage and Failure. Appl. Sci. 2023, 13, 8971. [Google Scholar] [CrossRef]

- Xiong, Y.; Yin, J. A Review on Microscopic Property of Concrete’s Aggregate-Mortar Interface Transition Zone. Appl. Mech. Mater. 2016, 847, 544–552. [Google Scholar] [CrossRef]

- Horník, J.; Čižmárová, E.; Krum, S.; Krčil, J.; Mára, V. The Influence of Microstructure on the Fracture Development in Engineering Parts. Solid State Phenom. 2017, 270, 74–79. [Google Scholar] [CrossRef]

- Zhu, Y.; Wen, C.; Chen, J. Influence of Stone Powder on Properties of Concrete with Low Cementitious Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 371, 012021. [Google Scholar] [CrossRef]

- Srirangam, S.K.; Anupam, K.; Scarpas, A.; Kasbergen, C. Development of a Thermomechanical Tire-Pavement Interaction Model. Int. J. Pavement Eng. 2014, 16, 721–729. [Google Scholar] [CrossRef]

- Anupam, K.; Srirangam, S.K.; Scarpas, A.; Kasbergen, C. Influence of Temperature on Tire-Pavement Friction: Analyses. Transp. Res. Rec. 2013, 2369, 114–124. [Google Scholar] [CrossRef]

- Dong, W.; Liu, C.; Bao, X.; Xiang, T.; Chen, D. Advances in the Deformation and Failure of Concrete Pavement under Coupling Action of Moisture, Temperature, and Wheel Load. Materials 2020, 13, 5530. [Google Scholar] [CrossRef]

- Fattah, M.Y.; El-Ghany, S.A.; Abdaljabbar, A.S. Analysis of the Performance of Flexible Pavement under the Effect of Wheel and Thermal Loads. Eng. Technol. J. 2010, 28, 5782–5802. [Google Scholar] [CrossRef]

- Coughlin, J.P.; Campbell, C.D.; Mays, D.C. Infiltration and Clogging by Sand and Clay in a Pervious Concrete Pavement System. J. Hydrol. Eng. 2012, 17, 68–73. [Google Scholar] [CrossRef]

- Kampmann, R.; Roddenberry, M.; Ping, W.V. Contribution of Specimen Surface Friction to Size Effect and Rupture Behavior of Concrete. ACI Mater. J. 2013, 110, 169–176. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Use of Limestone Powder to Improve the Properties of Self-Compacting Concrete Produced Using Cathode Ray Tube Waste as Fine Aggregate. Appl. Mech. Mater. 2012, 193–194, 472–476. [Google Scholar] [CrossRef]

| Specimen Number | Content of Various Materials (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Water | Cement | Gravel | Adjusted Sand | Effective Sand | Water Reducing Agent | Fly Ash | |

| S80 | 97 | 342 | 922 | 131 | 526 | 1.29 | 38 |

| S85 | 99 | 558 | |||||

| S90 | 66 | 591 | |||||

| S95 | 33 | 624 | |||||

| S100 | 0 | 657 | |||||

| Specimen Number | Content of Various Materials (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Water | Fly Ash | Cement | Stone Powder | MS | Gravel | Water Reducing Agent | |

| J0 | 97 | 38 | 342 | 0 | 657 | 922 | 1.29 |

| J3 | 332 | 10 | |||||

| J5 | 325 | 17 | |||||

| J7 | 318 | 24 | |||||

| J9 | 311 | 31 | |||||

| J12 | 301 | 41 | |||||

| J15 | 291 | 51 | |||||

| Content of Various Materials (kg/m3) | ||||||

|---|---|---|---|---|---|---|

| Specimen Number | Water | Fly Ash | Cement | Sand | Gravel | Water Reducing Agent |

| RS/LS/GS | 97 | 38 | 342 | 657 | 922 | 1.29 |

| Description of Sample | BPN | Coefficient of Friction | Standard Deviation of BPN | Coefficient of Variation of BPN | Standard Deviation of Coefficient of Friction | Coefficient of Variation of Coefficient of Friction |

|---|---|---|---|---|---|---|

| A1 | 78 | 0.81 | 0.829 | 1.08% | 0.01479 | 1.88% |

| 76 | 0.78 | |||||

| 76 | 0.77 | |||||

| 77 | 0.79 | |||||

| A2 | 77 | 0.79 | 0.816 | 1.07% | 0.01054 | 1.36% |

| 75 | 0.76 | |||||

| 76 | 0.77 | |||||

| 76 | 0.77 | |||||

| A3 | 78 | 0.81 | 0.957 | 1.24% | 0.01118 | 1.40% |

| 78 | 0.8 | |||||

| 77 | 0.79 | |||||

| 76 | 0.78 | |||||

| A4 | 75 | 0.77 | 0.816 | 1.07% | 0.01054 | 1.36% |

| 77 | 0.79 | |||||

| 76 | 0.77 | |||||

| 76 | 0.76 |

| Indicators | Calculation Formula | Note |

|---|---|---|

| Arithmetic average value Ra | n is the number of sampling points on the surface; is the average value of Z; σ is the standard deviation of Z. | |

| Cross-section standard deviation Rq | ||

| Skewness Rsk | ||

| Kurtosis Rku |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Shu, B.; Du, C.; Zhuo, Y.; Chen, Z.; Zhang, W.; Yang, X.; Chen, Y.; Pan, M. Evaluation of Long-Term Skid Resistance in Granite Manufactured Sand Concrete. Lubricants 2025, 13, 375. https://doi.org/10.3390/lubricants13090375

Li H, Shu B, Du C, Zhuo Y, Chen Z, Zhang W, Yang X, Chen Y, Pan M. Evaluation of Long-Term Skid Resistance in Granite Manufactured Sand Concrete. Lubricants. 2025; 13(9):375. https://doi.org/10.3390/lubricants13090375

Chicago/Turabian StyleLi, Hongjie, Biao Shu, Chenglin Du, Yingming Zhuo, Zongxi Chen, Wentao Zhang, Xiaolong Yang, Yuanfeng Chen, and Minqiang Pan. 2025. "Evaluation of Long-Term Skid Resistance in Granite Manufactured Sand Concrete" Lubricants 13, no. 9: 375. https://doi.org/10.3390/lubricants13090375

APA StyleLi, H., Shu, B., Du, C., Zhuo, Y., Chen, Z., Zhang, W., Yang, X., Chen, Y., & Pan, M. (2025). Evaluation of Long-Term Skid Resistance in Granite Manufactured Sand Concrete. Lubricants, 13(9), 375. https://doi.org/10.3390/lubricants13090375