Predicting Asphalt Pavement Friction by Using a Texture-Based Image Indicator

Abstract

1. Introduction

2. Laboratory Experiment and Data Collection

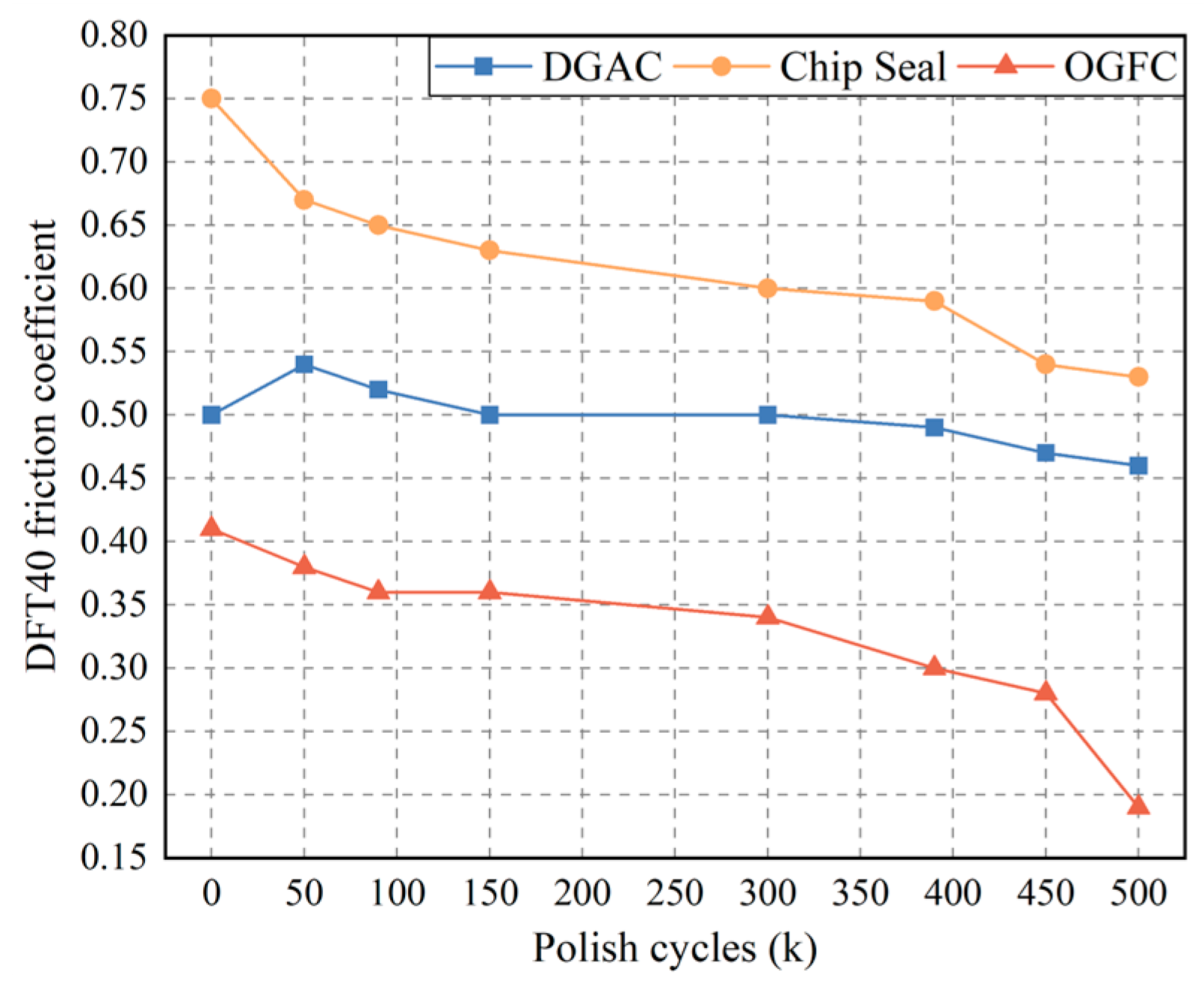

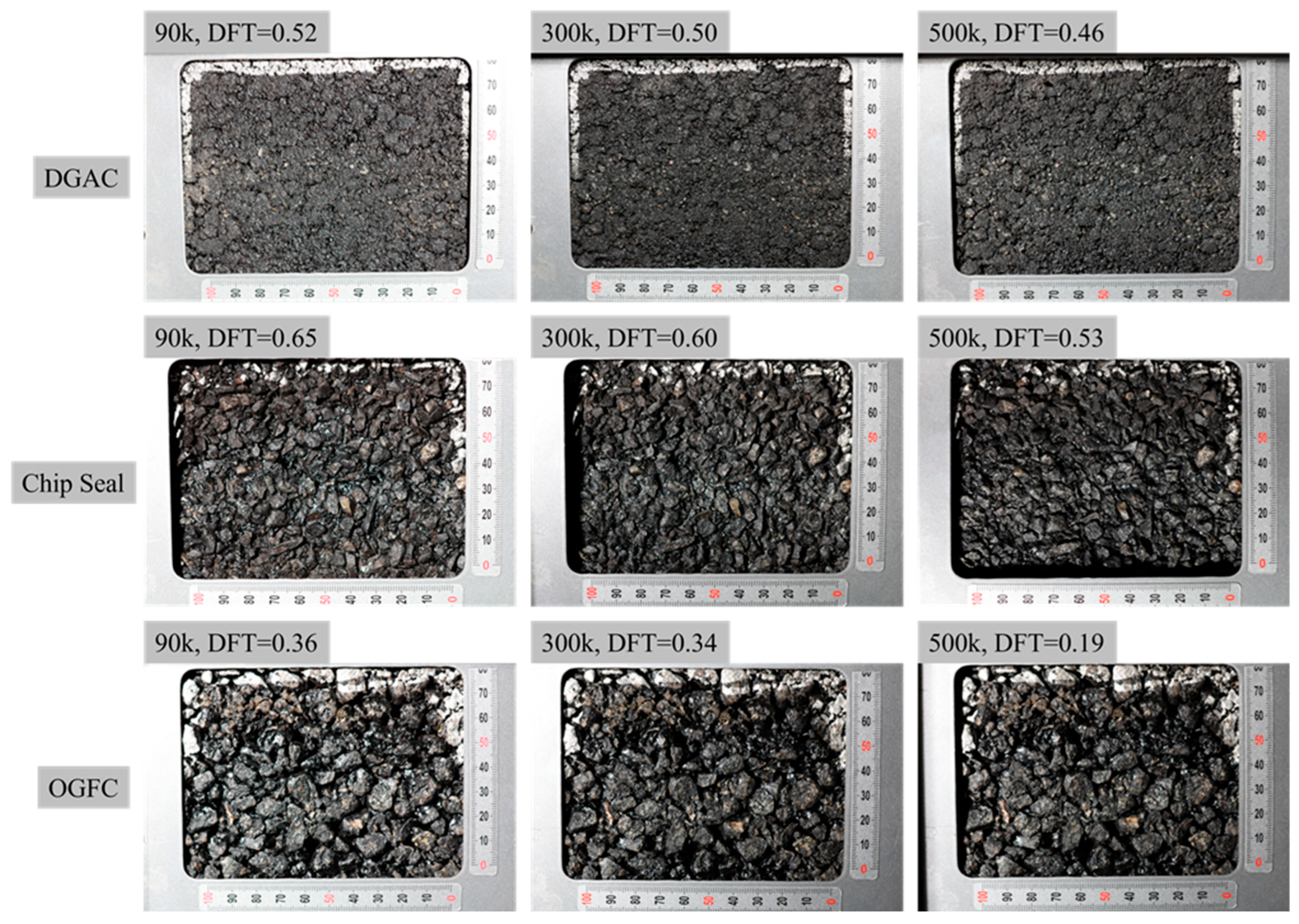

2.1. Friction Data Acquisition

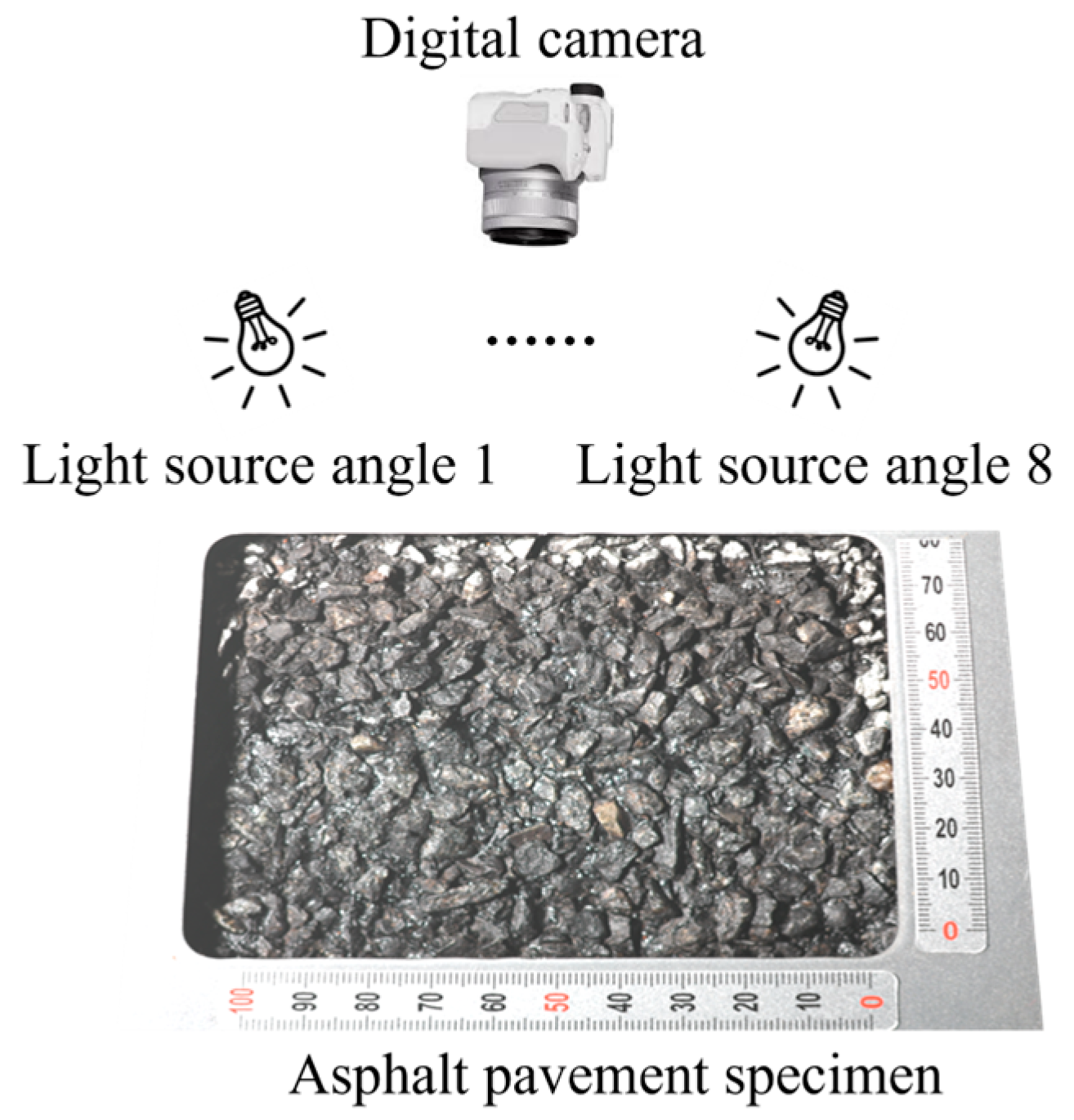

2.2. Digital Image Acquisition

3. Analysis Methodology

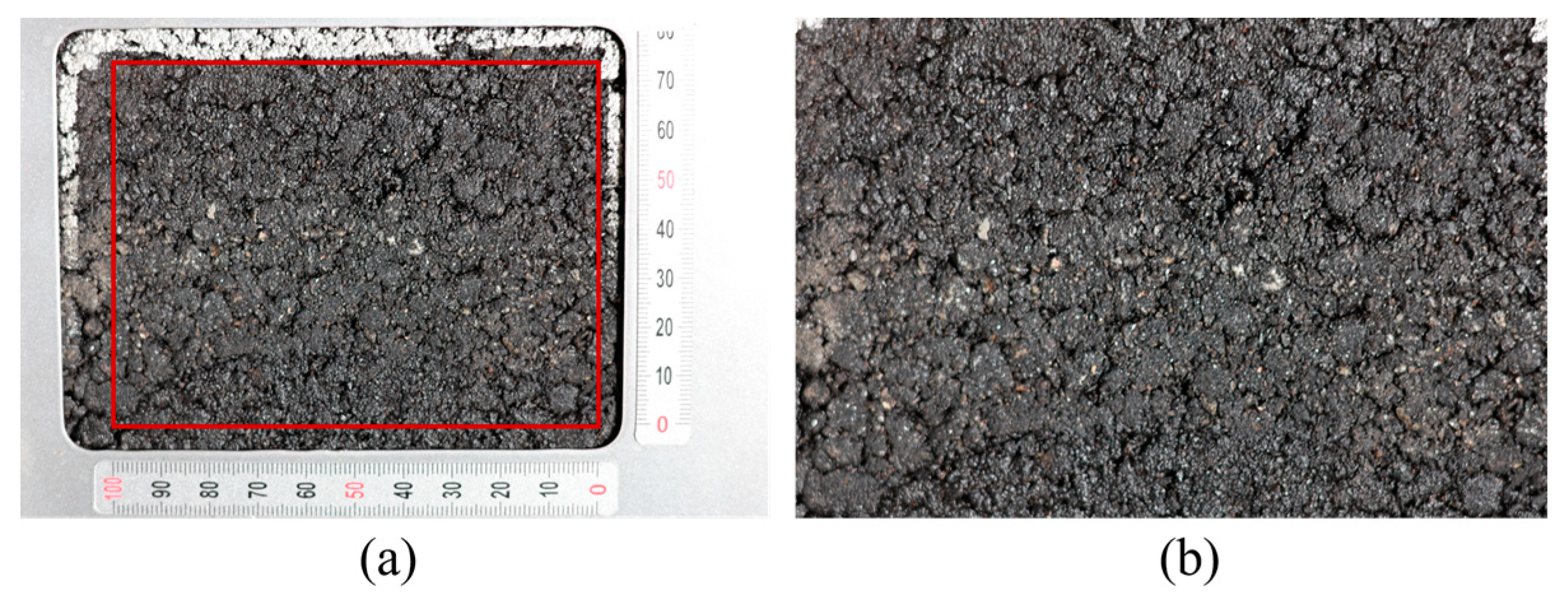

