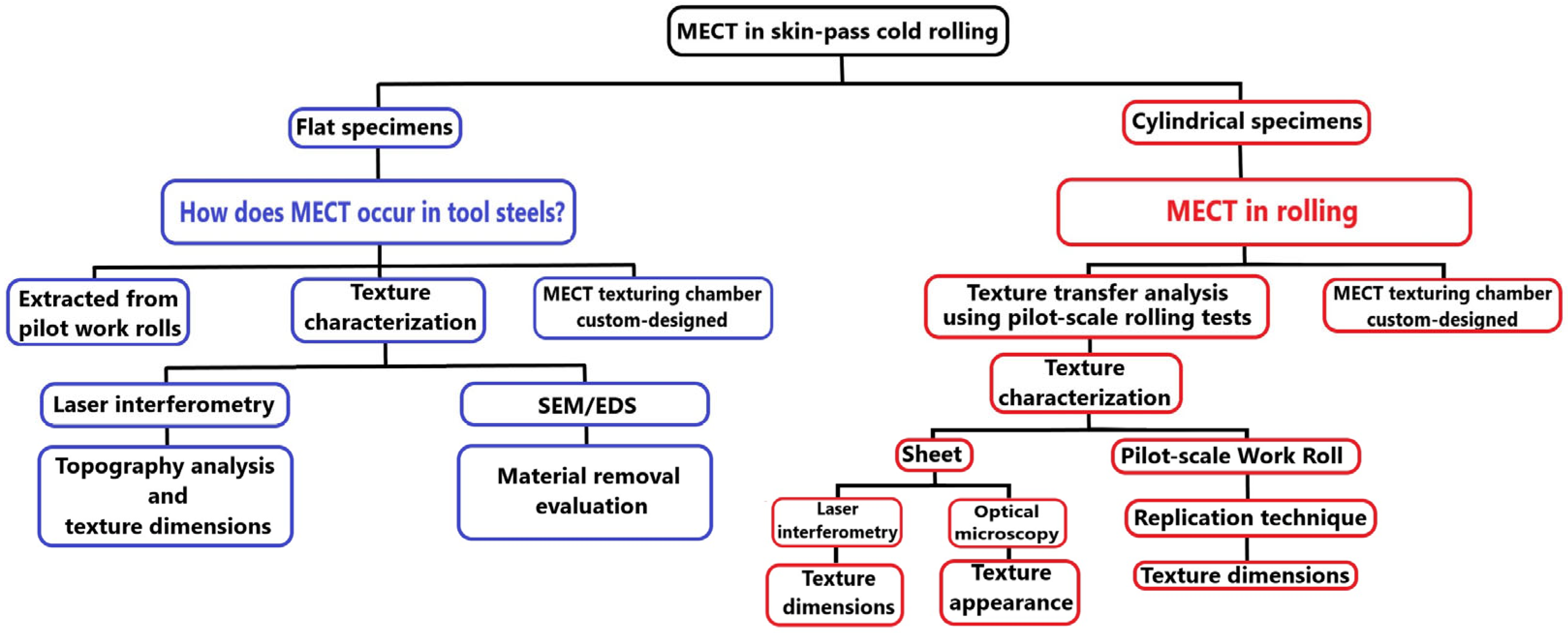

Maskless Electrochemical Texturing (MECT) Applied to Skin-Pass Cold Rolling

Abstract

1. Introduction

2. Experimental Procedure

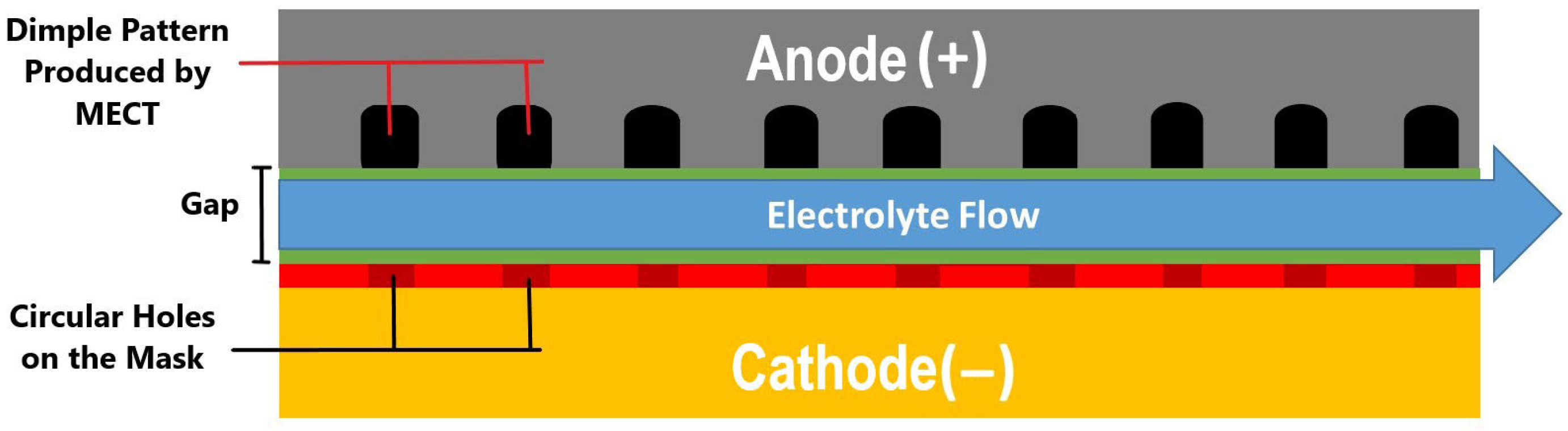

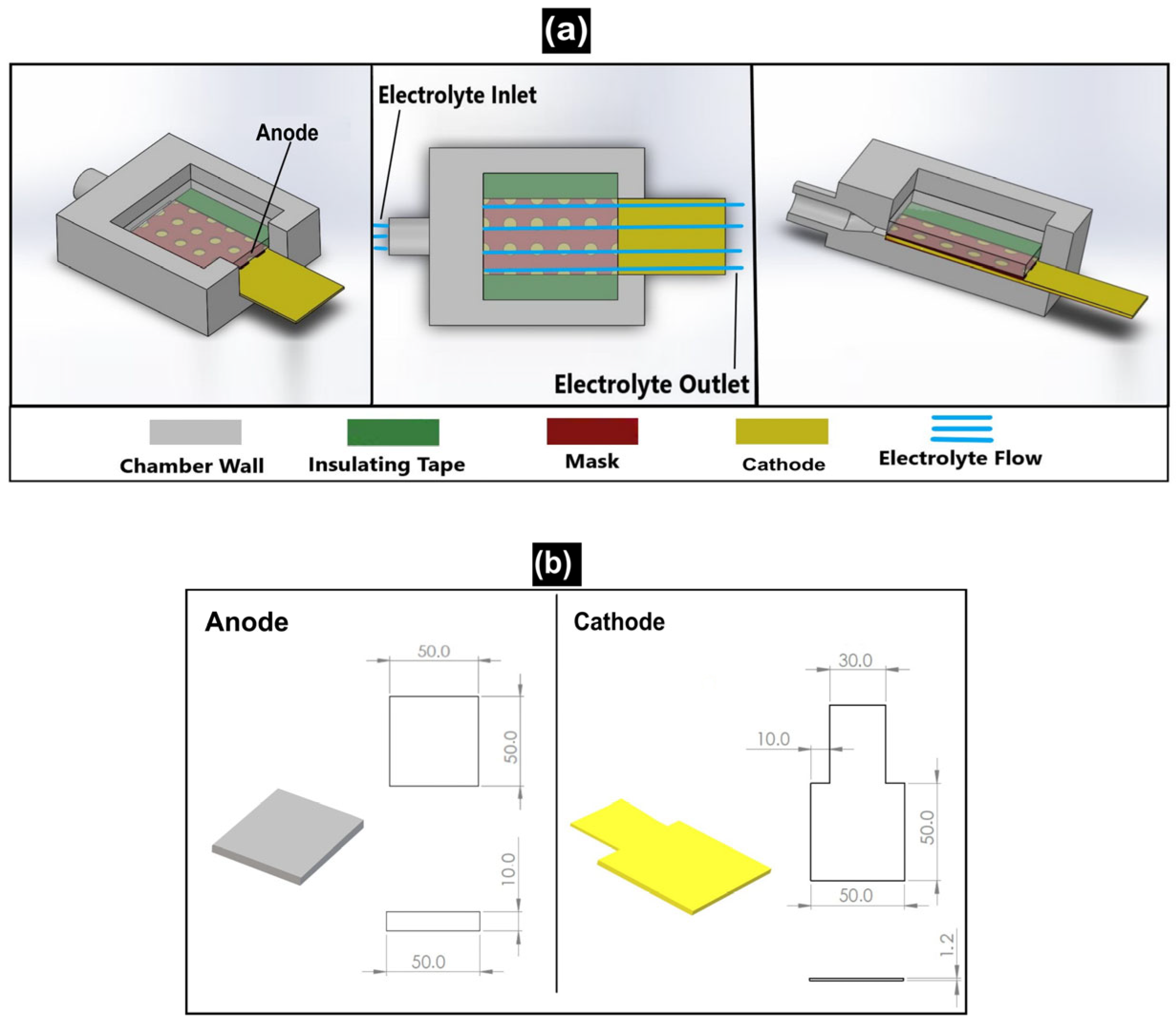

2.1. MECT Texturing of Flat Specimens

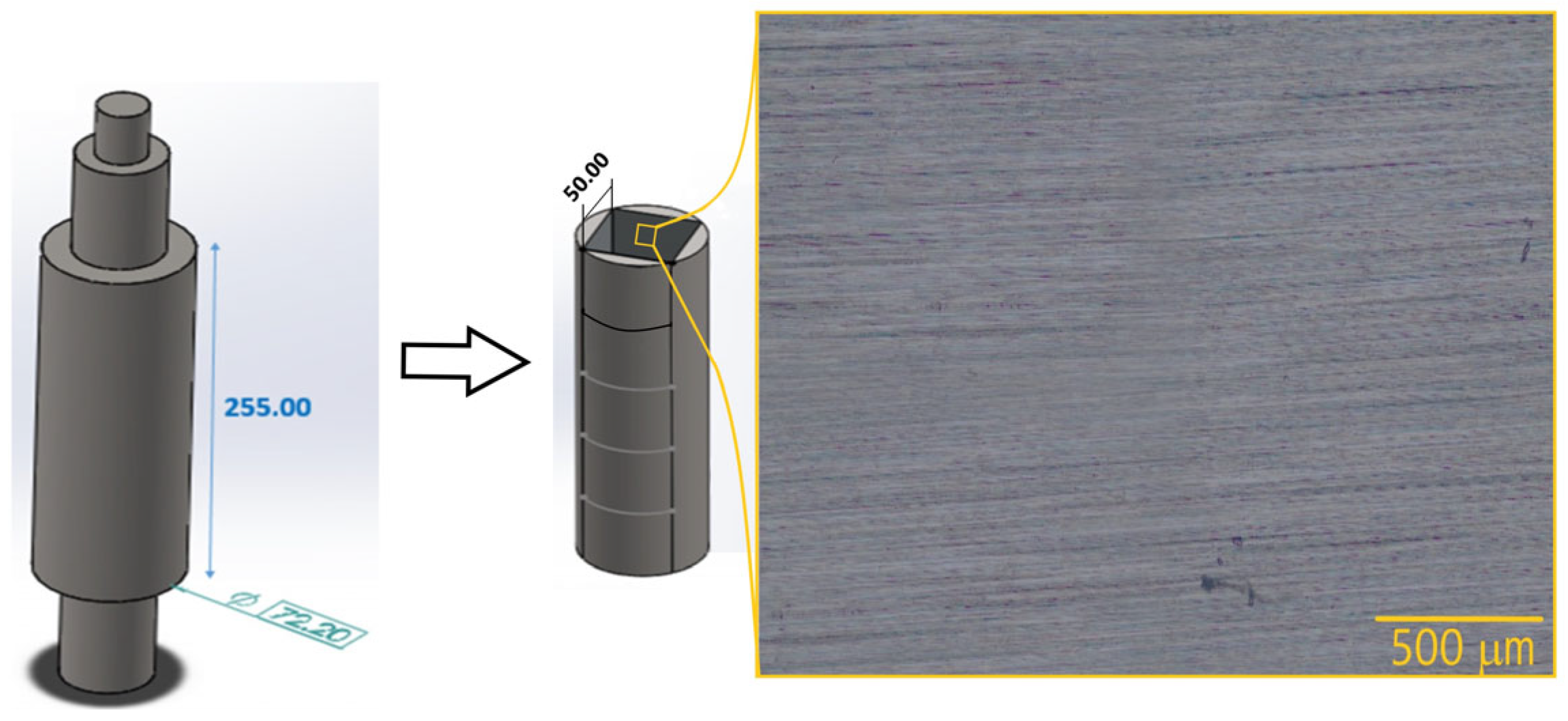

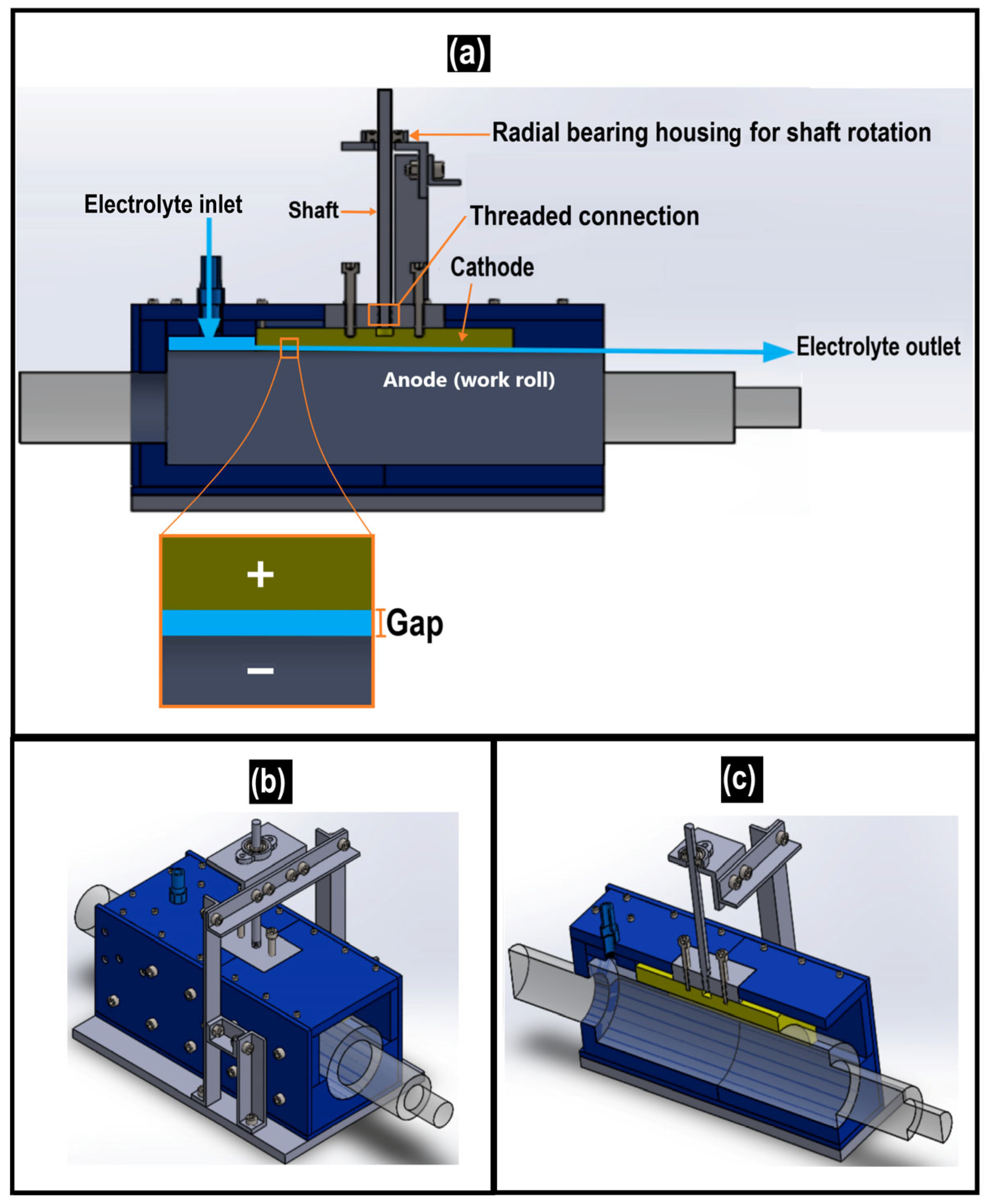

2.2. MECT Texturing of Rolls

2.3. Texture Transfer from Work Roll to Sheet

3. Results and Discussion

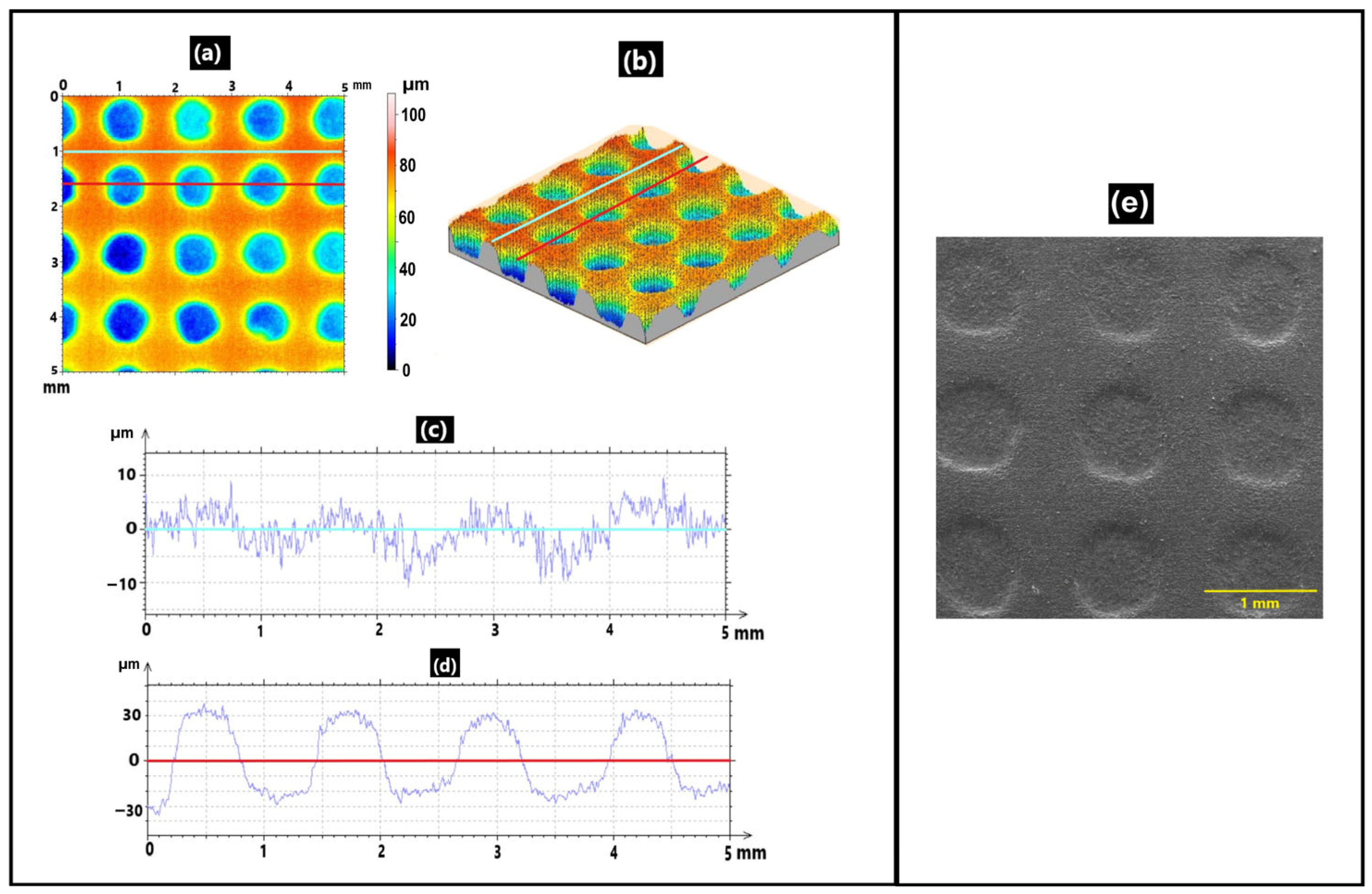

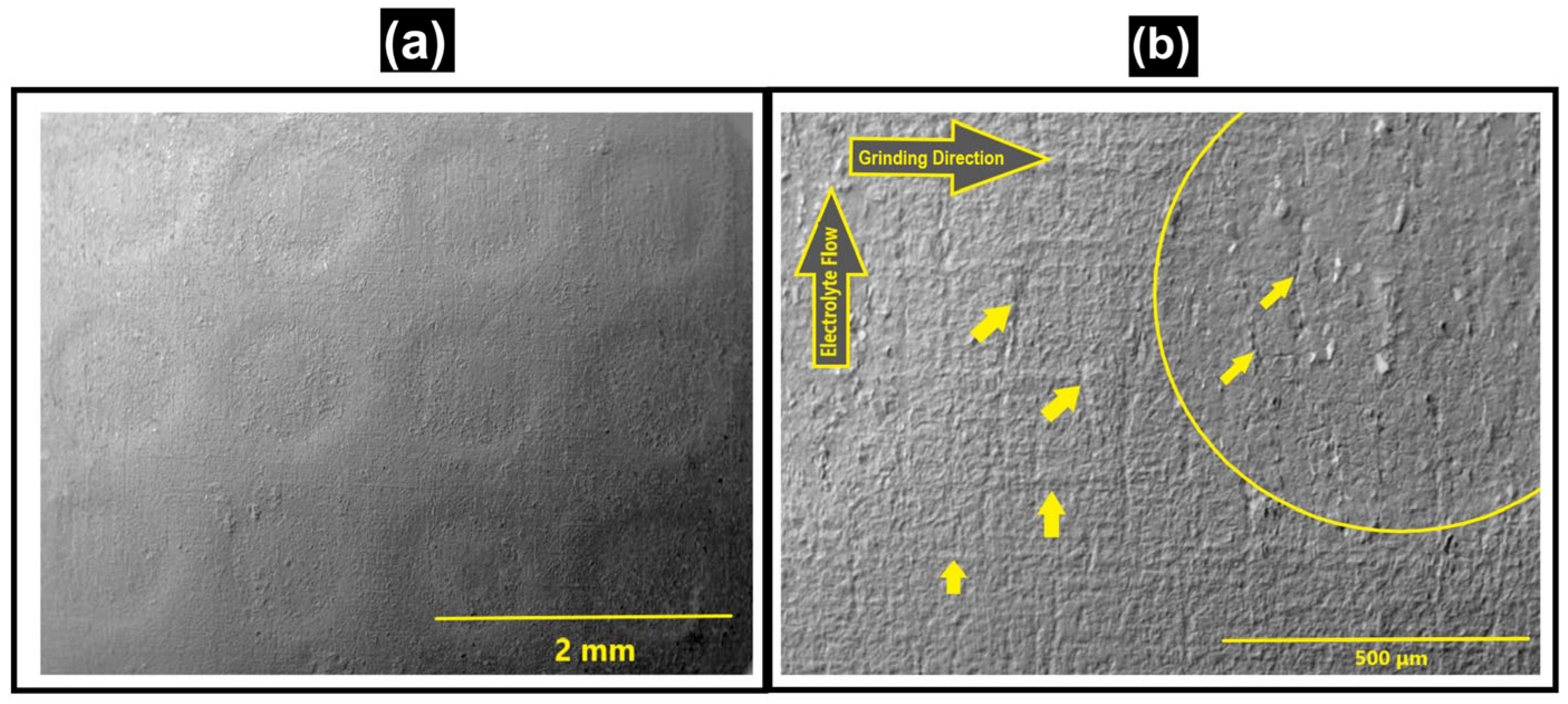

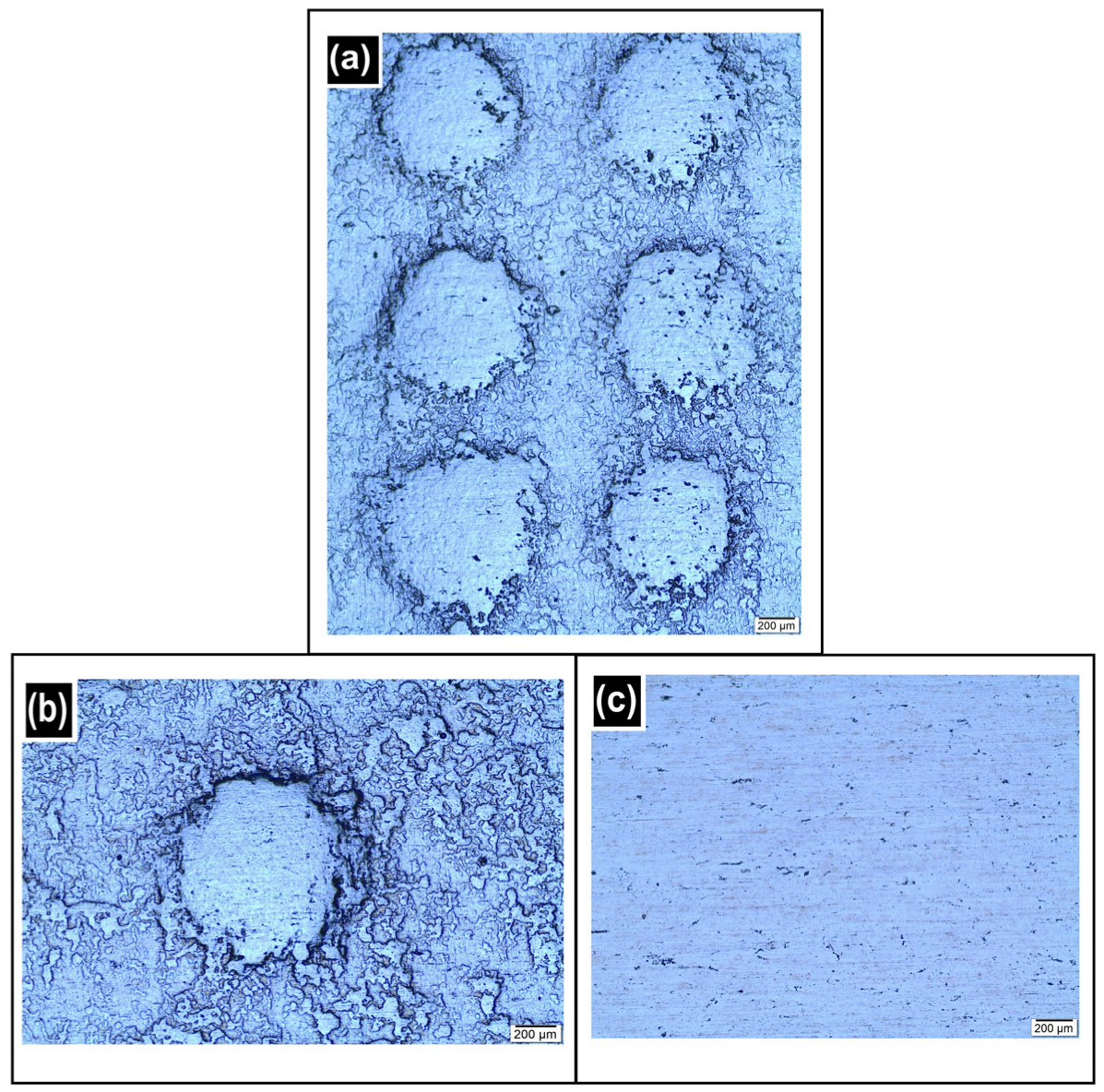

3.1. Texturing of the AISI 1010 Reference Flat Samples

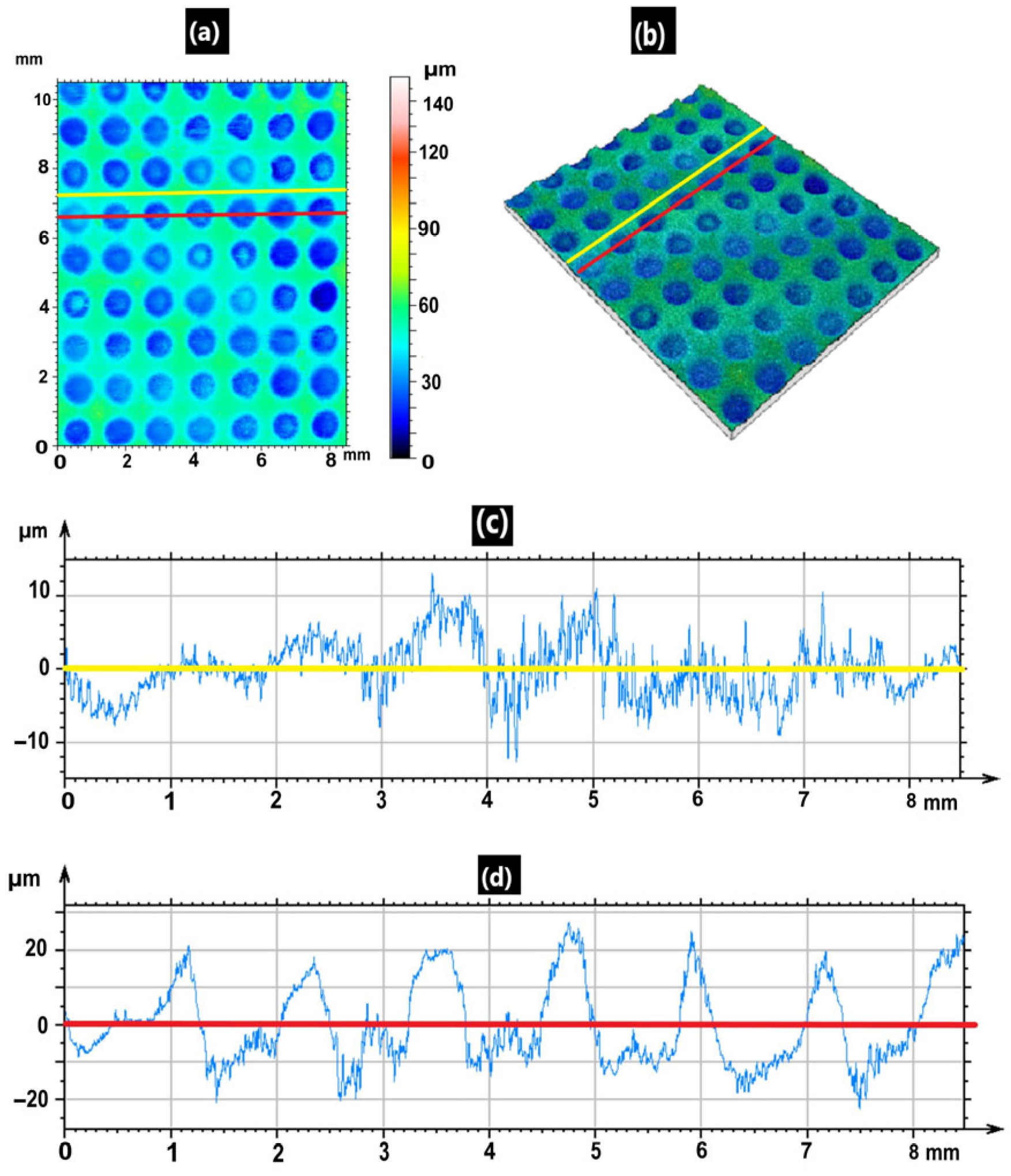

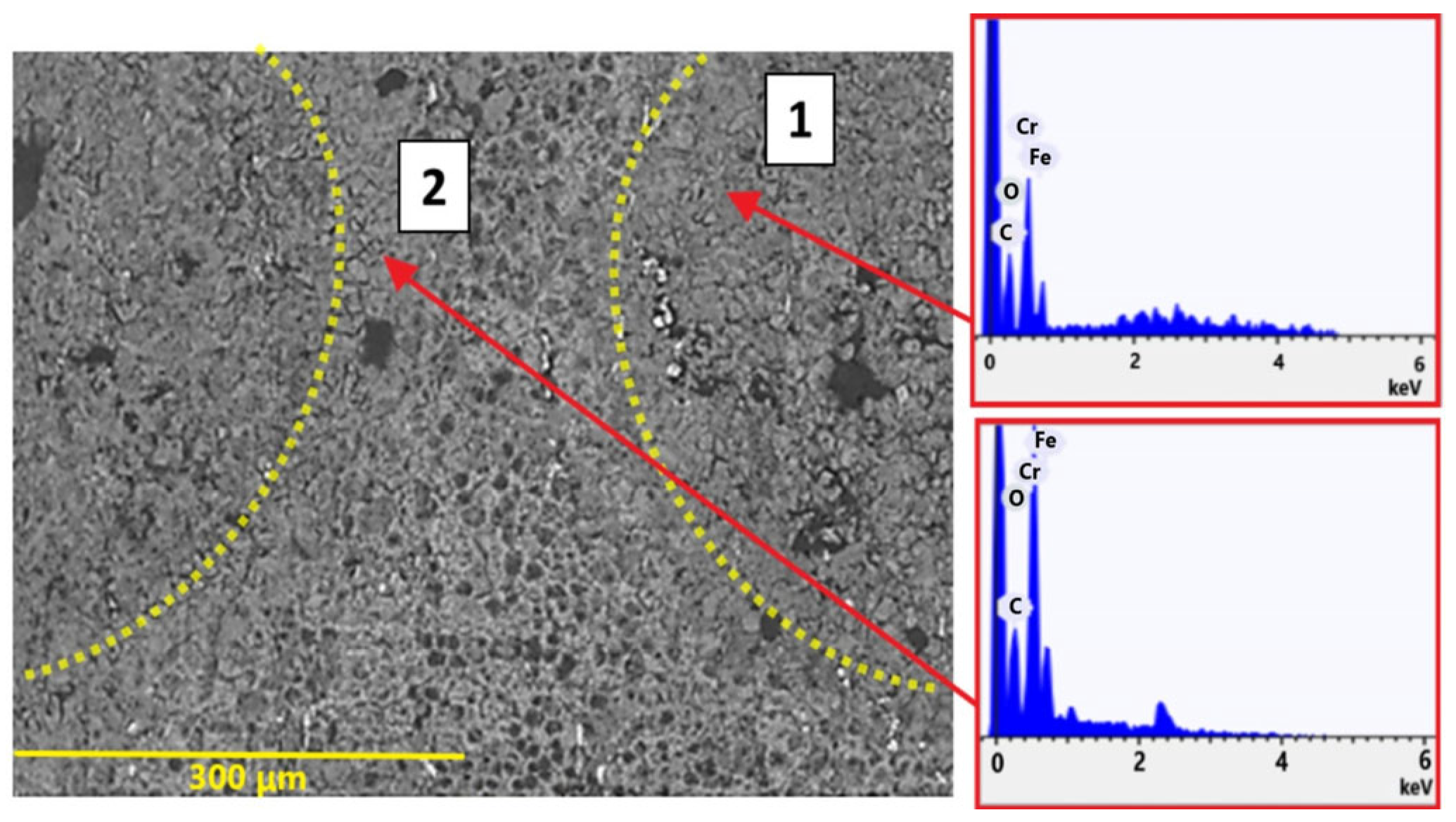

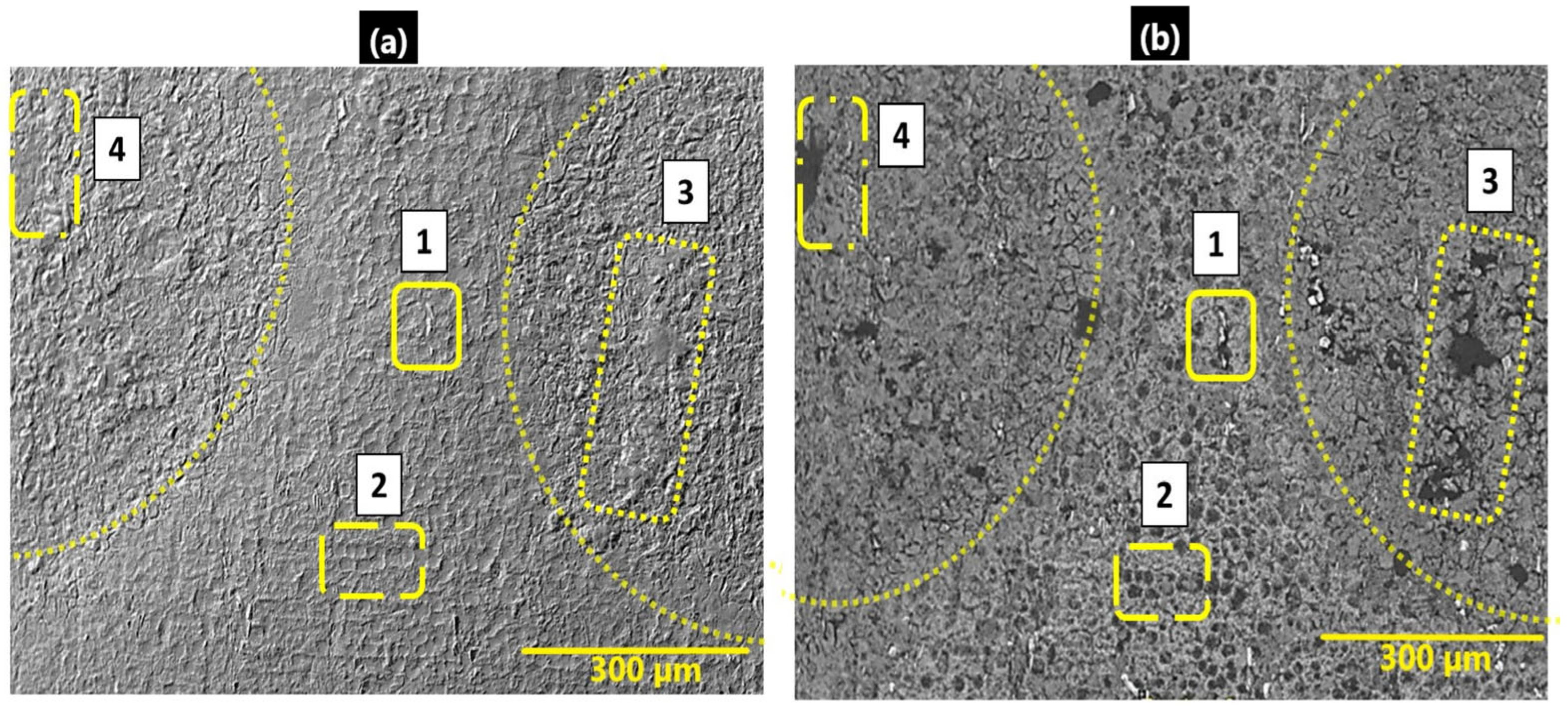

3.2. Texturing of Tool Steel Flat Samples

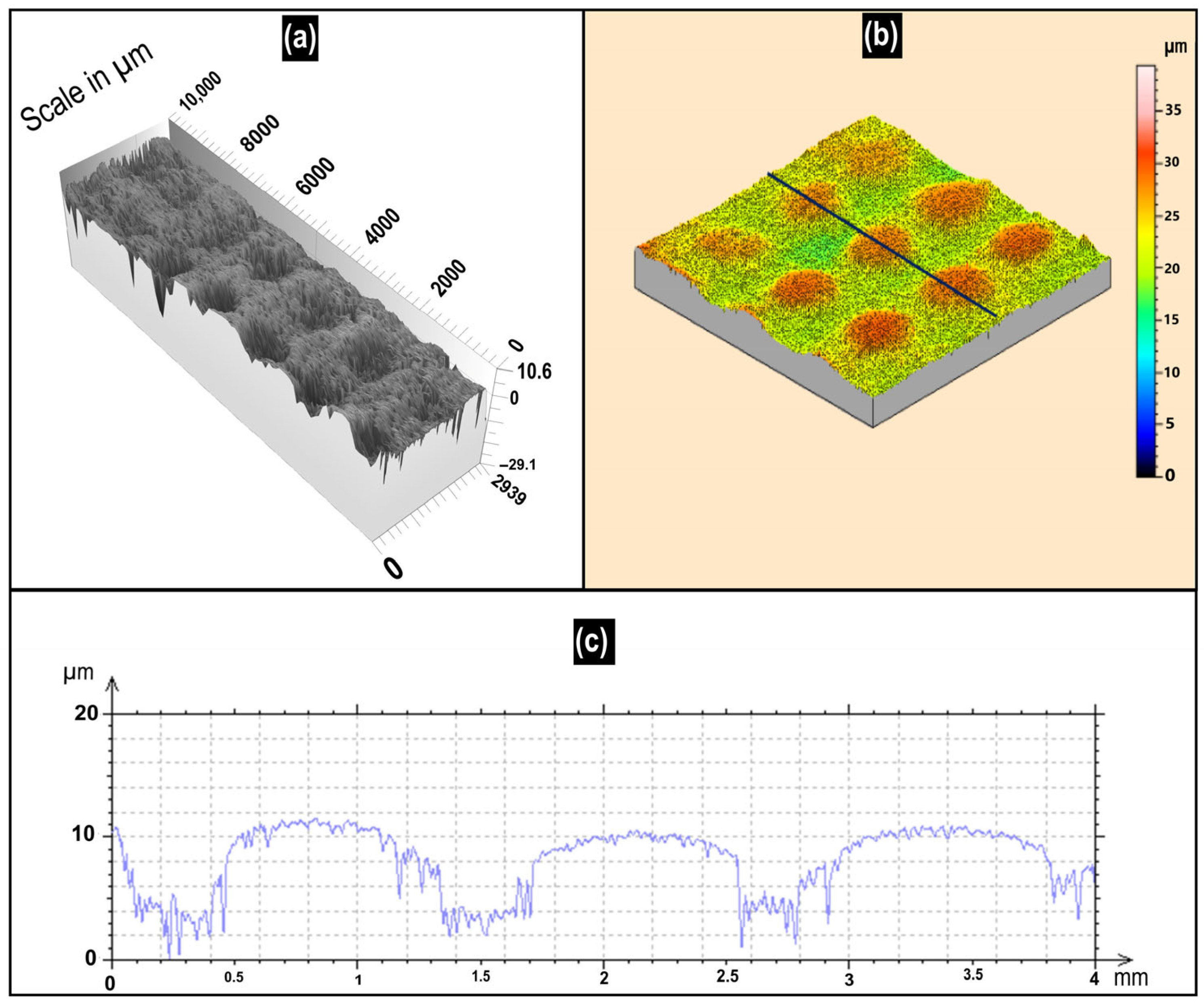

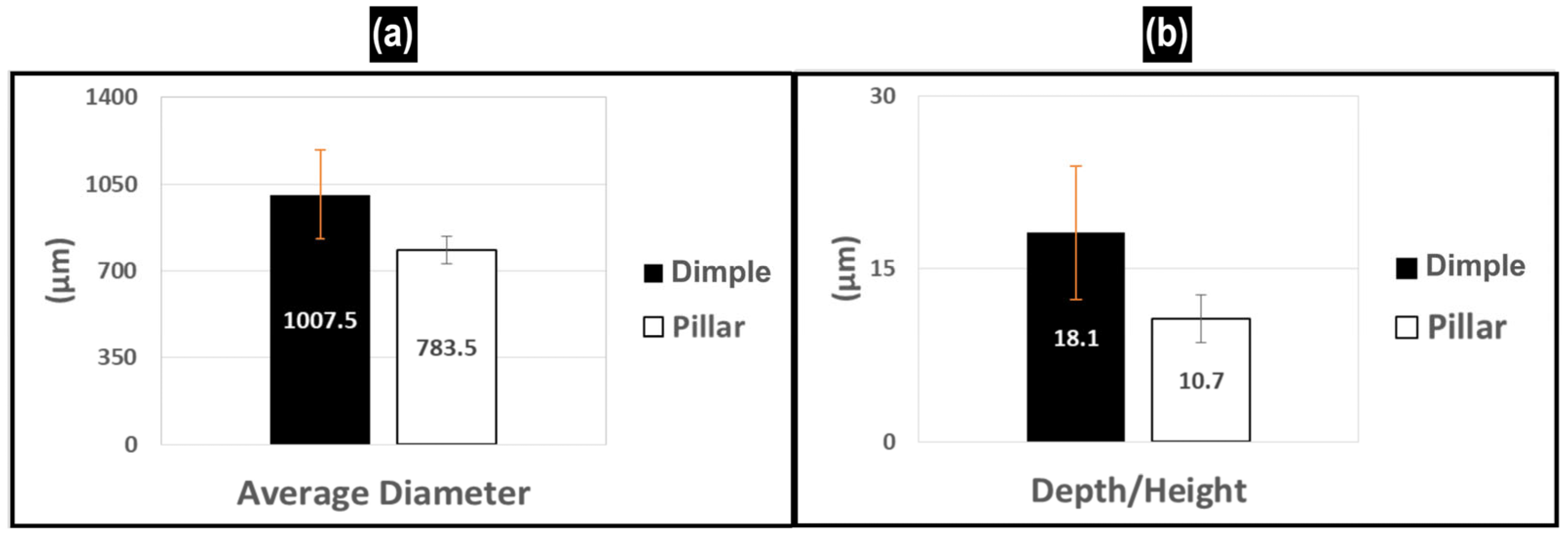

3.3. Texture Transfer Results

3.4. Assessment of MECT in the Context of Industrial Work Roll Texturing

