Response Surface Optimization Design for High-Speed Ball Bearing Double-Lip Seals Considering Wear Characteristics

Abstract

1. Introduction

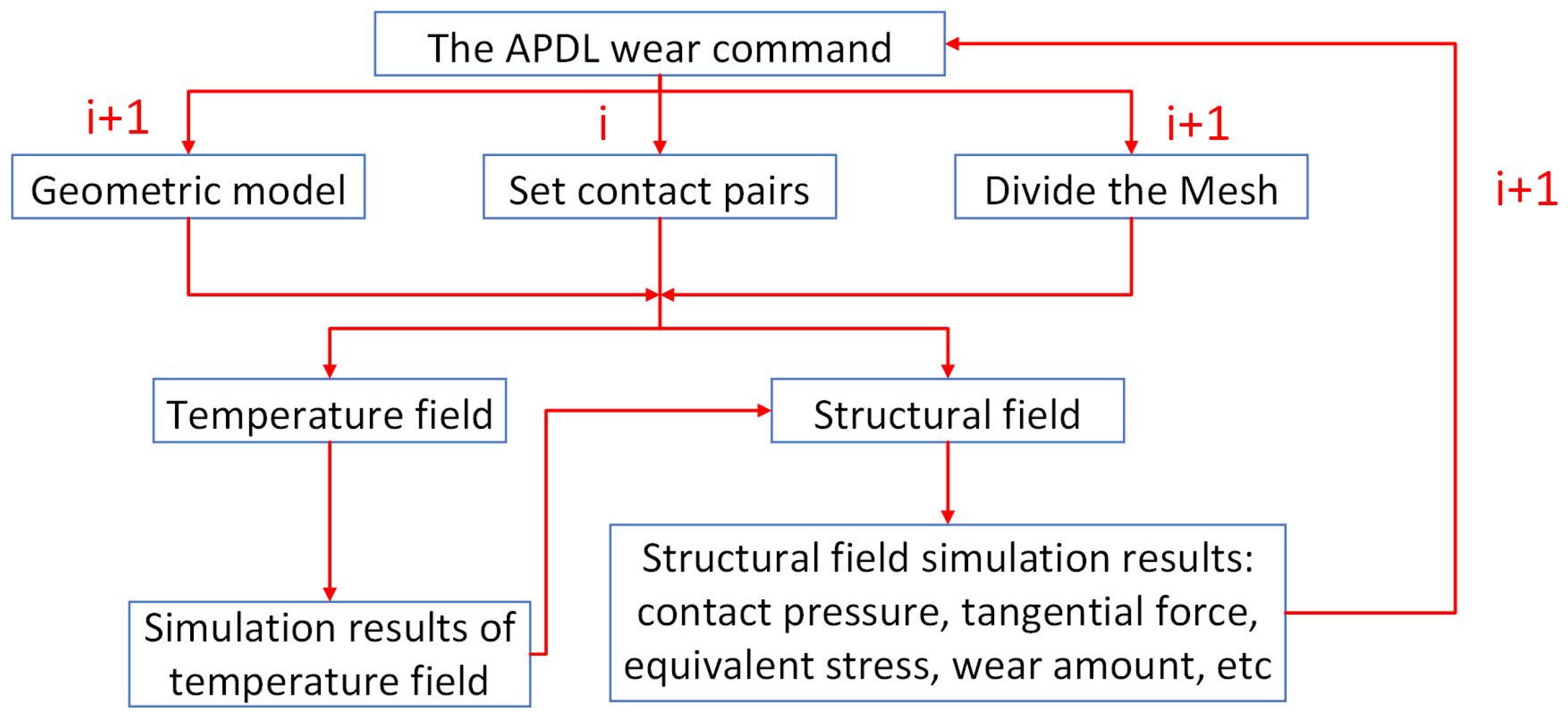

2. Thermal–Stress–Wear Coupled Finite Element Simulation Analysis

- Due to the huge amount of bidirectional coupling calculation, this paper establishes a sequential coupling model from the temperature field to the structural field. The influence of the structural field on the temperature field is achieved by adding frictional power consumption to the temperature field.

- Since the deformation of the lip seal is relatively small, the changes in material parameters such as Young’s Modulus and Poisson’s Ration of the rubber material with temperature and deformation are not considered.

- We suppose that the rubber material is an ideal elastic material that is uniform, continuous and isotropic.

