Investigation of the Effects of Cutting Tool Coatings and Machining Conditions on Cutting Force, Specific Energy Consumption, Surface Roughness, Cutting Temperature, and Tool Wear in the Milling of Ti6Al4V Alloy

Abstract

1. Introduction

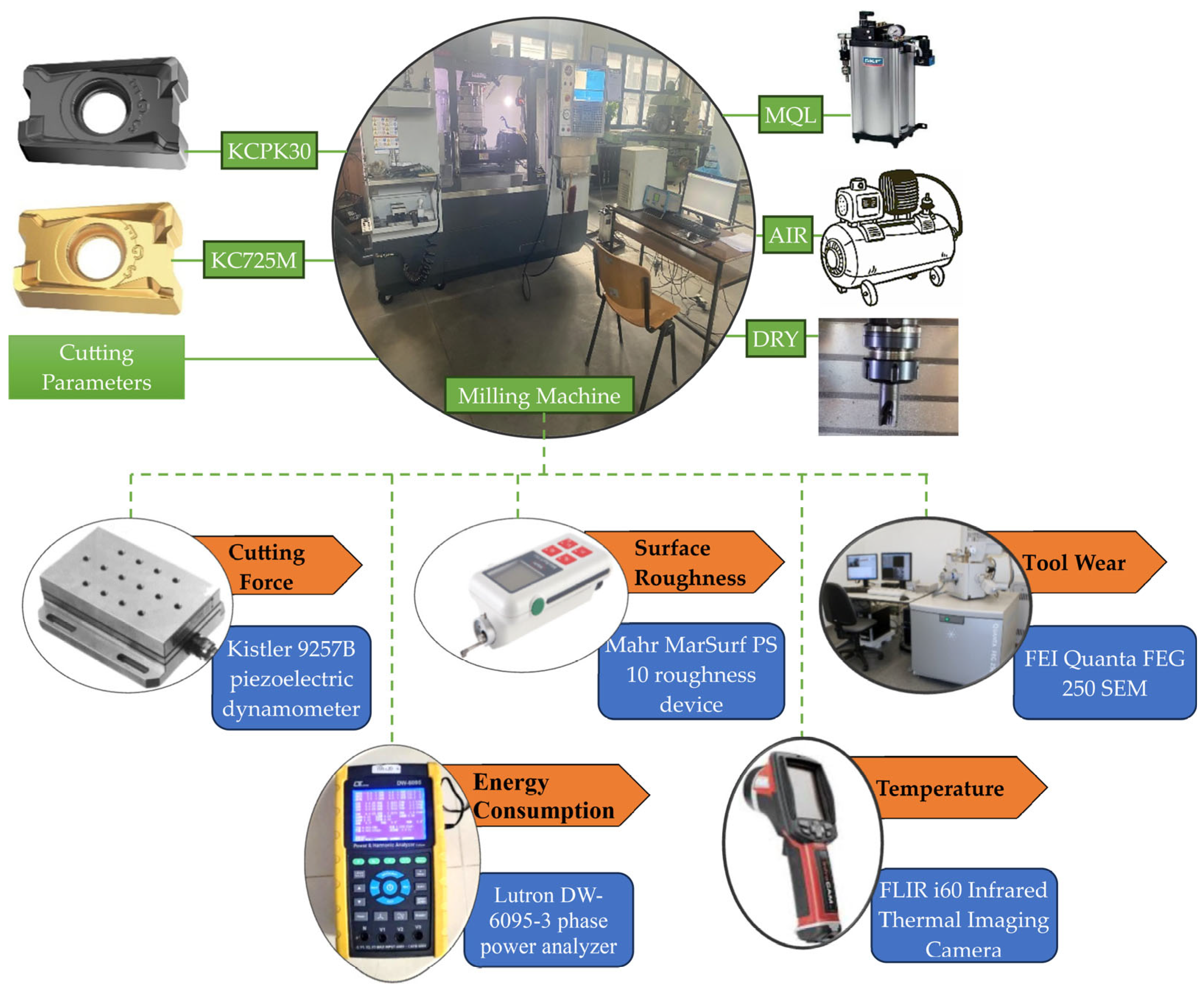

2. Materials and Methods

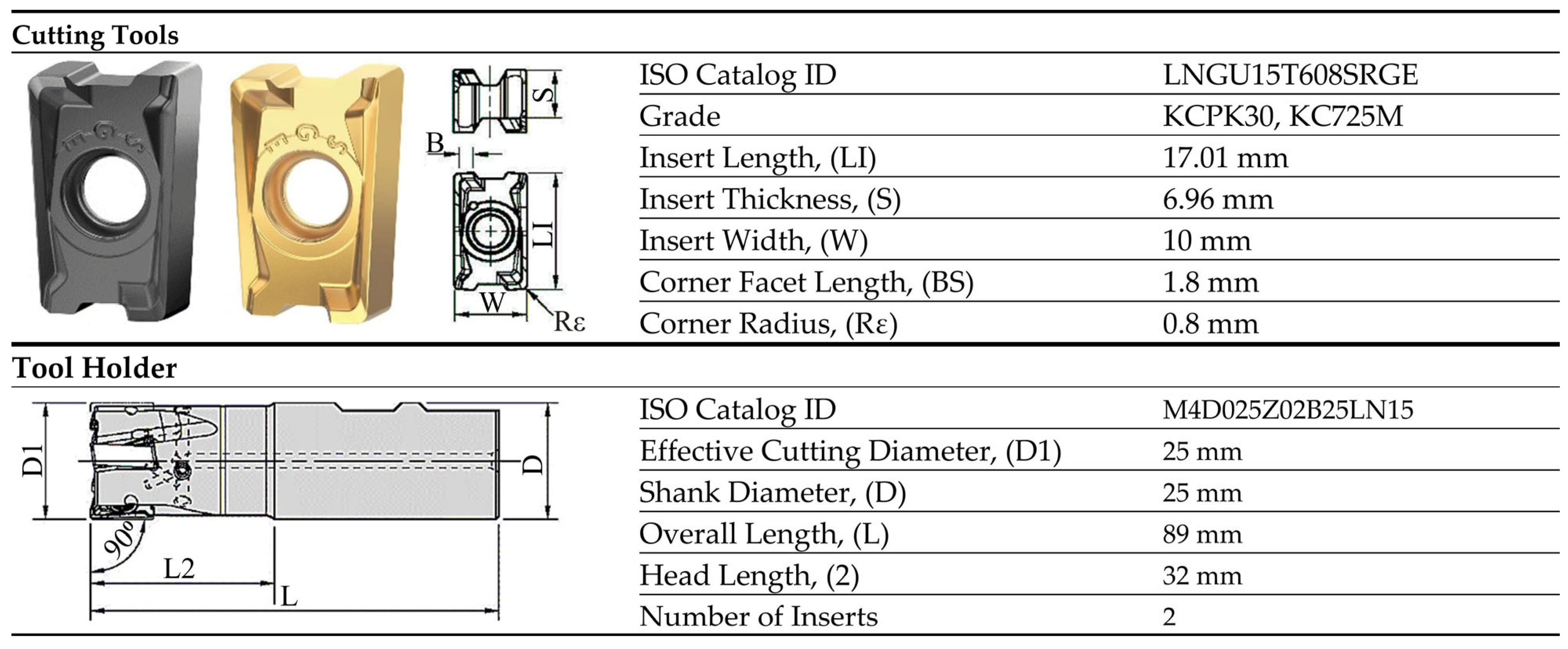

2.1. Experiment Material and Cutting Inserts

2.2. Experiment Material and Cutting Inserts

2.3. Cooling Conditions

2.4. Measurements

3. Results

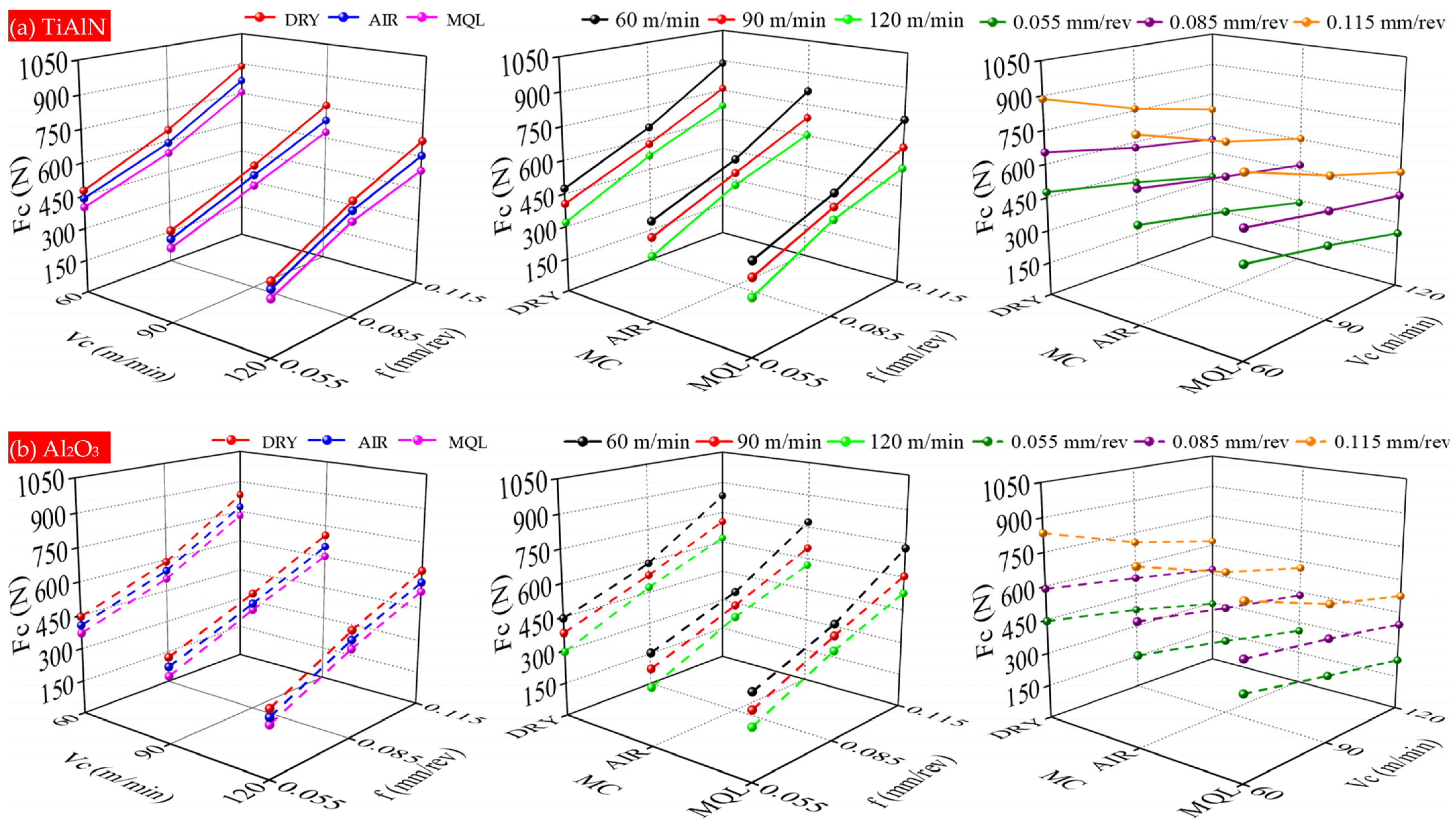

3.1. Evaluation of Cutting Force

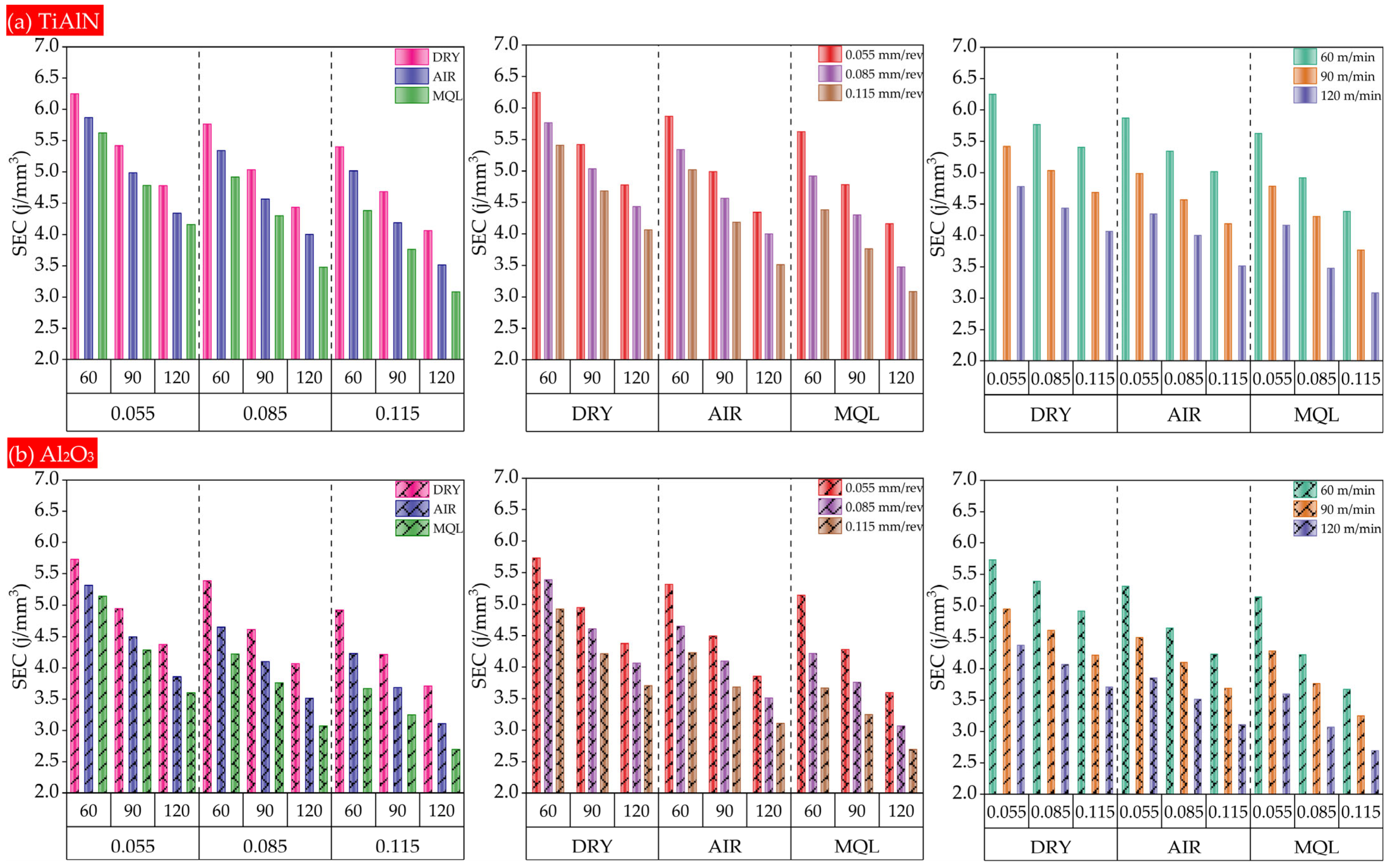

3.2. Evaluation of Specific Energy Consumption

3.3. Evaluation of Surface Roughness

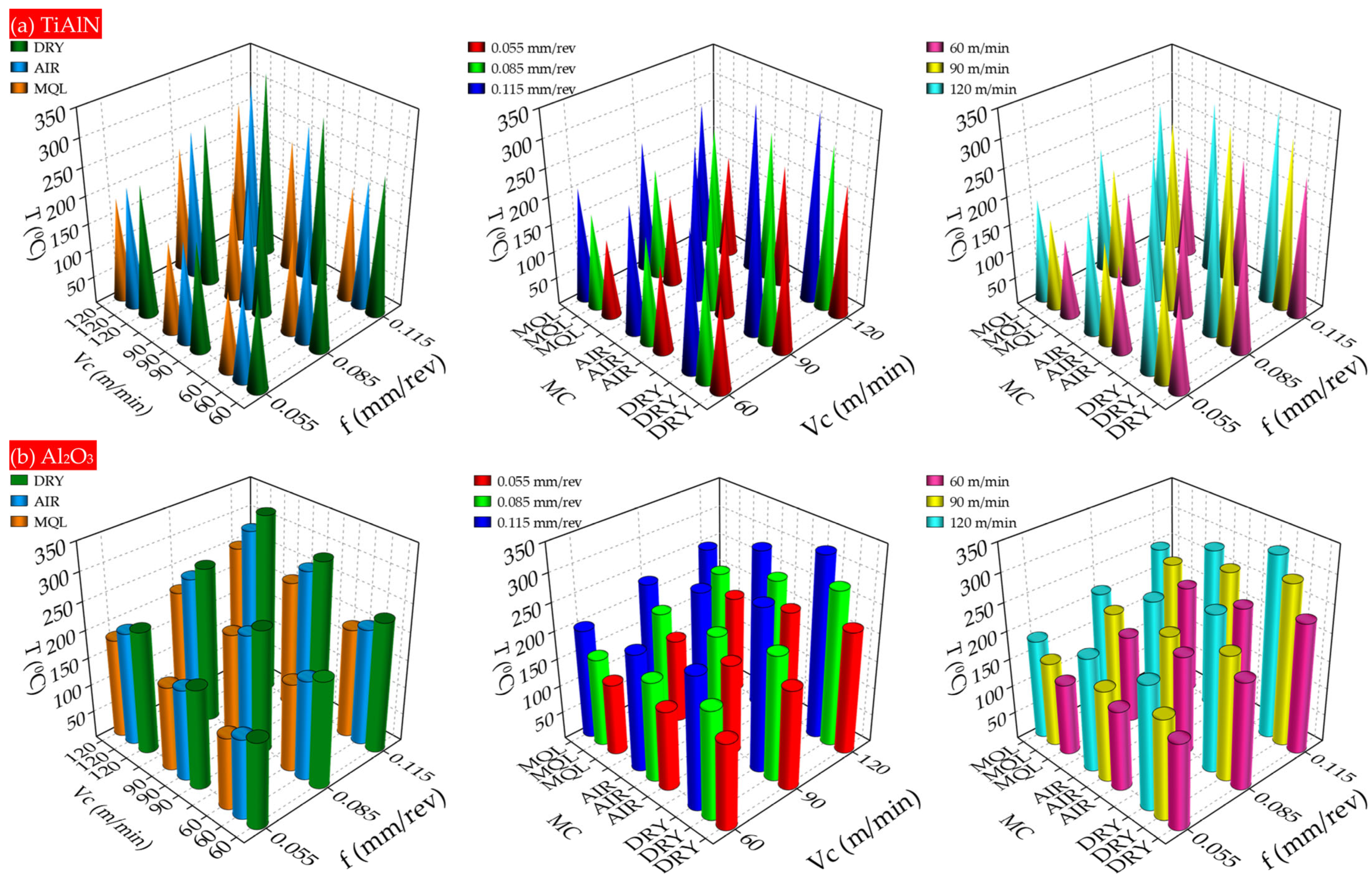

3.4. Evaluation of Cutting Temperature

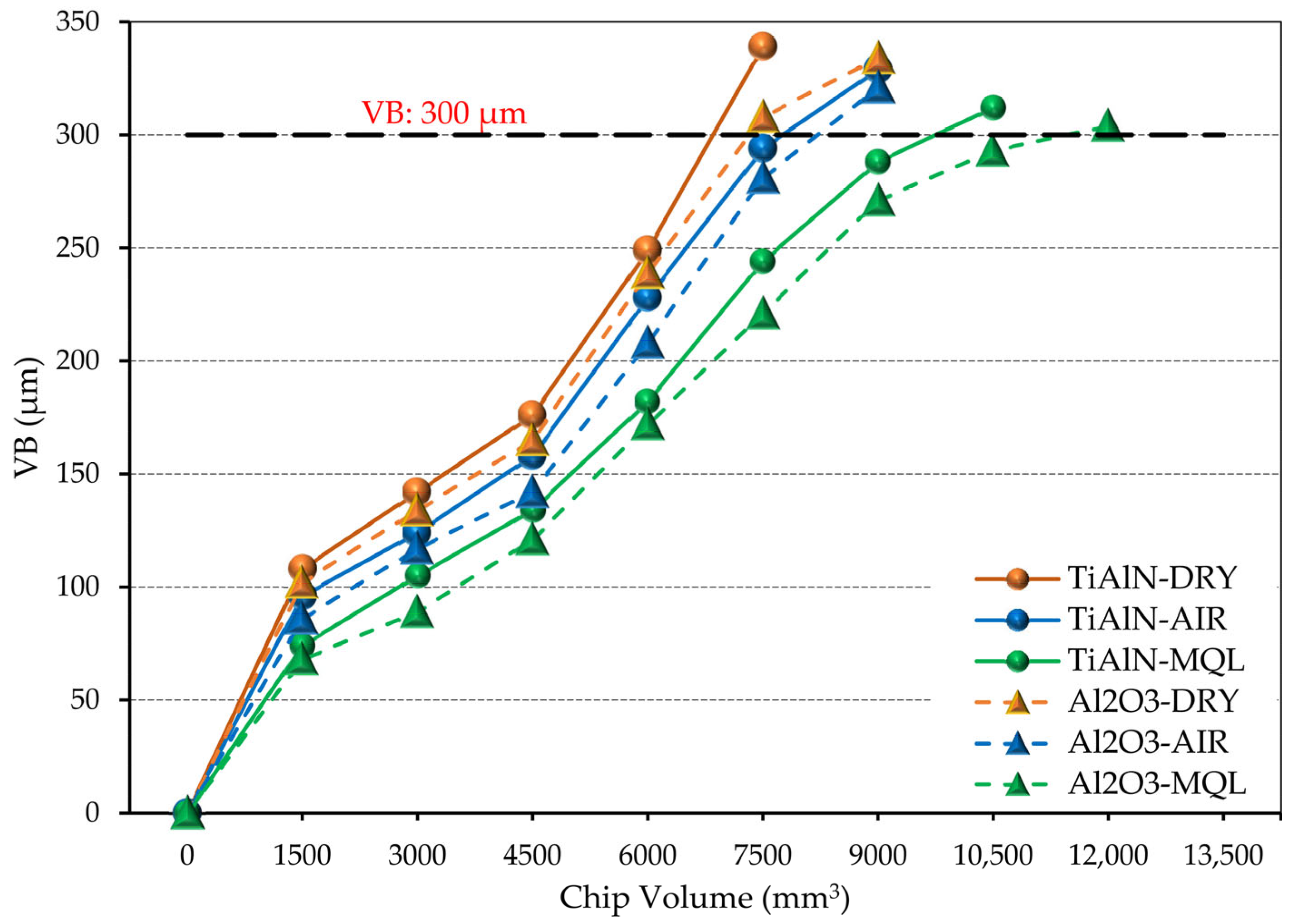

3.5. Evaluation of Tool Wear

4. Conclusions

- The lowest cutting force of 228.33 N was achieved using an Al2O3-coated tool at a cutting speed of 120 m/min, a feed rate of 0.055 mm/rev, and under MQL machining conditions. According to ANOVA analysis, the feed rate was the most influential parameter on cutting force, with a contribution of 74.81%.