4. Conclusions

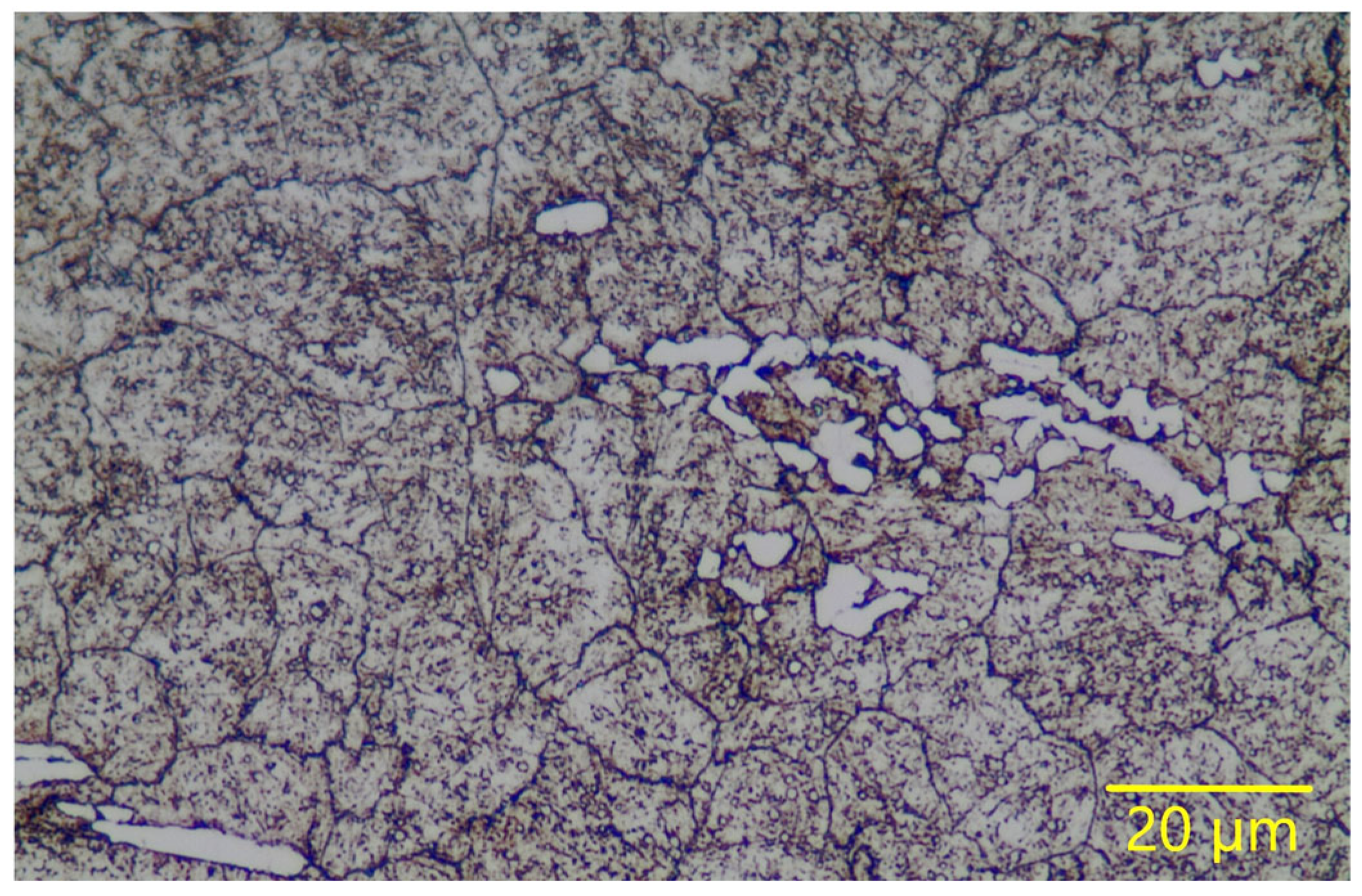

- The anodic dissolution involved in texturing the samples from the work rolls occurs preferentially around the primary carbides, probably due to the depletion of alloying elements (Mo, V, Cr) for primary carbide formation, making these regions more susceptible to intense oxidation;

- Additionally, a loss of mechanical support from the matrix due to the preferential removal of Fe, characteristic of the electrochemical texturing process, can favor the detachment of some of these carbides;

- The textured dimples on the work roll surface were transferred as pillars to the sheet surfaces. However, the pillars produced on the sheet are not the exact negative of the dimples on the rolls. In other words, only a percentage of the texture is transferred to the sheets.

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Junior, P.L.M.; Labiapari, W.S.; Da Silva, W.M.J.; Costa, H.L. Durability of Deterministic Textures Produced by Maskless Electrochemical Texturing (Mect) During Skin Pass Cold Rolling. Wear 2025, 562, 205638. [Google Scholar]

