U-Net Segmentation with Bayesian-Optimized Weight Voting for Worn Surface Analysis of a PEEK-Based Tribological Composite

Abstract

1. Introduction

2. Methodology

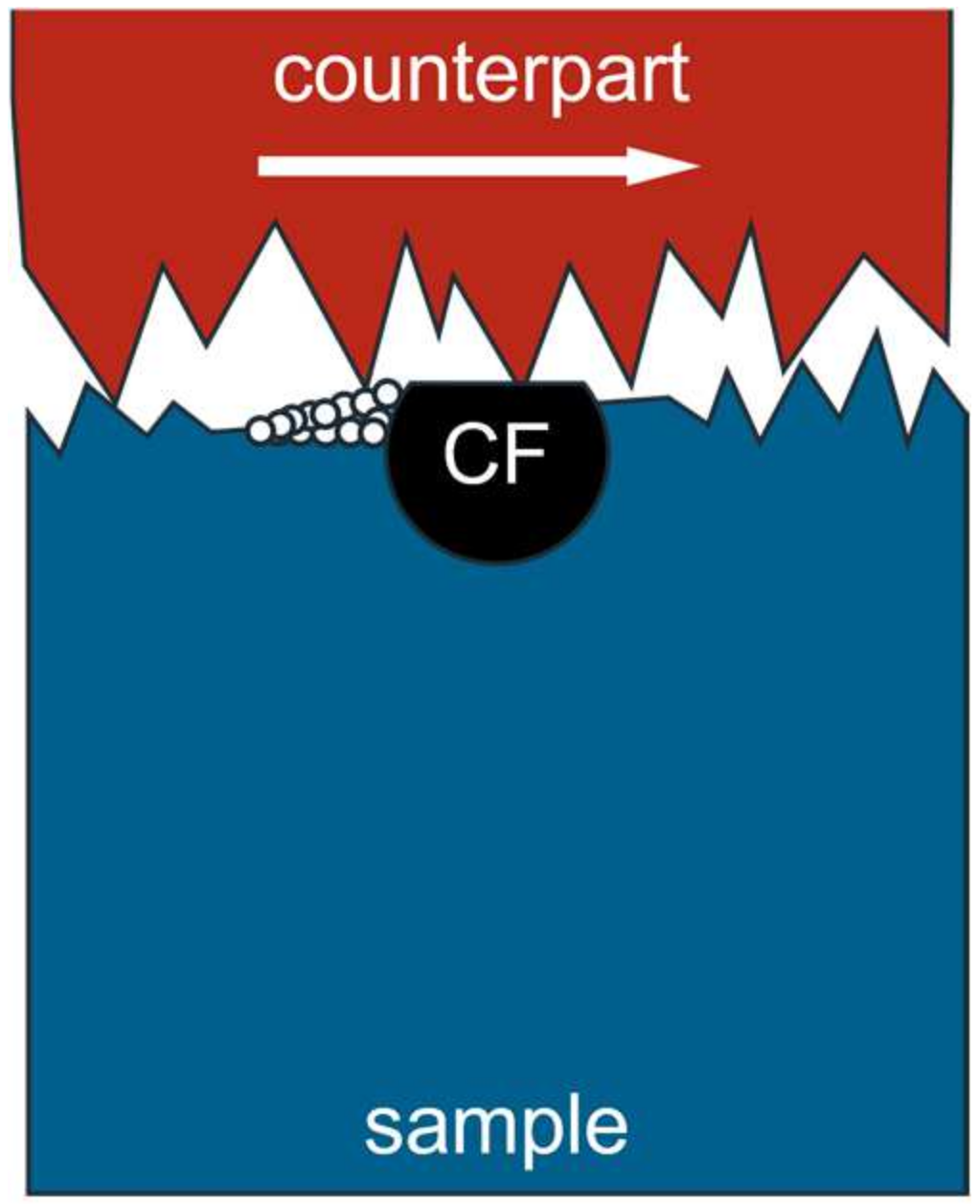

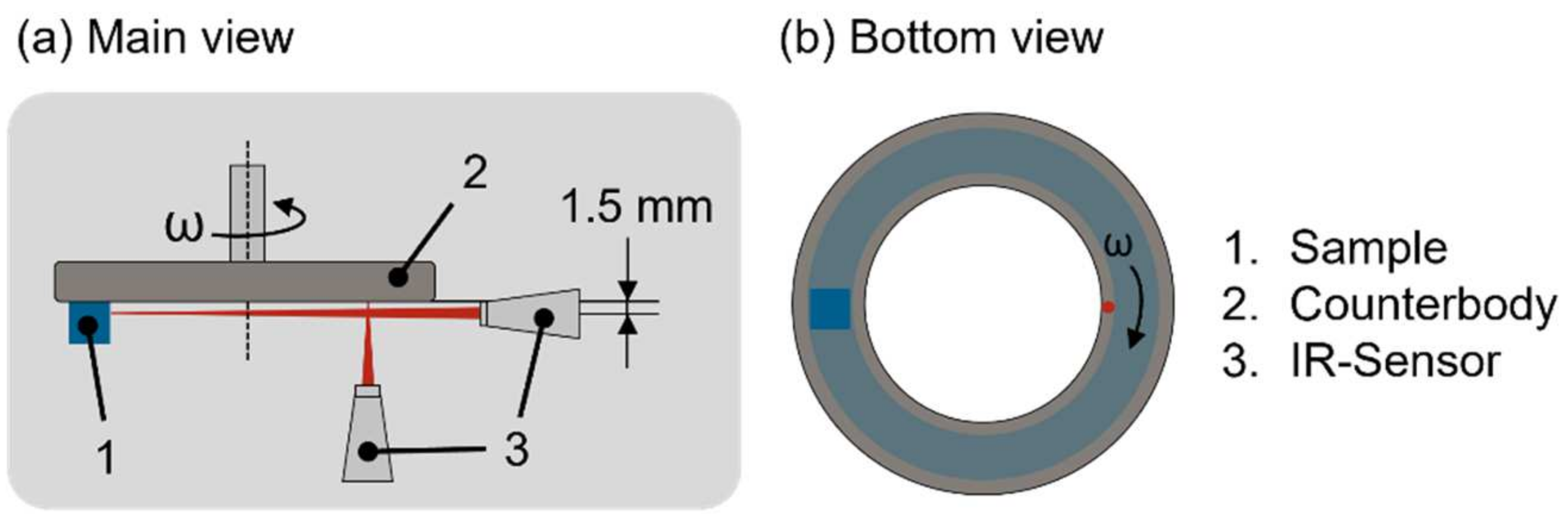

2.1. Tribological Sample Preparation

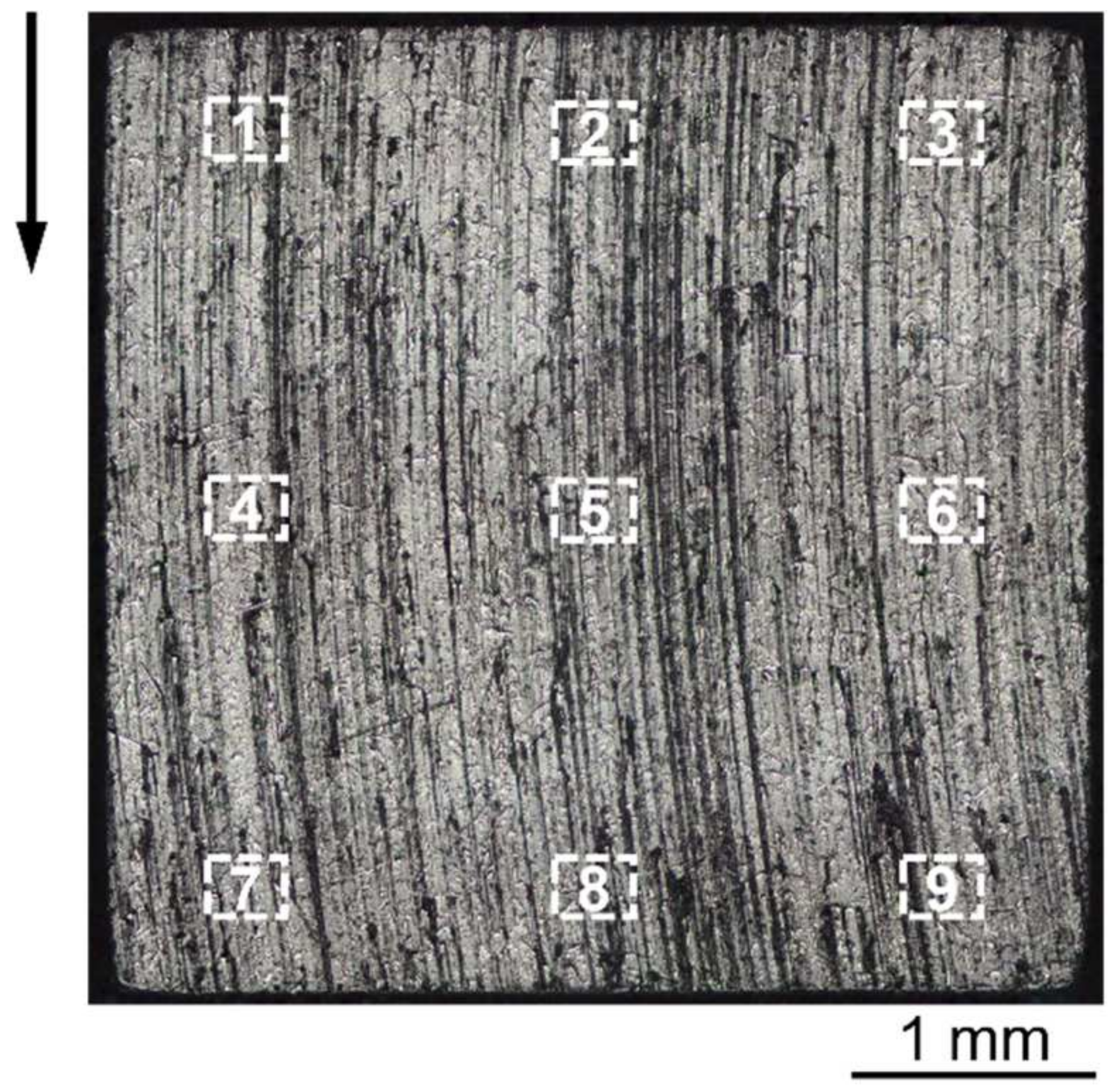

2.2. Image Acquisition and Annotation

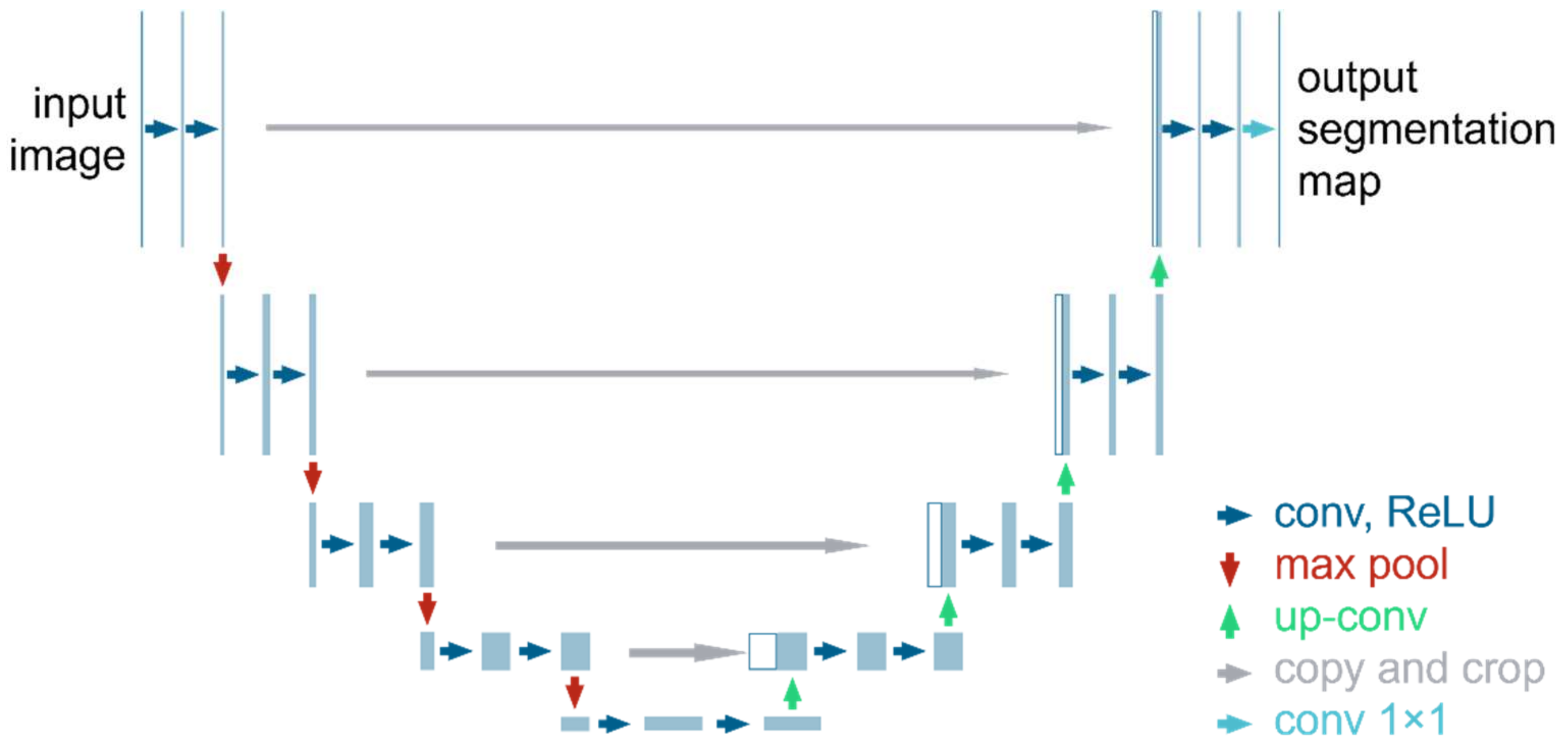

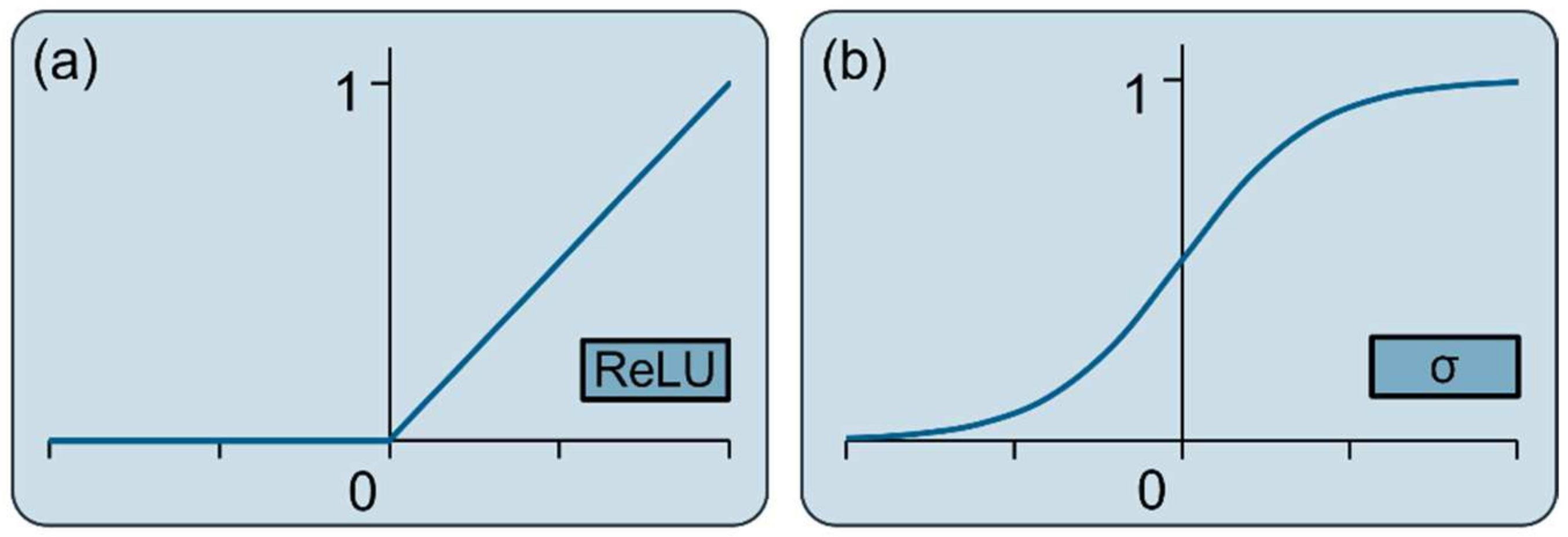

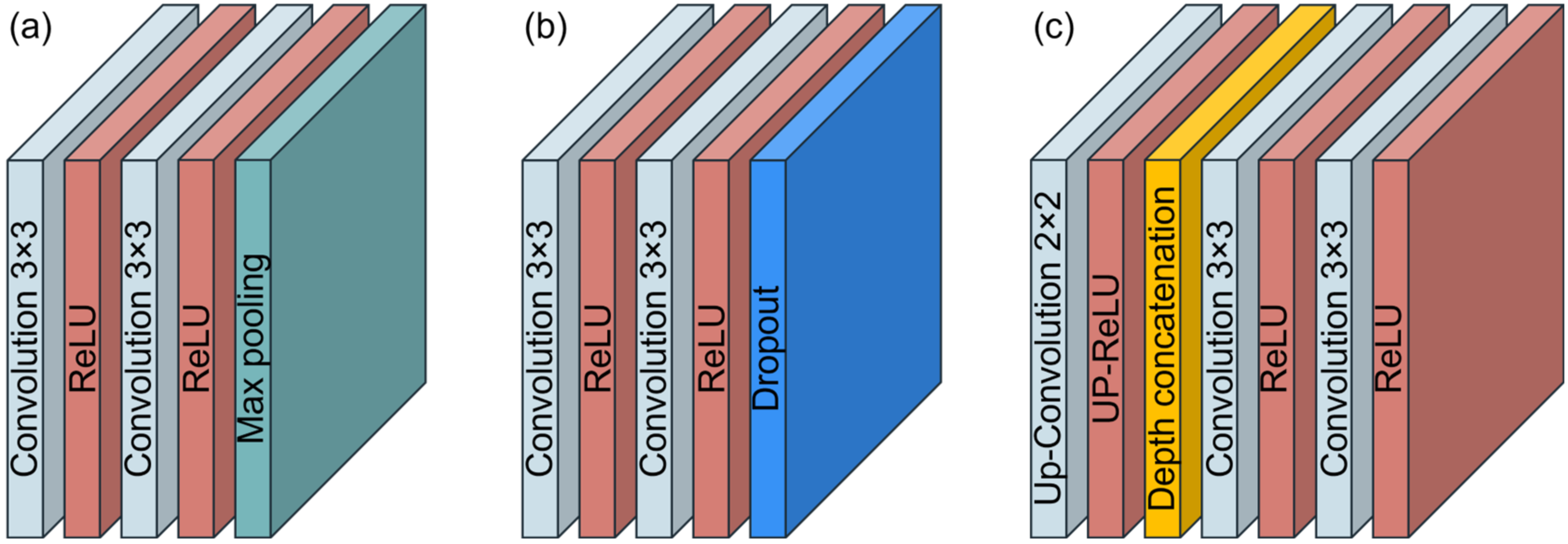

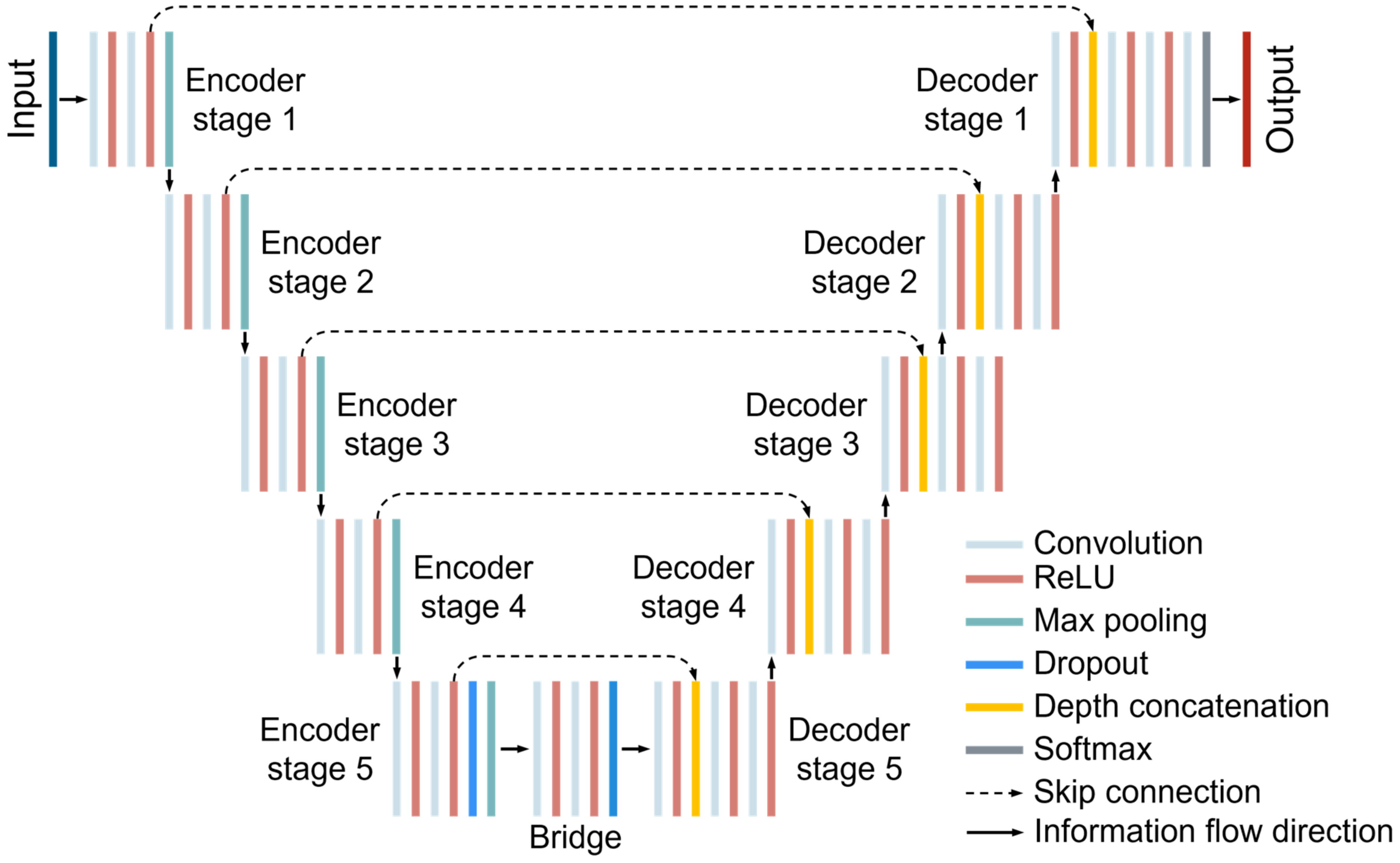

2.3. U-Net Architecture Design

2.4. Training Data Preparation and Network Training