- In the machining tests, the minimum energy consumption was measured as 2.694 J/mm3 using an Al2O3-coated tool at a cutting speed of 120 m/min, a feed rate of 0.115 mm/rev, and under MQL conditions. ANOVA results showed that cutting speed was the most significant factor affecting energy consumption, accounting for 46.73%.

- The best surface finish was obtained with an Al2O3-coated tool under MQL conditions at a cutting speed of 120 m/min and a feed rate of 0.055 mm/rev, yielding a surface roughness of 0.402 µm. The feed rate was found to be the most effective parameter on surface roughness, with a contribution ratio of 70.13%.

- The minimum cutting temperature (129 °C) was recorded using an Al2O3-coated tool under MQL conditions at a cutting speed of 60 m/min and a feed rate of 0.055 mm/rev. According to ANOVA analysis, the feed rate (49%) and cutting speed (30.79%) were the most influential parameters affecting cutting temperature.

- The MQL machining condition proved to be the most effective, followed by air and then dry machining conditions. Owing to its superior lubrication and cooling characteristics, MQL significantly reduced cutting force, energy consumption, temperature, and tool wear.

- The CVD Al2O3-coated cutting tool outperformed the PVD TiAlN-coated tool across all performance indicators, providing lower cutting force and energy consumption, better surface quality, lower cutting temperatures, and enhanced tool wear resistance.

- SEM and EDX analyses revealed that wear mechanisms such as built-up edges (BUEs), built-up layers (BULs), and flank wear were predominant, particularly under dry machining conditions. MQL effectively reduced adhesion-related wear due to the formation of a lubricating oil film at the tool–chip interface.

- Tool wear was found to be lowest under MQL conditions for both cutting tools. The Al2O3-coated tool exhibited 9% less wear under MQL compared to dry machining, confirming its superior wear resistance attributed to lower friction coefficients.

- The low thermal conductivity of the Al2O3-coated cutting tool helped mitigate thermal damage by directing heat towards the chip and workpiece rather than the tool itself, thereby contributing to extended tool life and lower cutting temperatures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Vc | Cutting speed |

