Effect of Nanographene Water-Based Lubricant (NGWL) on Removal Behavior of Pure Copper

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

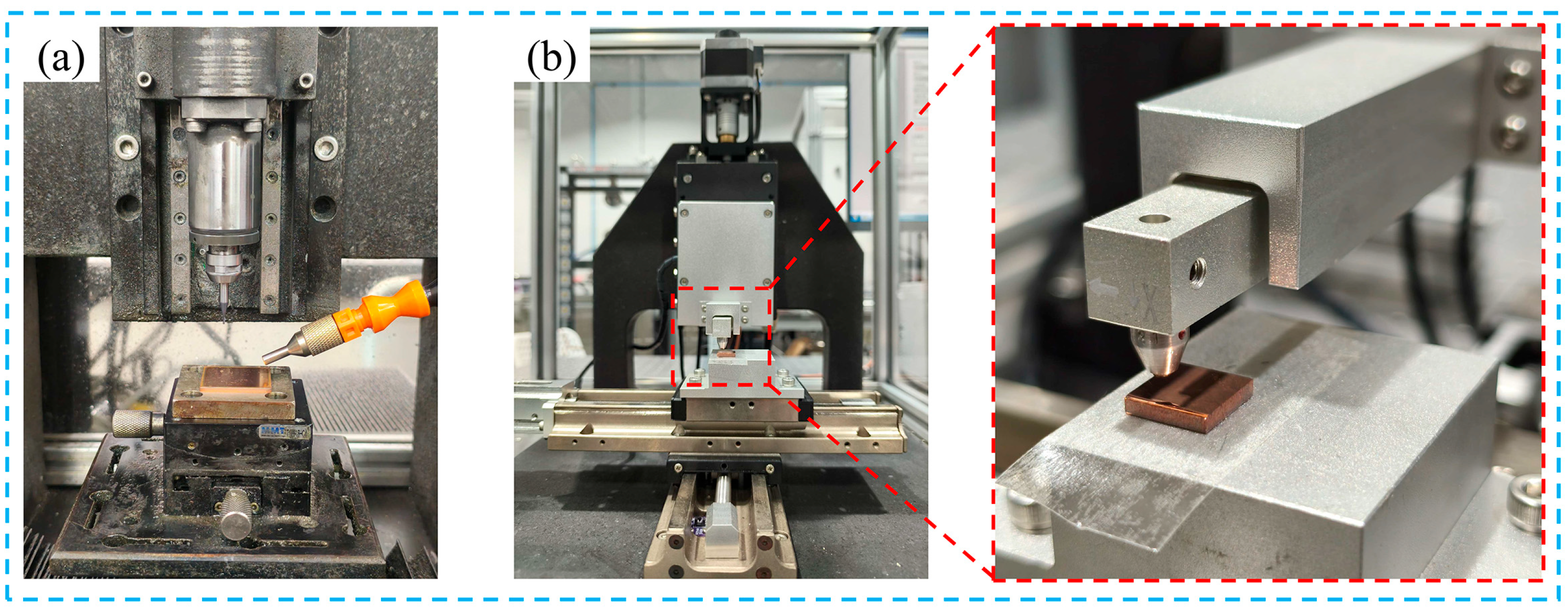

2.2. Experimental Devices

2.3. Characterization Methods

3. Results

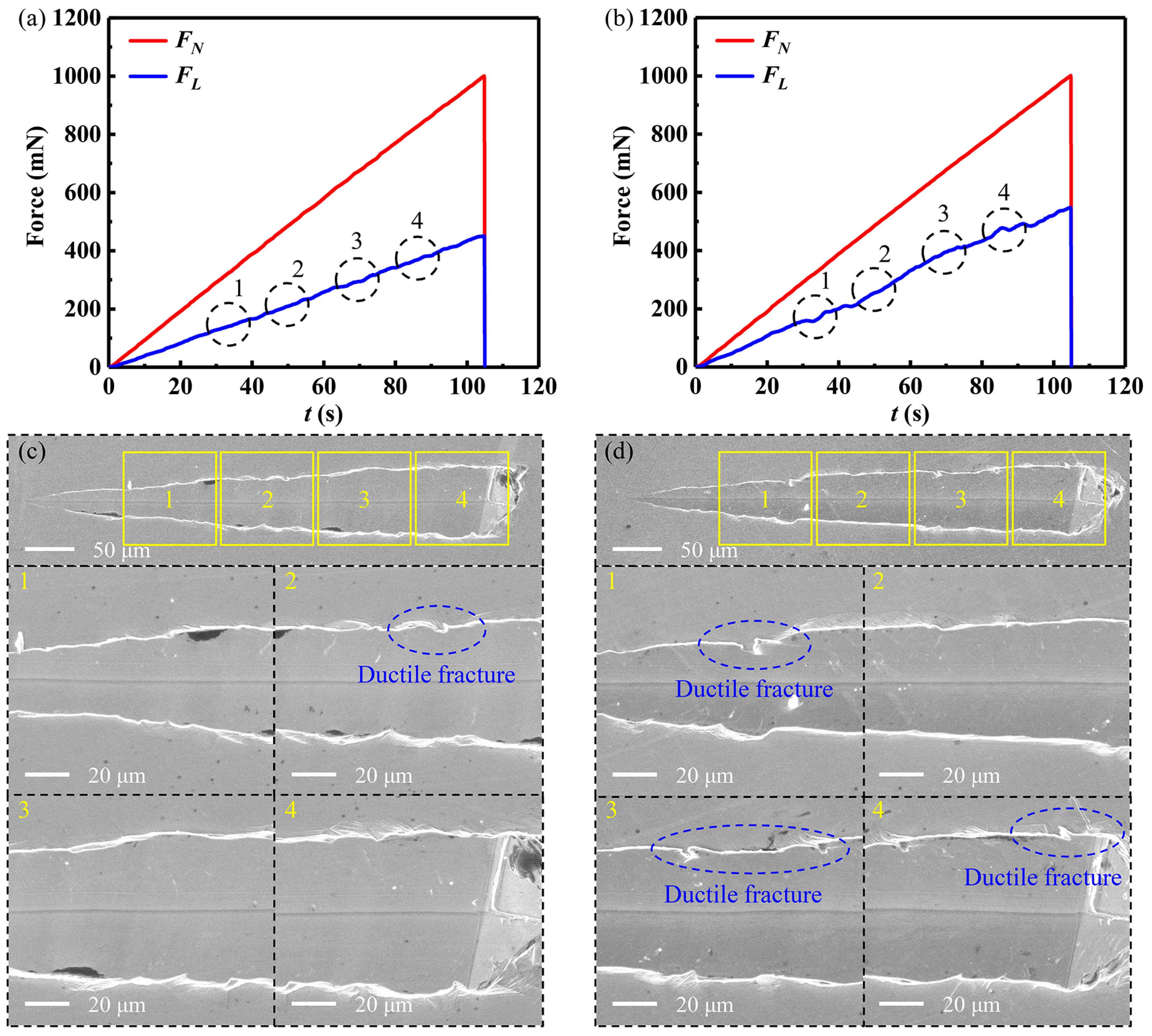

3.1. Single-Grain Diamond Scribing Experiment

3.1.1. Variable-Force Scribing

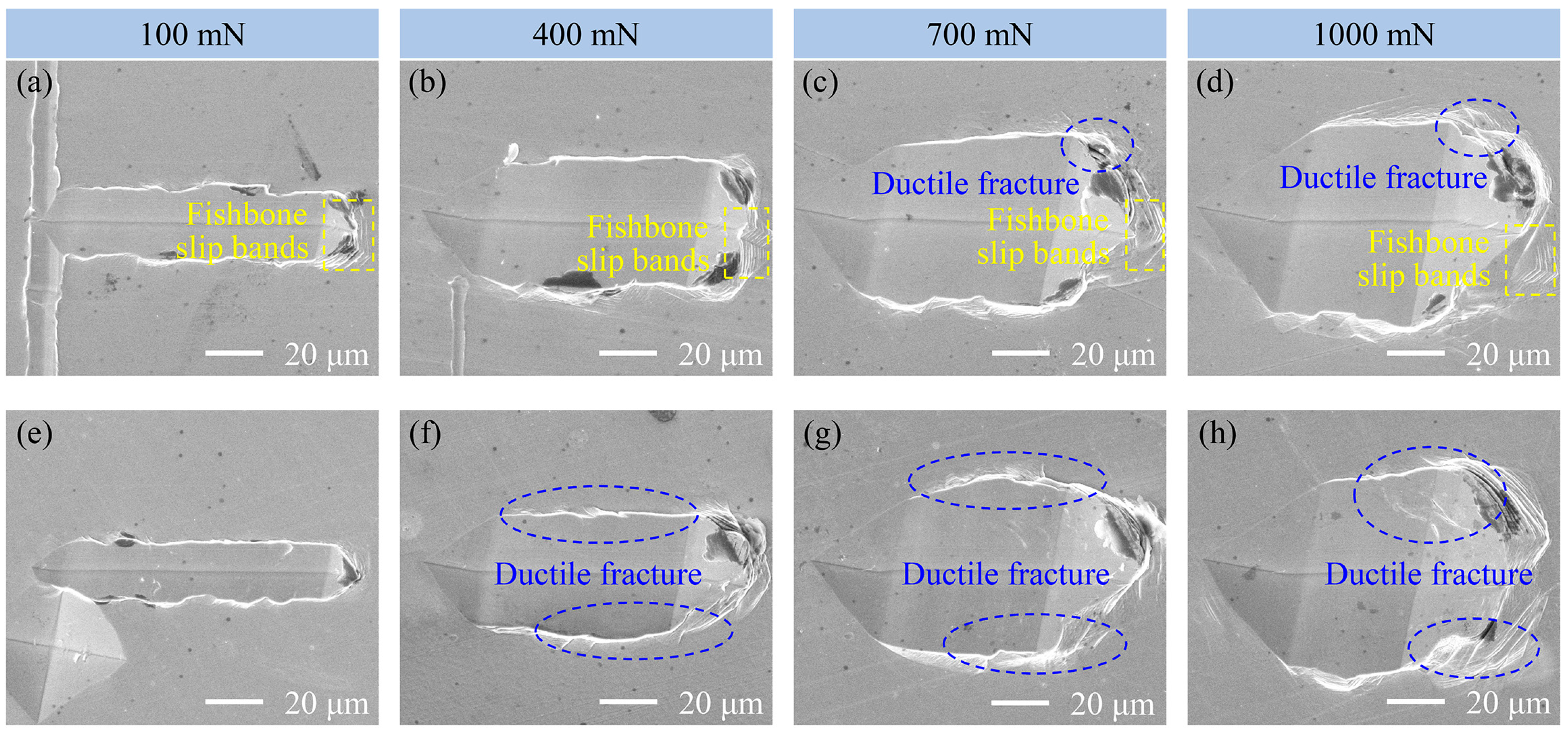

3.1.2. Constant-Force Scribing

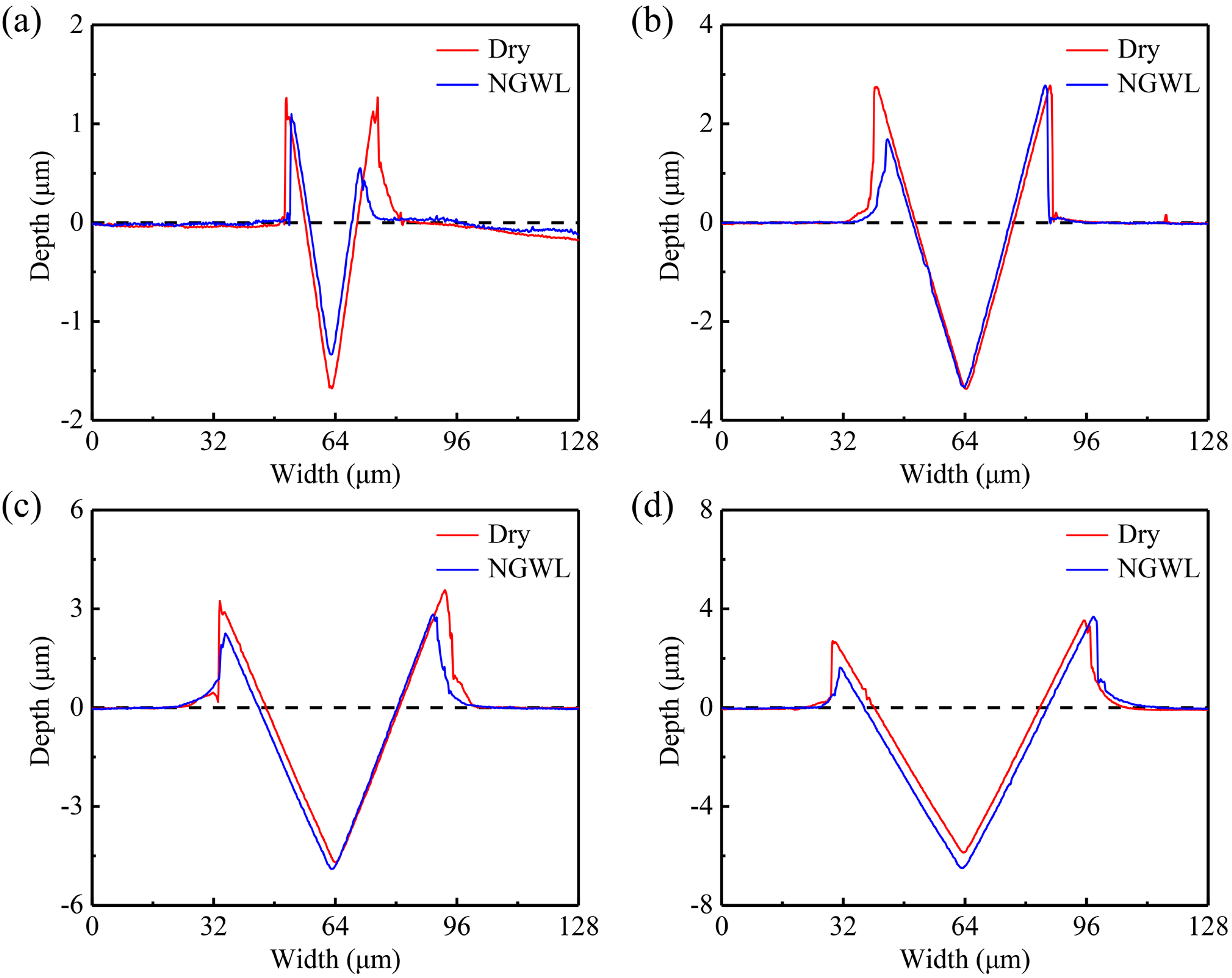

3.2. NGWL Assisted Micro-Milling Experiment

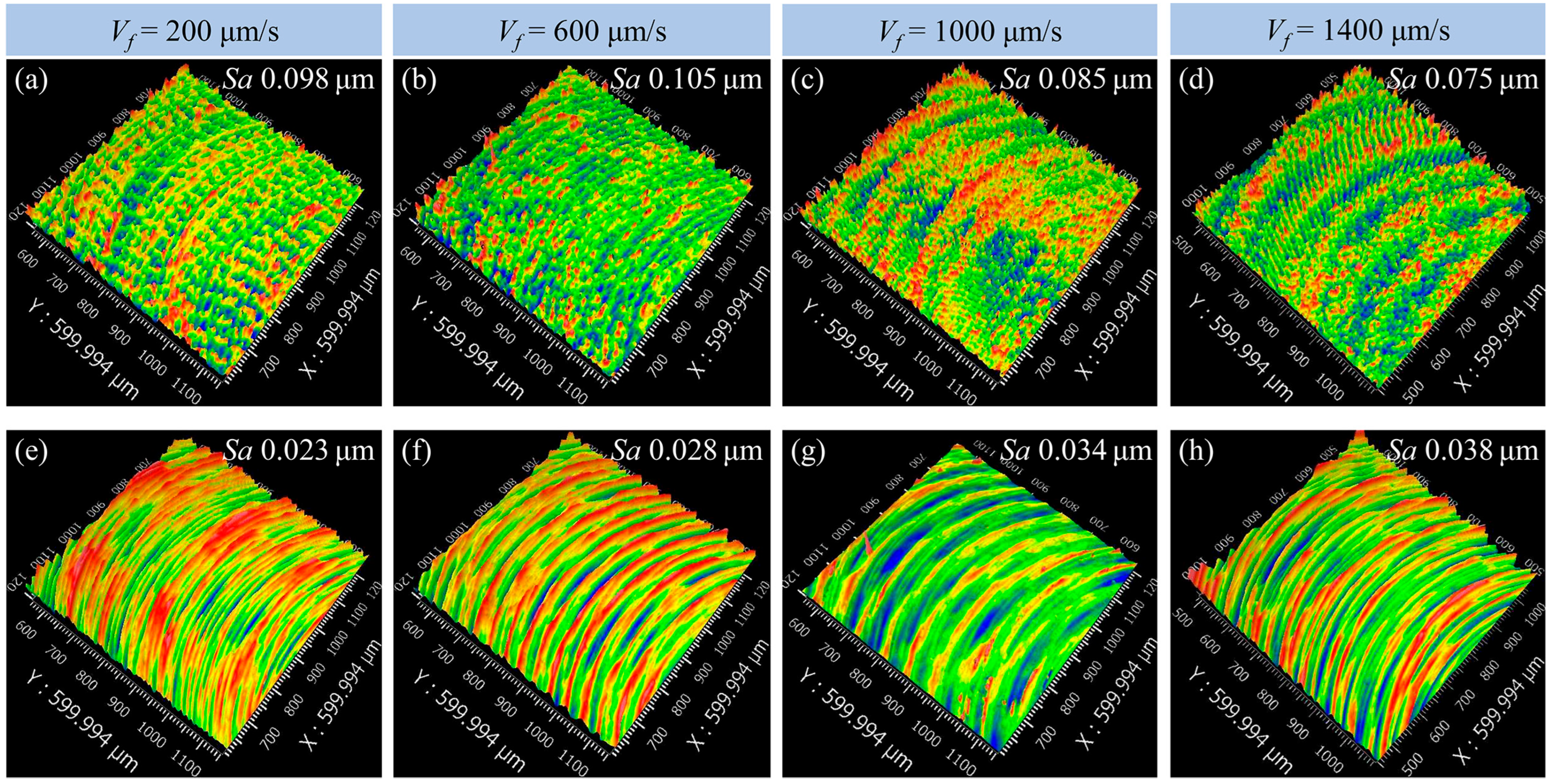