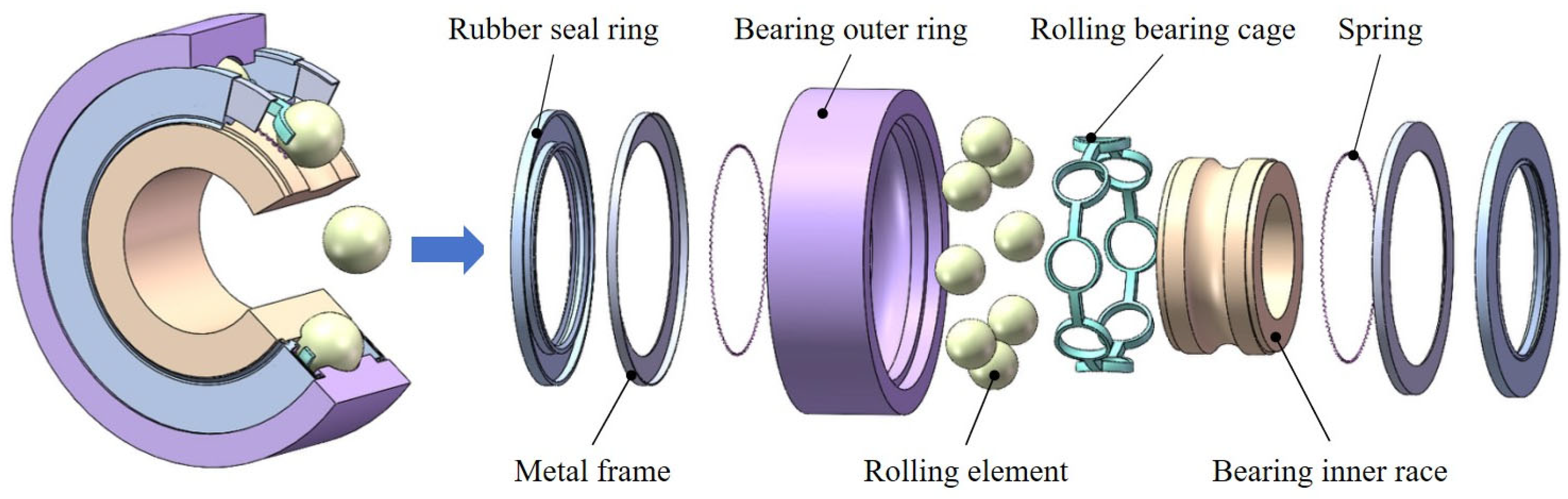

2.1. Geometric Models and Material Parameters Settings

2.1.1. Geometric Model

2.1.2. Material Parameters

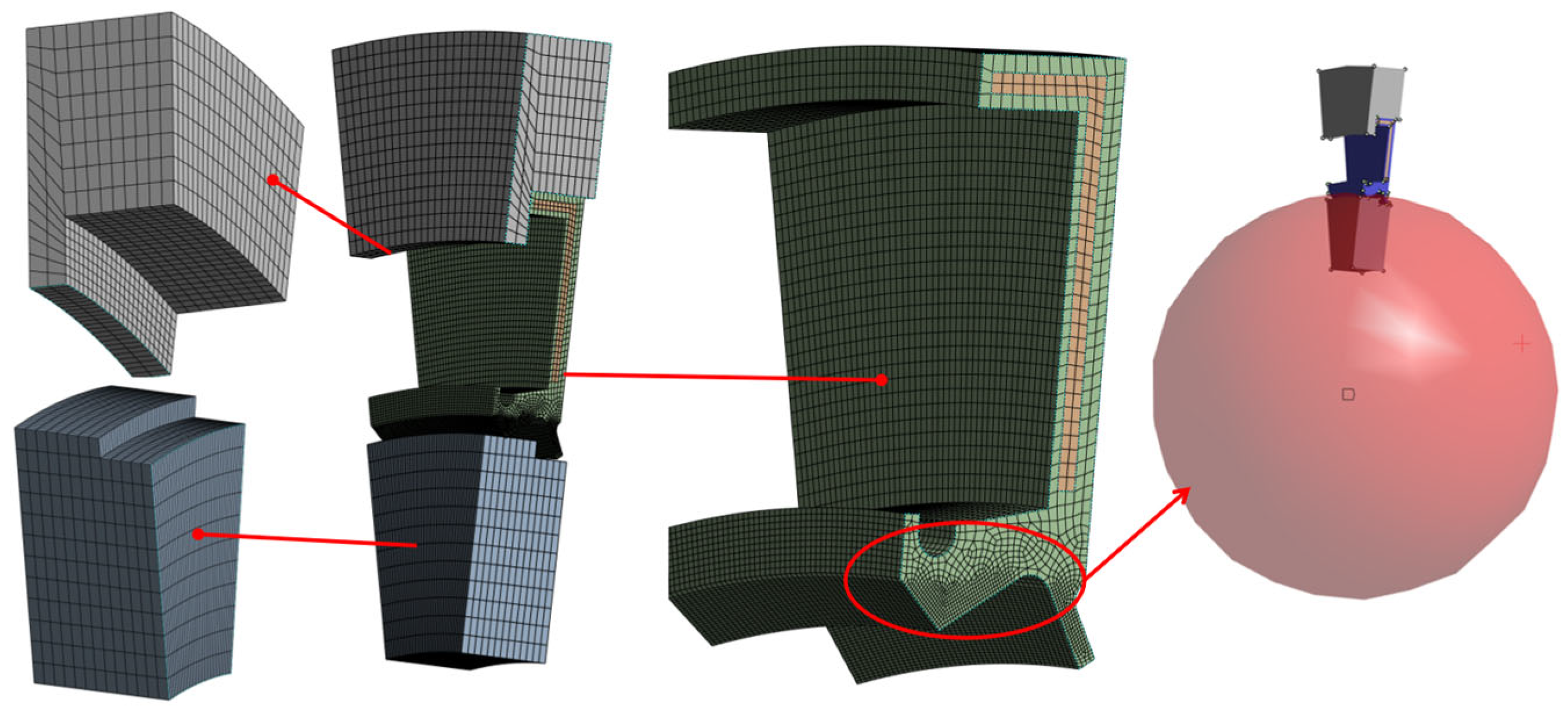

2.2. Mesh Generation

2.3. Add APDL Wear Program

2.4. Boundary Condition Setting

2.4.1. Setting of Temperature Field Boundary Conditions

