Abstract

This study focuses on investigating the manufacturing, characterization, and assessment of palm kernel nut oil as a cutting fluid (CF) in the machining of aluminium 6061 alloy. Cutting fluids are vital in machining operations as they reduce friction, dissipate heat, and prolong the lifespan of tools. Palm kernel nut oil, derived from the fruit of a palm kernel, has attracted attention due to its environmentally friendly and readily biodegradable characteristics. This study involved the extraction, refinement, and characterization of palm kernel nut oil for its potential application as a cutting fluid. An experimental investigation was conducted to evaluate the performance of palm kernel nut oil (PKNO) as a CF through turning operations on aluminium 6061 alloy. The experimental parameters included the cutting speed, feed rate, and depth of cut, while the effectiveness of the CF was assessed based on key performance indicators such as surface roughness and cutting temperature. The findings demonstrated that the PKNO-CF exhibited favourable physical properties, including optimal viscosity, density, and pH levels. Furthermore, a detailed chemical analysis confirmed the absence of hazardous components, establishing palm kernel nut oil as a safer and more environmentally friendly alternative to conventional cutting fluids. This study aligns with United Nations Sustainable Development Goal (SDG) 12: Responsible Consumption and Production as it promotes the use of an environmentally friendly and biodegradable cutting fluid, reducing reliance on conventional, potentially hazardous cutting fluids and reducing environmental pollution. By utilizing palm kernel nut oil as a sustainable alternative, this research supports eco-friendly manufacturing practices and minimizes environmental impact in machining operations

1. Introduction

Machining is an essential aspect of the manufacturing process. It refers to a set of procedures that involve the removal of material from a workpiece and a change in its surface after various methods have been used [1,2]. Metal cutting converts almost all of the energy consumed to heat [3]. Heat at the cutting point is generated from three primary sources: (i) the main cutting zone, where most of the energy is transformed into heat; (ii) the secondary deformation zone at the tool-chip interface, where additional heat is produced through friction and shearing; and (iii) the flank zone, where abrasion between the tool and the machined surface induces thermal stress [2,4]. Metal cutting is a type of operation of employing a cutting instrument to remove unwanted material from a piece of metal in the form of chips. The main elements in this operation are as follows: (i) a metallic block (work piece); (ii) a cutting instrument; (iii) a tool for machining; (iv) a fluid for cutting; (v) the cutting rate (speed); (vi) input secondary motion (feed); (vii) shards (chips); (viii) fixturing and securing the work; (ix) dissipated force and energy; and (x) surface treatment. For a successful metal cutting job, keep the following in mind: (i) work and cutting instruments should have relative movement; (ii) the content used for tooling must be tougher than the content being worked on; (iii) jigs and fixtures must hold the work and tool in place; (iv) the sharpness of the cutting tool’s cutting edge; (v) primary movement (cutting speed); and (vi) secondary movement (cutting feed).

Furthermore, the heat generated during metal cutting causes tool wear, resulting in increased workpiece surface roughness [5]. Thermal cracking caused by expansion and cracking caused by severe temperatures is another cause of cutting tool failure [6,7,8]. Wearing (crater and flank) on the surface lowers the mass of the cutting instrument with time [9]. Thermal distortion and the expansion–contraction effects caused by high temperatures during machining can damage the workpiece surface, leading to dimensional inaccuracy [10]. Coolants are responsible for transporting the heat generated during the process of metal deformation, whereas lubricants serve to reduce friction and prevent wear between the tool and the workpiece [11,12]. Choosing and applying a CF is nowadays considered a technique for reducing heat in the cutting zone [13,14]. Researchers posit that cutting fluids infiltrate the boundary between the tool and chip by seeping out from the edges of the chip through the capillary action of the interlocking surface roughness network.

Lubricants minimize the resistance and damage caused by friction between the tool and the workpiece, while coolants dissipate the heat generated during metal deformation [15,16]. The CF also enhances surface quality and dimensional control [17]. It decreases the energy consumption required for substance removal. Additionally, it serves the purpose of preventing heated chips from entering the cutting region [18,19,20]. Consequently, chips start to break into tiny fragments. Furthermore, cutting fluids serve the purpose of safeguarding the machined surface against any harm caused by the environment [11]. Diverse types of cutting fluids are available for use in performing machining operations [13,17,18,21]. Mineral oil-based cutting fluids (MOCFs) are widely used and highly preferred in industrial operations for shaping and cutting processes due to their ability to enhance efficiency and quality. Abegunde et al., Jeevan et al. and Liu et al. [22,23,24] report that factory workers face a potential danger of developing allergies and illnesses due to their exposure to mineral oil in the workplace.

The potential health risks associated with contact between machine tool operators and cutting fluids are a significant concern [25]. The inhalation of CF fumes, smoke, mist, and smells can lead to severe respiratory complications and allergies, particularly when mineral oil contains chemical components such as biocides, phosphorus, sulphur, hydrocarbon, chlorine, and other additives. Alaba et al. [26] reports that almost 80% of employment hazards faced by operators are associated with the direct contact of their skin with cutting fluids. Xu and Liu et al. [27,28] concluded that the tool insert in their study did not show any signs of tool wear. However, significant tool degradation was seen in both flooded and dry states. The utilization of MQL derived from canola led to a decrease in friction and the provision of robust lubrication at the interface between the workpiece and the tool. Abbasi et al. [29] demonstrated that an increase in the fluid flow rate led to an increase in tool life, causing a consistent decrease in surface roughness characteristics and having a minimal impact on burr length. Abrasion was identified as the predominant form of wear observed in all mill cutters examined in the studies.

The term “cutting fluid” can also be referred to as “cutting oil”, “cutting compound”, “coolant”, or “lubricant”, depending on the circumstances and the specific kind of CF that is being discussed. It is possible to use CF in virtually all metalworking and machining procedures; however, this is contingent upon the composition of the individual work piece.

Today, businesses have access to a wide variety of CFs and have a variety of alternative means for applying them. Nevertheless, the economic basis and right selection of these fluids are not quite as logical as they could be. This study outlines the various classes of CFs and their basic behaviours, laying the groundwork for selection techniques. Cutting fluids have indeed been known for decades to have three fundamental effects that can alter the cutting process. They are as follows: (i) friction reduction (lubrication); (ii) cooling; and (iii) work material shear strength reduction. Initially, CFs were supposed to serve largely as coolants. Traditional cooling lubricants used in most machining operations have been re-evaluated because of growing cost demands on industrial organizations and a shift in environmental concern [30].

Vegetable-based cutting fluids (VBMCFs) in different machining processes such as grinding, turning, drilling, and milling have become well-established lubricating oils used to increase tool life and achieve the required workpiece surface smoothness, decreased cutting forces, and so forth. These VBMCFs, which were originally developed for the turning process, have been commonly employed for drilling, and their capability is being investigated for cutting with a non-geometrically defined tooltip, such as in milling and grinding, as described in previous research. Though dry cutting is the preferred method for environment-conscious machining and low machining costs, its use may not be possible in all cutting situations [31]. In comparison to MBMCFs, which are non-biodegradable and cause harmful effects to operators, dry machining has paved the path for the use of VBMCFs. For its application in diverse machining processes, VBMCFs are constantly being developed and changed. The physics of metal cutting under various lubrication and cooling environments has been the subject of intense research. A critical analysis of research advances in the machining of engineering components under VBMCF settings is attempted in this project report. A VBMCF can be quite successfully used for cutting metal and non-metals with carbide and coated carbide tools, according to a study conducted by several experts [32].

VBMCFs have been shown to increase machining performance in comparison with MO-based CFs (MBMCFs) and synthetic CFs by many writers. A VBMCF regulates not just the temperature rise in a workpiece but also the temperature of the tool surface and cutting boundary. Frictional heat is greatly reduced when the lubrication is optimal. The ability and potential breadth of VBMCFs have been demonstrated by their application in various machining procedures. The effects of SR have been investigated in a dry-cutting setting. Because the feed rate was maintained all through the trial, changing the cutting speed did not affect SR. Because of average flank wear, the wear rate was visible after every machining cut [30,31]. The impact of developed CFs on the cutting force and SR when turning AISI 4340 steel with coated carbide using the Taguchi method was explored and compared with traditional emulsified CFs [10,32]. The design of the experiments (L27) consisted of four variables and three stages. The feed rate, cutting speed and cut depth, and CF types were all used as input variables. The feed rate (32.19 percent) and cutting speed (64.64 percent) have profound impacts on the SR, while the DOC (33.1 percent) and type of CFs (51.1 percent) have major impacts on the cutting force, according to the ANOVA results.

Researchers have embraced the use of the MQL procedure with a VO-based CF in the milling of TC4 [33,34,35]. Additionally, graphene as nanoparticles was scattered into the VO-based CF to enhance lubricating and cooling behaviour. To assess their capacities, a sequence of machining tests was conducted under four lubricating/cooling environments (gas, dry, unadulterated MQL, and MQL with graphene). The milling attributes of TC4 regarding the machining force, temperature of the cutter, wear of tool, and surface quality were compared. The results showed that the graphene chemical was efficient in further improving the machining. The outcomes suggest that the graphene chemical could improve the lubrication and cooling behaviour of the oil film framed in the machining zone. According to the literature, tests have been conducted on milled EN8 steel in three distinct lubricating scenarios: water-soluble oil, dry conditions, and a VO-based nano CF [36,37]. The nano CF was developed using modified corn oil as a base fluid and CuO nanoparticles were distributed using an ultrasonicator at a wt% of 0.3 percent. The Taguchi and ANOVA methodologies were utilized in this study to determine the best process conditions for milling grooves in EN8 steel. The surface finish and wear rate of tool results obtained during cutting using typical machining variables were evaluated, and it was discovered that the machining efficiency of VO-based nano CFs is superior to dry conditions and MO-based CFs.

The synergistic impact of titanium dioxide (TiO2) and graphene (GnP) nanoparticle additions on the cutting qualities of biodegradable VO has been explored by several researchers [12,36,38,39]. Rice bran oil was used in the MQL process to turn M2 steel. The impacts of various concentrations of hybrid (rice bran oil/TiO2/graphene) nanofluids (0.5 and 1 wt. percent) and mono (rice bran oil/TiO2) oils were investigated. The fluidity of hybrid and mono oils improved as the nanoparticle content increased, according to tribological experiments. Moreover, at elevated temperatures, hybrid fluids demonstrated significant improvement in fluidity. When contrasted with the TiO2-based lubricant used alone, the trials demonstrated that the hybrid and nano lubricants reduced SR and flank wear by 11 and 38 percent, respectively. Compared to the base oil, tool wear fell by around 29 and 32 percent, equivalent to 500 and 1200 rpm, respectively, in the case of the hybrid fluid (1 wt. percent TiO2 + graphene), which significantly increased tool life. The processes of tool wear at crater and flank faces were investigated using SEM. The suitable chips were subjected to microscopic analysis, which included examining the structure and colour of the chips and estimating generated heat via the workpiece–tool interface. The findings show that combining GnP and TiO2 improves tribological qualities, resulting in a more environmentally friendly and efficient lubricating system. Jamaluddin et al. [40] investigated the use of chemically modified jatropha (MJO) oils as a CF in an orthogonal cutting operation without or with the addition of hBN nanoparticles. The characteristics being assessed were cutting force, oil viscosity, CT, and chip–tool contact length. MJO + 0.05 wt. percent hBN had a high viscosity index, which was correlated with a low cutting temperature, cutting force, and contact length according to the findings.

