Recent Developments in Self-Lubricating Thin-Film Coatings Deposited by a Sputtering Technique: A Critical Review of Their Synthesis, Properties, and Applications

Abstract

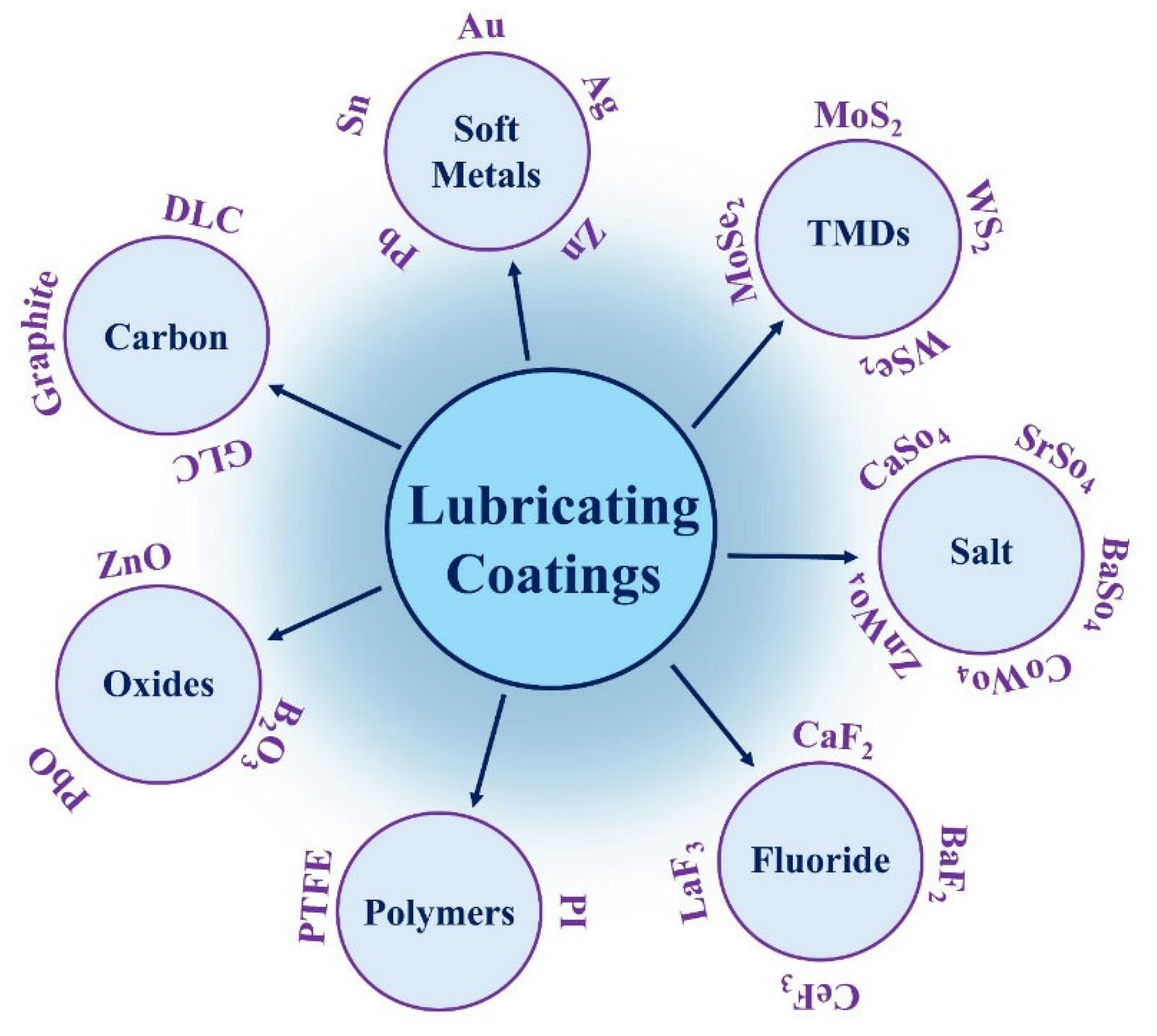

1. Introduction

- (a)

- Stability of mechanical and tribological properties, and thermal and corrosion resistance;

- (b)

- Enhanced ductility and low shear strength in the sliding direction;

- (c)

- Low and controlled diffusion to minimize the depletion of the solid lubricant.

- (a)

- Low-temperature self-lubricating coatings;

- (b)

- Moderate temperature self-lubricating coatings;

- (c)

- High-temperature self-lubricating coatings.