| f | Feed rate |

| ap | Depth of cut |

| MQL | Minimum Quantity Lubrication |

| MC | Machining Conditions |

| BUE | Built-Up Edge |

| BUL | Built-Up Layer |

| Vb | Flank wear |

| SEM | Scanning Electron Microscope |

| EDX | Energy-Dispersive X-Ray Analysis |

References

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, J.; Zhang, B.; An, K.; Wang, Y.; Liu, D.; Lua, W.; Zhucand, L.; Liu, C. Recent advance in laser powder bed fusion of Ti–6Al–4V alloys: Microstructure, mechanical properties and machinability. Virtual Phys. Prototyp. 2025, 20, e2446952. [Google Scholar] [CrossRef]

- Qu, Z.; Zhang, Z.; Liu, R.; Xu, L.; Zhang, Y.; Li, X.; Zhao, Z.; Duan, Q.; Wang, S.; Li, S.; et al. High fatigue resistance in a titanium alloy via near-void-free 3D printing. Nature 2024, 626, 999–1004. [Google Scholar] [CrossRef]

- Zhao, D.P.; Tang, J.C.; Nie, H.M.; Zhang, Y.; Chen, Y.K.; Zhang, X.; Li, H.X.; Yan, M. Macro-micron-nano-featured surface topography of Ti-6Al-4V alloy for biomedical applications. Rare Met. 2018, 37, 1055–1063. [Google Scholar] [CrossRef]