Vegetable oils are now widely used as lubricants when machining AA6061. This is because vegetable oils are unsaturated carbon compounds, which are harmless to both the environment and the operators working with it. Several studies on AA6061 have found that vegetable oils might efficiently substitute traditional mineral oil as metal working fluids. Mineral oil is non-biodegradable and hazardous, posing risks to operators [41]. Mineral oil is exhaustible and cannot be renewed. Research into the use of vegetable oil as a cutting lubricant has been motivated by the recent economic reality in most nations due to the high pricing of petroleum supplies. In Nigeria, for instance, a legislative body recently announced the complete elimination of oil subsidies, which resulted in increasing petroleum product costs and highlighted the need for an alternative supply of cutting fluids [42].

It is essential to know which vegetable oil is the most plentiful and efficient to use as a cutting lubricant when making your choice. One of the most popular vegetable oils in the world is palm kernel oil. According to Tan et al. [43], Nigeria was expected to produce 393 thousand metric tons of palm kernel oil in 2023. The nation’s palm kernel oil harvest increased by 88 thousand metric tons between 2010 and 2023. The output volume increased by over 10.4% in 2021 compared to the previous year, which was the biggest rise ever recorded. From 2021 to 2023, the production volume was unchanged [44]. The application of palm kernel oil as a lubricant or CF in machining has been studied by a number of writers. Using a complete factorial L16 (24) design, Abutu et al. [45] characterized and formulated palm kernel oil. Using GRA and Behnken’s L15 (33) design technique, the MRR, CT, and SR were examined in order to assess the efficacy of the mineral and established cutting fluids. The outcomes showed that palm kernel oil’s characteristics were within the range that is ideal for vegetable oils, according to published research. The GRA results indicated that for palm kernel oil, a speed of 600 rev/min, FR of 0.3 mm/rev, and DOC of 1.5 mm were the ideal turning conditions. Using an MQL technique, Alaba et al. [26] assessed the functioning of palm kernel oil as a lubricant in AISI 1039 steel turning. For the experiment, a Taguchi L9 method was utilized. During the turning procedures, various parameters were measured, including the chip thickness ratio, SR, MRR and CT. When compared to MO, palm kernel oil’s CT and SR increased by 12% and 44%, respectively. Kazeem et al. [46] used the MQL approach to study the influence of palm kernel oil and MO on AISI 304 steel turning. The Taguchi L9 (3)3 matrix was used in this study. The response variables were SR and CT, while the cutting parameters were the feed rate, depth of cut, and spindle speed. According to the test results, MO outperformed palm kernel oil by 48.2% in terms of SR. In comparison to MO, palm kernel oil enhanced CT by around 0.89%. Ojolo and Ohunakin [42] investigated the effects of the cutting speed, DOC, feed, and rake angle on major cutting forces during the turning of mild steel, brass and aluminium rods using palm kernel oil and a high-speed steel tool. Palm kernel oil was more effective on aluminium than mild steel and brass. Ojolo et al. [47] investigated the effect of different vegetable oils on cutting force when turning mild steel, aluminium, and copper workpieces. The findings indicated that natural oils are suitable as cutting fluids; nevertheless, their effects on cutting force differ based on the material. While turning, groundnut oil lowered the cutting force most substantially. Palm kernel oil performed effectively, while copper was machined at FRs lesser than 0.15 mm/rev. It was discovered that palm kernel and groundnut oils were effective at reducing the cutting force. Though the cooling and lubricating action differed depending on the substrate, groundnut oil beat the other four bio-oils tested. Abegunde et al. [22] studied the significance of palm kernel, neem, and MOs on AISI 1045 steel turning using the MQL approach. Cutting temperature and SR were assessed at various stages of the machining procedure. According to the trial results, neem oil outscored the other oils in terms of SR, but MO surpassed them all in terms of CTs. Mahadi et al. [48] investigated the operating characteristics of palm kernel oil with boric acid over traditional oil in machining AISI 431 with MQL. A 24 complete factorial DOE was carried out, including the FR, cutting speed, DOC, and lubricant types as input process parameters. Surface finish was assessed in each of the machining scenarios. The variety of lubricants and feed have been found to be key variables affecting surface finish [49], with a boric acid-assisted lubricant outperforming regular lubricants. The average improvement in surface finish using boric acid powder-assisted vegetable oil is 7.21%.

According to the literature reviewed thus far, all researchers have investigated the applicability of vegetable oils in their research. Some of the vegetable oils considered in studies are Kapok oil, groundnut oil, castor oil, sunflower oil, cottonseed oil, palm oil, palm kernel oil, watermelon oil, jatropha oil, rapeseed oil, coconut oil, mustard oil, canola oil, shea butter oil, etc. Generally, the performance of vegetables in comparison with mineral oil equivalents was superior in most machining scenarios. By paying close attention to this review, it will be noticed that the use of African seed oil as cutting fluids in machining has not been fully explored. This study, therefore, aims to employ African seed oil as a CF in the turning operation of AISI 1034 steel. Surface roughness and cutting fluids will be examined, and the results will be compared to conventional cutting fluids under dry and flood cooling environments. The experimental result of the two cutting fluids will be optimized using the Taguchi grey relational approach. It can be seen from the literature review that aluminium alloy 6061 has not been harmed by the use of palm kernel oil as a lubricant during machining. With a tungsten carbide tool, this study examines the efficacy of palm kernel oil during the MQL turning of aluminium alloy 6061.

2. Materials and Method

2.1. Sample Collection and Processing

Palm kernel nuts were collected in an Afe Babalola University compound, Ado-Ekiti, Ekiti State, the south-western part of Nigeria. The weight of the palm kernel nut collected was 30 kg. The seeds were firstly sun-dried to remove the moisture contents in them. Afterwards, the fibre surrounding the dried palm kernel nuts was removed. The next step was to separate the palm kernels from their shells. The kernels were cleaned to remove any foreign materials or debris. The cleaned kernels were crushed into smaller pieces to increase the surface area for better oil extraction. The crushed kernels were then steamed to reduce moisture content and improve oil yield. The processing pictorial procedures are depicted in Figure 1.

Figure 1.

(a) Palm kernel seed. (b) Peeled palm kernel seed. (c) Palm kernel shell. (d) Dried palm kernel nut. (e) Ground palm kernel nut.

2.2. The Procedure for the Extraction of Palm Kernel Seed Oil

The dried seeds are ground using a laboratory mill. Then, we measure 400 mL of N-hexane in a round-bottom flask and then 50 g of ground palm nut powder. The extraction process is performed with the solvent apparatus following an already established standard procedure. The heater is switched on to warm the hot plate, after which the round-bottom flask containing the solvent, along with the sample holder and condenser, is placed on the heated surface. The water is syphoned through the condenser and the solvent is allowed to boil at 60 °C; the solvent is called N-hexane.

The solvent vapor rises from the round-bottom flask and passes through the sample holder containing the dissolved sample particles. It then reaches the condenser, where it condenses and drips back into the thimble. The condenser is covered to prevent contamination. The oil produced is collected and drops back into the round-bottom flask.

In this research, oil from the palm kernel nut is extracted and then converted to a bio lubricant, which is further used for the machining of an aluminium alloy on a lathe. The oil is extracted, evaluated, and carefully kept for subsequent testing at room temperature. The yield is further evaluated.

2.3. Physio-Chemical Properties of Palm Kernel Nut Oil

2.3.1. Density and Specific Gravity

The density of the palm kernel nut oil is determined using a density bottle and an electronic weighing balance. An empty density bottle was weighed using an electronic weighing balance, and then the bottle was filled with distilled water, sealed, and weighed once more. Before being weighed once more on the computerized scale, the density container was likewise closed and filled with palm kernel nut oil. Simply dividing the mass of palm kernel nut oil by the mass of water yields the palm kernel nut oil specific gravity, and multiplying the palm kernel nut oil specific gravity by the reference density (water) yields the palm kernel nut oil density. In Equation (1), the formula is displayed.

The specific gravity:

NB. The density, ρ

2.3.2. Viscosity

A rheometer was used to calculate the palm kernel nut oil’s viscosity. The palm kernel nut oil was heated with an electric heater to a temperature greater than 40 °C before being filled to the level specified on the rheometer cup. After the rheometer was turned on and calibrated, a spindle and thermometer were placed inside the rheometer cup that was filled with heated palm kernel nut oil. The spindle was turned on at 40 °C to measure the dynamic viscosity (Equation (2)) of the palm kernel nut oil. Kinematic viscosity can be estimated by multiplying the computed dynamic viscosity by the spindle factor.

2.3.3. Moisture Content

To calculate the moisture content, the palm kernel nut oil’s weight before and after an hour of heating in a 100 °C oven was simply subtracted. The [250 mL] beaker used was weighed. Once emptied, it was then filled with palm kernel nut oil before being put into an oven that was preheated to 100 °C. The moisture content of the palm kernel nut oil was determined by comparing the measurements taken before and after an hour in the oven. The following mathematical formula, Equation (3), was used.

where EP is the empty pan, PU is the beaker with palm kernel nut oil and PUH is the beaker with palm kernel nut oil after heating.

2.3.4. Acid Value

The ASTM-D664 method was used to determine palm kernel nut oil’s acid value [50]. First, 5.61 g of KOH pellets was dissolved in 1000 mL of distilled water to produce 0.1 mol of KOH. Then, 25 mL of diethyl ether and 25 mL of toluene were prepared in one beaker, and 2 g of palm kernel nut oil was added in another. The prepared liquid was mixed with two drops of phenolphthalein indicator before being poured into the 2 g of palm kernel nut oil. Then, it was titrated using the prepared KOH as the titrant until the solution turned pink. The amount of KOH used was recorded and used to calculate the acid value. The formula required to calculate the acid value is given in Equation (4).

2.3.5. Free Fatty Acid Weight Percent

The free fatty acid (FFA) content, expressed as a weight percentage, can be determined by dividing the acid value by two. The FFA weight percent must be less than 3 weight percent in order to use the transesterification method. Simply put, this shows that the palm kernel nut oil has a low acid value. In order to remove the substantial quantity of acid in the palm kernel nut oil, esterification must be performed prior to transesterification if the FFA weight % is greater than 3 weight percentage, resulting in a two-step biodiesel production process. To calculate the FFA weight %, one should use Equation (5).

2.3.6. Saponification Value

To start, 0.5 mol of KOH was produced by dissolving 28.06 g of KOH pellets in 1000 mL of distilled water. Then, 18.25 mL of concentrated HCL was diluted in 250 mL of distilled water to provide 0.5 mol of HCL. Then, a milky solution was created by mixing 50 mL of HCL and 50 mL of ethanol in a beaker before adding it to the 2 g of palm kernel nut oil. Then, 2 g of palm kernel nut oil was added in a beaker. The milky mixture was then warmed by an electric heater while stirring at regular intervals to saponify the palm kernel nut oil. Two drops of phenolphthalein were added to the heated milky solution, and the mixture instantly became pink. It was back-titrated to produce a clear solution using the diluted HCL as the titrant. We calculated how much HCL was saponified using the amount that was consumed. The formula for saponification is shown in Equation (6).