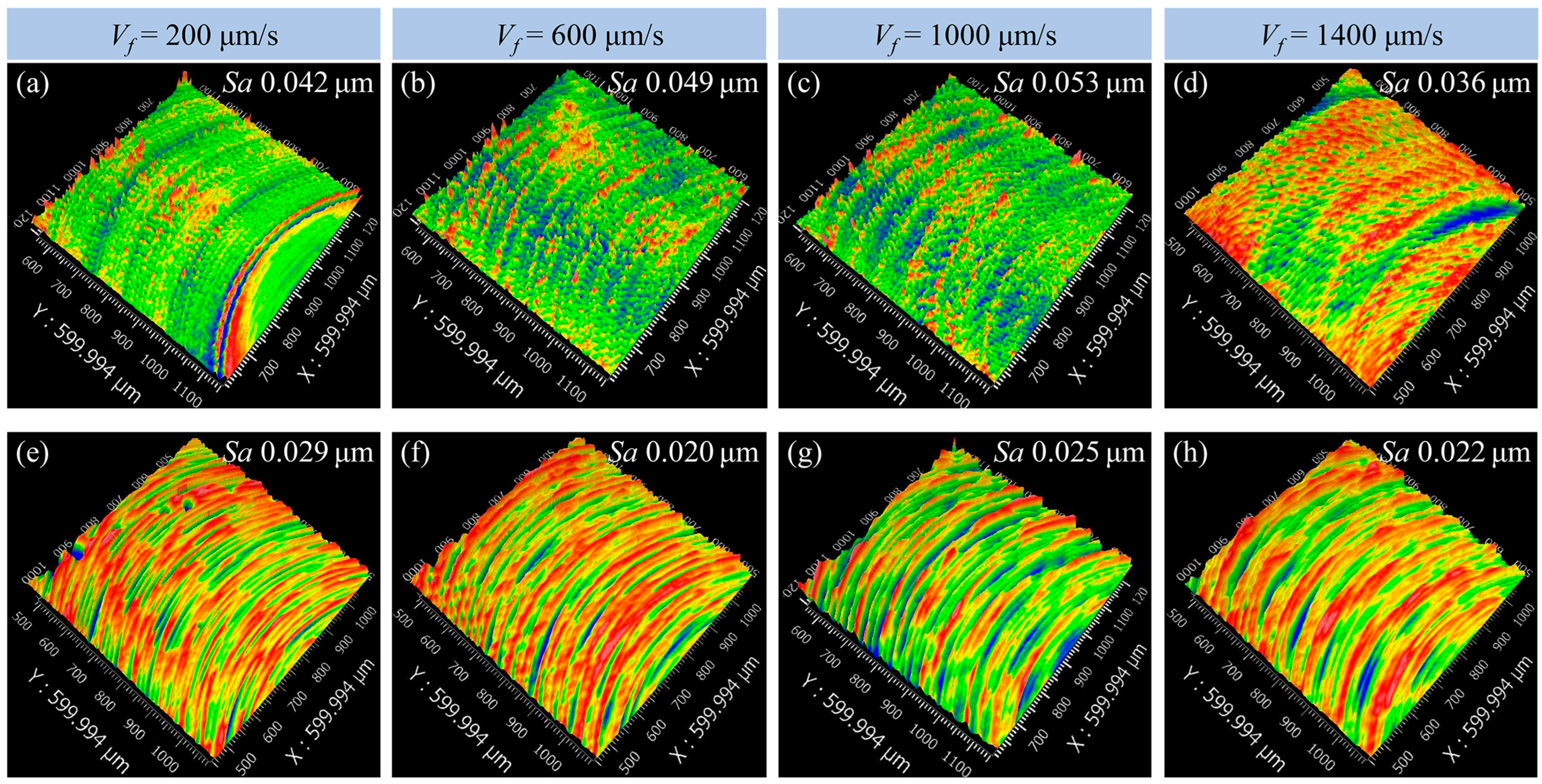

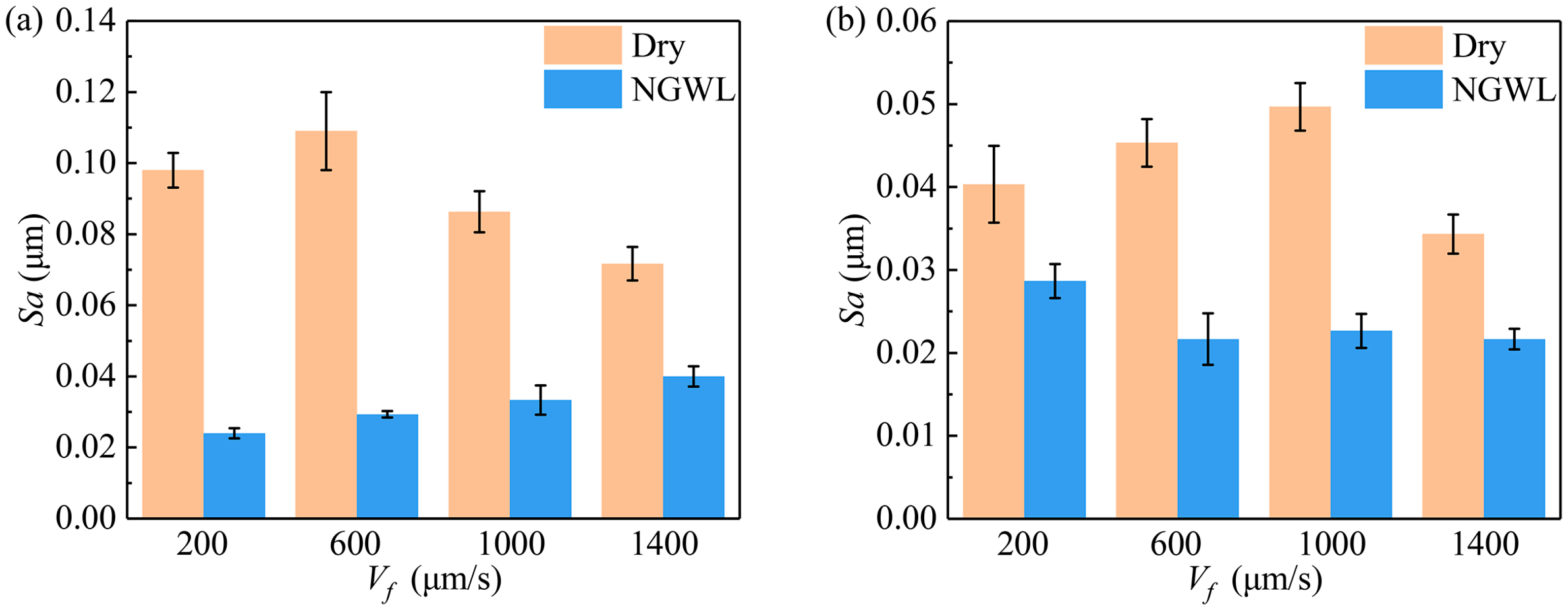

3.2.1. Surface Roughness

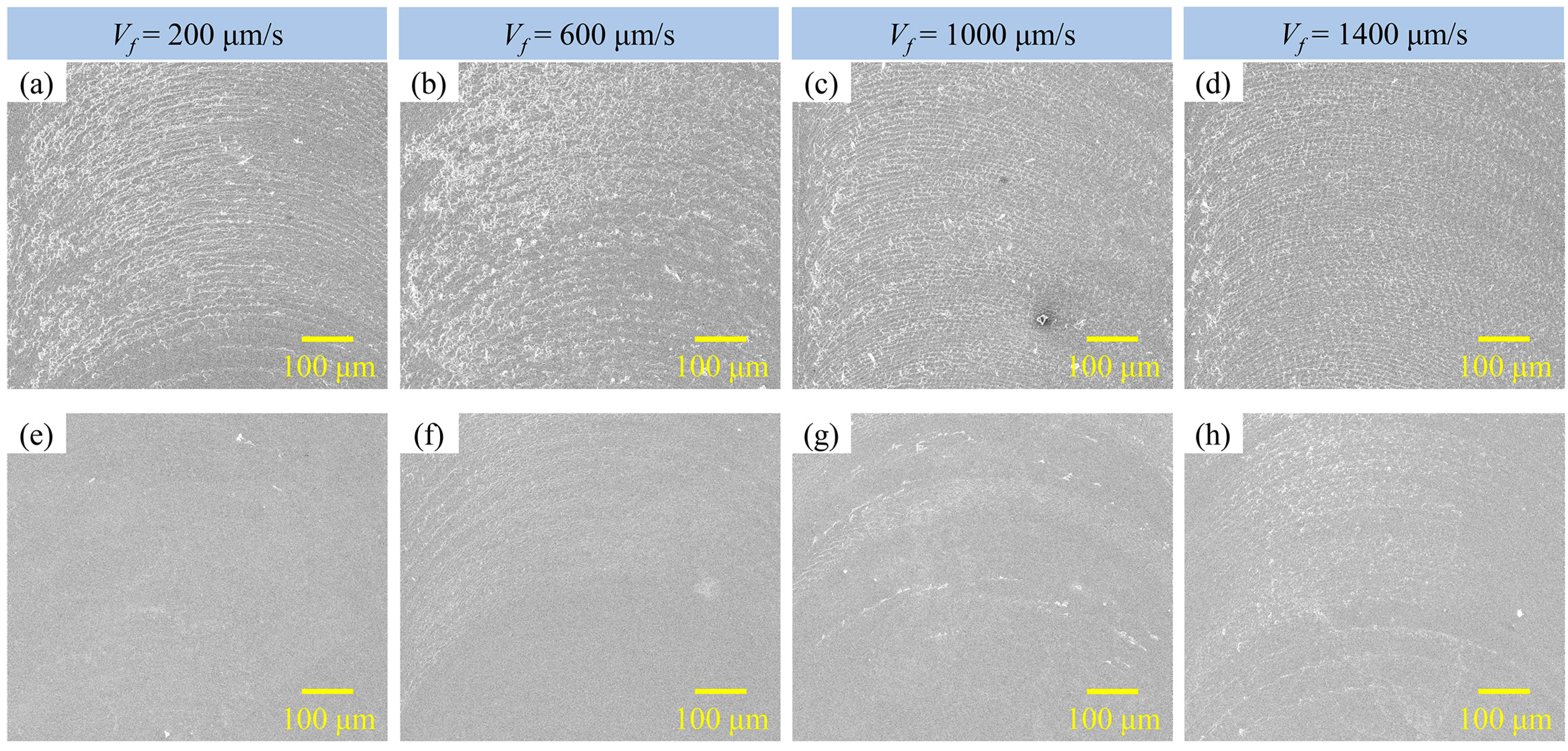

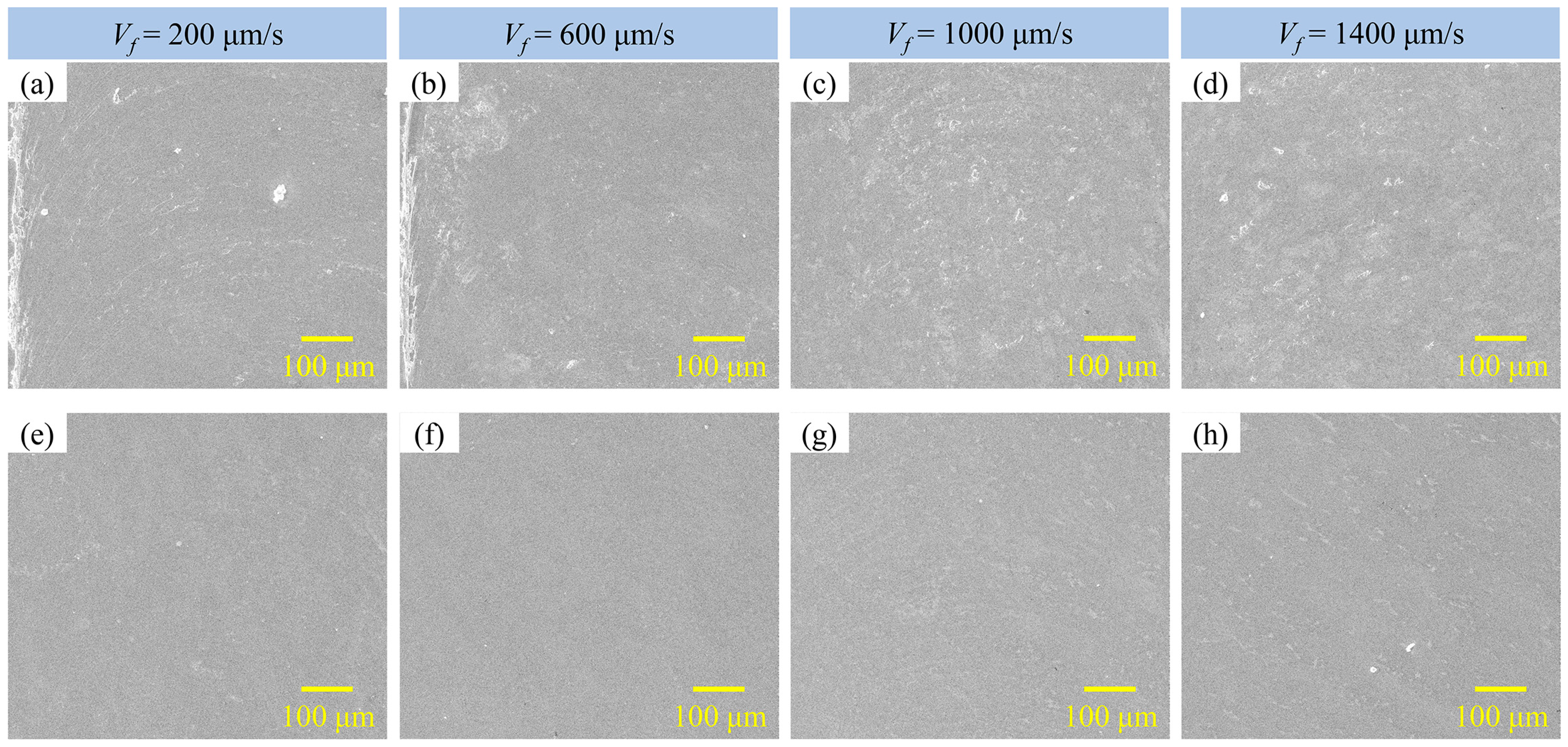

3.2.2. Surface Micromorphology

4. Discussion

5. Conclusions

- (1)

- In the single-grain diamond scribing test, NGWL could alleviate the plastic deformation of pure copper, reduce plastic accumulation, and promote ductile fracture. Compared with dry scribing at FN values of 100, 400, 700, and 1000 mN, the material removal efficiency R assisted by NGWL was increased by 54.1%, 80.7%, 44.8%, and 30.3%, respectively.

