Abstract

As a core component of industrial robots, the transmission accuracy life (TAL) of rotary vector (RV) reducers constitutes a primary factor determining the high-precision operation of robotic systems. However, current life evaluation methods for RV reducers predominantly rely on conventional bearing strength life calculations, while neglecting its transmission accuracy degradation during operation. To address this limitation, a static analysis model of RV reducers is established, through which a calculation method for transmission accuracy and TAL is presented. Simultaneously, tooth surface and bearing wear models are developed based on Archard’s wear theory. Through coupled analysis of the aforementioned models, the transmission accuracy degradation law of RV reducers is revealed. The results show that during the operation of the RV reducer, the transmission error (TE) maintains relative stability over time, whereas the lost motion (LM) exhibits a continuous increase. Based on this observation, LM is defined as the evaluation metric for TAL, and a novel TAL estimation model is proposed. The feasibility of the developed TAL estimation model is ultimately validated through accelerated transmission accuracy degradation tests on RV reducers. The error between the predicted and experimental results is 11.06%. The proposed TAL estimation model refines the life evaluation methodology for RV reducers, establishing a solid foundation for real-time transmission accuracy compensation in reducer operation.

1. Introduction

The rotary vector (RV) reducer is widely adopted in robotic joints due to its high transmission ratio, precision, torsional stiffness, efficiency, and compact design. While its lifetime is typically assessed using conventional bearing strength life calculations, the key performance parameter for RV reducers in robotic joints is transmission accuracy. RV reducers may not undergo fatigue failure, yet their transmission accuracy may degrade beyond the acceptable threshold during operation. To extend service life and maintain high-precision motion transmission, real-time compensation for transmission accuracy is essential. Therefore, investigating the degradation of RV reducer accuracy and developing a method to estimate its transmission accuracy life (TAL) hold practical and theoretical significance.

The transmission accuracy of RV reducers is evaluated using transmission error (TE) and lost motion (LM). Blanche and Yang [1,2] were the first to analyze the transmission accuracy of cycloidal drives and to derive a computation formula for backlash influenced by various manufacturing errors (MEs). Hidaka et al. [3,4,5] developed a 20-degrees-of-freedom (DoFs) mathematical model to assess the rotational transmission accuracy of RV reducers, examining the impacts of individual MEs, assembly errors (AEs), and their combined effects. Experimental findings validated consistency with Blanche’s conclusions. In recent years, research has increasingly focused on the influence of gear MEs and AEs on the transmission accuracy of cycloid-pin drives. Li et al. [6] studied how clearance and eccentricity errors affect transmission ratio, TE, bearing load, and contact stress in cycloidal reducers. Lin et al. [7] investigated the influence of deviations in pin radius, pin position, tooth profile, and tooth pitch on TE in cycloid-pin reducers. Li et al. [8] further studied the effects of tooth profile errors and tooth pitch errors on the TE and backlash of cycloid-pin transmission, achieving effective pre-control measures to enhance tooth profile and meshing contact performance. Yang et al. [9] developed an analytical error model for RV reducers using the loop incremental method, where MEs and AEs were represented as linkage length errors in the equivalent mechanism. Wang et al. [10] established an innovative bi-directional drive transmission error analytical model that integrates TE and LM predictions, revealing the output mechanism’s significant effect on the overall positioning accuracy. Huang et al. [11] calculated TE for a new cycloidal pinwheel meshing pair, considering both rolling and sliding contacts, and analyzed the influence of various design parameters, including sliding parameters, pin radius, pin position radius, and eccentricity. Xie et al. [12] proposed an improved dynamic model to study the moment rigidity and rotational precision of the angular contact ball bearing-planetary frame rotor system in RV reducers. Yang et al. [13] introduced a theoretical analysis and performance prediction method for NN-type precision cycloidal drives, incorporating friction and clearance effects in the cycloidal-pin gear pair, and investigated how radial clearance and torque variations influence TE. Xu and Wu [14] studied the dynamic transmission accuracy of joint RV reducers in industrial robots under variable speed conditions. Most previous studies have relied on two-dimensional geometric methods, with limited focus on three-dimensional tooth surface analysis. Although RV reducers use straight-toothed cycloidal gears, pins, and involute gears, errors along the tooth-width direction, such as lead crowning and misalignments induced by AEs, cannot be neglected. Therefore, a novel three-dimensional tooth surface-based transmission accuracy analysis method is essential for a comprehensive evaluation of these effects.

In addition to gear MEs and AEs, the transmission accuracy of RV reducers is influenced by tooth surface wear. Early research primarily focused on the tooth surface wear of a single gear pair. For example, Wu and Cheng [15,16] established a sliding wear model by approximating spur gear meshing as contact between two cylindrical bodies with time-varying radii, calculating the tooth surface wear under constant load. Wojnarowski and Onishchenko [17] developed a 2-DoFs elastic dynamic model for spur gear pairs incorporating tooth surface wear, revealing that gear deformation and tooth surface wear significantly influence the dynamic behavior of spur gear pairs and must be considered for accurate gear life prediction. Bajpai et al. [18,19] established tooth surface wear models for straight and helical gears using a three-dimensional (3D) finite element gear contact analysis model and Archard’s wear law, examining the effect of tooth profile deviations on tooth surface wear. Ding and Kahraman [20] integrated the previous tooth surface wear model with a nonlinear dynamic model considering tooth flank clearance and time-varying meshing stiffness, analyzing the interaction between tooth surface wear and gear dynamic response. Recently, increasing attention has been given to how tooth surface wear affects the overall transmission accuracy of RV reducers. Zhang et al. [21] investigated the effect of tooth surface wear on TE and torsional stiffness of RV reducers by employing the centralized parameter method and dynamic subsystem method, incorporating variations in wear coefficient. Ahn et al. [22] established a finite element-based analytical model for two-disk RV reducers and eccentric shafts, examining the effects of tolerance and friction on multi-contact and output torque. Han et al. [23,24] proposed a transient hybrid elastohydrodynamic lubrication model for cycloidal pinwheel transmissions to analyze mixed lubrication characteristics, accounting for variable parameters along the meshing surface, including contact load, curvature contact radius, and entrainment speed. Qi et al. [25] introduced a comprehensive methodology that incorporates clearance, deformation, and friction effects, enabling computationally efficient multi-parameter optimization of cycloidal drives. The rotational accuracy and durability of two-stage cycloidal reducers exhibit strong dependence on the performance and wear condition of rotary arm bearings. To address this issue, Sun et al. [26] developed a component error selection method that significantly reduces maximum contact stress at the bearing needle roller contact area, thereby alleviating wear at the cycloidal gear-bearing hole. To further improve gear reliability and minimize tooth surface relative sliding, Sheng et al. [27] designed a novel internal gear drive with a low sliding ratio. Gao et al. [28] studied the effect of various friction losses, such as meshing loss, output dowel pin loss, bearing rotation loss, sealing element loss, and lubrication loss, on the transmission efficiency of CT-CHR-type cycloid pinwheel reducers. Bearing wear influences bearing stiffness and clearance, and it also plays a critical role in the transmission accuracy of RV reducers. Orlov [29] proposed a method to compute ball bearing wear based on the actual loading conditions of worn components. Tiwari and Gupta [30] investigated how radial clearance of rolling bearings affects the dynamic response of balanced horizontal rotors, analyzing its effect on bearing stiffness. Guo and Parker [31] developed a dynamic model of a planetary gear transmission system that considers bearing clearance to analyze its influence on nonlinear dynamics. These studies identify gears and bearings as key factors influencing the transmission accuracy of RV reducers. However, research on the degradation law of transmission accuracy over the full lifecycle of RV reducers remains limited, and no effective or feasible transmission accuracy prediction model currently exists. This gap hinders real-time compensation of transmission accuracy, which is critical for maintaining high-precision performance in robotic systems.

Testing transmission accuracy remains a major challenge in evaluating the TAL of RV reducers. In recent years, researchers have developed diverse testing methodologies and constructed specialized test benches for this purpose. Qiu and Xue [32] systematically reviewed key testing parameters for high-precision reducers in industrial robots, assessed existing methods, and outlined requirements based on the mechanical structure, metrology principles, and engineering applications. Ge et al. [33] explored the failure mechanisms of RV reducers through accelerated degradation tests using motor torque as the accelerated stress, developed a corresponding accelerated degradation model, and predicted the RV reducer’s lifespan. The experimental results confirmed that wear is the primary failure mode in RV reducers. Similarly, Huang et al. [11] also constructed a TE test platform and performed accelerated life testing on a cycloidal pinwheel reducer. Chen et al. [34] investigated the influence of MEs and AEs on the measurement accuracy of angular encoders, and proposed an error compensation strategy, which was validated through a custom-built measurement system. Peng and Wang [35] constructed an RV reducer test rig using angle encoders and magnetic powder brakes to evaluate the effectiveness and feasibility of a fault diagnosis method under various operating conditions. Wang et al. [36] constructed an RV reducer test bench to investigate the effects of input speed and output load on TE, employing a bidirectional TE method to measure the dynamic LM of RV reducers.

In addition, precision test platforms developed for harmonic drives provide valuable insights for RV reducer testing. Ghorbel et al. [37] experimentally demonstrated that kinematic error in harmonic drives comprised a basic component and an additional component caused by torsional flexibility. Their test apparatus also revealed the dependence on inertial loads, gear assembly parameters, and rotational speeds on kinematic error. Jia et al. [38] validated the mechanism of pure kinematic error in harmonic drives using a specialized test device designed to measure kinematic error, efficiency, and stiffness. This electromechanical system included a servo-drive motor, a load motor, rotary encoders, torque sensors, a harmonic drive unit, and a digital control module, with bellows-type flexible couplings at all connections. Existing rig tests predominantly use magnetic powder brakes as loading devices. However, this configuration restricts bidirectional power transmission from the output side, reducing system scalability and integration. Furthermore, to accommodate reducer disassembly and reassembly, elastic couplings are widely implemented in test setups. In most transmission accuracy measurement systems, angle encoders are mounted on the outer side of these elastic couplings at the input and output shaft ends. This conventional arrangement introduces significant measurement errors due to output shaft torque fluctuations and elastic coupling clearance.

According to the aforementioned analysis, current research predominantly focuses on isolated investigations of either gear tooth surface wear or bearing wear. However, the mechanism of their impact on the overall transmission accuracy degradation of RV reducers remains unclear, and a systematic evaluation methodology for the TAL of RV reducers is lacking. To fill this gap, a static analysis model of RV reducers is established, through which a calculation method for transmission accuracy and TAL is presented. Simultaneously, tooth surface and bearing wear models are developed based on Archard’s wear theory. Through coupled analysis of the aforementioned models, the transmission accuracy degradation law of RV reducers is revealed, and a novel TAL estimation model is proposed. The feasibility of the developed TAL estimation model is ultimately validated through accelerated transmission accuracy degradation tests on RV reducers. This study aims to achieve precise prediction of the TAL for RV reducers, thereby advancing the methodology for evaluating their operational lifespan.

2. Static Analysis Model of RV Reducer

2.1. Transmission Principle

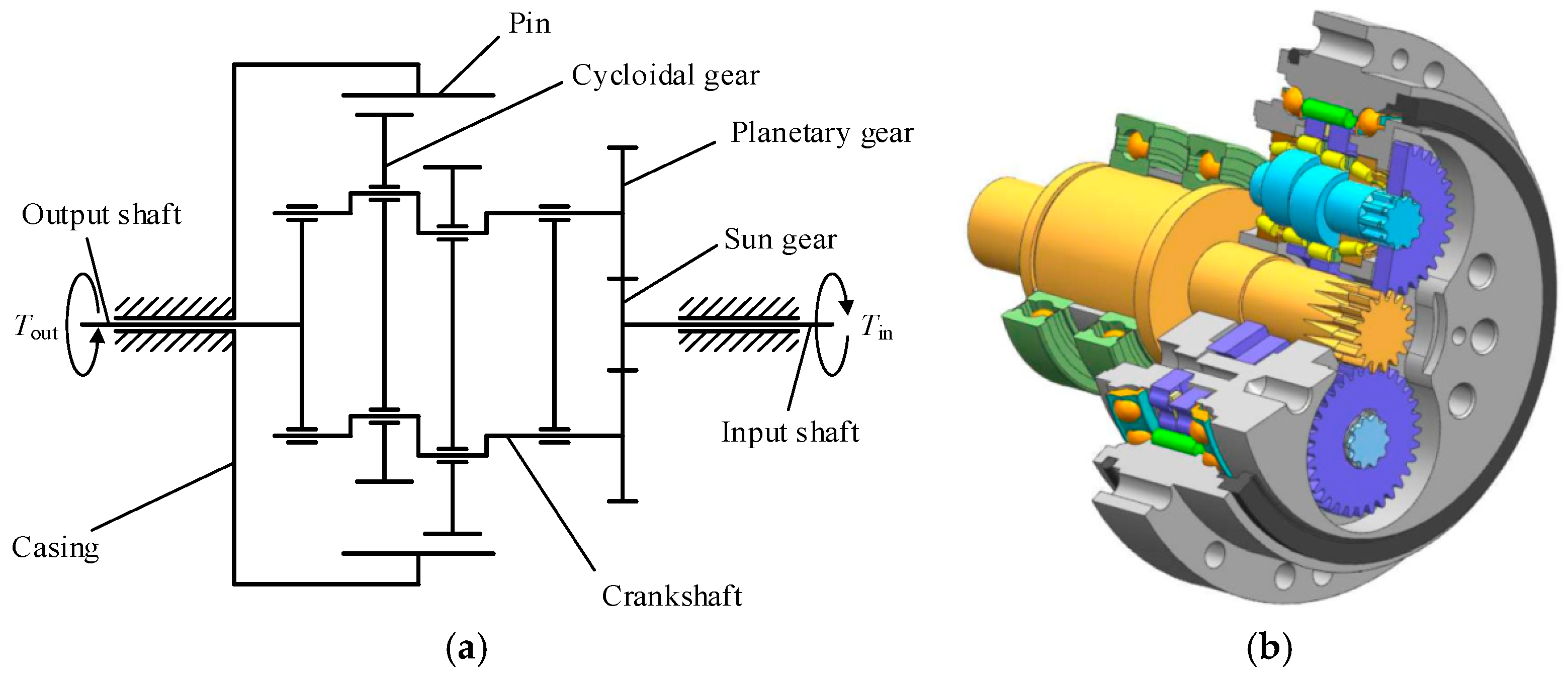

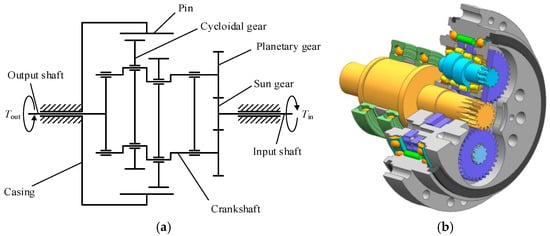

RV reducers typically comprise a K-H differential gear system with involute spur gears and a K-H-V planetary gear system with single-tooth-difference cycloid-pin gears. The transmission principle and 3D model are illustrated in Figure 1. During the transmitting motion, torque is transmitted from the input shaft to the first-stage sun gear (with zs teeth), which meshes with multiple planetary gears (zp teeth) mounted on crankshafts. The crankshafts’ self-rotation drives the cycloidal gears (zc teeth) in the second stage into a planetary revolution motion. Through meshing with the pins (zr teeth), the cycloidal gears generate a counteracting force that induces the crankshafts revolve. This revolutionary motion is transferred via the planetary carrier producing the gear system’s output motion. The transmission ratio of the RV reducer is derived as follows:

Figure 1.

(a) Transmission principle and (b) 3D model of an RV reducer.

2.2. Error Tooth Surface Model

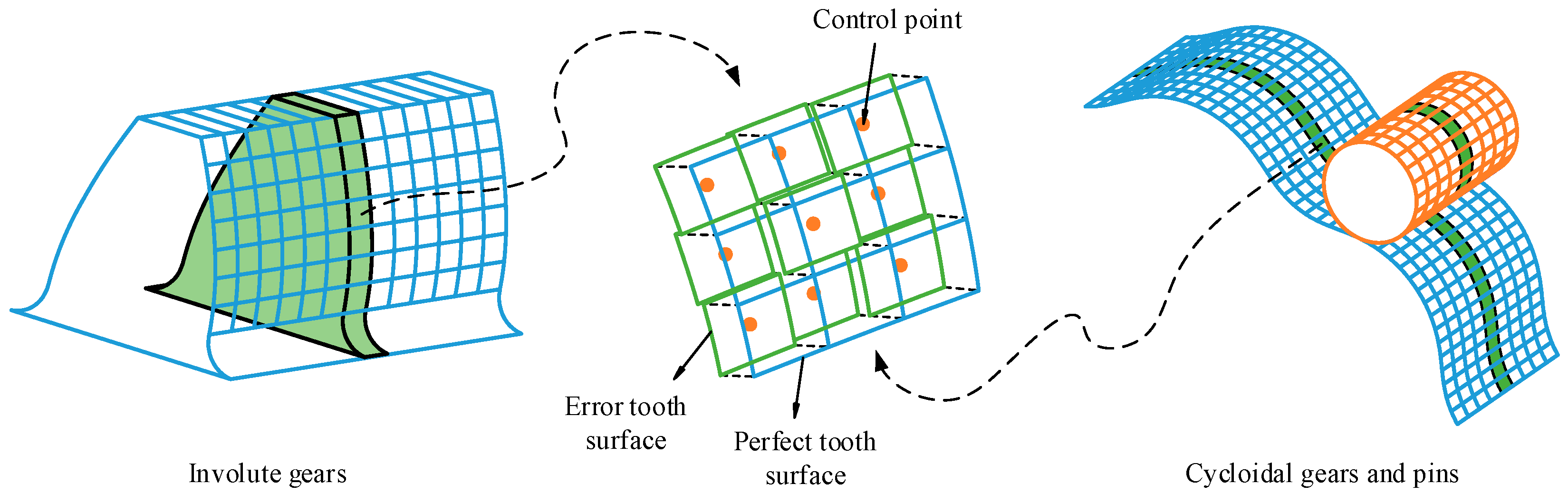

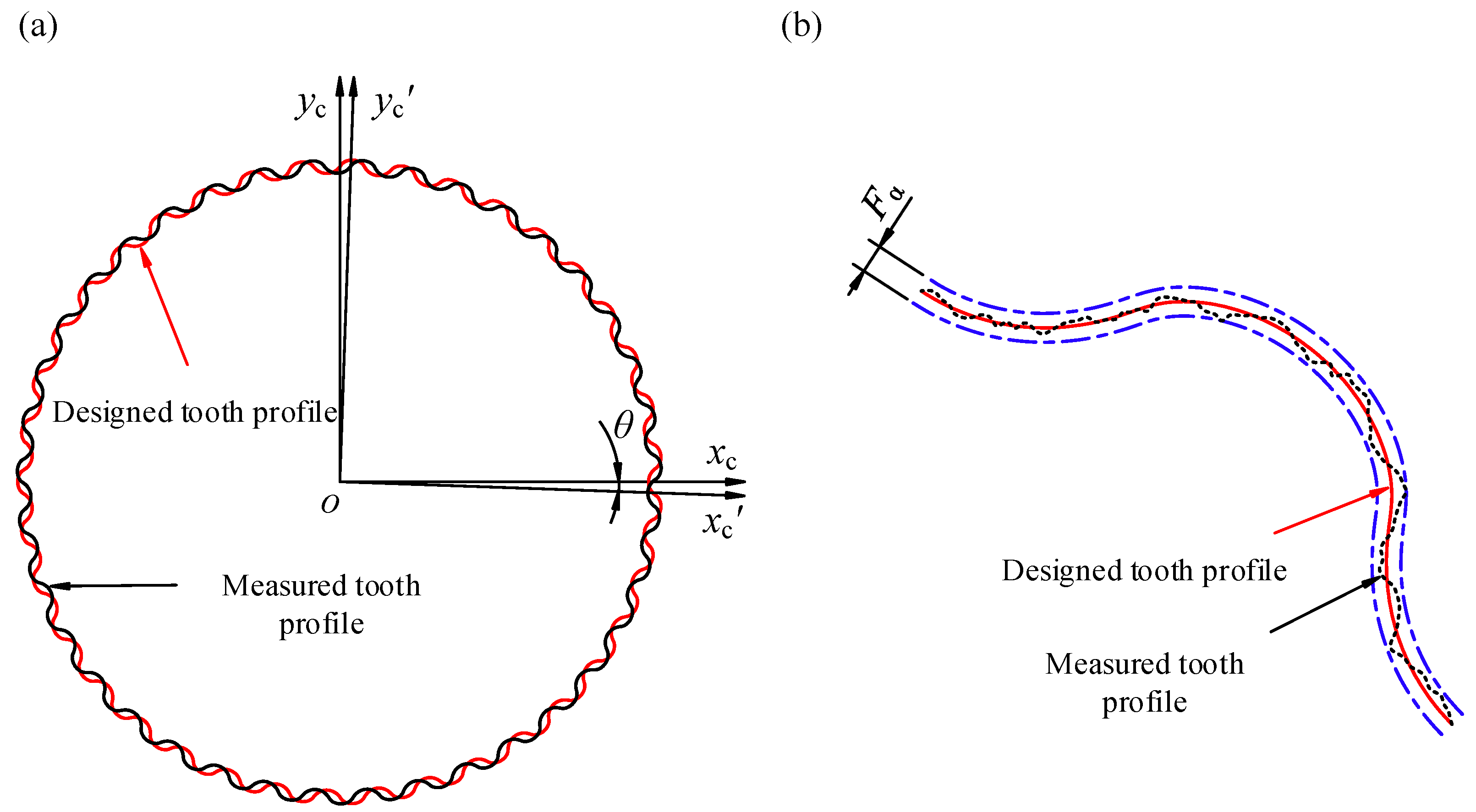

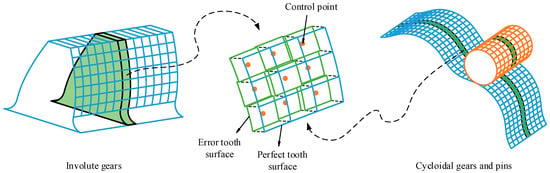

To comprehensively account for the effects of gear MEs, AEs, and tooth modifications (TMs), the authors previously developed error tooth surface models for involute gears and cycloidal gears and pins in [39,40], as shown in Figure 2. In this model, gear tooth surfaces are discretized into multiple uniformly sized micro-elements, each defined by a control point located at its geometric center. The cumulative geometric deviations induced by MEs, AEs, and TMs are transformed into equivalent normal displacements at these control points. Additionally, a tooth contact analysis algorithm and an improved gear meshing model for error tooth surfaces are proposed to support this framework, as detailed in the aforementioned references.