2.4.2. Setting of Boundary Conditions for Structural Field

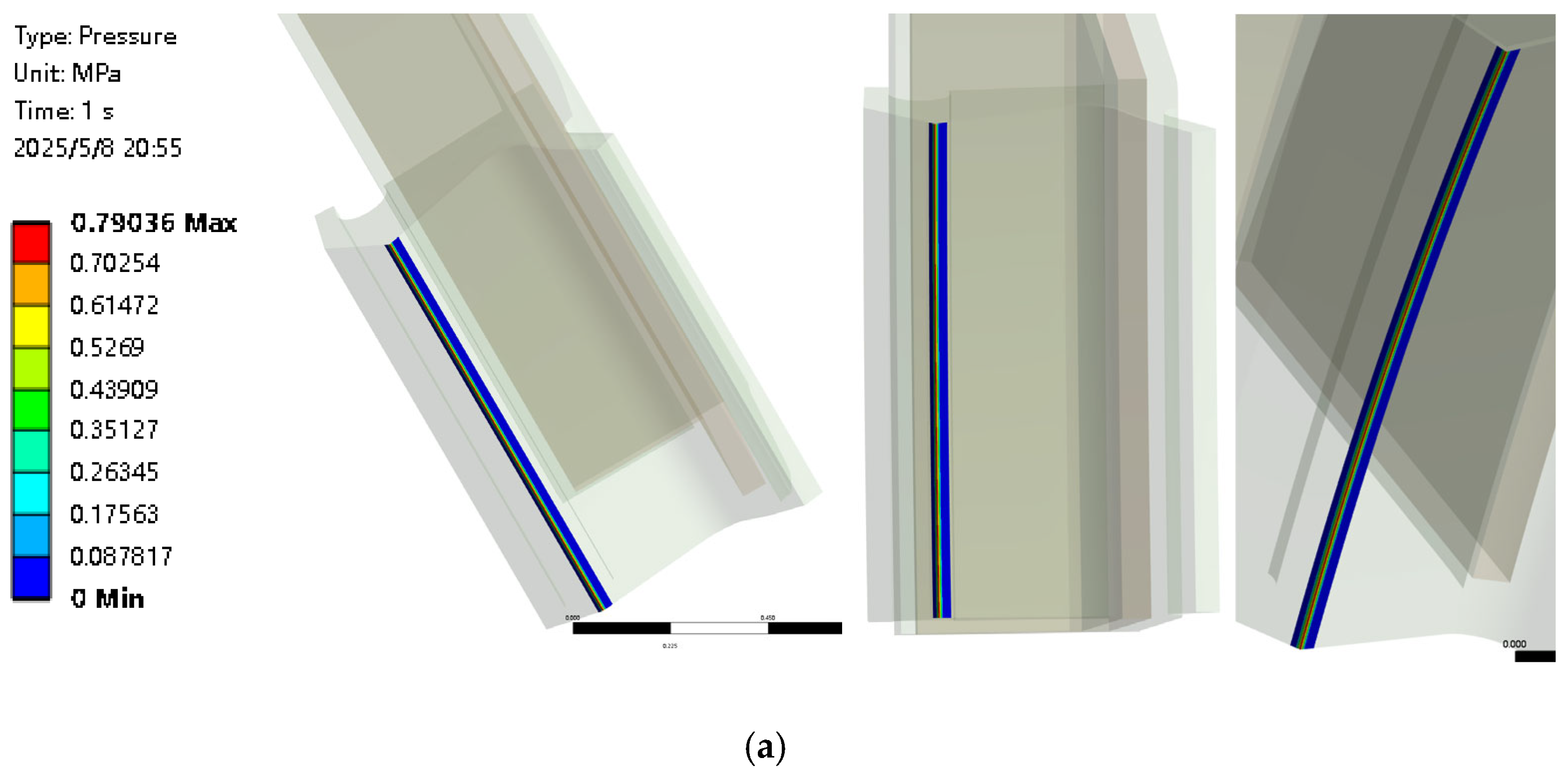

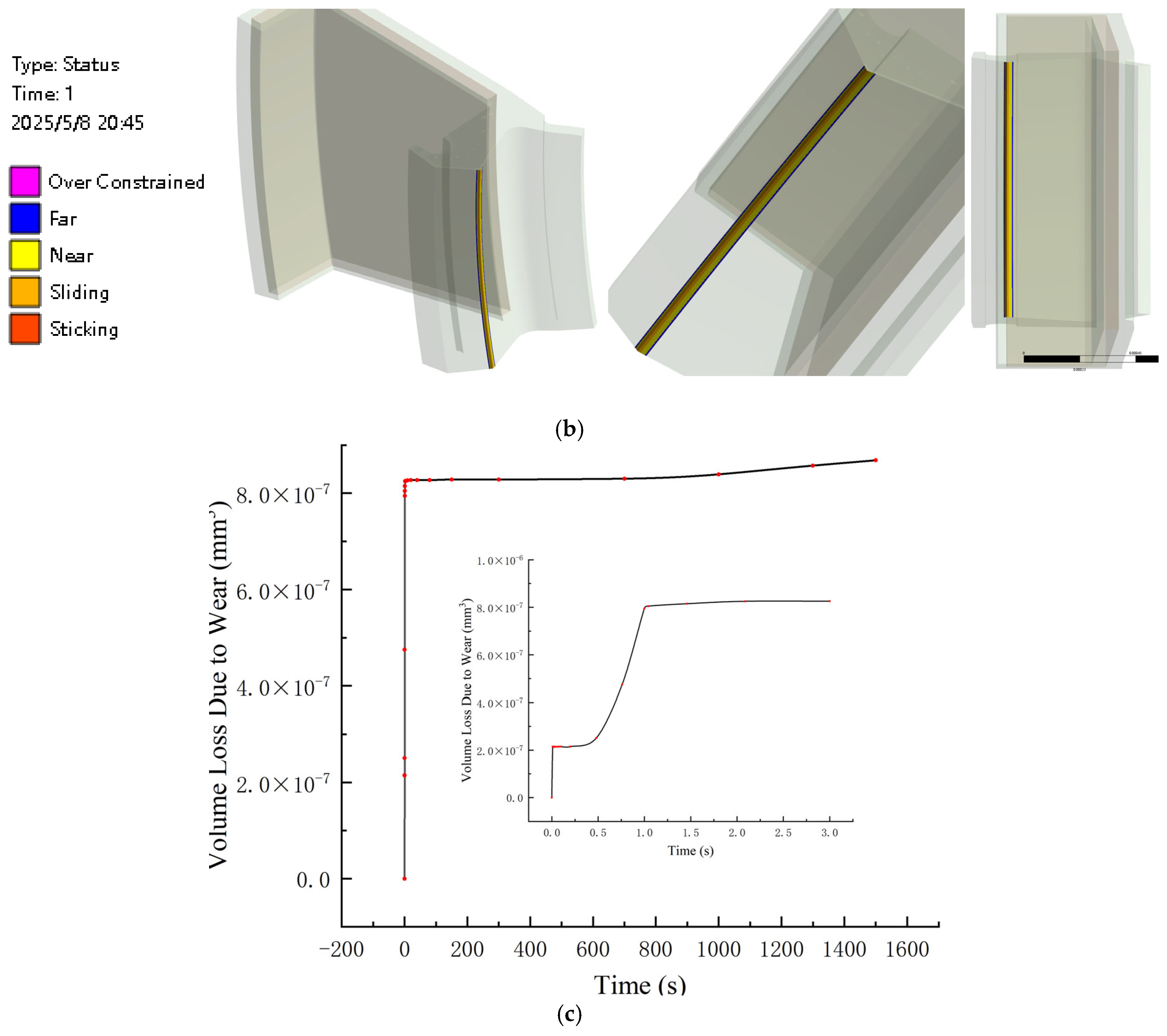

2.5. Finite Element Analysis Results of Thermal–Stress–Wear

2.5.1. Simulation Results of the Temperature Field

2.5.2. Simulation Results of the Structural Field