- (2)

- Compared with dry micro-milling at Vf values of 200, 600, 1000, and 1400 μm/s, for the 75°XT4E tool, the Sa with NGWL-assisted micro-milling was reduced by 75.5%, 73.1%, 61.4%, and 44.2%, respectively. Similarly, for the 65°UDT4E tool, compared to dry micro-milling, the Sa with NGWL lubrication was also reduced by 28.9%, 52.2%, 54.4%, and 36.9%, respectively.

- (3)

- NGWL could reduce the plastic deformation caused by dislocation accumulation, thereby inhibiting the burr phenomenon in the cutting process and improving surface quality. After the introduction of NGWL, the surface roughness Sa of pure copper could be as low as about 20 nm, and there were no scales. This is of great significance for achieving high-quality and efficient processing of pure copper. Moreover, the stability of NGWL should be addressed in the future by methods such as nanographene wettability modification to realize its application in high-performance manufacturing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EDM | Electric discharge machining |

| MQL | Minimum quantity lubrication |

| NMQL | Nanofluid minimum quantity lubrication |

| NGWL | Nanographene water-based lubricant |

| LSCM | Laser scanning confocal microscopy |

| SEM | Scanning electron microscopy |

| FLNG | Few-layer nanographene |

| FN | Normal force |

| FL | Lateral force |

| R | Material removal efficiency |

| n | Spindle speed |

| ap | Micro-milling depth |

| Vf | Feed speed |

| Sa | Surface roughness |

References

- Popescu, I.N.; Alhalaili, B.; Anghelina, F.V.; Nicolicescu, C.; Vidu, R. Tribological Behaviors and Statistical Experimental Design of Sintered and Age-Hardened Aluminum–Copper Based Composites. Lubricants 2025, 13, 172. [Google Scholar] [CrossRef]