Figure 2.

Error tooth surface model.

2.3. Static Equilibrium and Deformable Compatibility Conditions

Based on the transmission principle of RV reducers, the sun gear experiences both the input torque and the forces exerted by the planetary gears. Its static equilibrium is governed as follows:

where Np denotes the number of planetary gears, Fspi represents the force exerted by the ith planetary gear on the sun gear, Tin signifies the input torque of the reducer, and rbs is the base radius of the sun gear.

The ith planetary gear maintains static balance under forces from both the sun gear and crankshaft, expressed as follows:

where FHpi and THpi represent the force and torque applied by the crankshaft, respectively, and rbp denotes the base radius of the planetary gear.

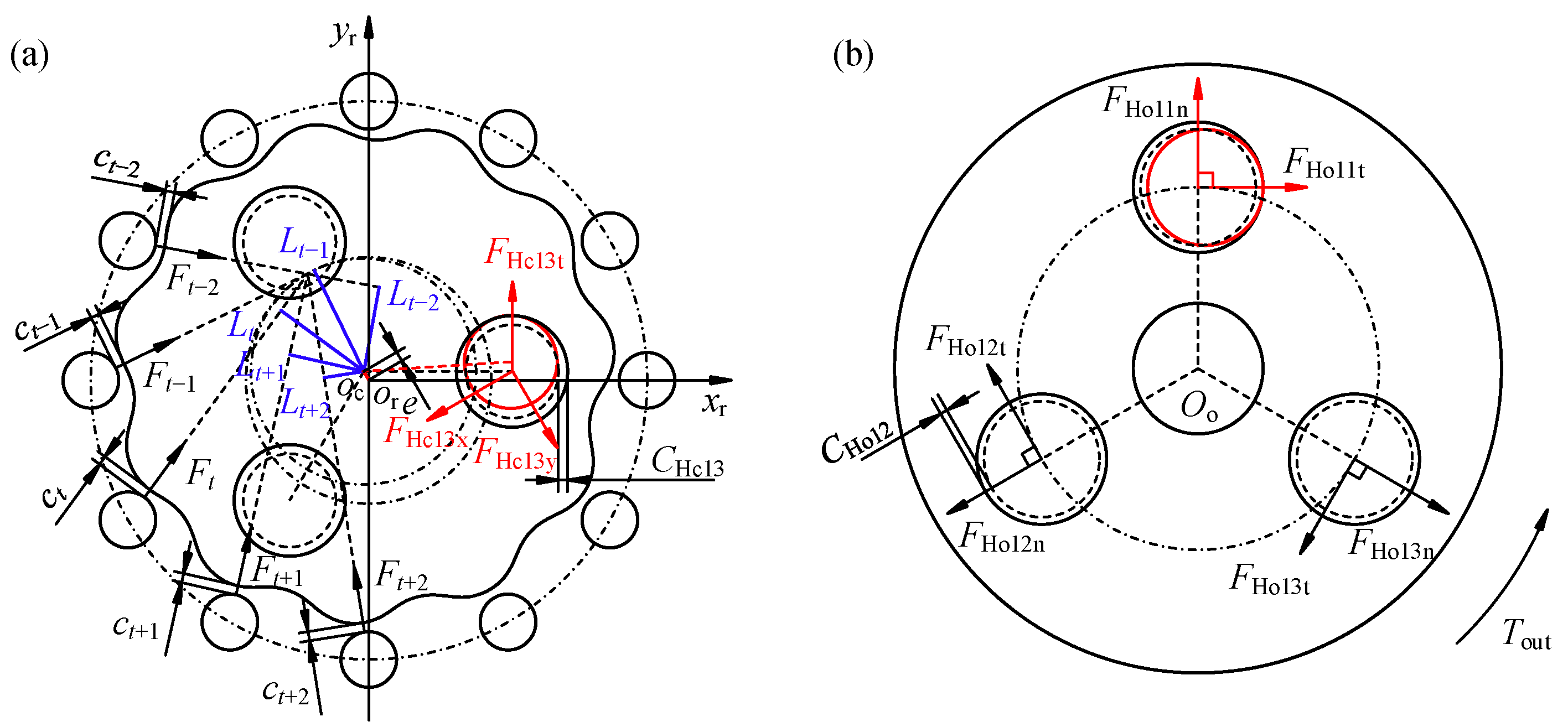

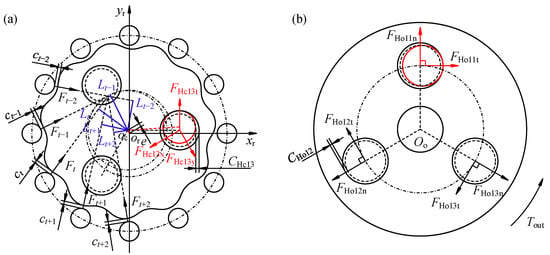

The force analysis of the jth cycloidal gear is depicted in Figure 3a. As this gear rotates around its geometric center oc, it also revolves around the pin distribution circle center or. It remains in equilibrium under the forces of pins and crankshafts. The force (Ft) and force arm (Lt) exerted by the pins are determined using the loaded tooth contact analysis algorithm for the cycloid-pin gear pair proposed in [40]. The crankshaft force acting on the cycloidal gear is decomposed into three components: FHcjit (perpendicular to cycloidal gear radius), FHcjiy (along oc-or line), and FHcjix (perpendicular to oc-or line). Therefore, the static equilibrium equations of the jth cycloidal gear about its center are expressed as follows:

where Nr denotes the number of pins in contact with the jth cycloidal gear; Fjt and Ljt represent the force and force arm exerted by the tth pin on the jth cycloidal gear, respectively; θjt signifies the angle between Fjt and the direction perpendicular to ocor, and θjt = θjtr − θjcr, with θjtr being the angle between Fjt and the positive direction of the xr axis in the fixed coordinate system orxryr, and θjcr being the rotation angle of the jth cycloidal gear around or; and asp is the center distance between the sun and planetary gears.

Figure 3.

Force analyses of (a) cycloidal gear and (b) planet carrier.

The force analysis of the planetary carrier is showcased in Figure 3b, where only the forces on the output side of the reducer are shown for clarity. The forces exerted by the crankshaft on the planetary carrier are decomposed into two directional components: FHojin (along crankshaft-carrier centerline) and FHojit (perpendicular to carrier radius). The static equilibrium equation of the planetary carrier is governed by:

where FHo1it and FHo2it denote the tangential forces of the planetary carrier near the output and input sides of the reducer, respectively, and Tout represents the output torque of the reducer.

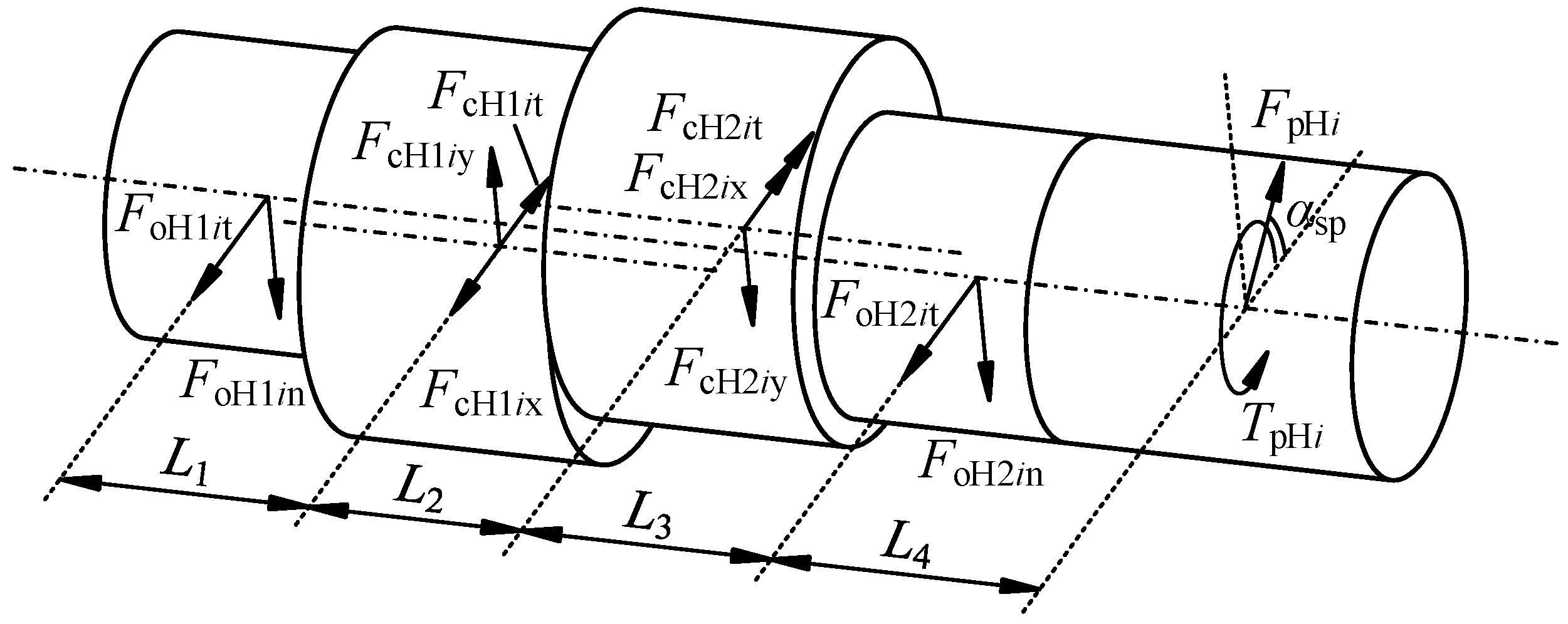

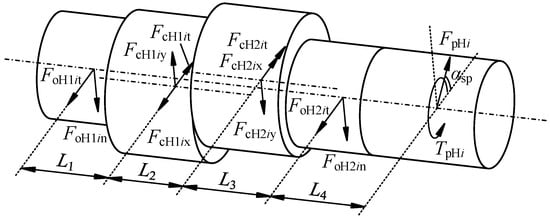

Based on the force interactions among the components and the balance between applied and reactive forces, the crankshaft is subjected to the planetary gear forces (FpHi and TpHi), the cycloidal gear forces (FcHjix, FcHjiy, and FcHjit), and planetary carrier forces (FoH1it, FoH1in, FoH2it, and FoH2in). These interactions are illustrated in Figure 4. Accordingly, the static equilibrium equations for the ith crankshaft are expressed as follows:

where θcs denotes the angle between the forces FcH1ix and FoH1it, representing the crankshaft’s rotational angle; αsp refers to the meshing angle between the sun and planetary gears; Nc signifies the number of cycloidal gears; and e is the eccentric distance of the crankshaft.

Figure 4.

Force analysis of the crankshaft.

Additionally, the bending moment equilibrium equations of the crankshaft in the horizontal and vertical planes are given as follows:

where L1, L2, L3, and L4 denote the distances along the crankshaft axis direction of each force application point.

As illustrated in Figure 3a, due to the high rigidity of cycloidal gears and crankshafts, only the turning-arm bearings and crankshaft support bearings are modeled as elastic bodies during the force transmission process. Identical support stiffness is assumed for all turning-arm bearings acting on the cycloidal gears. Under ideal meshing conditions between the cycloidal gears and pins, the elastic displacements of each turning-arm bearing along the xc, yc, and the direction perpendicular to the cycloidal gear radius are considered equal. However, due to the influence of MEs and AEs, the torque TpHi transmitted by each crankshaft varies, resulting in unequal elastic deformations along the xc direction among the bearings. Given a uniform radial clearance CHcji for all turning-arm bearings, the deformation compatibility conditions are defined as follows:

where δHcjiy and δHcjit denote the elastic displacements of the turning-arm bearing along the yc axis and perpendicular to the cycloidal gear radius, respectively, computed as follows:

where KHcjiy and KHcjit represent the support stiffness of the turning-arm bearing to the cycloidal gear in different directions. This study neglects the influence of the xc-direction elastic deformation of the turning-arm bearing on the crankshaft rotation angle.

As depicted in Figure 3b, assuming a uniform radial clearance CHoji, the displacement of each crankshaft support bearing perpendicular to the planetary carrier radius is equal under the applied output torque. The corresponding deformation compatibility condition for the crankshaft support bearing is given as follows:

where δHojit represents the elastic displacement of the crankshaft support bearing perpendicular to the planetary carrier radius, computed as follows:

where KHojit signifies the support stiffness of the crankshaft support bearing perpendicular to the planetary carrier radius and is assumed identical for each crankshaft support bearing.

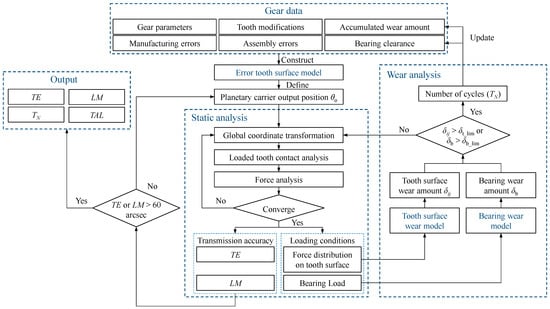

2.4. Calculation Method for Transmission Accuracy and TAL

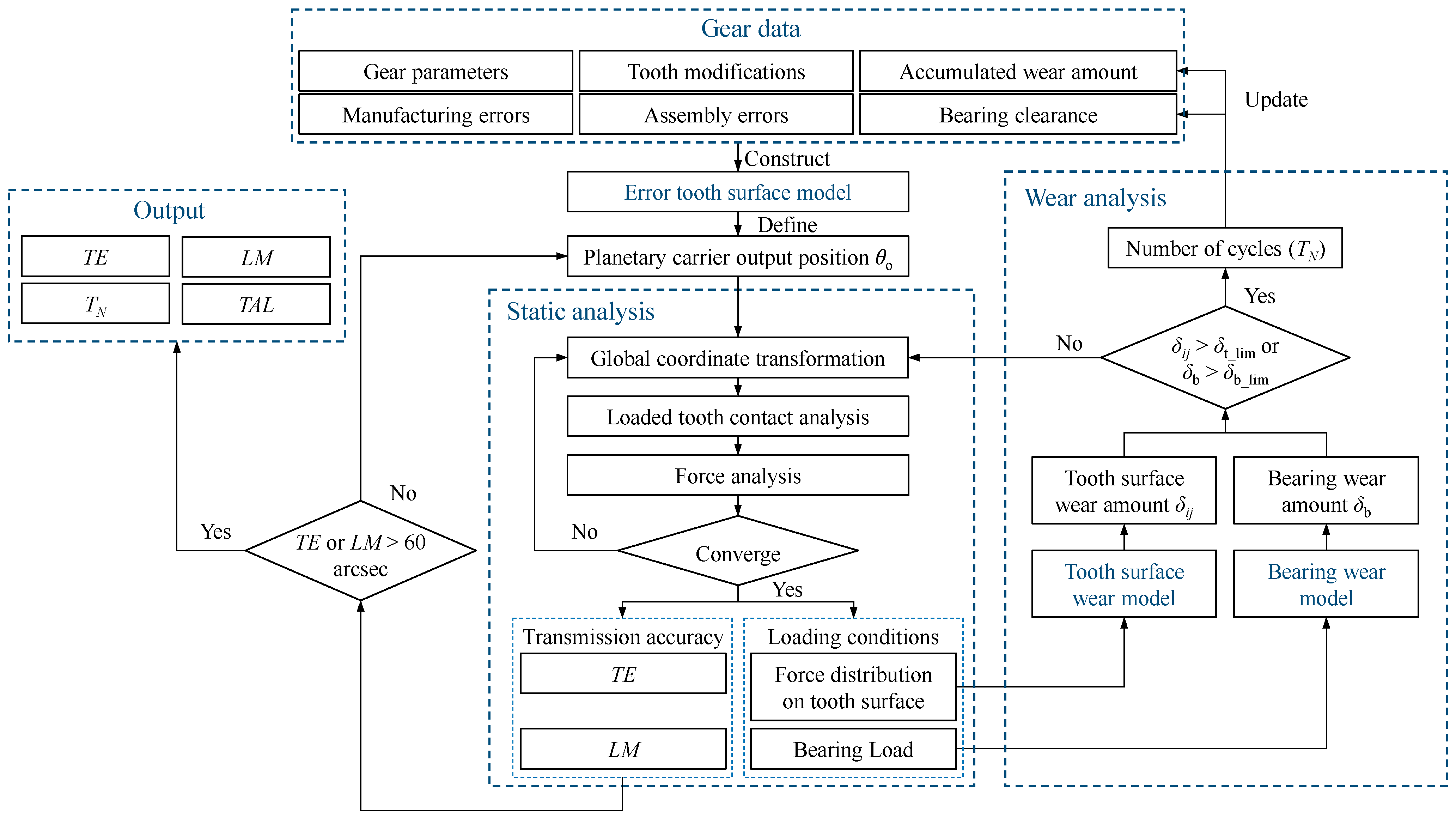

The transmission accuracy and TAL of RV reducers were determined through an iterative process, as shown in Figure 5. To account for the coupling effects of multiple error sources, error tooth surface models for the cycloid-pin and involute gear pairs were first established, incorporating gear parameters, the distribution law of MEs and AEs, tooth modification methods and amounts, radial bearing clearances, and the accumulated wear of tooth surfaces. The planetary carrier’s rotation direction and step size were then defined, yielding a series of carrier positions (θo). At each position, a global coordinate transformation was performed for all reducer components, followed by a loaded tooth contact and force analysis of both the cycloid-pin and involute gear pairs. When the calculated forces and angular displacements of all components satisfied the convergence criteria, the transmission accuracy of the RV reducer at that carrier position was recorded.

