Abstract

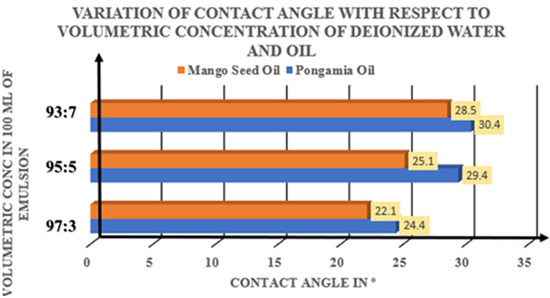

In today’s industrial applications, cutting fluids have attained prime importance due to their all-round features, including increase of tool life by lubrication of the tool at the tool–workpiece interface. This study compares the effects of mango seed oil and pongamia oil on cutting force and surface morphology during the turning of AISI 304 steel. The design of experiments was applied using Taguchi’s method with an L9 array of experiments. During the experiment, it was discovered that mango seed and pongamia-based cutting fluid exhibited the lowest contact angles of 22.1° and 24.4°, respectively, at a 97:3 volumetric concentration of deionized water and eco-friendly oil. The use of mango seed oil as a cutting fluid with MQL (Minimum Quantity Lubrication) resulted in the lowest surface roughness of 0.809 µm, compared to 0.921 µm with pongamia-based cutting fluid. The cutting force was reduced by a maximum of 28.68% using mango seed-based cutting fluid, compared to pongamia-based cutting fluid. ANOVA analysis revealed that feed rate had the maximum influence on the optimization of output parameters for mango seed cutting fluid. For pongamia-based cutting fluid, feed rate had the maximum influence on cutting force, while the depth of cut had the strongest influence on surface roughness.

1. Introduction

Turning is a machining process used to reduce the external diameter of cylindrical workpieces. In this operation, the workpiece is mounted on the headstock and rotated at high speeds relative to a stationary cutting tool, which moves linearly along the axis, either to the left or right. As a result, the cutting tool traces a helical path along the workpiece. Typically, tools are used in the form of inserts, as employing full bar-shaped tools leads to excessive material loss during machining.

Turning is ideal for producing axisymmetric components with various features such as grooves, holes, and tapers. However, machining heat-resistant alloys like nickel, titanium, and chromium alloys generates significant heat, which adversely affects tool life and overall machining performance. The elevated temperatures make turning economically inefficient due to accelerated tool wear and compromised surface finish.

The nature of the chips produced during turning is influenced by factors such as cutting speed, tool geometry, and the workpiece material. Ductile materials usually form long, continuous chips unless chip breakers are used, while brittle materials tend to produce shorter, fragmented chips. These chips, generated at high temperatures due to friction at the tool–workpiece interface, pose safety risks to machine operators.

Increased cutting forces not only raise tool wear but also distort surface finish, resulting in higher surface roughness characterized by pronounced peaks and valleys. Additionally, dry machining, while environmentally friendly, tends to elevate tool tip temperatures, accelerating tool degradation. To address these issues, advanced cooling strategies such as cryogenic cooling and Minimum Quantity Lubrication (MQL) have been explored. Among different techniques, the use of MQL has shown appreciable results due to the superior heat dissipation capabilities with optimum usage of cutting fluid [1].

Nanofluids, particularly those enriched with noble metals, exhibit enhanced thermo-physical properties, thermal conductivity, and stability, making them effective as sustainable cooling agents. Several researchers have explored the use of vegetable and edible oils as base fluids, emulsified in deionized water for improved cooling performance [2]. Jeevan et al. [3] reported that modified jatropha oil significantly reduced thrust and cutting forces during turning. Similarly, Abutu et al. [4] demonstrated that neem and mahogany seed oils reduced both surface roughness and cutting temperatures more effectively than mineral oils.

Additional studies further support the effectiveness of nano-enhanced lubricants. Du et al. [5] found that MQL reduced tool wear and cutting temperature significantly. Naik and Sharma [6] employed MSO as a cooling fluid when machining titanium alloy. They found that MSO outperformed mahua seed oil and sunflower oil in terms of lubrication. Shukla et al. [7] demonstrated the role of surfactants in optimizing nanofluid performance, reporting up to 53% reduction in tool wear.

Traditional fluids, despite their excellent lubricating qualities, cannot serve as cooling fluids in industrial settings due to their minimal thermal response. Therefore, the suspension of nanoparticles in base cutting fluid has been investigated by many researchers to study their impact on wettability characteristics, effect on reduction of cutting force, and Ra [8]. Furthermore, use of MQL with hybrid nanofluids blending materials like graphene, alumina, and carbon nanotubes have emerged as superior alternatives due to their enhanced wettability and cooling performance [9,10,11,12]. Malika and Sonawane [13] noticed significant results while using MQL with hybrid nano fluid consisting of Fe2O3 and silicon carbide and studied thermal properties.