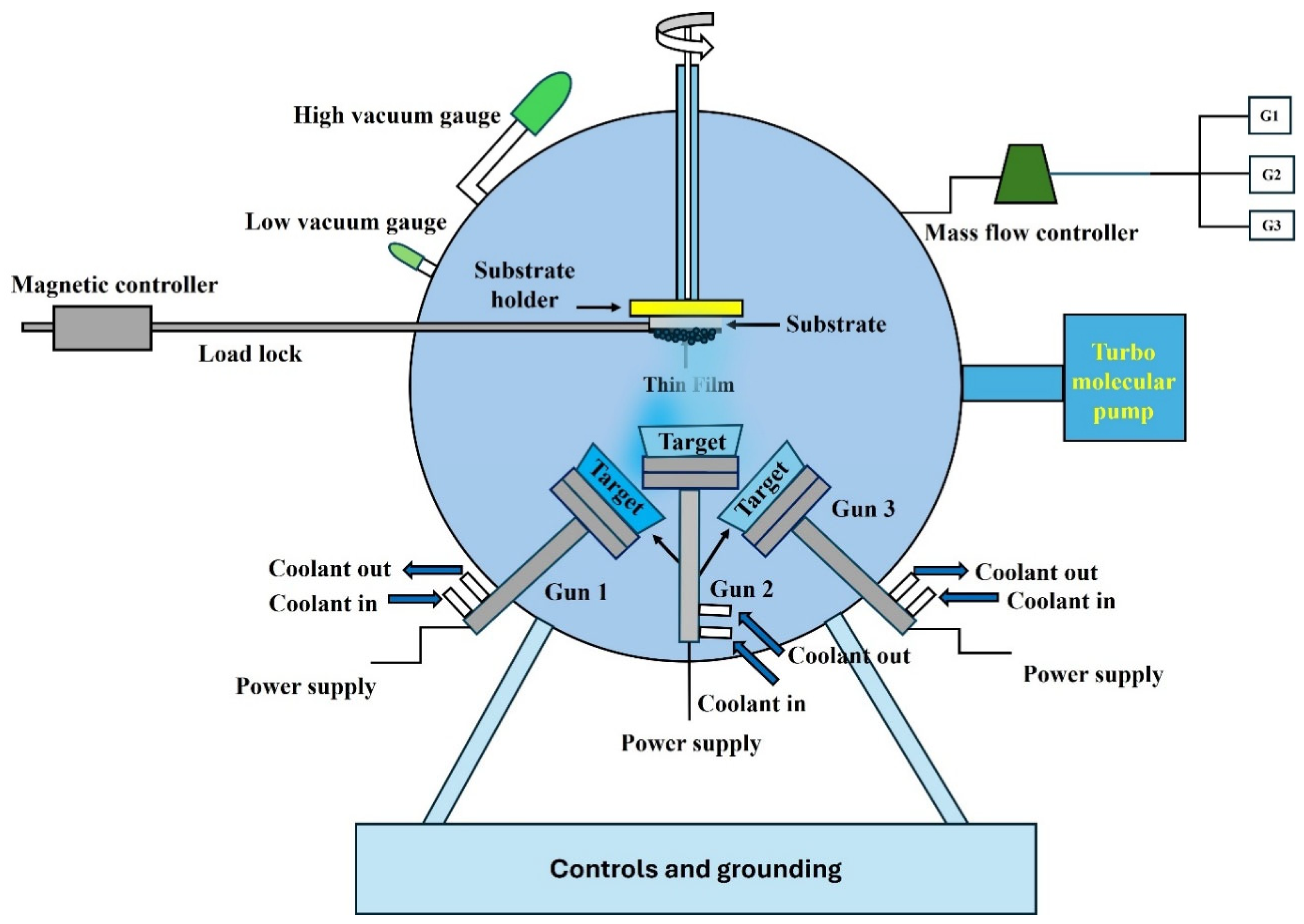

2. Self-Lubricating Films Synthesized by Sputtering

2.1. Nitride-Based Coatings

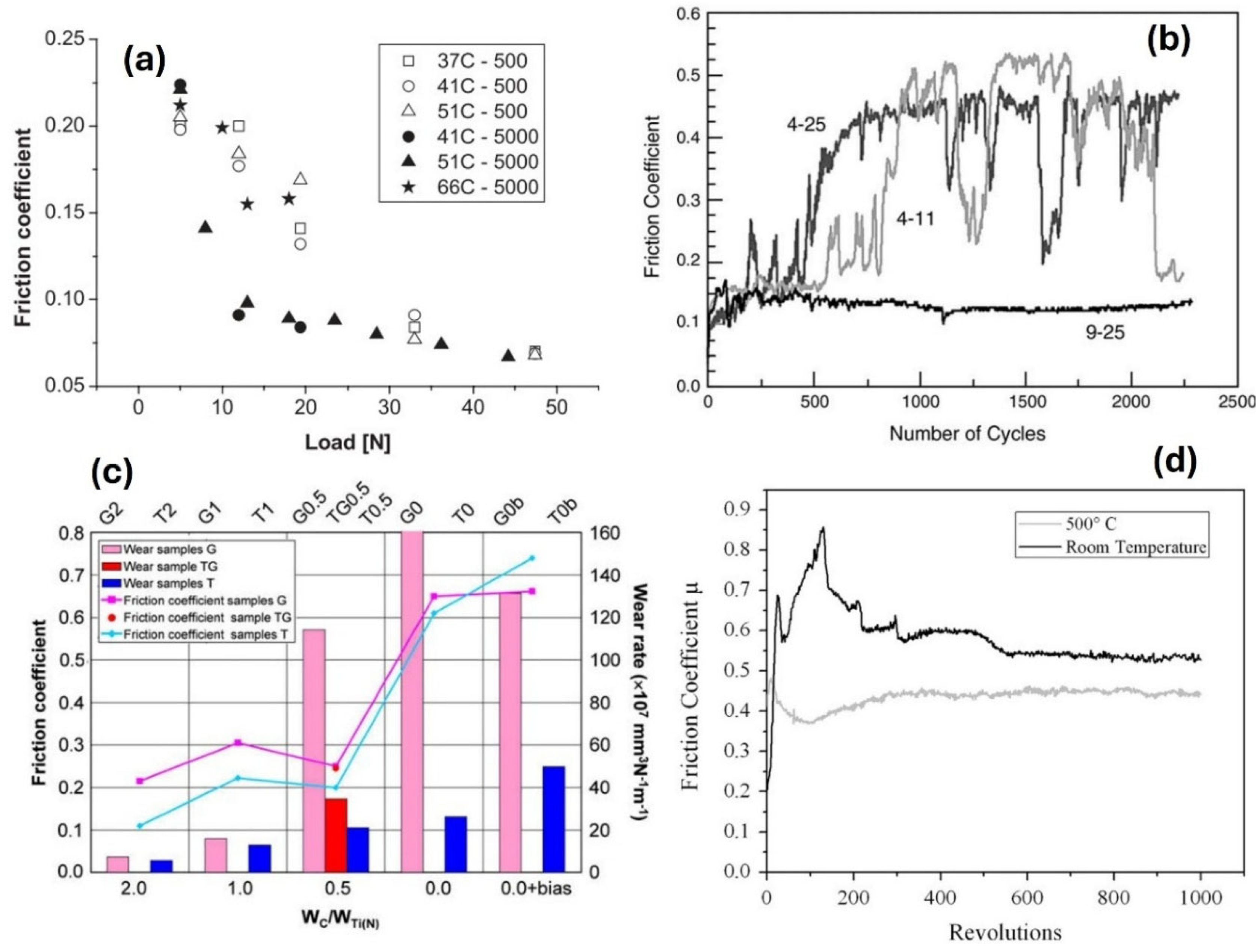

2.2. TMC-Based Coatings

2.3. DLC-Based Coatings

3. Optimization of Parameters

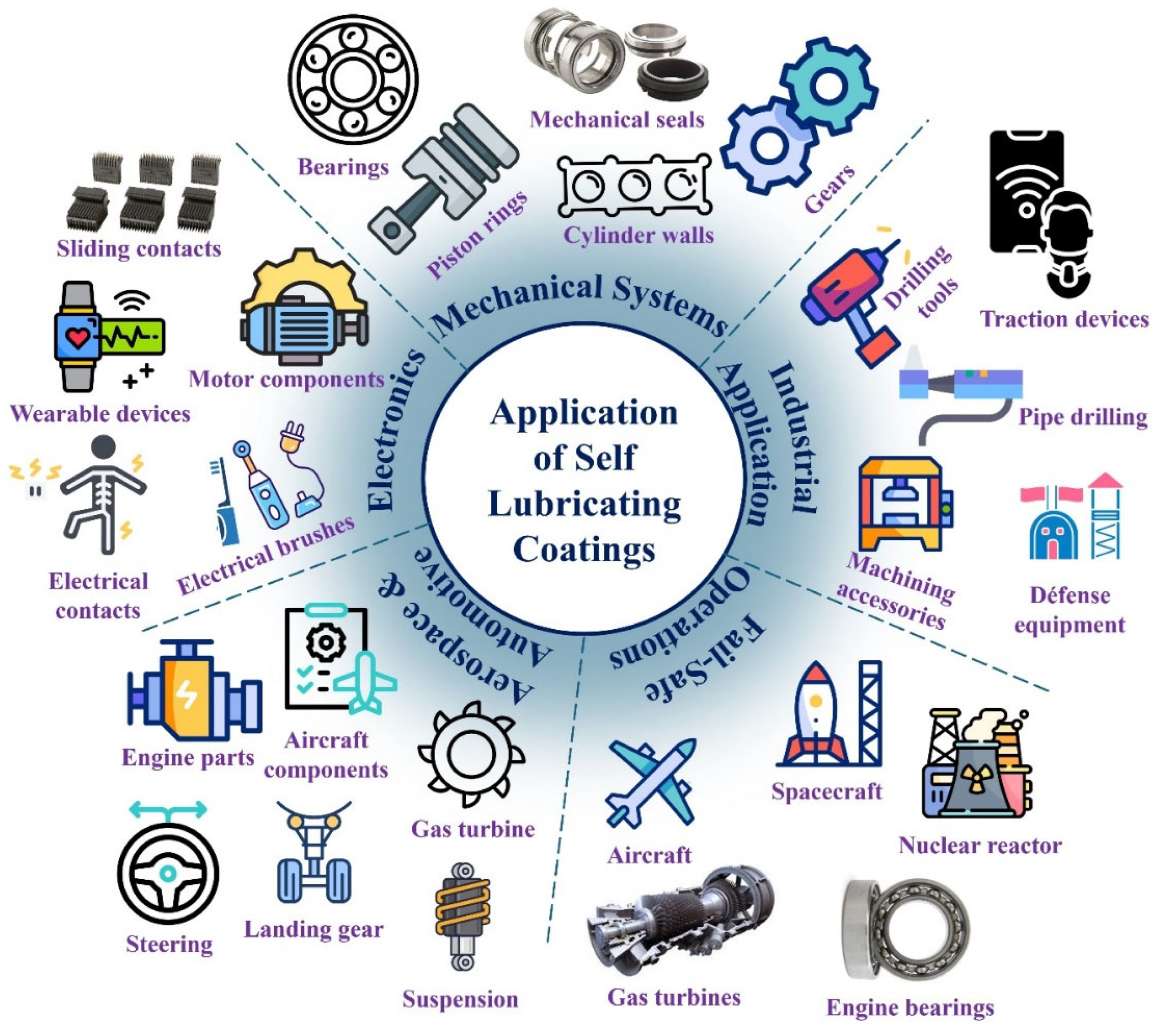

4. Advanced Applications

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Polcar, T.; Cavaleiro, A. Review on self-lubricant transition metal dichalcogenide nanocomposite coatings alloyed with carbon. Surf. Coat. Technol. 2011, 206, 686–695. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, M.; Tailor, S. Self-lubricating composite coatings: A review of deposition techniques and material advancement. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Akhtar, S.S. A critical review on self-lubricating ceramic-composite cutting tools. Ceram. Int. 2021, 47, 20745–20767. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Zouari, M.; Kharrat, M.; Dammak, M. Wear and friction analysis of polyester coatings with solid lubricant. Surf. Coat. Technol. 2010, 204, 2593–2599. [Google Scholar] [CrossRef]