Figure 5.

Flowchart of transmission accuracy and TAL analysis for RV reducers.

TE is defined as the angular deviation between the actual and theoretical rotation angles of the output shaft. If the actual rotation angle of the sun gear is θs, the TE of the RV reducer for any planetary carrier position θo can be expressed as follows:

In the calculation of LM, the load induced deformation of RV reducer components is generally neglected. Accordingly, for any planetary carrier position θo, forward and inverse coordinate transformations of the cycloid-pin and involute gear pairs are performed, and tooth contact analyses are conducted. When the output shaft of the RV reducer is fixed at position θo, and the actual forward and reverse rotation angles of the sun gear are θsF and θsR, respectively, the LM at the output end of the RV reducer can be expressed as follows:

In addition, the static analysis of the RV reducer was used to provide loading conditions for both the tooth surface wear model and the bearing wear model. Under these conditions, the wear increments of each discrete tooth surface element, Δδij, and the bearing, Δδb, per cycle were calculated, and their total wear amounts, δij and δb, were accumulated. When δij or δb exceeded a defined threshold (δt_lim or δb_lim), the total number of output shaft cycles (TN) was recorded, and an updated error tooth surface model was reconstructed based on the accumulated wear. This procedure was repeated until the TE or LM of the RV reducer surpassed the allowable limit (e.g., 60 arcsecs), at which point the transmission accuracy across different cycle counts and the TAL of the RV reducer were determined. The TAL can be expressed as follows:

where Nrc denotes the number of reconstructions of the error tooth surface model, and no represents the output speed of the RV reducers.

3. Wear Model of the Tooth Surface and Bearing

Wear has been identified as the primary cause of RV reducer failures [33]. The wear of tooth surfaces and rolling bearings not only diminishes the transmission accuracy but also affects the smoothness of motion. To investigate the degradation behavior of the transmission accuracy of RV reducers, wear models for the cycloid-pin gear pairs, involute gear pairs, and rolling bearings were established in this section.

3.1. Tooth Surface Wear Model

(1) Archard’s wear formula

The Archard wear formula has been recognized as the most widely used and experimentally validated method for estimating tooth surface wear in practical applications. According to this formula:

where V signifies the wear volume, S denotes the relative sliding distance, W represents the normal load at the contact point, H refers to the surface hardness of the wear surfaces, and K is the wear coefficient of dimension one.

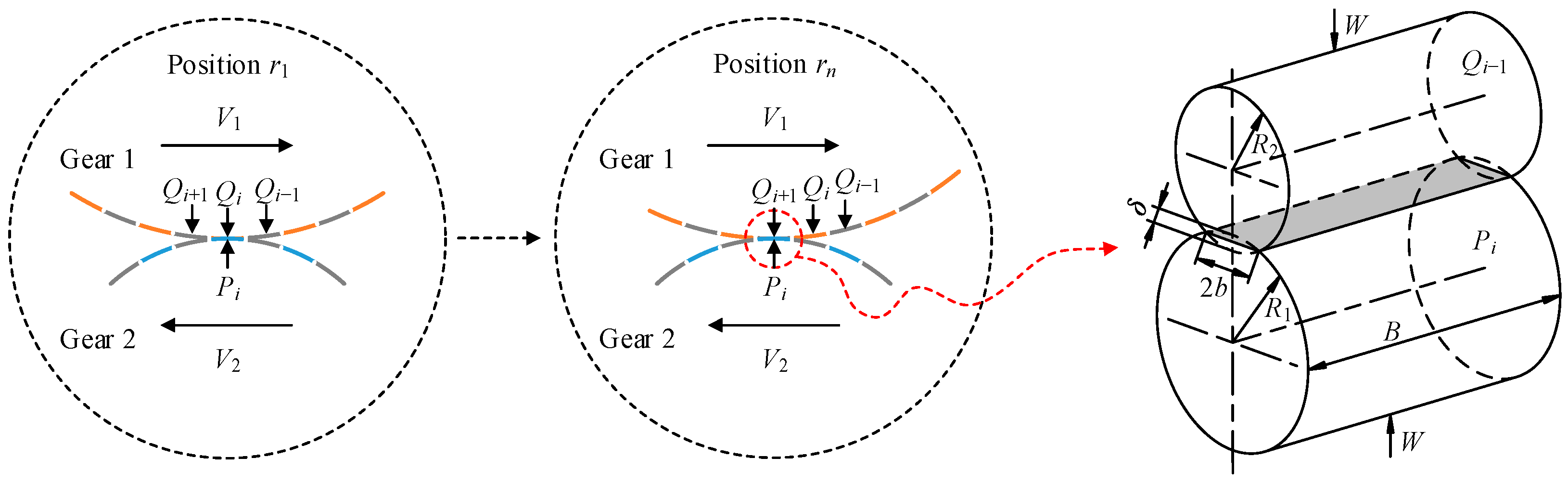

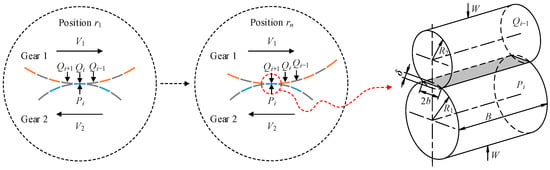

In the error tooth surface model, the tooth surfaces of the involute gears, cycloidal gears, and pins were discretized into microelements. The meshing process of a microelement is illustrated in Figure 6, where the microelement Qi on the tooth surface of gear 1 was assumed to mesh with the microelement Pi on the tooth surface of gear 2 at position r1. As the gears rotate, relative sliding occurs between the tooth surfaces until the microelements Qi and Pi lose contact, after which the microelement Pi engages with the adjacent microelement Qi+1 instead of Qi at position rn. The contact behavior of the microelement Pi is analogous to that of Qi. The interaction between microelements Qi and Pi can be equivalently modeled as the contact between two cylinders with different radii of curvature (R1 and R2) [15,16]. For detailed algorithms of tooth contact analysis, please refer to [39,40]. The wear depth of each microelement throughout the meshing process can be expressed as follows:

where p denotes the contact pressure, s signifies the sliding distance, and k = K/H is the wear coefficient, which is influenced by lubrication characteristics, surface roughness, material properties, and operating conditions, and can be obtained through a regression formula proposed by Janakiraman [41].

Figure 6.

Tooth surface wear model.

Because the engagement of each microelement lasts only a fraction of the total meshing cycle of a tooth, its wear depth is determined based on the average pressure acting during this interval. Accordingly, the wear depth of each microelement over the meshing process can be expressed as follows:

where the subscripts 1 and 2 designate the two meshing tooth surfaces, denotes the average pressure across the microelement’s contact area, and S1,2 indicates the sliding distance of the microelement over a single engagement cycle, defined as follows:

where ε1 and ε2 denote the sliding coefficients of the two contacting elements, with their analytical expressions introduced later in this section, while b is the contact half-width (Figure 6), which can be determined via Hertzian contact theory.

Once the cumulative wear depth of discrete elements on the tooth surface exceeds the threshold δt_lim, a significant alteration of the contact pressure distribution occurs. In such cases, it becomes necessary to reconstruct the error tooth surface model and recalculate the average pressure acting on each element over an engagement cycle. The total number of engagement cycles in which a discrete element is involved before the cumulative wear depth on both surfaces reaches this threshold is defined as follows:

(2) Sliding coefficients in cycloid-pin drive

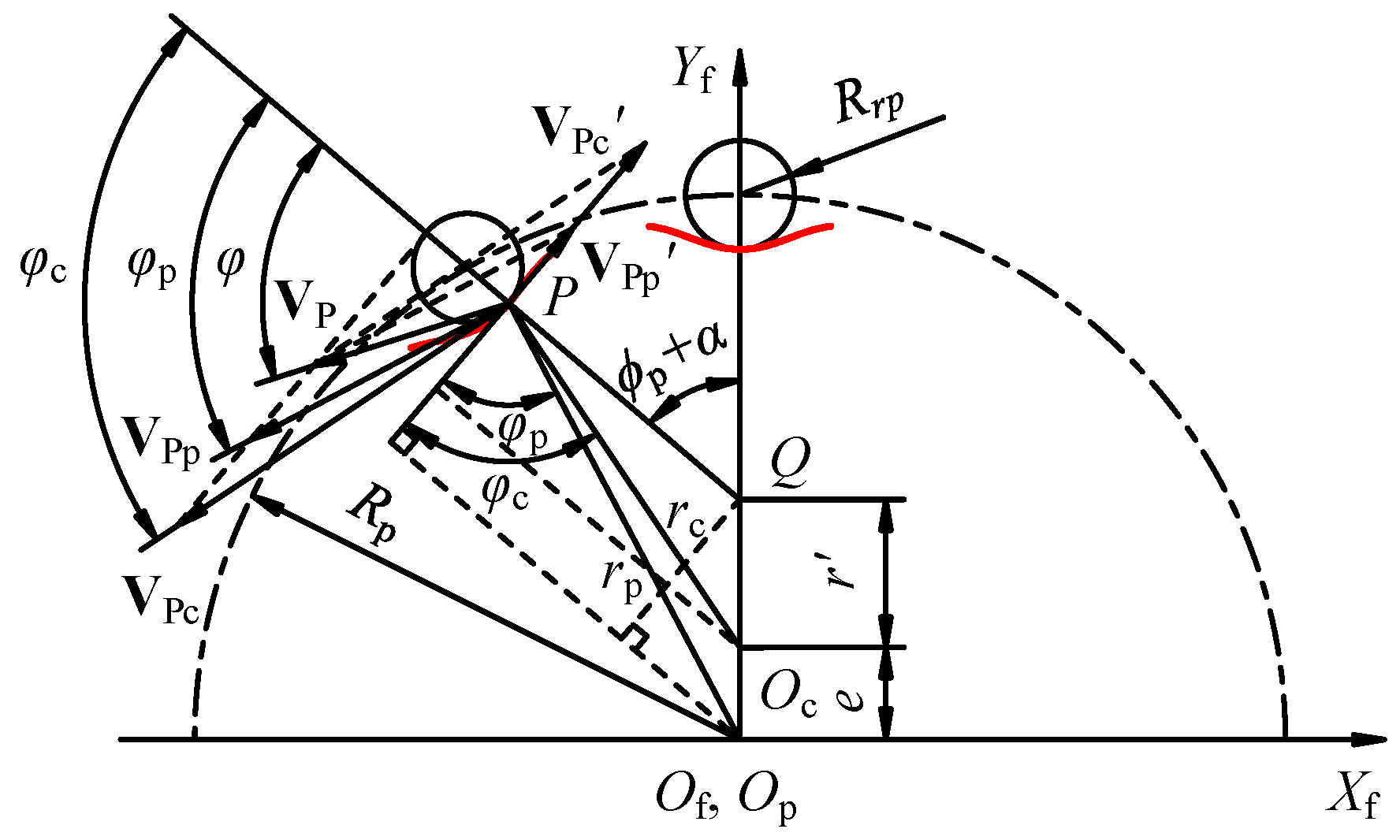

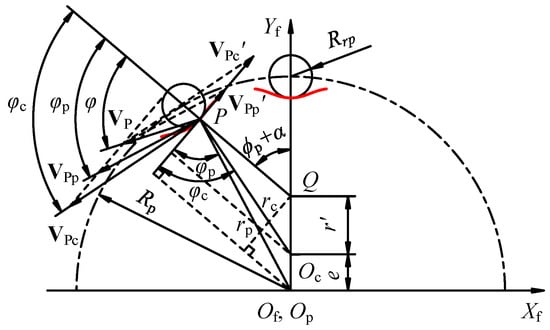

In this study, the effects of various errors on the sliding coefficient were neglected. For the cycloid-pin gear pair, the sliding coefficients of the cycloidal gear and the pin were derived from their relative kinematics within a transformed gear train (Figure 7). In this configuration, the turning-arm OpOc was treated as fixed, thereby allowing the cycloidal gear and the pin to be analyzed as a fixed-axis gear system relative to the turning arm, while the pin’s rotation within its groove was ignored.

Figure 7.

Meshing speed analysis of cycloidal gears and pins (red line: cycloid profile).

The coordinate system XfOfYf was fixed to the turning-arm OpOc (Figure 7). At any given moment, the coordinates of the contact point P between the cycloidal gear and the pin can be expressed as follows:

where ϕp denotes the rotation angle of the pin relative to the turning arm; Rrp and Rp represent the pin radius and pin center circle radius, respectively; ; and k1 is defined as the short addendum coefficient of cycloidal gear, expressed as k1 = eZr/Rp.

According to the velocity relationships depicted in Figure 7, the kinematic constraints along the common normal and tangent directions of the tooth profiles at point P must be satisfied as follows:

where Vp represents the velocity of the contact point P; VPp and indicate its velocity components due to the pin’s rotation and sliding along the pin surface, respectively; VPc and denote its velocity components due to the cycloidal gear’s rotation and sliding along the cycloidal tooth surface, respectively; and φ, φp, and φc define the orientations of Vp, VPp, and VPc relative to the line connecting point P to the pin’s center, respectively.

Moreover, based on the geometric relationships depicted in Figure 7, it can be established that

where and are derived by differentiating the derivative of in the coordinate expressions of point P; and denote the angular velocities of the pin and cycloidal gear within the transformed gear train, respectively; rp and rc represent the distances from point P to centers Op and Oc, respectively; and α is defined as follows:

The rolling velocity between the cycloidal gear and the pin is defined as follows:

where iH denotes the transmission ratio of the transformed gear train.

The relative sliding velocity at the contact point P is expressed as follows:

Accordingly, the sliding coefficients of the pin (εr) and the cycloidal gear (εc) can be defined as follows:

(3) Sliding coefficients in the involute gear drive

A detailed derivation of the sliding coefficients for involute gear pairs is presented in [42]. Assuming that the sun and planetary gears mesh at point Q, the sliding coefficients for the sun gear (εs) and the planetary gear (εp) are expressed as follows:

where αs represents the reference circle pressure angle, and αqs denotes the pressure angle at the sun gear meshing point Q.

3.2. Rolling Bearing Wear Model

Rolling bearing wear increases radial clearance and degrades the RV reducer’s transmission accuracy. In this context, the turning-arm bearings (cylindrical roller bearings) and crankshaft support bearings (tapered roller bearings) have been identified as the critical elements affecting precision. Therefore, this study is confined to the wear-induced clearance effects of these bearing types.

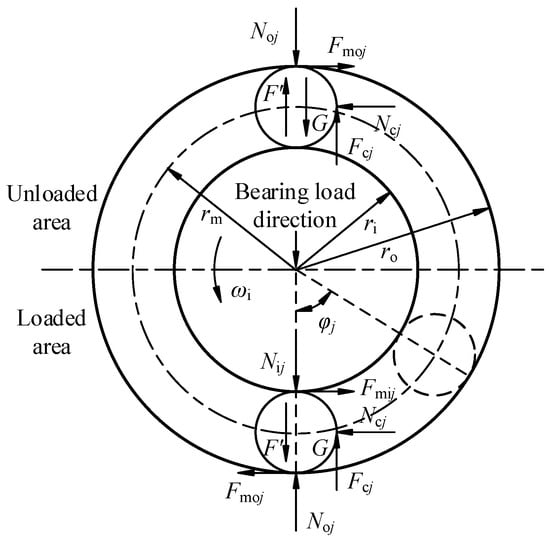

(1) Rolling element force analysis

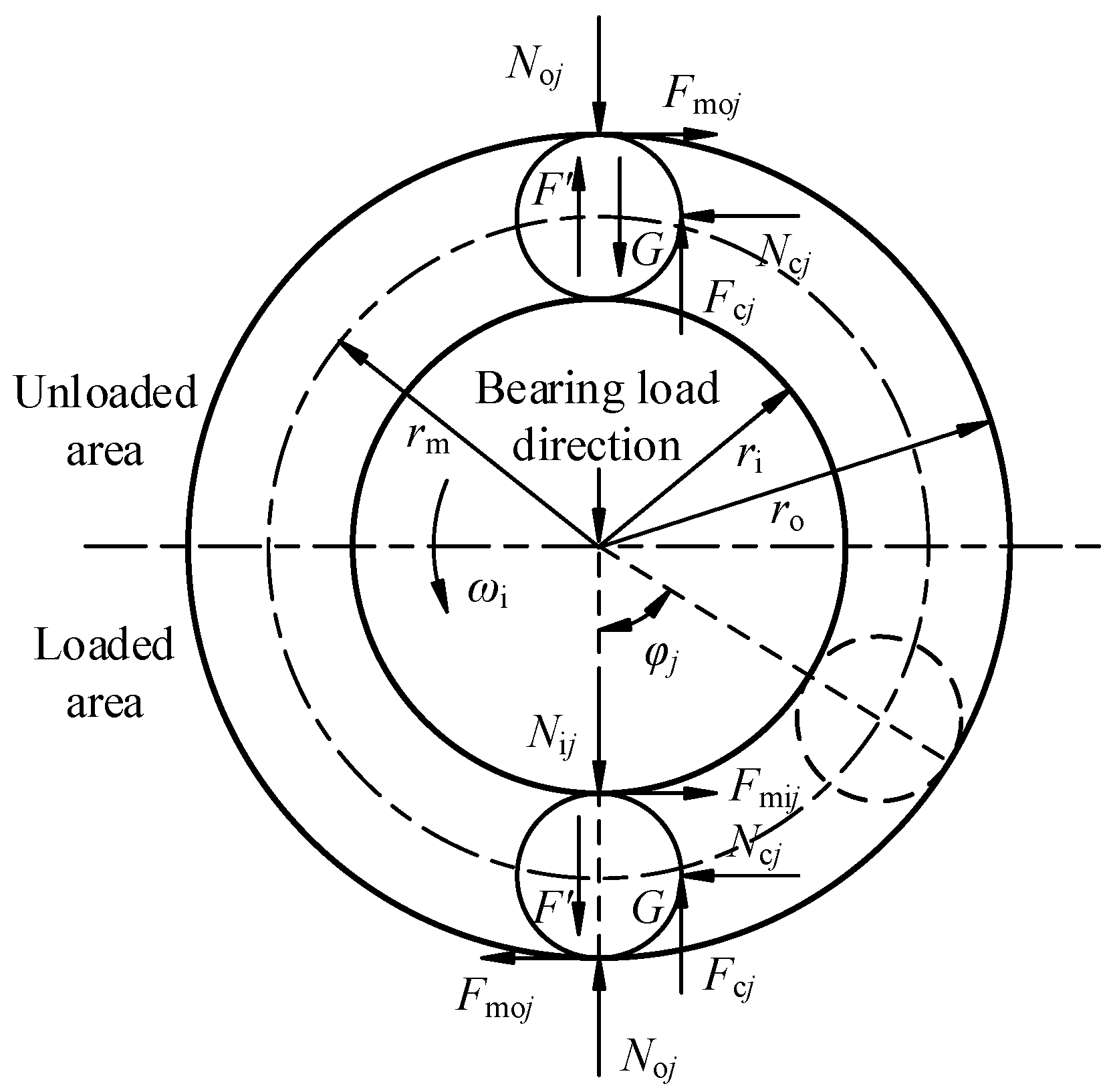

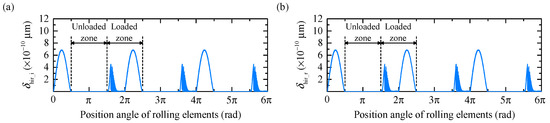

It is assumed that the inner ring rotates at constant angular velocity ωi. The positions of rolling elements vary continuously, although identical force and motion characteristics occur as each element passes the same position. Consequently, a single representative roller was selected for analysis (Figure 8). In operation, rolling bearings can be divided into loaded and unloaded zones. Because radial clearance and component deformation are negligible relative to the inner ring radius, it is assumed that roughly half the rolling elements operate within the loaded zone.

Figure 8.

Force analysis of the rolling bearing.