- Chi, Y.; Dong, Z.; Cui, M.; Shan, C.; Xiong, Y.; Zhang, D.; Luo, M. Comparative study on machinability and surface integrity of γ-TiAl alloy in laser assisted milling. J. Mater. Res. Technol. 2024, 33, 3743–3755. [Google Scholar] [CrossRef]

- Manepalli, S.; Purushothaman, S.; Maddula, S.S.; Bhagavathi, L.R.; Mamilla, R.S. Numerical modelling and simulation studies of laser beam heating parameters on depth of cut and surface temperature in laser-assisted machining of Ti6Al4V. J. Micromanuf. 2024, 25165984241281015. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Z.; Cai, J.; Xu, X.; Luo, K.; Wu, L.; Lu, J. Effects of laser shock peening on the hot corrosion behaviour of the selective laser melted Ti6Al4V titanium alloy. Corros. Sci. 2021, 188, 109558. [Google Scholar] [CrossRef]

- Al-Rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M.; Elbestawi, M.A.; Veldhuis, S.C. Machinability of SLM-produced Ti6Al4V titanium alloy parts. J. Manuf. Process. 2020, 57, 768–786. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.P.; Loureiro, A.J.R. Review on machinability of titanium alloys: The process perspective. Rev. Adv. Mater. Sci. 2013, 34, 148–164. [Google Scholar]

- Seid Ahmed, Y.; Ryon, A. Tribological performance of a hybrid CryoMQL system on Ti6Al4V milling. Int. J. Adv. Manuf. Technol. 2022, 120, 8185–8199. [Google Scholar] [CrossRef]

- An, Q.; Chen, J.; Tao, Z.; Ming, W.; Chen, M. Experimental investigation on tool wear characteristics of PVD and CVD coatings during face milling of Ti6242S and Ti-555 titanium alloys. Int. J. Refract. Met. Hard Mater. 2020, 86, 105091. [Google Scholar] [CrossRef]

- Abdullah, R.I.R.; Redzuwan, B.I.; Aziz, M.S.A.; Kasim, M.S. Comparative study of tool wear in milling titanium alloy (Ti-6Al-4V) using PVD and CVD coated cutting tool. Ind. Lubr. Tribol. 2017, 69, 363–370. [Google Scholar] [CrossRef]

- Yuan, S.M.; Yan, L.T.; Liu, W.D.; Liu, Q. Effects of cooling AIR temperature on cryogenic machining of Ti–6Al–4V alloy. J. Mater. Process. Technol. 2011, 211, 356–362. [Google Scholar] [CrossRef]

- Gajrani, K.K. Assessment of cryo-MQL environment for machining of Ti-6Al-4V. J. Manuf. Process. 2020, 60, 494–502. [Google Scholar] [CrossRef]

- Sahoo, S.P.; Datta, S.; Roy, T.; Ghosh, S. Machining performance of Ti6Al4V under DRY environment, pressurized AIR supply and water-MQL: Analysis of machining-induced vibration signals and captured thermographs. Sādhanā 2021, 46, 208. [Google Scholar] [CrossRef]

- Saravanan, P.; Raj, D.S.; Hussain, S.; Shankar, V.R.; Raj, N. Optimization of jet position and investigation of the effects of multijet MQCL during end milling of Ti-6Al-4V. J. Manuf. Process. 2021, 64, 392–408. [Google Scholar] [CrossRef]

- Jamil, M.; Zhao, W.; He, N.; Gupta, M.K.; Sarikaya, M.; Khan, A.M.; Sanjay, M.R.; Suchart, S.; Pimenov, D.Y. Sustainable milling of Ti–6Al–4V: A trade-off between energy efficiency, carbon emissions and machining characteristics under MQL and cryogenic environment. J. Clean. Prod. 2021, 281, 125374. [Google Scholar] [CrossRef]

- An, Q.; Cai, C.; Zou, F.; Liang, X.; Chen, M. Tool wear and machined surface characteristics in side milling Ti6Al4V under DRY and supercritical CO2 with MQL conditions. Tribol. Int. 2020, 151, 106511. [Google Scholar] [CrossRef]

- Ramesh, S.; Karunamoorthy, L.; Senthilkumar, V.S.; Palanikumar, K. Experimental study on machining of titanium alloy (Ti64) by CVD and PVD coated carbide inserts. Int. J. Manuf. Technol. Manag. 2009, 17, 373–385. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Cai, C.; Liang, X.; An, Q.; Tao, Z.; Ming, W.; Chen, M. Cooling/lubrication performance of DRY and supercritical CO2-based minimum quantity lubrication in peripheral milling Ti-6Al-4V. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 405–421. [Google Scholar] [CrossRef]

- Bandapalli, C.; Sutaria, B.M.; Bhatt, D.V.P.; Singh, K.K. Tool wear analysis of micro end mills-uncoated and PVD coated TiAlN & AlTiN in high-speed micro milling of titanium alloy-Ti-0.3 Mo-0.8 Ni. Procedia CIRP 2018, 77, 626–629. [Google Scholar]

- Park, K.H.; Yang, G.D.; Suhaimi, M.A.; Lee, D.Y.; Kim, T.G.; Kim, D.W.; Lee, S.W. The effect of cryogenic cooling and minimum quantity lubrication on end milling of titanium alloy Ti-6Al-4V. J. Mech. Sci. Technol. 2015, 29, 5121–5126. [Google Scholar] [CrossRef]

- Rotella, G.; Dillon, O.W., Jr.; Umbrello, D.; Settineri, L.; Jawahir, I.S. The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2014, 71, 47–55. [Google Scholar] [CrossRef]

- Bai, X.; Li, C.; Dong, L.; Yin, Q. Experimental evaluation of the lubrication performances of different nanofluids for minimum quantity lubrication (MQL) in milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 101, 2621–2632. [Google Scholar] [CrossRef]

- Şirin, Ş.; Sarıkaya, M.; Yıldırım, Ç.V.; Kıvak, T. Machinability performance of nickel alloy X-750 with SiAlON ceramic cutting tool under DRY, MQL and hBN mixed nanofluid-MQL. Tribol. Int. 2021, 153, 106673. [Google Scholar] [CrossRef]

- Monroy Vazquez, K.P.; Giardini, C.; Ceretti, E. Cutting force modeling. In CIRP Encyclopedia of Production Engineering; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–16. [Google Scholar]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology, 7th ed.; Pearson: Mexico City, México, 2014. [Google Scholar]

- Özlü, B.; Demir, H.; Türkmen, M.; Gündüz, S. Examining the machinability of 38MnVS6 microalloyed steel, cooled in different mediums after hot forging with the coated carbide and ceramic tool. Proc. Inst. Mech. Eng. Part C J. Mech. 2021, 235, 6228–6239. [Google Scholar] [CrossRef]