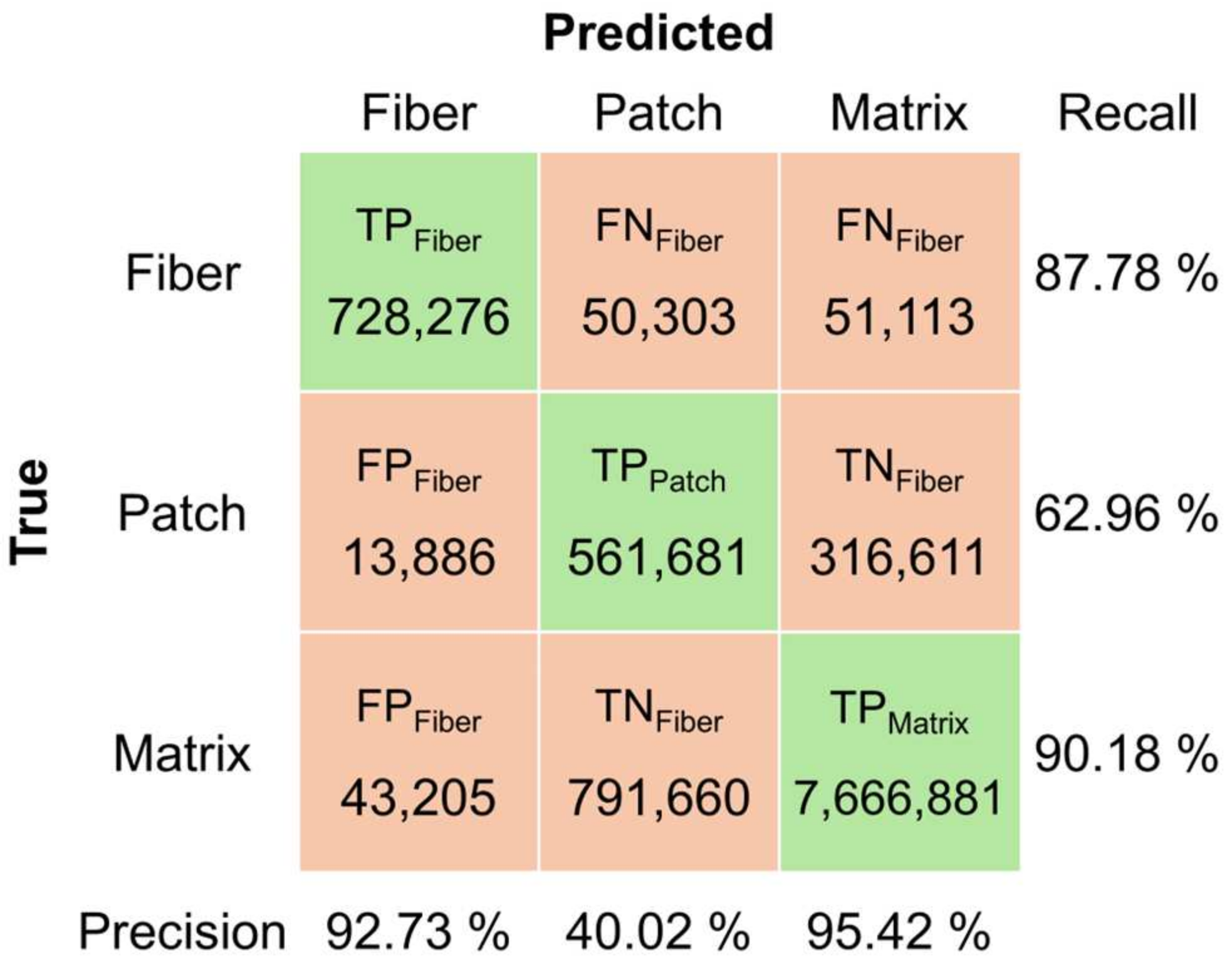

- Precision represents the proportion of correctly identified instances of a class among all instances predicted as that class. It quantifies the reliability of positive predictions and is computed as follows ( denotes the class index; same applies below):

- Recall measures the proportion of correctly identified instances of a class out of all actual instances belonging to that class. It indicates the model’s sensitivity to correctly detecting positive instances and is defined as follows:

- F1-score is the harmonic mean of precision and recall, providing a balanced measure between the two metrics. It is especially useful when dealing with imbalanced classes, as it equally emphasizes both false positives and false negatives:

- Overall accuracy (OA), defined as the ratio of the correctly classified pixels to the total number of pixels, provides an intuitive measure of general classification effectiveness:

- Mean Intersection-over-Union (mIoU) is calculated as the average Intersection-over-Union (IoU) across all segmentation classes. IoU for each class quantifies the overlap between the predicted and ground-truth regions, making it particularly suitable for evaluating segmentation tasks:

2.5. Multi Nets Weighted Voting

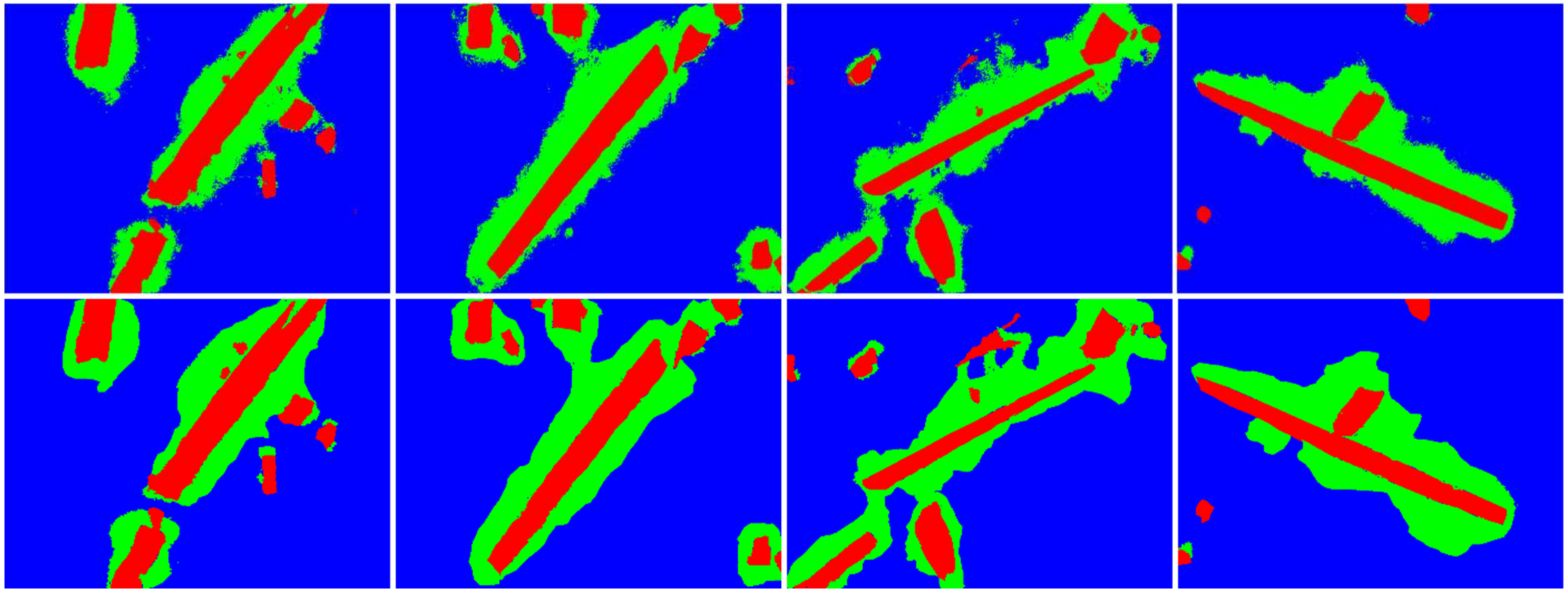

3. Results and Discussion

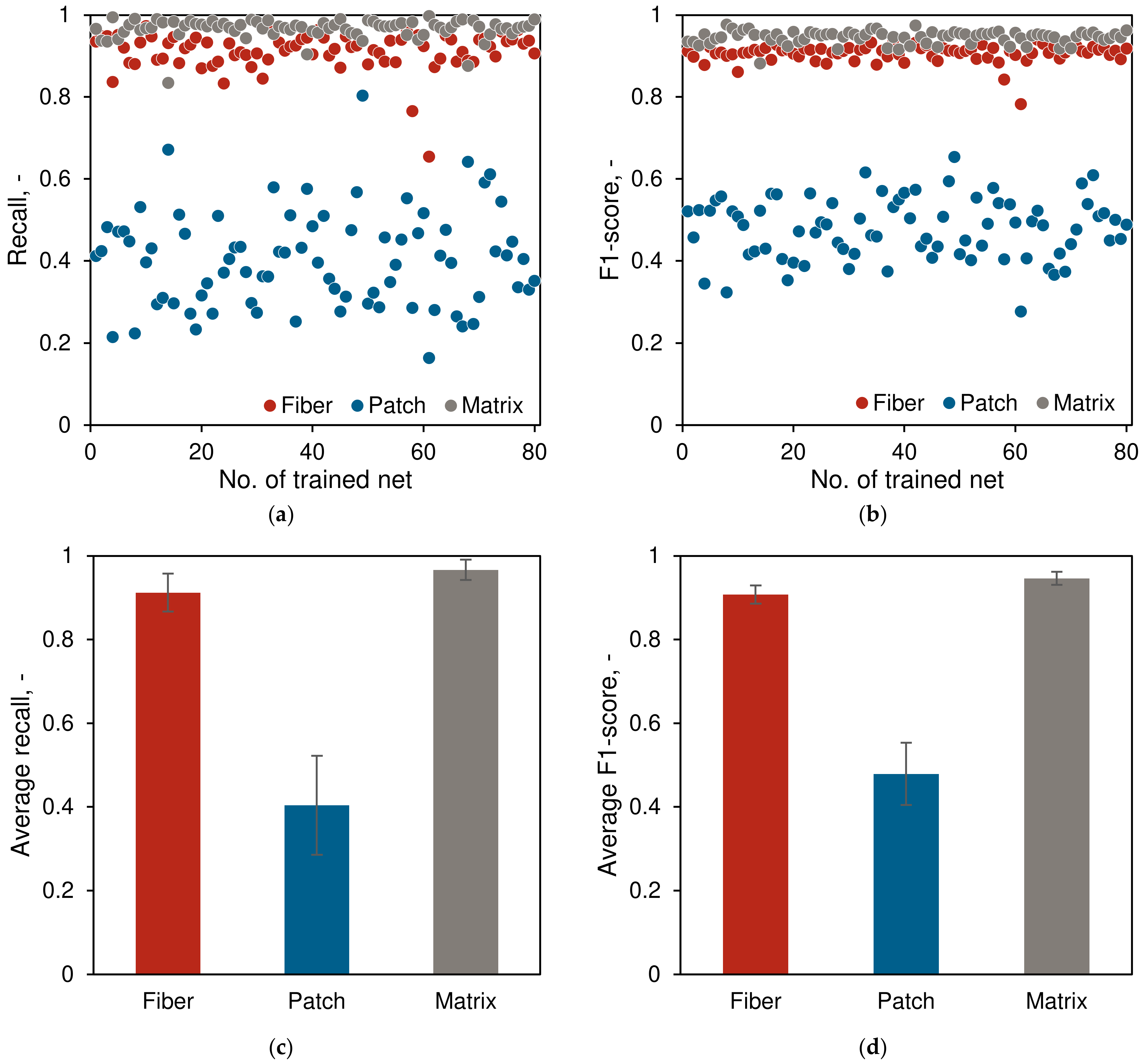

3.1. U-Net Training

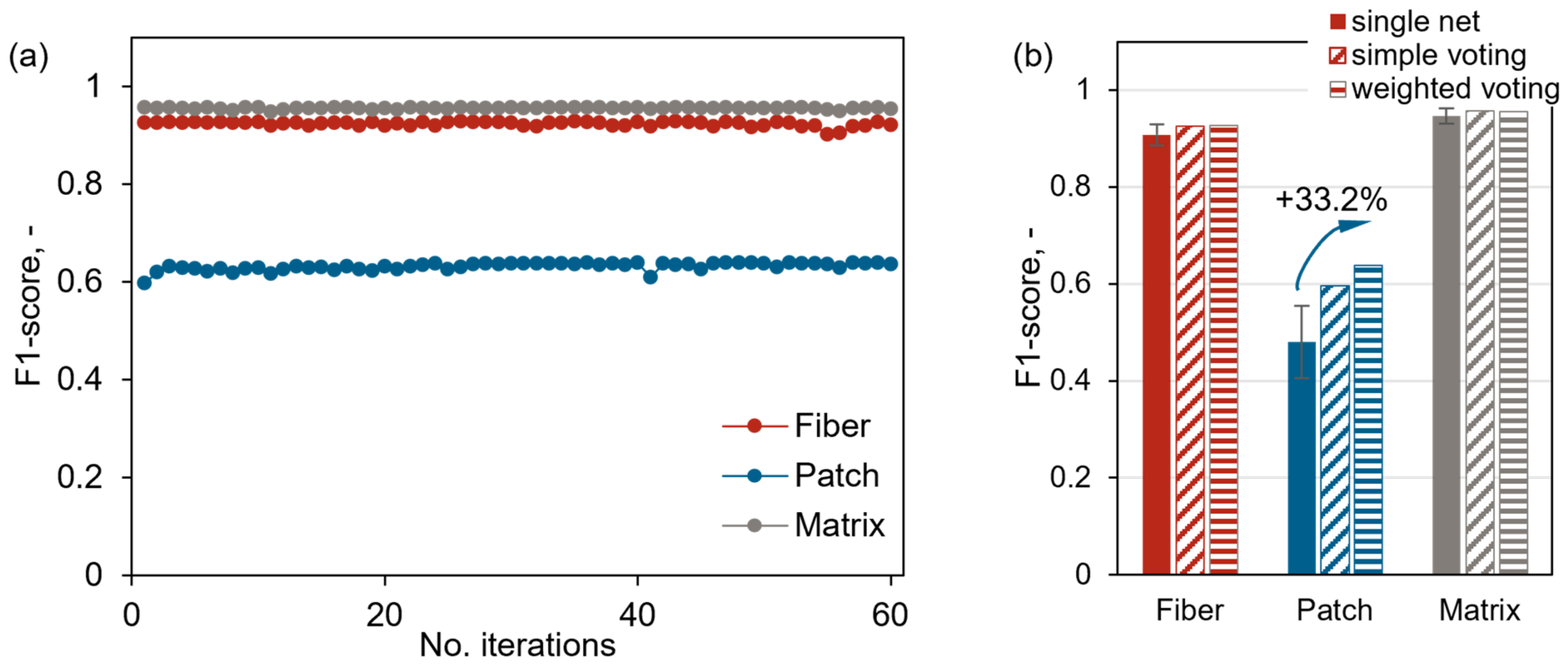

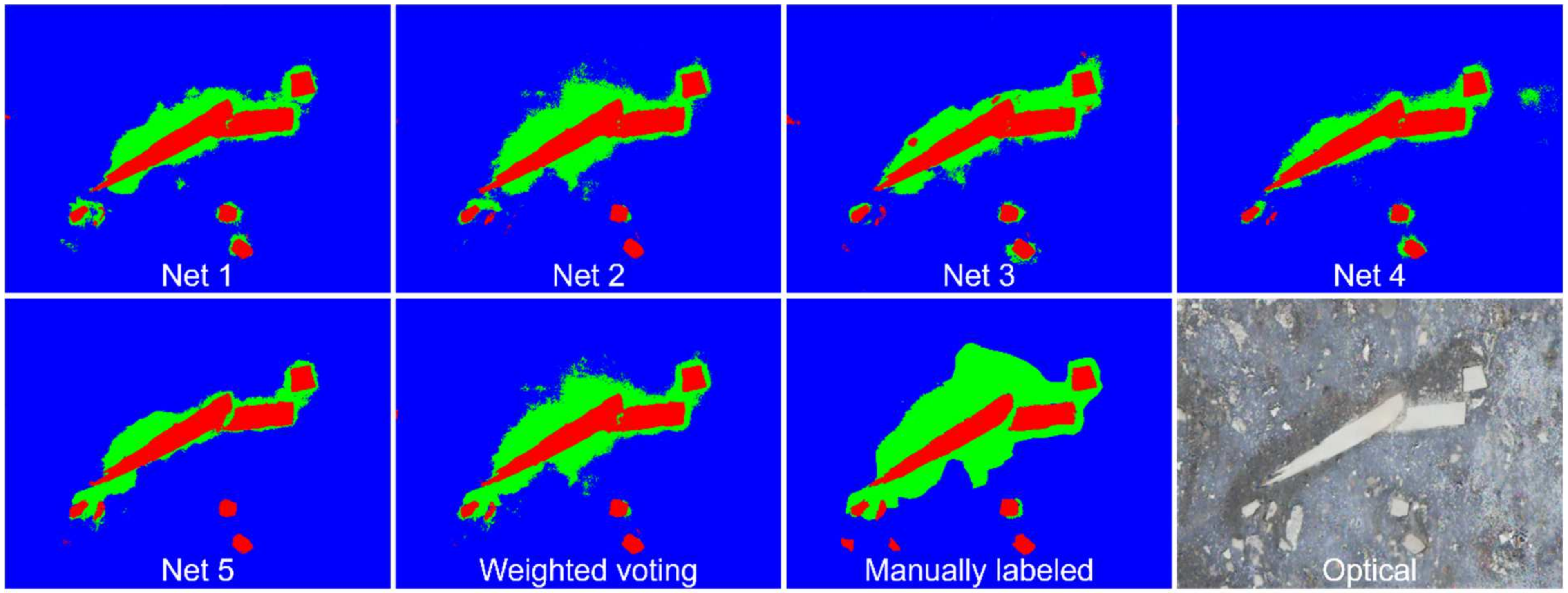

3.2. Bayesian-Optimized Weighted Voting

4. Conclusions

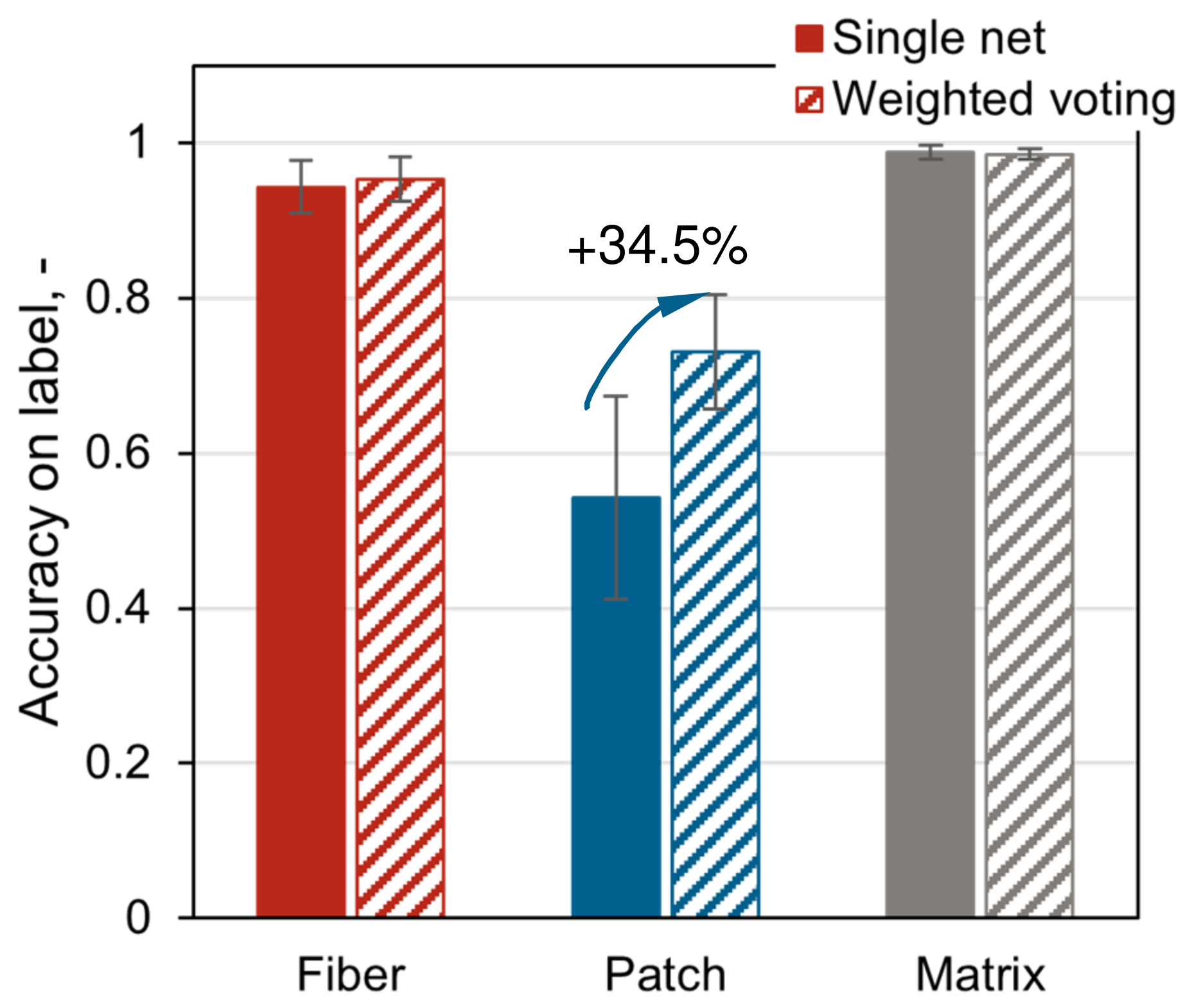

- By carefully selecting optimal hyperparameters, adopting an appropriate U-Net architecture, and employing data