- Monteiro, P.L.; Costa, H.L. A Holistic Review of Surface Texturing in Sheet Metal Forming: From Sheet Rolling to Final Forming. Lubricants 2025, 13, 253. [Google Scholar] [CrossRef]

- Steinhoff, K.; Rasp, W.; Pawelski, O. Development of deterministic-stochastic surface structures to improve the tribological conditions of sheet forming processes. J. Mater. Process. Technol. 1996, 60, 355–361. [Google Scholar] [CrossRef]

- Kijima, H. Mechanism of roughness profile transfer in skin-pass rolling of thin steel strip. JFE Tech. Rep. 2019, 24, 129–134. [Google Scholar]

- Rodriguez-Vidal, E.; Matthews, D.T.A.; de Viteri, V.S.; Korver, F.; Wentink, D.; Quintana, I. Surface design and texturing of strip steel using nanosecond pulsed lasers for simulated roughness transfer and paint appearance. J. Mater. Process. Technol. 2020, 275, 116365. [Google Scholar] [CrossRef]

- Hong, M.H.; Tark, H.J.; Park, J.S.; Paik, D.J. Improvement of surface texture on the hot dip galvanized and galvannealed steel sheets. Metall. Ital. 2012, 13, 9–13. [Google Scholar]

- Çolak, B. A comparison of tonnage-dependent shot blast and electro-discharge texturing methods. Surf. Topogr. Metrol. Prop. 2021, 9, 035051. [Google Scholar] [CrossRef]

- Vermeulen, M.; Scheers, J. Micro-hydrodynamic effects in EBT textured steel sheet. Int. J. Mach. Tools Manuf. 2001, 41, 1941–1951. [Google Scholar] [CrossRef]

- Gorbunov, A.; Belov, V.; Begletsov, D. Texturing of rollers for the production of auto-industry sheet. Steel Transl. 2009, 39, 696. [Google Scholar] [CrossRef]

- Hilgenberg, K.; Steinhoff, K. Texturing of skin-pass rolls by pulsed laser dispersing. J. Mater. Process. Technol. 2015, 225, 84–92. [Google Scholar] [CrossRef]

- Köhler, K.; Kwiaton, N.; Bretschneider, M. Skin pass rolling of high manganese steels. Mater. Sci. Forum 2016, 854, 93–98. [Google Scholar] [CrossRef]