3. Response Surface Optimization

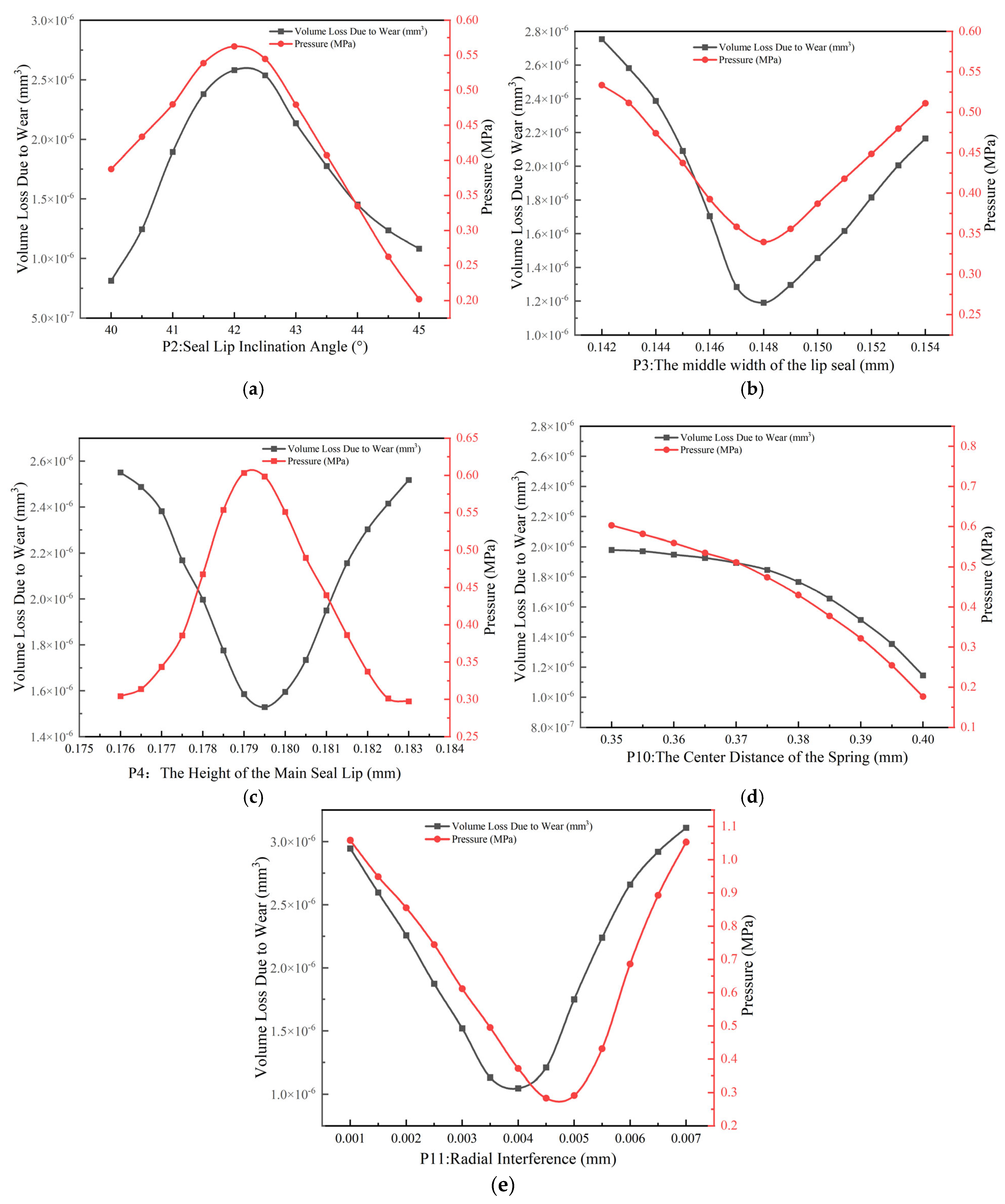

3.1. Determining the Optimization Range of the Response Surface

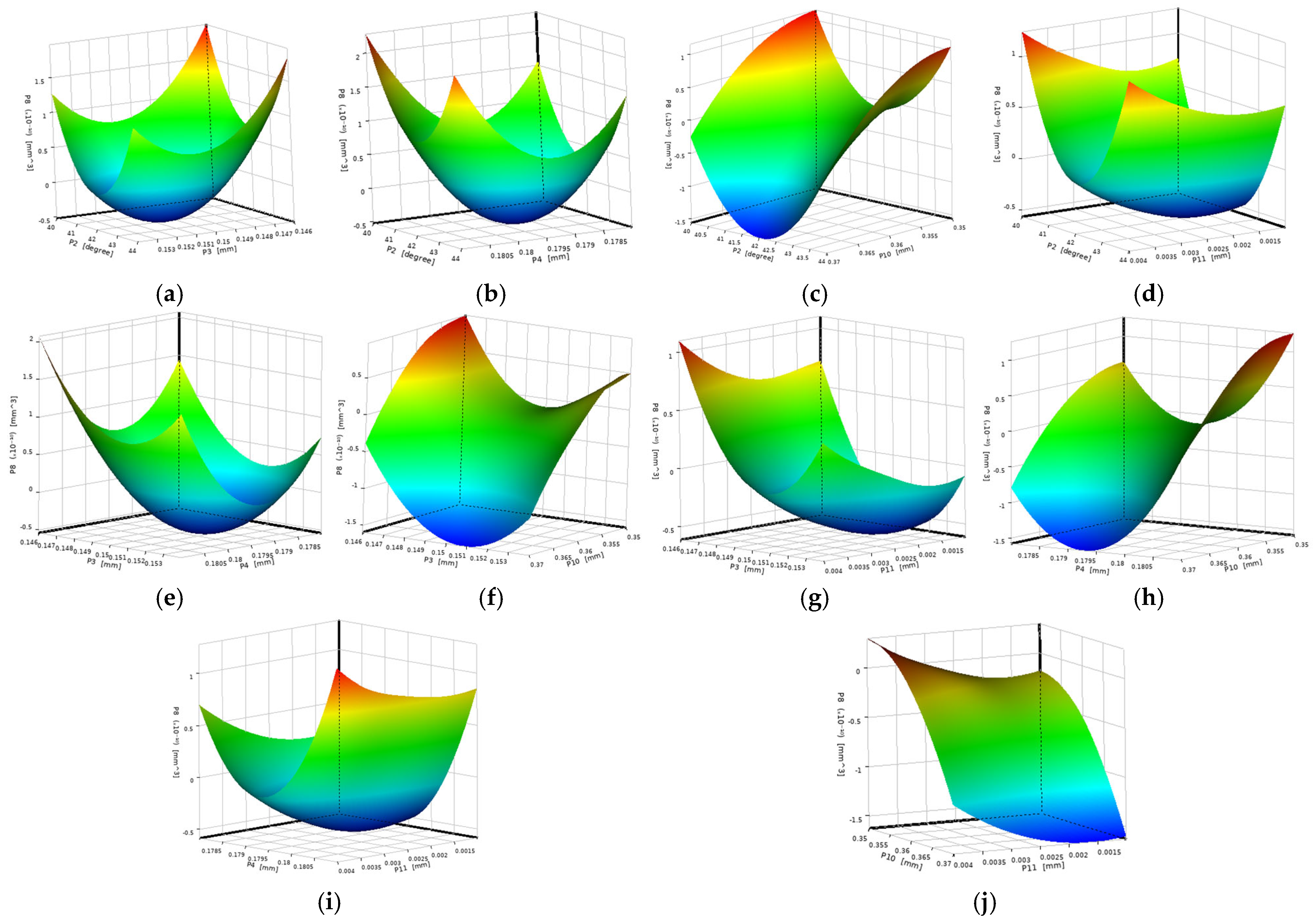

3.2. Optimal Design of Response Surface

3.3. Model Validation

3.4. Multi-Objective Optimization Results