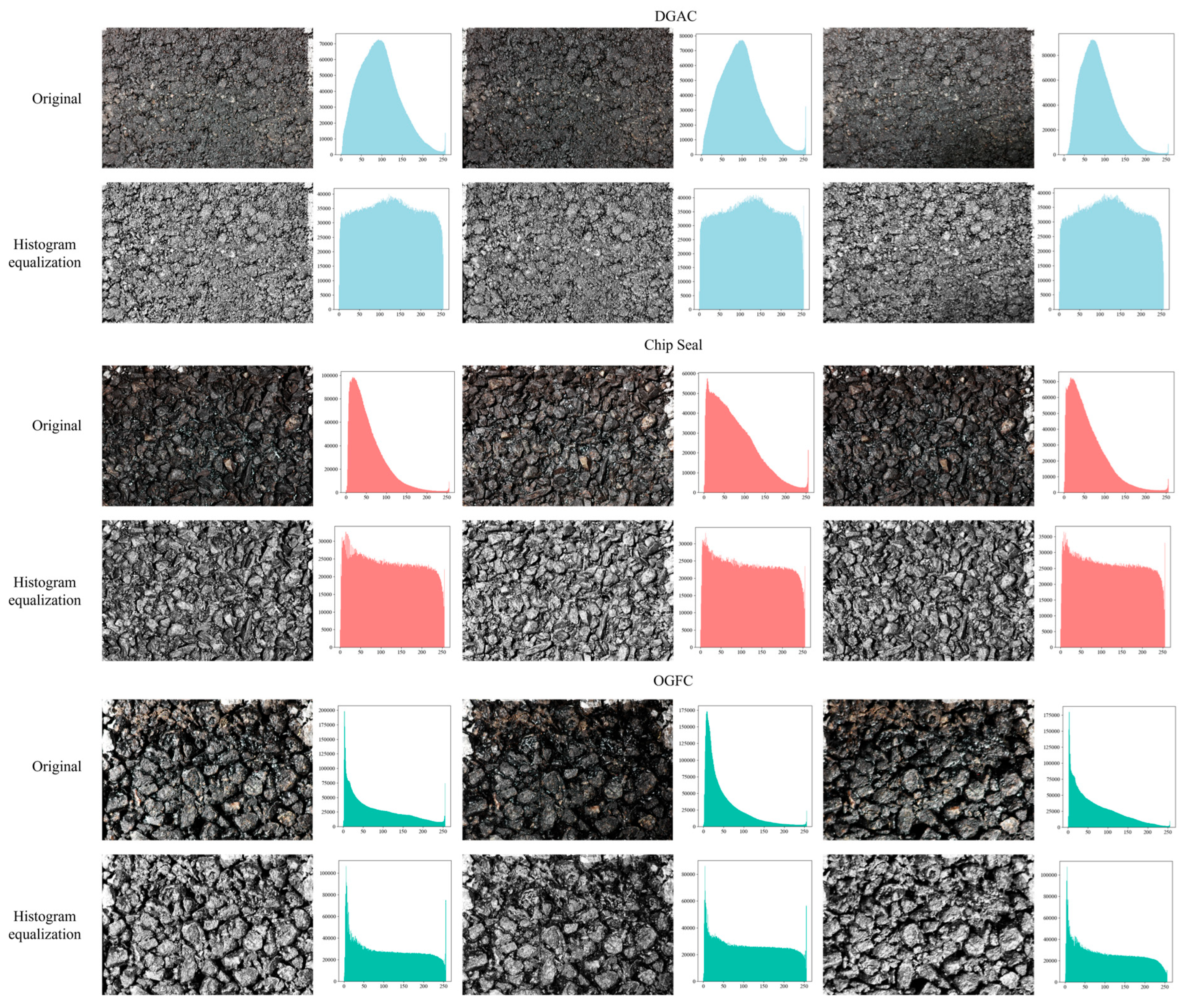

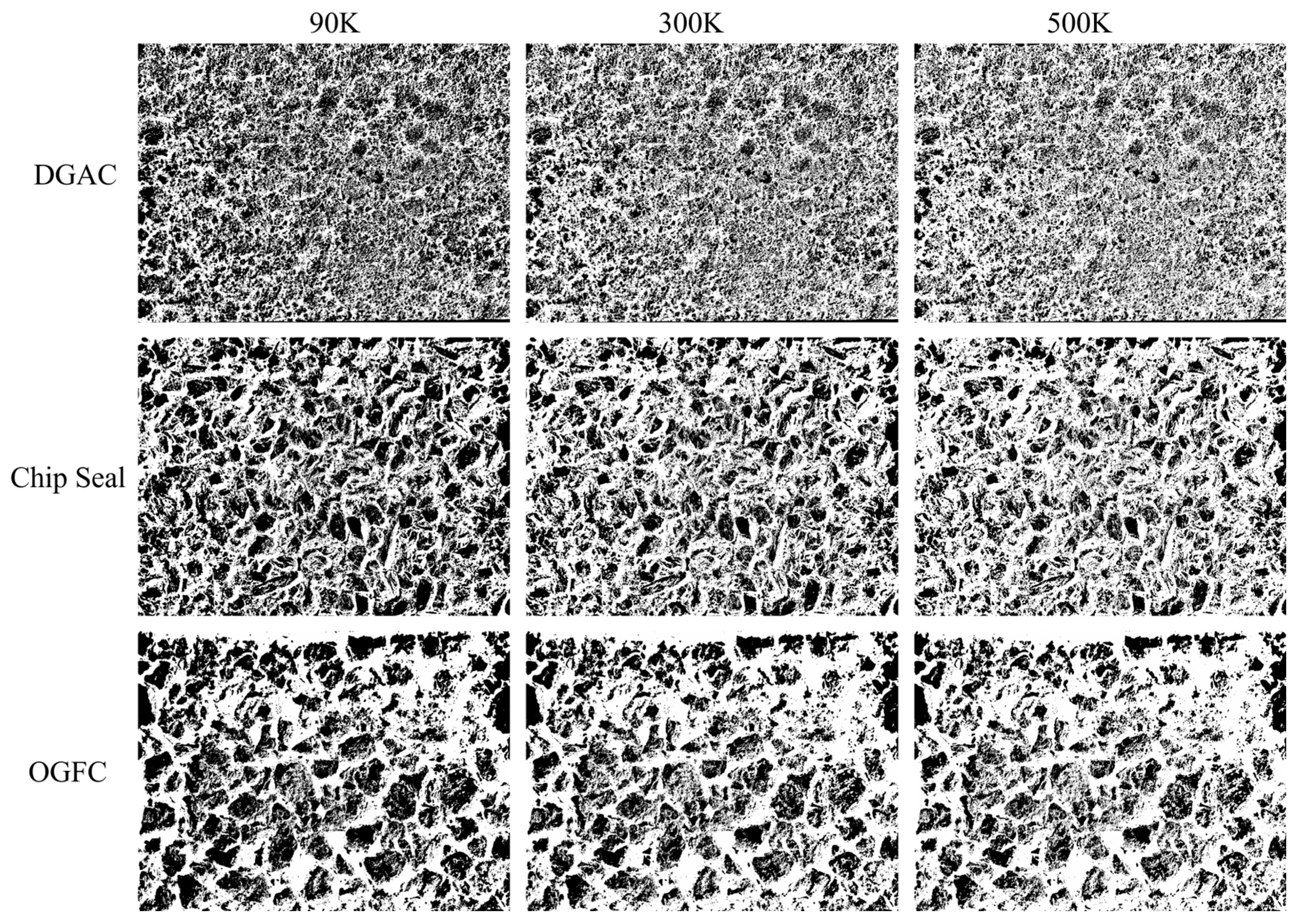

3.1. Image Preprocessing

3.2. Texture Feature Extraction

3.3. Other Image-Based Indicators from Literature

4. Results and Discussion

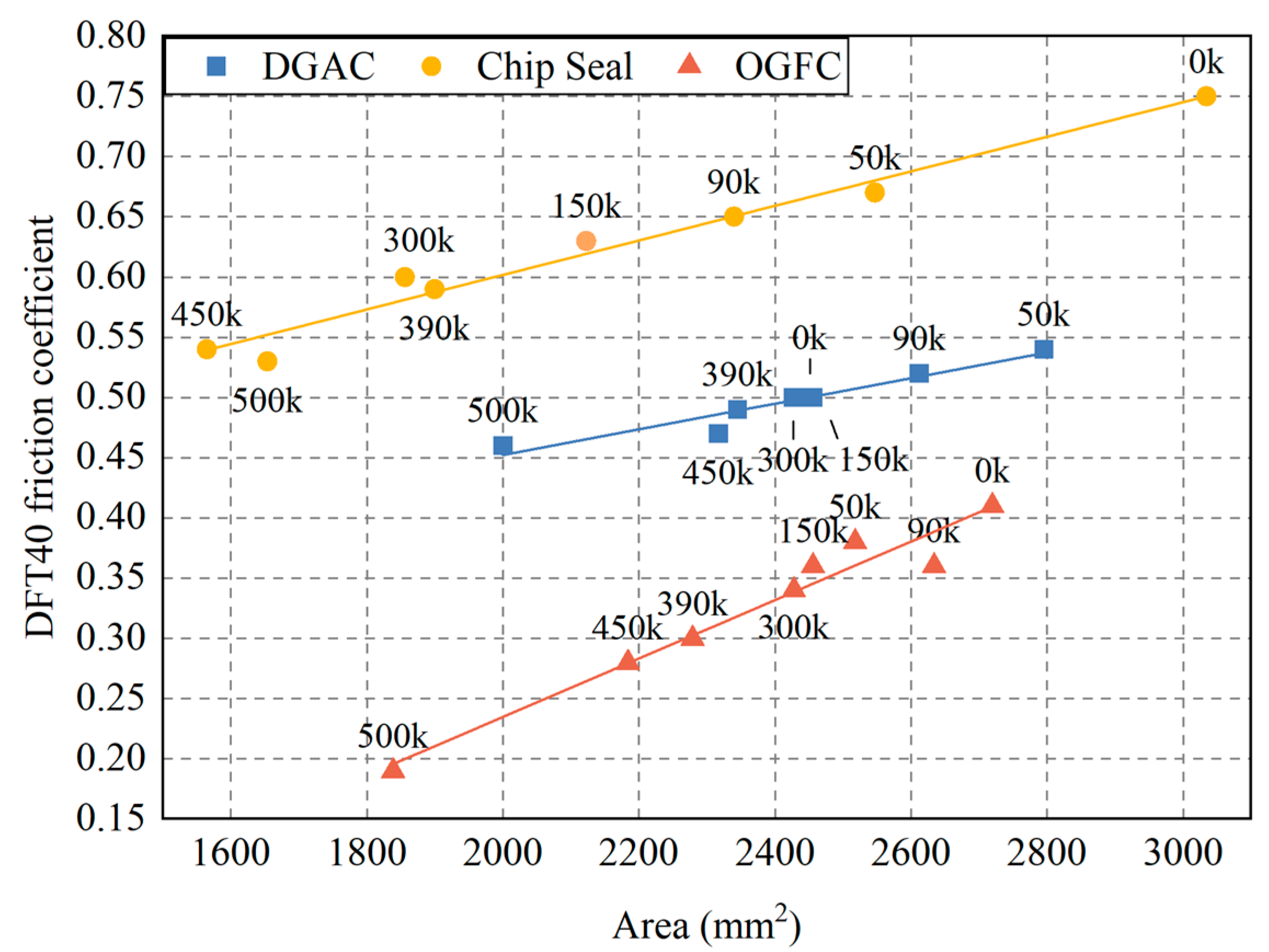

4.1. Evaluation of Proposed Image Indicator

4.2. Comparison of Accuracy for Different Image-Based Indicators

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grande, Z.; Castillo, E.; Mora, E.; Lo, H.K. Highway and road probabilistic safety assessment based on Bayesian network models. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 379–396. [Google Scholar] [CrossRef]

- Čelko, J.; Kováč, M.; Kotek, P. Analysis of the pavement surface texture by 3D scanner. Transp. Res. Procedia 2016, 14, 2994–3003. [Google Scholar] [CrossRef]

- Antle, C.E.; Wambold, J.; Henry, J.; Rado, Z. International PIARC Experiment to Compare and Harmonize Texture and Skid Resistance Measurement. PIARC Tech. Commitee Surf. Charact. C 1995, 1, 1995. [Google Scholar]

- Rezaei, A.; Masad, E.; Chowdhury, A.; Harris, P. Predicting asphalt mixture skid resistance by aggregate characteristics and gradation. Transp. Res. Rec. 2009, 2104, 24–33. [Google Scholar] [CrossRef]

