An Experimental Study of Wheel–Rail Creep Curves Under Dry Contact Conditions Using V-Track †

Abstract

1. Introduction

2. Materials and Methods

2.1. V-Track Test Rig

2.2. Test Procedure

2.2.1. Lateral Creep Curve Test

2.2.2. Longitudinal Creep Curve Test

2.3. Data Processing and Uncertainty Analysis

2.3.1. Calculation of Lateral Creepage

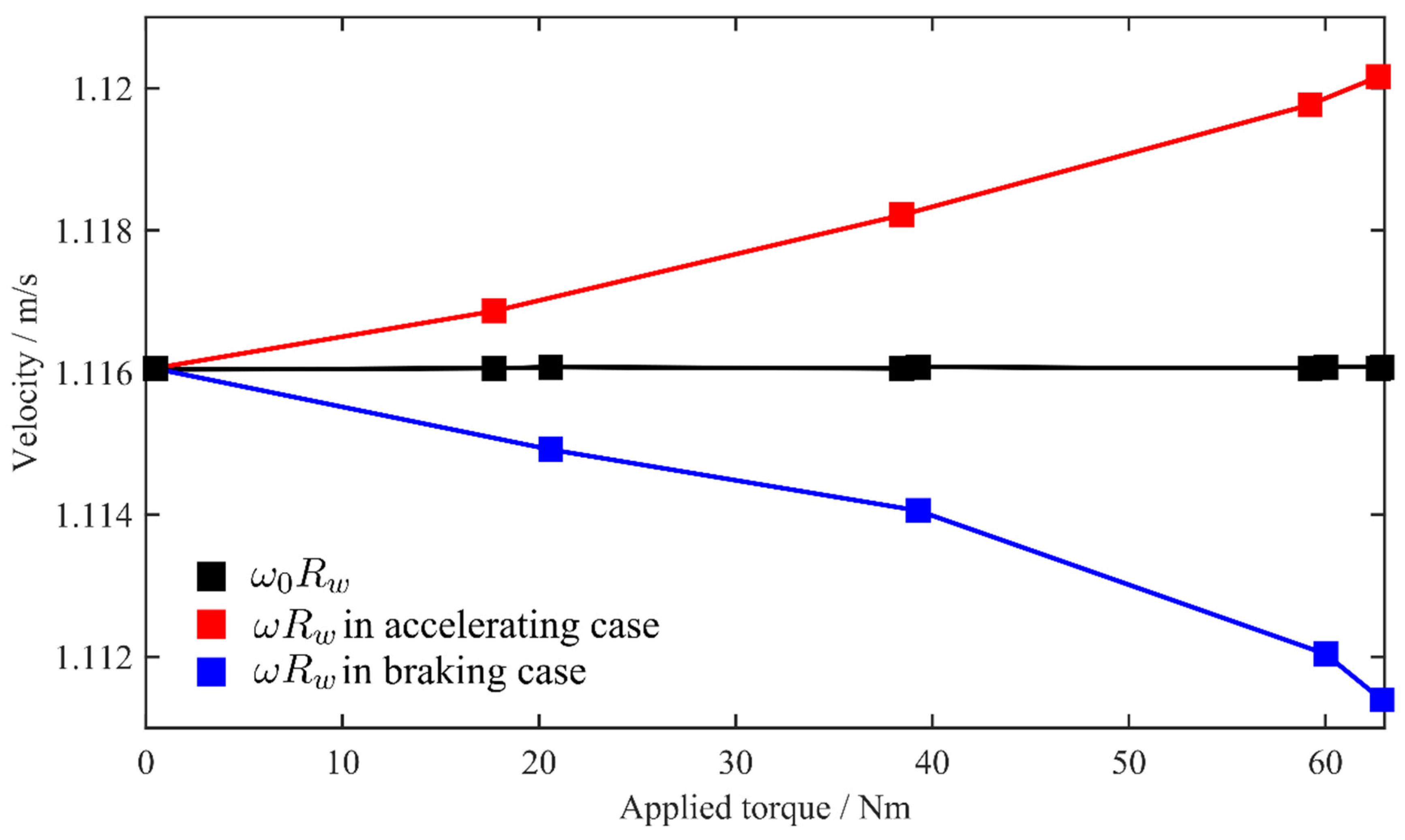

2.3.2. Calculation of Longitudinal Creepage

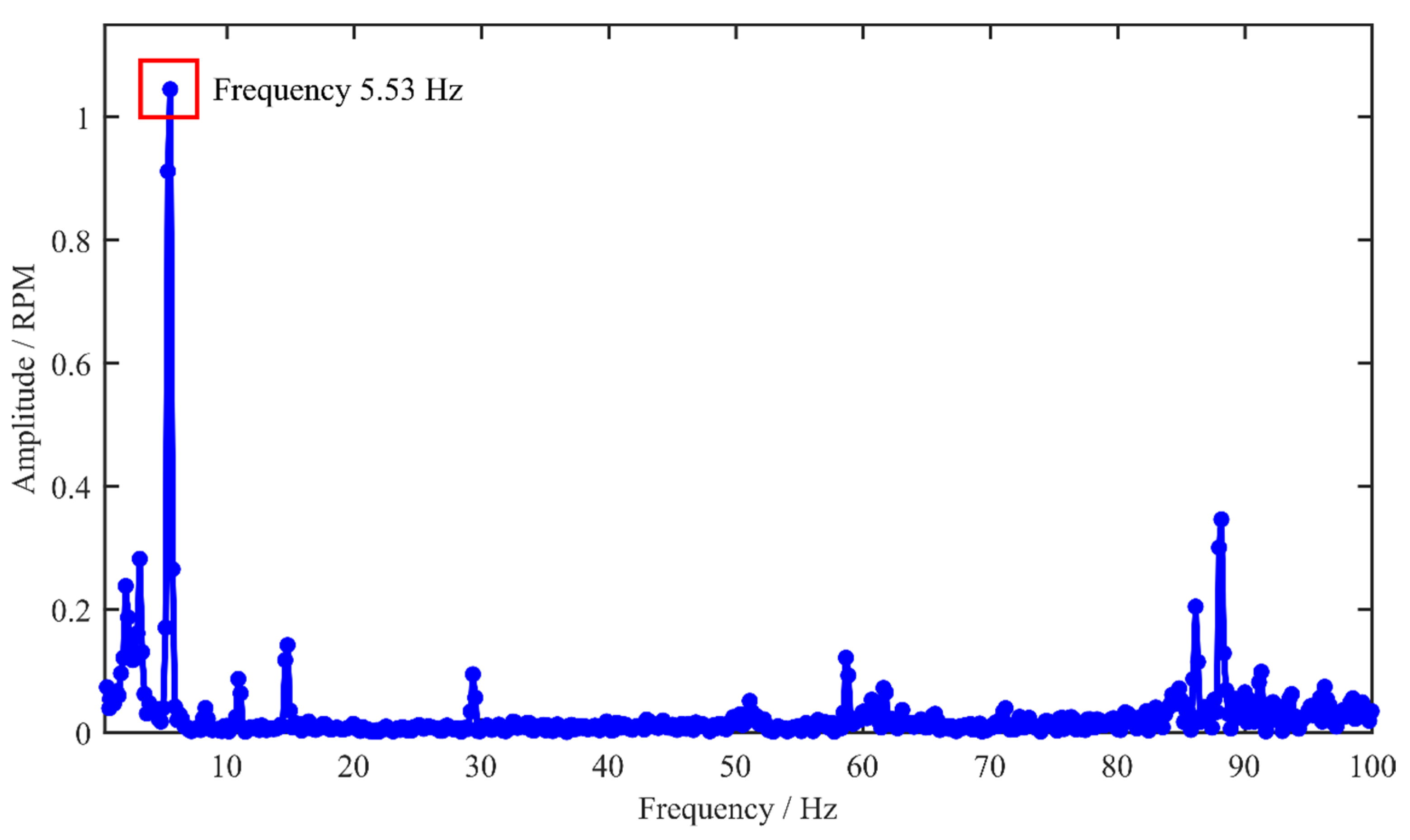