4. Experimental Verification

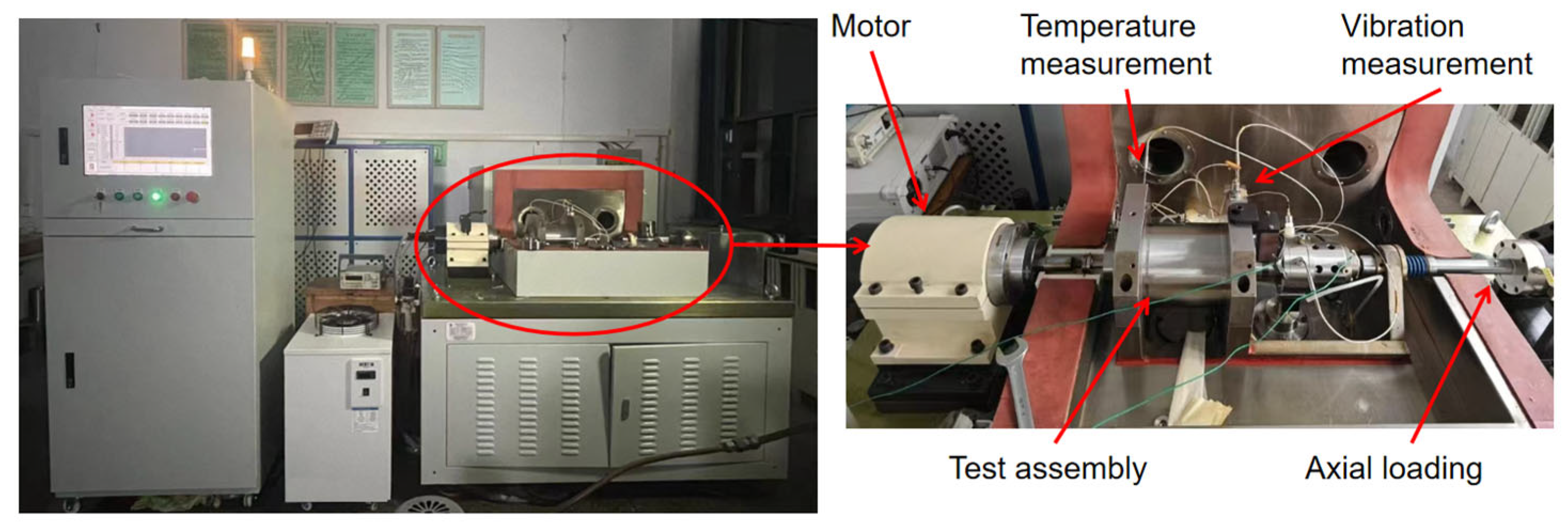

4.1. Experimental Instrument

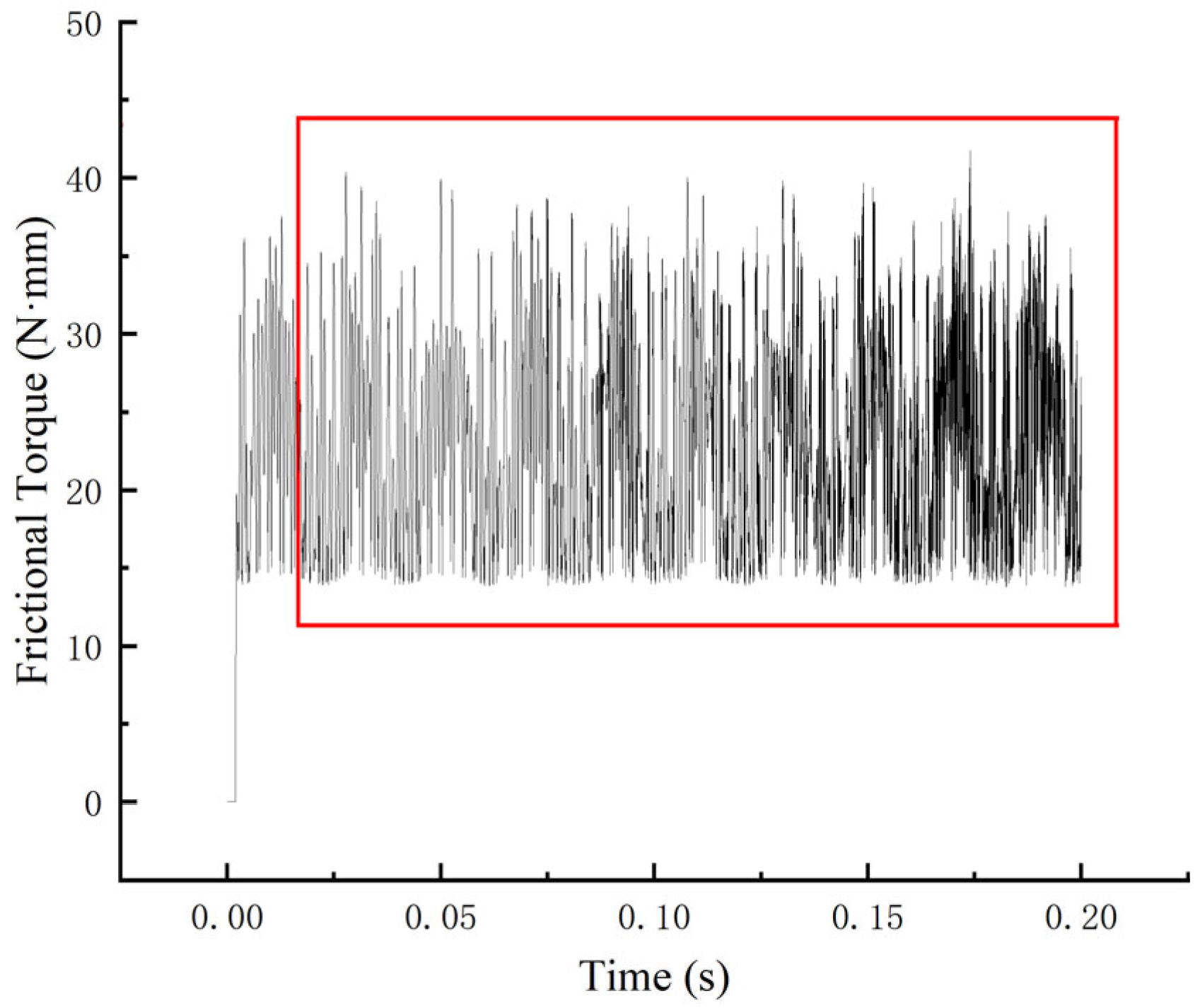

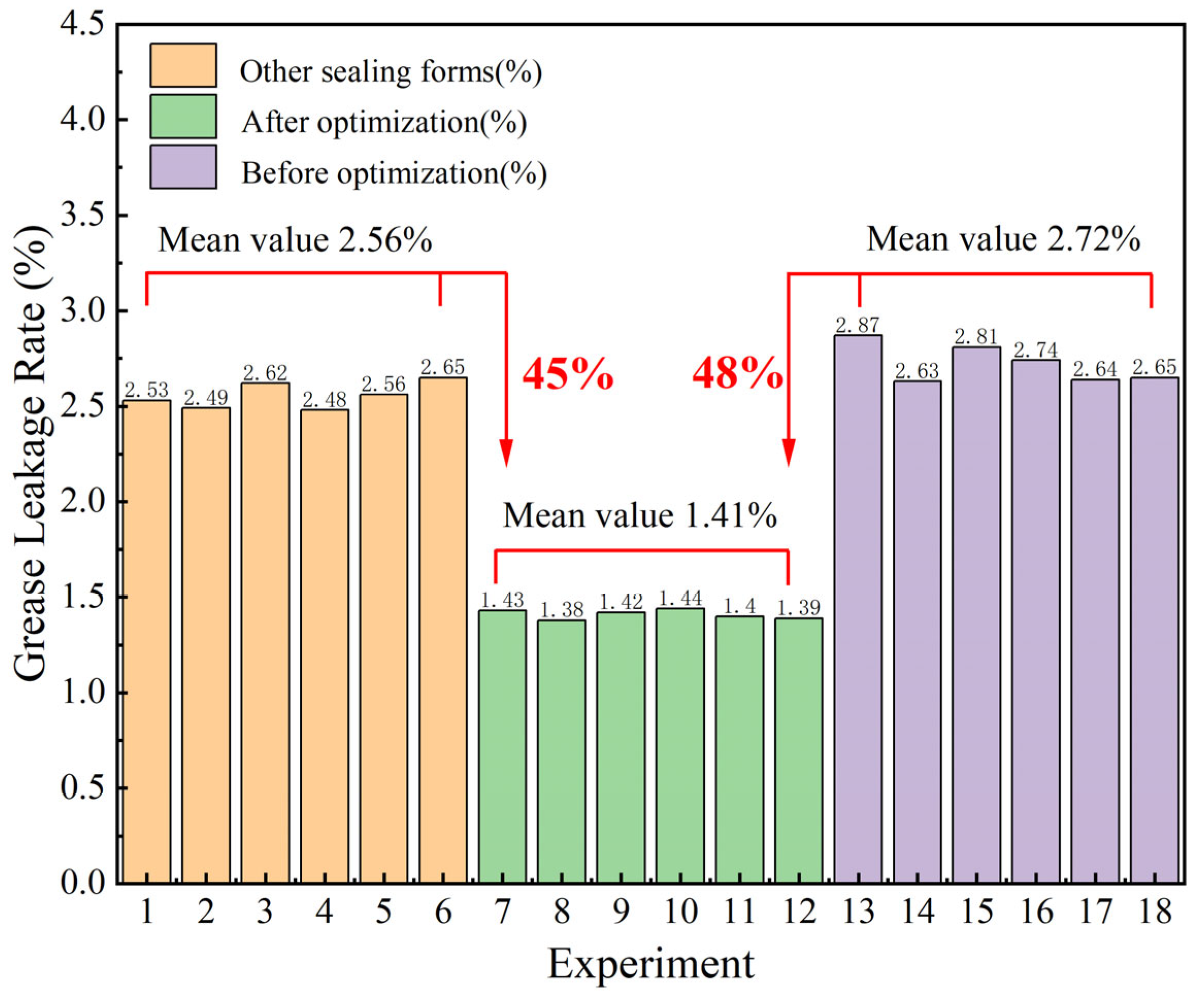

4.2. Results of the Experiment

5. Results

- The simulation results of the coupled finite element model of thermal–stress–wear show that the contact pressure at the main lip of the sealing lip is the highest, which is 0.79 Mpa. The contact states of the lip seal from the main lip end to both sides are sliding, near and far, respectively. The wear volume of the lip seal when it reaches the stable stage of operation is 7.94 × 10−7 mm3.