- de Argandoña, E.S.; Mendez, M.; Mendiguren, J.; Zabala, A. Tool surface texturing by shot peening: Initial results and lessons learned. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1307, 012017. [Google Scholar] [CrossRef]

- Simao, J.; Apinwall, D.; Wise, M.; Subari, K. Surface texture transfer in simulated tandem and temper mill rolling using electrical discharge textured rolls. J. Mater. Process. Technol. 1996, 56, 177–189. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M.; Kmec, J. Optimization of Electro-Discharge Texturing Parameters for Steel Sheets’ Finishing Rollers. Materials 2020, 13, 1223. [Google Scholar] [CrossRef] [PubMed]

- Elkoca, O. A study on the characteristics of electrical discharge textured skin pass mill work roll. Surf. Coat. Technol. 2008, 202, 2765–2774. [Google Scholar] [CrossRef]

- Gonçalves, J., Jr.; De Mello, J.; Costa, H. Tribological behaviour of alternative surface modifications for cold rolling mill rolls. Wear 2021, 470, 203614. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Lei, S.; Yu, X. Effect of micro/nano-textures and burnished MoS2 addition on the tribological properties of PVD TiAlN coatings against AISI 316 stainless steel. Surf. Coat. Technol. 2016, 291, 382–395. [Google Scholar] [CrossRef]

- Warneke, P.; Bohlen, A.; Seefeld, T. Texturing skin-pass rolls by high-speed laser melt injection, laser ablation, and electrolytic etching. J. Laser Appl. 2024, 36, 012011. [Google Scholar] [CrossRef]

- Pawelski, O.; Rasp, W.; Zwick, W.; Nettelbeck, H.-J.; Steinhoff, K. The influence of different work-roll texturing systems on the development of surface structure in the temper rolling process of steel sheet used in the automotive industry. J. Mater. Process. Technol. 1994, 45, 215–222. [Google Scholar] [CrossRef]

- Shimizu, I.; Andreasen, J.L.; Bech, J.I.; Bay, N. Influence of workpiece surface topography on the mechanisms of liquid lubrication in strip drawing. J. Trib. 2001, 123, 290–294. [Google Scholar] [CrossRef]

- Zhang, Z.-Q.; Liao, X.; Ren, Z.-K.; Wang, Z.-H.; Liu, Y.-X.; Wang, T.; Huang, Q.-X. Effect of two-pass rolling of textured roll and polished roll on surface topography and mechanical properties of 316L stainless steel ultra-thin strip. J. Iron Steel Res. Int. 2025, 32, 186–197. [Google Scholar] [CrossRef]

- Zabala, A.; Galdos, L.; Childs, C.; Llavori, I.; Aginagalde, A.; Mendiguren, J.; Saenz de Argandoña, E. The interaction between the sheet/tool surface texture and the friction/galling behaviour on aluminium deep drawing operations. Metals 2021, 11, 979. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V. Influence of Die Surface Textures during Metal Forming—A Study Using Experiments and Simulation. Mater. Manuf. Process. 2010, 25, 1030–1039. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Meng, R.; Lei, S.; Yu, X. Influence of laser substrate pretreatment on anti-adhesive wear properties of WC/Co-based TiAlN coatings against AISI 316 stainless steel. Int. J. Refract. Met. Hard Mater. 2016, 57, 101–114. [Google Scholar] [CrossRef]