augmentation along with cross-validation to mitigate overfitting, the resulting networks demonstrated high segmentation performance for fiber and matrix regions, achieving F1-scores of 0.912 and 0.946, respectively. However, segmentation accuracy for patch regions remained relatively low, with an F1-score of only 0.404.

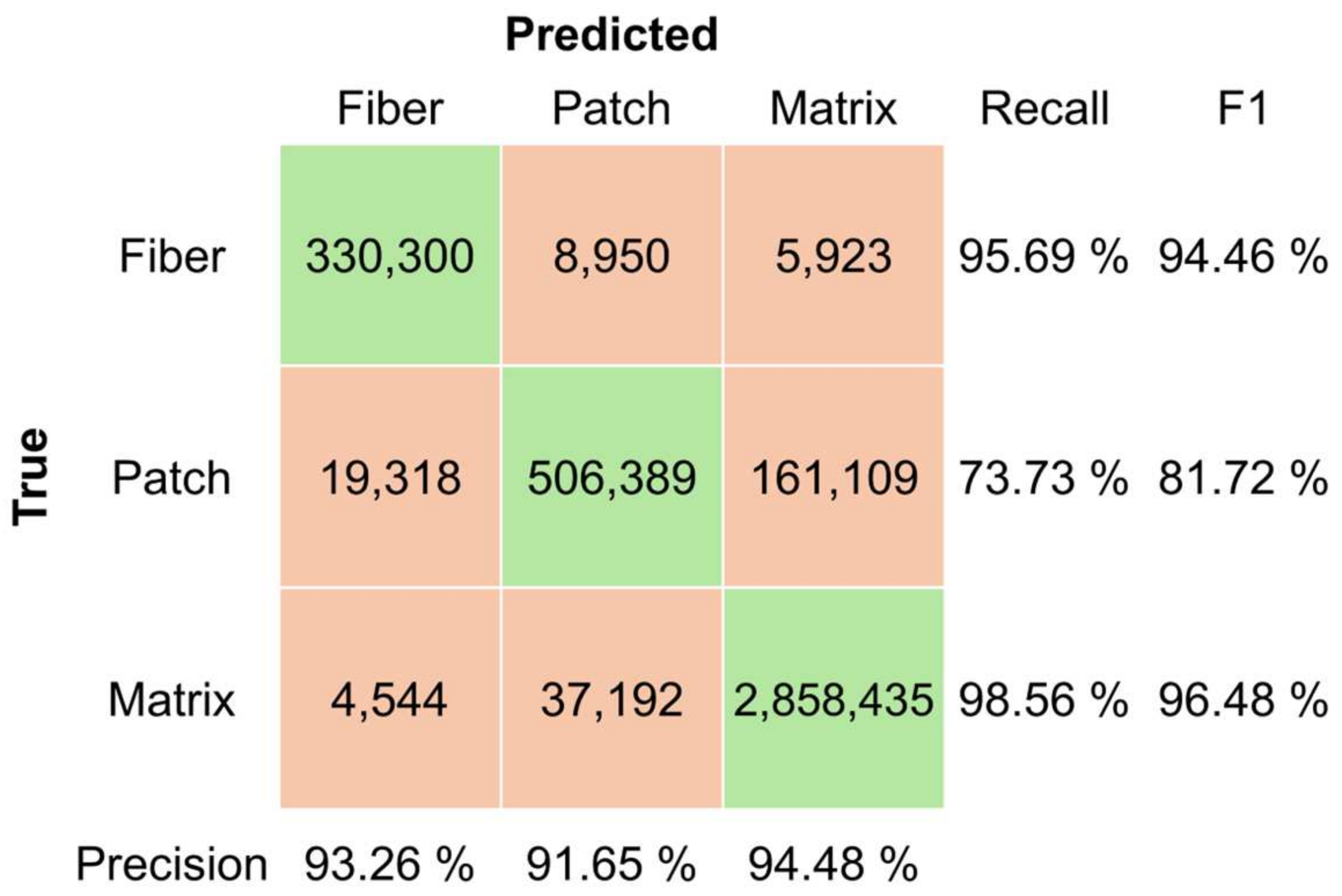

- Implementing Bayesian optimization to optimize and allocate seven individual weights for three segmentation classes across five selected U-Net models significantly improved patch region segmentation. The F1-score increased from an initial single network average of 0.404 to 0.638, representing an improvement of approximately 33%. Meanwhile, slight improvements in fiber and matrix segmentation accuracy were also observed, indicating that the weighted voting ensemble effectively harmonized the strengths and mitigated the weaknesses of individual networks.

