Abstract

Nickel-based superalloy Hastelloy C276 is widely used in high-performance industries due to its strength, corrosion resistance, and thermal stability. However, these same properties pose substantial challenges in machining, resulting in high tool wear, surface defects, and dimensional inaccuracies. This study investigates methods to enhance machining performance and surface quality by evaluating the tribological behavior of TiSiN/TiAlN-coated carbide inserts under six cooling and lubrication conditions: dry, MQL with coconut oil, Cryo-LN2, Cryo-LCO2, MQL–Cryo-LN2, and MQL–Cryo-LCO2. Open-slot finishing was performed at constant cutting parameters, and key indicators such as cutting zone temperature, tool wear, surface roughness, chip morphology, and microhardness were analyzed. The hybrid MQL–Cryo-LN2 approach significantly outperformed other methods, reducing cutting zone temperature, tool wear, and surface roughness by 116.4%, 94.34%, and 76.11%, respectively, compared to dry machining. SEM and EDS analyses confirmed abrasive, oxidative, and adhesive wear as the dominant mechanisms. The MQL–Cryo-LN2 strategy also lowered microhardness, in contrast to a 39.7% increase observed under dry conditions. These findings highlight the superior performance of hybrid MQL–Cryo-LN2 in improving machinability, offering a promising solution for precision-driven applications.

1. Introduction

Nickel alloys, composed primarily of nickel and alloying elements, are well known for their exceptional resistance to corrosion and their ability to perform reliably at elevated temperatures. These characteristics make them essential in a wide range of industries, including construction, chemical processing, environmental protection, power generation, and aerospace propulsion systems [1]. Despite these advantages, machining nickel-based alloys such as Hastelloy remains difficult due to their inherent toughness and tendency to work harden and the significant heat generated during cutting operations. Researchers have explored various cooling and lubrication strategies to address these challenges, aiming to improve surface finish, reduce tool wear, and enhance sustainability. The use of vegetable-based oils and nano-enhanced fluids has shown encouraging results compared to dry machining, offering reductions in cutting temperature, tool degradation, and surface roughness [2]. Studies on drilling using hybrid nanofluids with graphene nanoplatelets and hexagonal boron nitride additives have reported superior lubrication and heat transfer, improving hole quality and tool lifespan [3]. Experiments involving mist-based lubrication techniques have further supported the effectiveness of hybrid strategies in minimizing tool adhesion and maintaining cutting stability [4]. Environmentally conscious approaches, such as minimum quantity lubrication with liquid nitrogen and nanofluid combinations, are also gaining attention for enhancing machining performance while reducing ecological impact [5]. These advancements reflect a growing industrial emphasis on sustainable manufacturing [6] and form a strong foundation for studying the machining behavior of Hastelloy C276 under modern lubrication and cooling conditions. However, tool wear remains a major limitation in machining nickel-based alloys, due to intense thermal and mechanical loads at the tool–workpiece interface. Dominant wear mechanisms include adhesion, abrasion, diffusion, oxidation, and failure of the coating interface, each of which degrades machining performance and shortens tool life. Adhesion leads to material transfer and built-up edge formation, while abrasion occurs as hard inclusions in the material, which generate grooves on the tool surface. Diffusion wear results from atomic migration at high temperatures, especially in carbide tools, and oxidation contributes to coating degradation under thermal exposure [7]. In addition, Hastelloy X has demonstrated susceptibility to hot cracking in additive manufacturing processes, where high-temperature stress leads to intergranular microcrack formation [8]. Low cycle fatigue studies also reveal a shift in crack initiation patterns, from transgranular to intergranular fracture, under specific thermal and strain conditions [9]. A clear understanding of these wear mechanisms is essential for refining cooling and lubrication strategies and ensuring reliable machining of nickel-based superalloys.

Dry machining is increasingly considered a sustainable and cost-effective method for manufacturing, especially with difficult-to-machine materials such as Hastelloy and other superalloys. By removing cutting fluids, this technique reduces health risks from prolonged exposure and supports a cleaner work environment. However, widespread implementation remains limited due to the high temperatures generated at the tool–workpiece interface, which accelerate wear and compromise surface finish. While turning and milling operations benefit from efficient chip removal under dry conditions, drilling and tapping face challenges due to heat buildup and chip congestion. To overcome these issues, researchers are exploring advanced tool coatings and optimized machining parameters. Tribological coatings in particular show promise for increasing wear resistance and extending tool life. Although dry machining presents clear sustainability benefits, additional research is necessary to improve its performance and promote broader industrial use [10,11,12].

Flood machining is one of the earliest cooling methods in metal cutting, using large volumes of fluid to dissipate heat and reduce tool wear. It is widely applied in milling, grinding, and drilling, but faces limitations due to fluid delivery issues, environmental concerns, and high operational costs. Most conventional systems rely on water-based or oil-based fluids, the prolonged use of which raises sustainability concerns involving waste generation, bacterial growth, and harmful emissions [10,13,14]. Despite these drawbacks, flood cooling remains useful in high-pressure operations requiring efficient chip removal. However, its high resource use and maintenance demands continue to encourage interest in alternative lubrication strategies [15,16]. Health risks are also a concern, as chemical additives in coolants expose operators to mist and fumes that may cause respiratory and skin problems [14,16].

Minimum quantity lubrication has gained attention as an alternative to traditional cooling techniques, especially for machining superalloys. Unlike flood cooling, which uses large amounts of fluid, MQL applies a small aerosol-based lubricant, improving efficiency and reducing environmental impact [11,12,14]. Research has examined various MQL formulations, including biodegradable vegetable oils, solid lubricants like MoS2 and WS2, and nano-enhanced fluids with hexagonal boron nitride or graphene particles, which have improved lubrication performance and reduced tool wear. Although nano-lubricants reduce interface temperature and wear, challenges remain in ensuring their uniform dispersion and stable behavior at high cutting speeds [10,12,15,17]. Improvements in nozzle angle and flow rate control have enhanced cooling and tool life, underlining the importance of precise application [14,15,16]. These strategies aim to counteract thermal fatigue and tool wear, which are issues linked to the low thermal conductivity of superalloys such as Inconel 690 and Inconel 718. However, mist evaporation at high temperatures can cause a vapor layer (the Leidenfrost effect) that reduces heat transfer and leads to adhesion-driven tool failure [16,17]. While MQL offers strong sustainability benefits, some nanofluids with poor biodegradability have raised health concerns, including potential respiratory or genetic effects, prompting further study into their safety in manufacturing environments [18].

Cryogenic machining has gained momentum as an advanced cooling method, particularly in aerospace and medical manufacturing where precision and cleanliness are critical. Studies show significant improvements in machining performance for alloys like Inconel 625 and 718 when cryogenic cooling is applied. For example, turning with PVD TiAlN-coated inserts on Inconel 625 improved surface roughness by 50.5 percent, while milling Inconel 718 achieved up to an 88 percent gain in finish quality [10]. Cryogenic coolants such as liquid nitrogen and carbon dioxide help dissipate heat, reduce tool degradation, and improve surface integrity [11]. This method is environmentally friendly, as it reduces waste and suppresses excess heat, extending tool life and minimizing machining defects [12,14,15]. In drilling, cryogenic methods have enhanced hole accuracy and surface finish by up to 77 and 47 percent, respectively, compared to dry cutting [13]. To improve cooling precision, delivery systems now include spraying, jet streams, and pre-cooling of the workpiece [16]. Liquid nitrogen provides sustained ultra-cold temperatures, while carbon dioxide offers clean cooling through phase changes. Their use requires optimized delivery to ensure effective heat transfer and tool interaction [19,20]. Experiments on Inconel 718 show that cryogenic CO2 lowered temperatures by 80 percent and extended tool life by 70.8 percent compared to dry machining [21]. LN2 provides a 20 percent stronger cooling effect than LCO2, while LCO2 shows an 18 percent improvement in tool life [22]. Cryogenic machining also eliminates the need for secondary fluid cleaning, reducing waste disposal costs [23]. In Ti-6Al-4V turning, cryogenic cooling decreased flank and crater wear and extended tool life by 125 percent while lowering energy use and emissions [24]. However, certain setups such as multi-jet cryogenic drilling of CFRP composites increased thrust force by 35 percent, emphasizing the need for refined coolant targeting [25]. Continued development focuses on controlling temperature, preserving material properties, and increasing industrial adaptability [10,11,12,13,14,15,16,19,20,21,22,23,24,25].

The cost-effectiveness of Cryo-MQL depends on cutting conditions, but it offers clear benefits at higher machining speeds by improving energy efficiency and reducing tool replacement [26]. CMQL, a hybrid system using carbon dioxide and minimum quantity lubrication at the rake face, delivers frozen oil particles to the cutting zone, though precise nozzle control is essential for effectiveness [27]. Studies show that nitrogen combined with minimum quantity lubrication produces the lowest tool flank wear and more stable chip formation [28]. For Inconel 718, Cryo-MQL with carbon dioxide increases tool life by up to 93.5 percent, while also lowering cutting force and wear [20,29]. Combining cryogenic fluids with minimum quantity lubrication has proven highly effective for machining titanium alloys and nickel-based superalloys, reducing cutting forces, wear, and roughness and improving overall stability [14,20,28,30,31]. Hybrid approaches using carbon dioxide reduce flank wear by 31.8 percent, while liquid nitrogen achieves a 59.6 percent reduction at lower speeds [32]. Tool life can increase by 55 percent with nitrogen and over 100 percent with carbon dioxide compared to conventional methods [33]. Beyond wear reduction, Cryo-MQL lowers environmental impact, reduces power use, and enhances surface finish [34]. It also suppresses crater wear caused by dissolution and diffusion during high-speed cutting. Recent advances in dual nozzle Cryo-MQL show that optimized nozzle angles improve cooling efficiency and limit localized hardening and adhesion damage [35]. In Ti-6Al-4V cutting, Cryo-MQL reduces feed and cutting forces by 27 percent and surface roughness by 46 percent versus dry machining [36]. Carbon dioxide also extends tool life in Ti-6Al-4V by up to 65 percent over Inconel 718, due to its superior machinability and shorter tool chip contact length [37]. Additionally, cryogenic cooling combined with nano-minimum quantity lubrication improves friction at the tool–workpiece interface and reduces flank wear in Inconel 601, while hybrid methods enhance chip control and reduce adhesion-related tool damage at various speeds [38,39]. Ongoing research continues to refine hybrid strategies, aiming to balance machining performance and environmental sustainability through better nozzle alignment and coolant delivery [14,20,26,28,29,30,32,33,34,35,36,37,38,39].

Coating technologies play a crucial role in improving tool performance, minimizing wear, and enhancing machining efficiency, especially under dry cutting conditions. Without lubrication, adhesion, thermal degradation, and diffusion failures become more severe, which is why coatings such as TiN, TiCN, TiAlN, CrN, and Al2O3 are commonly applied using chemical or physical vapor deposition to increase tool life and thermal stability. Recent studies show that multi-layer coatings offer superior wear resistance and lower cutting forces in high-speed machining, particularly with PVD-coated carbide tools [10]. This study investigates the wear resistance and surface quality of a TiSiN/TiAlN-coated carbide tool under varying cooling and lubrication conditions. Laser cladding with high-entropy alloys also shows potential for improving surface durability through strong bonding and refined microstructure [40]. Coatings such as CoCrFeMnNi and AlTiVCrNb, applied via vapor deposition or cladding, improve friction behavior and protect surfaces through grain refinement [41,42]. Oxidation and adhesive wear remain dominant concerns, underlining the protective function of coatings [42]. PVD-based TiAlN and TiAlSiN coatings are especially effective in milling, reducing adhesion, abrasion, and delamination. Tools coated with TiAlSiN, such as ball nose cutters, outperform TiAlN-coated tools in wear and surface quality at high speeds [43]. The correlation between flank wear and material removal volume also emphasizes the need for tailored coating choices to enhance cutting performance. Additionally, variations in residual stress caused by tool wear reflect different mechanical responses among coating types, which can affect machining accuracy [44]. As industries pursue high-performance and sustainable production, continued refinement of coating compositions and tool geometries remains essential for reliable and efficient machining.

Optimizing cutting conditions, tool coatings, and machining strategies through systematic evaluation techniques such as SEM, EDS analysis, and quantitative assessment tools is essential for improving component quality in mechanical manufacturing. Although various cooling and lubrication approaches have been studied, most prior research has focused on turning, with fewer works addressing drilling and only limited attention given to milling Hastelloy C276. A clear gap remains in understanding the effects of cryogenic and hybrid cooling methods, combined with cutter coatings, on the machinability of this alloy. While earlier studies refer to hybrid systems such as Cryo-MQL or CryoLN2-MQL, this study introduces the notation MQL–Cryo-LN2 and MQL–Cryo-LCO2 to emphasize the sequence of lubrication and cooling. To address this research gap, we systematically examine the milling response of Hastelloy C276 using TiSiN/TiAlN-coated carbide inserts under six conditions: dry machining, minimum quantity lubrication with coconut oil, cryogenic cooling using LN2 and LCO2, and hybrid MQL–Cryo-LN2 and MQL–Cryo-LCO2. The study evaluates cutting temperature, tool wear, surface texture, chip morphology, and microhardness to identify dominant wear mechanisms, assess coating performance, and determine optimal machining parameters for open-slot finishing. The results aim to advance current milling methodologies and offer practical insights for enhancing efficiency and precision in manufacturing.

2. Equipment and Experimental Design

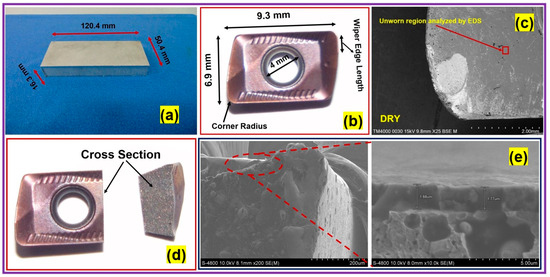

2.1. Material and Cutter

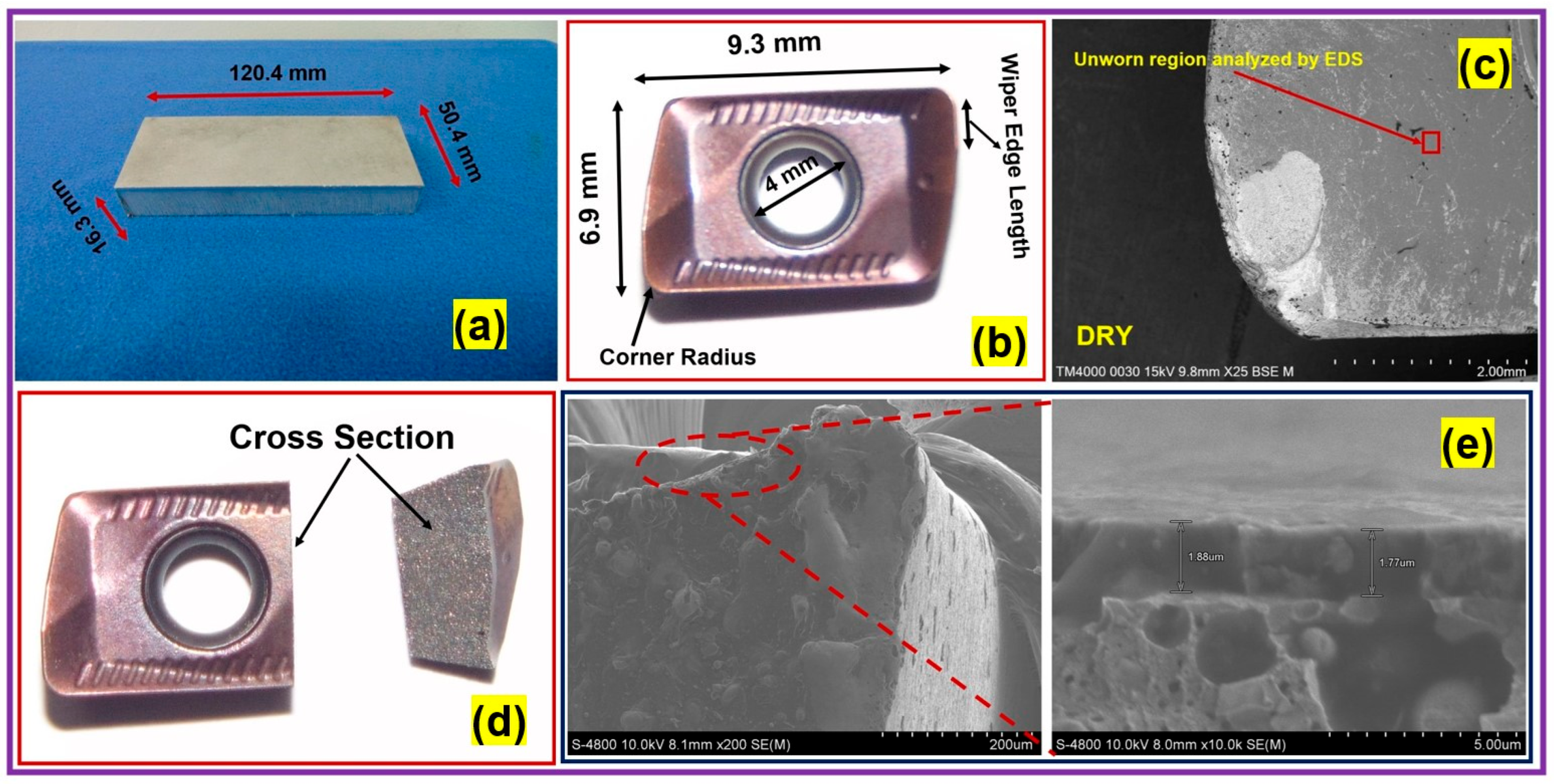

Rectangular blocks of Hastelloy C276 with a hardness of 9–11 HRC were used for the finishing experiments. The initial dimensions were 120.4 × 50.4 × 16.3 mm; after rough machining, the final block size measured 120 × 50 × 15.5 mm. The chemical composition of Hastelloy C276 is detailed in Table 1.