- Zheng, Y.; Niu, J.; Lu, Y.; Xu, S.; Li, Z.; Zhao, H.; La, P. High strength and high conductivity pure copper prepared by ECAP-Conform combined with cryogenic rolling and recrystallization annealing. J. Mater. Res. Technol. 2025, 36, 3192–3204. [Google Scholar] [CrossRef]

- Avila-Salgado, D.A.; Juárez-Hernández, A.; Izaguirre-Bonilla, N.J.; Muñoz Tabora, J.; Camacho-Martínez, J.L. Evolution of Microstructure, Hardness, and Wear Behavior of Medium-Entropy CuNiSiCrCoTiNbx Alloy. Lubricants 2025, 13, 164. [Google Scholar] [CrossRef]

- Goto, I.; Kurosawa, K.; Matsuki, T. Effect of 3D-printed sand molds on the soundness of pure copper castings in the vicinity of as-cast surfaces. J. Manuf. Process. 2022, 77, 329–338. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Aghayar, Y.; Ester, D.; Mohammadi, M.; Borisoff, J.; Dotto, K. Sintering process optimization of the additively manufactured pure copper parts through the metal paste deposited process. J. Alloys Compd. 2024, 1009, 176932. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, G.; Xiao, Z.; Zhang, Y.; Zhou, Y.; Liu, X.; Li, W.; Xu, J. Microstructures and mechanical properties of pure copper manufactured by high-strength laser powder bed fusion. Opt. Laser Technol. 2025, 182, 112134. [Google Scholar] [CrossRef]

- Fallböhmer, P.; Rodríguez, C.A.; Özel, T.; Altan, T. High-speed machining of cast iron and alloy steels for die and mold manufacturing. J. Mater. Process. Technol. 2000, 98, 104–115. [Google Scholar] [CrossRef]

- Shi, J.; Shan, Z.; Yang, H.; Huang, J.; Dong, S. Experimental and modeling studies on thermal-mechanical coupling of frozen sand molds cutting based on coarse-grained discrete element method. J. Clean. Prod. 2025, 500, 145250. [Google Scholar] [CrossRef]

- Li, K.; Huang, X.; Chen, Q.; Xu, G.; Xie, Z.; Wan, Y.; Gong, F. Flexible fabrication of optical glass micro-lens array by using contactless hot embossing process. J. Manuf. Process. 2020, 57, 469–476. [Google Scholar] [CrossRef]

- Kitada, R.; Wang, Q.; Tsuetani, S.; Okada, A. Influence of surface roughness of die sinking EDM on mold releasability in compression molding of thermosetting phenol resin. Procedia CIRP 2022, 113, 238–243. [Google Scholar] [CrossRef]

- Skiba, J.; Kulczyk, M.; Przybysz-Gloc, S.; Skorupska, M.; Kobus, M.; Nowak, K. Effect of microstructure refinement of pure copper on improving the performance of electrodes in electro discharge machining (EDM). Sci. Rep. 2023, 13, 16686. [Google Scholar] [CrossRef]

- Mahshid, R.; Zhang, Y.; Hansen, H.N.; Slocum, A.H. Effect of mold compliance on dimensional variations of precision molded components in multi-cavity injection molding. J. Manuf. Process. 2021, 67, 12–22. [Google Scholar] [CrossRef]

- Sinico, M.; Witvrouw, A.; Dewulf, W. Improving the surface quality of maraging 300 parts produced via laser powder bed fusion through powder distribution selection and optimized laser remelting. J. Manuf. Process. 2025, 138, 38–49. [Google Scholar] [CrossRef]

- Li, X.; Bonilla, M.R.; Lu, M.; Huang, H. Atomistic understanding of ductile-to-brittle transition in single crystal Si and GaAs under nanoscratch. Int. J. Mech. Sci. 2024, 282, 109689. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Y.; Cui, H.; Liu, S.; Li, C.; Geng, Y. Towards understanding the mechanisms of material removal and deformation in GaAs during nanomilling. J. Mater. Process. Technol. 2025, 337, 118712. [Google Scholar] [CrossRef]

- Wang, Z.; Duan, Z.; Wang, S.; Li, Y.; Liu, J.; Song, J.; Liu, X. Material Deformation and Damage Mechanism Based on In-Situ Plasma-Assisted Nanoscratch Test of Single Crystal Silicon. Chin. J. Mech. Eng. 2025, 38, 67. [Google Scholar] [CrossRef]

- Fu, W.; Chen, C.A.; Huang, K.; Chang, Y. Material removal mechanism of Cu-CMP studied by nano-scratching under various environmental conditions. Wear 2012, 278–279, 87–93. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, H.; Li, Z.; Li, G.; Zhang, J.; Zhang, J.; Hassan, H.U.; Yan, Y.; Hartmaier, A.; Sun, T. Crystal plasticity finite element simulation and experiment investigation of nanoscratching of single crystalline copper. Wear 2019, 430–431, 100–107. [Google Scholar] [CrossRef]

- Geng, Y.; Jia, J.; Li, Z.; Liu, Y.; Wang, J.; Yan, Y.; Gan, Y. Modeling and experimental study of machining outcomes when conducting nanoscratching using dual-tip probe on single-crystal copper. Int. J. Mech. Sci. 2021, 206, 106649. [Google Scholar] [CrossRef]

- Zhu, J.; Xiong, C.; Ma, L.; Zhou, Q.; Huang, Y.; Zhou, B.; Wang, J. Coupled effect of scratching direction and speed on nano-scratching behavior of single crystalline copper. Tribol. Int. 2020, 150, 106385. [Google Scholar] [CrossRef]

- Câmara, M.A.; Rubio, J.; Abrao, A.M.; Davim, J.P. State of the Art on Micromilling of Materials, a Review. J. Mater. Sci. Technol. 2012, 28, 673–685. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Wang, S.; Duan, Z.; Cao, X.; Zhou, Y.; Liu, X.; Liu, J. Feasibility and mechanism of atmospheric pressure cold plasma jet (APCPJ) assisted micro-milling of bulk metallic glasses (BMGs). Ceram. Int. 2024, 50, 11094–11105. [Google Scholar] [CrossRef]

- Duan, Z.; Wang, Z.; Wang, S.; Zhang, B.; Bian, P.; Li, Y.; Liu, J.; Song, J.; Li, C.; Liu, X. Tool wear in enhanced minimum quantity lubrication assisted milling: From mechanism to application. Chin. J. Aeronaut. 2025, 103597. [Google Scholar] [CrossRef]

- Gururaja, S.; Singh, K.K. Machine learning based assessment of audio signal features for chatter identification in high-speed micromilling of thin-walled TC4 alloy. Precis. Eng. 2025, 94, 820–840. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Ren, Y.; Zhou, Z. 3D chatter stability of high-speed micromilling by considering nonlinear cutting coefficients, and process damping. J. Manuf. Process. 2020, 57, 552–565. [Google Scholar] [CrossRef]

- Dambatta, Y.S.; Li, C.; Sayuti, M.; Sarhan, A.A.D.; Yang, M.; Li, B.; Chu, A.; Liu, M.; Zhang, Y.; Said, Z.; et al. Grindability Evaluation of Ultrasonic Assisted Grinding of Silicon Nitride Ceramic Using Minimum Quantity Lubrication Based SiO2 Nanofluid. Chin. J. Mech. Eng. 2024, 37, 25. [Google Scholar] [CrossRef]