2.4. Machining Operations

The experiments were conducted using a jet GH-1640 geared head precision lathe, as depicted Figure 2. The CF was delivered at a consistent flow rate of 2.7 mL/h. Each oil was introduced into the machining process using a new workpiece material and cutting tool. The technique of machining utilized ISO 513 K10 (N10) grade for tungsten carbide inserts tools as cutting tools [51].

Figure 2.

GH-1640 precision lathe machine.

2.4.1. Determination of Surface Roughness and Cutting Temperature

The use of SRT-6200 (a surface roughness tester) can be applied to determine the surface roughness of a workpiece or to obtain the average roughness (Ra). In the present study, each sample was taken in triplicate for consistency. The cutting temperature was determined using a PeakTech Infra-red thermometer. This was accomplished by directing the thermometer’s probing towards the interface between the chip and the tool while the cutting process was taking place. The infrared thermometer was carefully positioned at a spacing of 5 cm from the chip–tool interface. Each sample was measured three times, and the resulting average value was obtained and recorded.

2.4.2. Determination of Optimal Cutting Parameters

The optimization strategy in machining procedures plays an essential part in continuously improving the quality of output in both products and processes. The task involves creating a model that represents the data point for input and output parameters, as well as the interaction between process variables. Additionally, it requires identifying the best cutting conditions. The search for the best combination of cutting parameters was based on the average values of surface roughness and cutting temperature. The Minitab16 statistical analysis software was used to optimize the surface roughness, cutting temperature, and the impact of cutting parameters for each specific type of CF or lubricant.

The analysis was conducted utilizing the following tools: (i) Taguchi’s robust methodology design; (ii) an analysis of variance; (iii) the signal-to-noise ratio (S/N ratio); and (iv) grey relational analysis (GRA). The Taguchi robust design technique was effectively used to determine the most effective process parameters for reducing surface roughness and cutting temperature in the machining of a part using dry machining, palm kernel oil, and mineral oil lubrication. An analysis of variance (ANOVA) was conducted to determine the impact and effectiveness of each cutting variable in cutting. The analysis of variance (ANOVA) was conducted using Minitab software.

2.4.3. Evaluation of Signal-to-Noise (S/N) Ratio and Grey Relational Analysis for Turning Workpiece

The signal-to-noise ratio estimates for both surface roughness and cutting temperature were determined and optimized. The investigation utilized a combination of surface roughness and cutting temperature values, as given in Equation (7), where a lower S/N (dB) ratio was considered more favourable.

Grey relational analysis classifies scenarios with missing data and circumstances with all available data as black and white, respectively. However, in real-world scenarios, neither of these idealized answers materializes. Situations that fall within the spectrum between these two extremes and include only incomplete information are commonly known as ambiguous, indeterminate, or unsure.

The grey relational grade is used as the foundation for assessing the various process responses. The cutting variable corresponds to the grey relational rank with the highest grade. The cutting temperature and surface roughness found in the current study were evaluated utilizing Equation (8) [52].

In this context, xi(k) denotes the values obtained after the generation of the grey relational model, while yi(k) represents the minimum value of yi(k) for the kth response, and max kth indicates the maximum value of yi(k) for the same response. The ideal sequence is denoted as x0(k)x0(k) for k = 1,2,…,9; k = 1,2,…,9, which pertains to surface roughness and cutting temperature. The grey relational grade, a key concept in grey relational analysis, quantifies the degree of the relationship between the nine sequences .

The grey relational coefficient can be computed using Equation (9).

where the following applies:

= the difference in the absolute value between and ;

the distinguishing coefficient ;

is the smallest value of ;

is the largest value of .

The grey relational grade, γi, can be computed by using Equation (10) after obtaining the mean of the grey relational coefficients.

where No. of procedure responses. A greater value of the grey relational grade indicates a more robust level of correlation between the reference order, , and the provided sequence, xi(k). The contrasting grey relational grades of the differences provide a ranking of the choices, where a higher value signifies a superior choice. As mentioned earlier, the ideal reaction of the experimental setup is represented by reference sequence . The higher the grey relationship grade, the more optimal the corresponding cutting parameter is [53].

3. Results and Discussion

3.1. Characterization of Palm Kernel Nut Oil (PKNO)

The results from the characterization of palm kernel nut oil can be seen in Table 1.

Table 1.

Physiochemical results of palm kernel nut oil-based cutting fluid.

3.2. Discussion on Analysis of Experimental Data

The response parameters analysed in this study are the surface roughness and cutting temperature. The experimental data are displayed in Table 2, Table 3 and Table 4 and were later transformed into charts using Phyton software to enhance the visualization of the link between the response and process parameters. The experiments were conducted in triplicate, and the mean values of surface roughness and cutting temperature were determined for each machining condition (dry machining, mineral oil, and palm kernel nut oil). These findings were appropriately analysed and explained. The cutting temperature is abbreviated as CT and the surface roughness as Ra.

Table 2.

Experimental results for palm kernel nut oil machining.

Table 3.

Experimental results for mineral oil machining.

Table 4.

Experimental results for dry machining.

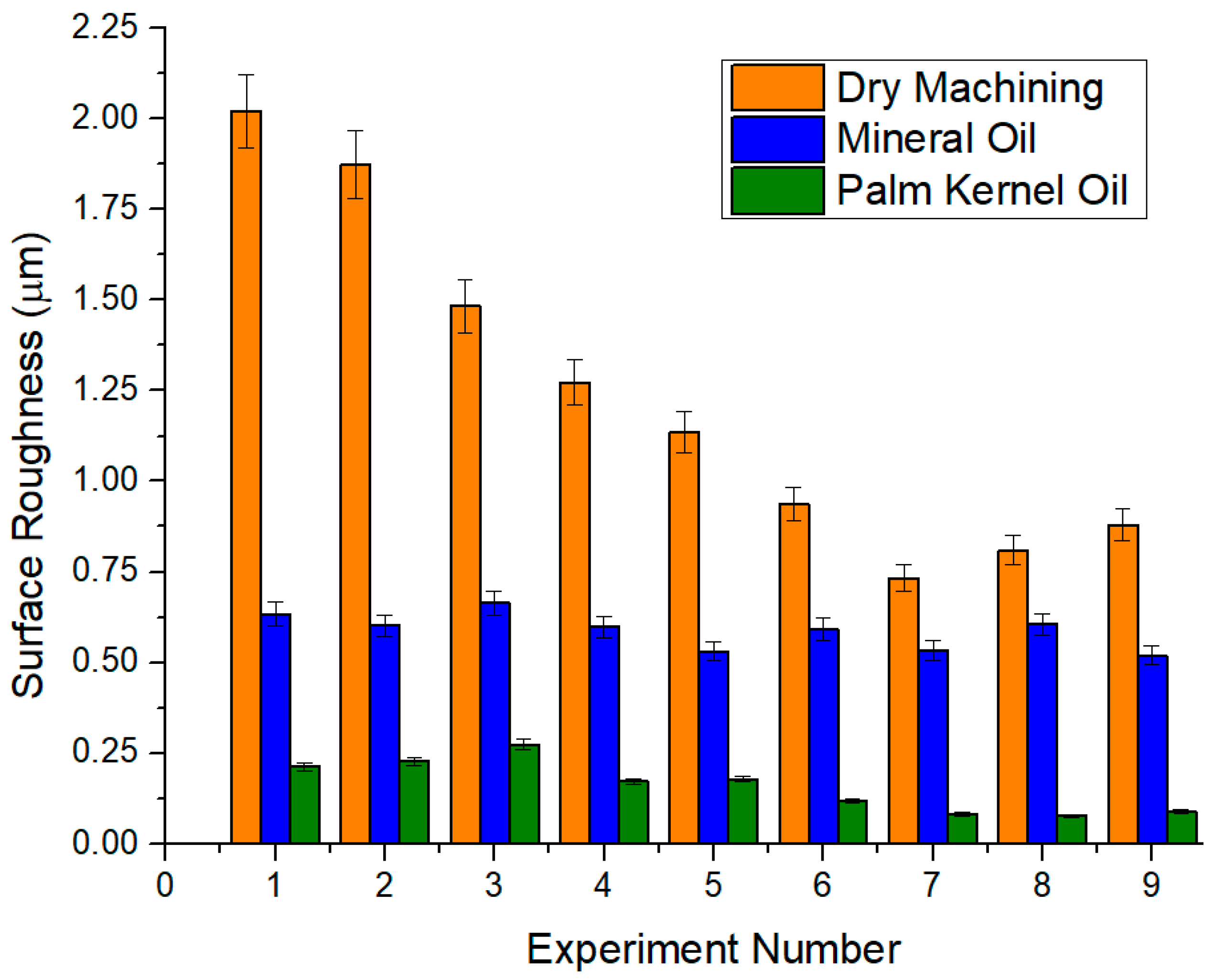

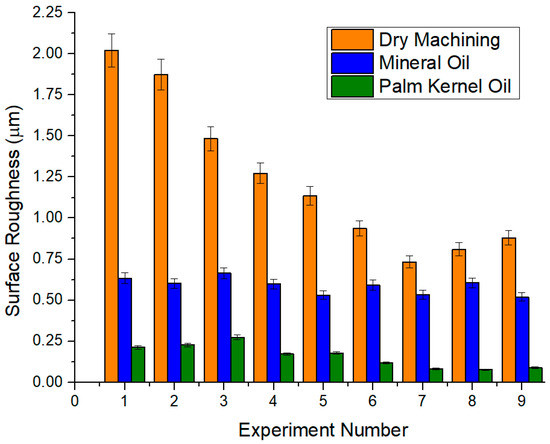

The surface roughness results for PKNO, mineral oil, and dry machining environments are shown in Table 2, Table 3 and Table 4 and contrasted in Figure 3. The surface roughness values measured for the dry condition range from 0.733 to 2.022 μm, whereas the range for mineral oil is 0.520 to 0.664 μm, and the range for PKNO is 0.077 to 0.274 μm. Upon calculating the mean and standard deviation of the surface roughness measurements, it was determined that the average surface roughness for the dry condition was 1.327 ± 0.509 μm, for mineral oil, it was 0.584 ± 0.049 μm, and for PKNO, it was 0.164 ± 0.070 μm. As previously stated, a lower surface roughness rating suggests a surface that is smoother. An examination of the experimental data revealed that palm kernel oil consistently yielded lower surface roughness values, whereas dry machining consistently yielded greater surface roughness values in comparison to mineral oil across all nine experiments. The increased surface roughness observed during dry machining may be due to unregulated heating occurring between the contact surfaces of the work–tool and chip–tool. This issue frequently arises due to inadequate lubrication or a lack of cutting fluids.

Figure 3.

Surface roughness analysis results.