Table 1.

Chemical composition of Hastelloy C276 (as provided by the supplier).

Open-slot finishing was conducted using a Turbo 10 square shoulder and slot milling cutter (SECO TOOLS, Turbo 10-R217.69-1416.0-10-2A, Fagersta, Sweden). The cutter featured a 16 mm diameter and maximum cutting depths of 6 mm in the feed direction and 9 mm radially and included two peripheral cutting edges. It had a cylindrical shank (160 mm overall length), with a 134 mm shank length and 112 mm of usable length. The cutter’s geometry included a −11.4° radial rake, 3.1° axial rake, and 90° cutting edge angles.

The end milling tests employed a carbide insert from SECO TOOLS, selected for its suitability in machining stainless steels and nickel-based superalloys under various cooling and lubrication strategies. The tool was used in its original commercial form without further modification prior to testing.

The inserts used (XOMX10T308TR-ME07, MP2050, Fagersta, Sweden) were coated with TiSiN/TiAlN via physical vapor deposition (PVD). Their chemical composition is detailed in Table 2. The cutting inserts used in this study were procured as pre-coated commercial tools featuring a multilayer (Ti, Si) N/(Ti, Al) N coating system. According to the supplier, the coatings were applied using a physical vapor deposition (PVD); however, the specific technique employed, such as cathodic arc or magnetron sputtering, was not disclosed. As a result, further characterization of the deposition process was not possible. The potential influence of the deposition method on coating morphology, particularly in relation to macroparticle formation, has been acknowledged as a limitation of this study. Cross-sectional SEM analysis determined the coating thickness to be approximately 1.88 µm. The insert featured a 15° clearance angle, 1.3 mm wiper edge, two cutting edges, 20.4° rake angle, 0.8 mm corner radius, 9.3 mm effective cutting edge length, 3.83 mm thickness, and 6.9 mm width. A SK40-Q6Z440 tool holder (EMCO GmbH, Hallein, Austria) was used to support the assembly.

Table 2.

Chemical composition of the TiSiN/TiAlN coating layer determined by SEM–EDS analysis.

The use of carbide inserts coated with TiSiN/TiAlN is supported by their proven ability to improve durability at lower cutting speeds. This allows wear to occur gradually on the flank face rather than through sudden edge chipping. The enhanced performance is attributed to the intact substrate and the beneficial compressive residual stresses introduced by the PVD coating, as supported by previous studies [1,40,41,42,43,44]. Figure 1 provides a comprehensive visual overview of the experimental setup and materials, including the dimensions of the Hastelloy C276 workpiece, the geometry of the TiSiN/TiAlN-coated carbide insert, and the SEM analyses used to characterize the insert before and after machining.

Figure 1.

(a) Overall dimensions of the Hastelloy C276 rectangular block after laser cutting, used as the workpiece material; (b) geometric dimensions of TiSiN/TiAlN-coated carbide insert, including width, length, wiper edge length, and corner radius; (c) SEM image of the coated insert after dry machining, highlighting the target point on the rake face at an unworn region selected for elemental analysis; (d) cross-sectional view of the coated insert prepared using wire electrical discharge machining (WEDM), used to expose the coating layers for thickness measurement; (e) SEM images of the cross-section used to determine the coating thickness of the TiSiN/TiAlN multi-layer system.

2.2. Machine and Machining Settings

2.2.1. Machine

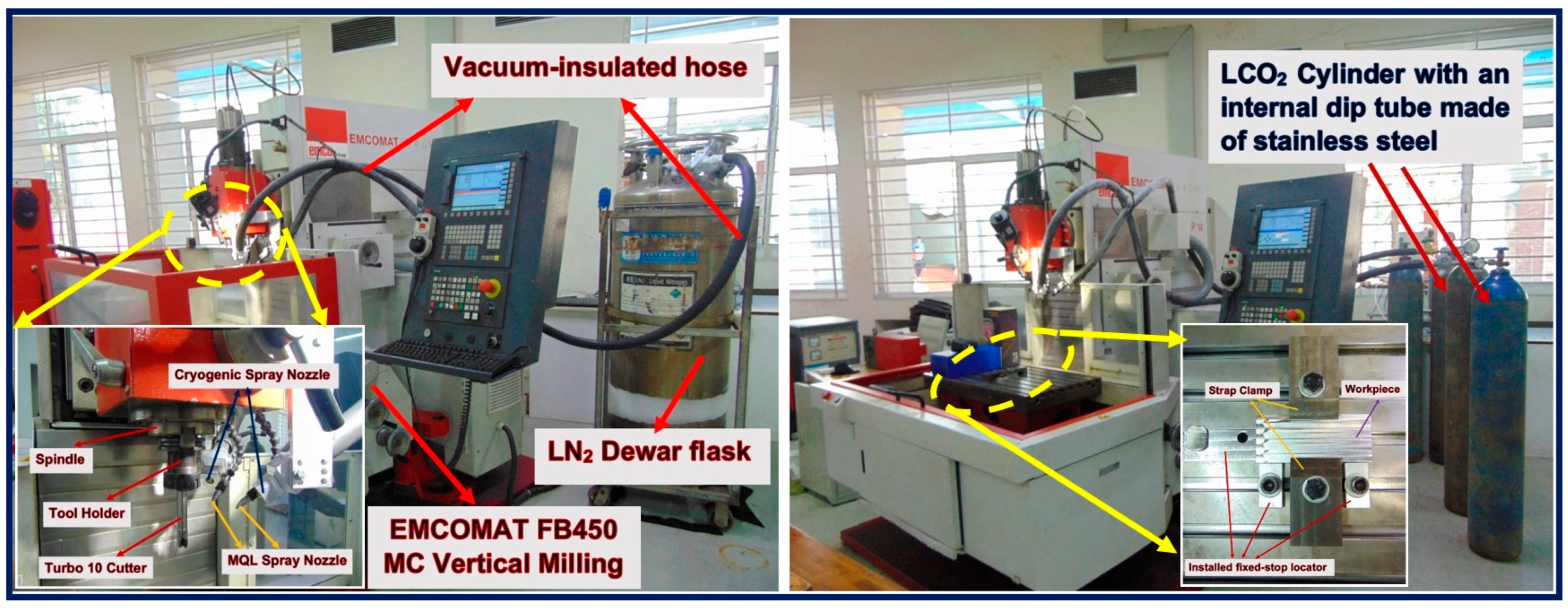

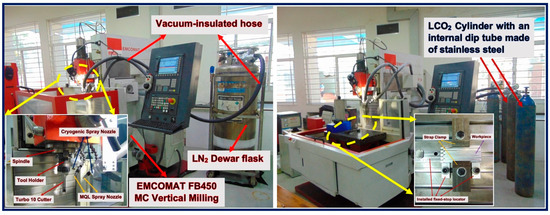

Open-slot finishing operations were performed using an EMCOMAT FB 450 MC vertical milling machine (EMCO GmbH, Hallein, Austria), equipped with a 10 kW motor and a maximum spindle speed of 5000 rpm. The worktable measures 800 × 400 mm and supports workpieces up to 150 kg. Based on prior studies and manufacturer guidelines, the machining parameters were standardized across all experiments: cutting depth (ap) was set to 0.3 mm, cutting feed (F) to 98.45 mm per minute, and cutting speed (V) to 45 m per minute [39,45,46,47,48]. Figure 2 outlines the preparation stages.

Figure 2.

Experimental setup showing the delivery systems for liquid nitrogen (LN2) and liquid carbon dioxide (LCO2), as well as hybrid configurations combining minimum quantity lubrication (MQL) with cryogenic cooling using LN2 and LCO2. The overall setup also includes the milling machine and workpiece fixture.

2.2.2. Dry Milling

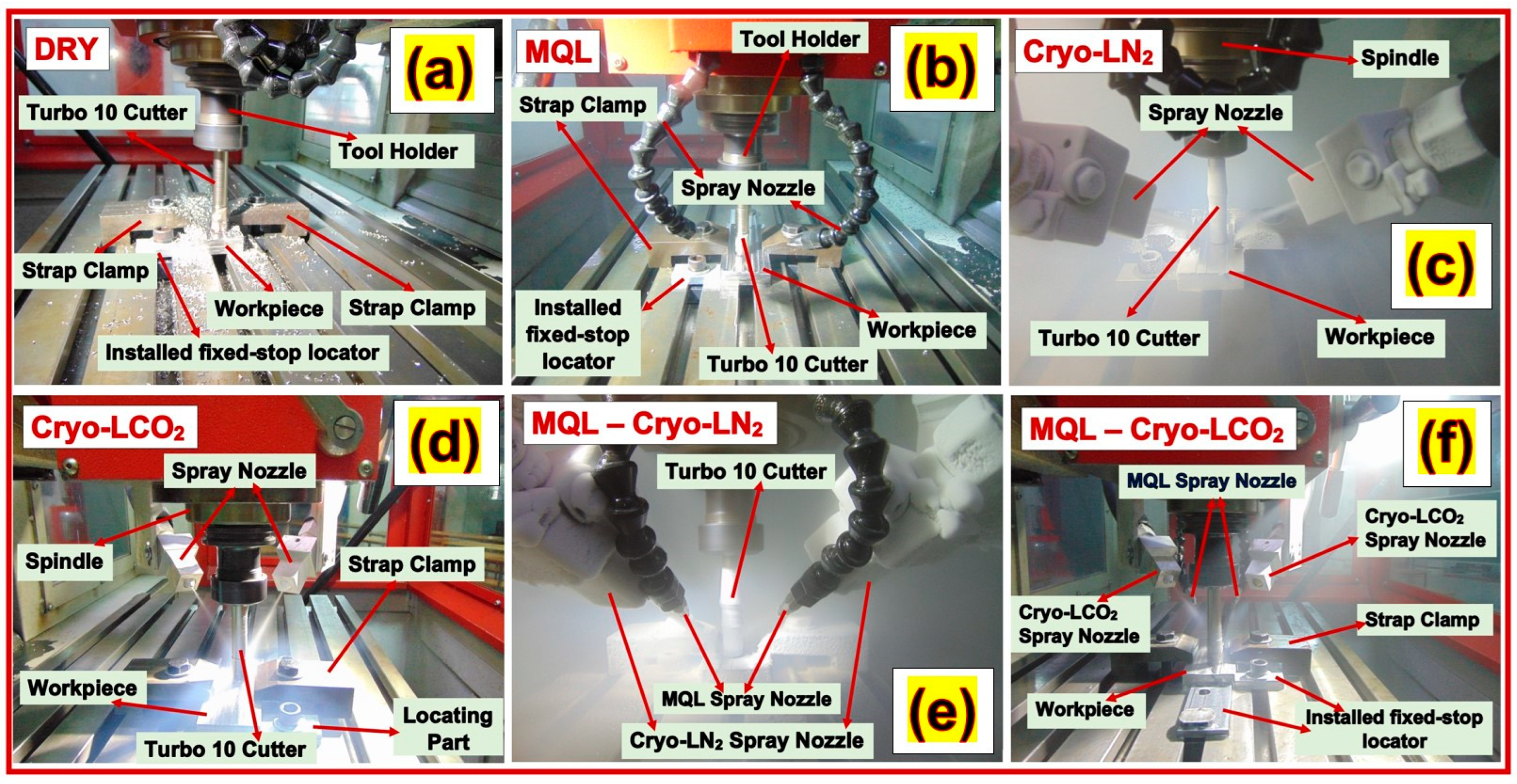

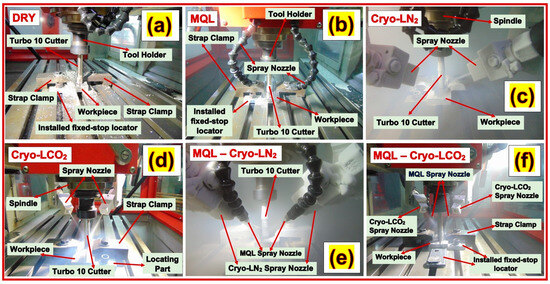

Dry milling was conducted without fluid application to observe tool wear and surface response under unlubricated conditions. The process settings followed prior studies and manufacturer recommendations. Figure 3a illustrates the experimental setup.

Figure 3.

Open-slot finishing milling under six machining environments: (a) dry machining, (b) minimum quantity lubrication (MQL), (c) cryogenic cooling with liquid nitrogen (Cryo-LN2), (d) cryogenic cooling with liquid carbon dioxide (Cryo-LCO2), (e) hybrid cooling using MQL combined with Cryo-LN2, and (f) hybrid cooling using MQL combined with Cryo-LCO2. Each subfigure illustrates the machine–tool setup and nozzle orientation specific to the respective cooling or lubrication method.

2.2.3. Minimum Quantity Lubrication (MQL)

An external MQL system (SKF Vario, Schweinfurt, Germany) was integrated into the milling platform. Pure coconut oil was supplied from a 500-milliliter reservoir and applied through two 2 mm nozzles at 3 bar pressure, delivering 200 milliliters per hour directly to the cutting zone. Nozzles were placed 85 mm from the cutting area at a 45-degree angle. Air pressure and flow rates were adjustable between 1 and 4 bar and 1 and 10 milliliters per minute, respectively. Figure 3b illustrates the MQL setup during open-slot finishing.

2.2.4. Cryogenic Cooling (Cryo-LN2 and Cryo-LCO2)

Liquid nitrogen and liquid carbon dioxide were introduced as cryogenic coolants. LN2 was delivered from a Taylor Wharton XL-45 tank via vacuum-insulated hoses to two 3 mm nozzles at 2.88 MPa. LCO2 was applied under similar configurations. Both nozzle systems were positioned 115 mm from the cutting zone at a 45-degree angle, operating at 2.5 bar pressure. Figure 3c,d illustrate the Cryo-LN2 and Cryo-LCO2 setups.