- Gao, T.; Xu, P.; Wang, W.; Zhang, Y.; Xu, W.; Wang, Y.; An, Q.; Li, C. Force model of ultrasonic empowered minimum quantity lubrication grinding CFRP. Int. J. Mech. Sci. 2024, 280, 109522. [Google Scholar] [CrossRef]

- Yang, M.; Ma, H.; Li, Z.; Hao, J.; Liu, M.; Cui, X.; Zhang, Y.; Zhou, Z.; Long, Y.; Li, C. Force model in electrostatic atomization minimum quantity lubrication milling GH4169 and performance evaluation. Front. Mech. Eng. 2024, 19, 28. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, F.; Zhang, S.; Zhang, J.; Liao, D.; Lei, X.; Wang, J.; Du, J. Effect of Bio-Based, Mixed Ester Lubricant in Minimum Quantity Lubrication on Tool Wear and Surface Integrity in Ultra-Precision Fly-Cutting of KDP Crystals. Lubricants 2025, 13, 156. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Jia, D.; Liu, X.; Zhang, Y.; Yang, M.; Cui, X.; Gao, T.; Dambatta, Y.S.; Li, R. Model of atomized droplets average particle size and verification of eco-friendly hybrid lubrication (CAMQL). Friction 2025, 13, 9440960. [Google Scholar] [CrossRef]

- Gu, G.; Wang, D.; Wu, S.; Zhou, S.; Zhang, B. Research Status and Prospect of Ultrasonic Vibration and Minimum Quantity Lubrication Processing of Nickel-based Alloys. Intell. Sustain. Manuf. 2024, 1, 10006. [Google Scholar] [CrossRef]

- Saha, S.; Deb, S.; Bandyopadhyay, P.P. An analytical approach to assess the variation of lubricant supply to the cutting tool during MQL assisted high speed micromilling. J. Mater. Process. Technol. 2020, 285, 116783. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.; Cui, X.; An, Q.; Xu, P.; Wang, W.; Jia, D.; Liu, M.; Dambatta, Y.S.; Li, C. Lubricant activity enhanced technologies for sustainable machining: Mechanisms and processability. Chin. J. Aeronaut. 2025, 38, 103203. [Google Scholar] [CrossRef]

- Filiz, S.; Conley, C.M.; Wasserman, M.B.; Ozdoganlar, O.B. An experimental investigation of micro-machinability of copper 101 using tungsten carbide micro-endmills. Int. J. Mach. Tools Manuf. 2007, 47, 1088–1100. [Google Scholar] [CrossRef]

- Büttner, H.; Vieira, G.; Hajri, M.; Vögtlin, M.; Kuster, F.; Stirnimann, J.; Wegener, K. A comparison between micro milling pure copper and tungsten reinforced copper for electrodes in EDM applications. Precis. Eng. 2019, 60, 326–339. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, B.; Ding, W. Solid Additives to Increase the Service Life of Ceramic Cutting Tool: Methodology and Mechanism. Intell. Sustain. Manuf. 2024, 1, 10009. [Google Scholar] [CrossRef]

- Liu, G.; Wang, J.; Zheng, J.; Ji, M.; Wang, X. An Experimental Study on Ultrasonic Vibration-Assisted Turning of Aluminum Alloy 6061 with Vegetable Oil-Based Nanofluid Minimum Quantity Lubrication. Lubricants 2023, 11, 470. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Yang, M.; Liu, M.; Gao, T.; Wang, X.; Said, Z.; Sharma, S.; Zhang, Y. Enhanced grindability and mechanism in the magnetic traction nanolubricant grinding of Ti-6Al-4 V. Tribol. Int. 2023, 186, 108603. [Google Scholar] [CrossRef]

- Bian, P.; Duan, Z.; Jia, Y.; Wang, Z.; Wang, S.; Tan, J.; Zhou, Y.; Song, J.; Liu, X. Evaluation of Surface Integrity of Multi-Energy Field Coupling-Assisted Micro-Grinding Hastelloy Alloy. Micromachines 2025, 16, 565. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Said, Z.; Debnath, S.; Sharma, S.; Ali, H.M.; Yang, M.; Gao, T.; Li, R. Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J. Manuf. Process. 2022, 80, 273–286. [Google Scholar] [CrossRef]

- Gao, T.; Liu, J.; Sun, X.; Zhang, Y.; Yang, M.; Liu, M.; Xu, W.; An, Q.; Wang, D.; Xu, P.; et al. Enhanced permeation mechanism and tribological assessment of ultrasonic vibration nanolubricants grinding CFRP. Tribol. Int. 2025, 204, 110494. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Ding, W.; An, Q.; Liu, B.; Li, H.N.; Said, Z.; Sharma, S.; Li, R.; et al. Comparative assessment of force, temperature, and wheel wear in sustainable grinding aerospace alloy using biolubricant. Front. Mech. Eng. 2022, 18, 3. [Google Scholar] [CrossRef]

- Yang, M.; Hao, J.; Wu, W.; Li, Z.; Ma, Y.; Zhou, Z.; Gao, T.; Liu, M.; Cui, X.; Zhang, Y.; et al. Critical cutting thickness model considering subsurface damage of zirconia grinding and friction–wear performance evaluation applied in simulated oral environment. Tribol. Int. 2024, 198, 109881. [Google Scholar] [CrossRef]

- Duan, Z.; Wang, S.; Li, C.; Wang, Z.; Bian, P.; Song, J.; Liu, X. Tribological and micro-milling performance of surfactant-free microwave plasma-modified Al2O3 nanoparticles biodegradable lubricants. J. Clean. Prod. 2025, 493, 144969. [Google Scholar] [CrossRef]

- Chu, A.; Li, C.; Zhou, Z.; Liu, B.; Zhang, Y.; Yang, M.; Gao, T.; Liu, M.; Zhang, N.; Dambatta, Y.S.; et al. Nanofluids Minimal Quantity Lubrication Machining: From Mechanisms to Application. Lubricants 2023, 11, 422. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Ding, W.; Chen, Y.; Mao, C.; Xu, X.; Liu, B.; Wang, D.; Li, H.N.; Zhang, Y.; et al. Minimum quantity lubrication machining of aeronautical materials using carbon group nanolubricant: From mechanisms to application. Chin. J. Aeronaut. 2022, 35, 85–112. [Google Scholar] [CrossRef]

- Xu, R.; Xue, Z.; Yang, D.; Li, X.; Nie, H.; Guo, Y.; Guo, H.; Yan, Q.; Gu, J. Highly Energy Release of Aluminum@Ammonium Perchlorate Composites Incorporated with Graphene Oxide-based Energetic Coordination Polymer. Adv. Funct. Mater. 2025, 35, 2423205. [Google Scholar] [CrossRef]

- Shi, J.; Yin, S.; Li, H.; Yi, X.; Wu, H.; Cao, T.; Fan, X.; Liu, J.; Zhou, F. Operando formation of hydration layer and tribofilm of graphene oxide for achieving synergistic lubrication on electrochemical boronizing surface. Carbon 2025, 235, 120089. [Google Scholar] [CrossRef]