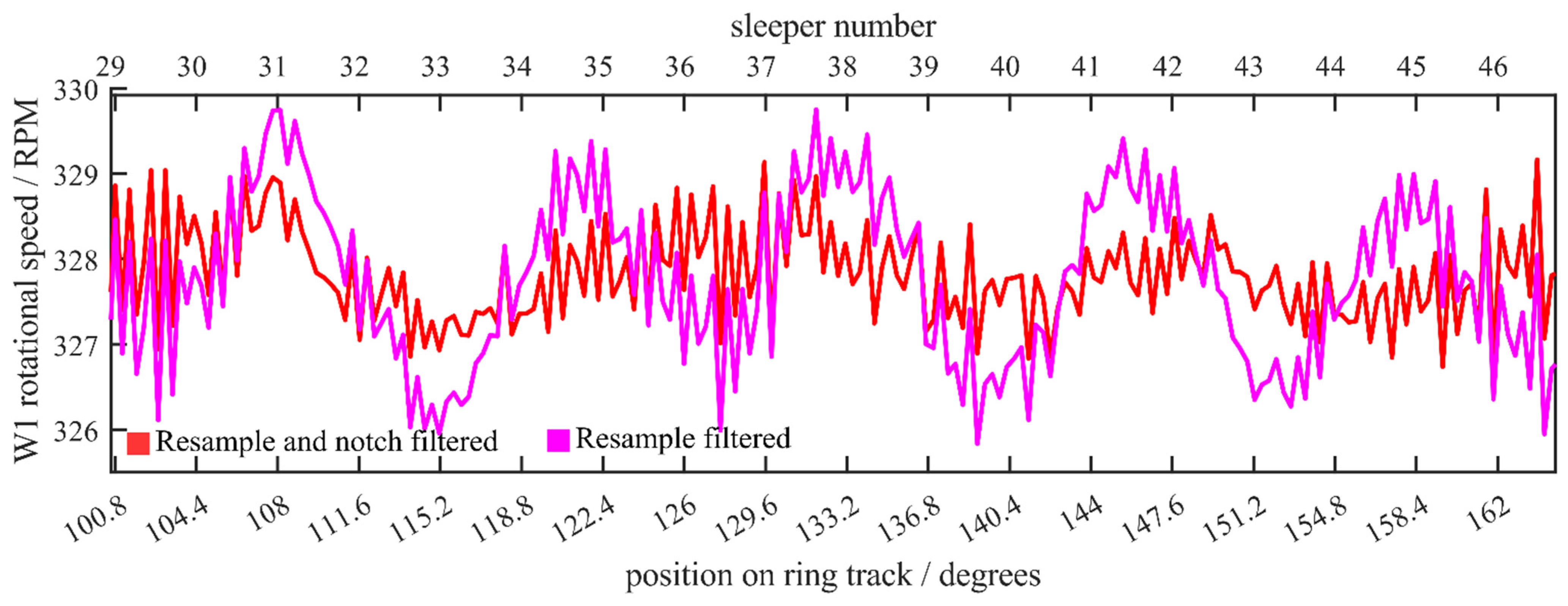

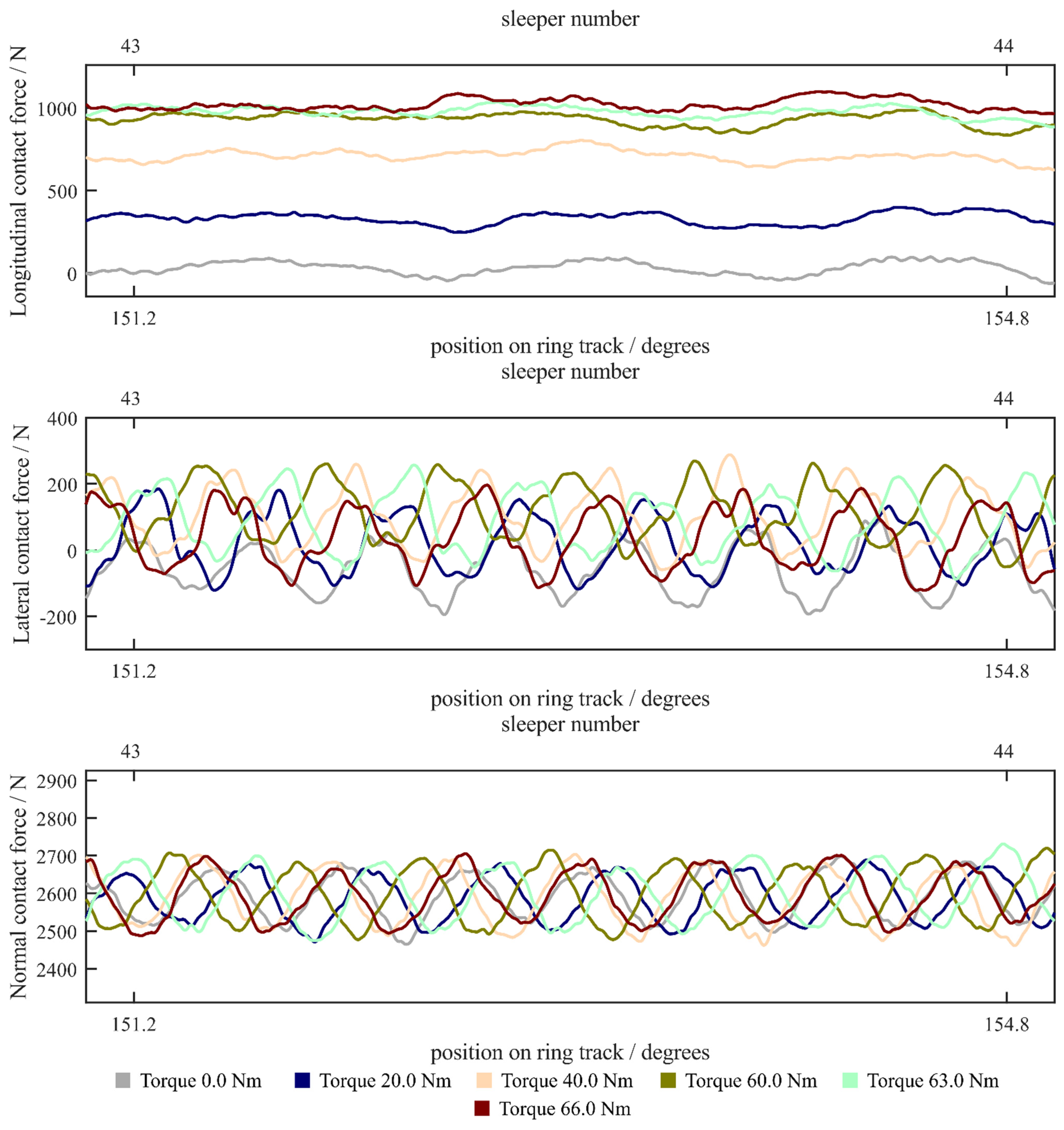

Reducing Short-Term Errors

Reducing Long-Term Errors

2.3.3. Calculation of the CoA

3. Results and Discussion

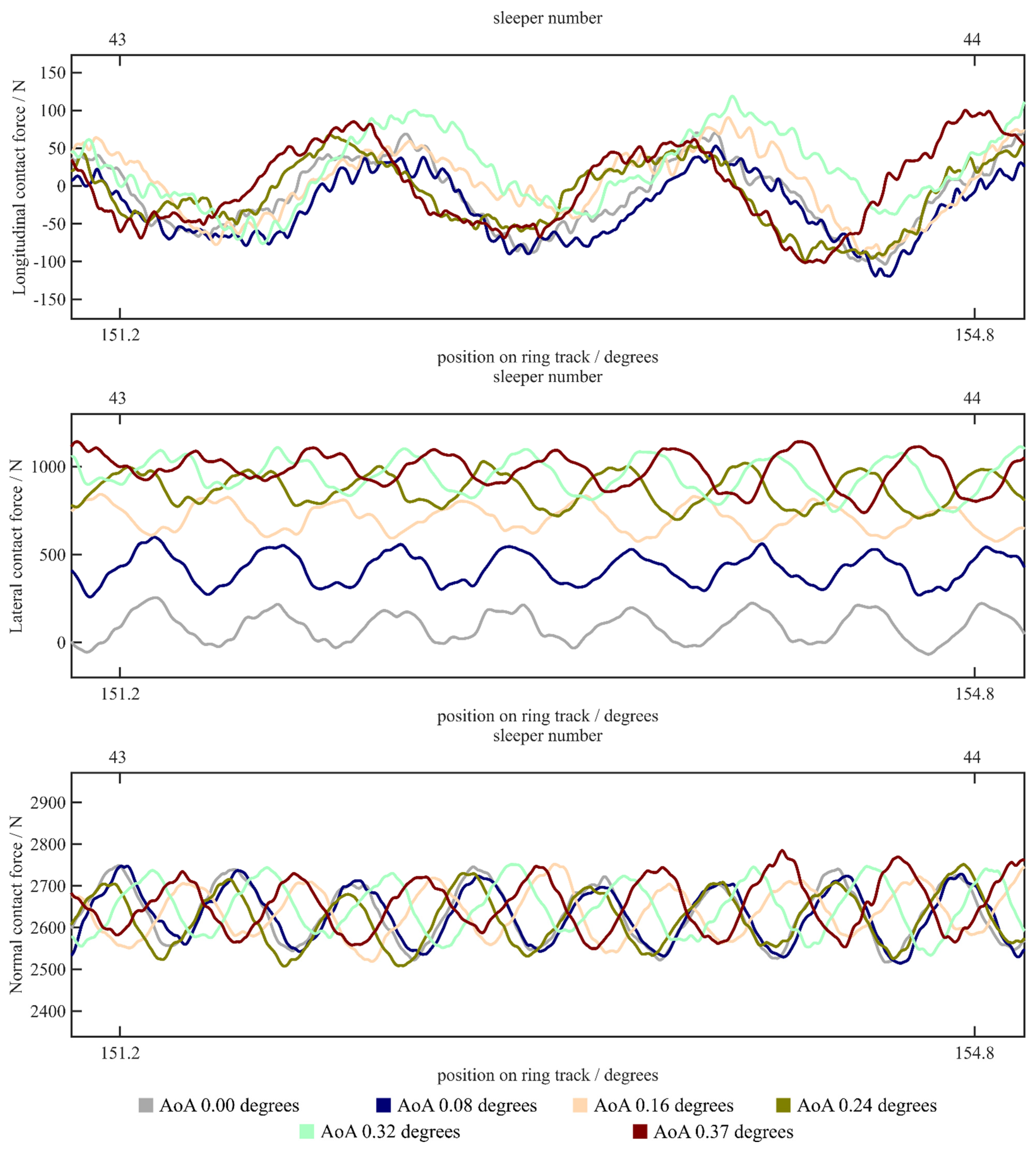

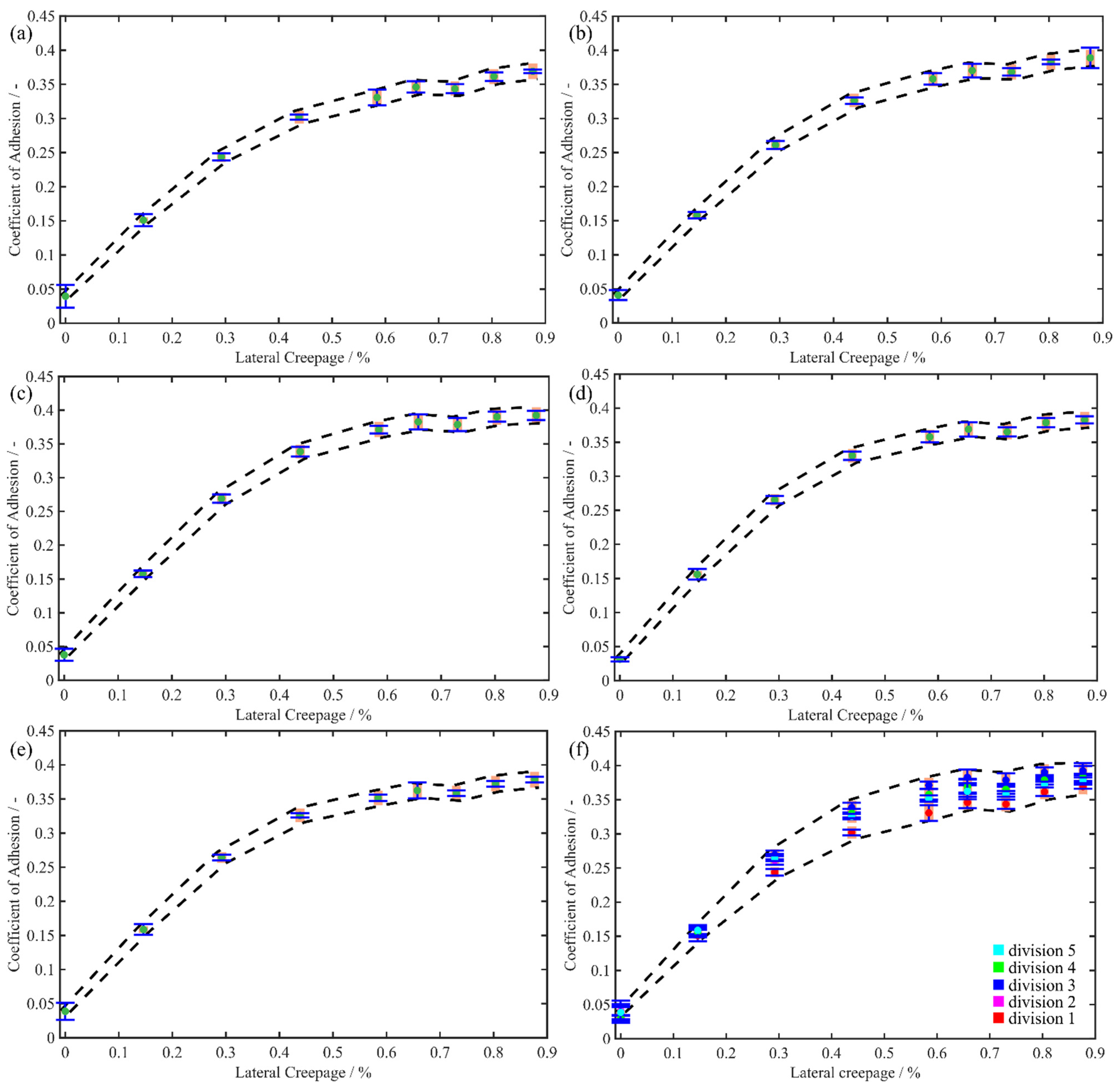

3.1. Lateral Creep Curves

3.1.1. Measured Creep Curves

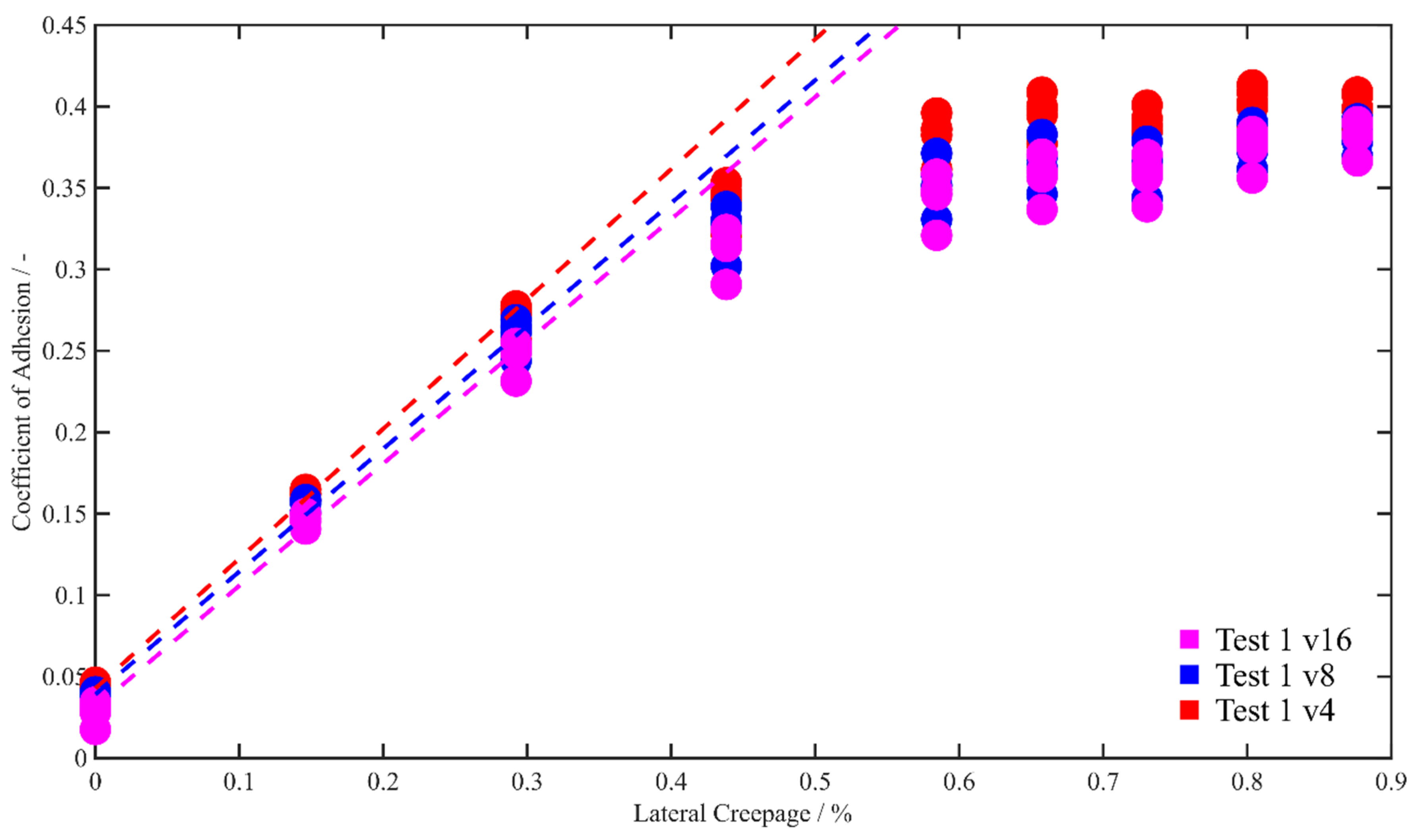

3.1.2. Influence of the Rolling Speed

3.1.3. Comparison with CONTACT

3.2. Longitudinal Creep Curves