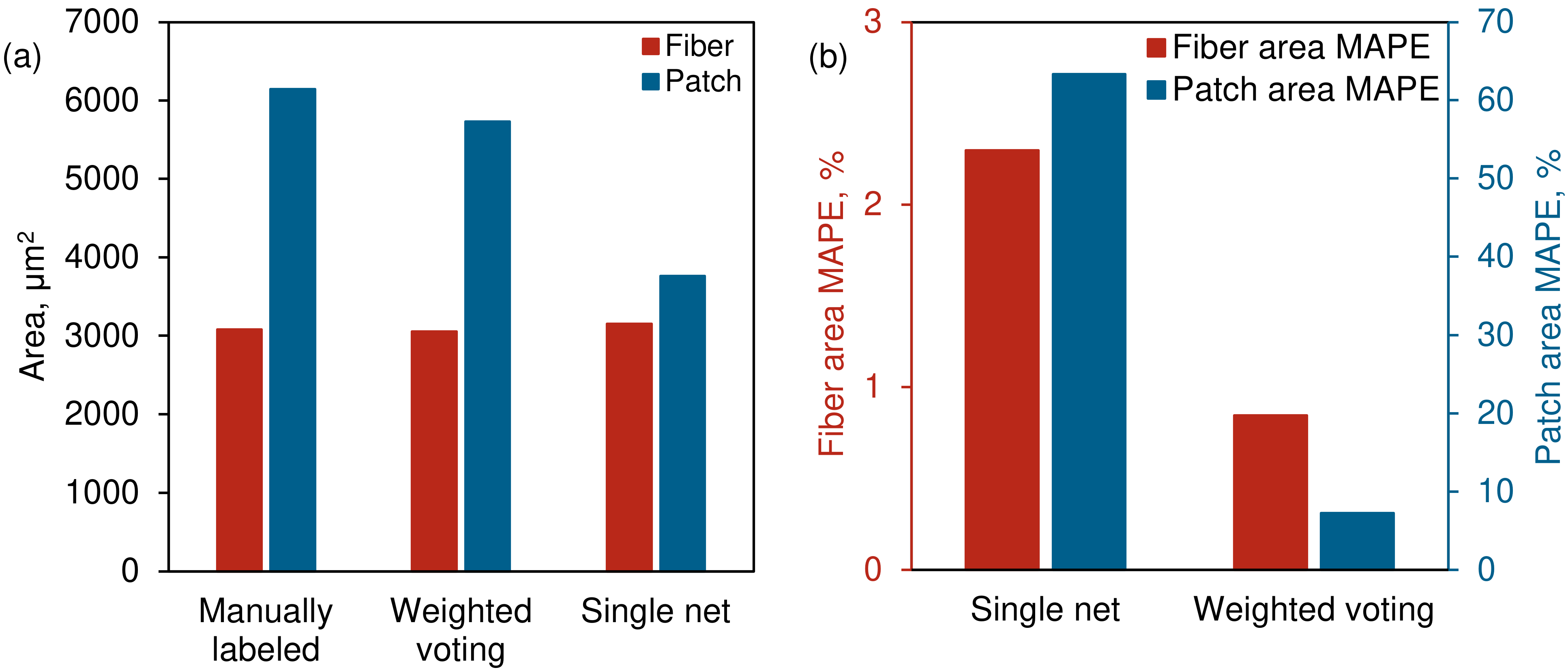

- Compared with single network segmentations, the optimized weighted voting scheme considerably reduced the MAPE of fiber area measurements from 2.3% to 0.8%, and dramatically improved patch area measurements from an initially unusable 63.3% down to a substantially more acceptable 7.2%. These improvements clearly indicate that our automated segmentation method provides sufficiently accurate morphological data for quantitative tribological analysis.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Voss, H.; Friedrich, K. On the wear behaviour of short-fiber-reinforced PEEK composites. Wear 1987, 116, 1–18. [Google Scholar] [CrossRef]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Pesetskii, S.S.; Grigoriev, A.Y. Polymer tribology: Current state and applications. Tribol. Ind. 2015, 37, 284–290. [Google Scholar]

- De Baets, P.; Glavatskih, S.; Ost, W.; Sukumaran, J. Polymers in tribology: Challenges and opportunities. In Proceedings of the 1st International Conference on Polymer Tribology, Bled, Slovenia, 11–12 September 2014; Volume 8. [Google Scholar]

- Lu, Z.; Friedrich, K.; Küntzler, B. On sliding friction and wear of polyetheretherketone (PEEK) composites at elevated temperatures. J. Synth. Lubr. 1995, 12, 103–114. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Rong, M.Z.; Yu, S.L.; Wetzel, B.; Friedrich, K. Effect of particle surface treatment on the tribological performance of epoxy based nanocomposites. Wear 2002, 253, 1086–1093. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Yao, L.H.; Stolarski, T.A. Friction and Wear of Poly(Tetrafluoroethylene)-Poly(Etheretherketone) Composities; An Initial Appraisal of the Optimum Composition. Wear Mater. Int. Conf. Wear Mater. 1985, 108, 725–741. [Google Scholar]

- Bahadur, S.; Polineni, V.K. Tribological studies of glass fabric-reinforced polyamide composites filled with CuO and PTFE. Wear 1996, 200, 95–104. [Google Scholar] [CrossRef]

- Rodriguez, V.; Sukumaran, J.; Schlarb, A.K.; De Baets, P. Influence of solid lubricants on tribological properties of polyetheretherketone (PEEK). Tribol. Int. 2016, 103, 45–57. [Google Scholar] [CrossRef]

- Jiang, Z.; Gyurova, L.A.; Schlarb, A.K.; Friedrich, K.; Zhang, Z. Study on friction and wear behavior of polyphenylene sulfide composites reinforced by short carbon fibers and sub-micro TiO2 particles. Compos. Sci. Technol. 2008, 68, 734–742. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. Friction and Wear Behavior of Basalt-Fabric-Reinforced/Solid-Lubricant-Filled Phenolic Composites. J. Appl. Polym. Sci. 2010, 117, 3428–3433. [Google Scholar] [CrossRef]

- Li, F.; Hu, Y.; Hou, X.; Hu, X.; Jiang, D. Thermal, mechanical, and tribological properties of short carbon fibers/PEEK composites. High Perform. Polym. 2018, 30, 657–666. [Google Scholar] [CrossRef]

- Friedrich, K.; Lu, Z.; Häger, A.M. Overview on polymer composites for friction and wear application. Theor. Appl. Fract. Mech. 1993, 19, 1–11. [Google Scholar] [CrossRef]

- Li, E.Z.; Guo, W.L.; Wang, H.D.; Xu, B.S.; Liu, X.T. Research on tribological behavior of PEEK and glass fiber reinforced PEEK composite. Phys. Procedia 2013, 50, 453–460. [Google Scholar] [CrossRef]

- Li, J.; Zhang, L.Q. The research on the mechanical and tribological properties of carbon fiber and carbon nanotube-filled PEEK composite. Polym. Compos. 2010, 31, 1315–1320. [Google Scholar] [CrossRef]

- Wang, Q.; Xue, Q.; Liu, H.; Shen, W.; Xu, J. The effect of particle size of nanometer ZrO2 on the tribological behaviour of PEEK. Wear 1996, 198, 216–219. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Zhang, H.; Schlarb, A.K. On the sliding wear of nanoparticle filled polyamide 66 composites. Compos. Sci. Technol. 2006, 66, 3188–3198. [Google Scholar] [CrossRef]

- Padhan, M.; Marathe, U.; Bijwe, J. Tribology of Poly(etherketone) composites based on nano-particles of solid lubricants. Compos. Part B Eng. 2020, 201, 108323. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Chang, L.; Friedrich, K. Enhancement effect of nanoparticles on the sliding wear of short fiber-reinforced polymer composites: A critical discussion of wear mechanisms. Tribol. Int. 2010, 43, 2355–2364. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Sinha, S.K. Chapter 1. Tribological applications of polymers and their composites: Past, present and future prospects. Tribol. Interface Eng. Ser. 2008, 55, 1–14. [Google Scholar] [CrossRef]

- Harsha, A.P.; Wäsche, R.; Hartelt, M. Friction and wear studies of polyetherimide composites under oscillating sliding condition against steel cylinder. Polym. Compos. 2015, 38, 1–212. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, G.; Wang, D.; Zhao, F.; Wang, T.; Wang, Q. Significance of combined functional nanoparticles for enhancing tribological performance of PEEK reinforced with carbon fibers. Compos. Part A Appl. Sci. Manuf. 2017, 102, 400–413. [Google Scholar] [CrossRef]

- Pei, X.Q.; Bennewitz, R.; Schlarb, A.K. Mechanisms of friction and wear reduction by carbon fiber reinforcement of PEEK. Tribol. Lett. 2015, 58, 42. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. Study on the friction and wear behavior of surface-modified carbon nanotube filled carbon fabric composites. Polym. Adv. Technol. 2011, 22, 2157–2165. [Google Scholar] [CrossRef]

- Lin, L.; Zhao, Y.; Xu, Y.; Sun, C.; Schlarb, A.K. Advanced recycled carbon fiber (rCF) reinforced PEEK composites—Excellent alternatives for high-performance tribomaterials. Mater. Today Sustain. 2022, 20, 100227. [Google Scholar] [CrossRef]

- Zhang, X. Study on the Tribological Properties of Carbon Fabric Reinforced Phenolic Composites Filled with Nano-Al2O3. J. Macromol. Sci. Part B Phys. 2017, 56, 568–577. [Google Scholar] [CrossRef]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437–452. [Google Scholar] [CrossRef]

- Denape, J. Third body concept and wear particle behavior in dry friction sliding conditions. Key Eng. Mater. 2015, 640, 1–12. [Google Scholar] [CrossRef]

- Krejčí, P.; Petrov, A. A mathematical model for the third-body concept. Math. Mech. Solids 2018, 23, 420–432. [Google Scholar] [CrossRef]

- Martinez Ostormujof, T.; Purushottam Raj Purohit, R.R.P.; Breumier, S.; Gey, N.; Salib, M.; Germain, L. Deep Learning for automated phase segmentation in EBSD maps. A case study in Dual Phase steel microstructures. Mater. Charact. 2022, 184, 111638. [Google Scholar] [CrossRef]

- Petkov, V.I.; Pakkam Gabriel, V.R.; Fernberg, P. Semantic segmentation of progressive micro-cracking in polymer composites using Attention U-Net architecture. Tomogr. Mater. Struct. 2024, 5, 100028. [Google Scholar] [CrossRef]