2.2.5. Hybrid MQL–Cryogenic Cooling (MQL–Cryo-LN2 and MQL–Cryo-LCO2)

Hybrid cooling strategies combined MQL and cryogenic fluids. LN2 and LCO2 were supplied through vacuum-insulated hoses to 3 mm nozzles under 2.5 bar pressure. MQL nozzles, delivering pure coconut oil at 3 bar and 200 milliliters per hour, were placed 85 mm from the cutting zone, while cryogenic nozzles were positioned 115 mm away. Both systems operated concurrently, as illustrated in Figure 3e,f.

2.3. Input Parameters and Experimental Methodology

Each experiment was conducted using a Turbo 10 square shoulder and slot milling cutter fitted with two new inserts. A single experiment involved one open-slot cycle of 240 mm in length and 0.3 mm depth. The process was executed using Siemens software version 828 V 02.60.44.00 with a down-cut single position strategy optimized for base finishing. Table 3 and Table 4 summarize the input parameters and experimental runs.

Table 3.

Experimental input variables and their specifications.

Table 4.

Experimental cutting parameters for Hastelloy C276: cutting speed (V) = 45 m/min, cutting feed (F) = 98.45 mm/min, and depth of cut = 0.3 mm.

2.4. Tools for Assessing Output Responses

2.4.1. Process Parameters

Cutting Zone Temperature

During open-slot finishing milling, the cutting zone temperature was measured in the final cutting cycle (e.g., the fifth slot of Experiment 5). A TG275 Flir thermal camera (Teledyne FLIR Commercial Systems, Taipei City, Taiwan) was positioned 300 mm from the work surface to record real-time temperature data. The camera offered a 19,200-pixel thermal resolution, an operational range from −25 °C to 550 °C, and a 320 × 240-pixel image resolution. These specifications ensured reliable monitoring of thermal behavior.

2.4.2. Cutting Tool Performance

Wear Characteristics

Tool wear in Experiment 5 was evaluated using a HITACHI TM4000Plus scanning electron microscope (Tokyo, Japan) with magnification up to 100,000 times, and a Bruker QUANTAX 75 energy dispersive X-ray spectroscopy unit (Bruker Nano GmbH, Berlin, Germany) for elemental analysis. A HITACHI S-4800 microscope (with magnification ranging from 20 to 800,000 times) was used for wear evaluation across all trials under uniform cooling and lubrication settings. Flank wear (VBmax) was measured according to ISO 3685:1993 [23,46,49,50].

Surface Finish (Ra)

A Mitutoyo SJ 210 roughness tester (Mitutoyo Corporation, Kawasaki, Japan) was used to assess surface quality. The measurements followed ISO 1997 guidelines [51] with a 0.8 mm cutoff length, a 7.2 mm evaluation span, and a traversal speed of 0.5 mm per second. Average Ra values were calculated from readings at nine surface positions.

2.4.3. Material Properties

Chip Morphology

Various chip types, including continuous, segmented, discontinuous, and lamellar forms, were investigated under different cooling and lubrication conditions. The analysis was conducted using the HITACHI S-4800 scanning electron microscope (SEM) (Hitachi High-Technologies Corporation, Tokyo, Japan), which provides detailed imaging of chip characteristics produced during machining.

Microhardness Evaluation

Surface microhardness was measured using an STCMC tester (STC (Guangdong) Company Limited, Dongguan, China) applying a load of 60 kg-force (588 newtons) for 10 s. Measurements were taken at three locations spaced 50 mm apart and oriented perpendicular to the machined surface. The average value was used for comparison.

3. Results and Discussions

3.1. Cutting Zone Temperature

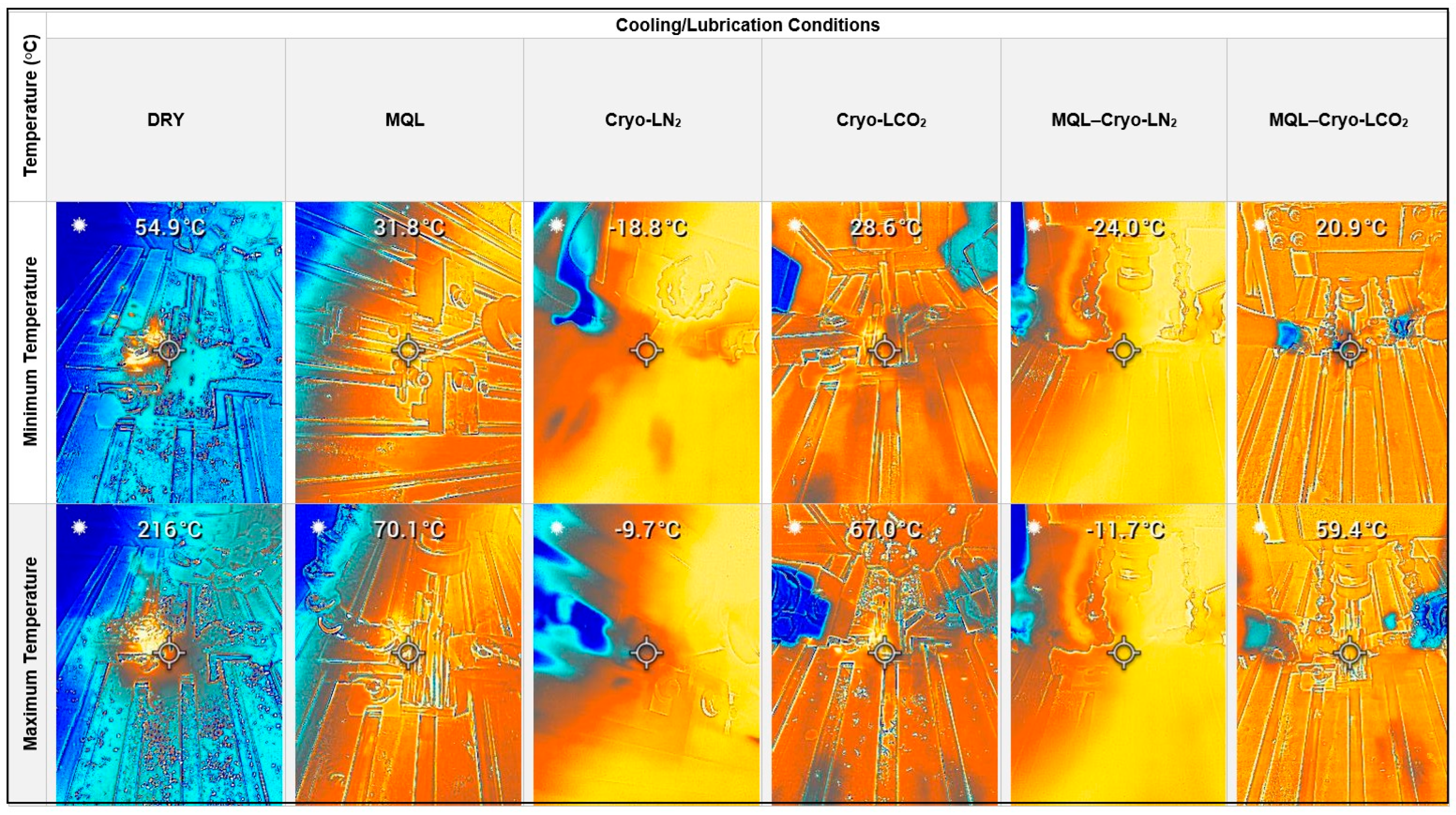

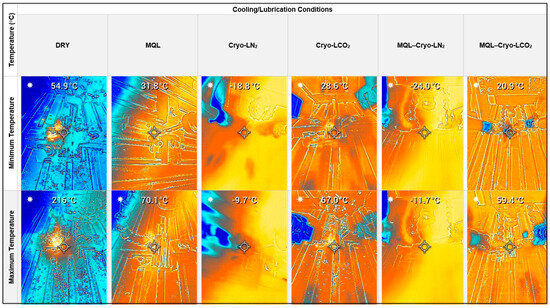

Thermal conditions in machining significantly impact tool life, chip morphology, and dimensional precision. Excessive heat promotes built-up edge formation, chip shrinkage, and post-machining surface hardening, particularly when machining difficult-to-cut materials like Hastelloy C276. Dry cutting amplifies these effects due to increased friction, accelerating tool degradation and reducing surface quality. Cooling and lubrication methods aim to mitigate thermal accumulation and improve process stability [51]. These thermal effects also influence cutter geometry, surface integrity, and machining productivity. Figure 4 illustrates temperature variations in the cutting zone during the fifth experiment for six machining environments, providing a visual benchmark of thermal mitigation strategies through thermal maps captured via infrared imaging. Real-time temperature distribution was monitored using a thermal camera to ensure accurate assessment of heat generation.

Figure 4.

Maximum and minimum cutting zone temperatures under six machining environments: dry machining, minimum quantity lubrication (MQL), cryogenic cooling with liquid nitrogen (Cryo-LN2), cryogenic cooling with liquid carbon dioxide (Cryo-LCO2), and hybrid approaches combining MQL with Cryo-LN2 and Cryo-LCO2. Thermal maps were captured using a TG275 FLIR camera with a temperature range from minus 25 degrees Celsius to 550 degrees Celsius and a thermal resolution of 19,200 pixels. Each subfigure includes a temperature value label at the top and follows the Ironbow palette: cooler areas are shown in purple and blue, while warmer zones appear in orange and white. This consistent color pattern enables visual comparison of thermal performance across machining strategies, even in the absence of embedded legends.

This study employed six cutting environments: dry, MQL with coconut oil, Cryo-LN2, Cryo-LCO2, MQL–Cryo-LN2, and MQL–Cryo-LCO2. A thermal camera was used to record temperature distributions during the fifth experiment, which involved five open-slot milling cycles. Each cycle was conducted at a 45 m per minute cutting speed, a 98.45 mm per minute feed, and a consistent 0.3 mm depth of cut, totaling a length of 1200 mm and a final depth of 1.5 mm.

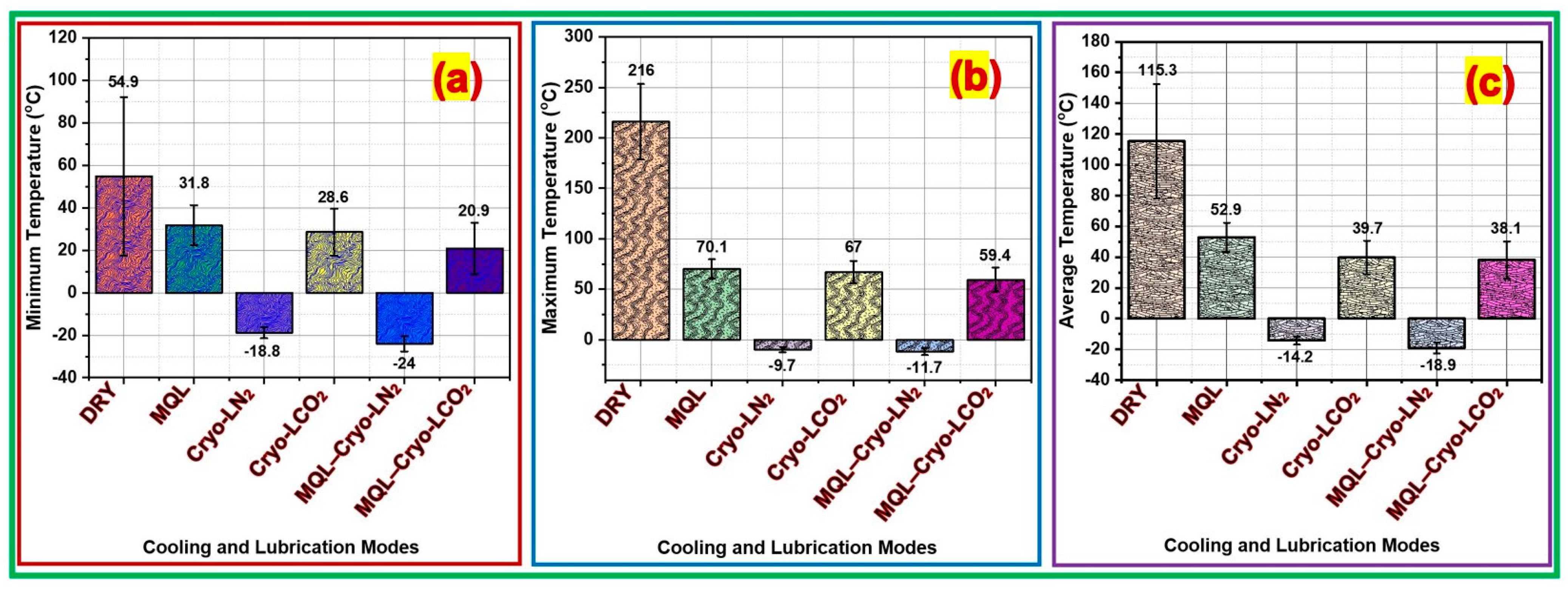

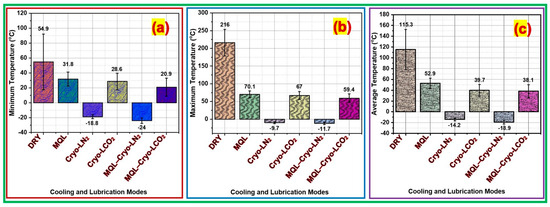

Figure 5a–c summarize the temperatures across these conditions. The average temperature reductions compared to dry machining were 54.1% (MQL), 112.3% (Cryo-LN2), 65.5% (Cryo-LCO2), 116.4% (MQL–Cryo-LN2), and 66.9% (MQL–Cryo-LCO2). Maximum temperature reductions followed similar trends, with the greatest thermal suppression observed under Cryo-LN2 and MQL–Cryo-LN2. These results illustrate the superior cooling capabilities of cryogenic and hybrid strategies in reducing thermal load at the tool–chip interface. Notably, under dry machining, peak temperatures reached 281 °C, underscoring the thermal challenges when cutting without lubrication.

Figure 5.

Column plots showing cutting zone temperatures under six machining environments: (a) minimum temperature, (b) maximum temperature, and (c) average temperature. Each column includes standard deviation error bars to indicate variability across trials under dry machining, minimum quantity lubrication (MQL), and cryogenic cooling with liquid nitrogen (Cryo-LN2) and liquid carbon dioxide (Cryo-LCO2), as well as hybrid combinations of MQL with Cryo-LN2 and Cryo-LCO2.

Dry machining produced the highest thermal stress, as evidenced by chip discoloration and insert wear. Cryogenic fluids like LN2 and CO2, maintained at sub-zero temperatures, absorb heat through evaporation, preventing localized overheating and minimizing thermal damage to tools [52]. However, cryogenic methods alone lack lubrication, which may reduce their effectiveness in controlling wear.

Hybrid systems address this by combining cryogenic cooling with MQL lubrication, forming a temporary thermal barrier at the interface and improving heat dissipation [29]. The presence of vegetable-based lubricants further aids thermal control by generating thin protective tribofilms that reduce friction and slow temperature rise [2]. Konya et al. [34] reported that hybrid MQL–Cryo strategies lowered interface temperatures more effectively than stand-alone cryogenic cooling.

Collectively, the findings confirm that hybrid MQL–Cryo approaches deliver the most effective temperature control in machining Hastelloy C276, contributing to better surface integrity, reduced tool wear, and improved sustainability in precision manufacturing.

3.2. Tool Wear

During machining, the cutting tool is subjected to severe mechanical and thermal stresses, including deformation, friction, and compressive loads, which progressively lead to wear, particularly on the rake and flank surfaces. Key wear mechanisms include abrasion, adhesion, tribo-oxidation, diffusion, and fatigue-induced damage. These phenomena, driven by high temperatures and tool–workpiece interactions, collectively influence tool life and machining efficiency [1].