- Shrivastava, A.; Kumar, D.R.; Manikandan, G.; Verma, R.K. Laser surface texturing of dies in strip drawing of DP600 steel sheet. Surf. Eng. 2023, 39, 870–881. [Google Scholar] [CrossRef]

- Patel, D.S.; Jain, V.; Shrivastava, A.; Ramkumar, J. Electrochemical micro texturing on flat and curved surfaces: Simulation and experiments. Int. J. Adv. Manuf. Technol. 2019, 100, 1269–1286. [Google Scholar] [CrossRef]

- Patel, D.S.; Agrawal, V.; Ramkumar, J.; Jain, V.; Singh, G. Micro-texturing on free-form surfaces using flexible-electrode through-mask electrochemical micromachining. J. Mater. Process. Technol. 2020, 282, 116644. [Google Scholar] [CrossRef]

- Galanin, S.I.; Viskovatyi, I.S. Electrochemical Surface Texturing of Silver. Surf. Eng. Appl. Electrochem. 2015, 51, 332–338. [Google Scholar] [CrossRef]

- Kunar, S.; Bhattacharyya, B. Fabrication of various micropatterns by maskless micro-electrochemical texturing. Manuf. Rev. 2019, 6, 6. [Google Scholar] [CrossRef]

- Hao, X.Q.; Wang, L.; Ding, Y.C.; Guo, F.L.; Lu, B.H. Finite Element Analysis of a Mask-Less Electrochemical Texturing (MECT) Method on Metallic Surface. Adv. Sci. Lett. 2011, 4, 1394–1398. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Arencibia, R.V.; Costa, H.; da Silva, W.M., Jr. Roughness analysis of electrochemically textured surfaces: Effects on friction and wear of lubricated contacts. Surf. Topogr. Metrol. Prop. 2020, 8, 024011. [Google Scholar] [CrossRef]

- Dias, L.C.; Ferri, G.G.B.; Costa, H.L. Maskless electrochemical surface texturing for cylindrical components: New developments. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 297. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, L. Surface texture transfer in skin-pass rolling under mixed lubrication. Int. J. Mech. Sci. 2025, 286, 109858. [Google Scholar] [CrossRef]

- Zhang, B.; Meng, W.J. Scaling Anomaly in the Mechanical Response in Microscale Reverse Extrusion of Copper. J. Micro Nano-Manuf. 2020, 8, 010910. [Google Scholar] [CrossRef]

- Wentink, D.; Matthews, D.; Appelman, N.; Toose, E. A generic model for surface texture development, wear and roughness transfer in skin pass rolling. Wear 2015, 328, 167–176. [Google Scholar] [CrossRef]

- Steinhoff, K.; Bünten, R.; Rasp, W.; Kopp, R.; Pawelski, O. Development of a model for the simulation of the transfer of surface structure in the temper-rolling process. Steel Res. 1995, 66, 520–525. [Google Scholar] [CrossRef]

- Silva, R.S.; Lopes, A.P.O.; Luz, F.K.C.; de Almeida, D.T.; Costa, H.L. Effect of tool microstructure on the tribological behaviour of electrochemically textured tools in strip drawing tests. Wear 2025, 571, 205759. [Google Scholar] [CrossRef]

- Ray, S. Principles and Applications of Metal Rolling; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Bünten, R.; Steinhoff, K.; Rasp, W.; Kopp, R.; Pawelski, O. Development of a FEM-model for the simulation of the transfer of surface structure in cold-rolling processes. J. Mater. Process. Technol. 1996, 60, 369–376. [Google Scholar] [CrossRef]

- Miguel, V.; Martínez, A.; Coello, J.; Avellaneda, F.J.; Calatayud, A. A new approach for evaluating sheet metal forming based on sheet drawing test. Application to TRIP 700 steel. J. Mater. Process. Technol. 2013, 213, 1703–1710. [Google Scholar] [CrossRef]

- Azushima, A.; Kudo, H. Direct observation of contact behaviour to interpret the pressure dependence of the coefficient of friction in metal forming. Ann. CIRP 1995, 44, 209–212. [Google Scholar] [CrossRef]

- Belov, V.; Begletsov, D.; D’yakova, M.; Gorbunov, A. Production of sheet with regulated surface microtopography. Steel Transl. 2014, 44, 298–305. [Google Scholar] [CrossRef]

- Costa, H.L.; Profito, F.J.; Zhang, X.; Thole, K.A. Optimizing the surface of manufactured components for friction, adhesion, and convective heat transfer. MRS Bull. 2022, 47, 1247–1259. [Google Scholar] [CrossRef]

- Yerramareddy, S.; Bahadur, S. The effect of laser surface treatments on the tribological behavior of Ti-6Al-4V. Wear 1992, 157, 245–262. [Google Scholar] [CrossRef]

- Mondal, A.K.; Kumar, S.; Blawert, C.; Dahotre, N.B. Effect of laser surface treatment on corrosion and wear resistance of ACM720 Mg alloy. Surf. Coat. Technol. 2008, 202, 3187–3198. [Google Scholar] [CrossRef]

- Jonasson, M.; Pulkkinen, T.; Gunnarsson, L.; Schedin, E. Comparative study of shotblasted and electrical-discharge-textured rolls with regard to frictional behavior of the rolled steel sheet surfaces. Wear 1997, 207, 34–40. [Google Scholar] [CrossRef]

- Merlo, A.; Léonard, G. Magnetron Sputtering vs. Electrodeposition for Hard Chrome Coatings: A Comparison of Environmental and Economic Performances. Materials 2021, 14, 3823. [Google Scholar] [CrossRef] [PubMed]

| Gap (µm) | NaCl Concentration (g/L) | Flow (mL/s) | Tension (V) | Time (s) |

|---|---|---|---|---|

| 100 | 200 | 20 | 30 | 300 |

| C | Si | Mn | Cr | Mo | Ni | V | Fe |

|---|---|---|---|---|---|---|---|

| 0.85 | 0.25 | 0.38 | 4.16 | 8.13 | 0.20 | 2.24 | Balance |

| Gap (µm) | NaCl Concentration (g/L) | Flow (mL/s) | Tension (V) | Time (s) |

|---|---|---|---|---|

| 300 | 200 | 20 | 30 | 300 |

| C | Mn | Si | P | S | Cr | Nb | N |

|---|---|---|---|---|---|---|---|

| wt.% | |||||||

| 0.021 | 0.20 | 0.31 | 0.030 | 0.001 | 16.15 | 0.336 | 0.0184 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monteiro, P.L., Jr.; Labiapari, W.; Da Silva, W.M., Jr.; de Azevedo Celente, C.; Costa, H.L. Maskless Electrochemical Texturing (MECT) Applied to Skin-Pass Cold Rolling. Lubricants 2025, 13, 312. https://doi.org/10.3390/lubricants13070312

Monteiro PL Jr., Labiapari W, Da Silva WM Jr., de Azevedo Celente C, Costa HL. Maskless Electrochemical Texturing (MECT) Applied to Skin-Pass Cold Rolling. Lubricants. 2025; 13(7):312. https://doi.org/10.3390/lubricants13070312

Chicago/Turabian StyleMonteiro, Paulo L., Jr., Wilian Labiapari, Washington M. Da Silva, Jr., Cristiano de Azevedo Celente, and Henara Lillian Costa. 2025. "Maskless Electrochemical Texturing (MECT) Applied to Skin-Pass Cold Rolling" Lubricants 13, no. 7: 312. https://doi.org/10.3390/lubricants13070312

APA StyleMonteiro, P. L., Jr., Labiapari, W., Da Silva, W. M., Jr., de Azevedo Celente, C., & Costa, H. L. (2025). Maskless Electrochemical Texturing (MECT) Applied to Skin-Pass Cold Rolling. Lubricants, 13(7), 312. https://doi.org/10.3390/lubricants13070312