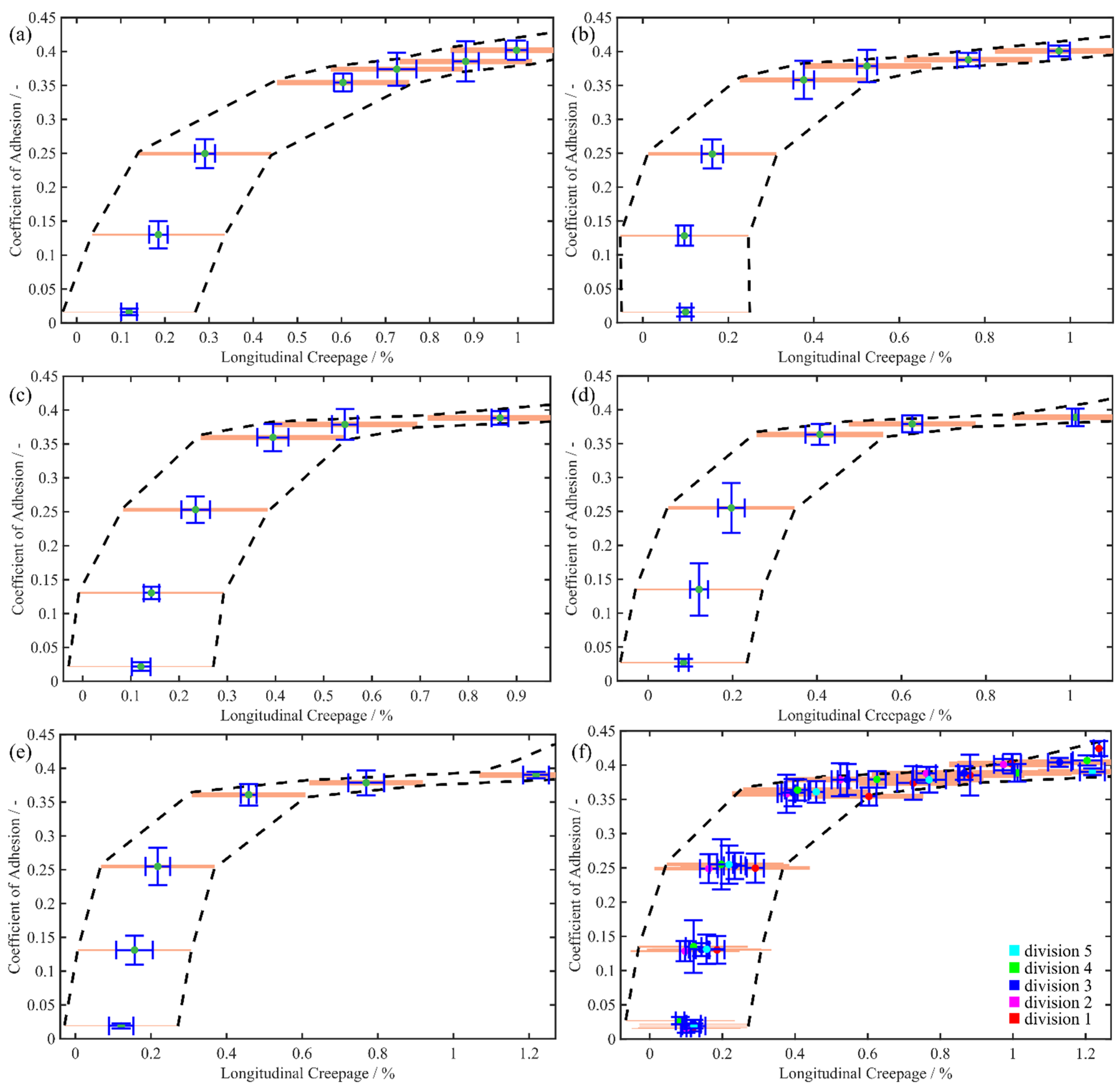

3.2.1. Measured Creep Curves

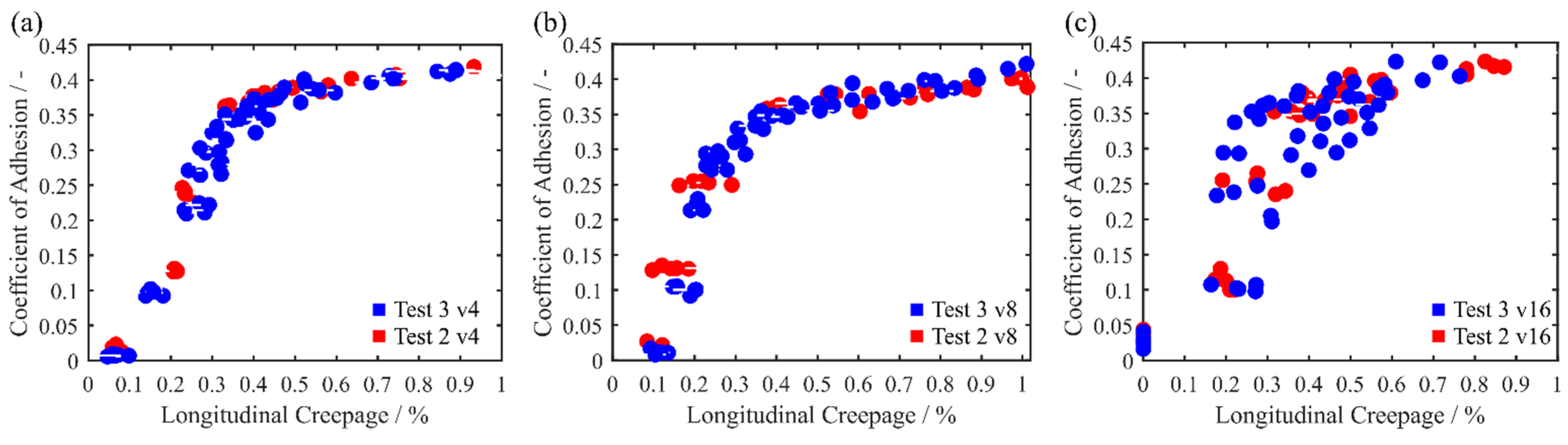

3.2.2. Influence of the Torque Direction

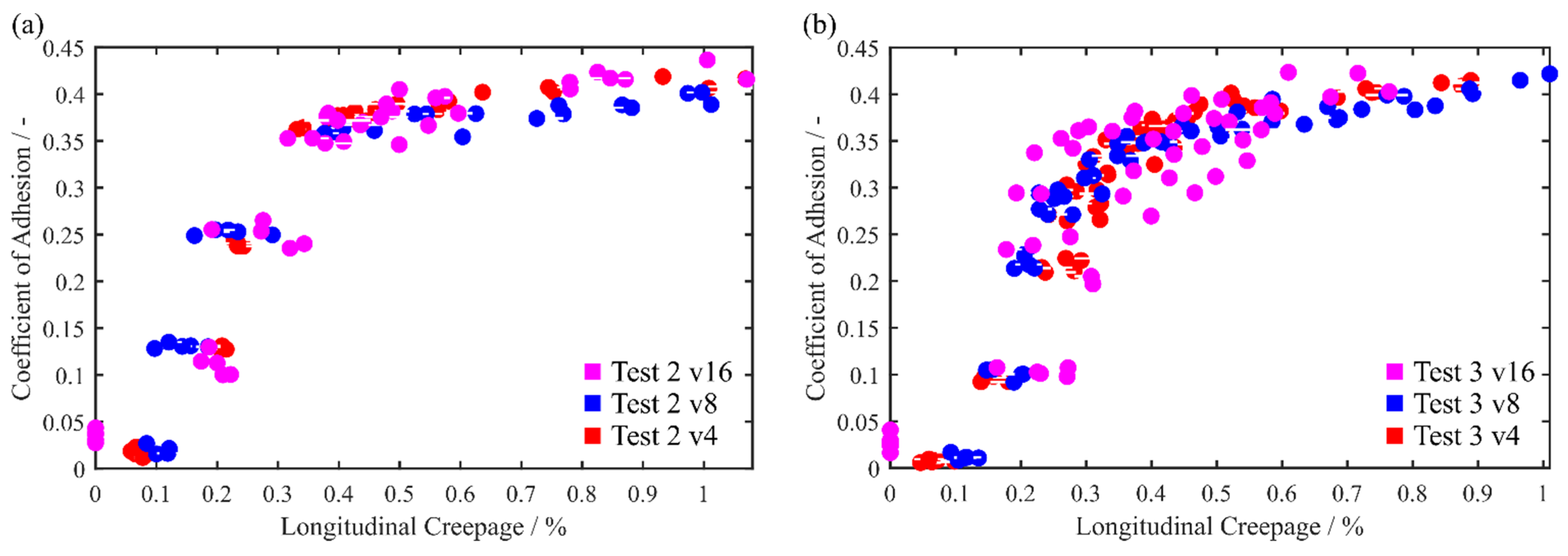

3.2.3. Influence of the Rolling Speed

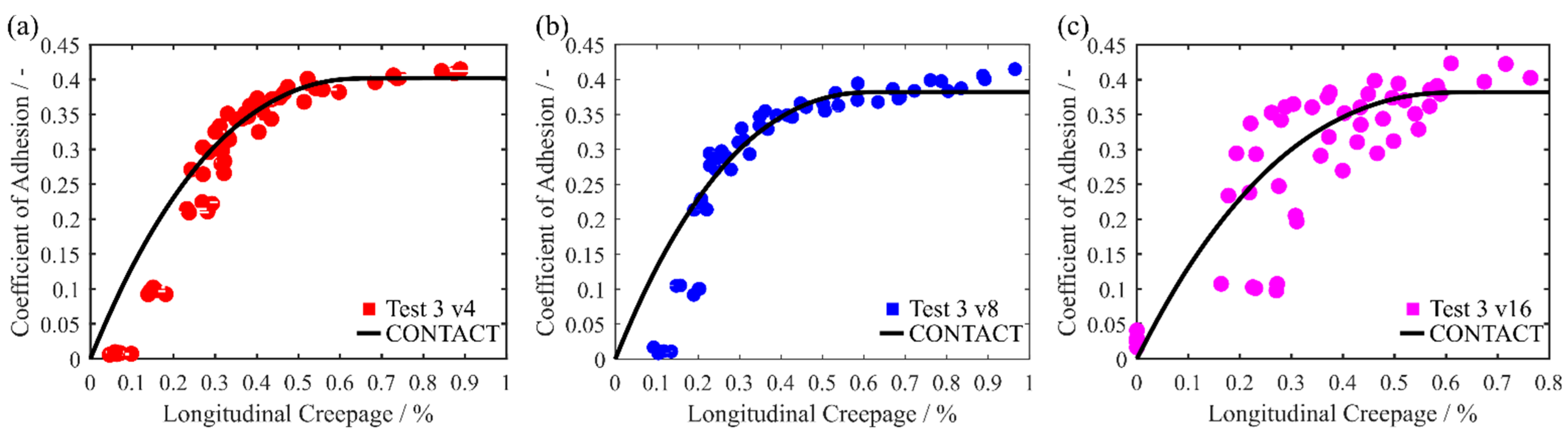

3.2.4. Comparison with CONTACT

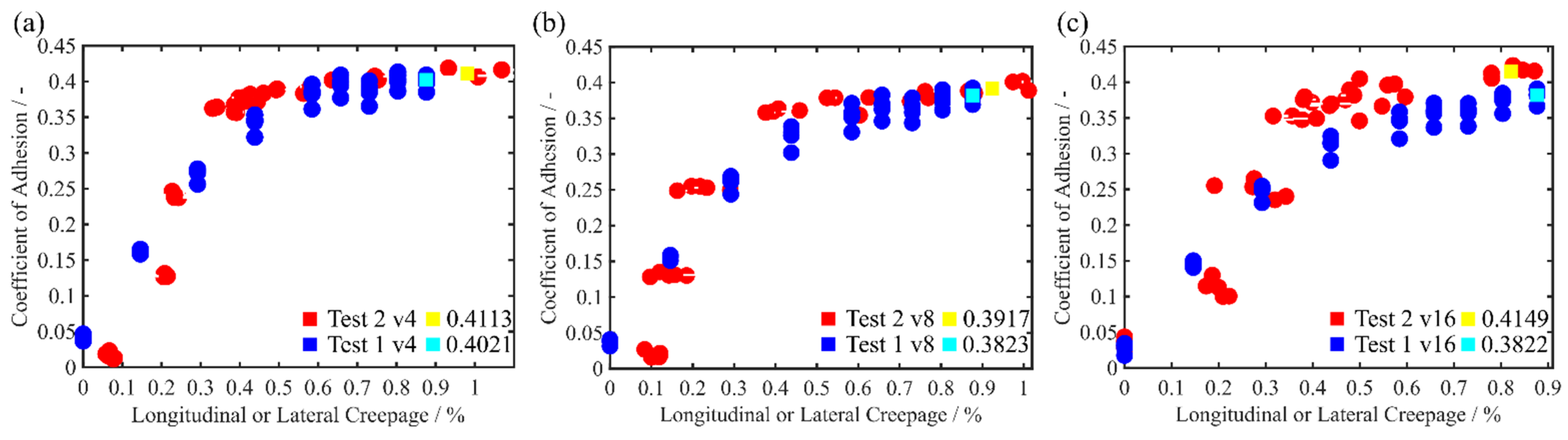

3.3. Comparison Between the Longitudinal and Lateral Creep Curves

4. Conclusions and Future Work

- For the lateral creep curve: the lateral creep curve tests indicate a slight decrease in the CoF value and a reduction in the creep coefficient with the increase in the wheel rolling speed. The CoF decrease with speed was in line with previous studies, while the creep coefficient reduction was probably induced by the debris of the wheel/rail material acting as a third-body layer at the wheel–rail interface for the higher-speed test cases. Excellent agreement was achieved between the experimental and theoretical lateral creep curves. Small discrepancies were found in the higher-speed test cases because the applied CONTACT programme does not consider the effect of third-body layers.

- For the longitudinal creep curve: the longitudinal creep curves measured with the accelerating and braking torques showed quite similar trends, corresponding well to the theoretical results. The speed dependence of the CoF that is often observed with high values of the absolute sliding speed (>1 m/s) did not occur in this study, possibly because the rolling speeds (<16 km/h) and the longitudinal creepage (<1%) values applied in this study produced sliding speeds not higher than 0.045 m/s. Good agreement was achieved between the measured and simulated longitudinal creep curves, especially when the longitudinal creepage was above 0.3%. The discrepancies below 0.3% could be due to the uncertainty of the wheel angular speed measurement in the current test setup.