Perera and Wegala [14] used MQL with nano-alumina and nano-graphene in turning SS 400 and AISI 304, and showed substantial improvements in surface finish. Rajeswari [15] showed that MQL significantly lowered surface roughness, temperature, and cutting force during turning of AISI 304 steel using corn oil as a lubricant.

Further evidence from Yang et al. [16] and S et al. [17] confirms the advantages of MQL with nanoparticle-laden fluids in reducing tool wear and improving machining outcomes as compared to dry conditions. The MQL usage with hybrid nanofluids has also enhanced cost-efficiency in milling operations. In aerospace applications, aluminium alloys, due to their favourable mechanical and microstructural properties, have been effectively machined using such fluids, as shown in studies involving AA 7075 and D3 steel using MQL with silver nanoplatelets [18,19,20,21].

In the present investigation AISI 304 stainless steel was chosen due to its widespread industrial application, especially in the food processing, automotive, and aerospace sectors, and its corrosion resistance. However, its poor thermal conductivity leads to slow heat dissipation out of machining zones and leads to softening of the tool, and hence, high tool wear and poor surface finish. This study addressed these issues using mango seed and pongamia oil-based cutting fluid with MQL, which reduced heat and improved surface quality [22].

The current study focuses on the use of mango seed oil and pongamia oil, both sustainable, biodegradable, and eco-friendly oils, as cutting fluids under MQL conditions. These oils are evaluated for their potential to improve the surface quality during the turning of AISI 304 stainless steel.

2. Materials and Methods

2.1. Workpiece Material

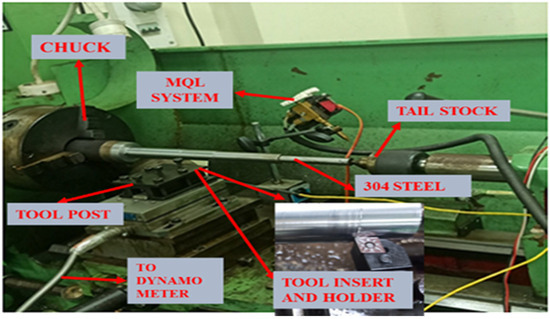

Due to its resistance to corrosion, toughness, and adaptability to different machining environments, AISI 304 steel, also known as austenitic steel, is used in a wide range of machining and engineering applications [21]. It is also good in ductility and is highly durable. The material’s low heat conductivity and hardness make dry machining difficult [22]. This is rectified by the use of conventional cutting fluid. Since there is a large amount of heat generation in the turning process, the heat produced at the site of interaction between the cutting tool and AISI 304 stainless steel is removed by traditional cutting fluids. The workpiece placed on lathe can be seen in Figure 1. Their respective properties are shown in Table 1 and Table 2 [23].

Figure 1.

Placement of AISI 304 rod in the lathe machine.

Table 1.

Mechanical and physical properties of workpiece.

Table 2.

Chemical composition of workpiece.

2.2. Machining Tool and Measurement Equipment

The machine tool used to turn AISI 304 stainless steel is a conventional lathe device (model: DMC-LM-1500 × 600) manufactured by Duo Machines at Gujrat, India. The cutting tool insert used is a CNMG 120408 tungsten carbide insert mounted on a shank designated as PCLNR2020K12 (insert and shank by Widia India Tooling Private Limited, Bangaluru, India). To measure the surface roughness, surface roughness tester SJ-210, manufactured by MITUTOYO Corporation, Kawasaki City, Japan, was used. Sample length of the tester is 0.8 mm. The measuring speed and returning speed were 0.5 mm/s and 1.5 mm/s respectively.

The cutting tool insert used in the turning process is coated tungsten carbide which is manufactured by WIDIA tools. It is a rhombic shaped insert with a negative rake angle and head angle of 80°.

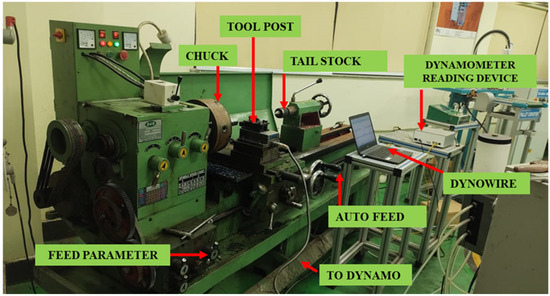

For the flow of cutting fluid, an MQL system which was fixed over the workpiece with its nozzle towards the workpiece and a diameter of 4 mm was used. The distance between the nozzle and the workpiece was kept at 10 cm as shown in Figure 2. The system was fixed at an angle of 15° from the perpendicular axis of the tool. To measure the cutting forces and note it on the computer, software DynoWare (version 2825A) and a piezoelectric dynamometer were used, as shown in the full setup (Figure 3).

Figure 2.

Experimental setup for turning process which includes an MQL system and attached dynamometer.

Figure 3.

Experimental setup. It includes a Kistler Dynamometer of Switzerland, which is used to measure the various forces experienced by the insert during turning.

The data acquisition was performed at a sampling rate of 1000 Hz to accurately capture cutting forces. The input parameters for turning are mentioned in Table 3.