In the loaded zone, each rolling element is simultaneously in contact with both the inner and outer raceways under radial load, while the cage is driven forward by the rolling elements. The rolling elements are primarily influenced by the normal forces (Nij and Noj) of the inner and outer raceways, the frictional forces (Fmij and Fmoj) of the inner and outer raceways, the cage’s normal and frictional forces (Ncj and Fcj), and the centrifugal and gravitational forces (F’ and G). Accordingly, the force equilibrium equations for the rolling elements in the bearing radial and circumferential directions, as well as for the rolling element rotation direction within the loaded zone, are established as follows:

where φj denotes the angular position of the jth rolling element; Jr and mr represent its moment of inertia and mass, respectively; ωr and ωm indicate the angular velocities of the rolling element about its center and about the bearing center, respectively; ri and ro signify the radii of the inner and outer raceways, respectively; and rr and rm are the radii of the rolling elements and the rolling bearing pitch circle, respectively. When applying these expressions to the crankshaft support bearings (tapered roller bearings), ri and ro are defined as the turning radii of the inner and outer raceway centers, respectively; rm is taken as the average of the inner and outer raceway radii; and rr is defined as the mean roller radius calculated from the small-end and large-end radii of the tapered roller.

In the unloaded zone, the rolling elements are acted upon by the centrifugal force F’ and gravity G, with the centrifugal force generally exceeding the gravitational effect. In this zone, the rolling elements remain pressed against the outer raceway, while no normal force is exerted on the inner raceway (Nij = 0). As a result, the rolling elements are primarily influenced by the normal forces Noj and Ncj, the friction forces Fmoj and Fcj, and the centrifugal and gravitational forces F’ and G. The force equilibrium equations for the rolling elements in the bearing radial and circumferential directions, as well as for the rolling element rotation direction within the unloaded zone, are expressed as follows:

where the centrifugal force F’ acting on the rolling elements in the preceding expressions is defined as follows:

Under typical lubrication conditions, the friction coefficient μ is generally defined as a piecewise linear function of the relative sliding velocity, while the influence of load magnitude is neglected [43]. The calculation for the friction coefficient is expressed as follows:

where ΔVi and ΔVo denote the relative sliding velocities between the rolling element and the inner and outer raceways, respectively, which are calculated as follows:

Due to the relatively high sliding velocity between the rolling elements and the cage, the corresponding friction coefficient μ is treated as a constant value of 0.002. Following Coulomb’s friction theory, the friction forces can be calculated as the product of the normal contact forces and the friction coefficient. Therefore, the expressions for the friction forces Fmij, Fmoj, and Fcj are defined as follows:

The radial support force acting on each crankshaft-mounted rolling bearing can be obtained through the static analysis of the RV reducer. As this force varies periodically with the crankshaft’s angular position, its average value over one cycle is used to approximate the radial load of each bearing for computational efficiency. The normal force Nij between the inner raceway and the rolling elements is then calculated based on Hertzian contact theory and the roller deformation compatibility conditions. Meanwhile, it is assumed that the cage rotates at a constant angular velocity ωc and that a clearance dc exists between the rolling elements and the cage pockets. Due to variations in the rolling elements’ angular velocity relative to the bearing center, contact alternation occurs between the front and rear sides of the cage pockets. Under these conditions, the normal force Ncj exerted by the cage pocket on the rolling element can be expressed as follows:

where Kc denotes the contact stiffness between the rolling element and the cage pocket, φc = ωct is the cage rotation angle, and the direction of Ncj is determined from the schematic shown in Figure 8. In the loaded zone, when φc < φj, the cage is driven by the rolling elements, yielding positive Ncj and Fcj values (aligned with Figure 8). Conversely, when φc > φj, both Ncj and Fcj assume negative values. In the unloaded zone, when φc < φj, the cage drags the rolling elements, causing Ncj and Fcj to be negative (opposite to Figure 8), whereas, for φc > φj, both forces assume positive values.

(2) Calculation formula for bearing wear

Each rolling element forms three friction pairs with the inner raceway, outer raceway, and cage within the loaded zone, and two friction pairs with the outer raceway and cage within the unloaded zone. Considering the cage’s lower wear resistance relative to the rolling elements, only wear between the rolling elements and the raceways is analyzed in this study. Based on the Archard wear model introduced above, the wear amounts at different angular positions φj are expressed as follows:

where δhij, δhoj, and δhrj denote the wear amounts of the inner and outer raceways and rolling elements, respectively; Kirj and Korj represent the wear coefficients for the rolling element’s contact with the inner and outer raceways, respectively; birj and borj are the corresponding Hertzian half-contact widths; εirj, εrij, εorj, and εroj indicate the sliding coefficients; and the average contact pressures, and , are calculated from the normal forces FNij and FNoj and the contact areas Sij and Soj, respectively, as follows:

For cylindrical roller bearings FNij = Nij and FNoj = Noj. In the case of tapered roller bearings, FNij and FNoj are calculated using the following expressions:

where αi and αo denote the contact angles between the tapered roller and the inner and outer raceways, respectively.

The sliding coefficients for the rolling elements relative to the inner and outer raceways are defined as follows:

Because the bearing radial force direction varies with the crankshaft rotation angle, the average wear of the inner and outer raceways and rolling elements over the range of position angle φj = 0–2π is approximated as the wear accumulated in one cycle at each contact point. Accordingly, the total wear of the bearing components per cycle is expressed as follows:

where m denotes the number of equal divisions of the contact area over the range φj = 0–2π.

The resulting increase in bearing clearance due to rolling bearing wear is expressed as follows:

where t represents the total operating time of the rolling bearing, and nbi, nbo, and nbr denote the number of wear cycles per unit time for the inner raceway, outer raceway, and rolling elements, respectively.

4. Degradation Law Analysis of Transmission Accuracy

In this section, the degradation of RV reducer transmission accuracy is characterized by integrating the static analysis model with the wear models of the tooth surfaces and bearings. As variations in tooth surface microgeometry and bearing radial clearance inevitably affect the load distribution within the reducer, it becomes necessary to reconstruct the error tooth surface and update bearing radial clearance once the accumulated wear exceeds a defined threshold. According to prior studies, changes in tooth surface pressure can be neglected when profile variation remains below 2.5 μm [44]. Therefore, a wear depth limit of δt_lim = 2.5 μm was adopted for each tooth surface element, and a wear depth limit of δb_lim = 2.5 μm was applied to the bearings. The lubrication pressure-viscosity coefficient was 2.1099 × 10−8 m2/N, and the surface roughness of the contacting surfaces was set at 0.2 μm. The detailed gear parameters of the RV reducer are listed in Table 1. The rated output torque and rotational speed were 412 N·m and 15 r/min, respectively, and the crankshaft distance parameters (shown in Figure 4) were L1 = 12 mm, L2 = 13 mm, L3 = 14.5 mm, and L4 = 12.5 mm.

Table 1.

Gear parameters of the RV reducer.

4.1. Sliding Coefficients of Tooth Surfaces and Rolling Bearings

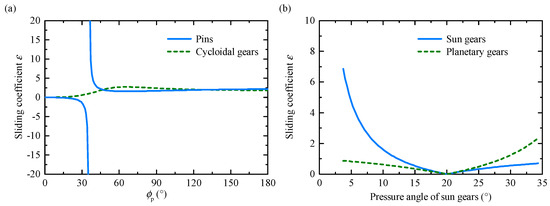

(1) Sliding coefficients of the cycloid-pin and involute gears

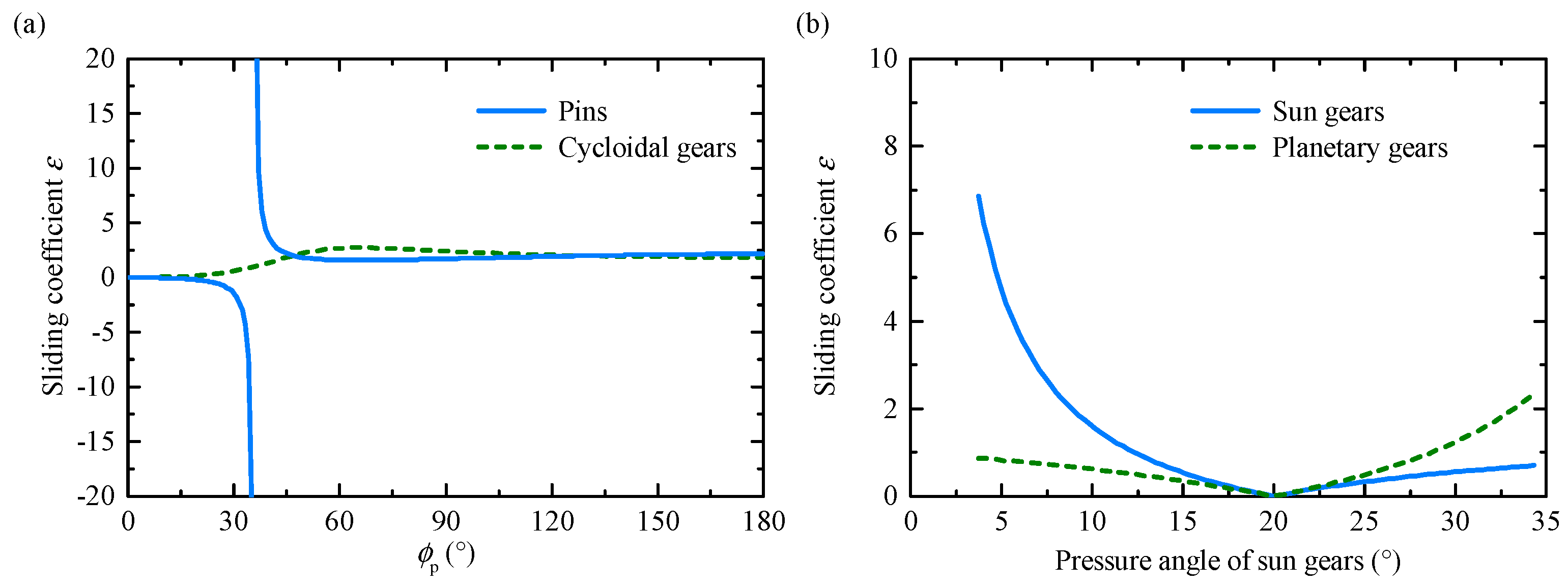

The sliding coefficients of the cycloid-pin and involute gear pairs are illustrated in Figure 9. The sliding coefficient of the cycloidal gear remained consistently positive, with a maximum value of 2.7258, while that of the pin approached infinity near ϕp = 36° (Figure 9a). This point coincided with the boundary of the meshing area, where the sliding velocity of the contact point was reduced to zero. As a result, wear was intensified in this region, making it susceptible to tooth scuffing and fatigue pitting.

Figure 9.

Sliding coefficients of (a) cycloid-pin gears and (b) involute gears.

The sliding coefficients of the sun and planetary gears were determined by their respective tooth surface contact positions. Unlike the pins in Figure 9a, both the sun and planetary gears displayed positive sliding coefficients, as absolute values were applied in (27). As shown in Figure 9b, these coefficients were observed to decrease and then rise from the tooth root toward the tooth tip, reaching their maximum values at the meshing-in and meshing-out points. At the pitch point, both coefficients were found to be zero, while the sliding coefficient at the root of the sun gear was significantly higher than that of the planetary gear. In general, the sliding coefficients at the roots of both gears were higher than those at their tips. It should be noted that this trend is specific to the involute gear pair defined in Table 1, and variations in gear parameters will result in changes to the sliding coefficient profiles.

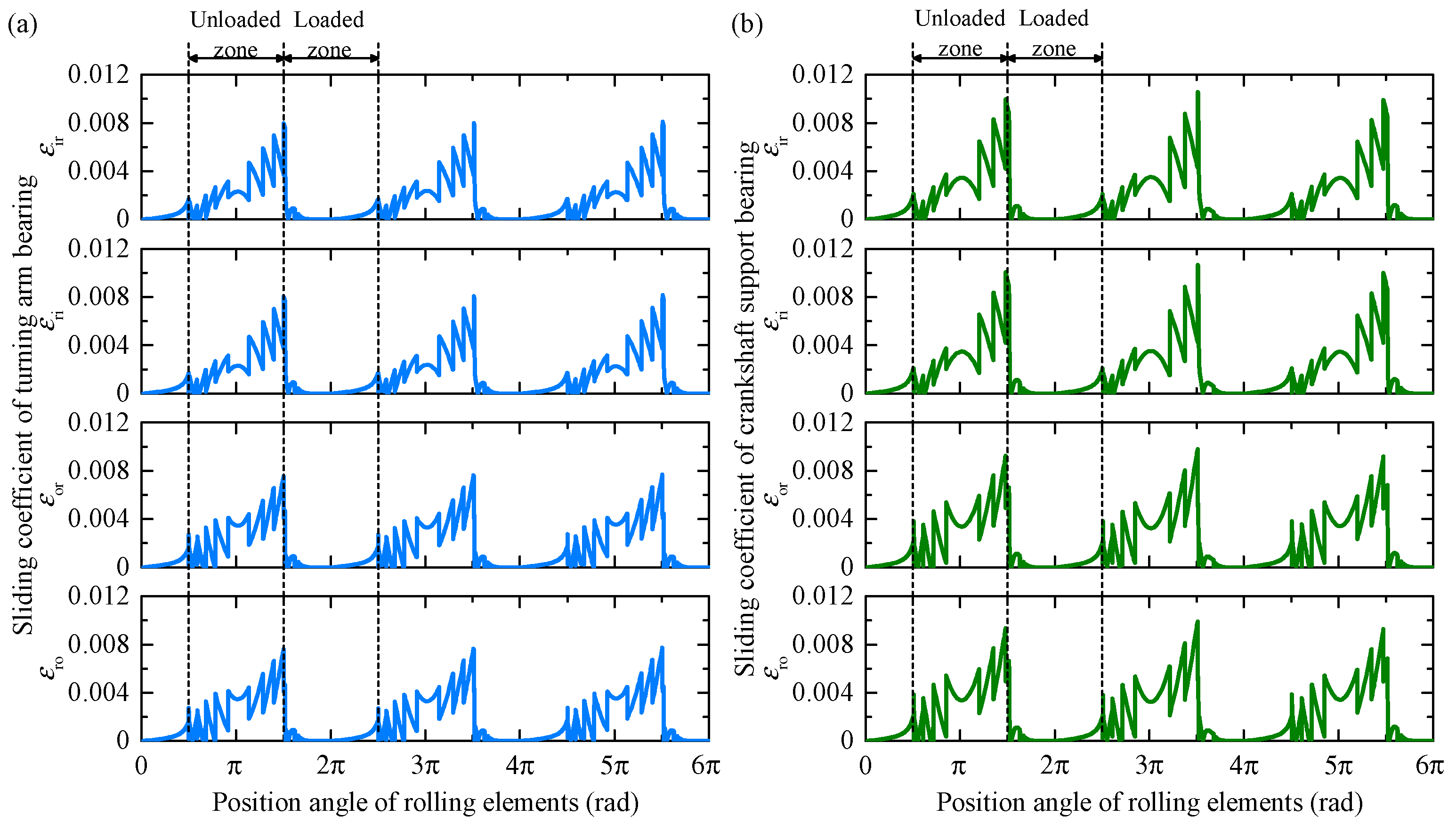

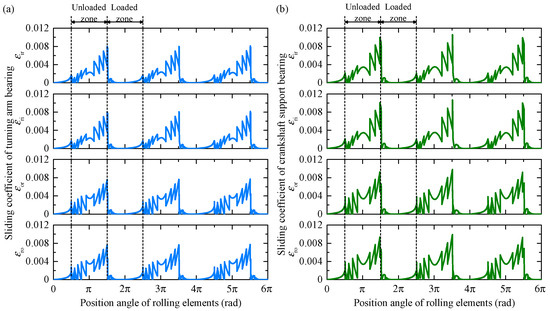

(2) Sliding coefficient of rolling bearing

The key parameters of the turning-arm bearings and the crankshaft support bearings in the RV reducer are presented in Table 2. According to the static analysis, the turning-arm bearings operated at a rated speed of 600 r/min and carried a maximum radial load of 4869.62 N, while the crankshaft support bearings operated at a rated speed of 585 r/min and bore a maximum radial load of 3558.39 N. the sliding coefficients for both bearing types are illustrated in Figure 10. As shown in Figure 10a, the sliding coefficient of the turning-arm bearing was found to be significantly higher in the unloaded zone than in the loaded zone. Notably, considerable sliding occurred between the rolling elements and both the inner and outer raceways as the elements entered and exited the loaded zone, with the sliding between rolling elements and the inner raceway being higher than that with the outer raceway. Figure 10b indicates that the trend of the sliding coefficients for the crankshaft support bearings was generally similar, although the sliding coefficients observed for these bearings were higher than those for the turning-arm bearings.

Table 2.

Parameters of the rolling bearings.

Figure 10.

Sliding coefficients of (a) turning-arm and (b) crankshaft support bearings.

4.2. Wearing Law of Tooth Surfaces and Rolling Bearings

Based on the tooth surface wear model developed in this study, the wear characteristics of cycloid-pin and involute gear tooth surfaces were analyzed under three distinct conditions: ideal tooth surfaces, modified tooth surfaces, and error tooth surfaces. At the same time, the variation in radial clearance in the rolling bearings throughout the operation of the RV reducer was examined.

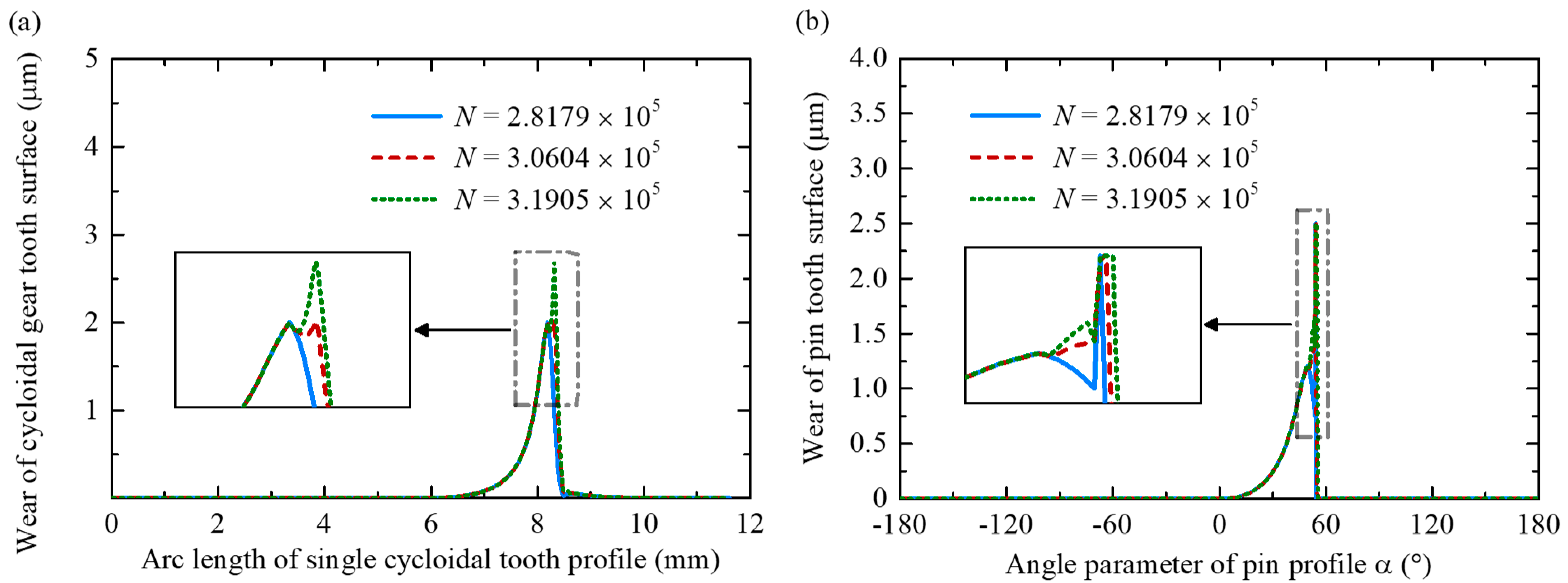

(1) Wear law of cycloid-pin gear tooth surfaces

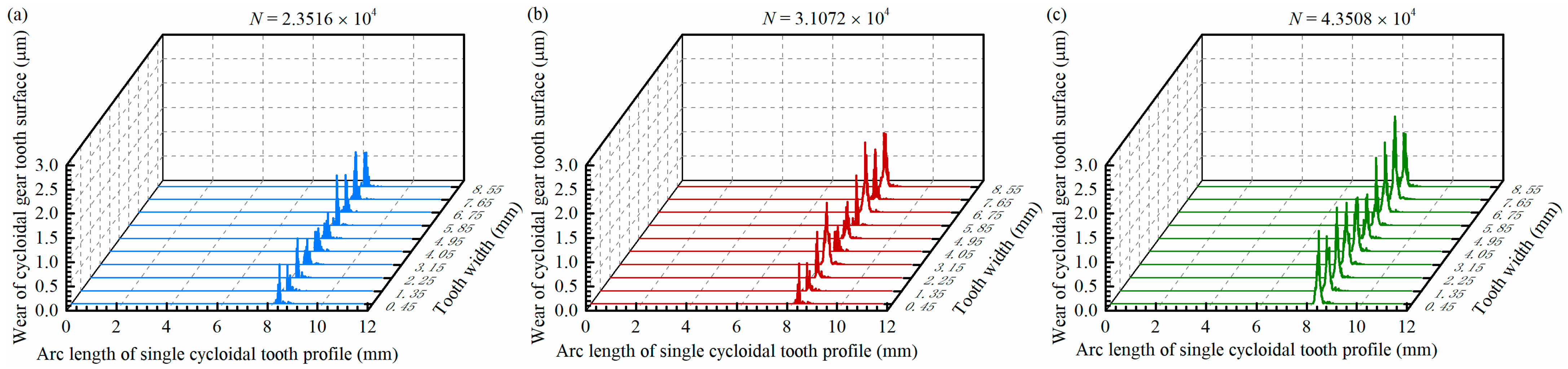

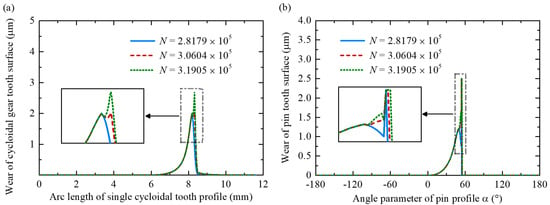

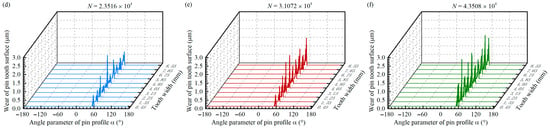

The wear amounts of the cycloid-pin tooth surfaces were calculated over three different operational cycles, and their distribution patterns are presented in Figure 11. In this figure, N denotes the number of revolutions of the cycloidal gear relative to the crankshaft. For a single meshing tooth pair, the total arc length of the cycloidal tooth profile was 11.6 mm, where the segment from 0 to 5.8 mm represented the non-working surface and the segment from 5.8 to 11.6 mm represented the working surface. As the arc length increased, the corresponding discrete element shifted from the tooth tip toward the tooth root. The theoretical contact area of the pin tooth surface was defined within α = 0–54.3692°, and a secondary meshing phenomenon occurred within the same discrete element in this contact area.