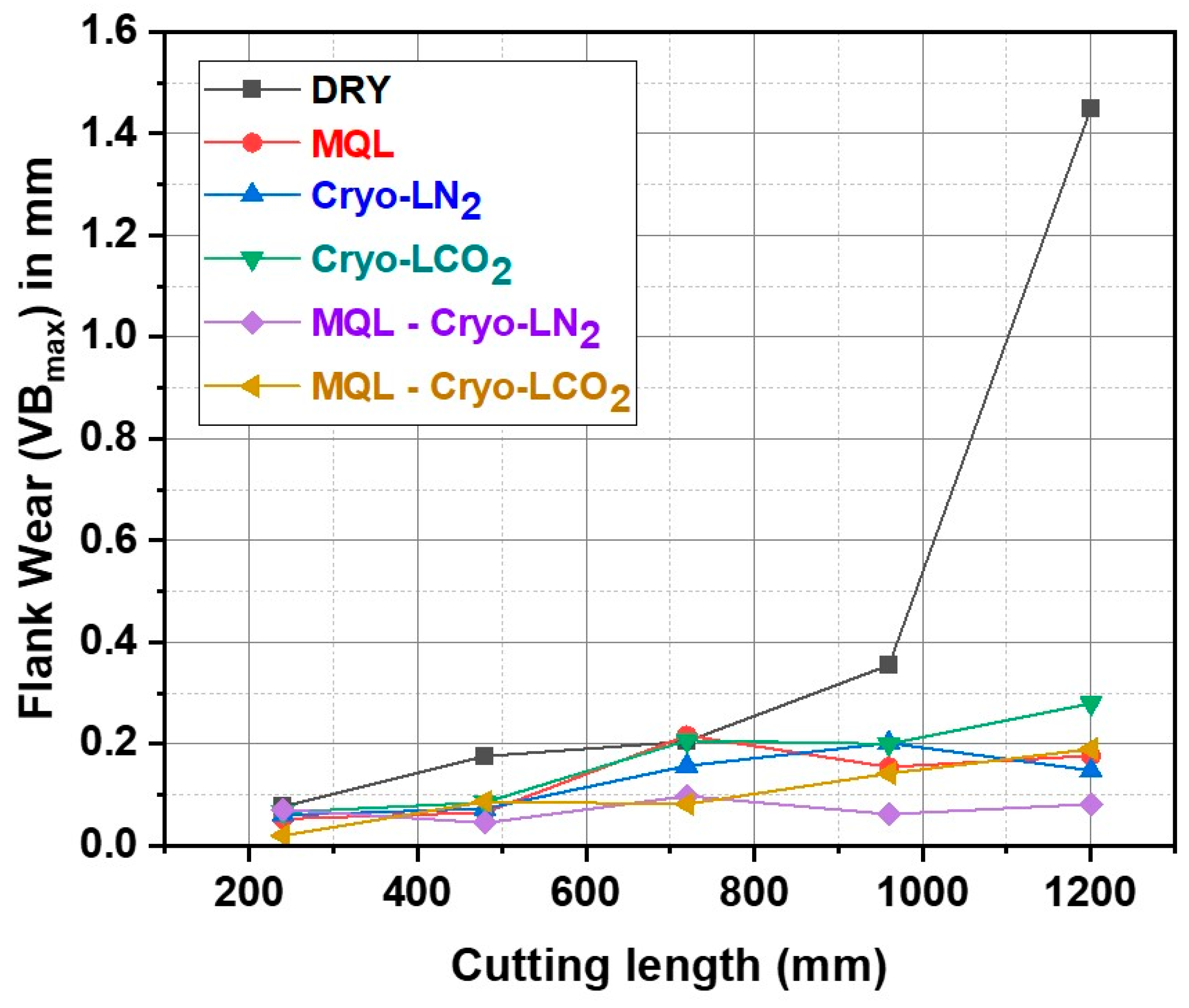

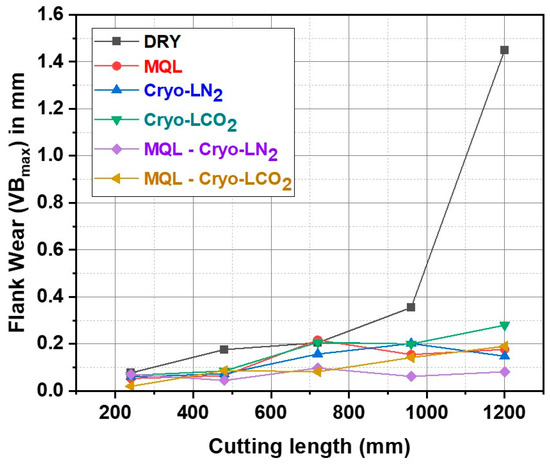

This study evaluated flank and rake wear progression during open-slot finishing of Hastelloy C276 over five cutting lengths (240–1200 mm) under various cooling and lubrication strategies. As shown in Figure 6, the maximum flank wear (VBmax) occurred under dry machining. In contrast, significantly lower wear values were observed under MQL, cryogenic, and hybrid cooling conditions. Quantitative analysis of tool flank wear revealed substantial differences between machining conditions. The measured values were 1.45 mm for dry machining, 0.177 mm under MQL, 0.148 mm for Cryo-LN2, 0.28 mm for Cryo-LCO2, 0.082 mm under hybrid MQL with LN2, and 0.19 mm under hybrid MQL with LCO2. These results demonstrate the superior wear-reducing capability of the hybrid MQL with LN2 strategy compared to all other environments. The process was halted once 1200 mm was reached or when tool wear exceeded 0.3 mm, ensuring consistent evaluation across trials. The hybrid MQL with liquid nitrogen configuration provided the greatest reduction in tool degradation, lowering flank wear by 94.34 percent compared to dry cutting, 53.67 percent relative to MQL, 44.59 percent compared to liquid nitrogen alone, 70.71 percent against carbon dioxide cooling, and 56.85 percent relative to hybrid MQL with carbon dioxide.

Figure 6.

Variation in maximum flank tool wear (VBmax) across five experimental trials during open-slot finishing under different cooling and lubrication conditions.

Relative to dry machining, the reduction in flank wear was 87.79% (MQL), 89.79% (Cryo-LN2), 80.68% (Cryo-LCO2), 94.34% (MQL–Cryo-LN2), and 86.89% (MQL–Cryo-LCO2). MQL–Cryo-LN2 exhibited the strongest wear mitigation, followed by Cryo-LN2 and MQL. The coconut oil used in MQL contributed to these results through its high oxidation stability (35.4 h at 100 °C) and flash point (325 °C) [53], allowing it to form a durable lubricating film that reduces friction and surface damage.

In contrast, Cryo-LCO2 provides efficient cooling via rapid sublimation but lacks inherent lubricity, limiting its ability to reduce wear independently or in hybrid applications. The intense cooling effect may also disrupt the film formation of coconut oil in MQL–Cryo-LCO2 setups, slightly diminishing effectiveness. By comparison, Cryo-LN2 establishes a low-temperature environment that minimizes thermal stress. When combined with MQL, the hybrid approach leverages both strong cooling and reliable lubrication, yielding superior performance in reducing tool wear.

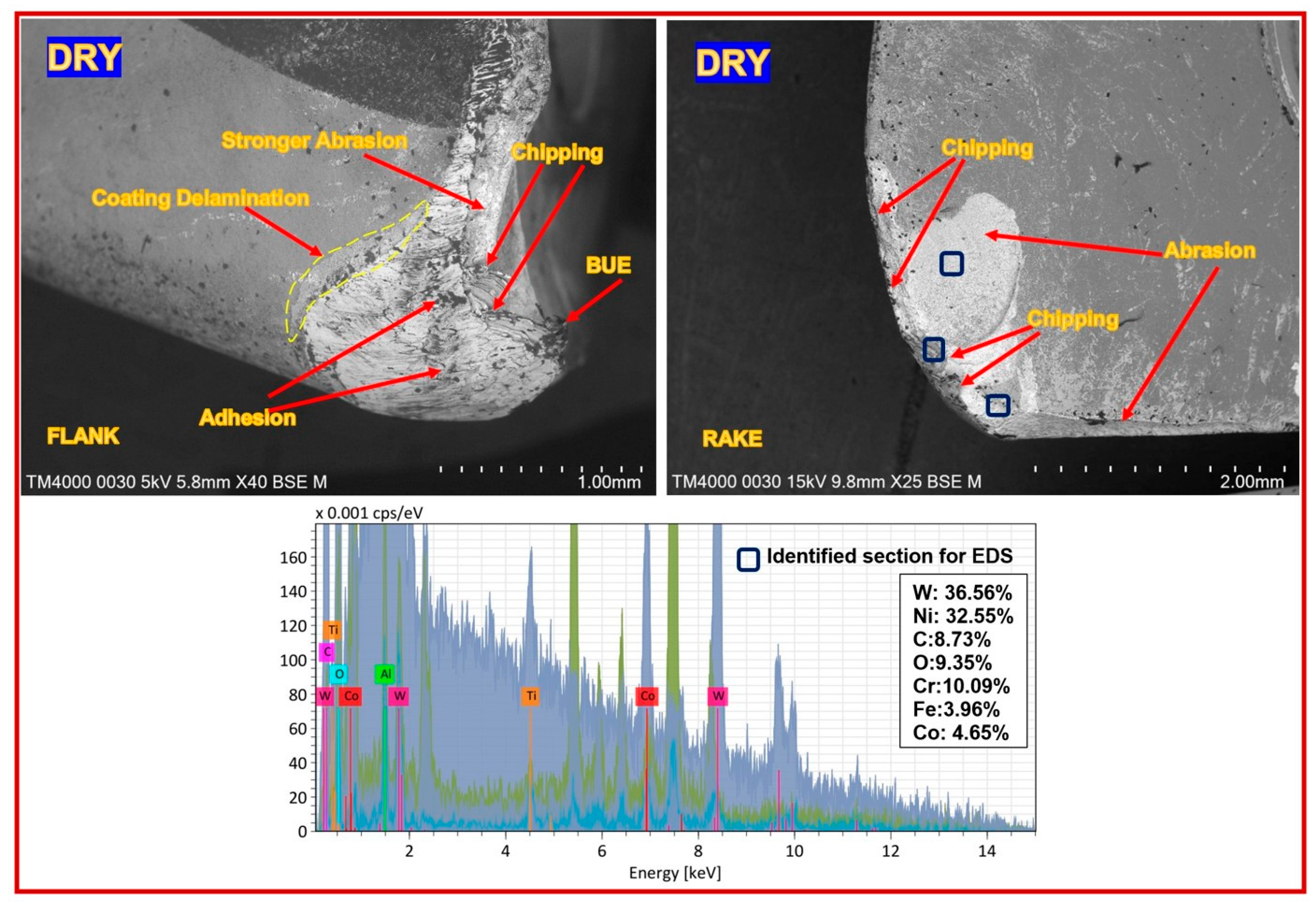

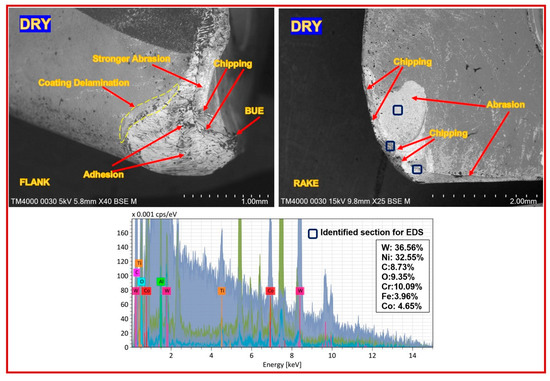

Figure 7 presents the primary wear mechanisms observed during dry machining, which include adhesive wear, oxidative degradation, and abrasive wear. Each of these mechanisms significantly affects tool performance and durability. Adhesive wear is predominant, as evidenced by the transfer of nickel (32.55 percent) and chromium (10.09 percent) from the workpiece to the tool, promoting strong material adhesion that accelerates surface deterioration. This leads to coating removal and exposure of the underlying carbide substrate, intensifying wear through continued interfacial bonding. Oxidative degradation results from elevated thermal exposure, where oxygen (9.35 percent) interaction weakens the surface integrity of the tool material, particularly in the absence of lubrication. Abrasive wear is also confirmed through the gradual depletion of TiSiN and TiAlN coatings, supported by EDS detection of tungsten (36.56 percent) and cobalt (4.65 percent), indicating direct contact with the tool substrate. These mechanisms reveal a sequential progression of wear that begins with adhesion, advances through oxidation, and leads to abrasion, particularly during the machining of work-hardened superalloys such as Hastelloy C276. This wear evolution is further illustrated by built-up edge formation and thin adhered layers on the rake and flank surfaces, which affect thermal conductivity and contribute to variations in tool behavior and wear severity during operation [7,45].

Figure 7.

SEM and EDS analysis of cutter surfaces after dry machining, performed at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