Table 3.

Input parameters for turning under different cutting fluids.

2.3. Cutting Fluid and Contact Angle Measurement

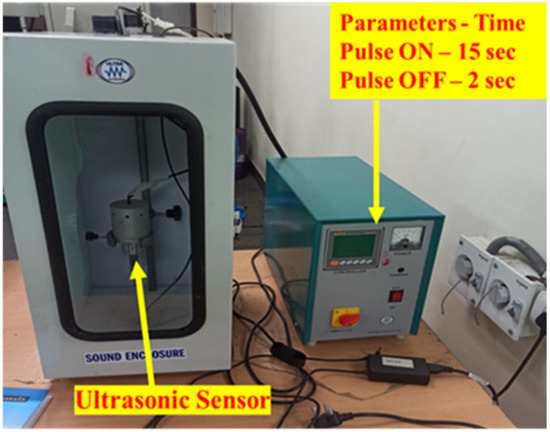

The base cutting fluid will be an emulsion of deionized water and two selective oils, namely, mango seed and pongamia oil. Mango seed oil was purchased from Salvia Cosmeceuticals Pvt Ltd., New Delhi, India, and pongamia oil was purchased from Vyas Pharmaceuticals, Indore, India. To prepare the cutting fluid, deionized water was mixed with different amounts of MSO and pongamia oil (vol%). A total of 1% detergent was added to make it an effective surfactant. To prevent the oil from forming a separate layer on the deionized water, they were kept in an Ultrasonicator, as shown in Figure 4 (model: ULTRA AUTOSONIC manufactured in Pune, India). The cutting fluid was kept in the ultrasonicator for 1 hr at 50 Hz frequency to obtain a homogeneous suspended cutting fluid.

Figure 4.

Ultrasonicator.

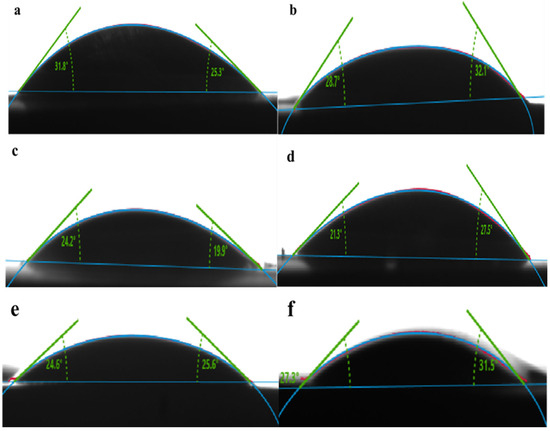

A cutting fluid’s wettability characteristic is its capacity to wet the surface of the material it is applied to. The capability of the tool in dissipating heat is indicated by this crucial feature. While measuring the contact angle on the CNMG 120408 WC insert, we can evaluate the wettability property of the fluid. The Kruss Drop Shape Analyzer (DSA) (Figure 5) from Hambarg Germany is readily available and is used to test the wettability of sustainable cutting fluid, which is examined on the tool. There is integrated software installed to measure the contact angle on the cutting tool. The ambient temperature of the software was 27 °C and the drop flow rate for each of the tests was put as 2 µL/s. The measurement of the contact angle was performed on the standard of water droplets, and the contact angle was measured at the tri-junction of the fluid, the solid contact surface, and the air interface. The technique used to make a drop is known as the sessile drop method. The high-resolution camera of the drop shape analyser gave the required measurement after the drop was stable for 10 s as shown in Figure 6. DSA Young’s contact angle equation is given below:

where ψ denotes surface tension to flow and the subscript SV indicates solid–vapour, SL: solid–liquid, and LV: liquid–vapour.

Figure 5.

Kruss Drop Shape Analyser.

Figure 6.

(a) MSO 93:7 (b) Pongamia 93:7 (c) MSO 97:3 (d) Pongamia 97:3 (e) MSO 95:5 (f) Pongamia 95:5. These represent the contact angle of the cutting fluid on the surface of tool inserts during turning.

The cutting fluid was prepared in a base fluid of deionized water and 3 samples each of mango seed and pongamia oil in the volumetric ratio of (93:7), (95:5), and (97:3), respectively. The contact angles of each of the samples were evaluated separately as shown in Figure 7.

Figure 7.

Graph showing contact angle variation with respect to concentration. The graph represents the comparison of the same concentration in the emulsion of both the oils.

The average value of the contact angles was taken. A little amount of surfactant was also added to make the oil and water mixable. Before each test, the corresponding fluid was heated in an oven and ultrasonicated to prevent the destabilizing of the emulsion. The above tests revealed that both of the oils had the lowest contact angle when they were suspended in the ratio of (97:3). Mango seed and pongamia oil in the ratio of (97:3) tended to spread more on the tungsten carbide cutting tool than the same oils at other tested concentrations.