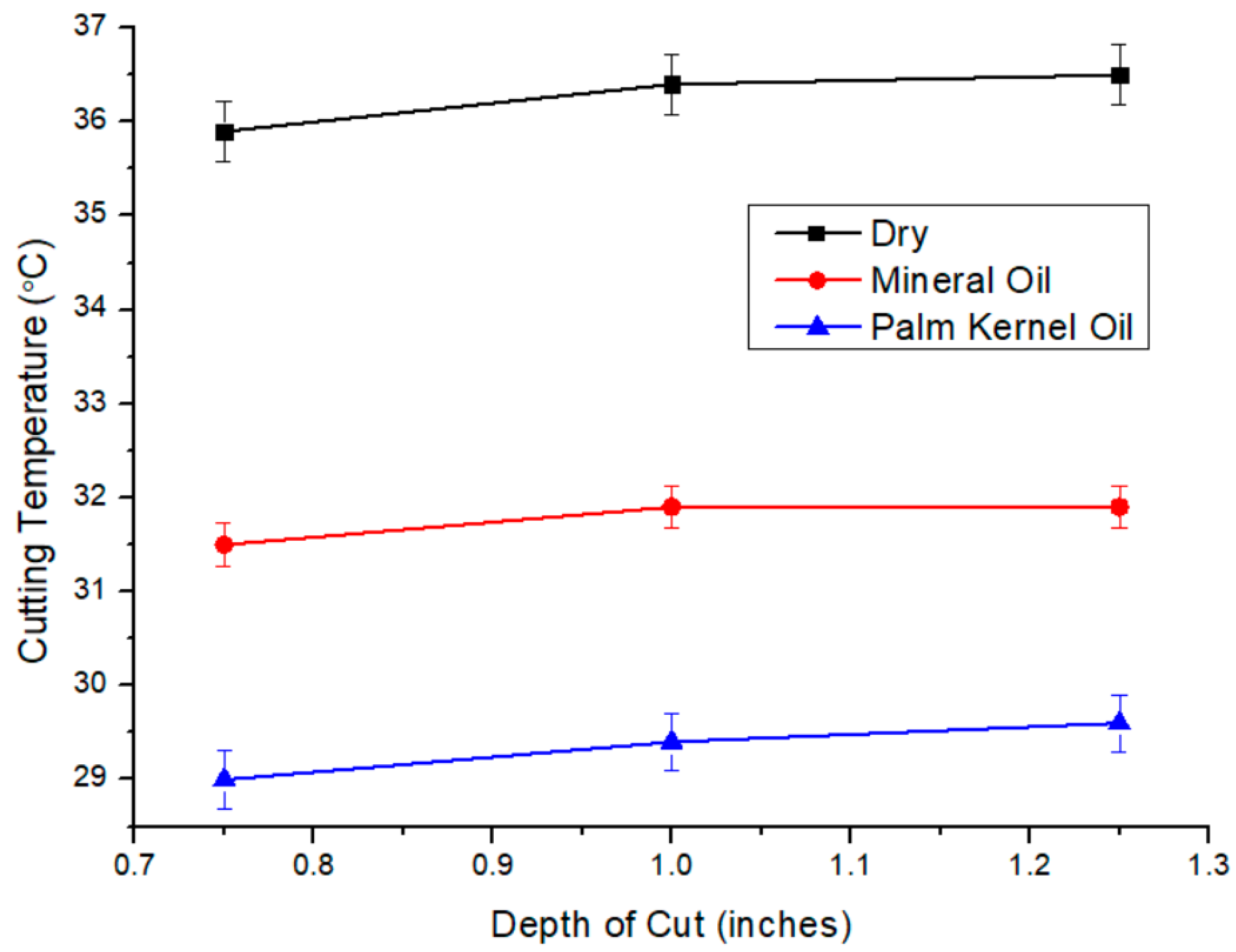

The surface roughness of machined workpieces is affected by multiple factors, such as the lubrication or CF employed during the machining procedure. Comparing the usage of PKNO and mineral oil for machining, it was observed that employing PKNO as a CF resulted in a significantly smoother surface finish compared to the use of mineral oil. This could be attributed to the enhanced interaction between the work and tool, leading to a decrease in the frictional forces between the contact surfaces of the work and tool. The surface roughness measurements obtained from mineral oil machining under various cutting settings are considerably greater than those obtained from palm kernel machining, which have an average roughness of 0.164 ± 0.070 μm. PKNO exhibits a surface roughness improvement of 71.8% compared to mineral oil. Optimal temperature regulation and the lubrication of contact surfaces in the designated cutting area using a CF can have a significant impact on minimizing surface roughness during mineral oil machining. The enhanced fluidity and accelerated lubricating capability of the produced oil, which surpass those of mineral oil, are accountable for its improved performance. These findings demonstrate that palm kernel oil meets the necessary criteria for lubricating qualities and has great promise for application in machining processes. The cutting temperature, on the other hand, is determined by several factors such as the depth of cut, feed rate, and spindle speed [53,54,55]. Consequently, the cutting temperature of PKNO and mineral oil under various cutting settings is shown in Figure 4.

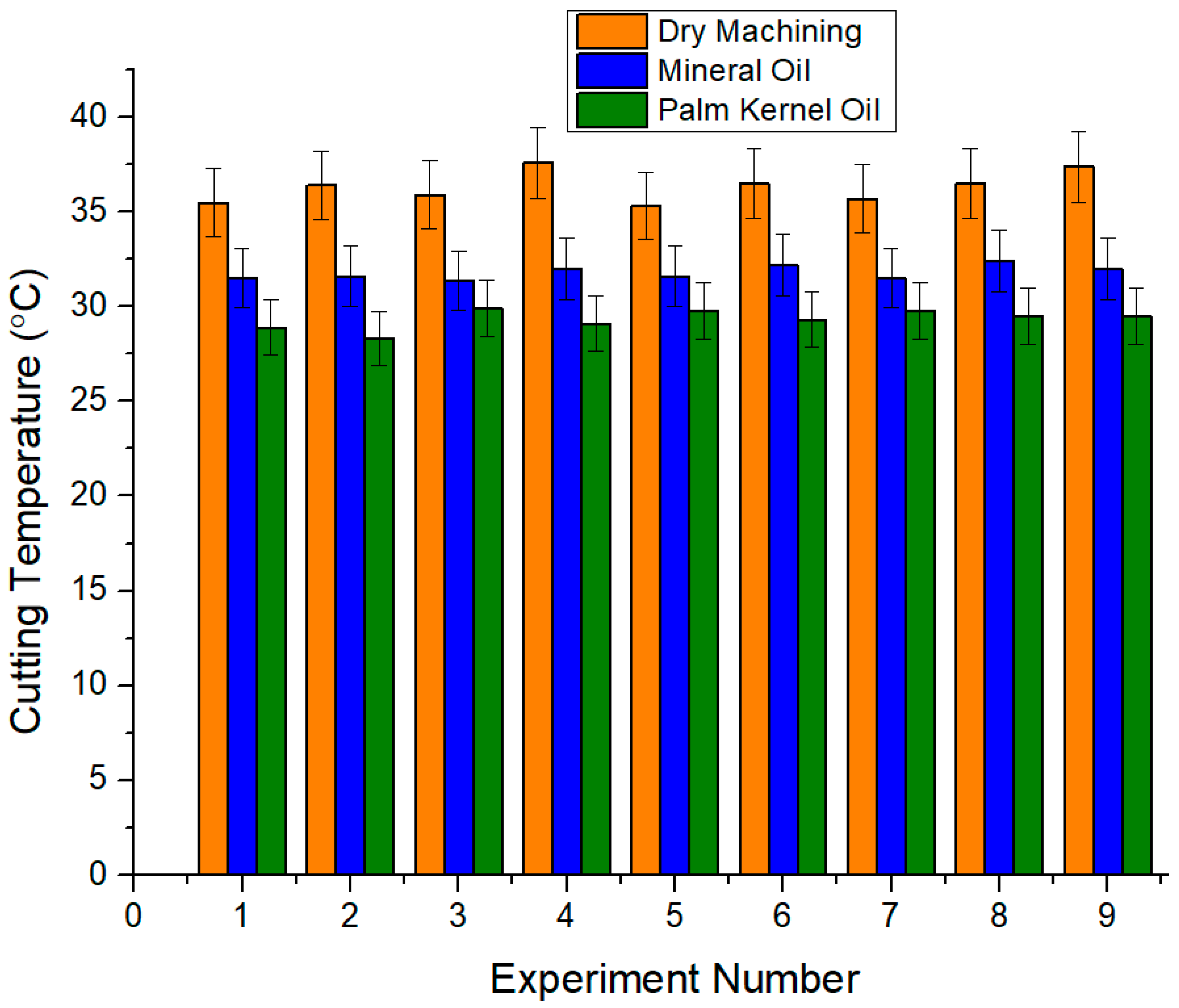

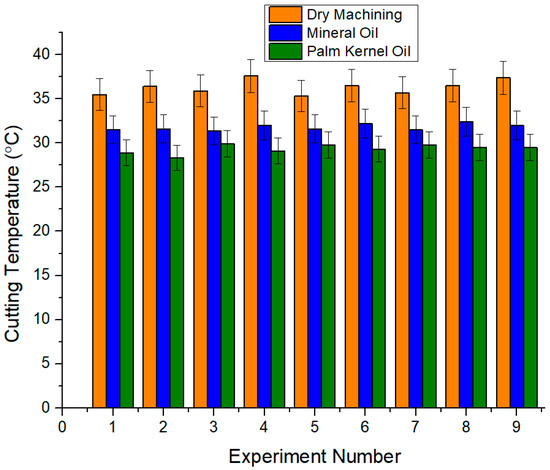

Figure 4.

Cutting temperature analysis results.

The process of optimizing complex multiple-procedural responses can be simplified by optimizing a single grey relational grade. The results of the grey relational analysis are illustrated in Table 5, Table 6 and Table 7.

Table 5.

Grey relational analysis for palm kernel nut oil.

Table 6.

Grey relational analysis for mineral oil.

Table 7.

Grey relational analysis for dry machining.

The cutting temperature of palm kernel nut oil (PKNO) ranged from 29.9 °C to 28.3 °C, that of mineral oil ranged from 32.4 °C to 31.4 °C, and that of dry machining ranged from 37.6 °C to 35.3 °C. When we calculated the mean and standard deviation of the cutting temperature measurements, we found that the average cutting temperature for PKNO was 29.34 ± 0.59 °C, for mineral oil, it was 31.74 ± 0.53 °C, and for dry machining, it was 36.10 ± 0.69 °C. It is evident that PKNO generally exhibits lower cutting temperatures than mineral oil across most cutting conditions. Comparatively, dry machining demonstrates an even higher cutting temperature than mineral oil, as illustrated in Figure 4, where mineral oil reaches a temperature of 31.74 °C and dry machining reaches 36.10 °C. The improvement in mineral oil over dry machining is approximately 13.1%, while PKNO exhibits the best performance in terms of heat removal in this study.