- Almonti, D.; Salvi, D.; Ucciardello, N.; Vesco, S. Enhanced Wear Resistance and Thermal Dissipation of Copper–Graphene Composite Coatings via Pulsed Electrodeposition for Circuit Breaker Applications. Materials 2024, 17, 6017. [Google Scholar] [CrossRef]

- Baiocco, G.; Salvi, D.; Ucciardello, N. Optimizing Graphene Nanoplatelet Coating for Enhanced Wear Resistance on Copper Through Electrophoretic Deposition Parameters. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Wu, H.; Huang, H.; Zhang, Z.; Yan, J. Micro-amplitude vibration-assisted scratching: A new method for one step and controllable fabrication of the microscale V-groove and nanoscale ripples. Int. J. Extrem. Manuf. 2025, 7, 035102. [Google Scholar] [CrossRef]

- Chi, Y.; Dong, Z.; Cui, M.; Shan, C.; Xiong, Y.; Zhang, D.; Luo, M. Comparative study on machinability and surface integrity of γ-TiAl alloy in laser assisted milling. J. Mater. Res. Technol. 2024, 33, 3743–3755. [Google Scholar] [CrossRef]

- Yan, D.; Lin, J.; Chen, Y.; Yang, X.; Lu, Y.; Song, J. High-Efficiency Water Collection of Superhydrophobic Condensation Absorber. Adv. Sci. 2025, 12, 2417024. [Google Scholar] [CrossRef]

- Lv, S.; Liu, F.; Yang, Z.; Han, J.; Zhai, Y.; Mao, C.; Yan, D. Superhydrophobic surface with rice leaf structures fabricated by laser processing. Opt. Laser Technol. 2025, 189, 113072. [Google Scholar] [CrossRef]

- Zan, Z.; Guo, K.; Sun, J.; Lu, Y.; Yang, B.; Jia, X.; Sivalingam, V.; Xi, J. Investigation on scratching force and material removal mechanism of 3D SiCf/C–SiC composites during single grain scratching. J. Eur. Ceram. Soc. 2022, 42, 5366–5379. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, W.; Duan, Z.; Wang, S.; Li, Y.; Zhou, Y.; Liu, J.; Song, J.; Liu, X. Experimental Study on Cold Plasma Jet (CPJ) Assisted Micro-Milling of 30CrMnSiNi2A. Intell. Sustain. Manuf. 2024, 1, 10017. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, B.; Lin, Q.; Wu, S.; Yang, R.; Wang, Z. Orientation-dependent plastic flow in nanoscratching of copper surfaces. Wear 2024, 544–545, 205316. [Google Scholar] [CrossRef]

- Kareer, A.; Tarleton, E.; Hardie, C.; Hainsworth, S.V.; Wilkinson, A.J. Scratching the surface: Elastic rotations beneath nanoscratch and nanoindentation tests. Acta Mater. 2020, 200, 116–126. [Google Scholar] [CrossRef]

- He, Q.; Yoshida, S.; Okajo, S.; Tanaka, M.; Tsuji, N. Characteristic dislocation slip behavior in polycrystalline HfNbTiZr refractory medium entropy alloy. J. Mater. Sci. Technol. 2025, 210, 29–39. [Google Scholar] [CrossRef]

- He, Y.; Xiao, G.; Zhu, S.; Liu, G.; Liu, Z.; Deng, Z. Surface formation in laser-assisted grinding high-strength alloys. Int. J. Mach. Tools Manuf. 2023, 186, 104002. [Google Scholar] [CrossRef]

- Duan, Z.; Wang, S.; Li, C.; Wang, Z.; Bian, P.; Sun, J.; Song, J.; Liu, X. Cold plasma and different nano-lubricants multi-energy field coupling-assisted micro-milling of Al-Li alloy 2195-T8 and flow rate optimization. J. Manuf. Process. 2024, 127, 218–237. [Google Scholar] [CrossRef]

- Wei, Y.; Zhu, L.; Li, Y.; Chen, Y.; Guo, B. Formation mechanism and microstructure evolution of Cu/Ti diffusion bonding interface and its influence on joint properties. Vacuum 2023, 213, 112167. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Xiong, J.; Zhang, F. Investigation of interdiffusion and intermetallic compounds in Al–Cu joint produced by continuous drive friction welding. Eng. Sci. Technol. 2016, 19, 90–95. [Google Scholar] [CrossRef]

- Chaudhari, A.; Soh, Z.Y.; Wang, H.; Kumar, A.S. Rehbinder effect in ultraprecision machining of ductile materials. Int. J. Mach. Tools Manuf. 2018, 133, 47–60. [Google Scholar] [CrossRef]

- Chaudhari, A.; Wang, H. Effect of surface-active media on chip formation in micromachining. J. Mater. Process. Technol. 2019, 271, 325–335. [Google Scholar] [CrossRef]

| Elements | Cu | P | Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O |

| Content | 99.97 | 0.002 | 0.001 | 0.002 | 0.002 | 0.004 | 0.002 | 0.003 | 0.002 | 0.004 | 0.003 | 0.002 |

| Parameters | Unit | Value |

|---|---|---|

| Elastic modulus | GPa | 128 |

| Hardness | HBS | 37 |

| Yield strength | MPa | 33.3 |

| Tensile strength | MPa | 209 |

| Elongation | 60% | |

| Fracture toughness | MPa·m1/2 | 30–50 |

| Experiment | Scribing Mode | Normal Force | Scribing Length |

|---|---|---|---|

| Exp. 1 | Variable-force | 0–1000 mN | 500 μm |

| Exp. 2 | Constant-force | 100 mN | 100 μm |

| Exp. 3 | Constant-force | 400 mN | 100 μm |

| Exp. 4 | Constant-force | 700 mN | 100 μm |

| Exp. 5 | Constant-force | 1000 mN | 100 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Duan, Z.; Wang, S.; Tan, J.; Bian, P.; Liu, J.; Song, J.; Liu, X. Effect of Nanographene Water-Based Lubricant (NGWL) on Removal Behavior of Pure Copper. Lubricants 2025, 13, 286. https://doi.org/10.3390/lubricants13070286

Wang Z, Duan Z, Wang S, Tan J, Bian P, Liu J, Song J, Liu X. Effect of Nanographene Water-Based Lubricant (NGWL) on Removal Behavior of Pure Copper. Lubricants. 2025; 13(7):286. https://doi.org/10.3390/lubricants13070286

Chicago/Turabian StyleWang, Ziheng, Zhenjing Duan, Shuaishuai Wang, Ji Tan, Peng Bian, Jiyu Liu, Jinlong Song, and Xin Liu. 2025. "Effect of Nanographene Water-Based Lubricant (NGWL) on Removal Behavior of Pure Copper" Lubricants 13, no. 7: 286. https://doi.org/10.3390/lubricants13070286

APA StyleWang, Z., Duan, Z., Wang, S., Tan, J., Bian, P., Liu, J., Song, J., & Liu, X. (2025). Effect of Nanographene Water-Based Lubricant (NGWL) on Removal Behavior of Pure Copper. Lubricants, 13(7), 286. https://doi.org/10.3390/lubricants13070286