3. Results

The technique used was the L9 Taguchi Method. The turning output responses are shown at different cutting conditions such as feed, depth of cut (doc), and cutting speed (Vc). The results under mango seed and pongamia oil are discussed below.

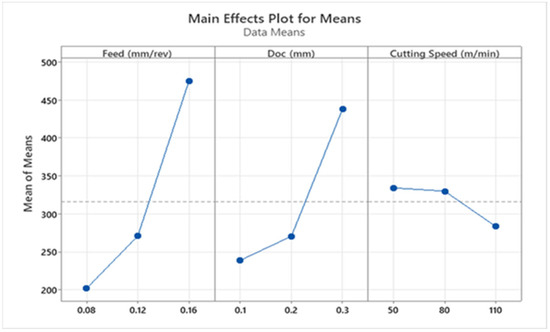

3.1. Turning with Mango Seed Oil-Based Cutting Fluid

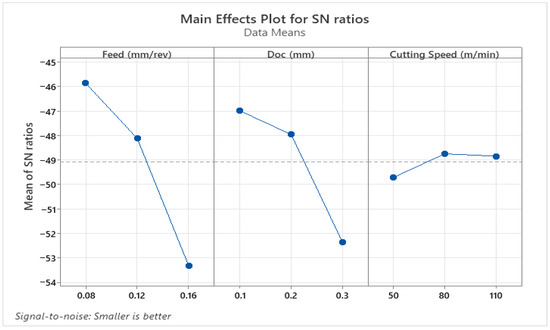

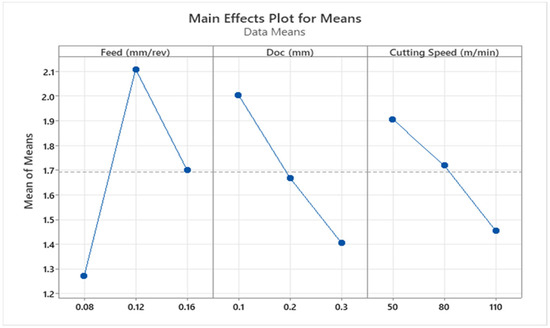

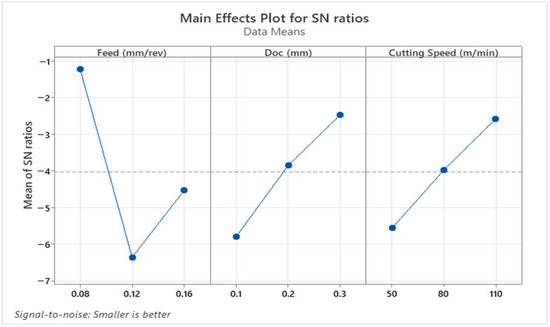

The output parameters in the case of turning with cooling fluid composed of MSO are shown in Table 4. An ANOVA table for cutting force was made (Table 5). It was determined through a variety of parameter analysis for cutting force optimization that feed rate contributed the most at 61.53%, followed by depth of cut at 35.04%. With a mere 0.02% contribution, Vc had the least impact on optimizing the cutting force. So it was concluded that in this set of experiments, feed rate contributes the maximum in the output response [24]. Table 6 displays the signal-to-noise (SN) ratio table, which is used to determine the minimum cutting force required. The minimum values are derived by analysing the SN ratio, where a smaller ratio indicates better performance. The optimum values displayed in the table were L1 for feed, L1 for cut depth, and L2 for cutting speed. The lowest cutting force will therefore be achieved with a feed of 0.08 mm/rev, doc of 0.1 mm, and Vc of 80 m/min. Table 7 reveals the means’ response, which is comparable to the SN ratio in Table 6. It illustrates the significance of the input parameters at the same optimization stage.

Table 4.

Resulting cutting force and surface roughness while turning with MSO-based cutting fluid.

Table 5.

Variance of means for cutting force under mango seed cutting fluid.

Table 6.

Signal-to-Noise Ratios response table.

Table 7.

Response Table for Means.

An ANOVA table (Table 8) was developed to investigate how various input parameters affected surface roughness. Of all the input parameters, it was discovered that the feed had the most effect (40.2%) on the reduction in surface roughness [25,26]. It was discovered that the reduction of surface roughness was affected by Vc by 11.76% and the doc by 20.64%. It was concluded that when optimizing the input parameters, feed rate had the greatest contribution

Table 8.

Analysis of variance for means for surface roughness.

The SN ratio table is shown in Table 9 to help determine the minimum surface roughness requirements. The SN ratios will be determined to identify the lowest value limits; lower is better in this case. The table displays the ideal values for feed, depth of cut, and cutting speed as L1, L3, and L3. Consequently, a feed rate of 0.08 mm/rev, a depth of cut of 0.3 mm, and a Vc of 110 m/min will result in the least surface roughness.

Table 9.

SN Ratios response table.