- Gola, J.; Britz, D.; Staudt, T.; Winter, M.; Schneider, A.S.; Ludovici, M.; Mücklich, F. Advanced microstructure classification by data mining methods. Comput. Mater. Sci. 2018, 148, 324–335. [Google Scholar] [CrossRef]

- Gola, J.; Webel, J.; Britz, D.; Guitar, A.; Staudt, T.; Winter, M.; Mücklich, F. Objective microstructure classification by support vector machine (SVM) using a combination of morphological parameters and textural features for low carbon steels. Comput. Mater. Sci. 2019, 160, 186–196. [Google Scholar] [CrossRef]

- Baak, N.; Hajavifard, R.; Lücker, L.; Vasquez, J.R.; Strodick, S.; Teschke, M.; Walther, F. Micromagnetic approaches for microstructure analysis and capability assessment. Mater. Charact. 2021, 178, 111189. [Google Scholar] [CrossRef]

- Pitz, E.; Pochiraju, K. A neural network transformer model for composite microstructure homogenization. Eng. Appl. Artif. Intell. 2024, 134, 108622. [Google Scholar] [CrossRef]

- Li, Y.; Guan, J.; Guo, L. Peridynamic-driven feature-enhanced Vision Transformer for predicting defects and heterogeneous materials locations: Applications of deep learning in inverse problems. Eng. Appl. Artif. Intell. 2025, 151, 110677. [Google Scholar] [CrossRef]

- Falk, T.; Mai, D.; Bensch, R.; Çiçek, Ö.; Abdulkadir, A.; Marrakchi, Y.; Böhm, A.; Deubner, J.; Jäckel, Z.; Seiwald, K.; et al. U-Net: Deep learning for cell counting, detection, and morphometry. Nat. Methods 2019, 16, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Siddiquee, M.M.R.; Tajbakhsh, N.; Liang, J. UNet++: A Nested U-Net Architecture. In Deep Learning in Medical Image Analysis and Multimodal Learning for Clinical Decision Support; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. In Medical Image Computing and Computer-Assisted Intervention—MICCAI 2015; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 234–241. [Google Scholar] [CrossRef]

- Oktay, O.; Schlemper, J.; Folgoc, L.L.; Lee, M.; Heinrich, M.; Misawa, K.; Mori, K.; McDonagh, S.; Hammerla, N.Y.; Kainz, B.; et al. Attention U-Net: Learning Where to Look for the Pancreas. arXiv 2018. [Google Scholar] [CrossRef]

- Warren, P.; Raju, N.; Prasad, A.; Hossain, M.S.; Subramanian, R.; Kapat, J.; Manjooran, N.; Ghosh, R. Grain and grain boundary segmentation using machine learning with real and generated datasets. Comput. Mater. Sci. 2024, 233, 112739. [Google Scholar] [CrossRef]

- Shi, P.; Duan, M.; Yang, L.; Feng, W.; Ding, L.; Jiang, L. An Improved U-Net Image Segmentation Method and Its Application for Metallic Grain Size Statistics. Materials 2022, 15, 4417. [Google Scholar] [CrossRef]

- Wang, N.; Guan, H.; Wang, J.; Zhou, J.; Gao, W.; Jiang, W.; Zhang, Y.; Zhang, Z. A deep learning-based approach for segmentation and identification of δ phase for Inconel 718 alloy with different compression deformation. Mater. Today Commun. 2022, 33, 104954. [Google Scholar] [CrossRef]

- Bertoldo, J.P.C.; Decencière, E.; Ryckelynck, D. A modular U-Net for automated segmentation of X-ray tomography images in composite materials. Front. Mater. 2021, 8, 761229. [Google Scholar] [CrossRef]

- Li, H.; Wei, C.; Cao, Z.; Zhang, Y.; Li, X. Deep learning-based microstructure analysis of multi-component heterogeneous composites during preparation. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108437. [Google Scholar] [CrossRef]

- Dong, J.; Kandemir, A.; Hamerton, I. Microstructural characterisation of fibre-hybrid polymer composites using U-Net on optical images. Compos. Part A Appl. Sci. Manuf. 2025, 190, 108569. [Google Scholar] [CrossRef]

- Firdaus-Nawi, M.; Noraini, O.; Sabri, M.Y.; Siti-Zahrah, A.; Zamri-Saad, M.; Latifah, H. DeepLabv3+_Encoder-Decoder with Atrous Separable Convolution for Semantic Image Segmentation. Pertanika J. Trop. Agric. Sci. 2011, 34, 137–143. [Google Scholar]

- Lin, L.; Schlarb, A.K. Development and optimization of high-performance PEEK/CF/Nanosilica hybrid composites. Polym. Adv. Technol. 2021, 32, 3150–3159. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM: West Conshohocken, PA, USA, 2023.

- Gholamalinezhad, H.; Khosravi, H. Pooling Methods in Deep Neural Networks, a Review. arXiv 2020. [Google Scholar] [CrossRef]

- Tasci, E.; Uluturk, C.; Ugur, A. A voting-based ensemble deep learning method focusing on image augmentation and preprocessing variations for tuberculosis detection. Neural Comput. Appl. 2021, 33, 15541–15555. [Google Scholar] [CrossRef]

- Coupé, P.; Mansencal, B.; Clément, M.; Giraud, R.; de Senneville, B.D.; Ta, V.T.; Lepetit, V.; Manjon, J.V. AssemblyNet: A large ensemble of CNNs for 3D whole brain MRI segmentation. NeuroImage 2020, 219, 117026. [Google Scholar] [CrossRef]

- Dang, T.; Nguyen, T.T.; Moreno-García, C.F.; Elyan, E.; McCall, J. Weighted Ensemble of Deep Learning Models based on Comprehensive Learning Particle Swarm Optimization for Medical Image Segmentation. In Proceedings of the 2021 IEEE Congress on Evolutionary Computation, CEC 2021—Proceedings, Kraków, Poland, 28 June–1 July 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 744–751. [Google Scholar] [CrossRef]

- Bergstra, J.; Bardenet, R.; Bengio, Y.; Kégl, B. Algorithms for hyper-parameter optimization. Adv. Neural Inf. Process. Syst. 2011, 24, 1–9. [Google Scholar]

- Mockus, J. The Bayesian Approach to Global Optimization. In System Modeling and Optimization; Springer Science and Business Media: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Pelikan, M.; Goldberg, D.E.; Cantú-Paz, E. Hierarchical problem solving by the Bayesian optimization algorithm. In Proceedings of the 2nd Annual Conference on Genetic and Evolutionary Computation, Las Vegas, NV, USA, 10–12 July 2000. [Google Scholar]

| Test Condition | Selected pv-Combinations | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pressure | MPa | 1 | 1 | 4 | 4 | 4 | 6 | 8 | 8 |

| Velocity | m/s | 1 | 4 | 1 | 2 | 4 | 4 | 1 | 4 |

| pv-product | MPa⋅m/s | 1 | 4 | 4 | 8 | 16 | 24 | 8 | 32 |

| Hyperparameter | Value |

|---|---|

| Initial learn rate | 2.6 × 10−4 |

| Mini batch size | 4 |

| Maximum epoch | 300 |

| Validation frequency | 30 |

| Encoder depth | 5 |

| No. of first encoder filters | 64 |

| Weight | Fiber | Matrix | Patch1 | Patch2 | Patch3 | Patch4 | Patch5 |

|---|---|---|---|---|---|---|---|

| Value | 0.212 | 0.216 | 0.280 | 1.763 | 0.336 | 0.365 | 2.750 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Lin, L. U-Net Segmentation with Bayesian-Optimized Weight Voting for Worn Surface Analysis of a PEEK-Based Tribological Composite. Lubricants 2025, 13, 324. https://doi.org/10.3390/lubricants13080324

Zhao Y, Lin L. U-Net Segmentation with Bayesian-Optimized Weight Voting for Worn Surface Analysis of a PEEK-Based Tribological Composite. Lubricants. 2025; 13(8):324. https://doi.org/10.3390/lubricants13080324

Chicago/Turabian StyleZhao, Yuxiao, and Leyu Lin. 2025. "U-Net Segmentation with Bayesian-Optimized Weight Voting for Worn Surface Analysis of a PEEK-Based Tribological Composite" Lubricants 13, no. 8: 324. https://doi.org/10.3390/lubricants13080324

APA StyleZhao, Y., & Lin, L. (2025). U-Net Segmentation with Bayesian-Optimized Weight Voting for Worn Surface Analysis of a PEEK-Based Tribological Composite. Lubricants, 13(8), 324. https://doi.org/10.3390/lubricants13080324