- Rado, Z.; Yager, T.; Wambold, J.; Hall, J. Guide for Pavement Friction; The National Academies Press: Washington, DC, USA, 2006. [Google Scholar]

- Asi, I.M. Evaluating skid resistance of different asphalt concrete mixes. Build. Environ. 2007, 42, 325–329. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Gonzalo-Orden, H.; Findley, D.J.; Rojí, E. A skid resistance prediction model for an entire road network. Constr. Build. Mater. 2020, 262, 120041. [Google Scholar] [CrossRef]

- Roy, N.; Mondal, P.G.; Kuna, K.K. Image-based indices of aggregates for predicting the initial skid resistance of bituminous pavements. Constr. Build. Mater. 2023, 400, 132776. [Google Scholar] [CrossRef]

- Du, Y.; Weng, Z.; Li, F.; Ablat, G.; Wu, D.; Liu, C. A novel approach for pavement texture characterisation using 2D-wavelet decomposition. Int. J. Pavement Eng. 2022, 23, 1851–1866. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, A.A.; Wang, K.C.; Li, J.Q.; Liu, W.; Liu, Y. Deep-learning based non-contact method for assessing pavement skid resistance using 3D laser imaging technology. Int. J. Pavement Eng. 2023, 24, 2147520. [Google Scholar] [CrossRef]

- Dan, H.-C.; Lu, B.; Li, M. Evaluation of asphalt pavement texture using multiview stereo reconstruction based on deep learning. Constr. Build. Mater. 2024, 412, 134837. [Google Scholar] [CrossRef]

- Feng, C.; Bačić, B.; Li, W. SCA-LSTM: A Deep Learning Approach to Golf Swing Analysis and Performance Enhancement. In Proceedings of the International Conference on Neural Information Processing, Auckland, New Zealand, 2–6 December 2024; pp. 72–86. [Google Scholar]

- Dan, H.-C.; Yan, P.; Tan, J.; Zhou, Y.; Lu, B. Multiple distresses detection for Asphalt Pavement using improved you Only Look Once Algorithm based on convolutional neural network. Int. J. Pavement Eng. 2024, 25, 2308169. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, B.; Zhang, X.; Liang, J. Automatic extraction and evaluation of pavement three-dimensional surface texture using laser scanning technology. Autom. Constr. 2022, 141, 104410. [Google Scholar] [CrossRef]

- ASTM E1911-09a; Standard Test Method for Measuring Paved Surface Frictional Properties Using the Dynamic Friction Tester. ASTM: West Conshohocken, PA, USA, 2009.

- Bazlamit, S.M.; Reza, F. Changes in asphalt pavement friction components and adjustment of skid number for temperature. J. Transp. Eng. 2005, 131, 470–476. [Google Scholar] [CrossRef]

- Li, Z.; Ji, Q.; Ling, X.; Liu, Q. A Comprehensive Review of Multi-Agent Reinforcement Learning in Video Games. Authorea Prepr. 2025. preprint. [Google Scholar] [CrossRef]

- Lu, B.; Dan, H.-C.; Zhang, Y.; Huang, Z. Journey into automation: Image-derived pavement texture extraction and evaluation. arXiv 2025, arXiv:2501.02414. [Google Scholar]

- Wang, R.; He, Y.; Sun, T.; Li, X.; Shi, T. UniTMGE: Uniform Text-Motion Generation and Editing Model via Diffusion. In Proceedings of the 2025 IEEE/CVF Winter Conference on Applications of Computer Vision (WACV), Tucson, AZ, USA, 28 February–4 March 2025; pp. 6104–6114. [Google Scholar]

- Yu, M.; You, Z.; Wu, G.; Kong, L.; Liu, C.; Gao, J. Measurement and modeling of skid resistance of asphalt pavement: A review. Constr. Build. Mater. 2020, 260, 119878. [Google Scholar] [CrossRef]

- Gonzalez, R.C. Digital Image Processing; Pearson Education: Chennai, India, 2009. [Google Scholar]

- Lu, Z.; Lu, B.; Wang, F. CausalSR: Structural causal model-driven super-resolution with counterfactual inference. Neurocomputing 2025, 646, 130375. [Google Scholar] [CrossRef]

- Shi, C.; Tao, Y.; Zhang, H.; Wang, L.; Du, S.; Shen, Y.; Shen, Y. Deep semantic graph learning via llm based node enhancement. arXiv 2025, arXiv:2502.07982. [Google Scholar]

- Lu, Z.; Lu, B.; Wang, W.; Wang, F. Differentiable NMS via Sinkhorn Matching for End-to-End Fabric Defect Detection. arXiv 2025, arXiv:2505.07040. [Google Scholar]

- Yu, S.; Li, Z.; Gu, J.; Wang, R.; Liu, X.; Li, L.; Guo, F.; Ren, Y. CWMS-GAN: A small-sample bearing fault diagnosis method based on continuous wavelet transform and multi-size kernel attention mechanism. PLoS ONE 2025, 20, e0319202. [Google Scholar] [CrossRef]

- Li, L.; Wang, R.; Zou, M.; Guo, F.; Ren, Y. Enhanced ResNet-50 for garbage classification: Feature fusion and depth-separable convolutions. PLoS ONE 2025, 20, e0317999. [Google Scholar] [CrossRef]

- Li, P.; Yang, Q.; Geng, X.; Zhou, W.; Ding, Z.; Nian, Y. Exploring diverse methods in visual question answering. In Proceedings of the 2024 5th International Conference on Electronic Communication and Artificial Intelligence (ICECAI), Shenzhen, China, 31 May–2 June 2024; pp. 681–685. [Google Scholar]

- Liu, Y.; Qin, X.; Gao, Y.; Li, X.; Feng, C. SETransformer: A hybrid attention-based architecture for robust human activity recognition. arXiv 2025, arXiv:2505.19369. [Google Scholar]

- Zheng, J.; Chen, L.; Wang, J.; Chen, Q.; Huang, X.; Jiang, L. Knowledge distillation with T-Seg guiding for lightweight automated crack segmentation. Autom. Constr. 2024, 166, 105585. [Google Scholar] [CrossRef]

- Ding, T.; Xiang, D.; Rivas, P.; Dong, L. Neural Pruning for 3D Scene Reconstruction: Efficient NeRF Acceleration. arXiv 2025, arXiv:2504.00950. [Google Scholar]

- Pizer, S.M.; Amburn, E.P.; Austin, J.D.; Cromartie, R.; Geselowitz, A.; Greer, T.; ter Haar Romeny, B.; Zimmerman, J.B.; Zuiderveld, K. Adaptive histogram equalization and its variations. Comput. Vis. Graph. Image Process. 1987, 39, 355–368. [Google Scholar] [CrossRef]