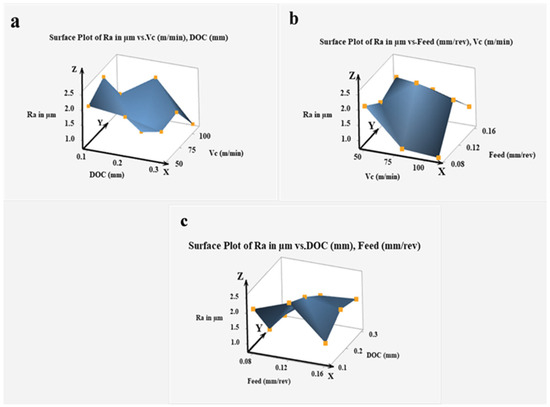

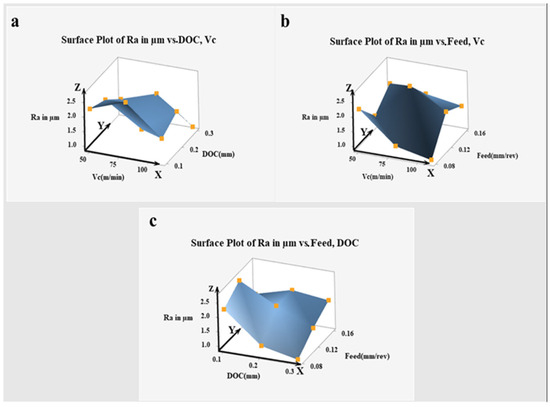

Table 10 reveals the means’ response, which is comparable to the SN ratio in Table 9. It illustrates the significance of the input parameters at the same optimization stage. A set of surface plots was created under turning with mango seed-based cutting fluid, and the response of Ra, taking two input parameters at a time, was depicted in Figure 8.

Table 10.

Response Table for Means for surface roughness.

Figure 8.

Surface plot of variation of surface roughness taking two input parameters at a time. (a) Cutting speed and doc, (b) feed and cutting speed, (c) doc and feed. The yellow squares reveal the position of the value of Ra.

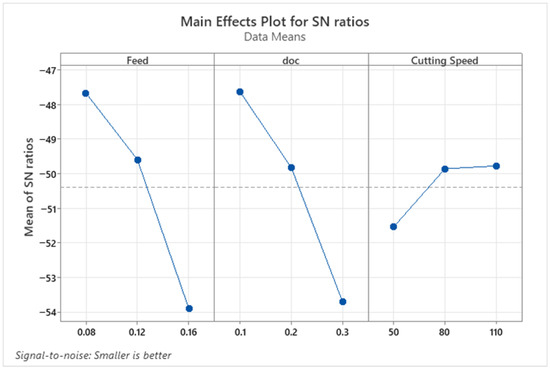

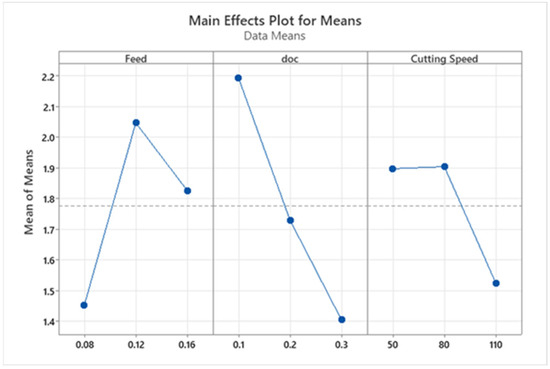

The primary effect graphs for means of cutting force and SN ratios, respectively, are displayed in Figure 9 and Figure 10. Similarly, the primary effect graphs for means of surface roughness and SN ratios, respectively, are displayed in Figure 11 and Figure 12. The response table determines the ideal values for a number of parameters, which are plotted prominently on the graph.

Figure 9.

Main effects plot for means for cutting force.

Figure 10.

Main effect plot for SN ratios for cutting force.

Figure 11.

Main effects plot for surface roughness means.

Figure 12.

Main effect plot for SN ratio for surface roughness.

3.2. Turning with Pongamia Oil-Based Cutting Fluid

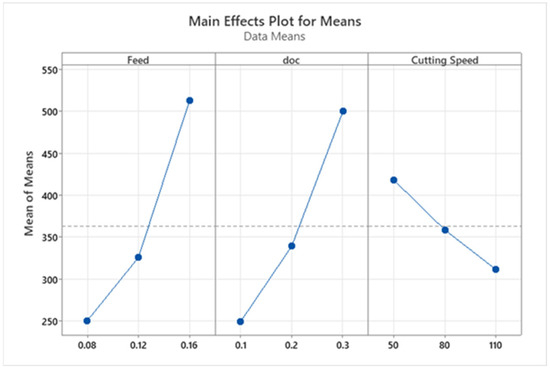

Table 11 shows the surface roughness and cutting forces after turning using pongamia oil-based cutting fluid. Table 12 shows the results of the ANOVA analysis of the cutting force under pongamia oil. After the study of the table, it can be revealed that the feed has the maximum contribution in optimization of the cutting force, contributing 48.89%. With a contribution of only 7.64%, Vc has the least impact on optimizing cutting force, whereas depth of cut has an influence of 43.27%. Therefore, feed plays the most significant role in determining the optimal parameters.