- Pimentel, J.V.; Polcar, T.; Evaristo, M.; Cavaleiro, A. Examination of the tribolayer formation of a self-lubricant WSC sputtered coating. Tribol. Int. 2012, 47, 188–193. [Google Scholar] [CrossRef]

- John, M.; Menezes, P.L. Self-lubricating materials for extreme condition applications. Materials 2021, 14, 5588. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Historical developments and new trends in tribological and solid lubricant coatings. Surf. Coat. Technol. 2004, 180–181, 76–84. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. A Review to the Laser Cladding of Self-Lubricating Composite Coatings. Lasers Manuf. Mater. Process. 2016, 3, 67–99. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Zhang, Y.Z.; Wang, Y.M.; Wang, Y.J. High-Temperature Solid Lubricants and Self-Lubricating Composites: A Critical Review. Lubricants 2022, 10, 177. [Google Scholar] [CrossRef]

- Singer, I.L. Solid Lubricating Films for Extreme Environments. MRS Proc. 1988, 140, 215–226. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; He, Y. Solid Lubrication System and Its Plasma Surface Engineering: A Review. Lubricants 2023, 11, 473. [Google Scholar] [CrossRef]

- Yang, J.F.; Jiang, Y.; Hardell, J.; Prakash, B.; Fang, Q.F. Influence of service temperature on tribological characteristics of self-lubricant coatings: A review. Front. Mater. Sci. 2013, 7, 28–39. [Google Scholar] [CrossRef]

- Gautam, R.K.S.; Tyagi, R.; Singh, S.; Ali, S.; Kumar, S.; Nautiyal, H. Evaluation of tribological characteristics for HVOF deposited Ni based self-lubricating coatings with different h-BN composition. Surf. Coat. Technol. 2023, 464, 129549. [Google Scholar] [CrossRef]

- Gautam, R.K.S.; Tripathi, V.M.; Gautam, J.K.; Singhania, S.; Singh, S.; Jha, P.; Shahab, S.; Mishra, S.; Nautiyal, H. Elevated temperature tribological assessment of Ni-based cermet self-lubricating coatings deposited by cold spray. Surf. Coat. Technol. 2024, 477, 130380. [Google Scholar] [CrossRef]

- Yaqub, T.B.; Vuchkov, T.; Evaristo, M.; Cavaleiro, A. DCMS Mo-Se-C solid lubricant coatings—Synthesis, structural, mechanical and tribological property investigation. Surf. Coat. Technol. 2019, 378, 124992. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Wang, C.; Deng, C.; Mao, J.; Tan, X.; Li, W.; Zhang, P.; Wang, Q. Self-lubricating design strategy for thermally sprayed ceramic coatings by in-situ synthesis of carbon spheres. Surf. Coat. Technol. 2022, 446, 128759. [Google Scholar] [CrossRef]

- Fernandes, F.; Oliveira, J.C.; Cavaleiro, A. Self-lubricating TiSi(V)N thin films deposited by deep oscillation magnetron sputtering (DOMS). Surf. Coat. Technol. 2016, 308, 256–263. [Google Scholar] [CrossRef]

- Basnyat, P.; Luster, B.; Kertzman, Z.; Stadler, S.; Kohli, P.; Aouadi, S.; Xu, J.; Mishra, S.R.; Eryilmaz, O.L.; Erdemir, A. Mechanical and tribological properties of CrAlN-Ag self-lubricating films. Surf. Coat. Technol. 2007, 202, 1011–1016. [Google Scholar] [CrossRef]

- Wang, H.; Wang, H. Fabrication of self-lubricating coating on aluminum and its frictional behaviour. Appl. Surf. Sci. 2007, 253, 4386–4389. [Google Scholar] [CrossRef]

- Badisch, E.; Mitterer, C.; Mayrhofer, P.H.; Mori, G.; Bakker, R.J.; Brenner, J.; Störi, H. Characterization of tribo-layers on self-lubricating PACVD TiN coatings. Thin Solid Films 2004, 460, 125–132. [Google Scholar] [CrossRef]

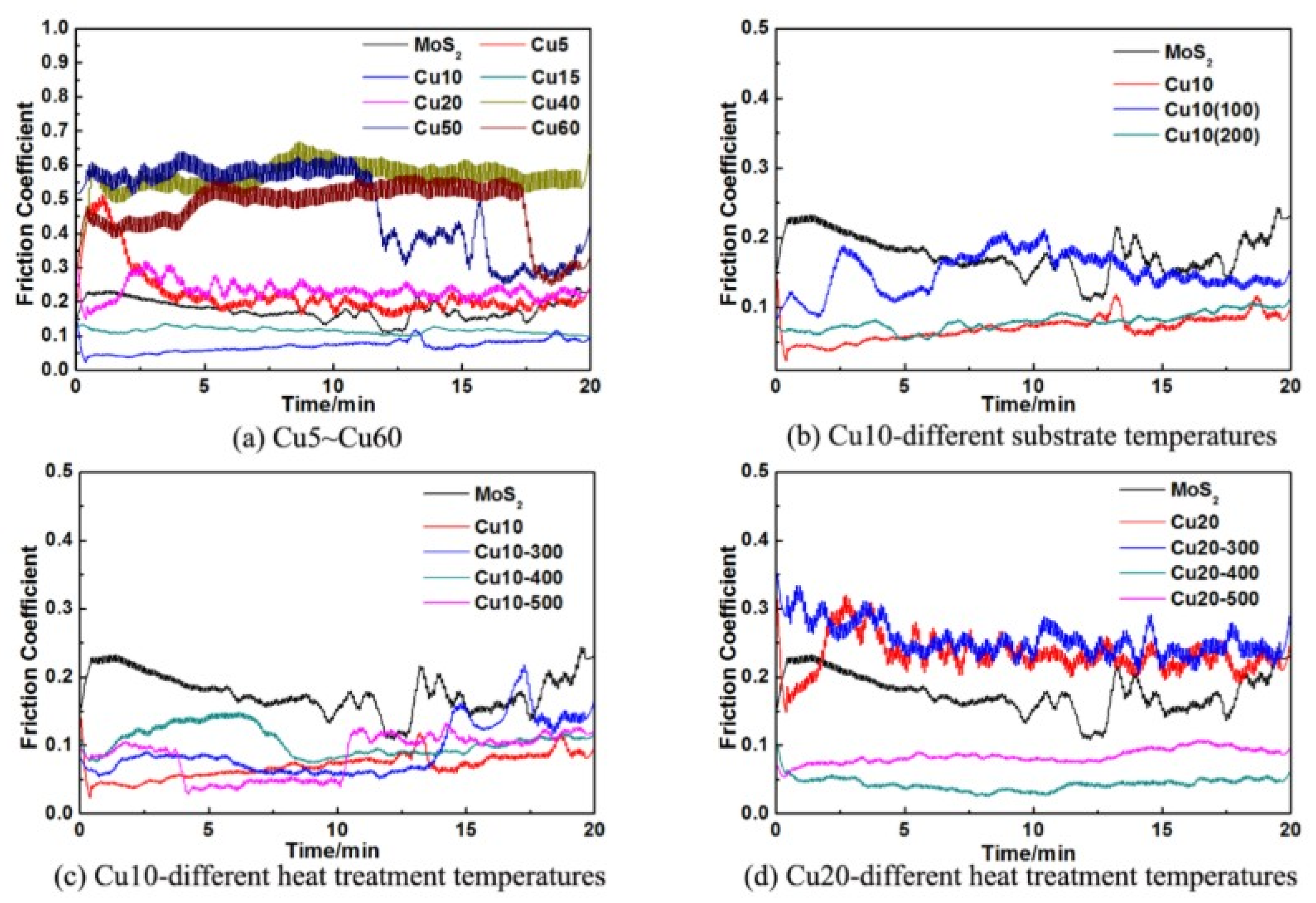

- Cao, M.; Zhao, L.; Wu, L.; Wang, W. Tribological properties of new Cu-Al/MoS2 solid lubricant coatings using magnetron sputter deposition. Coatings 2018, 8, 134. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Wang, Y.; Yan, C.; He, W. Nano-crystallization-Driven High Temperature Self-lubricating Properties of Magnetron-Sputtered WS2 Coatings. Tribol. Lett. 2020, 68, 50. [Google Scholar] [CrossRef]