Figure 11.

Wear behavior of (a) cycloidal gear and (b) pin with ideal tooth surfaces.

It was observed that the wear of the cycloidal gear tooth surface initial increased, followed by a sharp decrease (Figure 11a). Because the sliding coefficient of the convex tooth surface was higher than that of the concave tooth surface, wear predominantly occurred on the convex surface, while wear on the concave surface remained relatively low. As shown in Figure 11b, the wear of the pin tooth surface increased with rising angular parameter α, and a sharp rise was observed at the edge of the contact area (at the maximum α), due to the theoretically infinite sliding coefficient at this position. Moreover, during the first cycle, the wear of the pin tooth surface decreased slightly near the edge of the contact area. This was attributed to the proximity of the meshing point between the pin and the cycloidal gear to the transition point between the convex and concave tooth surfaces of the cycloidal gear, where the curvature radius of the cycloidal gear approached infinity, leading to a significant reduction in contact stiffness between the cycloidal gear and the pin. In the first cycle (N = 0–2.8179 × 105), the average wear of the pin tooth surface was smaller than that of the convex surface of the cycloidal gear. As wear accumulated, the wear areas of both the cycloidal and pin tooth surfaces gradually expanded outward during the second and third cycle periods, as indicated by the enlarged view in Figure 11. When the total wear per cycle reached the threshold of 2.5 μm, the number of cycles in the second and third periods was lower than that in the first period.

With cycloid tooth profile modification amounts of ΔRrp = −0.004 mm and ΔRp = −0.017 mm, the wear behavior of the tooth surfaces is shown in Figure 12. As the cycloidal gear and the pin no longer strictly conformed to the ideal meshing conditions after the profile modifications, the contact area between the cycloidal gear and the pin was significantly reduced, resulting in an increased contact pressure on the tooth surfaces. Compared with Figure 11, the number of cycles required for the wear to reach 2.5 μm in the first period in Figure 12 was notably decreased. Nonetheless, the overall wear patterns of the cycloidal gear and pin tooth surfaces after profile modification remained similar to those observed under ideal tooth surface conditions. As wear accumulated, the area of maximum wear on both the cycloidal gear and pin tooth surfaces gradually expanded outward.

Figure 12.

Wear behavior of (a) cycloidal gear, and (b) pin with modified tooth surfaces.

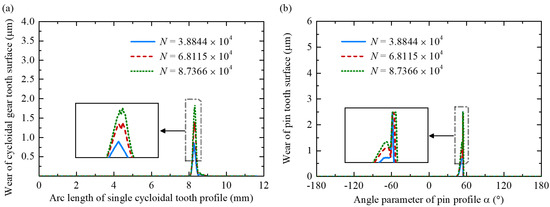

The wear behavior of the cycloid-pin gear pair under error tooth surface conditions is presented in Figure 13. The tooth profile of the cycloidal gear exhibited a deviation of ±4 μm, with single and cumulative pitch deviations of ±4 μm and 10 μm, respectively. The diameter and pin circle of the pins deviated by 4 μm and μm, respectively, while the center distance and misalignment between the cycloidal gear and pin were 3 μm and 0.005°, respectively. To prevent gear tooth interference, the cycloidal gear was modified using a combination of negative isometric and negative offset approaches, with modification amounts of ΔRrp = −0.004 mm and Δ Rp = −0.017 mm. Compared with Figure 12, the wear area of the cycloidal gear and pins in Figure 13 exhibited no significant change under error tooth surface conditions. In the early wear stage, only a limited number of surface elements participated in meshing due to the presence of gear errors, resulting in discontinuity along the tooth profile and significant variations in wear across the tooth width. As wear progressed, the micro-morphology of the tooth surface evolved, allowing more discrete elements to engage in contact. The overall wear behavior of the cycloidal gear and pin tooth surfaces remained similar to that observed for the modified tooth surface, and the differences in maximum accumulated wear between individual elements across each slice decreased. The error tooth surface condition led to fewer effective contact elements and more uneven load distribution across the tooth surface than the ideal and modified tooth surface conditions, causing a notable reduction in the number of cycles required to reach cumulative wear amounts of 2.5 μm, 5 μm, and 7.5 μm.

Figure 13.

Wear behavior of (a–c) cycloidal gear and (d–f) pin with error tooth surfaces.

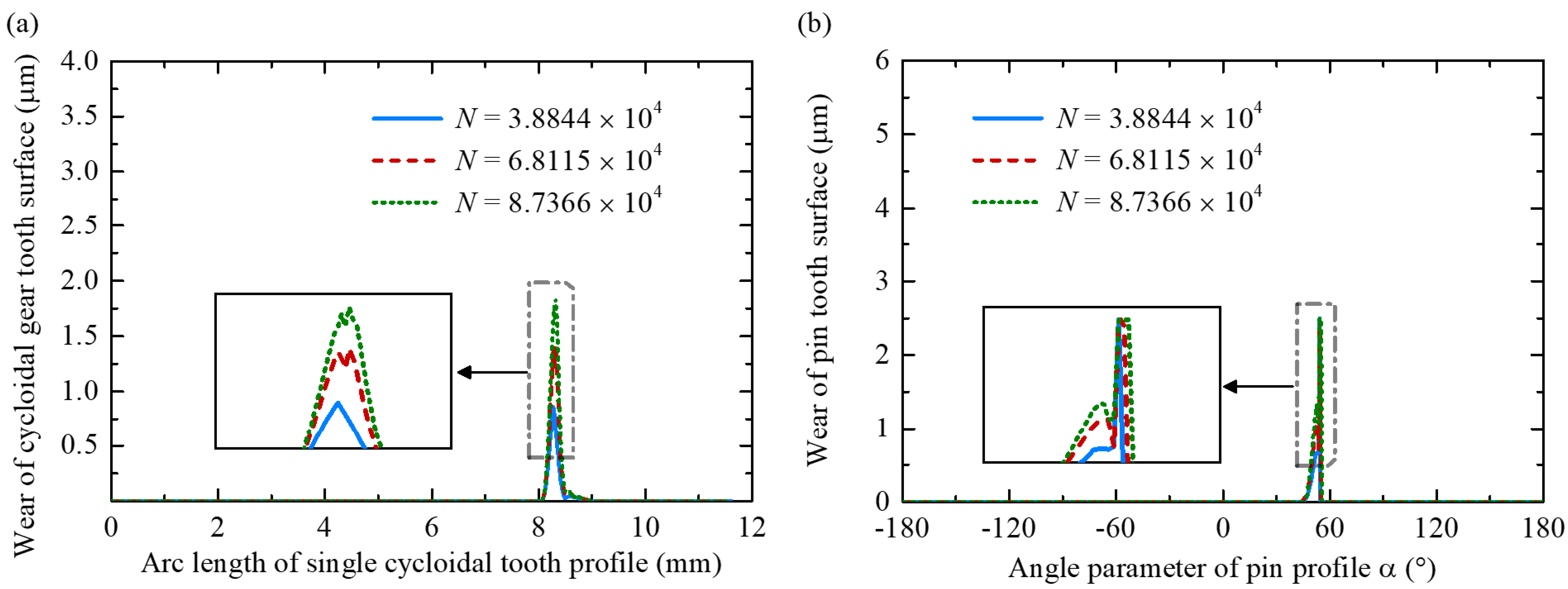

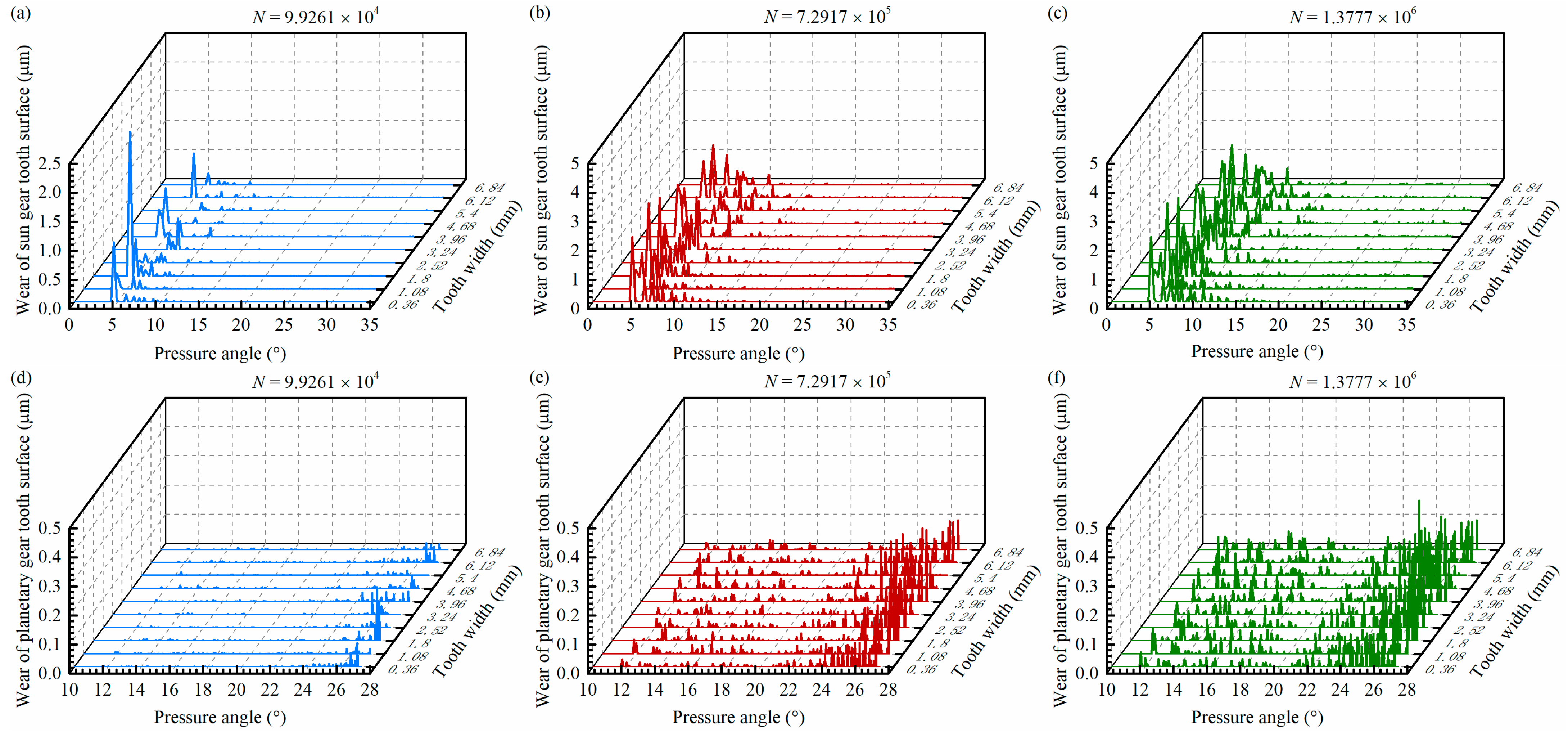

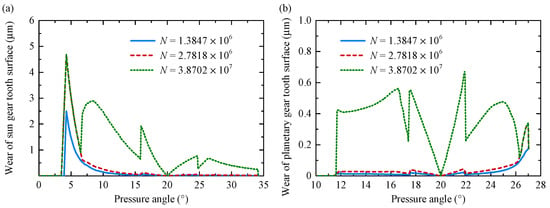

(2) Wear law of involute gear tooth surface

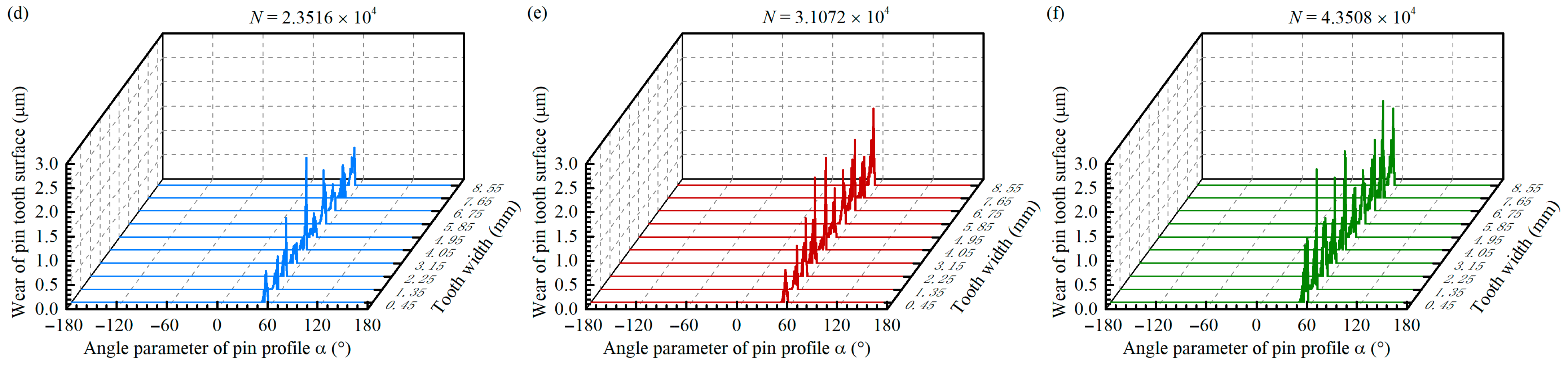

The wear behavior of the involute gear pair with ideal tooth surfaces is presented in Figure 14, where N represents the number of sun gear rotations. In the first-stage involute gear transmission, the pressure angles within the meshing area ranged from 3.7385° to 34.2995° for the sun gear and from 11.5788° to 27.1707° for the planetary gear. Overall, the wear of the sun gear tooth surface was found to be higher than that of the planetary gear. This was attributed to the larger sliding coefficient of the sun gear (Figure 9b), as well as the higher number of meshing instances for the sun gear due to its tooth count. At the pitch point, wear was minimal for both the sun and planetary gears, and the theoretical wear amounts were zero.

Figure 14.

Wear behavior of (a) sun and (b) planetary gears with ideal tooth surfaces.

In the early wear stage, meshing impacts occurred between the sun gear tooth root and the planetary gear tooth tip due to tooth deflection under load, generating high contact forces. At the same time, the significant sliding between these surfaces led to considerable wear. Between N = 2.7818 × 106 and N = 3.8702 × 107, the accumulated wear of the sun gear tooth root and the planetary gear tooth tip became substantial, and tooth deflection under load could no longer compensate for the clearance caused by surface wear. As a result, the sun gear tooth root and planetary gear tooth tip ceased to participate in meshing and no longer experienced surface wear. In addition, due to the shift between single-tooth and double-tooth meshing zones, noticeable abrupt changes occurred in the wear curve. For example, when the sun gear transitioned from the double-tooth to the single-tooth meshing area near a pressure angle of 15.8°, a significant increase in tooth surface wear was observed.

The influence of tooth profile modification and lead crowning on the wear behavior of involute gear pairs has been addressed in [42] and is not repeated here. The wear characteristics of the involute gears under error tooth surface conditions are shown in Figure 15. The error parameters of the sun and planetary gears were set according to ISO Grade 5, with center distance and misalignment deviations of 3 μm and 0.005°, respectively. To prevent tooth interference caused by these errors, a lead crowning of 0.003 mm was applied, and tooth profile modifications with a length of 1.6 mm and an amount of 0.008 mm were introduced. Overall, severe wear was observed at the tooth root of the sun gear and the tooth tip of the planetary gear, with the total wear of the sun gear being greater than that of the planetary gear. Due to variations in error parameters across discrete surface elements, certain elements engaged in meshing earlier, while others gradually participated as the wear amount progressed, leading to discontinuities and intermittency in the wear curve. Meanwhile, differences in error parameters across the tooth surface caused discontinuities in the contact lines along the tooth width direction, shortening the instantaneous contact line and increasing the contact pressure. As a result, the number of cycles required for the sun gear to reach wear thresholds of 2.5 μm, 5 μm, and 7.5 μm was significantly reduced.

Figure 15.

Wear behavior of (a–c) sun and (d–f) planetary gears with error tooth surfaces.