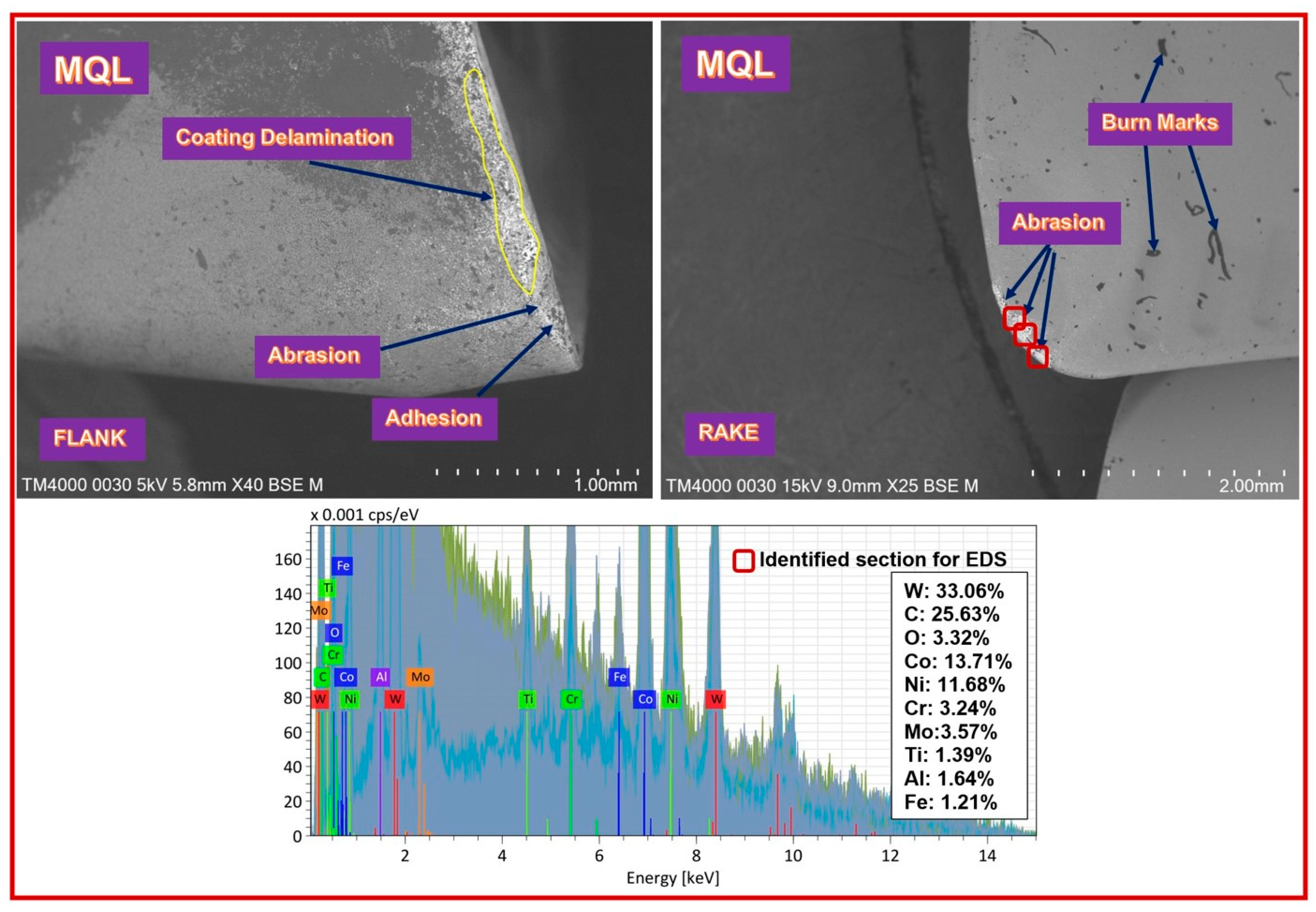

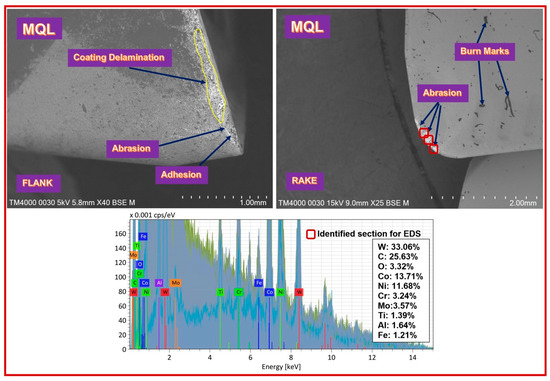

Figure 8 reveals the dominant wear mechanisms under MQL machining with pure coconut oil during open-slot finishing of Hastelloy C276. The primary wear types observed include adhesion, oxidation, and abrasion, each contributing differently to tool degradation. Adhesive wear is substantiated by the transfer of nickel (11.68 percent), chromium (3.24 percent), and molybdenum (3.57 percent) from the workpiece to the cutting tool, indicating localized bonding and material accumulation. This transfer promotes built-up edge formation and interrupts smooth chip flow. Oxidation is supported by the presence of oxygen (3.32 percent), suggesting thermal degradation of the coating surface due to insufficient cooling in high contact zones. Although coconut oil provides both lubrication and cooling, it does not fully prevent heat buildup, allowing oxidation to persist. Abrasive wear is evident from the detection of tungsten (33.06 percent) and cobalt (13.71 percent), confirming coating loss and substrate exposure caused by interaction with hard work-hardened chips. These mechanisms are further influenced by the tribological environment and the high work hardening tendency of Hastelloy C276, which intensifies adhesion at the nose of the insert while leaving the flank relatively intact. Compared with previous findings using other vegetable oils [6], coconut oil shows good lubrication but still permits moderate adhesive and oxidative wear due to its limited oxidative stability. These findings point to a critical limitation in using pure coconut oil as a lubricant in sustained MQL operations involving Hastelloy C276. Therefore, future studies should explore the effect of hybrid lubricants or additives designed to improve oxidation resistance and thermal regulation. Moreover, optimizing MQL flow parameters may help achieve a more uniform temperature field, thereby minimizing localized overheating and extending tool life. Overall, the interaction of thermal stress, chip morphology, and lubrication limits results in a transitional wear pattern dominated by adhesion and oxidation, with abrasion emerging through chip contact and coating failure.

Figure 8.

SEM and EDS analysis of cutter surfaces after machining with minimum quantity lubrication (MQL) using pure coconut oil, conducted at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

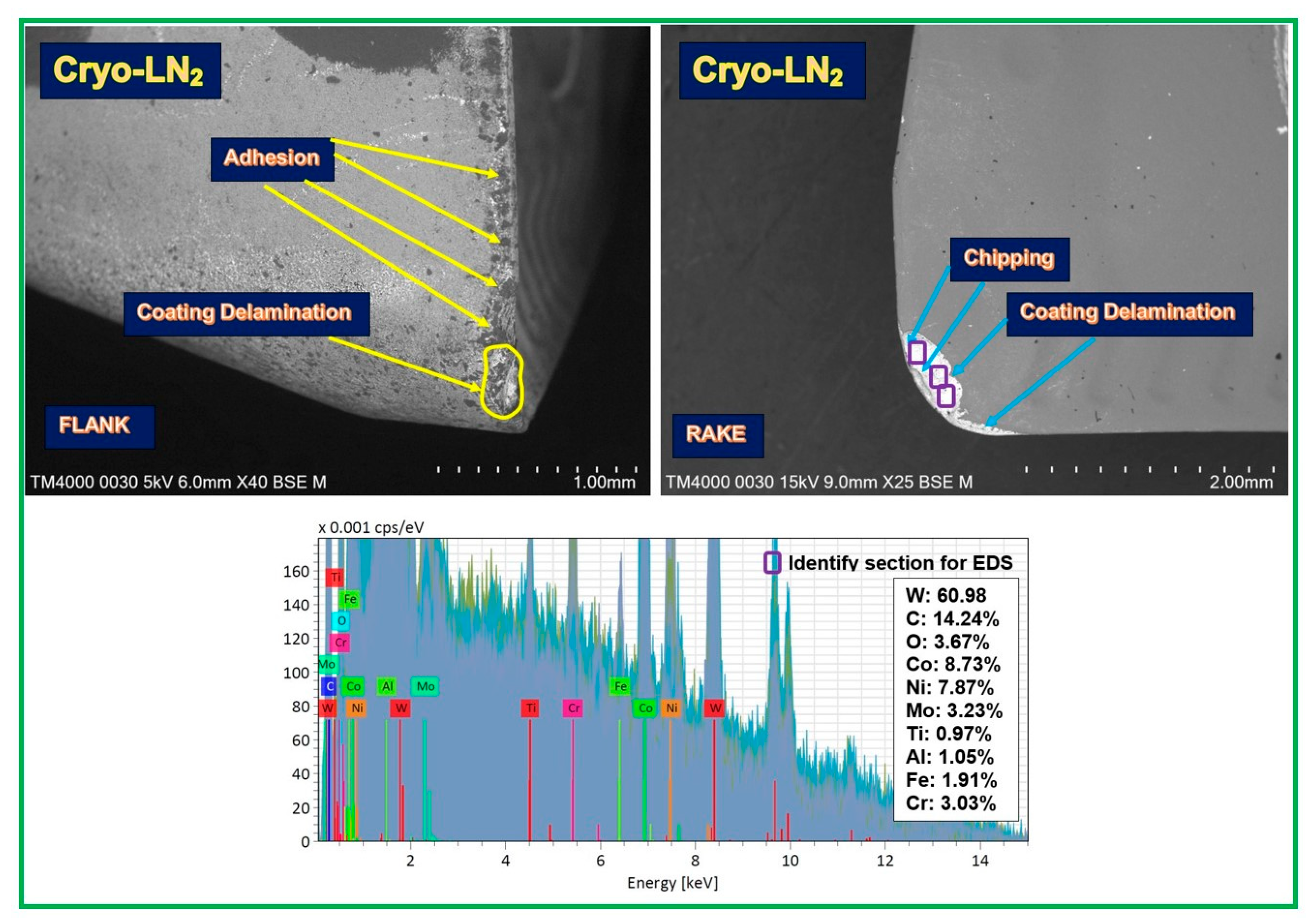

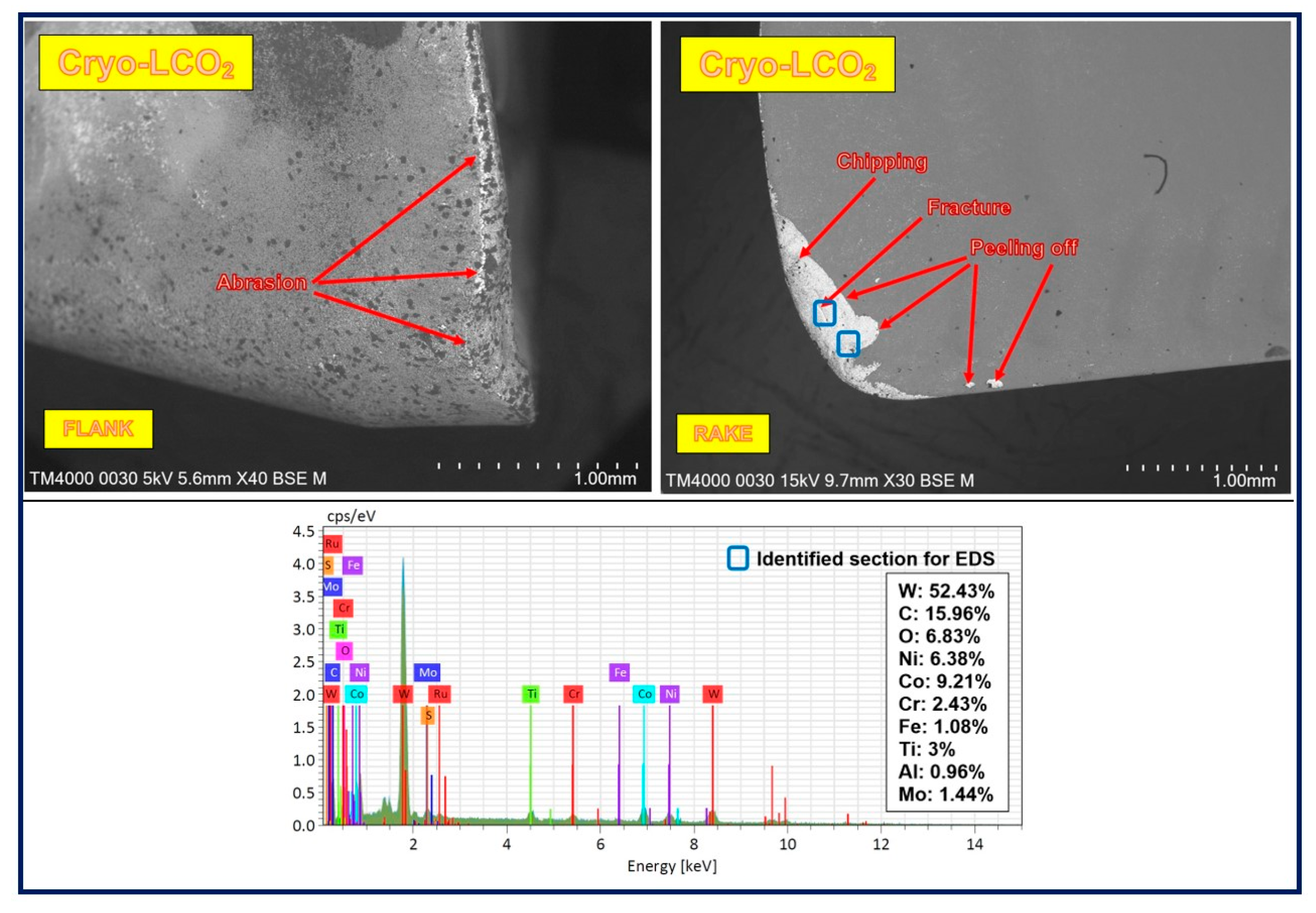

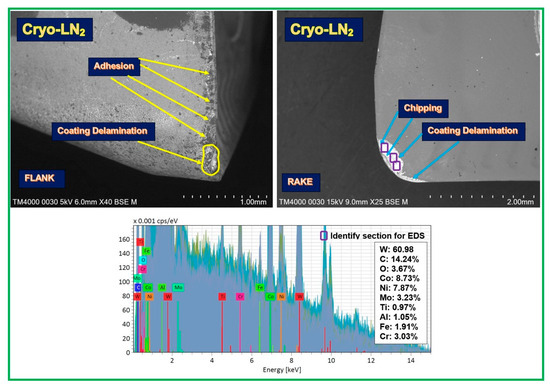

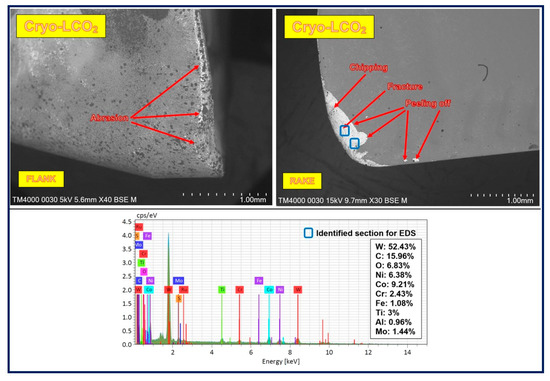

Figure 9 and Figure 10 present the wear mechanisms observed during open-slot milling of Hastelloy C276 under cryogenic cooling using LN2 and LCO2. The primary wear behaviors include oxidation, adhesion, and coating degradation, shaped by the altered thermal conditions and tribological dynamics introduced by cryogenic fluid. In Cryo-LN2 machining, oxygen (3.67 percent) and nickel (7.87 percent) content detected by EDS indicate oxidative film formation and material transfer from the workpiece. Although LN2 significantly reduces cutting temperature, it does not fully eliminate thermal activation at the tool interface. In Cryo-LCO2 machining, a higher oxygen level (6.83 percent) and comparable nickel presence (6.38 percent) imply a stronger oxidation tendency. In both conditions, high tungsten levels (60.98 percent for LN2 and 52.43 percent for LCO2) and cobalt readings reflect substantial coating removal and substrate exposure. Adhesive wear is driven by bonding of chromium, molybdenum, and cobalt to the tool surface, linked to the workpiece’s hardening behavior and localized heat spikes. Molybdenum may further contribute to diffusion wear where thermal gradients accelerate elemental migration. Abrasive effects, though less prominent, are suggested by scattered coating fragments that may result from impact loads near the contact zone. The cryogenic fluids alter chip formation and adhesion dynamics, and the coolant’s delivery precision significantly influences wear severity. Prior work by Ross et al. [45] showed that cryogenic carbon dioxide affects adhesion intensity based on its thermal dissipation behavior, while Gupta et al. [30] and Yildirim et al. [39] confirmed the coexistence of adhesive and abrasive effects under cryogenic machining. Despite improved thermal control, the presence of oxide films and workpiece alloy residues underscores the need for optimized fluid flow and nozzle design to suppress wear progression and protect the tool substrate.

Figure 9.

SEM and EDS characterization of cutter surfaces following Cryo-LN2 cooling, carried out at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

Figure 10.