- Mutafov, P.; Evaristo, M.; Cavaleiro, A.; Polcar, T. Structure, mechanical and tribological properties of self-lubricant W-S-N coatings. Surf. Coat. Technol. 2015, 261, 7–14. [Google Scholar] [CrossRef]

- Gu, L.; Ke, P.; Zou, Y.; Li, X.; Wang, A. Amorphous self-lubricant MoS2-C sputtered coating with high hardness. Appl. Surf. Sci. 2015, 331, 66–71. [Google Scholar] [CrossRef]

- Arslan, E.; Baran, Ö.; Efeoglu, I.; Totik, Y. Evaluation of adhesion and fatigue of MoS2-Nb solid-lubricant films deposited by pulsed-dc magnetron sputtering. Surf. Coat. Technol. 2008, 202, 2344–2348. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Lu, B.; Yu, W.; Wang, Y. Study on Microstructure and Properties of Al-Cu-Li/TiC Alloy. Mater. Sci. Eng. A 2024, 897, 146333. [Google Scholar] [CrossRef]

- Michael, P.C.; Rabinowicz, E.; Iwasa, Y. Friction and wear of polymeric materials at 293, 77 and 4.2 K. Cryogenics 1991, 31, 695–704. [Google Scholar] [CrossRef]

- Gamulya, G.D.; Kopteva, T.A.; Lebedeva, I.L.; Sentyurikhina, L.N. Effect of low temperatures on the wear mechanism of solid lubricant coatings in vacuum. Wear 1993, 160, 351–359. [Google Scholar] [CrossRef]

- Colbert, R.S.; Sawyer, G.W. Thermal dependence of the wear of molybdenum disulphide coatings. Wear 2010, 269, 719–723. [Google Scholar] [CrossRef]

- Maréchal, N.; Pauleau, Y.; Quesnel, E.; Juliet, P.; Rouzaud, A.; Zimmermann, C. Sputter-deposited lubricant thin films operating at elevated temperatures in air. Surf. Coat. Technol. 1994, 68–69, 416–421. [Google Scholar] [CrossRef]

- Kloos, K.H.; Bruszeit, E.; Gabriel, H.M. Tribological properties of soft metallic coatings deposited by conventional and thermionically assisted triode ion plating. Thin Solid Films 1981, 80, 307–319. [Google Scholar] [CrossRef]

- Ito, H.; Yamamoto, K.; Masuko, M. Thermal stability of UBM sputtered DLC coatings with various hydrogen contents. Thin Solid Films 2008, 517, 1115–1119. [Google Scholar] [CrossRef]

- Prasad, S.V.; Zabinski, J.S. Tribological behavior of nanocrystalline zinc oxide films. Wear 1997, 203–204, 498–506. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Rao, A.U.; Verma, P.C.; Pant, G.; Avasthi, D.K.; Sen, S.; Chawla, A.K. Investigation of microstructural and mechanical properties of sputter-deposited Ni 3 Al films at different substrate temperatures. Radiat. Eff. Defects Solids 2024, 179, 909–920. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Rao, A.U.; Kharb, A.S.; Chawla, V.; Pandey, J.K.; Saxena, V.; Sardana, N.; Avasthi, D.K.; Chawla, A.K. Microstructural and Mechanical Properties of Cr-Ni3Al Alloy Films Synthesized by Magnetron Sputtering. J. Mater. Eng. Perform. 2023, 33, 8994–9003. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Rao, A.U.; Kharb, A.S.; Verma, P.C.; Dubey, P.; Chawla, V.; Sardana, N.; Kumar, S.; Avasthi, D.K.; Chawla, A.K. Sputter-deposited zirconium doped nickel-aluminide coatings for high-temperature oxidation-resistant applications. J. Vac. Sci. Technol. A 2024, 42, 053408. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Rao, A.U.; Kharb, A.S.; Chawla, A.K.; Avasthi, D.K. A review of mechanical and tribological properties of Ni 3 Al-based coatings-synthesis and high-temperature behavior. Phys. Scr. 2023, 98, 72001. [Google Scholar] [CrossRef]

- Rao, A.U.; Tiwari, S.K.; Kharb, A.S.; Sardana, N.; Chawla, V.; Kumar, S.; Saxena, V.; Chawla, A.K. Synthesis and characterization of low-friction W-V-N alloy coatings using reactive magnetron sputtering technique for tribological applications. J. Vac. Sci. Technol. A 2024, 42, 023408. [Google Scholar] [CrossRef]

- Rao, A.U.; Tiwari, S.K.; Kharb, A.S.; Hothi, N.; Saxena, V.; Chawla, A.K. Harnessing innovative sputtering approaches to enhance VN coatings with superior mechanical and self-lubricating properties. J. Mater. Sci. 2025, 60, 7429–7465. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. Self-adaptive low friction coatings based on transition metal dichalcogenides. Thin Solid Films 2011, 519, 4037–4044. [Google Scholar] [CrossRef]