- Özlü, B. Investigation of the effect of cutting parameters on cutting force, surface roughness and chip shape in turning of Sleipner cold work tool steel. J. Fac. Eng. Archit. Gazi Univ. 2021, 36, 1241–1251. [Google Scholar]

- Özlü, B. Evaluation of energy consumption, cutting force, surface roughness and vibration in machining toolox 44 steel using taguchi-based gray relational analysis. Surf. Rev. Lett. 2022, 29, 2250103. [Google Scholar] [CrossRef]

- Zou, Y.; Tang, S.; Guo, S.; Song, X. Tool wear analysis in turning inconel-657 using various tool materials. Mater. Manuf. Process. 2024, 39, 1363–1368. [Google Scholar] [CrossRef]

- Vieira, J.M.; Machado, A.R.; Ezugwu, E.O. Performance of cutting fluids during face milling of steels. J. Mater. Process. Technol. 2001, 116, 244–251. [Google Scholar] [CrossRef]

- Cicek, A.; Kıvak, T.; Ekici, E.; Kara, F.; Ucak, N. Performance of multilayer coated and cryo-treated uncoated tools in machining of AISI H13 tool steel—Part 1: Tungsten carbide end mills. J. Mater. Eng. Perform. 2021, 30, 3436–3445. [Google Scholar] [CrossRef]

- Khanna, N.; Wadhwa, J.; Pitroda, A.; Shah, P.; Schoop, J.; Sarıkaya, M. Life cycle assessment of environmentally friendly initiatives for sustainable machining: A short review of current knowledge and a case study. Sustain. Mater. Technol. 2022, 32, e00413. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Wadhwa, J.; Pitroda, A.; Schoop, J.; Pusavec, F. Energy consumption and lifecycle assessment comparison of cutting fluids for drilling titanium alloy. Procedia CIRP 2021, 98, 175–180. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Ercan, H.; Sarıkaya, M. An attempt towards green machining of Ni-based Hastelloy C4 alloy: Effect of vegetable oils and their combination with TiO2 and SiO2 nanoparticles on outputs. Sustain. Mater. Technol. 2023, 37, e00668. [Google Scholar] [CrossRef]

- Öztürk, B.; Kara, F. Multi-objective optimization of machinability and energy consumption of cast iron depending on cooling rate. Machines 2025, 13, 84. [Google Scholar] [CrossRef]

- Akgün, M.; Özlü, B.; Kara, F. Effect of PVD-TiN and CVD-Al2O3 coatings on cutting force, surface roughness, cutting power, and temperature in hard turning of AISI H13 steel. J. Mater. Eng. Perform. 2023, 32, 1390–1401. [Google Scholar] [CrossRef]

- Çelik, M.; Şencan, A.Ç.; Şirin, Ş.; Erdoğan, B.; Şencan, C. Effect of hBN and SDS added vegetable based cutting fluid application on the performance of turning Ti6Al4V alloys: A comparative analysis with Taguchi and ANN approaches. Mater. Chem. Phys. 2024, 322, 129552. [Google Scholar] [CrossRef]

- Demir, H. The effects of microalloyed steel preheat treatment on microstructure and machinability. Int. J. Adv. Manuf. Technol. 2008, 35, 1041–1046. [Google Scholar] [CrossRef]

- Akgün, M.; Demir, H.; Çiftçi, İ. Optimization of surface roughness in turning Mg2Si particle reinforced magnesium alloys. J. Polytech. 2018, 21, 645–650. [Google Scholar]

- Ferreira, R.; Carou, D.; Lauro, C.H.; Davim, J.P. Surface roughness investigation in the hard turning of steel using ceramic tools. Mater. Manuf. Process. 2016, 31, 648–665. [Google Scholar] [CrossRef]

- Demir, H.; Gündüz, S. The effects of aging on machinability of 6061 aluminium alloy. Mater. Des. 2009, 30, 1480–1483. [Google Scholar] [CrossRef]

- Akgün, M. Measurement and optimization of cutting forces, surface roughness and temperature in turning of AZ91 Mg alloy. Sādhanā 2023, 48, 60. [Google Scholar] [CrossRef]

- Binali, R. Experimental and machine learning comparison for measurement the machinability of nickel based alloy in pursuit of sustainability. Measurement 2024, 236, 115142. [Google Scholar] [CrossRef]

- Davim, J.P.; Figueira, L. Machinability evaluation in hard turning of cold work tool steel (D2) with ceramic tools using statistical techniques. Mater. Des. 2007, 28, 1186–1191. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Figueira, L.; Davim, J.P. Performance comparison of conventional and wiper ceramic inserts in hard turning through artificial neural network modeling. Int. J. Adv. Manuf. Technol. 2011, 52, 101–114. [Google Scholar] [CrossRef]

- Kıvak, T. Optimization of surface roughness and flank wear using the Taguchi method in milling of Hadfield steel with PVD and CVD coated inserts. Measurement 2014, 50, 19–28. [Google Scholar] [CrossRef]

- Storchak, M.; Stehle, T.; Möhring, H.C. Determination of thermal material properties for the numerical simulation of cutting processes. Int. J. Adv. Manuf. Technol. 2022, 118, 1941–1956. [Google Scholar] [CrossRef]

- Hao, G.; Liu, Z. The heat partition into cutting tool at tool-chip contact interface during cutting process: A review. Int. J. Adv. Manuf. Technol. 2020, 108, 393–411. [Google Scholar] [CrossRef]

- Kara, F. Investigation of the effect of Al2O3 nanoparticle-added MQL lubricant on sustainable and clean manufacturing. Lubricants 2024, 12, 393. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Sarıkaya, M. The effect of nanofluids reinforced with different surfactants on the machining and friction-wear properties of Waspaloy. Tribol. Int. 2023, 181, 108316. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Fan, G. Effects of tool coating materials and coating thickness on cutting temperature distribution with coated tools. Int. J. Appl. Ceram. Technol. 2022, 19, 2276–2284. [Google Scholar] [CrossRef]

- Jena, A.; Pattnaik, S.K.; Sarangi, S.K. Multi-spindle drilling tools used for DRY machining of aluminium. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 441. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K. Multi-spindle drilling of Al2024 alloy and the effect of TiAlN and TiSiN-coated carbide drills for productivity improvement. Int. J. Adv. Manuf. Technol. 2021, 114, 3047–3056. [Google Scholar] [CrossRef]

- Zhang, S.J.; Liu, Z.Q. Heat conduction analysis of coated cutting tools with temperature-dependent properties. Adv. Mater. Res. 2009, 69, 389–393. [Google Scholar] [CrossRef]

- Balaji, A.K.; Mohan, V.S. An ‘effective cutting tool thermal conductivity’ based model for tool–chip contact in machining with multi-layer coated cutting tools. Mach. Sci. Technol. 2002, 6, 415–436. [Google Scholar] [CrossRef]