3.3. Analysis on the Impact of Cutting Conditions on Surface Roughness

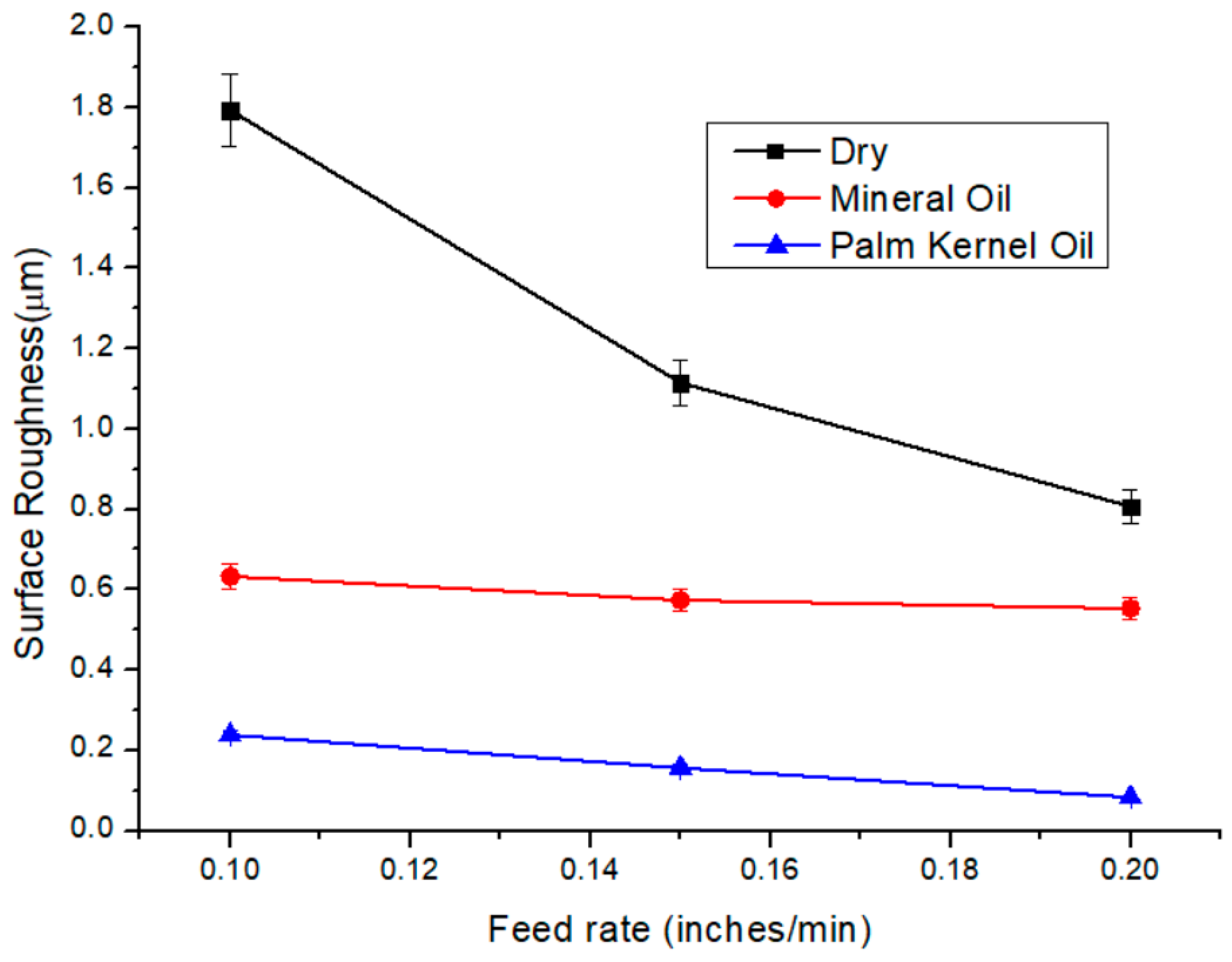

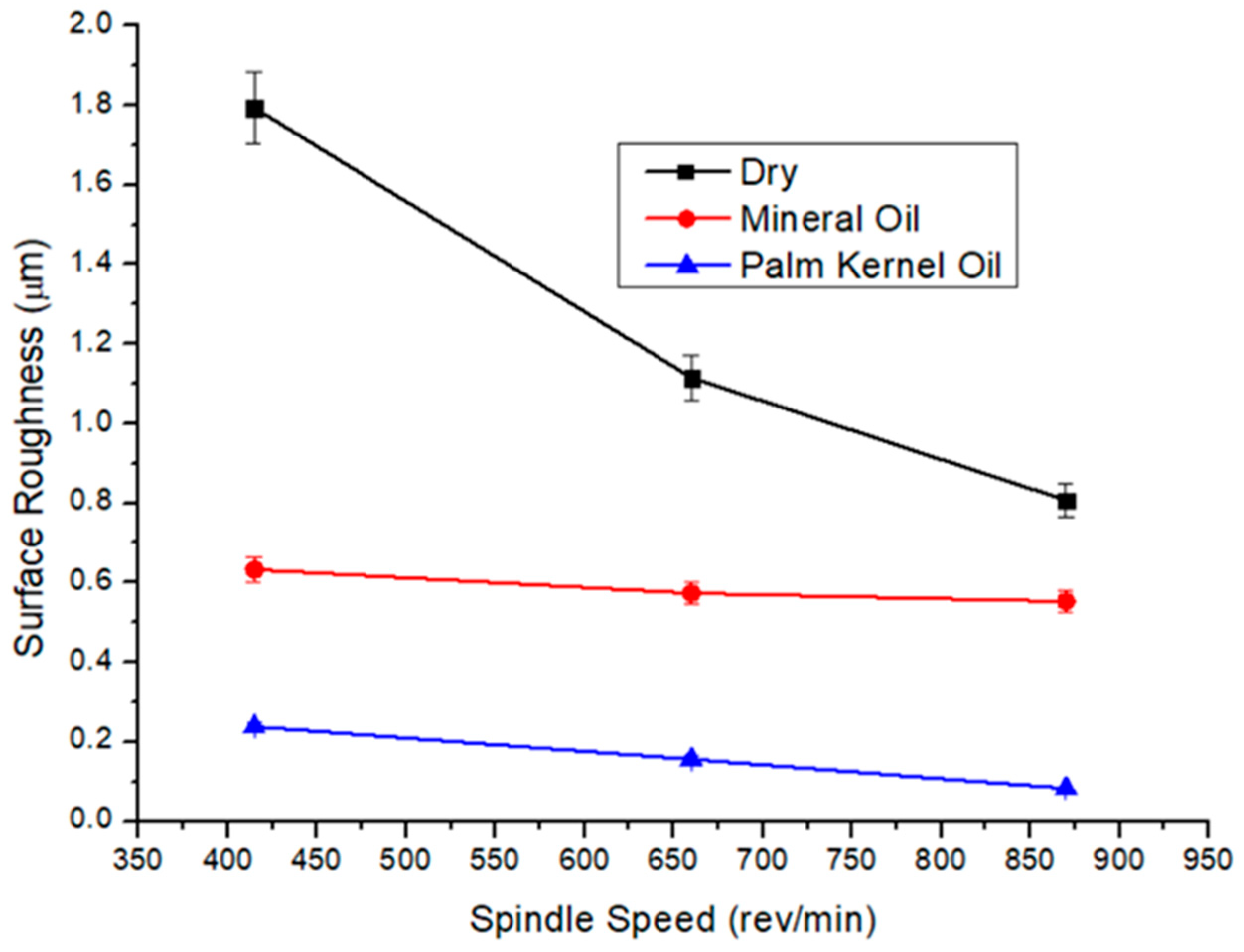

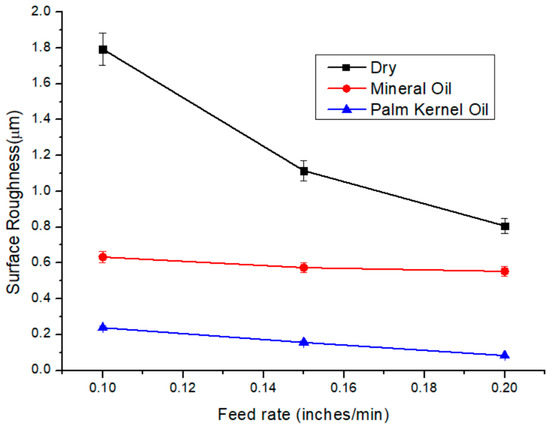

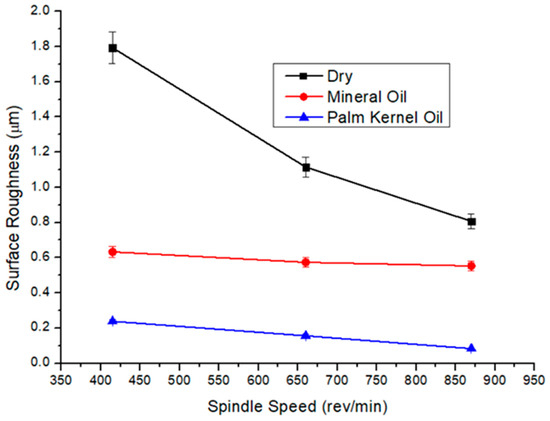

Figure 5, Figure 6 and Figure 7 demonstrate the impact of cutting parameters—specifically the spindle speed, feed rate, and depth of cut—on surface roughness under three distinct conditions: dry machining, mineral oil lubrication, and palm kernel oil nut (PKNO). Figure 5 illustrates the relationship between the material feed rate and the resulting surface unevenness. The data indicate that dry machining results in the highest surface roughness at elevated spindle speeds, whereas PKNO consistently yields the lowest surface roughness under the same conditions. In contrast, the surface roughness when using mineral oil remains relatively stable as the feed rate increases. When the feed rate transitions from low to medium, a slight reduction in surface roughness is observed for the dry machining condition. However, increasing the feed rate further from medium to high leads to a significant increase in surface roughness. The slope of the line for PKNO is measured at 0.05, indicating a positive correlation; thus, for each unit increase in the feed rate, the surface roughness increases by 0.05 units. This suggests that higher feed rates result in a rougher surface finish. Similarly, the line representing mineral oil also displays a positive slope of 0.026, highlighting a direct relationship where surface roughness increases by 0.026 units for every unit increment in the feed rate. This indicates that, with rising feed rates, the surface tends to become more refined.

Figure 5.

Efficacy of feed rate on surface roughness showing error bars.

Figure 6.

Effect of spindle speed on surface roughness showing error bars.

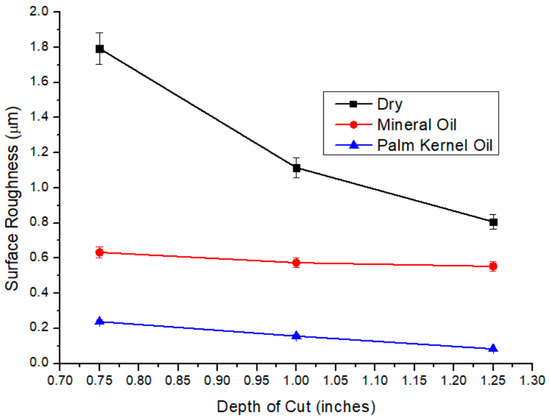

Figure 7.