- He, Y.; Wang, X.; Shi, T. Ddpm-moco: Advancing industrial surface defect generation and detection with generative and contrastive learning. In Proceedings of the International Joint Conference on Artificial Intelligence, Jeju Island, Republic of Korea, 3–9 August 2024; pp. 34–49. [Google Scholar]

- Li, Z. Retrieval-Augmented Forecasting with Tabular Time Series Data. In Proceedings of the 4th Table Representation Learning Workshop at ACL 2025, Vienna, Austria, 31 July 2025. [Google Scholar]

- Wu, C.; Huang, H.; Zhang, L.; Chen, J.; Tong, Y.; Zhou, M. Towards automated 3D evaluation of water leakage on a tunnel face via improved GAN and self-attention DL model. Tunn. Undergr. Space Technol. 2023, 142, 105432. [Google Scholar] [CrossRef]

- Zuiderveld, K. Contrast limited adaptive histogram equalization. In Graphics Gems IV; Elsevier: Amsterdam, The Netherlands, 1994; pp. 474–485. [Google Scholar]

- Liu, S.; Zhang, Y.; Li, X.; Liu, Y.; Feng, C.; Yang, H. Gated multimodal graph learning for personalized recommendation. arXiv 2025, arXiv:2506.00107. [Google Scholar]

- Jähne, B. Digital Image Processing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Wu, C.; Huang, H.; Chen, J.; Zhou, M.; Han, S. A novel Tree-augmented Bayesian network for predicting rock weathering degree using incomplete dataset. Int. J. Rock Mech. Min. Sci. 2024, 183, 105933. [Google Scholar] [CrossRef]

- Lee, J.-S. Digital image smoothing and the sigma filter. Comput. Vis. Graph. Image Process. 1983, 24, 255–269. [Google Scholar] [CrossRef]

- Gonzales, A.L.; Ramos, A.L.; Lacson, J.M.; Go, K.S.; Furigay, R.B. Optimizing Image and Signal Processing Through the Application of Various Filtering Techniques: A Comparative Study. In Proceedings of the Novel & Intelligent Digital Systems Conferences, Athens, Greece, 28–29 September 2023; pp. 151–170. [Google Scholar]

- Zheng, B.; Chen, J.; Zhao, R.; Tang, J.; Tian, R.; Zhu, S.; Huang, X. Analysis of contact behaviour on patterned tire-asphalt pavement with 3-D FEM contact model. Int. J. Pavement Eng. 2022, 23, 171–186. [Google Scholar] [CrossRef]

- Yun, D.; Hu, L.; Tang, C. Tire–road contact area on asphalt concrete pavement and its relationship with the skid resistance. Materials 2020, 13, 615. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Y.; Wu, C.-T.; Clarke, R.; Yu, G.; Van Eyk, J.E.; Herrington, D.M.; Wang, Y. Data-driven detection of subtype-specific differentially expressed genes. Sci. Rep. 2021, 11, 332. [Google Scholar] [CrossRef] [PubMed]

- Du, D.; Bhardwaj, S.; Lu, Y.; Wang, Y.; Parker, S.J.; Zhang, Z.; Van Eyk, J.E.; Yu, G.; Clarke, R.; Herrington, D.M. Embracing the informative missingness and silent gene in analyzing biologically diverse samples. Sci. Rep. 2024, 14, 28265. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Qin, B.; Weng, Z.; Wu, D.; Liu, C. Promoting the pavement skid resistance estimation by extracting tire-contacted texture based on 3D surface data. Constr. Build. Mater. 2021, 307, 124729. [Google Scholar] [CrossRef]

- Jiang, J.; Ni, F.; Gao, L.; Yao, L. Effect of the contact structure characteristics on rutting performance in asphalt mixtures using 2D imaging analysis. Constr. Build. Mater. 2017, 136, 426–435. [Google Scholar] [CrossRef]

- Shah, S.M.R.; Abdullah, M.E. Effect of aggregate shape on skid resistance of compacted hot mix asphalt (HMA). In Proceedings of the 2010 Second International Conference on Computer and Network Technology, Bangkok, Thailand, 23–25 April 2010; pp. 421–425. [Google Scholar]

- Ma, C.; Hou, D.; Jiang, J.; Fan, Y.; Li, X.; Li, T.; Ma, Z.; Ben, H.; Xiong, H. Elucidating the synergic effect in nanoscale MoS2/TiO2 heterointerface for Na-ion storage. Adv. Sci. 2022, 9, 2204837. [Google Scholar] [CrossRef]

- Han, D.; Qi, H.; Hou, D.; Wang, S.; Kong, J.; Xu, X.; Wang, C. Dynamic detection mechanism model of acoustic emission for high-speed train axle box bearings with local defects. Mech. Syst. Signal Process. 2025, 235, 112943. [Google Scholar] [CrossRef]

- Li, P.; Abouelenien, M.; Mihalcea, R.; Ding, Z.; Yang, Q.; Zhou, Y. Deception detection from linguistic and physiological data streams using bimodal convolutional neural networks. In Proceedings of the 2024 5th International Conference on Information Science, Parallel and Distributed Systems (ISPDS), Guangzhou, China, 31 May–2 June 2024; pp. 263–267. [Google Scholar]

- Xing, Z.; Zhao, W. Unsupervised action segmentation via fast learning of semantically consistent actoms. In Proceedings of the AAAI Conference on Artificial Intelligence, Vancouver, BC, Canada, 20–27 February 2024; pp. 6270–6278. [Google Scholar]

- Xing, Z.; Zhao, W. Calibration-free indoor positioning via regional channel tracing. IEEE Internet Things J. 2024, 12, 5449–5461. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. Automatica 1975, 11, 23–27. [Google Scholar] [CrossRef]

- Ridler, T.W.; Calvard, S. Picture thresholding using an iterative selection method. IEEE Trans. Syst. Man Cybern 1978, 8, 630–632. [Google Scholar]

- Sezgin, M.; Sankur, B.l. Survey over image thresholding techniques and quantitative performance evaluation. J. Electron. Imaging 2004, 13, 146–168. [Google Scholar] [CrossRef]

- Xing, Z.; Zhao, W. Segmentation and completion of human motion sequence via temporal learning of subspace variety model. IEEE Trans. Image Process. 2024, 33, 5783–5797. [Google Scholar] [CrossRef]

- Zuo, H.; Li, Z.; Gong, J.; Tian, Z. Intelligent road crack detection and analysis based on improved YOLOv8. In Proceedings of the 2025 8th International Conference on Advanced Algorithms and Control Engineering (ICAACE), Shanghai, China, 21–23 March 2025; pp. 1192–1195. [Google Scholar]

- Hawkins, D.M. The problem of overfitting. J. Chem. Inf. Comput. Sci. 2004, 44, 1–12. [Google Scholar] [CrossRef]

- Ding, T.; Xiang, D.; Sun, T.; Qi, Y.; Zhao, Z. AI-driven prognostics for state of health prediction in Li-ion batteries: A comprehensive analysis with validation. arXiv 2025, arXiv:2504.05728. [Google Scholar]