Table 11.

Resulting cutting force and surface roughness while turning with pongamia cutting fluid.

Table 12.

Analysis of variance for means for cutting force under pongamia-based cutting fluid.

The SN ratio table is displayed in Table 13, which can be used to determine the minimum cutting force requirements. The SN ratios will be assessed to identify the lowest value limits; lower is better in this case. The ideal values displayed in the table were L1 for feed, L1 for doc, and L3 for Vc. The lowest cutting force while using pongamia-based cutting fluid will therefore be achieved by combining a feed of 0.08 mm/rev, a doc of 0.1 mm, and a Vc of 110 m/min.

Table 13.

Response Table for Signal-to-Noise Ratios.

Table 14 reveals the means’ response, which is comparable to the SN ratio in Table 13. It illustrates the significance of the input parameters at the same optimization stage.

Table 14.

Response table for means.

An ANOVA table (Table 15) was developed to investigate how various input parameters affected surface roughness. Out of all the input parameters, it was found that the doc had the biggest influence on the reduction of surface roughness (39.96%). It was discovered that the feed and Vc had an impact on surface roughness improvements by 29.99% and 12.00%, respectively. In a similar study, the reduction in surface roughness by 21% was observed using MQL in the turning of nickel-based superalloy [27]. It was concluded that while optimizing the input parameters, doc had the greatest contribution. The SN ratio table is displayed in Table 16, which can be used to determine the minimum surface roughness requirements [28,29]. By reviewing the SN ratio—smaller is better—the limits for minimum values will be established. The ideal values for feed, depth of cut, and cutting speed were represented in the table as L1, L3, and L3. When the feed is 0.08 mm/rev, the doc is 0.3 mm, and the Vc is 110 m/min, the surface roughness will be at a minimum.

Table 15.

Analysis of variance for means for surface roughness.

Table 16.

SN Ratios response table.

Table 17 reveals the means’ response, which is comparable to the SN ratio in Table 16. It illustrates the significance of the input parameters at the same optimization stage. A set of surface plots was created under turning with pongamia oil-based cutting fluid, and the response of Ra, taking two input parameters at a time, was depicted in Figure 13.

Table 17.

Response table of means.

Figure 13.

Variation in surface roughness using different input parameters while turning with pongamia oil. (a) Cutting speed and doc, (b) feed and cutting speed, (c) doc and feed. The subfigures depict the variation of Ra with variation in two input parameters. Yellow marks represent the position of the value of Ra.

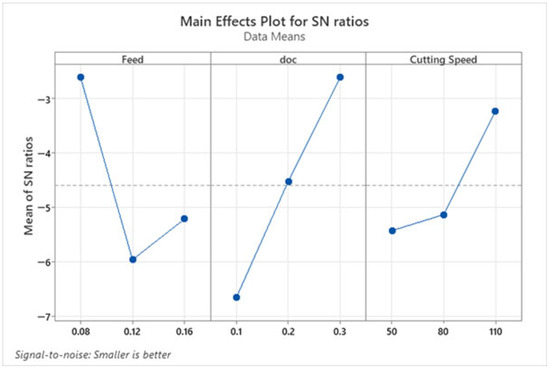

The primary effect graphs for the means of cutting force and SN ratios, respectively, are displayed in Figure 14 and Figure 15. The response table determines the ideal values for a number of parameters. The primary effect graphs for mean of surface roughness and SN ratios, respectively, are displayed in Figure 16 and Figure 17.

Figure 14.

Main effect plot for cutting force.

Figure 15.

Main effect plot for SN ratio of Vc.

Figure 16.

Main effect plot for means of surface roughness.

Figure 17.

Main effect plot for SN ratio of surface roughness.

4. Discussion

In future studies, MSO can be utilized as a base oil for nanofluid and low and high cutting parameters can be experimented on. Mango seed oil and pongamia oil have low contact angles, as they both have low surface tension in comparison to mineral oil, which favours spreading. Also, they possess high polarity and availability of a functional group which aids in adhesion for metallic or oxide surfaces, thereby reducing the contact angle [30]. The higher composition of active fatty acids presented in the two oils acts as a natural surfactant and reduces surface tension [25]. Additionally, the pongamia and mango seed oil possesses lower viscosity compared to synthetic mineral oil that promotes spreading over the surface, thereby reducing the contact angle.

Since MSO has better tribological properties compared to most of the commonly used edible oils, studies can be further expanded on other machining operations such as drilling and milling. The effectiveness of mahua and mango seed oils as base cutting fluids in various machining processes has not been extensively studied. In all parts of the world, the consumers readily discard mango seeds after eating the mango. India has a large number of mango tree plantations; hence, mango seeds are readily available. Thus, it can be stated that mango seed oil is a reasonably priced substitute for cutting fluids that consist of minerals.