- Şirin, E.; Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Sarıkaya, M. Comprehensive analysis of cutting temperature, tool wear, surface integrity and tribological properties in sustainable milling of Ti6Al4V alloy: LN2, nanofluid and hybrid machining. J. Manuf. Process. 2024, 131, 1360–1371. [Google Scholar] [CrossRef]

- Aghababaei, R. Effect of adhesion on material removal during adhesive wear. Phys. Rev. Mater. 2019, 3, 063604. [Google Scholar] [CrossRef]

- Alparslan, C.; Bayraktar, Ş. Tool wear in machining of wrought and cast aluminium alloys: Literature review. Manuf. Technol. Appl. 2021, 2, 34–46. [Google Scholar] [CrossRef]

- Fang, N.; Pai, P.S.; Mosquea, S. The effect of built-up edge on the cutting vibrations in machining 2024-T351 aluminum alloy. Int. J. Adv. Manuf. Technol. 2010, 49, 63–71. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, D.; Mazur, M.; Mo, J.P.; Li, G.; Ding, S. The state of the art in machining additively manufactured titanium alloy Ti-6Al-4V. Materials 2023, 16, 2583. [Google Scholar] [CrossRef] [PubMed]

- Bermingham, M.J.; Sim, W.M.; Kent, D.; Gardiner, S.; Dargusch, M.S. Tool life and wear mechanisms in laser assisted milling Ti–6Al–4V. Wear 2015, 322, 151–163. [Google Scholar] [CrossRef]

- Ding, F.; Wang, C.; Zhang, T.; Deng, Y.; Zhu, X. Adhesive wear mechanism of coated tools and its influence on cutting performance during machining of Zr-based bulk metallic glass. J. Mater. Res. Technol. 2023, 27, 5489–5506. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

| Author(s) | Material | Machining Conditions | Cutting Tool Coating | Output Response | Summary |

|---|---|---|---|---|---|

| Seid Ahmed and Ryon (2022) [10] | Ti6Al4V | LN2, MQL | TiAlN | Tool wear, cutting force, surface roughness, and microhardness | Compared to MQL and LN2 cryogenic cooling, LN2 cryogenic cooling provided the best machining results. |

| An et al. (2020) [11] | Ti-64, Ti-6242S, Ti-555 | DRY | Uncoated, PVD (TiN), CVD (Al2O3) | Tool wear | Mechanical properties significantly affect machinability and tool life. PVD tools demonstrated better wear and fracture resistance than uncoated and CVD tools. |

| Abdullah et al. (2017) [12] | Ti6Al4V | DRY | PVD (TiAlN/AlCrN), CVD (TiCN/Al2O3) | Tool wear | PVD tools produce the least tool wear compared to CVD tools. Depth of cut is the primary factor affecting tool life, followed by cutting speed and feed rate. |

| Yuan et al. (2011) [13] | Ti6Al4V | DRY, WET, MQL (Room Temperature), MQL Cooling AIR (0 °C), MQL Cooling AIR (−15 °C), MQL Cooling AIR (−30 °C), MQL Cooling AIR (−45 °C) | Uncoated cemented carbide | Cutting force, flank wear, surface roughness | They observed that cutting force, tool wear, and surface roughness were significantly reduced under MQL machining conditions. MQL (−15 °C) machining conditions performed better than other temperatures. |

| Gajrani (2020) [14] | Ti6Al4V | DRY, MQL, Cryo-MQL | Uncoated tungsten carbide | Cutting force, surface roughness, microhardness, tool wear | As a result of milling tests, better results were obtained for cutting force, surface roughness, microhardness, and tool wear in Cryo-MQL machining conditions. |

| Sahoo et al. (2021) [15] | Ti6Al4V | DRY, AIR, MQL | Uncoated tungsten carbide | Cutting force, tool-tip temperature, flank wear, chip morphology, vibration | As a result of tests conducted under MQL machining conditions, it was observed that Ti6Al4V machining performance improved. |

| Saravanan et al. (2021) [16] | Ti6Al4V | DRY, Flood, MQL, Multijet MQCL | Uncoated tungsten carbide | Temperature, force, surface roughness | The best results in terms of cutting temperature, cutting force, and surface roughness were obtained under MJMQCL conditions. |

| Jamil et al. (2021) [17] | Ti6Al4V | DRY, MQL, LN2 | Cemented tungsten carbide | Cutting temperature, P total, tool wear, surface roughness, tool life | The best machining performance was achieved with CO2–snow, while the minimum cutting temperature was obtained with cryogenic LN2. |

| An et al. (2020) [18] | Ti6Al4V | DRY, scCO2, scCO2-WMQL, scCO2-OoWMQL | Cemented carbide | Tool wear, cutting torque, surface morphology | As a result of the machining tests, the best results for tool wear, cutting torque, and surface roughness were obtained under scCO2-OoWMQL lubrication conditions. |

| Ramesh et al. (2009) [19] | Ti6Al4V | DRY | PVD (TiN), CVD (Al2O3) | Cutting temperature, chip formation | PVD and CVD tools performed similarly; CVD produced shorter chips, while PVD produced longer ones. |

| Shokrani et al. (2019) [20] | Ti6Al4V | Conventional Flooding, MQL, Cryogenic, Hybrid Cryogenic MQL | Solid carbide end mill | Tool life, tool wear model, surface roughness | The hybrid cryogenic MQL system showed better machining performance in machining Ti-6Al-4V alloy compared to overflow machining. |

| Cai et al. (2021) [21] | Ti6Al4V | DRY, scCO2, scCO2-wMQL, scCO2-OoWMQL | Cemented carbide end mill | Milling force, cutting temperature, surface roughness, vibration | Machining tests showed that scCO2-OoWMQL achieved the lowest cutting force, temperature, and surface roughness. |

| Bandapalli et al. (2018) [22] | Ti6Al4V | DRY | Uncoated, PVD (TiAlN), PVD (AlTiN) | Tool wear | The main wear mechanisms in micro-end mills were diffusion, oxidation, adhesion, and abrasion. In titanium alloy machining, uncoated tools outperformed AlTiN- and TiAlN-coated carbide tools. |

| Park et al. (2015) [23] | Flood Coolant, Nano-MQL, External Cryogenic, Internal Cryogenic, Nano-MQL + Internal Cryogenic | Solid end mill | Milling force, tool wear | They stated that Nano-MQL + Internal Cryogenic hybrid machining gives more efficient results in terms of cutting force and tool wear. | |

| Rotella et al. (2014) [24] | DRY, Cryogenic, MQL | PVD (TiAlN) | Surface roughness, microstructure, hardness, grain refinement, phase transformation | Cryogenic machining yielded the best surface roughness, higher surface hardness, and fewer cracks compared to other methods. | |