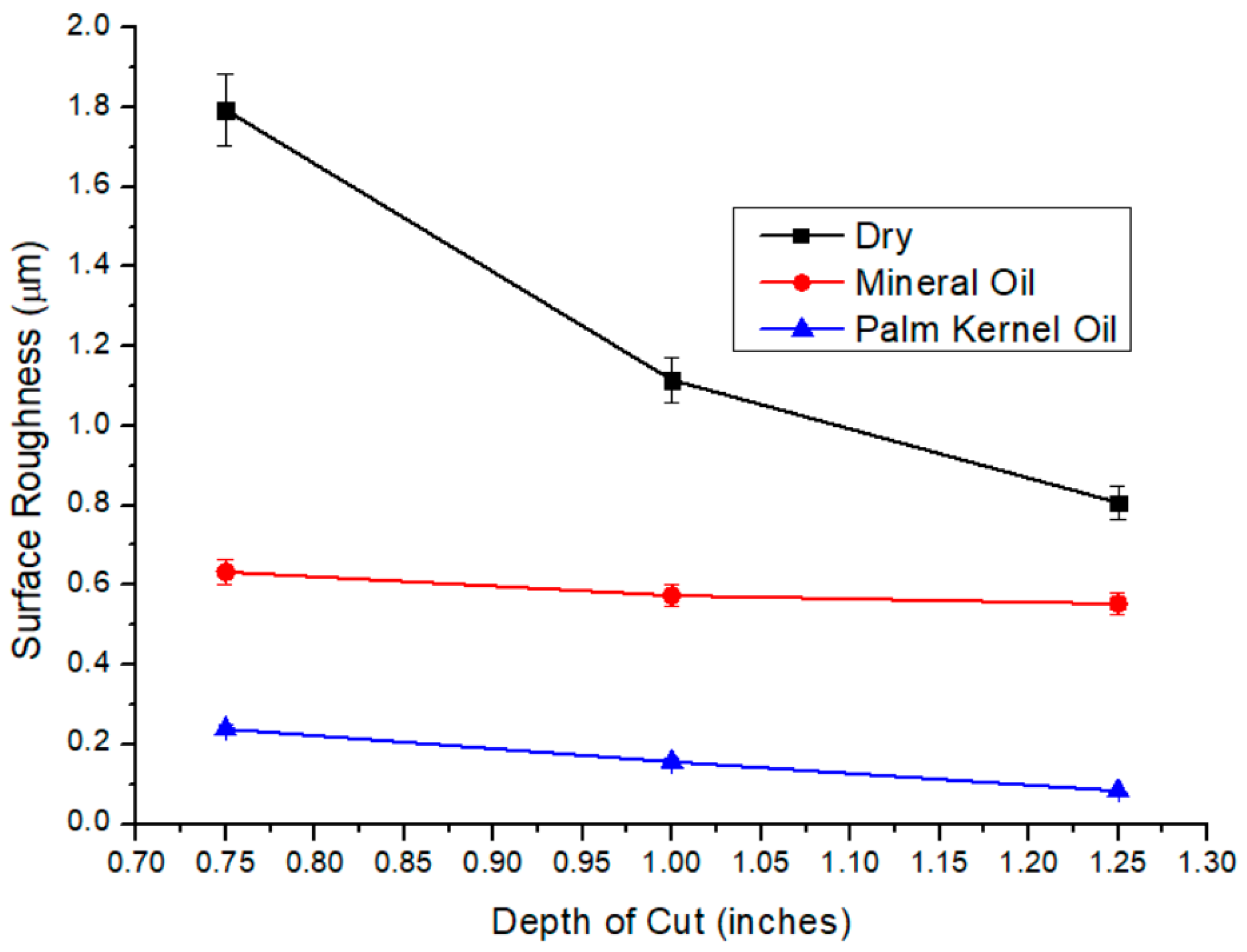

Effect of depth of cut on surface roughness showing error bars.

Further analysis in Figure 5 regarding spindle speed reveals its relationship with surface roughness. The average surface roughness was recorded for various spindle speed settings. For PKNO, a diminishing correlation between spindle speed and surface roughness was noted, suggesting that as spindle speed increases, the relationship weakens. Additionally, for mineral oil, a slight reduction in surface roughness occurs as spindle speed rises from low to high levels. In contrast, the surface roughness for dry machining decreases significantly with increasing spindle speeds, indicating a more favourable outcome in terms of surface finish under those conditions. It is worth noting that the error bars for Figure 5, Figure 6 and Figure 7 are taken at 5%. It was noted that under the same cutting conditions of a spindle speed of 415 rev/min, the average surface roughness values for PKNO, mineral oil and dry machining were, respectively, recorded as 0.238 ± 0.019 μm, 0.633 ± 0.03165 μm and 1.793 ± 0.08965 μm. Also, at a 660 rev/min machining rate, the average surface roughness values for PKNO, mineral oil and dry machining were 0.156 ± 0.0078 μm, 0.574 ± 0.0287 μm and 1.115 ± 0.05575 μm, respectively. Lastly, at the highest spindle speed of 870 rev/min, the average surface roughness values for PKNO, mineral oil and dry machining were estimated to be 0.083 ± 0.00415 μm, 0.553 ± 0.92765 μm, and 0.807 ± 0.04035 μm, respectively. The same values of surface roughness as recorded above were noted under different feed rates of 0.1 inches/min, 0.15 inches/min and 0.2 inches/min. It can be inferred from the results above that a higher speed produces a smoother surface with a lower depth of cut and feed rate and that there is a significant effect caused by the use of the produced PKNO compared to the mineral oil under the same cutting condition; this can be attributed to its favourable physicochemical properties. PKNO possesses a higher viscosity index, better lubricity, and a higher flash point, which contribute to enhanced lubrication, reduced friction, and lower tool wear during machining.

Figure 7 depicts the fluctuations in surface roughness and the depth of cut under three different conditions: dry, mineral oil, and PKNO. Surface roughness in the dry environment rises continually when the depths of cut range from low to high. The surface roughness remains roughly consistent as the depth of cut for PKNO increases. The line for PKNO has a negative slope of −0.0133. This suggests that there is a minor drop of 0.0133 units in surface roughness for each unit rise in depth. Put simply, as the depth increases, the surface becomes smoother. The gradient of the line representing mineral oil is negative and has a value of −0.016. For each incremental rise in depth, the surface roughness reduces by 0.016 units. Put simply, as the depth increases, the surface experiences a slight increase in smoothness.