SEM and EDS analysis of cutter surfaces after Cryo-LCO2 cooling, performed at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

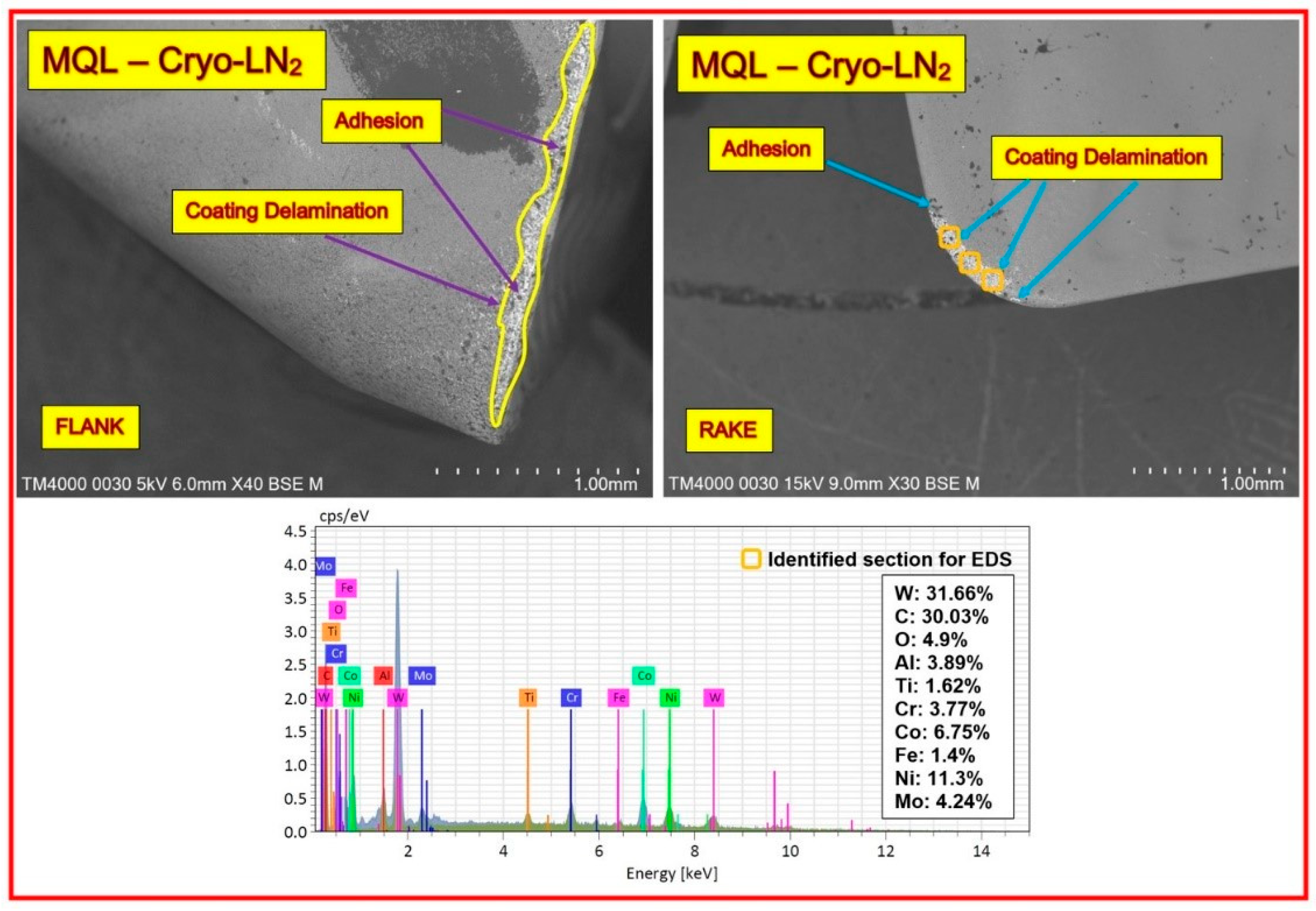

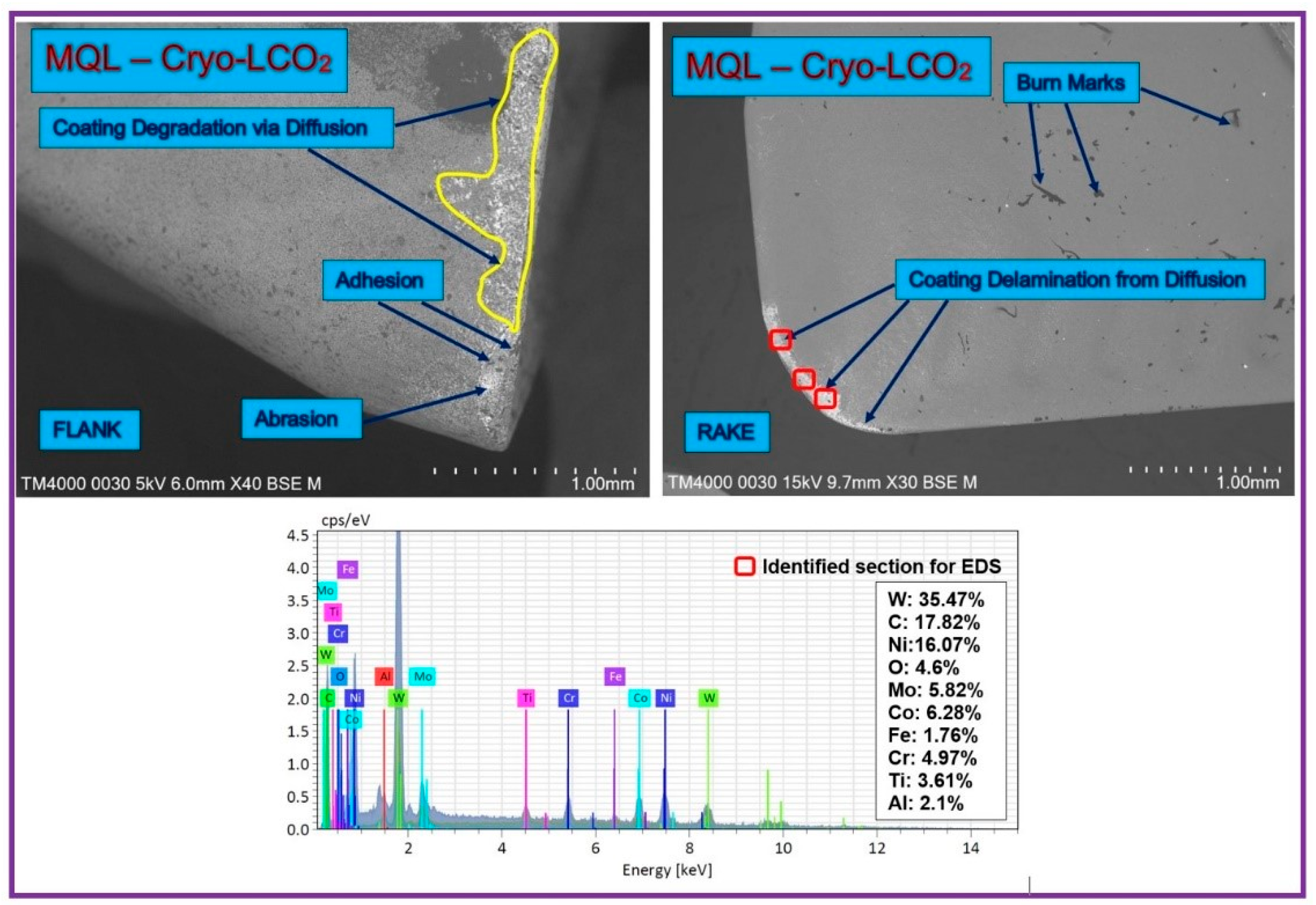

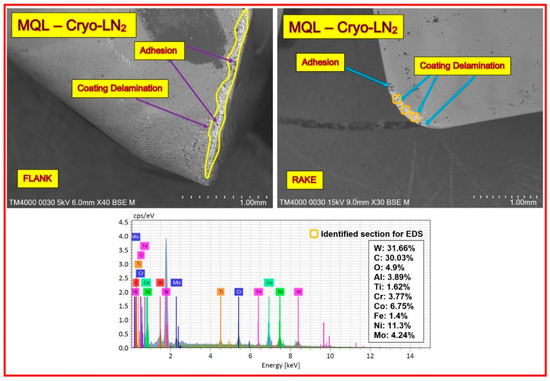

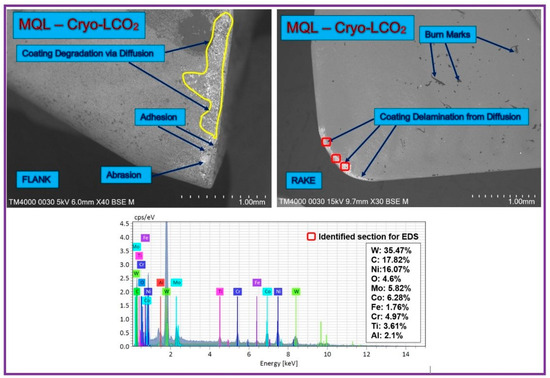

Figure 11 and Figure 12 show the wear mechanisms observed under hybrid lubrication strategies combining minimum quantity lubrication with pure coconut oil and cryogenic cooling using LN2 or LCO2 during open-slot milling of Hastelloy C276. In both MQL–Cryo-LN2 and MQL–Cryo-LCO2 conditions, adhesion remains the dominant wear mechanism, supported by EDS data indicating the transfer of workpiece elements such as nickel (11.3 percent for LN2, 16.07 percent for LCO2), cobalt, chromium, and molybdenum onto the tool surface. These elements accumulate due to strong bonding at the chip–tool interface, intensified by Hastelloy C276’s high toughness and work hardening behavior. Although cryogenic fluids reduce cutting temperature and coconut oil promotes tribological film formation, oxygen is still present (4.9 percent for LN2 and 4.6 percent for LCO2), revealing that oxidative degradation remains active in regions with prolonged tool contact or limited coolant access. The presence of tungsten (31.66 percent for LN2 and 35.47 percent for LCO2) and cobalt indicates partial coating erosion and exposure of the tool substrate. SEM inspection also reveals built-up edge and built-up layer formations consistent with adhesive layer accumulation. These findings are aligned with those of Danish et al. [29], who confirmed adhesion as a primary wear mode in Cryo-MQL conditions, and Gupta et al. [30], who emphasized the stabilizing role of cryogenic cooling on oil film thickness and thermal effects. Additionally, our results support observations by Yildirim et al. [39], who noted the persistence of adhesion in hybrid environments regardless of fluid type. While cryogenic cooling enhances lubrication and thermal stability compared to MQL alone, intermittent oxidation and micro-abrasive effects are still observed, evidenced by gradual coating loss and retention of essential elements like tungsten, chromium, and molybdenum. This supports Ross et al. [45], who highlighted the complex thermal interactions between cryogenic coolants and tool coatings. Overall, although hybrid cooling improves surface protection and tool lifespan, the coexistence of adhesion, oxidation, and minor abrasion emphasizes the need for further refinement in coolant flow rate and tribofilm optimization to fully suppress wear progression in nickel-based alloy machining.

Figure 11.

SEM and EDS investigation of cutter surfaces subjected to hybrid cooling using MQL with coconut oil and Cryo-LN2, conducted at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

Figure 12.

SEM and EDS analysis of cutter surfaces under hybrid cooling with MQL using coconut oil and Cryo-LCO2, at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

The SEM observations, as presented in Figure 7, Figure 8, Figure 9, Figure 10, Figure 11 and Figure 12, show typical features of adhesive and abrasive wear on the worn cutting tools. Corresponding EDS results from the same figures confirm oxygen enrichment in the affected areas, supporting the identification of oxidative wear phenomena. Specifically, oxygen content on the worn surfaces was measured as follows: 9.35 at.% in dry machining, 6.83 at.% under carbon dioxide cooling, 4.9 at.% for minimum quantity lubrication with liquid nitrogen, 4.6 at.% for minimum quantity lubrication with carbon dioxide, 3.67 at.% under liquid nitrogen, and 3.32 at.% for minimum quantity lubrication. These results indicate that oxidative wear occurred under all machining conditions, with higher oxygen levels observed in settings involving greater thermal exposure.

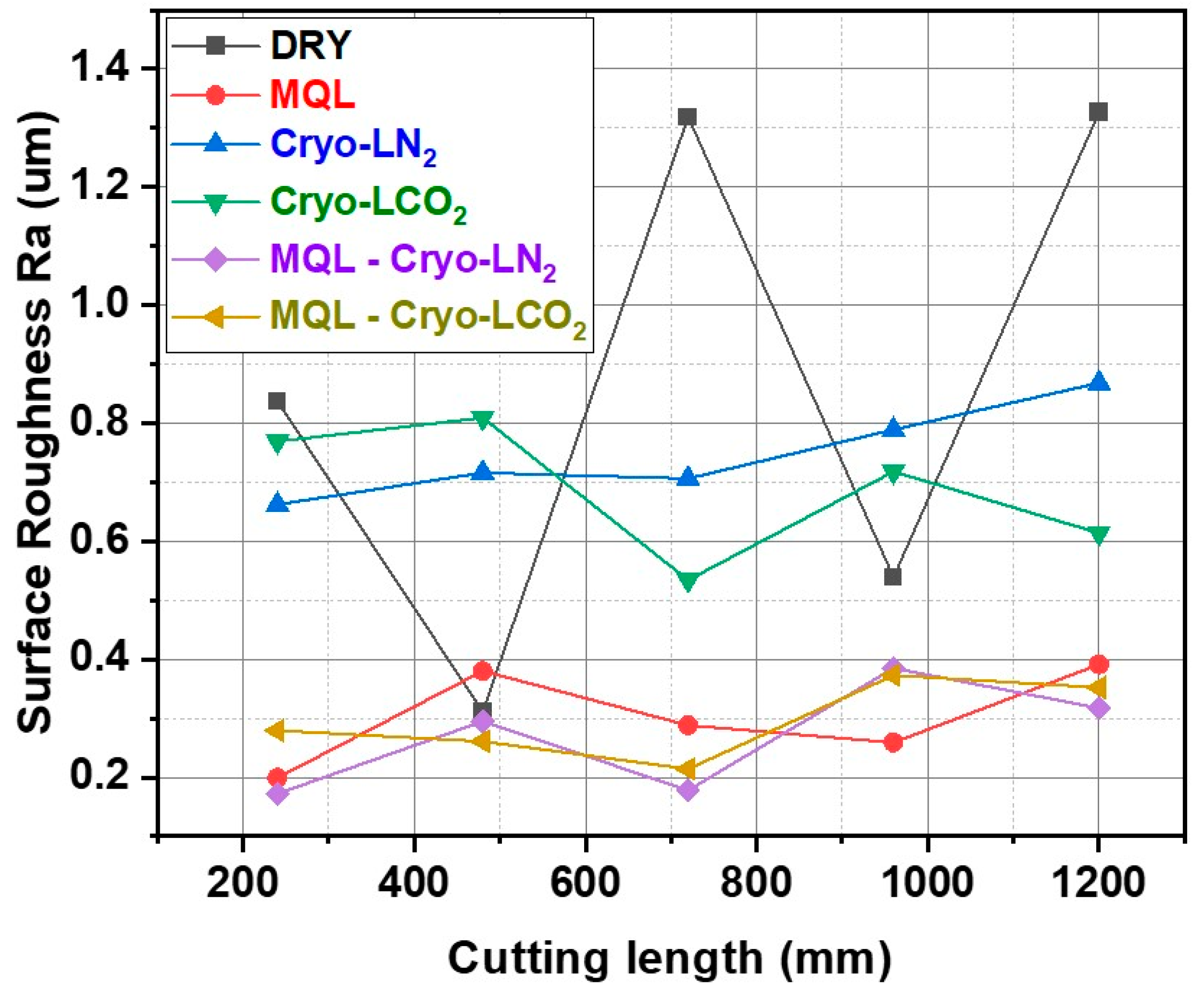

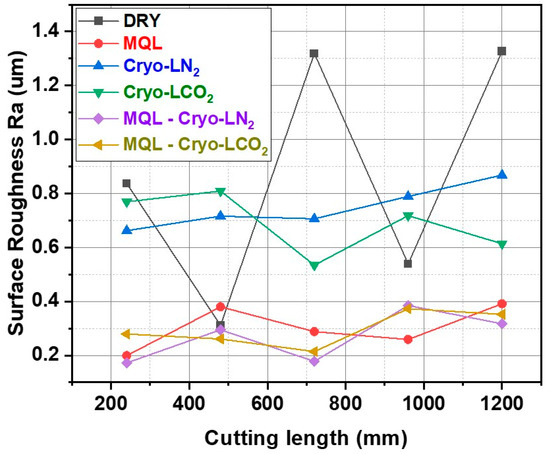

3.3. Surface Roughness Ra

Figure 13 displays the measured surface roughness (Ra) during open-slot finishing of Hastelloy C276 under six different cooling and lubrication strategies: dry machining, MQL, Cryo-LN2, Cryo-LCO2, MQL–Cryo-LN2, and MQL–Cryo-LCO2. Hybrid MQL–Cryo-LN2 achieved the smoothest surfaces, followed by MQL–Cryo-LCO2 and MQL. Compared to dry cutting, surface roughness was reduced by 70.53% (MQL), 34.59% (Cryo-LN2), 50.73% (Cryo-LCO2), 76.11% (MQL–Cryo-LN2), and 73.47% (MQL–Cryo-LCO2), demonstrating the effectiveness of hybrid cooling–lubrication in enhancing surface finish. The values recorded included 1.327 µm for dry machining, 0.391 µm for MQL, 0.868 µm for Cryo-LN2, 0.614 µm for Cryo-LCO2, 0.317 µm for MQL–Cryo-LN2, and 0.352 µm for MQL–Cryo-LCO2. To deepen the interpretation of surface profiles, the analysis of surface roughness using the arithmetic average parameter (Ra) was complemented by the root mean square roughness (Rq). While Ra provides a general assessment of surface deviations, Rq offers greater sensitivity to peaks and valleys, reflecting the distribution of higher amplitude features across the machined surface. Including both indicators allows a more comprehensive evaluation of surface integrity under different cooling and lubrication strategies. This dual-parameter approach ensures that localized irregularities and broader texture variations are adequately captured and interpreted. Table 5 presents additional surface roughness metrics, including root mean square roughness (Rq ± SD), to further evaluate the consistency and quality of the machined surfaces under each cooling and lubrication strategy.