| Bai et al. (2019) [25] | MQL (Al2O3), MQL (SiO2), MQL (MoS2), MQL (CNTs), MQL (SiC), MQL (Graphite) | Cemented carbide | Milling force, surface roughness, surface morphology, viscosity analysis | As a result of the machining tests, the best cutting force, surface roughness, and viscosity of nanofluids were obtained from MQL (Al2O3). |

| Elements | Al | V | Fe | C | N | O | Ti |

|---|---|---|---|---|---|---|---|

| Weight % | 6.42 | 4.2 | 0.19 | 0.027 | 0.028 | 0.185 | Balance |

| Tensile Strength (MPa) | Yield Strength (MPa) | Modulus of elasticity (×106 MPa) | Hardness Rockwell C | ||||

| 886 | 827 | 11.3 | 36 | ||||

| Milling Parameters | Levels | ||

|---|---|---|---|

| Level 1 | Level 2 | Level 3 | |

| Cutting tools | TiAlN | Al2O3 | - |

| Machining conditions | DRY | AIR | MQL |

| Cutting speed, Vc (mm/min) | 60 | 90 | 120 |

| Feed rate, f (mm/rev) | 0.055 | 0.085 | 0.115 |

| Feature | Explanation |

|---|---|

| pH | 9.5 |

| Density (15 °C, kg/m3) | 1.070 |

| Appearance | Clear red-brown |

| Smell | Typical |

| Yield point (°C) | −22 |

| Refractive Index (n20/D) | 1.4222 |

| Cutting Parameters | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value | Contribution (%) |

|---|---|---|---|---|---|---|---|

| CT | 1 | 16,980 | 16,980 | 16,980 | 39.32 | 0.000 | 1.24 |

| MC | 2 | 77,451 | 77,451 | 38,725 | 89.68 | 0.000 | 5.68 |

| Vc (m/min) | 2 | 229,343 | 229,343 | 114,672 | 265.55 | 0.000 | 16.81 |

| f (mm/rev) | 2 | 1,020,693 | 1,020,693 | 510,347 | 1181.84 | 0.000 | 74.81 |

| Error | 46 | 19,864 | 19,864 | 432 | 1.46 | ||

| Total | 53 | 1,364,332 | 100.00 |

| Cutting Parameters | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value | Contribution (%) |

|---|---|---|---|---|---|---|---|

| CT | 1 | 3.4016 | 3.4016 | 3.40155 | 273.26 | 0.000 | 9.92 |

| MC | 2 | 6.8334 | 6.8334 | 3.41670 | 274.47 | 0.000 | 19.93 |

| Vc (m/min) | 2 | 16.0236 | 16.0236 | 8.01181 | 643.61 | 0.000 | 46.73 |

| f (mm/rev) | 2 | 7.4557 | 7.4557 | 3.72783 | 299.47 | 0.000 | 21.74 |

| Error | 46 | 0.5726 | 0.5726 | 0.01245 | 1.67 | ||

| Total | 53 | 34.2868 | 100.00 |

| Cutting Parameters | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value | Contribution (%) |

|---|---|---|---|---|---|---|---|

| CT | 1 | 0.007585 | 0.007585 | 0.007585 | 78.30 | 0.000 | 1.37 |

| MC | 2 | 0.048029 | 0.048029 | 0.024015 | 247.90 | 0.000 | 8.65 |

| Vc (m/min) | 2 | 0.105832 | 0.105832 | 0.052916 | 546.25 | 0.000 | 19.05 |

| f (mm/rev) | 2 | 0.389584 | 0.389584 | 0.194792 | 2010.84 | 0.000 | 70.13 |

| Error | 46 | 0.004456 | 0.004456 | 0.000097 | 0.80 | ||

| Total | 53 | 0.555486 | 100.00 |

| Cutting Parameters | DF | Seq SS | Adj SS | Adj MS | F-Value | p-Value | Contribution (%) |

|---|---|---|---|---|---|---|---|

| CT | 1 | 2688 | 2688 | 2688.2 | 32.29 | 0.000 | 2.02 |

| MC | 2 | 20,321 | 20,321 | 10,160.5 | 122.05 | 0.000 | 15.30 |

| Vc (m/min) | 2 | 40,879 | 40,879 | 20,439.6 | 245.51 | 0.000 | 30.79 |

| f (mm/rev) | 2 | 65,061 | 65,061 | 32,530.3 | 390.74 | 0.000 | 49.00 |

| Error | 46 | 3830 | 3830 | 83.3 | 2.88 | ||

| Total | 53 | 132,779 | 100.00 |

| EDS Spot | Element Weights (%) | ||||||

|---|---|---|---|---|---|---|---|

| C | Al | Si | Sn | Ti | V | Fe | |

| 1 | 28.13 | 4.31 | 0.07 | 0.37 | 63.31 | 3.70 | 0.11 |

| 2 | 27.31 | 3.96 | 0.11 | 0.28 | 64.06 | 4.20 | 0.08 |

| 3 | 26.97 | 5.12 | 0.04 | 0.41 | 65.26 | 2.16 | 0.04 |

| 4 | 29.54 | 3.88 | 0.09 | 0.32 | 63.05 | 2.99 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özlü, B.; Ulaş, H.B.; Kara, F. Investigation of the Effects of Cutting Tool Coatings and Machining Conditions on Cutting Force, Specific Energy Consumption, Surface Roughness, Cutting Temperature, and Tool Wear in the Milling of Ti6Al4V Alloy. Lubricants 2025, 13, 363. https://doi.org/10.3390/lubricants13080363

Özlü B, Ulaş HB, Kara F. Investigation of the Effects of Cutting Tool Coatings and Machining Conditions on Cutting Force, Specific Energy Consumption, Surface Roughness, Cutting Temperature, and Tool Wear in the Milling of Ti6Al4V Alloy. Lubricants. 2025; 13(8):363. https://doi.org/10.3390/lubricants13080363

Chicago/Turabian StyleÖzlü, Barış, Hasan Basri Ulaş, and Fuat Kara. 2025. "Investigation of the Effects of Cutting Tool Coatings and Machining Conditions on Cutting Force, Specific Energy Consumption, Surface Roughness, Cutting Temperature, and Tool Wear in the Milling of Ti6Al4V Alloy" Lubricants 13, no. 8: 363. https://doi.org/10.3390/lubricants13080363

APA StyleÖzlü, B., Ulaş, H. B., & Kara, F. (2025). Investigation of the Effects of Cutting Tool Coatings and Machining Conditions on Cutting Force, Specific Energy Consumption, Surface Roughness, Cutting Temperature, and Tool Wear in the Milling of Ti6Al4V Alloy. Lubricants, 13(8), 363. https://doi.org/10.3390/lubricants13080363