- Kaiser, E.; Kutz, J.N.; Brunton, S.L. Sparse identification of nonlinear dynamics for model predictive control in the low-data limit. Proc. R. Soc. A 2018, 474, 20180335. [Google Scholar] [CrossRef] [PubMed]

- Chen, B. The Pivotal Role of Accounting in Civilizational Progress and the Age of Advanced AI: A Unified Perspective. Econ. Manag. Innov. 2025, 2, 49–54. [Google Scholar] [CrossRef]

- Yang, H.; Yu, L.; Lin, X.; Liu, Y.; Qiao, X.; Li, H.; Dong, B.; Chen, T. An edge computing-based lightweight topology identification method for low voltage power distribution networks. In Proceedings of the International Conference on Smart Electrical Grid and Renewable Energy, Suzhou, China, 9–12 August 2024; pp. 269–282. [Google Scholar]

- Valikhani, A.; Jaberi Jahromi, A.; Pouyanfar, S.; Mantawy, I.M.; Azizinamini, A. Machine learning and image processing approaches for estimating concrete surface roughness using basic cameras. Comput. Aided Civ. Infrastruct. Eng. 2021, 36, 213–226. [Google Scholar] [CrossRef]

- Wan, T.; Wang, H.; Feng, P.; Diab, A. Concave distribution characterization of asphalt pavement surface segregation using smartphone and image processing based techniques. Constr. Build. Mater. 2021, 301, 124111. [Google Scholar] [CrossRef]

- Li, Z. Physics-Informed Neural Networks (PINNs) for Building Thermal Dynamics: Benchmarking on ASHRAE RP-1312 and BOPTEST. In Proceedings of the ICML 2025 CO-BUILD Workshop on Computational Optimization of Buildings, Vancouver, BC, Canada, 13–19 July 2025. [Google Scholar]

- Huo, M.; Lu, K.; Li, Y.; Zhu, Q.; Chen, Z. Ct-patchtst: Channel-time patch time-series transformer for long-term renewable energy forecasting. arXiv 2025, arXiv:2501.08620. [Google Scholar]

- Vieira, T.; Sandberg, U.; Erlingsson, S. Negative texture, positive for the environment: Effects of horizontal grinding of asphalt pavements. Road Mater. Pavement Des. 2021, 22, 1–22. [Google Scholar] [CrossRef]

- Prowell, B.D.; Zhang, J.; Brown, E.R. Aggregate Properties and the Performance of Superpave-Designed Hot Mix Asphalt; Transportation Research Board: Washington, DC, USA, 2005. [Google Scholar]

- Praticò, F.; Vaiana, R. A study on the relationship between mean texture depth and mean profile depth of asphalt pavements. Constr. Build. Mater. 2015, 101, 72–79. [Google Scholar] [CrossRef]

- Kang, Z.; Zhang, Y.; Deng, X.; Li, X.; Zhang, Y. LP-DETR: Layer-wise Progressive Relations for Object Detection. arXiv 2025, arXiv:2502.05147. [Google Scholar]

- Wu, Q.; Xia, C.; Tian, S. AI-Driven Sentiment Analytics: Unlocking Business Value in the E-Commerce Landscape_v1. arXiv 2025, arXiv:2504.08738. [Google Scholar]

- Qiu, X.; Hu, J.; Zhou, L.; Wu, X.; Du, J.; Zhang, B.; Guo, C.; Zhou, A.; Jensen, C.S.; Sheng, Z. Tfb: Towards comprehensive and fair benchmarking of time series forecasting methods. arXiv 2024, arXiv:2403.20150. [Google Scholar] [CrossRef]

- Gao, L.; Cui, L.; Chen, S.; Deng, L.; Wang, X.; Yan, X.; Zhu, H. AMTrans: Auto-Correlation Multi-Head Attention Transformer for Infrared Spectral Deconvolution. Tsinghua Sci. Technol. 2024, 30, 1329–1341. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, H.; Shen, Y.; Wang, L.; Shi, C.; Du, S.; Tao, Y. Altgen: Ai-driven alt text generation for enhancing epub accessibility. In Proceedings of the 2025 International Conference on Artificial Intelligence and Computational Intelligence, Kuala Lumpur, Malaysia, 14–16 February 2025; pp. 78–83. [Google Scholar]

- Song, J.; Ding, K.; Cheng, R.; Zhao, X.; Luo, X.; Liu, Y.; Tian, Y.; Duan, Z. Research on brand strategy of hotel enterprises—Taking hyatt hotel group as an example. Open J. Bus. Manag. 2025, 13, 861–869. [Google Scholar] [CrossRef]

- Song, J.; Ding, K.; Cheng, R.; Luo, X.; Liu, Y.; Tian, Y.; Duan, Z. Research on the internationalization process of chinese hotel management groups—Taking jinjiang hotel group as an example. Open J. Bus. Manag. 2024, 13, 41–48. [Google Scholar] [CrossRef]

- Zhong, J.; Wang, Y. Enhancing Thyroid Disease Prediction Using Machine Learning: A Comparative Study of Ensemble Models and Class Balancing Techniques. Researh Sq. 2025, preprint. [Google Scholar]

- Zhong, J.; Wang, Y.; Zhu, D.; Wang, Z. A Narrative Review on Large AI Models in Lung Cancer Screening, Diagnosis, and Treatment Planning. arXiv 2025, arXiv:2506.07236. [Google Scholar]

- Qiu, X.; Wu, X.; Lin, Y.; Guo, C.; Hu, J.; Yang, B. Duet: Dual clustering enhanced multivariate time series forecasting. arXiv 2024, arXiv:2412.10859. [Google Scholar]

- Xu, J.; Zhao, Y.; Li, X.; Zhou, L.; Zhu, K.; Xu, X.; Duan, Q.; Zhang, R. Teg-di: Dynamic incentive model for federated learning based on tripartite evolutionary game. Neurocomputing 2025, 621, 129259. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, M.; Gui, K.; Yu, J.; Hao, Y.; Sun, H. Development and application of a monte carlo tree search algorithm for simulating da vinci code game strategies. In Proceedings of the 2024 5th International Conference on Intelligent Computing and Human-Computer Interaction (ICHCI), Nanchang, China, 27–29 September 2024; pp. 5–11. [Google Scholar]

- Li, X.; He, Y.; Zu, S.; Li, Z.; Shi, T.; Xie, Y.; Zhang, K. Multi-Modal Large Language Model with RAG Strategies in Soccer Commentary Generation. In Proceedings of the 2025 IEEE/CVF Winter Conference on Applications of Computer Vision (WACV), Tucson, AZ, USA, 28 February–4 March 2025; pp. 6197–6206. [Google Scholar]

- Qiu, X.; Li, Z.; Qiu, W.; Hu, S.; Zhou, L.; Wu, X.; Li, Z.; Guo, C.; Zhou, A.; Sheng, Z. Tab: Unified benchmarking of time series anomaly detection methods. arXiv 2025, arXiv:2506.18046. [Google Scholar]