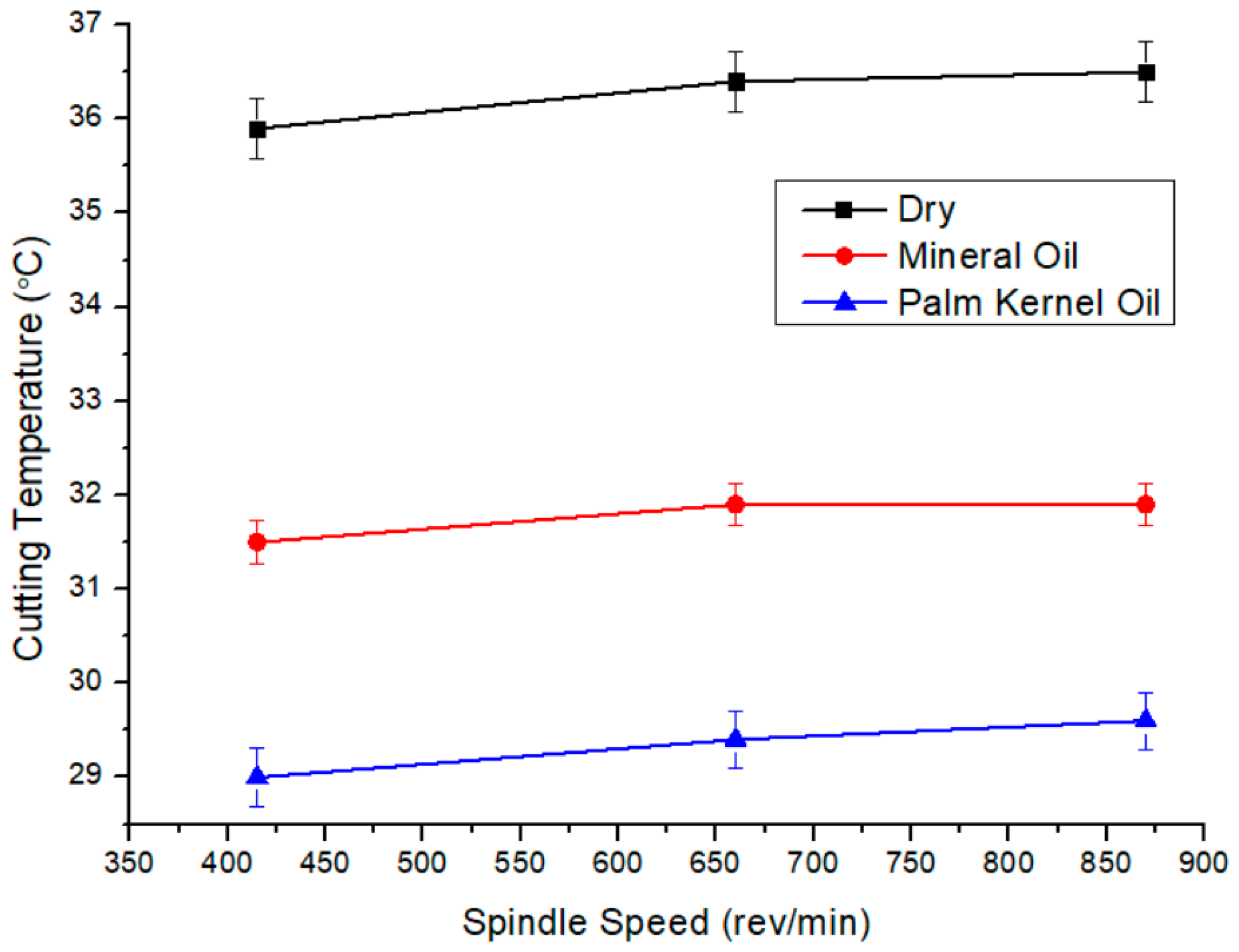

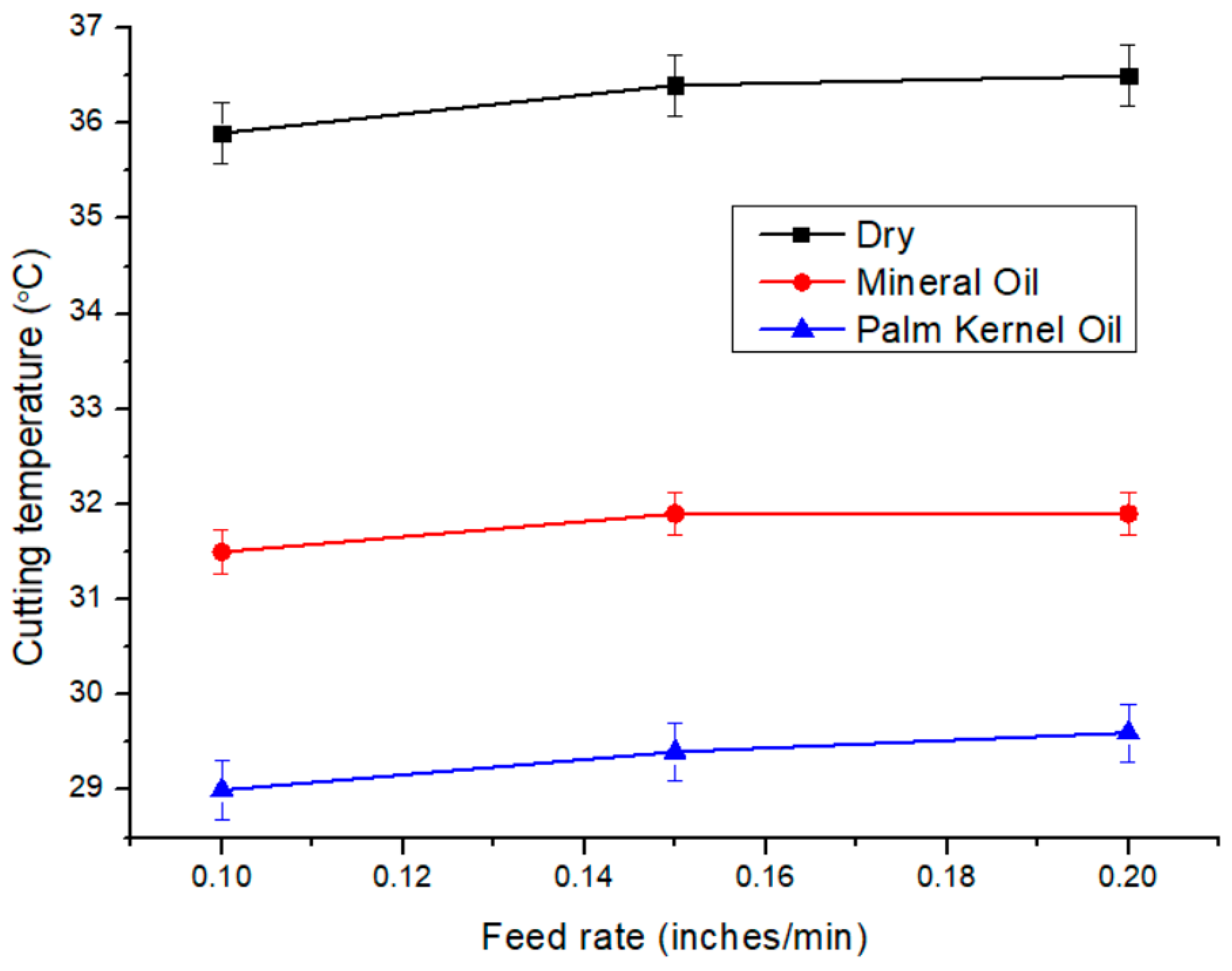

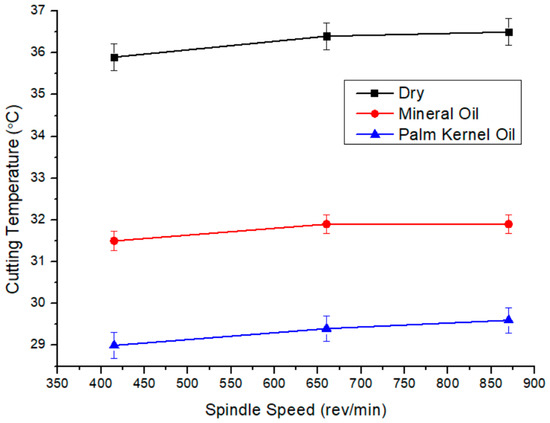

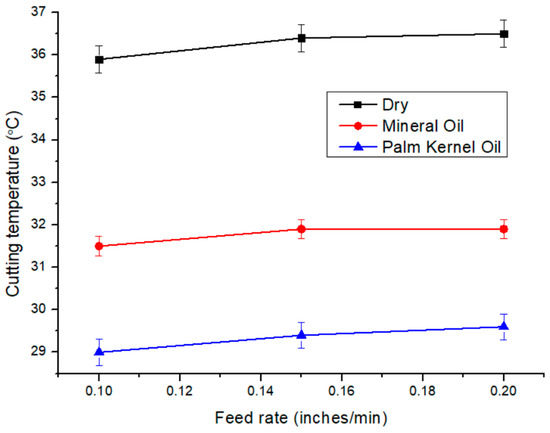

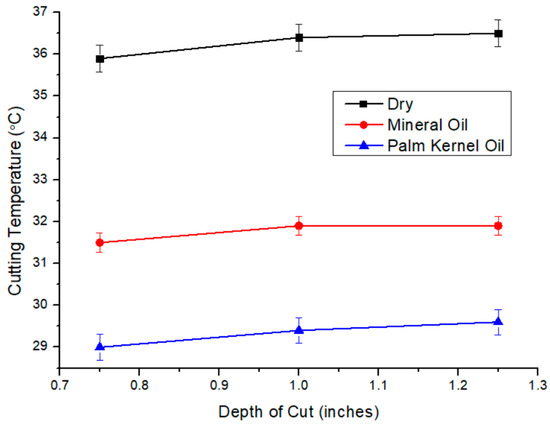

3.4. Effect of Cutting Parameters on Cutting Temperature

Figure 8, Figure 9 and Figure 10 illustrate the influence of cutting parameters on the temperature at which emulsion metal cutting fluids are used, each figure showing a standard deviation of 0.69 for dry machining, 0.53 for mineral oil and 0.59 for PKNO. During machining with PKNO, the cutting temperature remains generally constant regardless of the spindle speed, ranging from 29.06 to 29.63 degrees Celsius. Similarly, the cutting temperature exhibits negligible fluctuations across various feed rates, ranging from 29.21 to 29.58 degrees Celsius. The depth of cut has a minimal impact on the cutting temperature during machining with PKNO, since temperatures range from 29.21 to 29.63 degrees Celsius. When observing mineral oil, it is evident that the cutting temperature experiences a modest increase as the spindle speeds rise, ranging from 31.49 to 31.97 degrees Celsius. Similarly, the cutting temperature exhibits a modest increase as the feed rates increase, ranging from 31.68 to 31.88 degrees Celsius. The depth of cut has little effect on the cutting temperature of mineral oil, which ranges from 31.68 to 31.88 degrees Celsius. However, for dry machining, the cutting temperature tends to rise with greater spindle speeds, ranging from 35.94 to 36.54 degrees Celsius. The cutting temperature exhibits a marginal increase as the feed rates increase, ranging from 36.27 to 36.61 degrees Celsius. Unlike the lubricants, the depth of cut has a minimal impact on the cutting temperature for dry machining. The temperatures range from 36.27 to 36.61 degrees Celsius. From our experimental results, the average cutting temperature under PKNO was 29.34 ± 0.59 °C compared to 31.74 ± 0.53 °C for mineral oil and 36.10 ± 0.69 °C under dry conditions. These values reinforce the thermal performance advantages of PKNO. As recorded in the literature [22,26,53], the flash point of PKNO was measured at >250 °C, indicating good thermal stability during high-temperature operations. This makes it suitable for sustained cooling without rapid degradation, unlike lower-flash-point synthetic fluids. It was further noted from the literature [46,52] that PKNO possesses a high specific heat capacity (approximately 2.1 kJ/kg·K), enabling it to absorb and retain more heat energy, while its optimal viscosity (measured at 35–42 cSt at 40 °C as reported in our previous study [26,52]) ensures good flow and coverage over the tool and workpiece surface. This helps in both lubrication and heat removal. Though vegetable oils typically have lower thermal conductivity than water-based coolants, PKNO exhibits moderate thermal conductivity (~0.17–0.22 W/m·K), which is sufficient to aid heat dissipation when combined with its superior lubrication. For comparison, mineral oil has a thermal conductivity in the range of 0.13–0.15 W/m·K, making PKNO relatively more effective in dissipating heat. It is imperative to note that PKNO forms a stable lubricating film between the tool and the workpiece, which significantly reduces friction. The coefficient of friction for PKNO has been reported in the literature to range between 0.10 and 0.15, which is lower than many mineral-based oils (~0.17–0.22). This reduced friction directly contributes to lower heat generation in the cutting zone.

Figure 8.

Effect of spindle speed on cutting temperature showing standard deviation for each cutting condition.

Figure 9.

Effect of feed rate on cutting temperature showing standard deviation for each cutting condition.

Figure 10.

Effect of depth of cut on cutting temperature showing standard deviation for each cutting condition.