(3) Wear law of rolling bearings

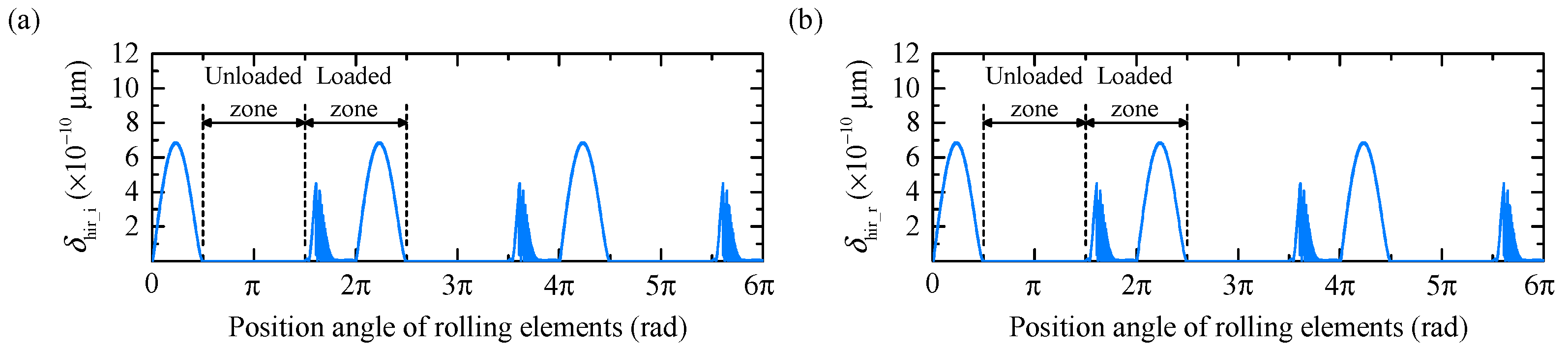

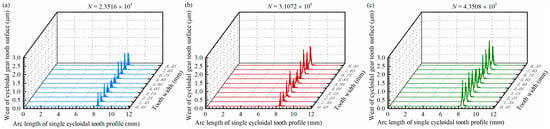

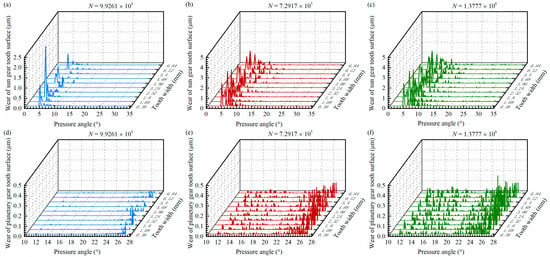

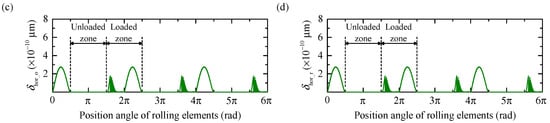

Taking the rated speed of the turning-arm bearing (600 r/min) and a maximum radial load of 4869.62 N as an example, the wear amounts of the inner raceway, outer raceway, and rolling elements at various position angles were calculated for a single rolling element. The results are presented in Figure 16, where the vertical axes δhir_i and δhir_r denote the wear amounts of the inner raceway and the rolling element at their contact point, respectively, while δhor_o and δhor_r indicate the wear amounts of the outer raceway and the rolling element at their respective contact point.

Figure 16.

Wear of the turning-arm bearing at different positions: (a) δhir_i, (b) δhir_r, (c) δhor_o, and (d) δhor_r.

The wear of the turning-arm bearing occurred predominantly as the rolling elements entered and exited the loaded zone (Figure 16). Although the sliding coefficient of the turning-arm bearing was relatively low in these regions, the contact force between the rolling elements and both the inner and outer raceways was significant, leading to severe wear (Figure 10a). In the unloaded zone, the rolling elements were influenced only by gravity, centrifugal force, and cage force, yielding a combined radial load far smaller than the bearing load and resulting in negligible wear. Moreover, for the same angular position of the rolling elements, the wear between the rolling elements and the inner raceway was found to be greater than that between the rolling elements and the outer raceway, primarily due to differences in the wear coefficients for the inner and outer raceways.

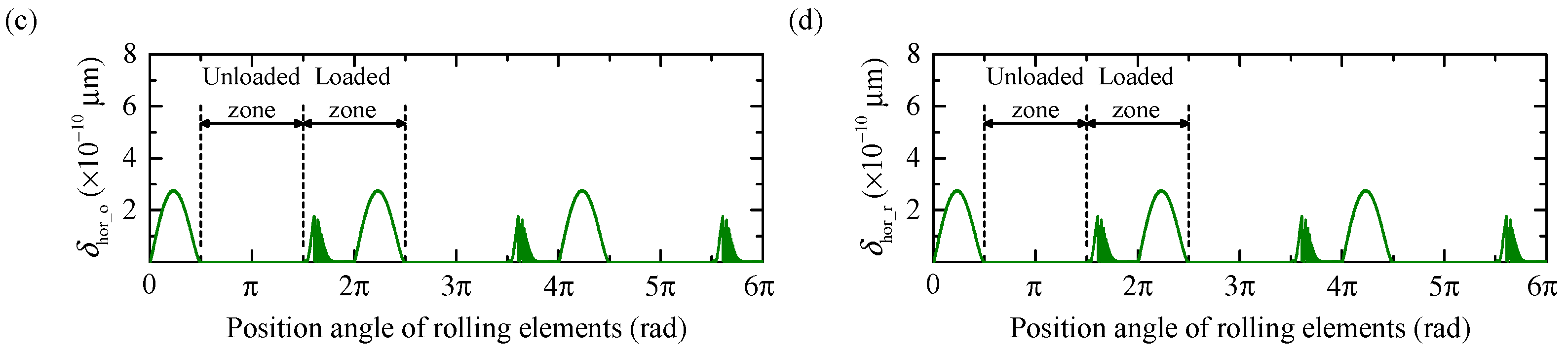

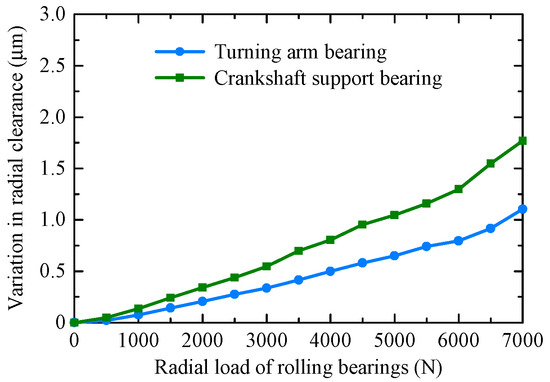

To evaluate the influence of bearing wear on the transmission accuracy of RV reducers, the changes in radial clearance of the turning-arm and crankshaft support bearings were calculated at the rated speed after 6000 h of operation (Figure 17). It was observed that the radial clearance of both bearing types increased with load and that these changes were approximately linear concerning the radial load. The average slopes of the clearance-load curves were approximately 1.15 × 10−4 μm/N for the turning-arm bearings and 1.90 × 10−4 μm/N for the crankshaft support bearings. Under the same radial load, the change in radial clearance of the crankshaft support bearing was found to be greater than that of the turning-arm bearing.

Figure 17.

Radial clearance variation in the rolling bearings.

Based on the force analysis results for the turning-arm and crankshaft support bearings under ideal tooth surface conditions, the average radial loads of these bearings in the RV reducer used in this study were determined to be 3177.72 N and 2905.11 N, respectively. According to the average slopes of the clearance-load curves in Figure 17, the radial clearance changes corresponding to these loads were calculated to be approximately 0.3654 μm and 0.5520 μm, respectively. In practice, the actual radial clearance changes were found to be slightly larger. This discrepancy occurred because the calculated results were based on average radial loads, whereas the actual loads fluctuated periodically in both magnitude and direction. In addition, the bearings experienced severe wear when entering and exiting the loaded zone, and the wear at certain positions was significantly higher than the average value used for clearance calculations. Moreover, the peak radial load of each bearing, influenced by MEs, AEs, and TMs, was higher than the maximum radial load estimated for the ideal tooth surface. The LM of the RV reducer was found to be highly sensitive to the radial clearance of the rolling bearings. For example, an increase of 1 μm in the radial clearance of the crankshaft support bearing could cause the LM of the RV reducer to rise by approximately 3.2229 arcsecs. Therefore, the effects of rolling bearing wear on the transmission accuracy of RV reducers must be fully considered, especially to mitigate the significant increases in bearing radial loads caused by MEs and AEs.

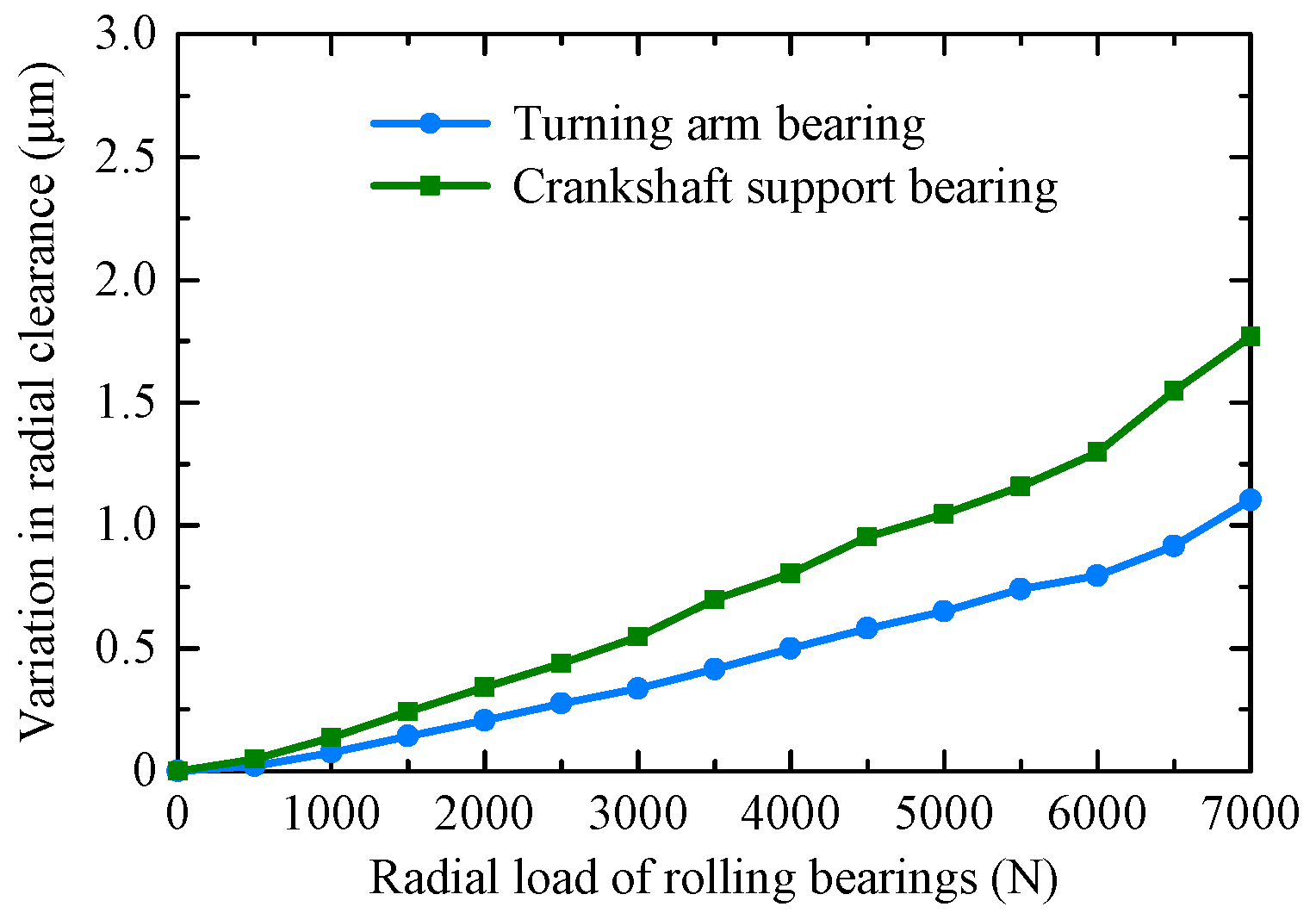

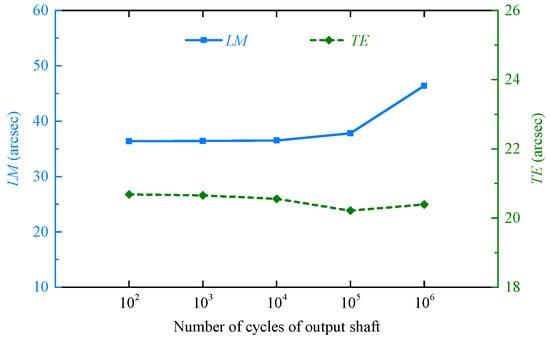

4.3. Degradation Law of Transmission Accuracy

According to the TAL analysis flowchart in Figure 5, the transmission accuracy of the RV reducer across different cycle times of the output shaft is presented in Figure 18. In this figure, the mean value of the LM curve and the peak-to-peak value of the TE curve were used to characterize the LM and TE of the RV reducer, respectively.

Figure 18.

Degradation curve of transmission accuracy.

Based on the results, TE was found to vary only slightly during operation. In the early stages, TE decreased marginally as the differences between discrete surface elements caused by gear MEs were reduced, leading to a smoother tooth surface. As the operation progressed, intensified tooth surface wear primarily affected the average TE value, with little impact on its peak-to-peak range. In contrast, LM increased significantly across different output cycles over time. This was attributed to the thinning of tooth thickness caused by tooth surface wear and the enlargement of rolling bearing clearances due to bearing wear, both of which resulted in a continuous rise in LM.

4.4. Estimation Model of Transmission Accuracy Life

According to the observed degradation of the RV reducer’s transmission accuracy, tooth surface and bearing wear resulted in an increase in LM while exerting only a minor influence on TE. Based on this finding, the mean LM was defined as the evaluation index for the TAL of RV reducers. LM is typically defined as the absolute value of the output shaft angular displacement at ±3% of the rated torque on the hysteresis curve, without considering load-induced deformation effects of the reducer’s components. Although engineering practice can maintain a consistent accuracy level across gears in mass production, variations in the meshing sequence can still cause differences in LM. Therefore, only the initial LM of the RV reducer, influenced by the combined effects of various errors, was considered, and detailed error parameter values of individual gears were not introduced into the TAL estimation model. This initial LM can be obtained either from testing under specific application conditions or from the RV reducer transmission accuracy model developed in this study.

Tooth surface wear causes to an increase in backlash, thereby leading to a rise in the LM of RV reducers. According to the established influence of isometric profile modification of the cycloidal gears and the LM of the RV reducer, the relationship between the tooth surface wear of the cycloid-pin gear pair and the LM of the RV reducer can be expressed as follows:

where ΔEc denotes the accumulated wear of the cycloid-pin gear tooth surfaces, defined as the average wear of the tooth surfaces over one complete output shaft cycle of the RV reducer, and it can be expressed as follows:

where and denote the average tooth surface wear of the cycloidal gear and pin tooth surfaces, respectively, within one output shaft cycle. Due to the effects of cycloidal gear profile modification and pin pitch deviation, the average number of contact pins was found to be significantly lower than the theoretical value. Therefore, a load coefficient for the cycloid-pin tooth surface (λHc) is introduced, and its expression is as follows:

where Nr and denote the average numbers of contact pins under ideal and error tooth surface conditions, respectively; represents the actual output torque of the RV reducer; and the range of the load coefficient λHc is (0, 1], with λHc = 1 when the tooth surfaces of the cycloidal gear and pins are ideal. In the presence of negative tooth pitch deviations, certain pins engage first, and as cumulative wear of the tooth surfaces increases, the average number of contact pins and the load coefficient gradually rise. A new pin is assumed to participate in the load when the cumulative wear of the cycloidal gear and pins exceeds the single tooth pitch deviation of the pin. Therefore, the expression for can be defined as follows:

where Nout denotes the number of cycles of the RV reducer output shaft, Nr0 represents the initial average number of contact pins under the error tooth surface, and signifies the single tooth pitch deviation of the pins.

Similarly, following the transmission principle of the RV reducer, the relationship between the tooth surface wear of involute gears and the LM of the RV reducer is as follows:

where ΔEi denotes the cumulative wear of the involute gear tooth surface; ΔEi is defined by the average wear of the tooth surface within one output shaft cycle of the RV reducer under ideal tooth surface conditions. Therefore, it can be expressed as follows:

where and denote the average tooth surface wear of the sun and planetary gears in a single cycle of the output shaft, respectively; and λHi is the load coefficient of the involute gear tooth surface, which is expressed as follows:

where Ni0 denotes the initial average number of contact teeth of involute gears under error tooth surfaces, εinv represents the theoretical contact ratio of the involute gear pair, and signifies the actual input torque of the RV reducer. The influence of the tooth surface wear on the load coefficient of involute gears is neglected, and the value range of λHi is (0, 1]. When the tooth surface of involute gears is perfect, λHi = 1.

In addition, the wear of rolling bearings increases their radial clearance, which increases the LM of the RV reducer. The relationship between the clearance of the turning-arm bearing and the LM of the RV reducer is given as follows:

where denotes the variation in the turning-arm bearing clearance.

Similarly, the relationship between the clearance of the crankshaft support bearing and the LM of RV reducers is expressed as follows:

where represents the variation in the crankshaft support bearing clearance, and rh signifies the distribution circle radius of crankshafts.

Both clearance variations and within a single cycle of the RV reducer output shaft can be expressed as follows:

where the subscripts tb and cb represent the turning-arm bearing and the crankshaft support bearing, respectively; ktb,cb denotes the average slope of the radial clearance variation curve for rolling bearings operating at the rated speed for 6000 h; and Ftb,cb signifies the average radial load on the rolling bearings.

Therefore, the TAL of the RV reducer can be expressed as follows:

where TLM represents the TAL of the RV reducer evaluated by the average LM, expressed in hours; LMlim and LM0 denote the threshold and initial values of the RV reducer’s LM under error tooth surfaces, respectively.