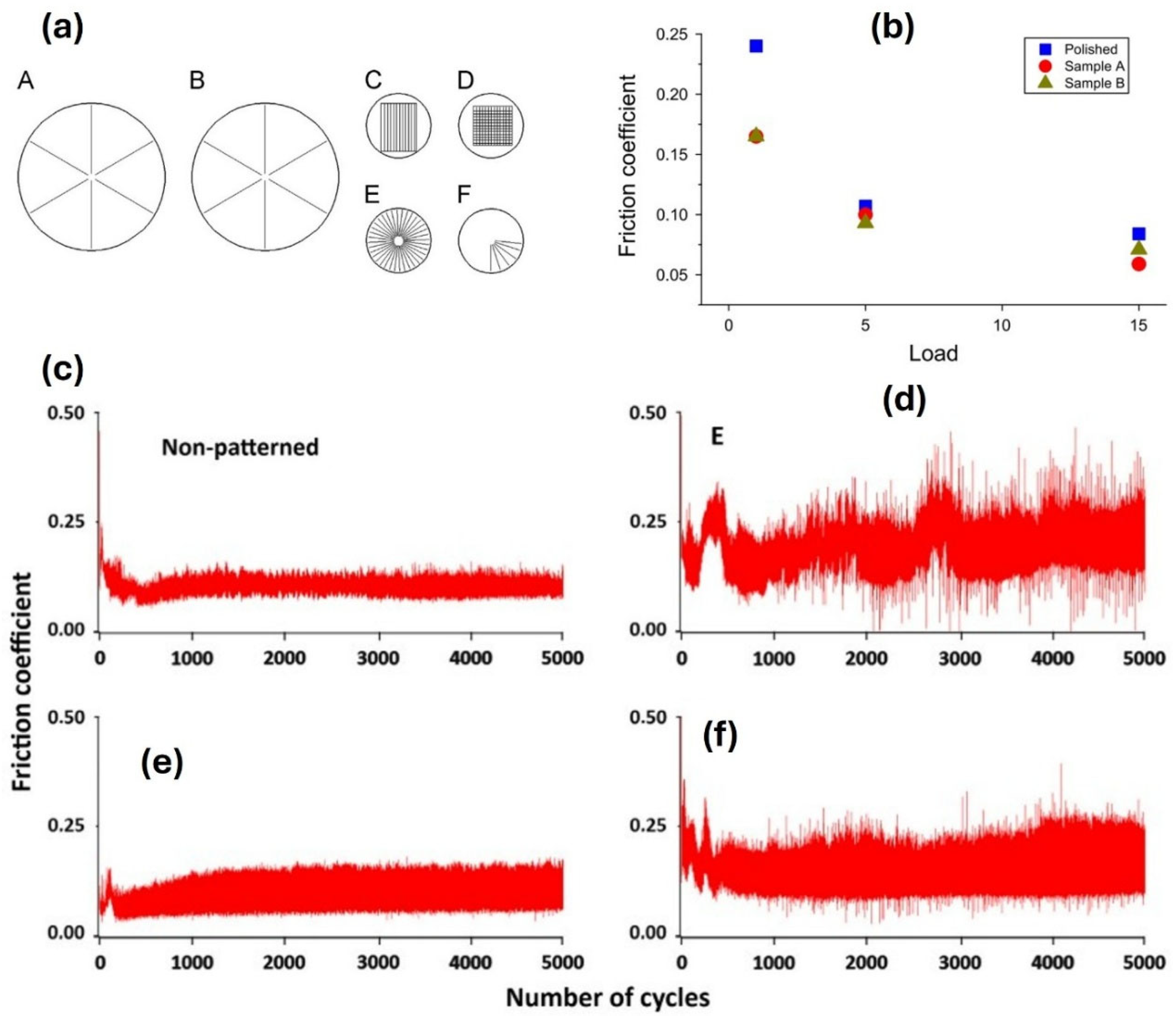

- Pimentel, J.V.; Danek, M.; Polcar, T.; Cavaleiro, A. Effect of rough surface patterning on the tribology of W-S-C-Cr self-lubricant coatings. Tribol. Int. 2014, 69, 77–83. [Google Scholar] [CrossRef]

- Tillmann, W.; Momeni, S.; Hoffmann, F. A study of mechanical and tribological properties of self-lubricating TiAlVN coatings at elevated temperatures. Tribol. Int. 2013, 66, 324–329. [Google Scholar] [CrossRef]

- Polcar, T.; Evaristo, M.; Cavaleiro, A. Comparative study of the tribological behavior of self-lubricating W-S-C and Mo-Se-C sputtered coatings. Wear 2009, 266, 388–392. [Google Scholar] [CrossRef]

- Huang, Y.Z.; Stueber, M.; Hovsepian, P. The significance of carbon on the microstructure of TiAlN{single bond}C coatings deposited by reactive magnetron sputtering. Appl. Surf. Sci. 2006, 253, 2470–2473. [Google Scholar] [CrossRef]

- Guleryuz, C.G.; Krzanowski, J.E. Mechanisms of self-lubrication in patterned TiN coatings containing solid lubricant microreservoirs. Surf. Coat. Technol. 2010, 204, 2392–2399. [Google Scholar] [CrossRef]

- Renevier, N.M.; Hamphire, J.; Fox, V.C.; Witts, J.; Allen, T.; Teer, D.G. Advantages of using self-lubricating, hard, wear-resistant MoS2-based coatings. Surf. Coat. Technol. 2001, 142–144, 67–77. [Google Scholar] [CrossRef]

- Athmani, M.; Kong, F.L.; Ju, H.; Luan, J.; Zhang, C.; Ma, B.; Cavaleiro, A.; Fernandes, F. RF magnetron sputtered Nb–V–N composite coatings for high-temperature self-lubricant applications. Vacuum 2024, 219, 112657. [Google Scholar] [CrossRef]

- Martínez-Martínez, D.; López-Cartes, C.; Justo, A.; Fernández, A.; Sánchez-López, J.C. Self-lubricating Ti-C-N nanocomposite coatings prepared by double magnetron sputtering. Solid State Sci. 2009, 11, 660–670. [Google Scholar] [CrossRef]

- Ma, S.L.; Ma, D.Y.; Guo, Y.; Xu, B.; Wu, G.Z.; Xu, K.W.; Chu, P.K. Synthesis and characterization of super hard, self-lubricating Ti-Si-C-N nanocomposite coatings. Acta Mater. 2007, 55, 6350–6355. [Google Scholar] [CrossRef]

- Incerti, L.; Rota, A.; Valeri, S.; Miguel, A.; García, J.A.; Rodríguez, R.J.; Osés, J. Nanostructured self-lubricating CrN-Ag films deposited by PVD arc discharge and magnetron sputtering. Vacuum 2011, 85, 1108–1113. [Google Scholar] [CrossRef]

- Luo, J.; Liu, X.B.; Xiang, Z.F.; Shi, S.H.; Chen, Y.; Shi, G.L.; Wu, S.H.; Wu, Y.N. Synthesis of High-Temperature Self-lubricating Wear Resistant Composite Coating on Ti6Al4V Alloy by Laser Deposition. J. Mater. Eng. Perform. 2015, 24, 1881–1889. [Google Scholar] [CrossRef]

- Kumar, D.D.; Kumar, N.; Kalaiselvam, S.; Radhika, R.; Maximus Rabel, A.; Jayavel, R. Tribo-mechanical properties of reactive magnetron sputtered transition metal carbide coatings. Tribol. Int. 2017, 114, 234–244. [Google Scholar] [CrossRef]

- Polcar, T.; Evaristo, M.; Cavaleiro, A. Friction of self-lubricating W-S-C sputtered coatings sliding under increasing load. Plasma Process. Polym. 2007, 4, 541–546. [Google Scholar] [CrossRef]

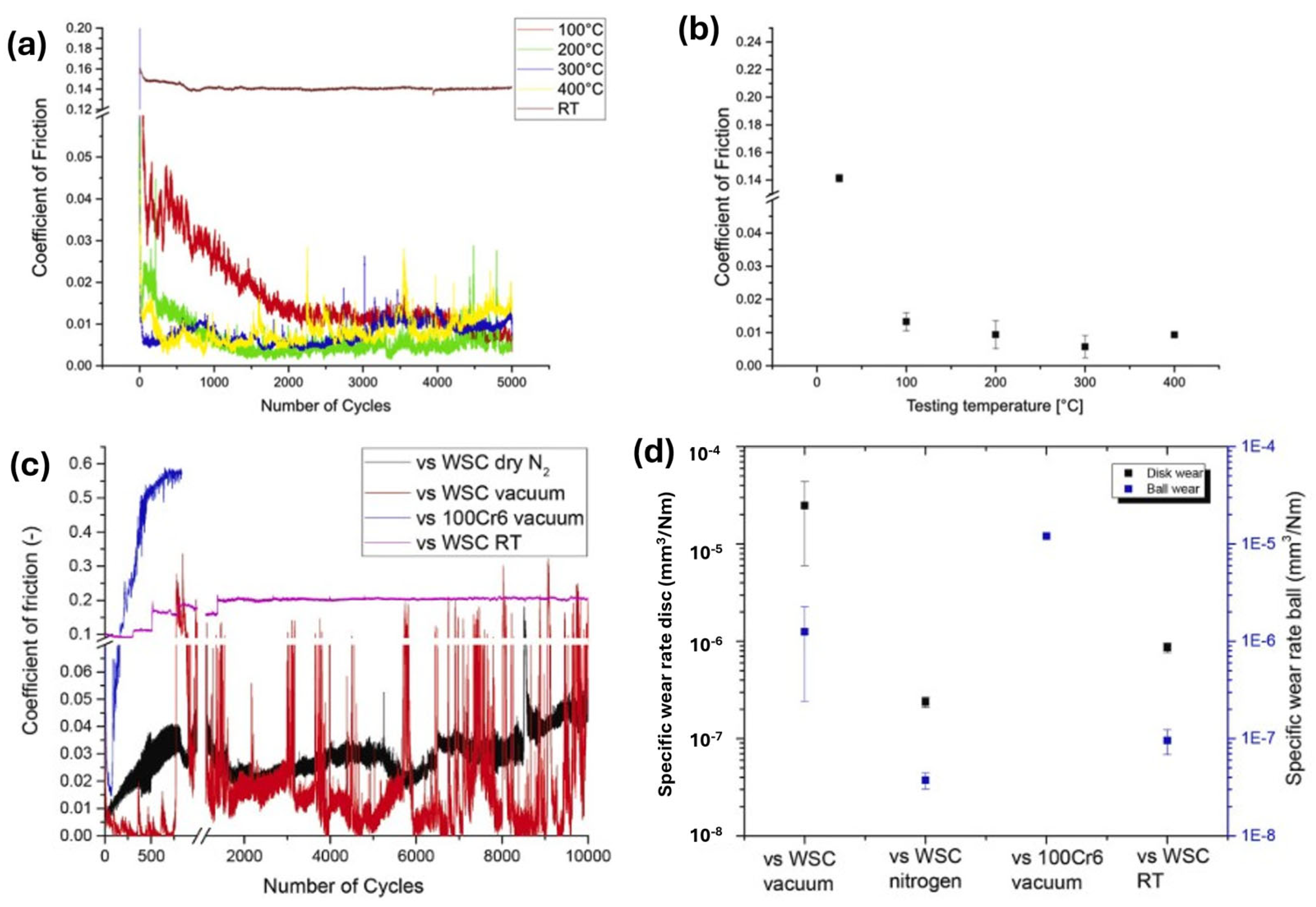

- Vuchkov, T.; Evaristo, M.; Yaqub, T.B.; Polcar, T.; Cavaleiro, A. Synthesis, microstructure and mechanical properties of W–S–C self-lubricant thin films deposited by magnetron sputtering. Tribol. Int. 2020, 150, 106363. [Google Scholar] [CrossRef]