- Zhang, H.; Shen, Y.; Wang, L.; Shi, C.; Du, S.; Tao, Y.; Shen, Y. Comparative analysis of large language models for context-aware code completion using safim framework. In Proceedings of the 2025 International Conference on Artificial Intelligence and Computational Intelligence, Kuala Lumpur, Malaysia, 14–16 February 2025; pp. 572–576. [Google Scholar]

- Diao, X.; Zhang, C.; Wu, T.; Cheng, M.; Ouyang, Z.; Wu, W.; Gui, J. Learning musical representations for music performance question answering. arXiv 2025, arXiv:2502.06710. [Google Scholar]

- Diao, X.; Zhang, C.; Wu, W.; Ouyang, Z.; Qing, P.; Cheng, M.; Vosoughi, S.; Gui, J. Temporal working memory: Query-guided segment refinement for enhanced multimodal understanding. arXiv 2025, arXiv:2502.06020. [Google Scholar]

- Gao, H.; Wang, Z.; Li, Y.; Long, K.; Yang, M.; Shen, Y. A survey for foundation models in autonomous driving. arXiv 2024, arXiv:2402.01105. [Google Scholar]

- Zhu, K.; Xu, J.; Zhou, L.; Li, X.; Zhao, Y.; Xu, X.; Li, S. Dmaf: Data-model anti-forgetting for federated incremental learning. Clust. Comput. 2025, 28, 30. [Google Scholar] [CrossRef]

- Chen, B. Leveraging Advanced AI in Activity-Based Costing (ABC) for Enhanced Cost Management. J. Comput. Signal Syst. Res. 2025, 2, 53–62. [Google Scholar] [CrossRef]

- Liu, F.; Liu, J.; Wang, B.; Wang, X.; Liu, C. SiamBRF: Siamese broad-spectrum relevance fusion network for aerial tracking. IEEE Geosci. Remote Sens. Lett. 2024, 21, 6002405. [Google Scholar] [CrossRef]

- Huang, J.; Du, L.; Chen, X.; Fu, Q.; Han, S.; Zhang, D. Robust mid-pass filtering graph convolutional networks. In Proceedings of the ACM Web Conference, Austin TX USA, 30 April–4 May 2023; pp. 328–338. [Google Scholar]

- Dong, B.; Guo, Z.; Mulat, A.; Tian, Y.; Lu, M.; Yuan, Y.; Liu, X. Leveraging heterogeneous networks to analyze energy storage systems in power systems and renewable energy research: A scientometric study. Front. Energy Res. 2024, 12, 1424928. [Google Scholar] [CrossRef]

- Liu, F.; Liu, J.; Chen, Q.; Wang, X.; Liu, C. SiamHAS: Siamese tracker with hierarchical attention strategy for aerial tracking. Micromachines 2023, 14, 893. [Google Scholar] [CrossRef]

- Liu, F.; Wang, X.; Chen, Q.; Liu, J.; Liu, C. SiamMAN: Siamese multi-phase aware network for real-time unmanned aerial vehicle tracking. Drones 2023, 7, 707. [Google Scholar] [CrossRef]

- Huang, J.; Mo, Y.; Hu, P.; Shi, X.; Yuan, S.; Zhang, Z.; Zhu, X. Exploring the role of node diversity in directed graph representation learning. In Proceedings of the Thirty-Third International Joint Conference on Artificial Intelligence, Jeju Island, Republic of Korea, 3–9 August 2024; pp. 2072–2080. [Google Scholar]

- Ke, Z.; Cao, Y.; Chen, Z.; Yin, Y.; He, S.; Cheng, Y. Early warning of cryptocurrency reversal risks via multi-source data. Financ. Res. Lett. 2025, 85, 107890. [Google Scholar] [CrossRef]

- Yu, D.; Liu, L.; Wu, S.; Li, K.; Wang, C.; Xie, J.; Chang, R.; Wang, Y.; Wang, Z.; Ji, R. Machine learning optimizes the efficiency of picking and packing in automated warehouse robot systems. In Proceedings of the 2025 IEEE International Conference on Electronics, Energy Systems and Power Engineering (EESPE), Shenyang, China, 17–19 March 2025; pp. 1325–1332. [Google Scholar]

- Diao, X.; Cheng, M.; Barrios, W.; Jin, S. Ft2tf: First-person statement text-to-talking face generation. In Proceedings of the 2025 IEEE/CVF Winter Conference on Applications of Computer Vision (WACV), Tucson, AZ, USA, 28 February–4 March 2025; pp. 4821–4830. [Google Scholar]

| Pavement Type | Area (mm2) | Friction | Polishing Cycles (k) |

|---|---|---|---|

| DGAC | 2795.53 | 0.54 | 50 |

| 2611.88 | 0.52 | 90 | |

| 2427.15 | 0.50 | 150 | |

| …… | |||

| Chip Seal | 2547.03 | 0.67 | 50 |

| 2122.78 | 0.63 | 90 | |

| 1856.24 | 0.60 | 150 | |

| …… | |||

| OGFC | 2518.15 | 0.38 | 50 |

| 2634.07 | 0.36 | 90 | |

| 2456.65 | 0.36 | 150 | |

| …… | |||

| Pavement Type | Pearson’s Correlation | R2 | R2adj | Regression Models |

|---|---|---|---|---|

| DGAC | 0.9620 | 0.9255 | 0.9130 | DFT = 0.2396 + 1.0632 × 10−4 Area |

| Chip Seal | 0.9851 | 0.9704 | 0.9655 | DFT = 0.3151 + 1.4331 × 10−4 Area |

| OGFC | 0.9782 | 0.9569 | 0.9498 | DFT = −0.2504 + 2.4260 × 10−4 Area |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, B.; Lu, Z.; Qi, Y.; Guo, H.; Sun, T.; Zhao, Z. Predicting Asphalt Pavement Friction by Using a Texture-Based Image Indicator. Lubricants 2025, 13, 341. https://doi.org/10.3390/lubricants13080341

Lu B, Lu Z, Qi Y, Guo H, Sun T, Zhao Z. Predicting Asphalt Pavement Friction by Using a Texture-Based Image Indicator. Lubricants. 2025; 13(8):341. https://doi.org/10.3390/lubricants13080341

Chicago/Turabian StyleLu, Bingjie, Zhengyang Lu, Yijiashun Qi, Hanzhe Guo, Tianyao Sun, and Zunduo Zhao. 2025. "Predicting Asphalt Pavement Friction by Using a Texture-Based Image Indicator" Lubricants 13, no. 8: 341. https://doi.org/10.3390/lubricants13080341

APA StyleLu, B., Lu, Z., Qi, Y., Guo, H., Sun, T., & Zhao, Z. (2025). Predicting Asphalt Pavement Friction by Using a Texture-Based Image Indicator. Lubricants, 13(8), 341. https://doi.org/10.3390/lubricants13080341