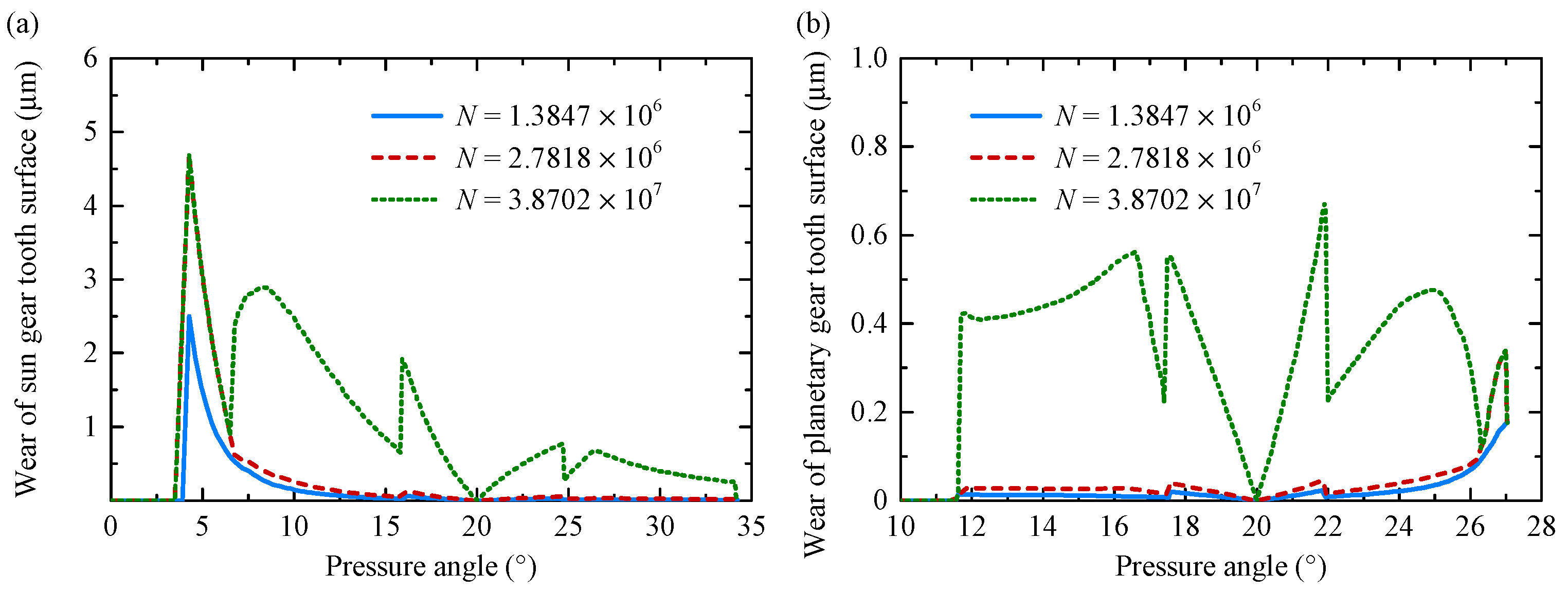

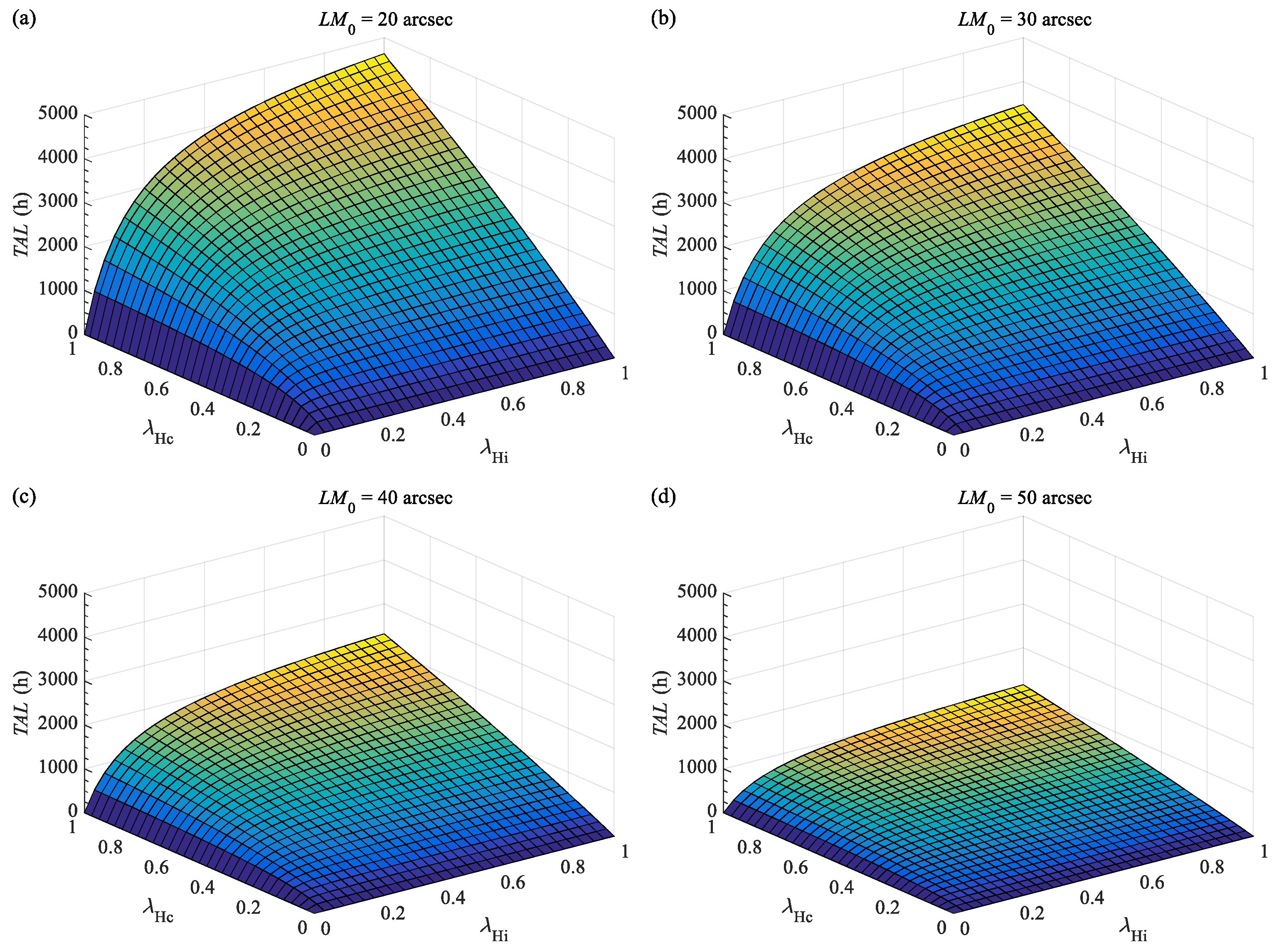

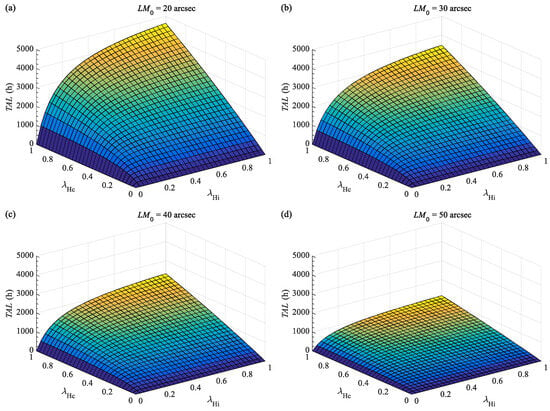

The analysis indicated that, under ideal tooth surface conditions, the average wear per output shaft cycle was 2.6999 × 10−5 μm and 1.1719 × 10−5 μm for the cycloidal gear and pins ( and ), respectively, and 2.9892 × 10−5 μm and 1.3688 × 10−5 μm for the sun and planetary gears ( and ), respectively. Under error tooth surface conditions, the instantaneous number of meshing teeth for both the cycloid-pin and involute gear pairs is influenced by multiple factors, yielding highly complex relationships. The instantaneous meshing tooth counts can be determined using the error tooth surface transmission accuracy prediction model proposed in this study or estimated by empirical formulas. For example, it is generally accepted that, when the effects of profile modification, gear MEs, and elastic deformation of RV reducer components are accounted for, the meshing tooth count of the cycloid-pin gear pair is approximately one-third of the total tooth count. In this context, the TAL of the RV reducer was calculated for different initial LM values, with the load coefficients of the cycloid-pin and involute gear pairs (λHc and λHi) treated as independent variables, and the results are presented in Figure 19.

Figure 19.

TAL prediction results for RV reducers with different initial LM values: (a) LM0 = 20 arcsec, (b) LM0 = 30 arcsec, (c) LM0 = 40 arcsec, and (d) LM0 = 50 arcsec.

The LM threshold was set at 60 arcsecs (Figure 19). According to the results, the TAL of the RV reducer was primarily influenced by the load coefficient of the cycloid-pin tooth surface, which is related to the average number of contact pins in the cycloid-pin gear pair. Under the same load conditions, a lower average number of contact pins resulted in increased tooth surface load, intensified wear, and a shorter TAL of the RV reducer. Based on the TAL model for the RV reducer, λHc = 1 when the cycloid-pin gear had a perfect tooth surface, and λHi = 1 when the involute gear had a perfect tooth surface. When the initial LM values were 20, 30, 40, and 50 arcsecs, the TAL values of the RV reducer with ideal tooth surfaces were 4637 h, 3478 h, 2319 h, and 1160 h, respectively (Figure 19a–d). To enable convenient estimation, a multivariable linear regression model was developed to predict the TAL of the RV reducer, as expressed below:

where a0 denotes the intercept, and a1, a2, a3, a4, and a5 represent the regression coefficients of the variables, respectively.

Based on the TAL estimation model described above, a multivariable linear regression was performed for the TAL of the RV reducer under different initial LM conditions (Figure 19). Because the instantaneous number of contacting teeth in the cycloid-pin and involute gear pairs must be at least one, data points with λHc < 0.025 and λHi < 0.318 were excluded from the analysis. The resulting regression coefficients and intercept of the TAL model are presented in Table 3.

Table 3.

TAL estimation model parameters for RV reducers.

5. Experimental Validation

In this study, a TAL test rig was first constructed, and an accelerated TAL test of the RV reducer was conducted for 1550 h. The initial gear MEs were measured, and the actual tooth surface load coefficients in (43) and (47) were determined through static analysis of the RV reducer with error tooth surfaces. The TAL of the tested RV reducer was then predicted, and the calculated results were compared with the experimental outcomes to verify the effectiveness of the TAL estimation model proposed in this study.

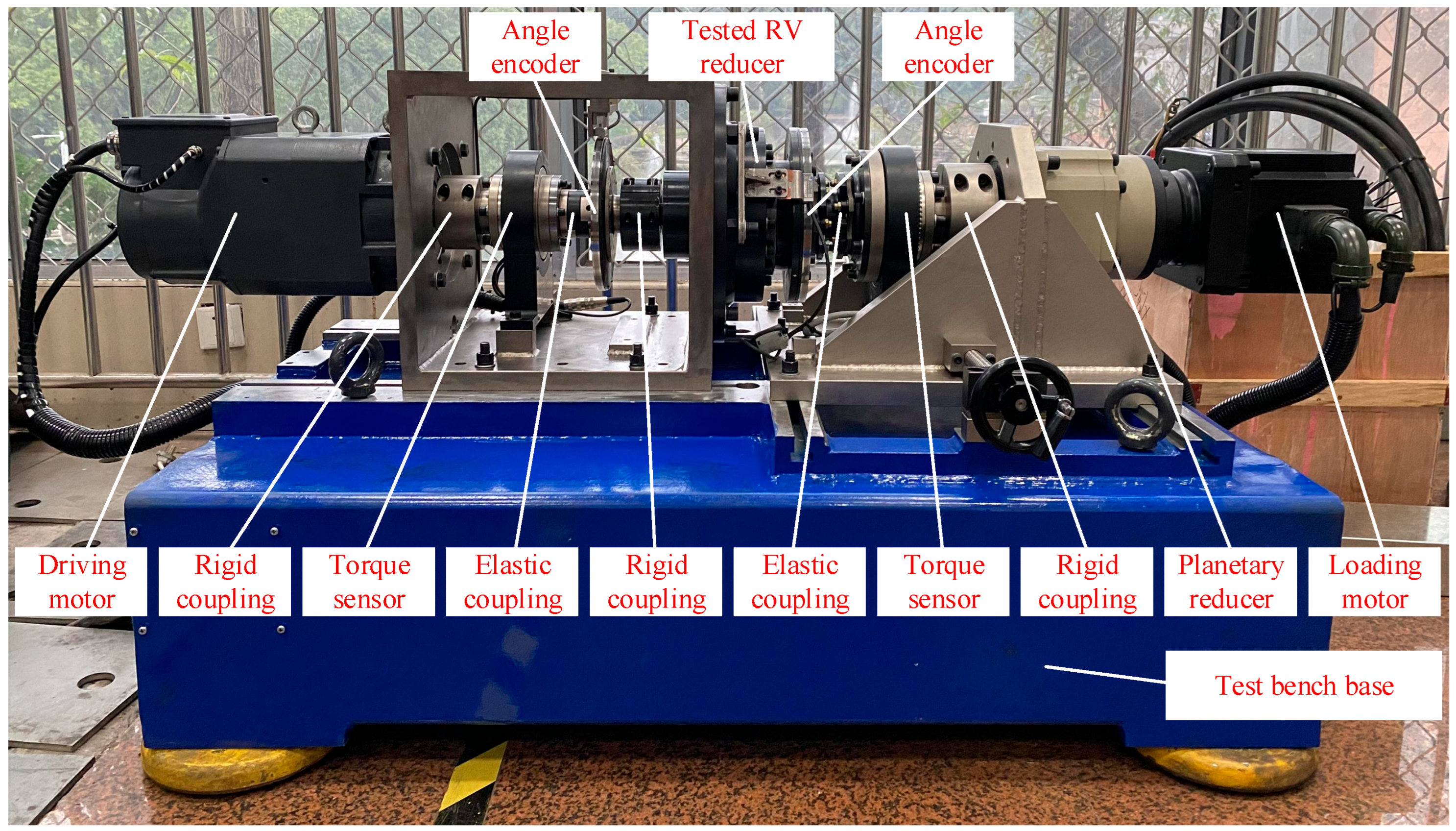

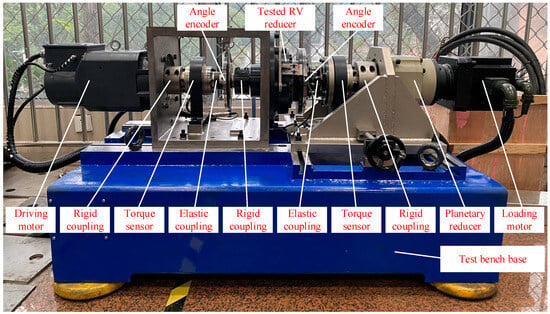

5.1. TAL Test of RV Reducers

The TAL test rig is illustrated in Figure 20, consisting of a driving system, a loading system, and the tested RV reducer. The driving system comprises a driving motor, a torque sensor, and an angle encoder, while the loading system includes a loading motor, a planetary reducer, a torque sensor, and an angle encoder. To eliminate the influence of torque fluctuations and elastic coupling clearance on test results, the elastic coupling was positioned outside the angle encoder. The angle encoders used for the input and output shafts were RESM20USA200 and RESM20USA229 manufactured by Renishaw plc, Gloucester, UK, with system accuracies of ±1.05 arcsecs and ±0.92 arcsecs, respectively. In order to expand the test rig’s applicability, two slide rails were incorporated for horizontal and vertical movements, implemented via ball screws. This configuration allows the test rig to measure the transmission accuracy of both coaxial input-output reducers and parallel-shaft reducers with different center distances.

Figure 20.

Test rig for TAL of RV reducers.

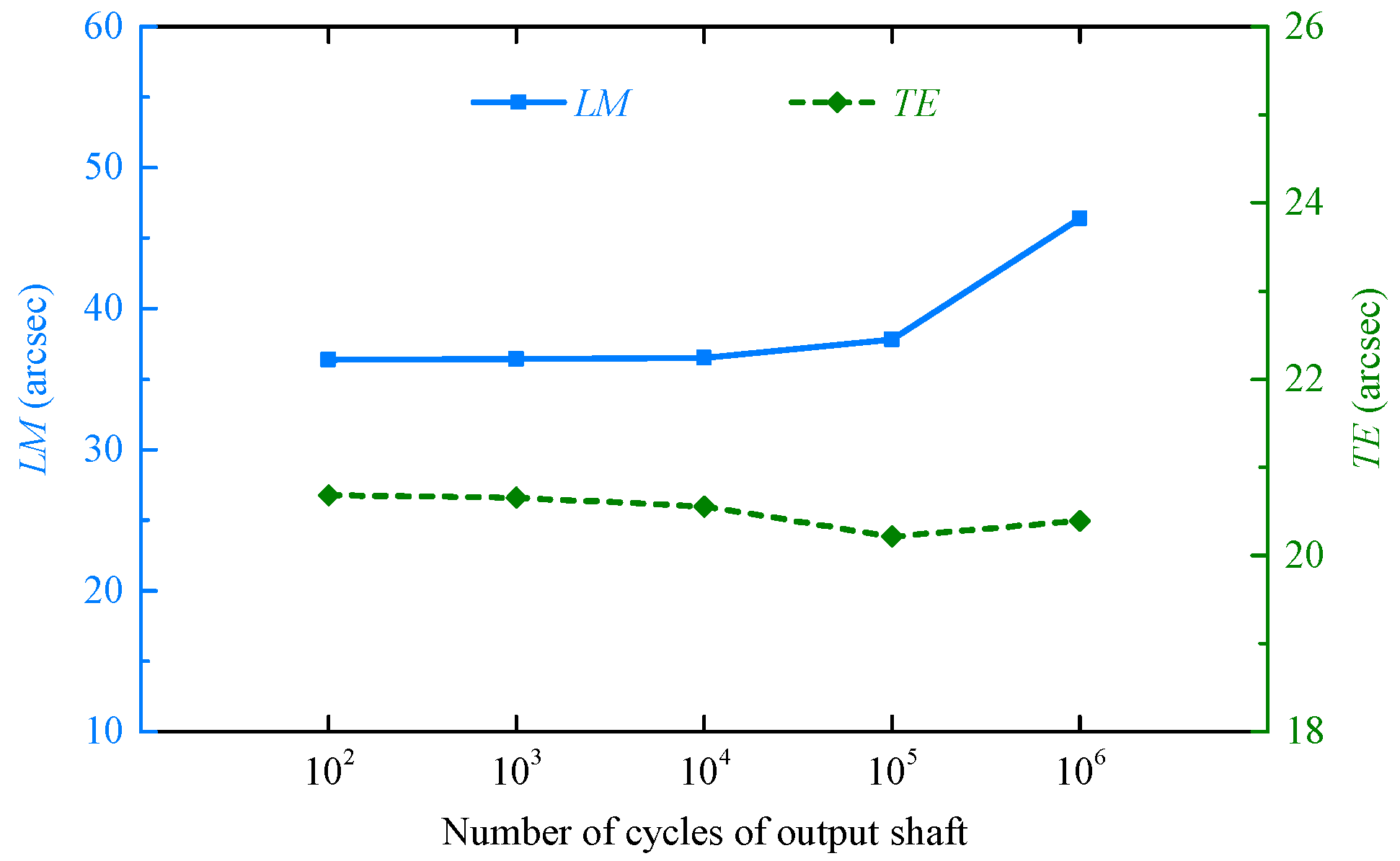

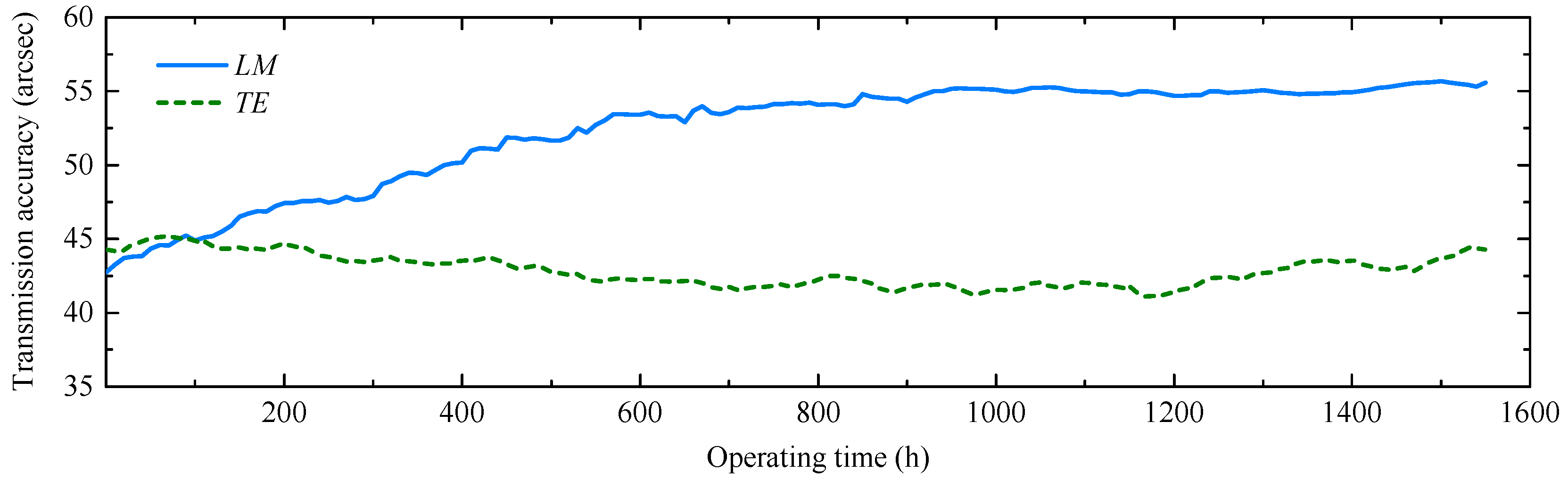

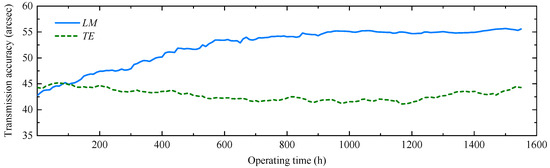

During the TE test, the input shaft of the RV reducer was driven by the driving system, and after achieving stable operation, the real-time rotation angles of the input and output shafts were recorded to obtain the TE curve. The LM was typically determined from the hysteresis curve of the reducer, which required fixing the input shaft and gradually loading the output shaft to its rated load before unloading. To avoid measurement errors caused by repeated disassembly of the input shaft fixture, the bidirectional TE method was adopted for LM measurement. In this method, the forward and reverse TE curves of the reducer were first tested under stable load, and their difference was used to obtain the dynamic LM curve of the reducer [10,36]. The average value of this dynamic LM curve was taken as the LM of the RV reducer at a specific moment. This approach ensured that the transmission accuracy data were obtained under consistent AEs throughout the service life of the RV reducer. In the accelerated TAL test, the reducer was operated forward for 5 h and backward for 5 h, and the TE and LM were tested and recorded every 10 h. The output torque and rotational speed were set to 572 N·m and 5 r/min, respectively. The total test duration was 1550 h, and the degradation curves of TE and LM are shown in Figure 21.