- Chen, Z.; Qiao, L.; Hillairet, J.; Song, Y.; Turq, V.; Wang, P.; Laloo, R.; Bernard, J.M.; Lu, K.; Cheng, Y.; et al. Development and characterization of magnetron sputtered self-lubricating Au-Ni/a-C nano-composite coating on CuCrZr alloy substrate. Appl. Surf. Sci. 2019, 492, 540–549. [Google Scholar] [CrossRef]

- Vuchkov, T.; Yaqub, T.B.; Evaristo, M.; Cavaleiro, A. Synthesis, microstructural and mechanical properties of self-lubricating Mo-Se-C coatings deposited by closed-field unbalanced magnetron sputtering. Surf. Coat. Technol. 2020, 394, 125889. [Google Scholar] [CrossRef]

- Fiaschi, G.; Rota, A.; Ballestrazzi, A.; Marchetto, D.; Vezzalini, E.; Valeri, S. A chemical, mechanical, and tribological analysis of DLC coatings deposited by magnetron sputtering. Lubricants 2019, 7, 38. [Google Scholar] [CrossRef]

- Guo, C.Q.; Lin, S.S.; Gao, D.; Shi, Q.; Wei, C.B.; Dai, M.J.; Su, Y.F.; Xu, W.; Tang, P.; Li, H.; et al. Modulation of Si on microstructure and tribo-mechanical properties of hydrogen-free DLC films prepared by magnetron sputtering. Appl. Surf. Sci. 2020, 509, 145381. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, M.; Yang, Y.; Zhang, Y.; Yan, F.; Li, H. Excellent mechanical, tribological and anti-corrosive performance of novel Ti-DLC nanocomposite thin films prepared via magnetron sputtering method. Carbon 2019, 151, 136–147. [Google Scholar] [CrossRef]

- Asikainen, T.; Ritala, M.; Markku, L. ALD grown Zr-doped In2O3 films. Thin Solid Films 2003, 440, 60–65. [Google Scholar] [CrossRef]

- Lugscheider, E.; Bärwulf, S.; Barimani, C. Properties of tungsten and vanadium oxides deposited by MSIP-PVD process for self-lubricating applications. Surf. Coat. Technol. 1999, 120–121, 458–464. [Google Scholar] [CrossRef]

- House, T.H.E.P.; The, O.F.; Academy, R. Tribological Properties of Solid Lubricant Nanocomposite Coatings Obtained By Magnetron Sputtered of MoS2/Metal (Ti, Mo). World 2007, 8, 1–5. [Google Scholar]

- Mu, M.; Zhou, X.; Xiao, Q.; Liang, J.; Huo, X. Preparation and tribological properties of self-lubricating TiO2/graphite composite coating on Ti6Al4V alloy. Appl. Surf. Sci. 2012, 258, 8570–8576. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhang, P.; Yu, Z.; Li, C.; Xu, P.; Lu, Y. Laser cladding of Co-based alloy/TiC/CaF2 self-lubricating composite coatings on copper for continuous casting mold. Surf. Coat. Technol. 2013, 232, 362–369. [Google Scholar] [CrossRef]

- Dominguez-Meister, S.; Justo, A.; Sanchez-Lopez, J.C. Synthesis and tribological properties of WSex films prepared by magnetron sputtering. Mater. Chem. Phys. 2013, 142, 186–194. [Google Scholar] [CrossRef]

- Fernandes, F.; Polcar, T.; Cavaleiro, A. Tribological properties of self-lubricating TiSiVN coatings at room temperature. Surf. Coat. Technol. 2015, 267, 8–14. [Google Scholar] [CrossRef]

- Torres, H.; Vuchkov, T.; Rodríguez Ripoll, M.; Prakash, B. Tribological behaviour of MoS2-based self-lubricating laser cladding for use in high temperature applications. Tribol. Int. 2018, 126, 153–165. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Hoffmann, D.C.; Klocke, F.; Mattfeld, P.; Trauth, D.; Hild, R. Tribological studies on self-lubricating (Cr,Al)N+Mo:S coatings at elevated temperature. Surf. Coat. Technol. 2018, 353, 282–291. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Liu, X.B.; Zhuang, S.G.; Yang, X.H.; Wang, M.; Sun, C.F. Preparation and high temperature tribological properties of laser in-situ synthesized self-lubricating composite coatings containing metal sulfides on Ti6Al4V alloy. Appl. Surf. Sci. 2019, 481, 209–218. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, Y.; Xu, B.; Lu, Y.; Zhou, C.; Wu, X.; Li, J. Fabrication and tribological properties of a self-lubricating wear-resistant coating based on structural coupling. Ceram. Int. 2019, 45, 3910–3920. [Google Scholar] [CrossRef]

- Gautam, R.K.S.; Rao, U.S.; Tyagi, R. High temperature tribological properties of Ni-based self-lubricating coatings deposited by atmospheric plasma spray. Surf. Coat. Technol. 2019, 372, 390–398. [Google Scholar] [CrossRef]

- Yuan, J.; Yao, Y.; Zhuang, M.; Du, Y.; Wang, L.; Yu, Z. Effects of Cu and WS2 addition on microstructural evolution and tribological properties of self-lubricating anti-wear coatings prepared by laser cladding. Tribol. Int. 2021, 157, 106872. [Google Scholar] [CrossRef]

- Liu, S.; Pang, M.; Ji, F. Tribological properties of laser cladding nickel-based WC reinforced Ag self-lubricating coating on RuT450 surface. Opt. Laser Technol. 2023, 163, 109393. [Google Scholar] [CrossRef]

- Wang, B.; Lai, W.; Li, S.; Huang, S.; Zhao, X.; You, D.; Tong, X.; Li, W.; Wang, X. Self-lubricating coating design strategy for titanium alloy by additive manufacturing. Appl. Surf. Sci. 2022, 602, 154333. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Rao, A.U.; Kharb, A.S.; Chawla, V.; Sardana, N.; Avasthi, D.K.; Chawla, A.K. Investigation of mechanical and microstructural properties of sputter-deposited Zr-Ni3Al coatings. J. Vac. Sci. Technol. A 2023, 41, 063407. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Rao, A.U.; Chawla, V.; Pant, G.; Verma, P.C.; Gunupuru, R.; Avasthi, D.K.; Pandey, J.K.; Chawla, A.K. Effect of Ni Enrichment on the Microstructure, Mechanical, and Tribological Properties of Hydrophobic Ni3Al Alloy Coatings. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Zhou, C.; Li, T.; Wei, X.; Yan, B. Effect of the sputtering power on the structure, morphology and magnetic properties of fe films. Metals 2020, 10, 896. [Google Scholar] [CrossRef]

- Posadowski, W.M.; Wiatrowski, A.; Dora, J.; Radzimski, Z.J. Magnetron sputtering process control by medium-frequency power supply parameter. Thin Solid Films 2008, 516, 4478–4482. [Google Scholar] [CrossRef]

- Chan, K.Y.; Teo, B.S. Sputtering power and deposition pressure effects on the electrical and structural properties of copper thin films. J. Mater. Sci. 2005, 40, 5971–5981. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Zhou, Y.; Fu, H.; Zhang, Z.; Xiang, G.; Zhao, Y.; Zhuang, S.; Yang, F.; Wang, H. Effect of sputtering power on the structural and optical properties of InN nanodots on Al2O3 by magnetron sputtering. Mater. Res. 2020, 22, e20190380. [Google Scholar] [CrossRef]