- The agreement between the experimental and theoretical results, as well as the aligned CoFs measured with the lateral and longitudinal creep curve tests, demonstrated the reliability of the V-Track for wheel–rail creep curve measurements and its suitability for studying the wheel–rail frictional rolling contact.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fletcher, D.I.; Lewis, S. Creep Curve Measurement to Support Wear and Adhesion Modelling, Using a Continuously Variable Creep Twin Disc Machine. Wear 2013, 298–299, 57–65. [Google Scholar] [CrossRef]

- Kalker, J.J. Three-Dimensional Elastic Bodies in Rolling Contact; Springer Nature: Dordrecht, The Netherlands, 1990. [Google Scholar] [CrossRef]

- Tanimoto, H.; Chen, H. Influence of Surface Roughness and Temperature on Wheel/Rail Adhesion in Wet Conditions. Q. Rep. RTRI 2015, 56, 206–211. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, J.; Wu, X.; Jin, X. Wheel/rail Adhesion and Analysis by Using Full Scale Roller Rig. Wear 2002, 253, 82–88. [Google Scholar] [CrossRef]

- Li, Z.; Arias-Cuevas, O.; Lewis, R.; Gallardo-Hernández, E.A. Rolling–Sliding Laboratory Tests of Friction Modifiers in Leaf Contaminated Wheel–Rail Contacts. Tribol. Lett. 2009, 33, 97–109. [Google Scholar] [CrossRef]

- Chen, Q.; Ge, X.; Shi, Z.; Ling, L.; Hu, X.; Hu, Y.; Wang, K. Measurement of Vehicle Speed Based on the GCC Algorithm and its Application in Anti-Slip Control. Measurement 2023, 219, 113298. [Google Scholar] [CrossRef]

- Pichlik, P.; Bauer, J. Analysis of the Locomotive Wheel Slip Controller Operation During Low Velocity. IEEE Trans. Intell. Transp. Syst. 2021, 22, 1543–1552. [Google Scholar] [CrossRef]

- Engelberg, T. Design of a Correlation System for Speed Measurement of Rail Vehicles. Measurement 2001, 29, 157–164. [Google Scholar] [CrossRef]

- Giner, J.; Baeza, L.; Vila, P.; Alonso, A. Study of the Falling Friction Effect on Rolling Contact Parameters. Tribol. Lett. 2017, 65, 29. [Google Scholar] [CrossRef]

- Briales, E.; Urda, P.; Escalona, J.L. Track Frame Approach for Heading and Attitude Estimation in Operating Railways Using On-Board MEMS Sensor and Encoder. Measurement 2021, 184, 109898. [Google Scholar] [CrossRef]

- Alonso, A.; Guiral, A.; Baeza, L.; Iwnicki, S. Wheel–Rail Contact: Experimental Study of the Creep Forces–Creepage Relationships. Veh. Syst. Dyn. 2014, 52, 469–487. [Google Scholar] [CrossRef]

- Gutsulyak, D.V.; Stanlake, L.J.E.; Qi, H. Twin Disc Evaluation of Third Body Materials in the Wheel/Rail Interface. Tribol.-Mater. Surf. Interfaces 2021, 15, 115–126. [Google Scholar] [CrossRef]

- Ahn, K.; Park, J.; Ryew, S. The Construction of a Full-Scale Wheel/Rail Roller Rig in Korea. In Proceedings of the 2012 IEEE International Conference on Automation Science and Engineering (CASE), Seoul, Republic of Korea, 20–24 August 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 802–803. [Google Scholar] [CrossRef]

- Boyacioglu, P.; Bevan, A.; Allen, P.; Bryce, B.; Foulkes, S. Wheel Wear Performance Assessment and Model Validation Using Harold Full Scale Test Rig. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 406–417. [Google Scholar] [CrossRef]

- Meymand, S.Z.; Ahmadian, M. Design, Development, and Calibration of a Force-Moment Measurement System for Wheel–Rail Contact Mechanics in Roller Rigs. Measurement 2016, 81, 113–122. [Google Scholar] [CrossRef]

- Radmehr, A.; Hosseinian Ahangarnejad, A.; Tajaddini, A.; Ahmadian, M. Investigating the Influence of Angle of Attack (Yaw) on Wheel-Rail Interface (WRI) Dynamics. In Proceedings of the 2020 Joint Rail Conference, American Society of Mechanical Engineers, St. Louis, MO, USA, 20–22 April 2020; p. V001T13A003. [Google Scholar] [CrossRef]

- Shu, X.; Zeng, Y.; Wilson, N.; Thompson, R.; Tajaddini, A. Wheel/Rail Contact Creep Curve Measurement and Low Speed Wheel Climb Derailment Investigation. In Advances in Dynamics of Vehicles on Roads and Tracks; Klomp, M., Bruzelius, F., Nielsen, J., Hillemyr, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 660–668. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, C.; Meehan, P.A. The Effect of Rolling Speed on Lateral Adhesion at Wheel/Rail Interface Under Dry and Wet Condition. Wear 2019, 438–439, 203073. [Google Scholar] [CrossRef]

- Petersen, D.; Link, R.; Fletcher, D.; Beynon, J. Development of a Machine for Closely Controlled Rolling Contact Fatigue and Wear Testing. J. Test. Eval. 2000, 28, 267–275. [Google Scholar] [CrossRef]

- Naeimi, M.; Li, Z.; Petrov, R.H.; Sietsma, J.; Dollevoet, R. Development of a New Downscale Setup for Wheel-Rail Contact Experiments under Impact Loading Conditions. Exp. Tech. 2018, 42, 1–17. [Google Scholar] [CrossRef]

- Zhang, P.; Moraal, J.; Li, Z. Design, Calibration and Validation of a Wheel-Rail Contact Force Measurement System in V-Track. Measurement 2021, 175, 109105. [Google Scholar] [CrossRef]

- Ren, F.; Yang, Z.; Li, Z. Experimental and Numerical Investigation into Rolling Contact Fatigue Crack Initiation on the V-Track Test Rig. Eng. Fail. Anal. 2025, 170, 109206. [Google Scholar] [CrossRef]

- Zhang, P.; He, C.; Shen, C.; Dollevoet, R.; Li, Z. Comprehensive Validation of Three-Dimensional Finite Element Modelling of Wheel-Rail High-Frequency Interaction via the V-Track Test Rig. Veh. Syst. Dyn. 2024, 62, 2785–2809. [Google Scholar] [CrossRef]

- Krishnan, G.J.; Yang, Z.; Li, Z. Wheel/Rail Adhesion and Coefficient of Friction Measurement using Downscaled Test Rig. In Proceedings of the Sixth International Conference on Railway Technology: Research, Development and Maintenance, Prague, Czech Republic, 1–5 September 2024; Pombo, J., Ed.; Online volume: CCC 7, Paper 2.5. Civil-Comp Press: Edinburgh, UK, 2024. [Google Scholar] [CrossRef]

- Guides in Metrology. JCGM. 2008. Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement. Available online: https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf/cb0ef43f-baa5-11cf-3f85-4dcd86f77bd6 (accessed on 23 June 2025).

- Kavanagh, R. Improved Digital Tachometer with Reduced Sensitivity to Sensor Nonideality. IEEE Trans. Ind. Electron. 2000, 47, 890–897. [Google Scholar] [CrossRef]

- Prieto, E.; del Mar Pérez, M.; Yandayan, T.; Przybylska, J.; Just, A.; Geckeler, R. Guidelines on the Calibration of Angular Encoders. 2018. Available online: https://www.euramet.org/Media/news/I-CAL-GUI-023_Calibration_Guide_No._23_web.pdf (accessed on 23 June 2025).

- Avago Technologies. HEDM-55xx/560x & HEDS-55xx/56xx. Quick Assembly Two and Three Channel Optical Encoders Data Sheet. Available online: https://hades.mech.northwestern.edu/images/d/d7/HEDS5500-encoder.pdf (accessed on 23 June 2025).