5. Conclusions

This study analyses the cutting fluids based on pongamia and mango seed oil in terms of their ability to reduce cutting force and surface roughness. The Taguchi method was used to optimize the input parameters for feed, cutting velocity, and depth of cut. The following statements were drawn from the performed experiments and the ANOVA analysis.

- Mango seed oil-based cutting fluid has shown higher wettability property than pongamia oil-based cutting fluid considering each of the separate concentrations. Experiments revealed that MSO and pongamia oil have the lowest contact angles at 97:3 volumetric concentration with values of 22.1° and 24.4° respectively.

- The mango seed-based cutting fluid has recorded lower cutting force than the pongamia-based cutting fluid. The maximum reduction in cutting force was found to be 28.68% for the same input parameters of Vc = 50 m/min, doc = 0.2 mm, and feed = 0.16 mm/rev for both the cutting fluids.

- It is noticed that feed, together with doc, had the most significant effect on the performance of both oil-based cutting fluids for optimizing the output parameters.

- Using mango seed cutting fluid and pongamia cutting fluid, the lowest surface roughness values of 0.809 µm and 0.921 µm, respectively, were achieved at high depth of cut and high Vc. The analysis of the surface roughness values (Ra, Rq, Rz) indicates that MSO was able to reduce the surface roughness values more than pongamia oil.

Author Contributions

Conceptualization: S.Y. and A.M.; methodology: V.D.; software: A.M.; validation, S.Y., V.D. and A.K.S.; formal analysis: S.Y.; investigation, A.M.; resources, A.M.; data curation, A.M.; writing—original draft preparation: A.M.; writing—review and editing: A.M., S.Y., A.K.S., V.D., D.K.P. and U.S.; visualization: A.M. and S.Y.; supervision: A.K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Some or all data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

This work was carried out in the Industrial and Automation Laboratory of CAS, Lucknow. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Demirpolat, H.; Binali, R.; Patange, A.D.; Pardeshi, S.S.; Gnanasekaran, S. Comparison of Tool Wear, Surface Roughness, Cutting Forces, Tool Tip Temperature, and Chip Shape during Sustainable Turning of Bearing Steel. Materials 2023, 16, 4408. [Google Scholar] [CrossRef]

- Pereira, J.; Moita, A.; Moreira, A. Noble Nanofluids and Their Hybrids for Heat Transfer Enrichment: A Review and Future Prospects Coverage. Appl. Sci. 2023, 13, 9568. [Google Scholar] [CrossRef]

- Jeevan, T.P.; Jayaram, S.R.; Afzal, A.; Ashrith, H.S.; Soudagar, M.E.M.; Mujtaba, M.A. Machinability of AA6061 aluminum alloy and AISI 304L stainless steel using nonedible vegetable oils applied as minimum quantity lubrication. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 159. [Google Scholar] [CrossRef]

- Abutu, J.; Elachi, E.E.; Tanko, B.; Akene, P.; Musa, K.; Lawal, S.A. Development of Cutting Fluid from Mahogany Seed oil and Neem leaves for the Turning of AISI 304 Austenitic Stainless Steel. J. Mater. Environ. Sci. 2023, 14, 878–889. [Google Scholar]

- Du, F.; He, L.; Zhou, T.; Tian, P.; Zou, Z.; Zhou, X. Analysis of droplet characteristics and cooling lubrication effects in MQL milling of 316L stainless steel. J. Mater. Res. Technol. 2022, 19, 4832–4856. [Google Scholar] [CrossRef]

- Naik, D.N.S.; Sharma, V. Thermophysical Investigations of Mango Seed Oil as a Novel Cutting Fluid: A Sustainable Approach Toward Waste to Value Addition. J. Manuf. Sci. Eng. 2022, 144, 091004. [Google Scholar] [CrossRef]

- Shukla, R.; Tiwari, A.K.; Agarawal, S. Effects of surfactant and MoO3 nanofluid on tribological and machining characteristics in minimum quantity lubrication (MQL)-turning of AISI 304 steel. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 095440892211059. [Google Scholar] [CrossRef]

- Bai, X.; Jiang, J.; Li, C.; Dong, L.; Ali, H.M.; Sharma, S. Tribological Performance of Different Concentrations of Al2O3 Nanofluids on Minimum Quantity Lubrication Milling. Chin. J. Mech. Eng. 2023, 36, 11. [Google Scholar] [CrossRef]

- Sharma, P.; Sidhu, B.S.; Sharma, J. Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J. Clean. Prod. 2015, 108, 72–79. [Google Scholar] [CrossRef]

- Touggui, Y.; Uysal, A.; Emiroglu, U.; Belhadi, S.; Temmar, M. Evaluation of MQL performances using various nanofluids in turning of AISI 304 stainless steel. Int. J. Adv. Manuf. Technol. 2021, 115, 3983–3997. [Google Scholar] [CrossRef]

- Long, T.T. Experimental Investigation on Cutting Forces in Sustainable Hard Milling of Hardox 500 Steel Under Al2O3/MoS2 Hybrid Nanofluid MQCL Environment. Lubricants 2025, 13, 240. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K. Nano lubricants in machining and tribology applications: A state of the art review on challenges and future trend. J. Mol. Liq. 2024, 407, 125261. [Google Scholar] [CrossRef]