- Nair, P.B.; Justinvictor, V.B.; Daniel, G.P.; Joy, K.; Ramakrishnan, V.; Thomas, P.V. Effect of RF power and sputtering pressure on the structural and optical properties of TiO2 thin films prepared by RF magnetron sputtering. Appl. Surf. Sci. 2011, 257, 10869–10875. [Google Scholar] [CrossRef]

- Murakami, M.; Birukawa, M. Sputtering gases and pressure effects on the microstructure, magnetic properties and recording performance of TbFeCo films. J. Magn. Magn. Mater. 2008, 320, 608–611. [Google Scholar] [CrossRef]

- Jia, Z.C.; Zhu, J.Q.; Jiang, C.Z.; Shen, W.X.; Han, J.C.; Chen, R.R. Effect of gas flow ratio on the microstructure and mechanical properties of boron phosphide films prepared by reactive magnetron sputtering. Appl. Surf. Sci. 2011, 258, 356–360. [Google Scholar] [CrossRef]

- Liu, E.; Jin, G.; Cui, X.; Xiao, Q.; Shao, T. Effect of gas pressure on the mechanical properties of sputtered tan films. Phys. Procedia 2013, 50, 438–441. [Google Scholar] [CrossRef]

- Cao, H.; Zhang, C.; Chu, J. The effect of working gas pressure and deposition power on the properties of molybdenum films deposited by DC magnetron sputtering. Sci. China Technol. Sci. 2014, 57, 947–952. [Google Scholar] [CrossRef]

- Al-Mansoori, M.; Al-Shaibani, S.; Al-Jaeedi, A.; Lee, J.; Choi, D.; Hasoon, F.S. Effects of gas flow rate on the structure and elemental composition of tin oxide thin films deposited by RF sputtering. AIP Adv. 2017, 7, 125105. [Google Scholar] [CrossRef]

- OuYang, C.S.; Liu, X.B.; Luo, Y.S.; Liang, J.; Wang, M.; Chen, D.Q. Preparation and high temperature tribological properties of laser in-situ synthesized self-lubricating composite coating on 304 stainless steel. J. Mater. Res. Technol. 2020, 9, 7034–7046. [Google Scholar] [CrossRef]

- Yang, H.; Qin, L.; Wang, F.; Mawignon, F.J.; Dong, M.; Wu, Y.; Zhang, Y.; Ma, Z. A facile method to fabricate the durable and self-protective coating for marine applications. Surf. Coat. Technol. 2023, 452, 129124. [Google Scholar] [CrossRef]

- Jeffrey, R. Lince Effective Application of Solid Lubricants in Spacecraft Mechanisms. Lubricants 2020, 8, 74. [Google Scholar]

- Friedman, H.; Eidelman, O.; Feldman, Y.; Moshkovich, A.; Perfiliev, V.; Rapoport, L.; Cohen, H.; Yoffe, A.; Tenne, R. Fabrication of self-lubricating cobalt coatings on metal surfaces. Nanotechnology 2007, 18, 115703. [Google Scholar] [CrossRef]

| Coating | S-T Distance | Substrate Bias (V) | Power Applied to Targets (W/cm2) | Elemental Composition (at%) | S/W Ratio | Thickness (μm)/Deposition Rate (nm/min) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| WS2 | C (x2) | C | S | O | W | |||||

| WSC1-10 | 10 | 0 | 2.1 | 2.6 | 44.0 | 28.5 | 4.9 | 22.6 | 1.26 | 2/16.7 |

| WSC1-15 | 15 | 0 | 2.1 | 2.6 | 40.2 | 32.5 | 5.2 | 22.1 | 1.47 | 2.3/19.2 |

| WSC1-15 | 25 | 0 | 2.1 | 2.6 | 38.1 | 35.1 | 5.8 | 21.1 | 1.66 | 1.6/13.3 |

| WSC1-10 | 10 | 50 | 2.1 | 2.6 | 45.8 | 25.1 | 3.1 | 26.0 | 0.96 | 1.8/15 |

| WSC1-15 | 15 | 50 | 2.1 | 2.6 | 48.2 | 24.0 | 2.8 | 25.0 | 0.96 | 1.7/14.2 |

| WSC1-15 | 25 | 50 | 2.1 | 2.6 | 40.8 | 32.7 | 2.8 | 23.7 | 1.38 | 1/8.3 |

| WSC1-10 | 10 | 0 | 2.1 | 3.2 | 57.6 | 20.1 | 2.4 | 20.0 | 1.01 | 2/16.4 |

| WSC1-15 | 15 | 0 | 2.1 | 3.2 | 52.2 | 26.1 | 1.5 | 20.2 | 1.29 | 2/16.3 |

| WSC1-15 | 25 | 0 | 2.1 | 3.2 | 53.0 | 27.5 | 2.4 | 17.1 | 1.61 | 1.6/13.1 |

| Sample | Power Supply to Individual Targets | Heating Temperature | ||

|---|---|---|---|---|

| MoS2 | Cu | Al | ||

| Cu5 | 100 | 5 | 0 | RT |

| Cu10 | 100 | 10 | 0 | RT |

| Cu20 | 100 | 20 | 0 | RT |

| Cu40 | 100 | 40 | 0 | RT |

| Cu50 | 100 | 50 | 0 | RT |

| Cu60 | 100 | 60 | 0 | RT |

| Cu10 | 100 | 10 | 0 | 100 °C |

| Cu10 | 100 | 10 | 0 | 200 °C |

| Cu5Al5 | 100 | 5 | 5 | RT |

| Cu5Al10 | 100 | 5 | 10 | RT |

| Cu10Al5 | 100 | 5 | 10 | RT |

| Cu10Al10 | 100 | 10 | 5 | RT |

| Cu10Al10 | 100 | 10 | 10 | RT |

| Cu5Al10 | 100 | 5 | 5 | 100 °C |

| Cu5Al10 | 100 | 5 | 5 | 200 °C |

| Authors | Method of Fabrication | Matrix Material | Dopants | Friction Coefficient | Specific Wear Rate | Remarks | Ref. |

|---|---|---|---|---|---|---|---|

| Kloos et al. | Ion plating | Copper, | Pb, In, Ag | 0.08 for copper; 0.2 for Cu-In | - | Cu-In is better than Cu-Pb. | [32] |

| Lugscheider et al. | Magnetron sputter-ion plating | V2O5 and WO2.9 | - | A 2–5% oxygen and argon ratio gave the best results | - | O2 to Ar (0–50%) variation; substrate temperature of 400 °C | [62] |

| Basnyat et al. | Co-sputtering | CrAlN | Ag | 0.23 | 3.0 × 10−8 | These results are for 8% Ag. | [19] |

| Wang et al. | Anodization | PTFE | Al | - | - | The weight change after wear is 0.0022. | [19] |

| Ma et al. | PECVD | Ti-Si-C-N and Ti-Si-N | - | 0.75 for Ti-Si-N and 0.35 for Ti-Si-C-N | - | - | [50] |

| Filip et al. | Magnetron sputtering | MoS2 | Ti and Mo | 0.05 for MoS2 coatings, 0.03 for Ti/MoS2 coatings, and 0.08 for Mo/MoS2 coatings | - | A tribological test was performed for 36,000 cycles. | [63] |

| Incerti et al. | Arc discharge and magnetron sputtering | CrN | Ag | 0.75 for coatings at Rt and 0.78 for coatings at 400 °C | - | Ag clusters helped maintain a COF of 0.23. | [51] |

| Ming et al. | Plasma electrolytic oxidation (PEO) process | TiO2 and graphite | Oxygen | The COF for the uncoated substrate is ~0.35 to 0.45; the TiO2/graphite coating has a COF of 0.15. | 5.2 × 10−5 mm3/N m for the substrate and 1.7 × 10−5 mm3/N m for TiO2 coatings | The substrate used was Ti6Al4V. | [64] |

| Yan et al. | Laser cladding | Co | TiC and CaF2 | ~0.31 to 0.24 for Co-based coatings and 0.24, 0.19, 0.22 for 0%. 10%, and 20% CaF2, respectively. | - | Cr-Zr-Cu was used as a substrate; laser cladding was performed at 400 °C. | [65] |