Figure 13.

Effect of cutting length on surface roughness under various cooling and lubrication setups, measured at a cutting speed of 45 m per minute and a cutting feed of 98.45 mm per minute.

Table 5.

Surface roughness (Rq ± SD) under cooling and lubrication conditions at different cutting lengths.

These improvements reflect the synergistic thermal and tribological benefits of hybrid methods. Khanna et al. [23] noted that cryogenic machining reduces tool wear and enhances surface quality, while excessive wear in dry conditions compromises the finish. Gupta et al. [54] emphasized that LN2 cooling preserves tool geometry and minimizes distortion, aligning with the observed gains under Cryo-LN2 and Cryo-LCO2 in this study. Yildirim et al. [39] further confirmed that Cryo–MQL improves surface smoothness through combined cooling and lubrication effects.

Vegetable-based MQL lubricants, such as coconut oil, offer additional advantages. Danish et al. [29] reported that these lubricants form protective surface films that reduce friction and enhance finish. This mechanism supports the current findings, where MQL and hybrid strategies significantly lowered surface roughness. The role of tribofilms in reducing tool–workpiece adhesion and mitigating wear is particularly evident under hybrid MQL–Cryo conditions. Konya et al. [55] also found that LCO2 plus MQL yields superior finishes, reinforcing the benefits of hybrid MQL–Cryo-LCO2.

Overall, optimized cooling and lubrication not only improve surface quality but also enhance energy efficiency, reduce tool degradation, and support sustainable machining of advanced superalloys.

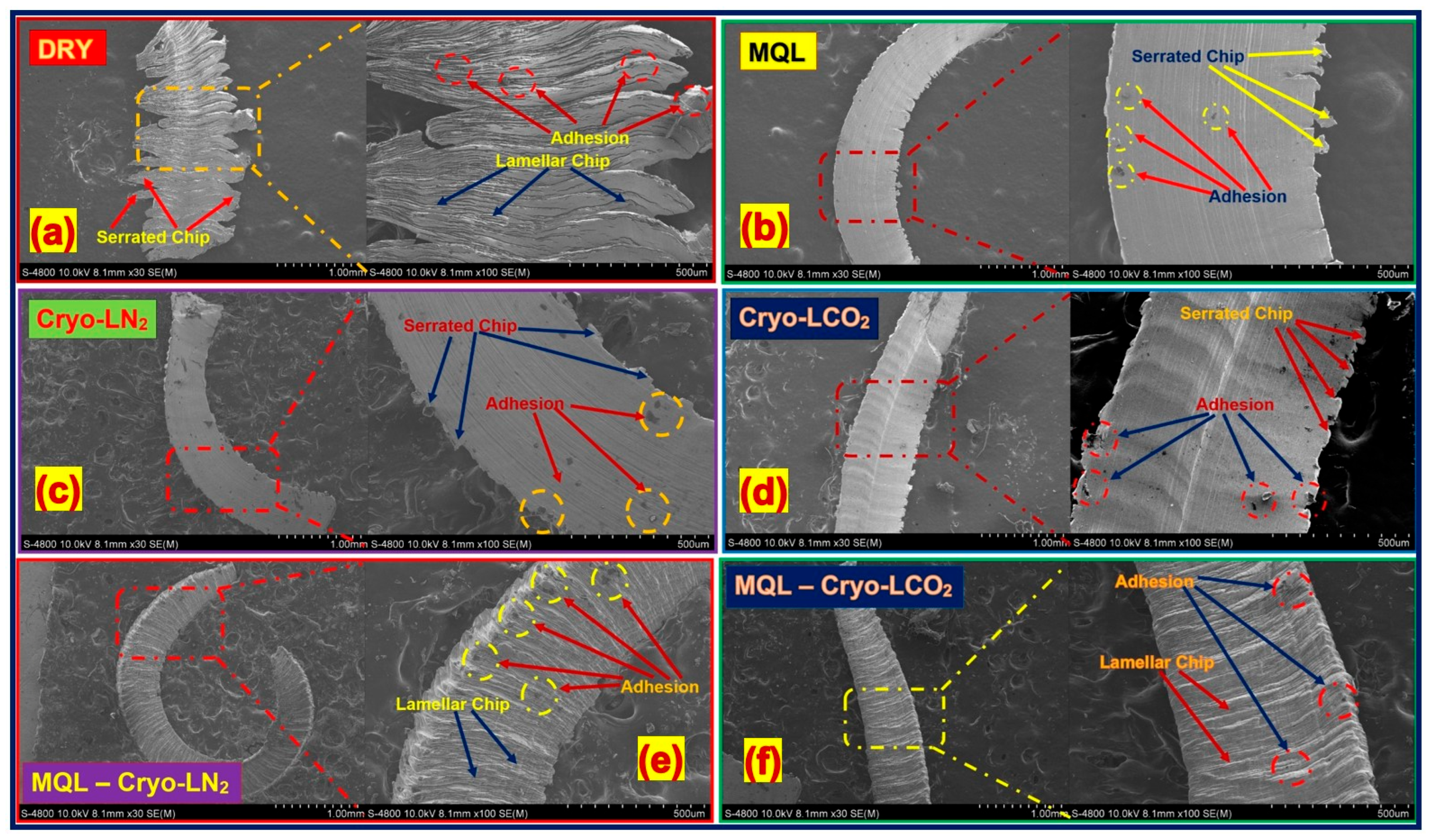

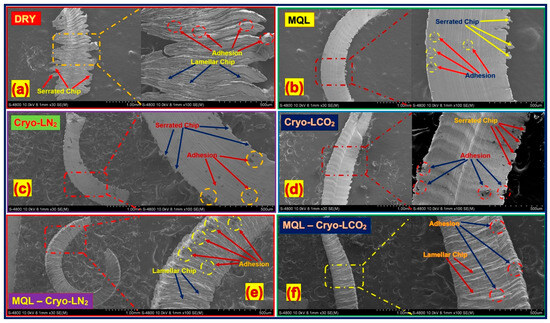

3.4. Chip Morphology

Chip formation plays a critical role in machining efficiency, directly influencing tool wear, material removal, and surface integrity. Factors such as shear stress, material deformation, and tribological conditions affect chip behavior, necessitating precise tool geometry for process stability. Among various mechanisms, self-breaking chip formation is preferred, as long, unbroken chips can obstruct tool movement, increase friction, and accelerate wear. To address this, modern chip breaker designs continue to evolve for optimized cutting across diverse materials [56].

Figure 14 illustrates chip morphologies observed via SEM during the milling of Hastelloy C276 under different cooling and lubrication strategies. Dry machining consistently produced the longest chips, often forming serrated spiral shapes due to progressive tool degradation. In contrast, strategies incorporating MQL, cryogenic cooling, and hybrid approaches generated significantly shorter chips, with hybrid MQL–Cryo systems achieving the most effective reduction in chip length.

Figure 14.

SEM images of chip morphologies during the milling of Hastelloy C276 under different cooling and lubrication strategies: (a) dry machining; (b) MQL; (c) Cryo-LN2; (d) Cryo-LCO2; (e) hybrid MQL–Cryo-LN2; (f) hybrid MQL–Cryo-LCO2. Chips vary in length, shape, and fragmentation depending on the strategy, with hybrid approaches producing shorter, more uniform chips.

These findings are consistent with prior studies. Ross et al. [31] observed thinner, continuous spiral chips under MQL and Cryo-CO2 conditions, attributing improvements to reduced friction and improved chip evacuation. Gupta et al. [28] reported smooth, fragmented chips when MQL was combined with nitrogen, highlighting the synergy between lubrication and cryogenic media. Salur et al. [52] identified characteristic S- and C-shaped chips in MQL and LN2-assisted milling, while Korkmaz et al. [38] noted that dry machining resulted in long, serrated, discolored chips with higher frictional effects. Usca et al. [57] demonstrated that Cryo-LN2 improved chip evacuation and surface quality due to shorter chip lengths.

The distinct behavior of Hastelloy C276 under thermal stress also plays a role in chip formation. Its high nickel content and toughness cause variability in chip morphology depending on cutting zone temperature. Cryogenic cooling effectively stabilizes interface temperatures, promoting thinner and more fragmentable chips. Additionally, interactions between vegetable-based MQL lubricants and cryogenic media form tribofilms at the contact zone, enhancing cutting efficiency by minimizing adhesion and altering chip breakage dynamics.

Beyond performance benefits, optimized chip morphology contributes to sustainable machining. As shown by Konya et al. [55], shorter chips simplify disposal and reduce material waste, making hybrid methods like MQL–Cryo-LN2 favorable from both efficiency and environmental perspectives. Overall, integrating effective cooling and lubrication techniques offers greater control over chip morphology, leading to enhanced surface integrity, tool life, and sustainability in high-precision manufacturing.

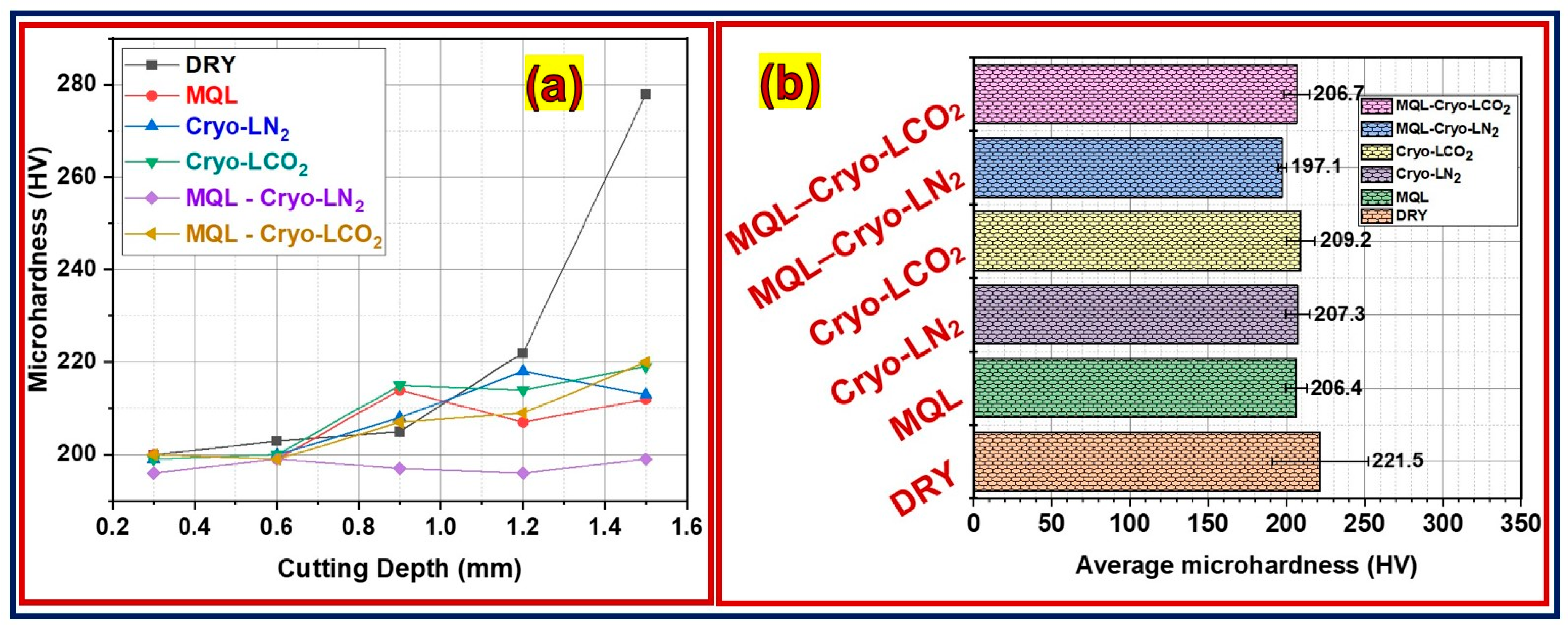

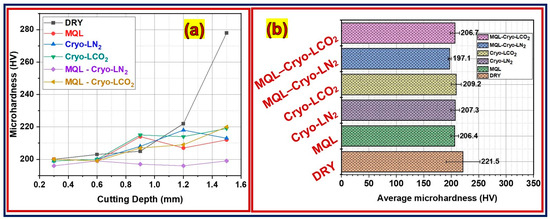

3.5. Microhardness

Figure 15 shows microhardness trends and average values for Hastelloy C276 under six cooling and lubrication conditions, based on measurements taken after five cutting lengths in each environment.

Figure 15.

Microhardness of Hastelloy C276 under six cooling and lubrication conditions. (a) Microhardness variation across five cutting lengths, with each point representing the average of three post-machining measurements per specimen. (b) Average microhardness calculated from five specimens per condition, with error bars indicating standard deviation.

Surface microhardness varied under different cooling and lubrication strategies. Dry machining exhibited the highest values (HV 200 to 278), followed by MQL (HV 200 to 214), Cryo-LN2 (HV 199 to 218), Cryo-LCO2 (HV 199 to 219), hybrid MQL–Cryo-LCO2 (HV 199 to 220), and hybrid MQL–Cryo-LN2 (HV 196 to 199). A gradual increase in hardness was observed across repeated cycles under all methods except hybrid MQL–Cryo-LN2, which maintained a more stable hardness profile. In contrast, dry machining showed a marked rise in surface hardening between the fourth and fifth cycles. Table 6 presents the mean values and standard deviations of surface microhardness (HV ± SD) across the cooling and lubrication conditions and cutting lengths discussed above. Although direct quantification was not performed, thermal stress was not quantified directly, its influence was inferred from cutting zone temperature observations and microhardness responses observed across various cooling conditions.

Table 6.

Microhardness (HV ± SD) across cooling and lubrication conditions and cutting lengths.

These trends align with Korkmaz et al. [38], who associated increased hardness with refined microstructure near the machined surface in dry conditions. The severe tool wear and elevated thermal load observed here likely contributed to that refinement. Salur et al. [52] similarly reported that cryogenic cooling helps retain microstructure and suppress thermal softening. Ross et al. [45] found that rapid heating and cooling during Cryo-CO2 machining may also enhance microhardness compared to conventional methods.

Collectively, the results highlight how cutting conditions and thermal control influence surface hardening. Optimized cooling strategies, particularly hybrid MQL–Cryo-LN2, provide more consistent microhardness, supporting better surface integrity and long-term performance in superalloy machining.

4. Conclusions

Machining Hastelloy C276 presents persistent challenges due to its tendency to accelerate tool wear and compromise surface quality and dimensional precision. This study examined multiple cooling and lubrication strategies, including dry machining, MQL with coconut oil, cryogenic cooling using LN2 and LCO2, and hybrid methods that combine MQL with cryogenic cooling, to improve performance in open-slot finishing.

Key Findings:

- ***

- Thermal performance: Hybrid MQL–Cryo-LN2 and Cryo-LN2 approaches provided excellent thermal protection, reducing cutting zone temperatures by up to 116.4 percent compared to dry conditions. These improvements were most notable at lower cutting speeds and feeds.