Figure 21.

Degradation of TE and LM over time.

According to the test results, TE decreased only slightly during the initial operation of the reducer, with its fluctuation range within 1550 h not exceeding 4.2 arcsecs. LM increased rapidly within the first 600 h of operation, which was attributed to significant micro-morphology differences caused by tooth profile deviations. The areas with larger tooth profile deviations wear worn first. Additionally, the initial number of contacting tooth pairs was low due to tooth pitch deviations, leading to higher tooth surface contact pressure and intensified wear. After the running-in period, the influence of tooth profile deviations on LM weakened. As wear accumulated, the average number of contacting tooth pairs increased, resulting in reduced tooth surface contact pressure and a slower tooth wear rate. Therefore, after 600 h, the LM growth rate stabilized at approximately 0.0024 arcsecs/h. Over the 1550 h test, the LM of the RV reducer increased from 42.7422 arcsecs to 55.6631 arcsecs, yielding a total rise of 12.9209 arcsecs. The degradation trends of TE and LM were consistent with the theoretical results presented in Figure 18.

5.2. Validation of TAL Estimation Model

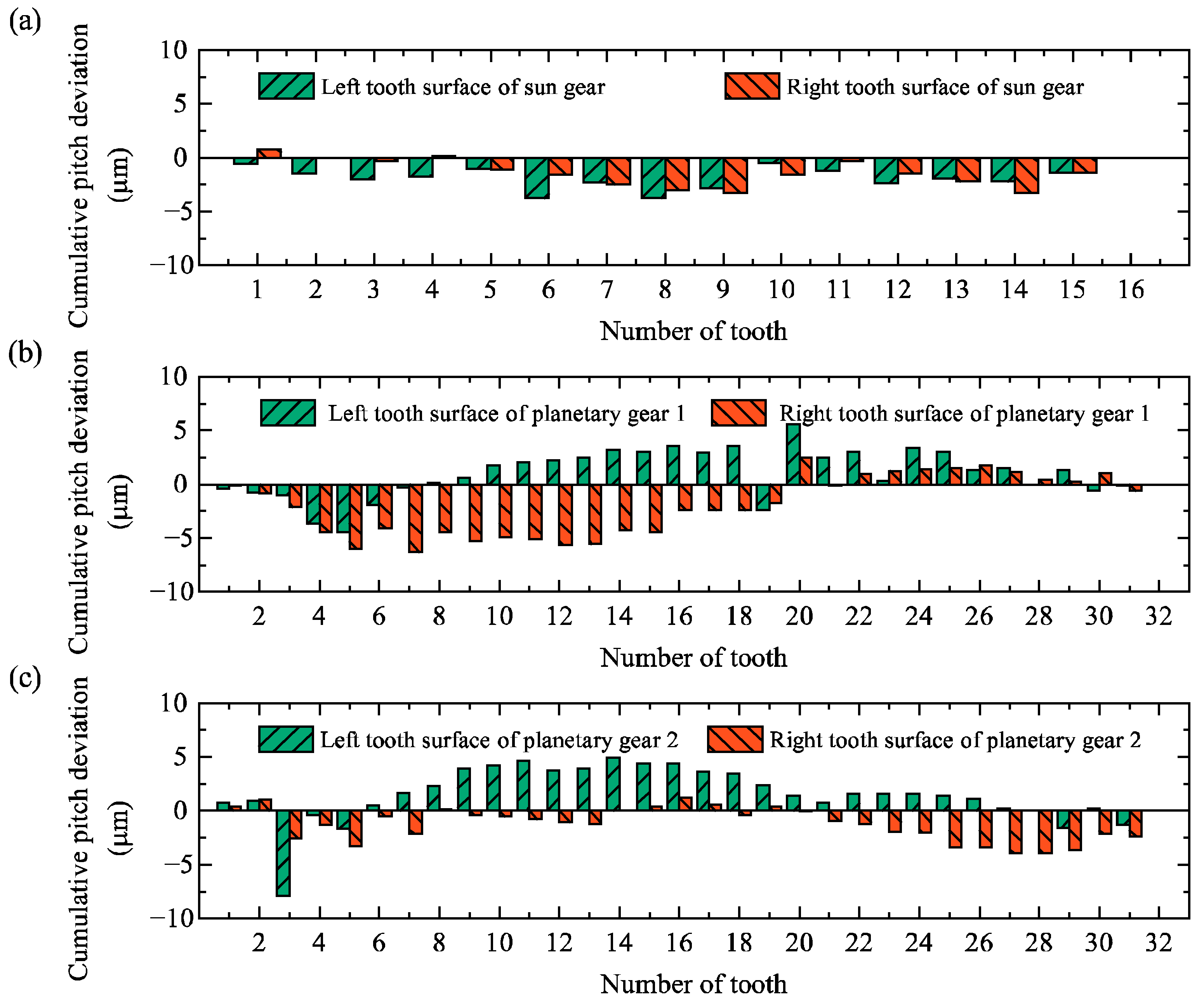

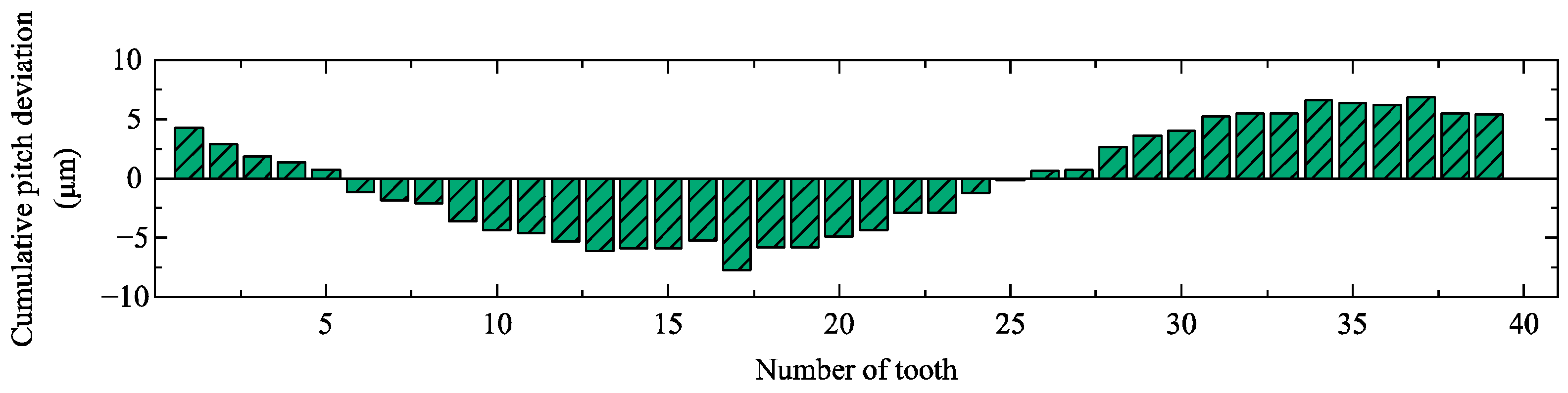

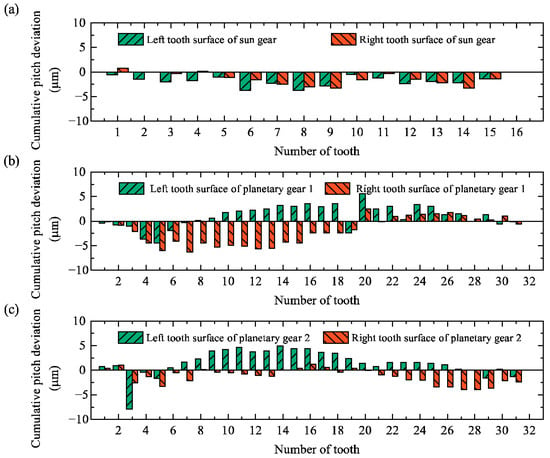

To determine the actual tooth surface load coefficients, the MEs of the gears were first measured. The involute gears were tested using the P26 comprehensive precision tooth profile tester manufactured by Klingelnberg, Hückeswagen, Germany. The involute planetary gear transmission of the RV reducer comprised one sun gear and two planetary gears. Their cumulative pitch deviations are shown in Figure 22a–c. Although the cumulative pitch deviations of the left and right tooth surfaces of each gear generally exhibited a sinusoidal curve distribution, distinct changes were observed on certain teeth. The detailed precision test results of the involute gears are provided in Table 4.

Figure 22.

Cumulative pitch deviations of (a) sun gear, (b) planetary gear 1, and (c) planetary gear 2.

Table 4.

Precision test results of the involute gears.

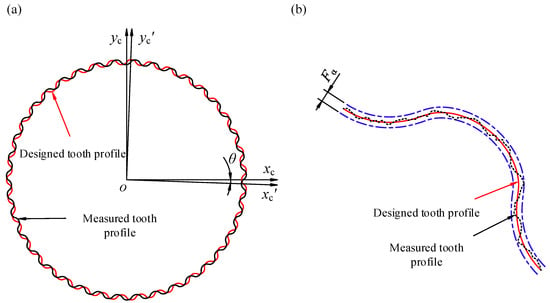

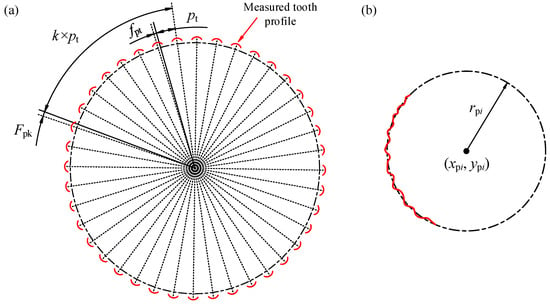

The cycloid-pin drive in RV reducers typically includes two cycloidal gears to improve the reducer’s smoothness. The accuracy of these gears was measured using the P26 comprehensive precision tooth profile tester. During testing, the gear rotated while a probe automatically traced the tooth surface to measure its 3D profile. Due to AEs and the random starting position of the measurement, the recorded tooth profile was eccentric and had a phase difference relative to the designed tooth profile (Figure 23a). To address this issue, the position of the measured tooth profile was corrected according to the minimum distance principle before data processing. The resulting tooth profile deviation is defined in Figure 23b, and the precision test results for the cycloidal gears are summarized in Table 5.

Figure 23.

(a) Designed vs. measured cycloidal tooth profile, and (b) definition of profile deviations.

Table 5.

Precision test results of the cycloidal gears.

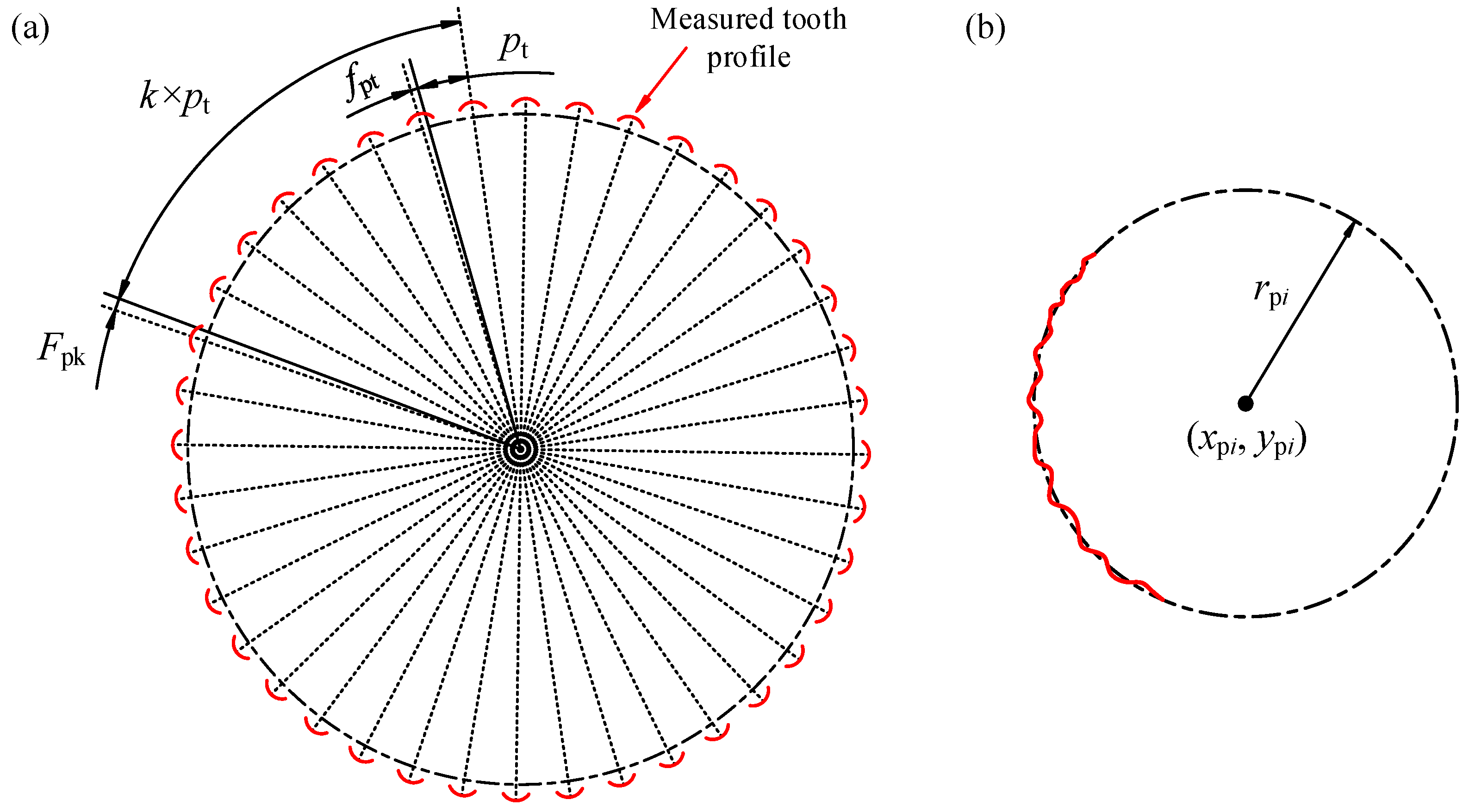

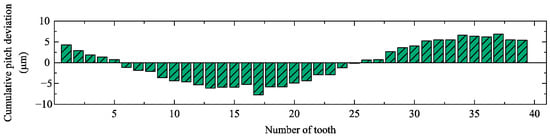

The MEs of the pin grooves were detected by a Leitz PMM-C coordinate measuring machine manufactured by Hexagon Manufacturing Intelligence, Wetzlar, Germany. The actual measured tooth profiles of the pin grooves and the definition of groove pitch deviations are illustrated in Figure 24a. Through nonlinear regression on the measured groove data points, the center and radius of each pin groove were obtained, as shown in Figure 24b. Subsequently, the actual radius of the pin groove distribution circle and the cumulative pitch deviations were computed, as shown in Figure 25. The measured diameter of the pin groove distribution circle was 63.9804 mm, with maximum and minimum cumulative pitch deviations of 6.8788 μm and –7.7211 μm, respectively.

Figure 24.

(a) Measured profiles with pitch deviation definitions, and (b) center and radius of the ith pin groove.

Figure 25.

Cumulative pitch deviation of pin grooves.

The diameter of each pin was measured using a spiral micrometer at three different positions, and the average value was taken as the actual diameter of the pin. According to the measurement results, the diameter consistency of the pins was found to be satisfactory. The average diameter of the 40 pins was 5.986 mm, with a maximum deviation of 0.001 mm.

To validate the proposed TAL estimation model for RV reducers, the error tooth surfaces of the involute gears, cycloidal gears, and pins were reconstructed based on the measured tooth surface data. In the involute planetary gear transmission, the tooth profile deviations, tooth thickness deviations, and helix deviations were defined according to the ISO Grade 5 standard. The cumulative pitch deviations of the involute gears are shown in Figure 22a–c. In the cycloid-pin drive, the profile modification and tooth profile deviation of the cycloidal gears are presented in Table 5. The diameter deviation of the pin distribution circle was measured as −0.010 mm, and the upper and lower diameter deviations of the pins were −0.013 mm and −0.014 mm, respectively. The cumulative pitch deviations of the pins are shown in Figure 25. Due to the difficulty of accurately measuring the AEs of each gear pair, their influences were not considered when reconstructing the error tooth surfaces, nor were the effects of tooth profile modification and lead crowning of involute gears. Under the error tooth surface condition, static analysis of the RV reducer indicated an average of 16.2542 contacting pins between the cycloidal gears and an average of 2.1747 contacting tooth pairs between the involute gears. Therefore, the load coefficients of the cycloidal and involute gear tooth surfaces were calculated as λHc = 0.2927 and λHi = 0.4986, respectively.

According to the accelerated TAL experimental results presented in Figure 21, LM threshold of 55.6631 arcsecs was used, and the initial LM was set to LM0 = 42.7422 arcsecs. Under this operating condition, the intercept and regression coefficients of the estimation model were recalculated as a0 = −134.0, a1 = −938.8, a2 = −757.5, a3 = 1492.2, a4 = 4029.7, and a5 = 770.1. Therefore, when the LM increased from 42.7422 arcsecs to 55.6631 arcsecs, the estimated TAL of the tested RV reducer is as follows:

The estimated TAL was found to be smaller than the value measured in the TAL test, with an error of approximately 11.06%. This discrepancy was attributed to two factors. First, when establishing the TAL estimation model, the LM change was calculated based on the average wear of the contacting tooth surfaces. However, due to the multi-tooth meshing effect of the cycloid-pin gear pair, LM is generally determined by the minimum wear of the tooth surfaces. Second, the rotation of pins within the pin grooves was neglected when calculating the average wear, resulting in a calculated average wear value that was higher than the actual value.

6. Conclusions

This study has established a static analysis model for RV reducers, as well as wear models for gear tooth surfaces and rolling bearings. By integrating these models, the transmission accuracy degradation law of RV reducers is revealed, and a corresponding estimation model for the TAL of RV reducers is developed. Finally, accelerated degradation testing of the RV reducer’s transmission accuracy is conducted to experimentally validate the theoretical findings. The main conclusions of this study are as follows:

- (1)

- In cycloid-pin transmission, the wear of cycloidal gears mainly occurs on the convex tooth surfaces, while the tooth surface wear of pins increases sharply at the edge of its contact area. In the involute gear drive, the sun gear tooth surface experiences more wear than the planetary gears, with minimal wear observed at the pitch point.

- (2)

- Rolling bearing wear is concentrated at the points where rolling elements enter and exit the loaded region. Bearing radial clearance increases approximately linearly with bearing radial load. Under identical radial loads, crankshaft support bearings exhibit greater radial clearance variation than turning-arm bearings.

- (3)

- Both theoretical and experimental results have revealed that the TE of RV reducers remain relatively stable during operation, while the LM increases notably due to the influence of tooth surface and bearing wear, particularly during the first 600 h of test. Beyond 600 h, LM increases at 0.0024 arcsecs/h. Over the 1550 h test, the LM exhibited a total growth of 12.9209 arcsec, representing a 30.23% growth relative to initial LM, with its growth rate substantially surpassing that of TE. Based on these findings, the progressive increase in LM is the primary cause of transmission accuracy degradation in RV reducers, and LM is recommended as the primary evaluation index for TAL of RV reducers.

- (4)

- The deviation between the estimated TAL of RV reducers and the experimental results is 11.06%, which verifies the feasibility of the estimation model proposed in this study.

The proposed TAL estimation model refines the life evaluation methodology for RV reducers, establishing a solid foundation for real-time transmission accuracy compensation in reducer operation. In the future, the TAL estimation model will be integrated into industrial robot servo-control systems to evaluate its effectiveness in improving robotic positioning accuracy through real-time compensation for RV reducer transmission accuracy.

Author Contributions

Conceptualization, C.L. and W.S.; methodology, C.L.; software, C.L. and H.Y.; validation, C.L. and H.Y.; formal analysis, K.L.; investigation, C.L.; data curation, C.L. and K.L.; writing—original draft preparation, C.L.; writing—review and editing, W.S.; visualization, H.Y. and K.L.; supervision, W.S.; project administration, W.S.; funding acquisition, W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51675061.

Data Availability Statement