- Malika, M.; Sonawane, S.S. Application of RSM and ANN for the prediction and optimization of thermal conductivity ratio of water based Fe2O3 coated SiC hybrid nanofluid. Int. Commun. Heat. Mass. Transfer. 2021, 126, 105354. [Google Scholar] [CrossRef]

- Perera, G.I.P.; Wegala, T.S. Improving the novel white coconut oil-based metalworking fluid using nano particles for minimum surface roughness and tool tip temperature. Clean. Mater. 2024, 11, 100227. [Google Scholar] [CrossRef]

- Rajeswari, R. Investigation on the Effect of Turning of AISI 304 Stainless Steel Using MQL Technique with Corn Oil as Cutting Fluid and Comparison with Dry Condition. Eng. Proc. 2024, 61, 35. [Google Scholar]

- Yang, X.; Cheng, X.; Li, Y.; Zheng, G.; Xu, R. Machinability investigation and sustainability analysis of minimum quantity lubrication–assisted micro-milling process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1388–1401. [Google Scholar] [CrossRef]

- S, V.; U, M.I.; Ghani, J.A. A Study on the Effects of Hybridized Metal Oxide and Carbonaceous Nano-Cutting Fluids in the End Milling of AA6082 Aluminum Alloy. Lubricants 2023, 11, 87. [Google Scholar] [CrossRef]

- Yadav, S.; Tewari, S.P.; Singh, J.K.; Ram, S.C. Effects of mechanical vibration on the physical, metallurgical and mechanical properties of cast A308 (LM21) aluminum alloy. Int. J. Miner. Metall. Mater. 2022, 29, 1206–1215. [Google Scholar] [CrossRef]

- Arifuddin, A.; Redhwan, A.A.M.; Syafiq, A.M.; Ariffin, S.Z.; Aminullah, A.R.M.; Azmi, W.H. Effectiveness of hybrid Al2O3-TiO2 nano cutting fluids application in CNC turning process. Arch. Mater. Sci. Eng. 2022, 117, 70–78. [Google Scholar] [CrossRef]

- Yadav, S.; Kumar, S.; Tewari, S.P.; Ram, S.C.; Prasad, R.; Sinha, N.K.; Deo, M.; Singh, J.K. Influence of high-intensity horizontal mould vibration on the density, grain refinement and mechanical characteristics of a die cast aluminium alloy (LM21). Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 237, 710–718. [Google Scholar] [CrossRef]

- Özbek, N.; Karadag, M.; Özbek, O. Optimization of Flank Wear and Surface Roughness during Turning of AISI 304 Stainless Steel Using the Taguchi Method. Mater. Test. 2020, 62, 957–961. [Google Scholar] [CrossRef]

- Babu, M.N.; Anandan, V.; Parthasarathi, N.L.; Yildirim, C.V.; Babu, M.D.; Das, S.R. Performance analysis in turning of D3 tool steel using silver nanoplatelets as additives under MQL. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 591. [Google Scholar] [CrossRef]

- Graves, R.S.; Kollie, T.G.; McElroy, D.L.; Gilchrist, K.E. The thermal conductivity of AISI 304L stainless steel. Int. J. Thermophys. 1991, 12, 409–415. [Google Scholar] [CrossRef]

- Mahdavinejad, R.A.; Saeedy, S. Investigation of the Influential Parameters of Machining of AISI 304 Stainless Steel. Sādhanā 2011, 36, 963–970. [Google Scholar] [CrossRef]

- Gunstone, F.D. The Chemistry of Oils and Fats: Sources, Composition, Properties and Uses, 1st ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Abellán-Nebot, J.V.; Vila Pastor, C.; Siller, H.R. A Review of the Factors Influencing Surface Roughness in Machining and Their Impact on Sustainability. Sustainability 2024, 16, 1917. [Google Scholar] [CrossRef]

- Mane, S.; Patil, R.B.; Al-Dahidi, S. Predictive Modeling of Surface Roughness and Cutting Temperature Using Response Surface Methodology and Artificial Neural Network in Hard Turning of AISI 52100 Steel with Minimal Cutting Fluid Application. Machines 2025, 13, 266. [Google Scholar] [CrossRef]

- Özbek, O. Evaluation of Nano Fluids with Minimum Quantity Lubrication in Turning of Ni-Base Superalloy UDIMET 720. Lubricants 2023, 11, 159. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Laseinde, O.T.; Kazeem, R.A.; Onu, P.; Ting, T.T. The Development and Performance Assessment of Palm Kernel Nut Oil as a Cutting Fluid for the Turning of AA6061. Lubricants 2025, 13, 279. [Google Scholar] [CrossRef]

- Biresaw, G.; Mittal, K. Surfactants in Tribology; CRC Press: Boca Raton, FL, USA, 2013; Volume 3. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).