| Meister et al. | Non-reactive RF magnetron sputtering | WSe2 | WC | 0.07 in atmospheric air and 0.03 in a nitrogen environment | 2 × 10−5 mm3 Nm−1 for non-heated samples and 3 × 10−7 mm3 Nm−1 for modulated bias samples | Coatings were deposited on Si substrates. The hardness of the films was nearly 4 to 5 GPa. | [66] |

| Gu et al. | DC magnetron sputtering | MoS2 | Carbon (graphite target) | Less than 0.1 for MoS2-C coatings | The wear rate of MoS2-C coatings was ~10−7 mm3/Nm. | The sliding time for the tribological test was 3600 s. | [25] |

| Fernandes et al. | DC reactive magnetron sputtering | TiN | Silicon and vanadium | ~1.09 to 1.15 for TiSiN coatings and 0.5 for TiSiVN coatings | - | Films were deposited over Si and steel. | [67] |

| Torres et al. | Laser cladding | NiCrSiB powder | Ag and MoS2 | 1.1 for most of the tests, but ~0.5 to 0.8 for 10 MoS2 and ~0.5 to 0.5 for Ag-10 MoS2 | 5.6 × 10−5 mm3/Nm for the nickel-based alloy and 2.7 × 10−5 mm3/Nm for the 5Ag-10MoS2 base alloy | The film was deposited over 1.4301 grade steel substrate. | [68] |

| Bobzin et al. | DC and high-power pulse magnetron sputtering | CrAlN | Mo:S | 0.77 for the uncoated AISI M2 sample | - | Films were deposited on cold-worked steel substrates AISI D2 and AISI M2. | [69] |

| Zhou et al. | Laser cladding | Ni60-16.8TiC-23.2WS2 as the Ni coating and Ni60-19.6TiC-20.4WS2 as the N2 coating | Ni and Cr as the main phase elements | The COF of the N1 and N2 coatings at different testing temperatures of 20 °C, 300 °C, 600 °C, and 800 °C are 0.444/0.489, 0.393/0.433, 0.357/0.440, and 0.321/0.404, respectively. | The wear rates of the N1 and N2 coatings at different testing temperatures of 20 °C, 300 °C, 600 °C, and 800 °C are 1.4 × 10−4/1.1 × 10−4, 5.9 × 10−5/4.8 × 10−5, 3.7 × 10−5/4.5 × 10−5, and 2.9 × 10−5/2.3 × 10−5 mm3/Nm, respectively. | The films were deposited over Ti6Al4V substrates. | [70] |

| Zhau et al. | Laser cladding + vacuum pressure thermal diffusion welding | NiCrSiB | WUs | 0.38 for the as-received substrate, 0.43 for NiCrSiB coatings, 0.14 for Cu-G coatings, and 0.12 for SSWC | 1.09 × 10−3 mm3/Nm for SSWC, ~4.83 × 10−4 mm3/Nm for the substrate, and 3.28 × 10−5 mm3/Nm for NiCrSiB coatings | SSWC 316 L steel was used as a substrate. | [71] |

| Gautam et al. | Atmospheric plasma spray | Ni-Al-Ag-MoS2 | hBN | 0.5 and 0.23 for Ni-Al-Ag-MoS2-5 wt% hBN at RT and 800 °C, respectively | - | The variation in hBN was fixed as 5 wt% hBN and 10 wt% hBN. | [72] |

| Zhu et al. | Magnetron sputtering | WS2 | - | 0.06 before 1200 s of the test and 0.09 at the end of the test; 0.07 at 100 °C and 0.2 at 300 °C | - | Films were deposited over high-speed steel substrates with a thickness of ~2.2 μm. | [23] |

| Yuan et al. | Laser cladding | NiCr/TiC | Cu and WS2 | 0.61 for NiCr/TiC, 0.4 for NiCr/TiC-Cu, and <0.4 for NiCr/TiC-WS2 | - | Films were deposited over 30CrMnSi steel substrates. | [73] |

| Liu et al. | Laser cladding | 46% nickel-coated WC | 718-WC + 8% Ag | 0.20 for substrates, 0.379 for the coating at 700 W laser power, and 0.335 for the coating at 1000 W laser power | 3.68281 × 10−5, 1.59918 × 10−5, and 0.93687 × 10−5 mm3/Nm at RT for the substrate and 700 W and 1000 W laser power coatings, respectively | Coatings were deposited on cast iron (RuT450) substrates. | [74] |

| Influencing Parameters | Effect on Coatings |

|---|---|

| Base pressure | Protects from contamination (ex-oxidation) |

| Working pressure | Influences the mean free path |

| Sputtering power | Influences the deposition rate and sputtering yield, and can generate stress in the coatings |

| Gas flow rate | Maintains the required pressure; influences the sputtering yield |

| Substrate–target distance | Impact on the film thickness |

| Substrate temperature | Enhances crystallization and adhesion |

| Substrate rotation | Enhances uniform and dense coatings |

| Bias voltage | Enhances adhesion and film density; increases residual stress |

| Dopants used | Alters the chemical composition and affects the film’s properties |

| Power source | Affects the film thickness and sputtering yield |

| Deposition time | Affects the film thickness and uniformity in microstructure |

| Post-deposition treatments | Alters the microstructural, topographical, and film properties |

| SN | Materials Used | Area of Application | Drawbacks | Future Scope |

|---|---|---|---|---|

| 1. | Nitride coatings like VN, TIN, CrN, TiAlN, and WN | Machine shops like cutting tools, bearings, dies, and actuators | A high COF in a moist environment, with a challenge in lubrication at low temperatures | It can be doped with V, W, and Mo, which enhance the lubricating properties |

| 2. | TMC-based coatings | Engine parts of an automobiles and aircraft, vacuum systems, and instruments | Problem of oxidation at elevated temperatures | Can be fabricated in the form of nano-composite coatings, which possess improved oxidation-resistant properties |

| 3. | DLC-based coatings | Generally used in bioimplants and precision tools | The problem of adhesion between coatings and substrates, and the problem of high-temperature stability | Use of high-temperature stable dopants in the matrix of DLC coatings |

| 4. | TMD-based coatings | Used in cryogenic environments and dry bearing equipment | Loss of mechanical and tribological properties at different temperature ranges | TMDs can be deposited in hybrid form using different metal layers |

| 5. | Oxide-based coatings | Used in braking systems and structural parts of turbines | Instability of the phase formed and brittle behavior | They can be deposited as toughened oxide coatings with healing properties |

| 6. | Composite coatings | Used in marine industries and heavy machinery | Achieving a smooth and homogeneous coating is a challenge | Can be deposited using different techniques |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiwari, S.K.; Narayana, T.; Tyagi, R.; Pant, G.; Verma, P.C. Recent Developments in Self-Lubricating Thin-Film Coatings Deposited by a Sputtering Technique: A Critical Review of Their Synthesis, Properties, and Applications. Lubricants 2025, 13, 372. https://doi.org/10.3390/lubricants13080372

Tiwari SK, Narayana T, Tyagi R, Pant G, Verma PC. Recent Developments in Self-Lubricating Thin-Film Coatings Deposited by a Sputtering Technique: A Critical Review of Their Synthesis, Properties, and Applications. Lubricants. 2025; 13(8):372. https://doi.org/10.3390/lubricants13080372

Chicago/Turabian StyleTiwari, Sunil Kumar, Turali Narayana, Rashi Tyagi, Gaurav Pant, and Piyush Chandra Verma. 2025. "Recent Developments in Self-Lubricating Thin-Film Coatings Deposited by a Sputtering Technique: A Critical Review of Their Synthesis, Properties, and Applications" Lubricants 13, no. 8: 372. https://doi.org/10.3390/lubricants13080372

APA StyleTiwari, S. K., Narayana, T., Tyagi, R., Pant, G., & Verma, P. C. (2025). Recent Developments in Self-Lubricating Thin-Film Coatings Deposited by a Sputtering Technique: A Critical Review of Their Synthesis, Properties, and Applications. Lubricants, 13(8), 372. https://doi.org/10.3390/lubricants13080372