- ***

- Tool wear reduction: Among all the strategies, hybrid MQL–Cryo-LN2 resulted in the lowest flank wear at 0.082 mm, representing a 94.34 percent improvement over dry machining. MQL with coconut oil also outperformed several cryogenic conditions, as confirmed by SEM analysis of rake wear.

- ***

- Wear mechanisms and coating effectiveness: EDS and SEM analyses identified adhesive, abrasive, and oxidative wear modes on the flank and rake faces of TiSiN/TiAlN-coated inserts. The coating showed high durability, especially under MQL and hybrid MQL–Cryo-LN2 environments, reinforcing its suitability for machining Hastelloy C276.

- ***

- Surface quality: While both Ra and Rq were analyzed, Ra was chosen for concluding remarks because it is more commonly referenced and directly reflects performance differences across cooling and lubrication strategies. Hybrid MQL–Cryo-LN2 produced the smoothest surfaces at 0.317 μm, while dry cutting resulted in the roughest finish at 1.327 μm.

- ***

- Chip formation: SEM imaging revealed extensive serrations and damage under dry machining, whereas hybrid MQL–Cryo-LN2 and MQL–Cryo-LCO2 generated more uniform lamellar chips and reduced frictional defects.

- ***

- Microhardness response: Dry machining produced the highest surface microhardness, increasing by 39.7 percent relative to hybrid MQL–Cryo-LN2. This was attributed to elevated thermal stress, tool wear, and surface hardening due to extreme operating conditions.

Overall, the results demonstrate that hybrid MQL–Cryo-LN2 significantly enhances tool life, reduces cutting temperatures, improves surface finish, and moderates material hardening. These insights provide a valuable foundation for developing efficient machining strategies for Hastelloy C276 and other advanced superalloys.

Author Contributions

Conceptualization, L.C.T.; methodology, L.C.T.; software, L.C.T.; validation, L.C.T.; formal analysis, L.C.T.; investigation, L.C.T.; resources, L.C.T.; data curation, L.C.T.; writing—original draft preparation, L.C.T.; writing—review and editing, L.C.T. and T.T.P.; visualization, L.C.T.; supervision, T.T.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data supporting the findings of this study are not publicly available due to institutional restrictions.

Acknowledgments

The authors deeply appreciate Le Dinh Kha and Tong Thanh Nhan for their valuable insights and contributions during our discussions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Klocke, F. Manufacturing Processes 1: Cutting, in RWTHedition; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-11979-8. [Google Scholar]

- Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Ercan, H.; Sarıkaya, M. An attempt towards green machining of Ni-based Hastelloy C4 alloy: Effect of vegetable oils and their combination with TiO2 and SiO2 nanoparticles on outputs. Sustain. Mater. Technol. 2023, 37, e00668. [Google Scholar] [CrossRef]

- Şirin, E.; Kıvak, T.; Yıldırım, Ç.V. Effects of mono/hybrid nanofluid strategies and surfactants on machining performance in the drilling of Hastelloy X. Tribol. Int. 2021, 157, 106894. [Google Scholar] [CrossRef]

- Panigrahi, D.R.; Bartarya, G.; Chetan. Drilling performance of Nickel-based Hastelloy C276 under mono and hybrid nanofluids environments. J. Manuf. Process. 2024, 120, 1213–1230. [Google Scholar] [CrossRef]

- Şirin, E.; Yıldırım, Ç.V.; Kıvak, T.; Şirin, Ş.; Sarıkaya, M. Experimental research on sustainable drilling of Hastelloy X superalloy: Impact of hBN, GNP, LN2 and hybrid eco-friendly cooling/lubrication strategies. Tribol. Int. 2024, 200, 110070. [Google Scholar] [CrossRef]

- Singh, G.; Aggarwal, V.; Singh, S.; Singh, B. Sustainable machining of Hastelloy C-276 enabling minimum quantity lubrication of environmentally compatible lubricants. J. Clean. Prod. 2022, 373, 133928. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, X.; Ding, H. Tool wear characteristics in machining of nickel-based superalloys. Int. J. Mach. Tools Manuf. 2013, 64, 60–77. [Google Scholar] [CrossRef]

- Han, Q.; Mertens, R.; Montero-Sistiaga, M.L.; Yang, S.; Setchi, R.; Vanmeensel, K.; Hooreweder, B.V.; Evans, S.L.; Fan, H. Laser powder bed fusion of Hastelloy X: Effects of hot isostatic pressing and the hot cracking mechanism. Mater. Sci. Eng. A 2018, 732, 228–239. [Google Scholar] [CrossRef]

- Hong, H.U.; Kim, I.S.; Choi, B.G.; Jeong, H.W.; Jo, C.Y. Effects of temperature and strain range on fatigue cracking behavior in Hastelloy X. Mater. Lett. 2008, 62, 4351–4353. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; da Silva, L.R.R.; Machado, A.R.; França, P.H.P.; Pintaude, G.; Unune, D.R.; Kunto, M.; Krolczyk, G.M. A comprehensive review of machinability of difficult-to-machine alloys with advanced lubricating and cooling techniques. Tribol. Int. 2024, 196, 109677. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production–A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Najiha, M.S.; Rahman, M.M.; Yusoff, A.R. Environmental impacts and hazards associated with metal working fluids and recent advances in the sustainable systems: A review. Renew. Sustain. Energy Rev. 2016, 60, 1008–1031. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Gupta, M.K.; Song, Q. Tool wear and hole quality evaluation in cryogenic Drilling of Inconel 718 superalloy. Tribol. Int. 2020, 143, 106084. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2020, 62, 179–201. [Google Scholar] [CrossRef]

- Yang, K.Z.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Shankar, S.; Dixit, S.; Kumar, K.; Vatin, N.I. Application of coolants during tool-based machining–A review. Ain Shams Eng. J. 2023, 14, 101830. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Ross, N.S.; Sivalingam, V. Implementation of green cooling/lubrication strategies in metal cutting industries: A state of the art towards sustainable future and challenges. Sustain. Mater. Technol. 2023, 36, e00641. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Rao, P.V. Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy. J. Clean. Prod. 2019, 231, 1036–1049. [Google Scholar] [CrossRef]

- Zadafiya, K.; Shah, P.; Shokrani, A.; Khanna, N. Recent advancements in nano-lubrication strategies for machining processes considering their health and environmental impacts. J. Manuf. Process. 2021, 68, 481–511. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Attia, H.; Biermann, D.; Duflou, J.; Klocke, F.; Meyer, D.; Newman, S.T.; Pusavec, F.; Putz, M.; Rech, J.; et al. Cryogenic manufacturing processes. CIRP Ann. 2016, 65, 713–736. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on design and development of cryogenic machining setups for heat resistant alloys and composites. J. Manuf. Process. 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Halim, N.H.A.; Haron, C.H.C.; Ghani, J.A.; Azhar, M.F. Tool wear and chip morphology in high-speed milling of hardened Inconel 718 under dry and cryogenic CO2 conditions. Wear 2019, 426–427, 1683–1690. [Google Scholar] [CrossRef]

- Shah, P.; Khanna, N.; Chetan. Comprehensive machining analysis to establish cryogenic LN2 and LCO2 as sustainable cooling and lubrication techniques. Tribol. Int. 2020, 148, 106314. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Chetan. Comparative analysis of dry, flood, MQL and cryogenic CO2 techniques during the machining of 15-5-PH SS alloy. Tribol. Int. 2020, 146, 106196. [Google Scholar] [CrossRef]

- Agrawal, C.; Wadhwa, J.; Pitroda, A.; Pruncu, C.I.; Sarikaya, M.; Khanna, N. Comprehensive analysis of tool wear, tool life, surface roughness, costing and carbon emissions in turning Ti–6Al–4V titanium alloy: Cryogenic versus wet machining. Tribol. Int. 2021, 153, 106597. [Google Scholar] [CrossRef]

- Agrawal, C.; Khanna, N.; Pimenov, D.Y.; Wojciechowski, S.; Giasin, K.; Sarıkaya, M.; Yıldırım, C.V.; Jamil, M. Experimental investigation on the effect of dry and multi-jet cryogenic cooling on the machinability and hole accuracy of CFRP composites. J. Mater. Res. Technol. 2022, 18, 1772–1783. [Google Scholar] [CrossRef]

- Khan, A.M.; Zhao, W.; Li, L.; Alkahtani, M.; Hasnain, S.; Jamil, M.; He, N. Assessment of cumulative energy demand, production cost, and CO2 emission from hybrid CryoMQL assisted machining. J. Clean. Prod. 2021, 292, 125952. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Budak, E. Investigation of machinability in turning of difficult-to-cut materials using a new cryogenic cooling approach. Tribol. Int. 2018, 119, 510–520. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Khanna, N.; Krolczyk, G.M. Experimental characterisation of the performance of hybrid cryo-lubrication assisted turning of Ti–6Al–4V alloy. Tribol. Int. 2021, 153, 106582. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Korkmaz, M.E. Influence of hybrid Cryo-MQL lubri-cooling strategy on the machining and tribological characteristics of Inconel 718. Tribol. Int. 2021, 163, 107178. [Google Scholar] [CrossRef]

- Gupta, M.K.; Niesłony, P.; Sarikaya, M.; Korkmaz, M.E.; Kunto, M.; Kr’olczyk, G.M.; Jamil, M. Tool wear patterns and their promoting mechanisms in hybrid cooling assisted machining of titanium Ti-3Al-2.5V/grade 9 alloy. Tribol. Int. 2022, 174, 107773. [Google Scholar] [CrossRef]

- Ross, N.S.; Ganesh, M.; Srinivasan, D.; Gupta, M.K.; Korkmaz, M.E.; Krolczyk, J.B. Role of sustainable cooling/lubrication conditions in improving the tribological and machining characteristics of Monel-400 alloy. Tribol. Int. 2022, 176, 107880. [Google Scholar] [CrossRef]

- Sartori, S.; Ghiotti, A.; Bruschi, S. Hybrid lubricating/cooling strategies to reduce the tool wear in finishing turning of difficult-to-cut alloys. Wear 2017, 376–377, 107–114. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; De Lacalle, L.N.L. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Kuram, E.; Budak, E. Experimental evaluation of eco-friendly hybrid cooling methods in slot milling of titanium alloy. J. Clean. Prod. 2021, 289, 125817. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Gajrani, K.K. Assessment of cryo-MQL environment for machining of Ti-6Al-4V. J. Manuf. Process. 2020, 60, 494–502. [Google Scholar] [CrossRef]

- Khanna, N.; Airao, J.; Kshitij, G.; Nirala, C.K.; Hegab, H. Sustainability analysis of new hybrid cooling/lubrication strategies during machining Ti6Al4V and Inconel 718 alloys. Sustain. Mater. Technol. 2023, 36, e00606. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Günay, M.; Boy, M.; Yasar, N.; Demirs¨oz, R.; Ross, K.N.S.; Abbas, Y. Comprehensive analysis of tool wear, surface roughness and chip morphology in sustainable turning of Inconel-601 alloy. J. Manuf. Process. 2023, 103, 156–167. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Sarıkaya, M.; Şirin, Ş. Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J. Mater. Res. Technol. 2020, 9, 2079–2092. [Google Scholar] [CrossRef]

- Xiang, D.; Liu, Y.; Yu, T.; Wang, D.; Leng, X.; Wang, K.; Liu, L.; Pan, J.; Yao, S.; Chen, Z. Review on wear resistance of laser cladding high-entropy alloy coatings. J. Mater. Res. Technol. 2024, 28, 911–934. [Google Scholar] [CrossRef]

- Meijun, L.; Xu, L.; Zhu, C.; Li, Z.; Wei, S. Research progress of high entropy alloy: Surface treatment improves friction and wear properties. J. Mater. Res. Technol. 2024, 28, 752–773. [Google Scholar] [CrossRef]

- Hao, X.; Liu, H.; Zhang, X.; Chen, L.; Wang, Y.; Yang, C.; Liu, Y. Friction–wear behaviors and microstructure of AlTiVCrNb lightweight refractory high-entropy alloy coating prepared by laser cladding on Ti–6Al–4V substrate. J. Mater. Res. Technol. 2024, 29, 1–11. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.; Alexandre, R.; Fecheira, J.S.; Silva, F.P.N. Study of the wear behaviour of TiAlSiN and TiAlN PVD coated tools on milling operations of pre-hardened tool steel. Wear 2021, 476, 203695. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, K.; Dang, J.; Tu, L.; Wang, Q.; Ming, W.; Wang, D.; Liu, Z.; Chen, M. Analysis of tool wear and cutting characteristics in milling of powder metallurgy nickel-based superalloy by various coatings. Wear 2024, 552–553, 205429. [Google Scholar] [CrossRef]

- Ross, N.S.; Srinivasan, N.; Amutha, P.; Gupta, M.K.; Korkmaz, M.E. Thermo-physical, tribological and machining characteristics of Hastelloy C276 under sustainable cooling/lubrication conditions. J. Manuf. Process. 2022, 80, 397–413. [Google Scholar] [CrossRef]

- Danish, M.; Rubaiee, S.; Gupta, M.K.; Yildirim, M.B.; Ahmed, A. Technological and tribological characteristics improvement of additively manufactured SS 316L components machined under sustainable cooling conditions. Tribol. Int. 2023, 181, 108329. [Google Scholar] [CrossRef]

- Sivalingam, V.; Sun, J.; Yang, B.; Liu, K.; Raju, R. Machining performance and tool wear analysis on cryogenic treated insert during end milling of Ti-6Al-4V alloy. J. Manuf. Process. 2018, 36, 188–196. [Google Scholar] [CrossRef]

- Wang, R.; Wang, X.; Yan, P.; Zhou, T.; Jiao, L.; Teng, L.; Zhao, B. The effects of cryogenic cooling on tool wear and chip morphology in turning of tantalum-tungsten alloys Ta-2.5W. J. Manuf. Process. 2023, 86, 152–162. [Google Scholar] [CrossRef]

- ISO 3685:1993; Tool-Life Testing with Single-Point Turning Tools. ISO: Geneva, Switzerland, 1993.

- Astakhov, V.P.; Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011; ISBN 978-1-84996-449-4. [Google Scholar]

- Trung, L.C.; Phuc, T.T. Wear Mechanism of an AlCrN-Coated Solid Carbide Endmill Cutter and Machined Surface Quality under Eco-Friendly Settings during Open Slot Milling of Tempered JIS SKD11 Steel. Coatings 2024, 14, 923. [Google Scholar] [CrossRef]

- Salur, E. Understandings the tribological mechanism of Inconel 718 alloy machined under different cooling/lubrication conditions. Tribol. Int. 2022, 174, 107677. [Google Scholar] [CrossRef]

- Berman, D. Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants 2024, 12, 300. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Kushvaha, V.; Singla, A.K.; Li, Z. Ecological, economical and technological perspectives based sustainability assessment in hybrid-cooling assisted machining of Ti-6Al-4 V alloy. Sustain. Mater. Technol. 2020, 26, e00218. [Google Scholar] [CrossRef]

- Kónya, G.; Kovács, Z.F. Experimental investigation of the effects of cooling-lubricating methods on the slot milling process of GTD-111 type nickel-based superalloy. J. Manuf. Process. 2024, 119, 98–108. [Google Scholar] [CrossRef]

- Machado, A.R.; Da Silva, L.R.R.; Pimenov, D.Y.; De Souza, F.C.R.; Kuntoğlu, M.; De Paiva, R.L. Comprehensive review of advanced methods for improving the parameters of machining steels. J. Manuf. Process. 2024, 125, 111–142. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Şap, S.; Giasin, K.; Pimenov, D.Y.; Prakash, C. Determination of machinability metrics of AISI 5140 steel for gear manufacturing using different cooling/lubrication conditions. J. Mater. Res. Technol. 2022, 21, 893–904. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).