- Based on the ANSYS Workbench software response surface optimization module, it is concluded that the sealing performance of the bearing lip seal is optimal when the lip inclination angle is 41.68°, the middle width of the lip seal is 0.153 mm, the height of the main seal lip is 0.179 mm, the center distance of the spring is 0.3698 mm and the radial interference fit is 0.0034 mm.

- A comparative test was conducted on the lip seal before and after optimization, and it was found that the grease leakage rate of the lip seal after optimization decreased by 48% compared to that before optimization, indicating that the thermal–stress–wear coupled finite element model established in this paper is correct.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Du, C.; Zhang, Y.; Han, P.; Wei, W. A Clustering-Based Coverage Path Planning Method for Autonomous Het-erogeneous UAVs. IEEE Trans. Intell. Transp. Syst. 2022, 23, 25546–25556. [Google Scholar] [CrossRef]

- Qi, J. The unmanned aerial vehicle industry is booming, the low-altitude economy has been integrated into various industries. China Secur. J. 2025. (In Chinese) [Google Scholar] [CrossRef]

- Qin, Y.; Jia, S. Exploration of the application of surveying and mapping technology in the planning and management of exhibition venues. China Conf. Exhib. 2025, 39–41. (In Chinese) [Google Scholar] [CrossRef]

- Tognon, M.; Alami, R. Physical Human-Robot Interaction With a Tethered Aerial Vehicle: Application to a Force-Based Human Guiding Problem. IEEE Trans. Robot. 2021, 37, 723–734. [Google Scholar] [CrossRef]

- Brown, M.W. Seals and Sealing Handbook, 3rd ed.; Elsevier: London, UK, 1990. [Google Scholar]

- Shen, D. Deterministic Modeling of Rotary Lip Seal with Microasperities on the Shaft Surface; Georigia Institute Technolohy: Atlanta, GA, USA, 2005. [Google Scholar]

- Dong, X.; Song, J. Simulation study of lip seal considering rotating shaft vibration. Lubr. Eng. 2025, 1–10. (In Chinese) [Google Scholar]

- Jagger, E.T. Rotary shaft seals: The sealing mechanism of synthetic rubber seals running at atmospheric pressure. Proc. Inst. Mech. Eng. 1957, 171, 597–616. [Google Scholar] [CrossRef]

- Jagger, E.T. Study of the lubrication of synthetic rubber rotary shaft seals. Proc. Inst. Mech. Eng. Conf. Lubr. Wear 1957, 409, 409–415. [Google Scholar]

- Jagger, E.T.; Walker, P.S. Further studies of the lubrication of synthetic rubber rotary shaft seals. Proc. Inst. Mech. Eng. 1966, 181, 191–204. [Google Scholar] [CrossRef]

- Poll, G.; Gabelli, A. Formation of lubricant film in rotary sealing contacts, Part II-A new measuring principle for lubricant film thickness. ASME J. Tribol. 1992, 114, 290–297. [Google Scholar] [CrossRef]

- Poll, G.; Gabelli, A.; Binnington, P.G.; Qu, J. Dynamic mapping of rotary lip seal lubricant films by fluorescent image processing. In Proceedings of the 13th BHRA International Conference on Fluid Sealing, Brugge, Belgium, 7–9 April 1992; pp. 55–77. [Google Scholar]

- Salant, R.F.; Flaherty, A.L. Elastohydrodynamic analysis of reverse pumping in rotary lip seals with microundulations. ASME J. Tribol. 1994, 116, 56–62. [Google Scholar] [CrossRef]

- Salant, R.F.; Flaherty, A.L. Elastohydrodynamic analysis of reverse pumping in rotary lip seals with micro asperities. ASME J. Tribol. 1995, 117, 53–59. [Google Scholar] [CrossRef]

- Salant, R.F.; Shen, D.W. Hydrodynamic effects of shaft surface roughness on rotary lip seal behaviour. Seal. Technol. 2003, 7, 5–9. [Google Scholar] [CrossRef]

- Wen, S.Z. Progress and Thoughts on Lubrication Theory Research. Tribology 2007, 6, 497–503. [Google Scholar] [CrossRef]

- Zhao, S.Q.; Wang, F.R. Optimal design and experimental verification of sealing structure of hub bearing units. Bearing 2025, 02, 39–45. [Google Scholar] [CrossRef]

- Pan, J.; Zou, G.F. Numerical analysis and limit condition study of temperature and deformation fields of high-speed bearing cavity magnetic seals. J. Mech. Electr. Eng. 2025, 42, 667–676. [Google Scholar] [CrossRef]

- Ma, L.B.; Ma, C.B. Sealing Performance of Lip Seal Ring in Eccentric State of Spherical Roller Bearing. Lubr. Eng. 2025, 1–9. (In Chinese) [Google Scholar]

- Wang, J.; Hao, H. The sealing performance of PTFE 0-rings at low temperature. J. Phys. Conf. Ser. 2024, 2842, 012014. [Google Scholar] [CrossRef]

- Wei, J.; Liu, C.; Guo, F.; Tian, J. Effect of angle eccentricity on lip seal performance of helicopter gearbox. Tribol. Int. 2025, 209, 110676. [Google Scholar] [CrossRef]

- Chen, S.S.; Guo, F. An improved mixed lubrication model for revealing the mechanism of high speed and frictional heat on sealing performance. Tribol. Int. 2024, 191, 109147. [Google Scholar] [CrossRef]

- Jing, S.; Mu, A. Finite-element analysis and structure optimization of X-O composite seal of cone bit. Adv. Mech. Eng. 2020, 12, 1687814020918686. [Google Scholar] [CrossRef]

- Li, X.; Peng, G.L. Prediction of seal wear with thermal–structural coupled finite element method. Finite Elem. Anal. Des. 2014, 83, 10–21. [Google Scholar] [CrossRef]

- Zhang, S.; Cui, Y.C. Thermal-stress-wear coupled characteristics of oil seal in airframe rod end-bearing. Tribol. Int. 2021, 163, 107132. [Google Scholar] [CrossRef]

- Bekesi, N.; Varadi, K. Wear simulation of a reciprocating seal by global remeshing. Period. Polytech. Mech. Eng. 2010, 54, 71–75. [Google Scholar] [CrossRef]

- Qiao, X.K.; Yang, M. An analytical model for stress distribution of NBR O-ring during dynamic hydrogen permeation. Int. J. Hydrog. Energy 2025, 109, 164–173. [Google Scholar] [CrossRef]