- Hace, A.; Čurkovič, M. Accurate FPGA-Based Velocity Measurement with an Incremental Encoder by a Fast Generalized Divisionless MT-Type Algorithm. Sensors 2018, 18, 3250. [Google Scholar] [CrossRef] [PubMed]

- Avago Technologies. HEDS-51X0/61X0 Series, HEDG-512X/612X Series HEDM-512X/61XX Series Two and Three Channel Codewheels for Use with Avago Technologies Optical Encoder Modules Technical Data. Available online: https://www.mouser.com/datasheet/2/38/V02-1450EN-107271.pdf?srsltid=AfmBOoqwyvsbxOHdvkm8F2RLrBlHsOt___mmPzTu6OHdr_1gegtcN55a (accessed on 23 June 2025).

- Aguado-Rojas, M.; Pasillas-Lépine, W.; Loría, A.; De Bernardinis, A. Angular velocity estimation from incremental encoder measurements in the presence of sensor imperfections. IFAC-PapersOnLine 2017, 50, 5979–5984. [Google Scholar] [CrossRef]

- Gallardo-Hernandez, E.; Lewis, R. Twin Disc Assessment of Wheel/Rail Adhesion. Wear 2008, 265, 1309–1316. [Google Scholar] [CrossRef]

- Monk-Steel, A.; Thompson, D.; de Beer, F.; Janssens, M. An Investigation into the Influence of Longitudinal Creepage on Railway Squeal Noise due to Lateral Creepage. J. Sound Vib. 2006, 293, 766–776. [Google Scholar] [CrossRef]

- Fletcher, D. A New Two-Dimensional Model of Rolling–Sliding Contact Creep Curves for a Range of Lubrication Types. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 529–537. [Google Scholar] [CrossRef]

- Vollebregt, E.; Six, K.; Polach, O. Challenges and Progress in the Understanding and Modelling of the Wheel–Rail Creep Forces. Veh. Syst. Dyn. 2021, 59, 1026–1068. [Google Scholar] [CrossRef]

| Parameter | Value/Range |

|---|---|

| Ring track diameter | 4.0 m |

| Wheel diameter | 130 mm |

| Wheel translational speed | up to 40 km/h |

| Wheel normal load | up to 7500 N |

| Wheel angle of attack | between −2 and 2 degrees |

| Wheel torque | between −500 and 500 N·m |

| Data sampling frequency | 16,670 Hz |

| Test Code | Type of Test | Wheel Rolling Speed |

|---|---|---|

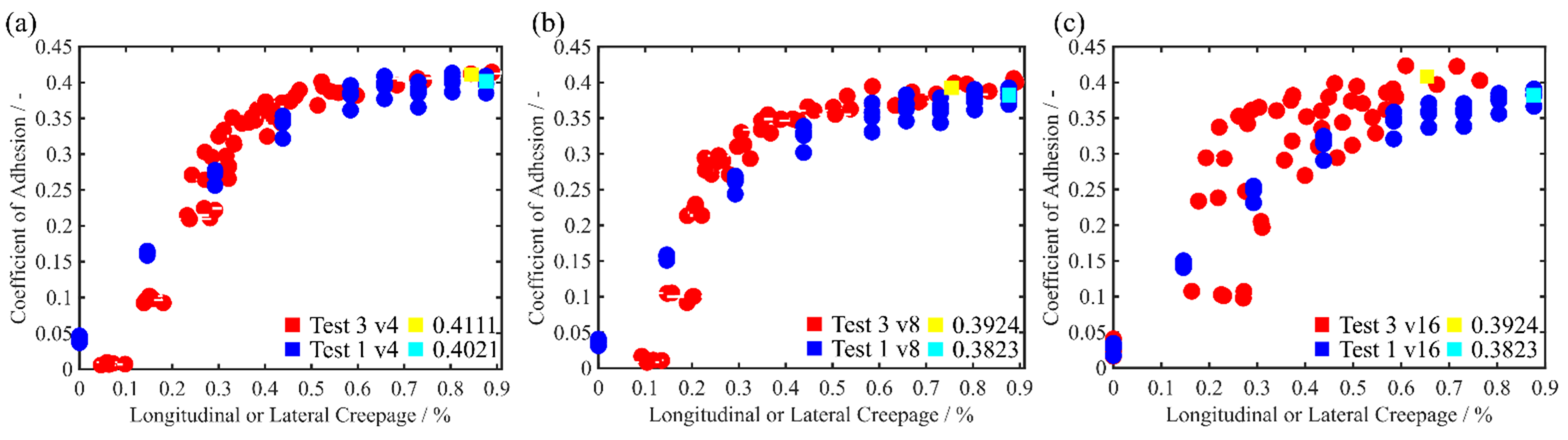

| Test 1 v4 | Lateral | 4 km/h |

| Test 1 v8 | Lateral | 8 km/h |

| Test 1 v16 | Lateral | 16 km/h |

| Test 2 v4 | Longitudinal, braking | 4 km/h |

| Test 2 v8 | Longitudinal, braking | 8 km/h |

| Test 2 v16 | Longitudinal, braking | 16 km/h |

| Test 3 v4 | Longitudinal, accelerating | 4 km/h |

| Test 3 v8 | Longitudinal, accelerating | 8 km/h |

| Test 3 v16 | Longitudinal, accelerating | 16 km/h |

| Wheel Translational Speed | Test 1 | Test 2 | Test 3 | Percentage Difference, Test 1 vs. Test 2 | Percentage Difference, Test 1 vs. Test 3 |

|---|---|---|---|---|---|

| 4 km/h | 0.4021 | 0.4113 | 0.4111 | 2.2879 | 2.2382 |

| 8 km/h | 0.3823 | 0.3917 | 0.3924 | 2.4588 | 2.6419 |

| 16 km/h | 0.3822 | 0.4149 | 0.4080 | 8.5557 | 6.7504 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krishnan, G.J.; Moraal, J.; Li, Z.; Yang, Z. An Experimental Study of Wheel–Rail Creep Curves Under Dry Contact Conditions Using V-Track. Lubricants 2025, 13, 287. https://doi.org/10.3390/lubricants13070287

Krishnan GJ, Moraal J, Li Z, Yang Z. An Experimental Study of Wheel–Rail Creep Curves Under Dry Contact Conditions Using V-Track. Lubricants. 2025; 13(7):287. https://doi.org/10.3390/lubricants13070287

Chicago/Turabian StyleKrishnan, Gokul J., Jan Moraal, Zili Li, and Zhen Yang. 2025. "An Experimental Study of Wheel–Rail Creep Curves Under Dry Contact Conditions Using V-Track" Lubricants 13, no. 7: 287. https://doi.org/10.3390/lubricants13070287

APA StyleKrishnan, G. J., Moraal, J., Li, Z., & Yang, Z. (2025). An Experimental Study of Wheel–Rail Creep Curves Under Dry Contact Conditions Using V-Track. Lubricants, 13(7), 287. https://doi.org/10.3390/lubricants13070287