- Zhang, S.L.; Qian, Z.H. Optimal Design and Analysis on Sealing Rings of Hub Bearings. Beraing 2020, 11, 6–11. [Google Scholar] [CrossRef]

- Mooney, M. A theory of larhe elastic deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Wang, W.; Deng, T.; Zhao, S.G. Determination of material constants in rubber Mooney-Rinlin model. Spec. Purp. Rubber Prod. 2004, 25, 8–10. [Google Scholar] [CrossRef]

- Qiu; Potapov; Song; Nordell, L. Prediction of wear of mill lifters using discrete ele-mentmethod. In Proceedings of the SAG Conference Proceedings, Vancouver, BC, Canada, 30 September–3 October 2001. [Google Scholar]

- Huo, J.J.; Gao, F. Medium Parameters Effect on Sealing Performance of Lip Seal Ring. Coal Mine Mach 2018, 39, 58–62. [Google Scholar] [CrossRef]

- Dai, Y.B. Research on Stress-Temperature Coupling Properties for Bearing Assembly of Control Momentum Gyroscope; Hennan University of Science and Technology: Luoyang, China, 2016. (In Chinese) [Google Scholar]

- Wang, J.Y.; Wang, L. A novel waste heat-driven methane reforming membrane reactor and parametric optimization study combining CFD simulation and response surface methodology. Case Stud. Therm. Eng. 2025, 70, 106111. [Google Scholar] [CrossRef]

- Feng, J.J.; Liu, B.X. Reliability Optimization Design of Hydrofoil Based on Response Surface Model. Chin. J. Hydrodyn. 2025, 40, 306–316. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M.B.; Yaro, N.S.A. Response Surface Methodology Optimization in Asphalt Mixtures: A Review [Internet]. In Response Surface Methodology Optimization in Asphalt Mixtures: A Review; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Chen, Y.T.; Xia, T.Y. The optimization method of underground powerhouse support based on LHS-SSA-BPNN. Water Resour. Power 2025, 6, 162–166. (In Chinese) [Google Scholar]

- Yang, X.; Zhang, Y.; Wang, T.; Zhang, H. An active learning reliability method combining population Monte Carlo and Kriging model for small failure probability. Structures 2024, 70, 107621. [Google Scholar] [CrossRef]

- Zhao, H.G.; Sun, W.H. Effect of Laser Cutting of Oak Wood Based on Response Surface Methodology. Sci. Silvae Sin. 2025, 1–10. (In Chinese) [Google Scholar]

- Wang, H.; Yue, Y.; Cui, Y.; Qiu, X.; Li, C. Sealing Performance Analysis of Lip Seal Ring for High-Speed Micro Bearing. Lubricants 2024, 12, 442. [Google Scholar] [CrossRef]

- Liu, S.X. Sealing performance test of sealed bearing. Beraing 1992, 41–44+61. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| P2: Seal lip inclination angle | 40–45° |

| P3: The middle width of the lip seal | 0.144–0.154 mm |

| P4: The heigh of the main seal lip | 0.177–0.182 mm |

| P10: The center distance of the spring | 0.35–0.40 mm |

| P11: Radial interference | 0.001–0.006 mm |

| Material | Poisson’s Ration | Density (g/cm3) | Young’s Modulus (MPa) | Isotropic Thermal Conductivity (W/(m·k)) | Coefficient of Thermal Expansion (/°C) |

|---|---|---|---|---|---|

| SPCC | 0.28 | 7.85 | 2 × 105 | 55 | 1.12 × 10−6 |

| GCr15 | 0.29 | 7.81 | 219 | 35 | 1.25 × 10−6 |

| NBR | 0.49 | 0.98 | 7.8 | 0.2 | 180 × 10−6 |

| Factor | Level | ||

|---|---|---|---|

| Initial Value | Lower Bound | Upper Bound | |

| P2: The inclination angle of the lip seal | 43° | 40° | 44° |

| P3: The middle width of the lip seal | 0.148 mm | 0.146 mm | 0.154 mm |

| P4: The height of the main seal lip | 0.178 mm | 0.178 mm | 0.181 mm |

| P10: The center distance of the spring | 0.36 mm | 0.35 mm | 0.37 mm |

| P11: Radial interference | 0.001 mm | 0.001 mm | 0.004 mm |

| Name | P2 (°) | P3 (mm) | P4 (mm) | P10 (mm) | P11 (mm) | P8 (mm3) | P9 (MPa) | ||

|---|---|---|---|---|---|---|---|---|---|

| Parameter Value | Variation from Reference | Parameter Value | Variation from Reference | ||||||

| Candidate Point 1 | 41.56 | 0.152 | 0.179 | 0.370 | 0.0035 | 1.18 × 10−10 | 3.14% | 0.654 | −1.16% |

| Candidate Point 1 | 41.80 | 0.153 | 0.179 | 0.3698 | 0.0034 | 1.16 × 10−10 | 1.66% | 0.655 | −0.98% |

| Candidate Point 1 | 41.68 | 0.153 | 0.179 | 0.3698 | 0.0034 | 1.14 × 10−10 | 0.00% | 0.661 | 0.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Yue, Y.; Cui, Y.; Lou, L.; Li, C. Response Surface Optimization Design for High-Speed Ball Bearing Double-Lip Seals Considering Wear Characteristics. Lubricants 2025, 13, 343. https://doi.org/10.3390/lubricants13080343

Wang H, Yue Y, Cui Y, Lou L, Li C. Response Surface Optimization Design for High-Speed Ball Bearing Double-Lip Seals Considering Wear Characteristics. Lubricants. 2025; 13(8):343. https://doi.org/10.3390/lubricants13080343

Chicago/Turabian StyleWang, Hengdi, Yulu Yue, Yongcun Cui, Lina Lou, and Chang Li. 2025. "Response Surface Optimization Design for High-Speed Ball Bearing Double-Lip Seals Considering Wear Characteristics" Lubricants 13, no. 8: 343. https://doi.org/10.3390/lubricants13080343

APA StyleWang, H., Yue, Y., Cui, Y., Lou, L., & Li, C. (2025). Response Surface Optimization Design for High-Speed Ball Bearing Double-Lip Seals Considering Wear Characteristics. Lubricants, 13(8), 343. https://doi.org/10.3390/lubricants13080343