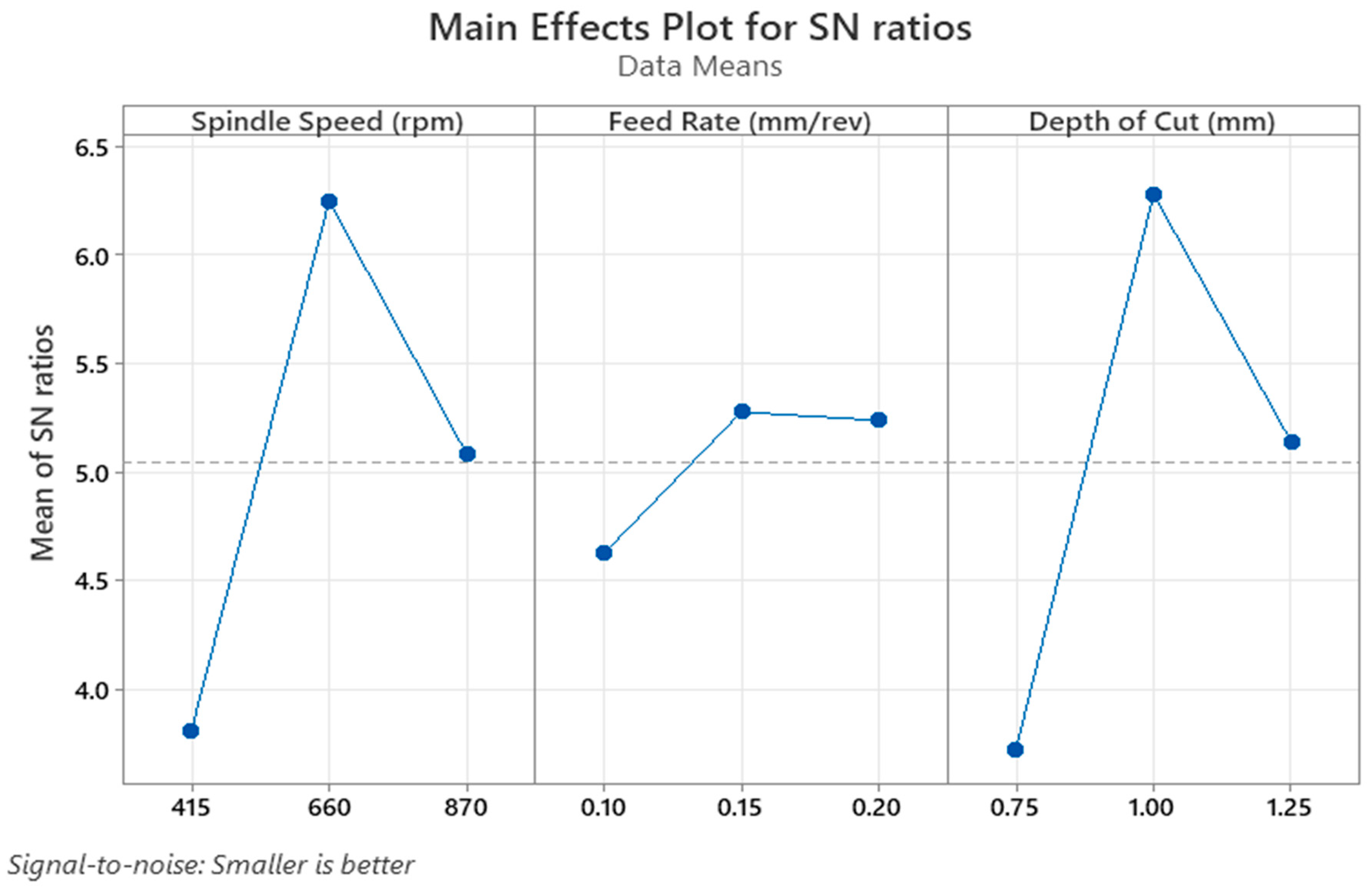

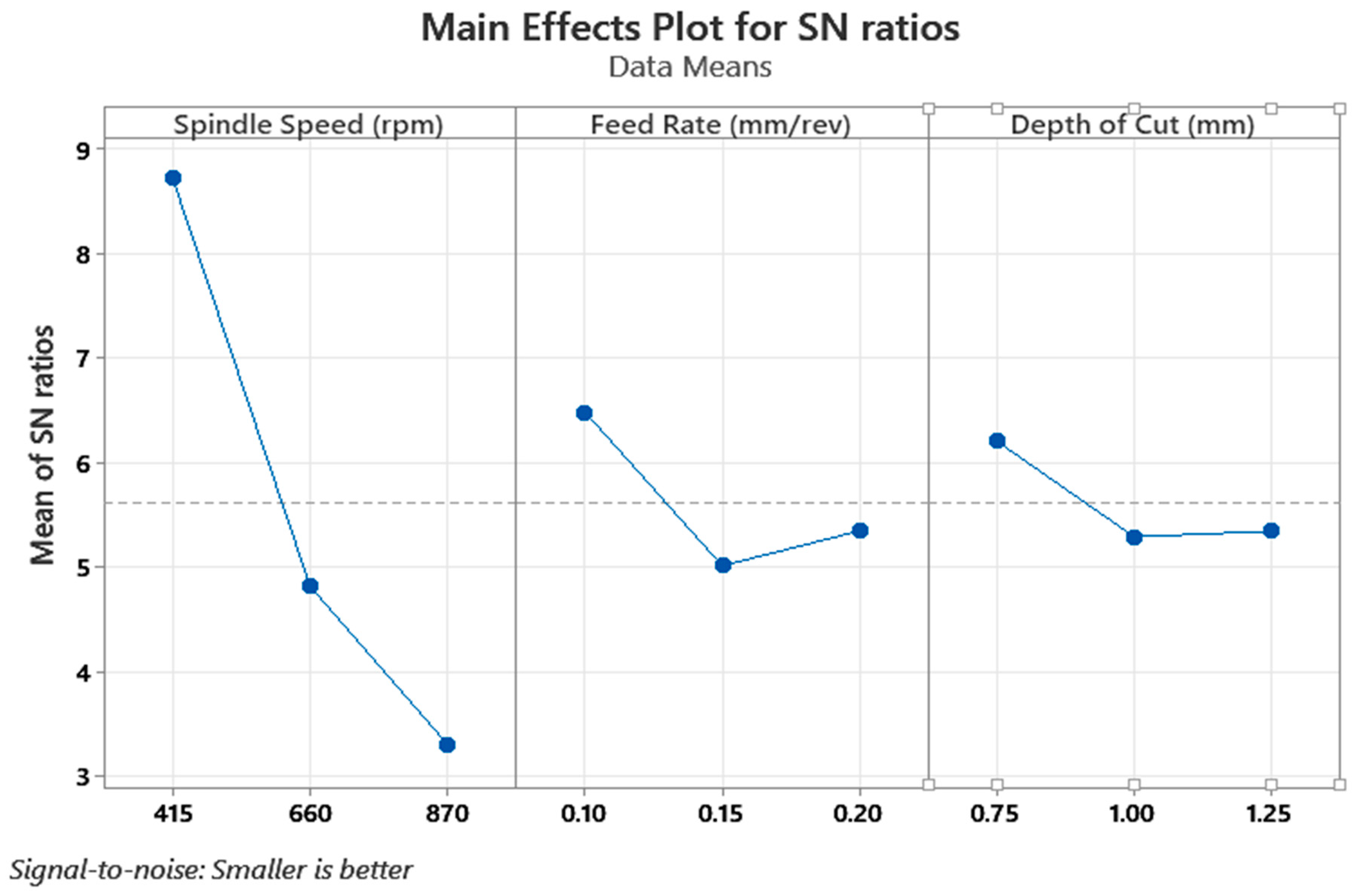

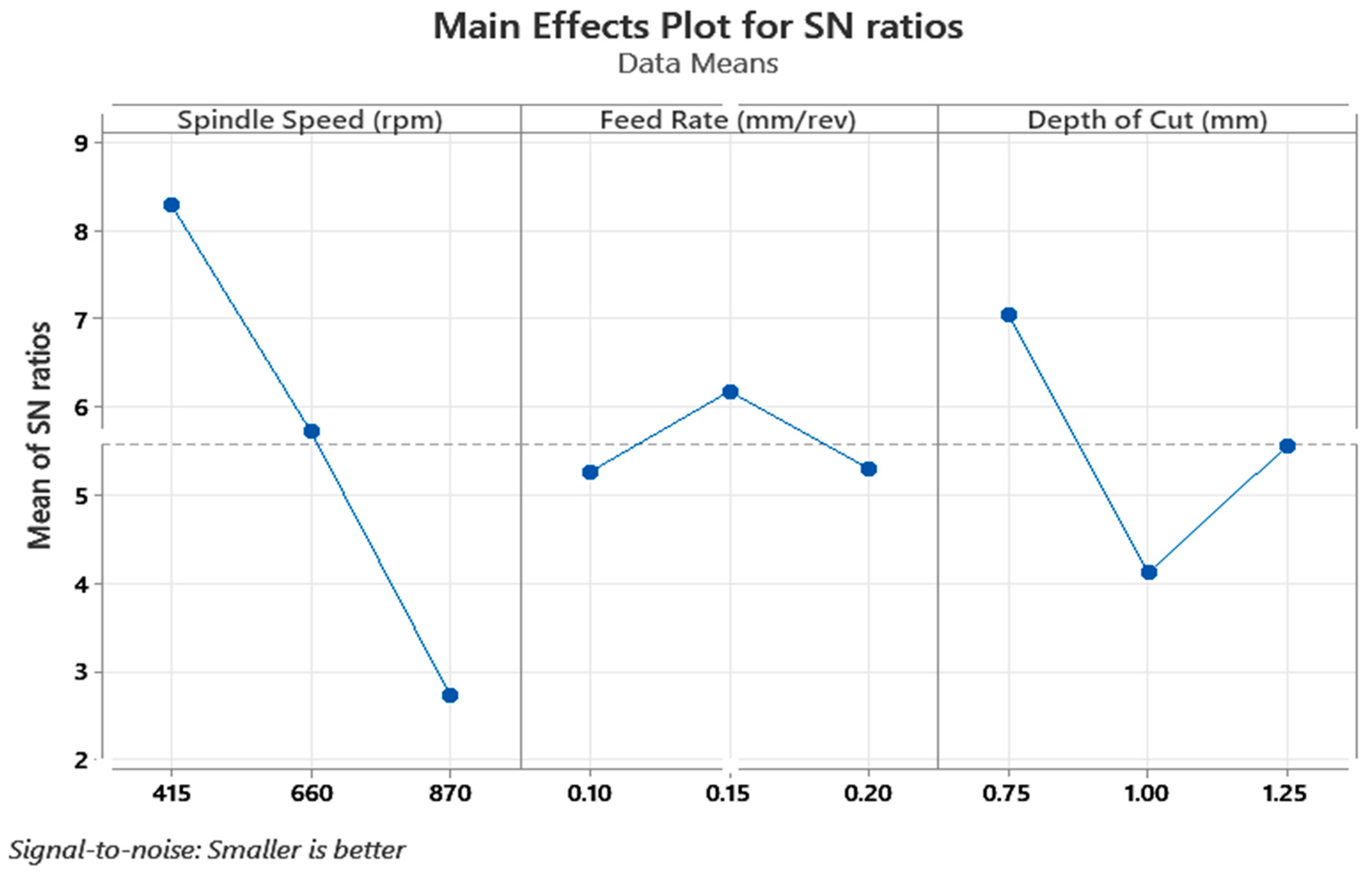

3.5. Main Effect Plot

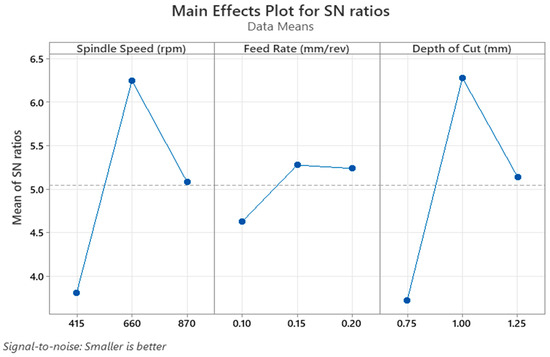

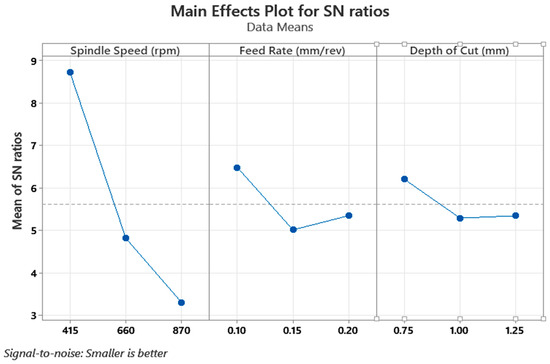

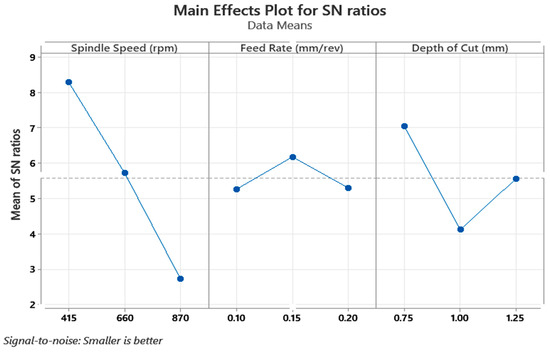

The primary impact plot was employed to identify both significant and minor contributors to the outcomes of this study. This graphical representation illustrates the average response values associated with specific parameters or input variables at each level, allowing for a comparative analysis of the relative effects exerted by various factors. The investigation concentrated on the combined influence of two control parameters: surface roughness and cutting temperature, utilizing a strategically selected inner array, L9. To highlight the potential trade-offs between the mean values of surface roughness and cutting temperature, significant effect plots are presented side by side. This analysis formed part of a broader multi-objective optimization effort. Figure 11 showcases the optimal parameter combinations derived from the dry machining performance studies, indicating that the highest spindle speed (Level 2) is deemed ideal. Additionally, the best performance outcomes were achieved by employing the lowest feed rate (Level 2) and the maximum depth of cut (Level 2) in their optimal configurations. By fine-tuning the spindle speed, feed rate, and depth of cut, one can effectively attain specific targets for surface finish and cutting temperature. Figure 12 presents a graph detailing the primary impacts associated with mineral oil. The primary effect plot revealed that the input parameters—the spindle speed, feed rate, and depth of cut—were prioritized in that order. The results indicated that spindle speed should be maintained at a low setting of 415 rpm. Similarly, the feed rate should remain low at 0.10 mm/rev, while the depth of cut should be set at a higher level of 0.75 mm. For palm kernel oil, the optimal parameter combinations identified for achieving the desired performance criteria include a spindle speed of 415 rpm, a feed rate of 0.15 mm/rev, and a depth of cut of 0.75 mm, as illustrated in Figure 13.

Figure 11.

Main effect plot for SN ratios (dry machining).

Figure 12.

Main effect plot for SN ratios (mineral oil).

Figure 13.

Main effect plot for SN ratios (Palm Kernel Oil).

3.6. Evaluation of Analysis of Variance

An analysis of variance (ANOVA) is a statistical method employed to determine which machining parameters significantly influence performance evaluation. This technique is widely used to assess the impact of individual components on experimental outcomes by analysing the effects and errors associated with specific machining settings. The parameter exhibiting the highest mean square value is identified as the most influential factor affecting various behavioural aspects [52].

Table 8 presents the ANOVA results for dry machining, palm kernel oil, and mineral oil lubricants. For mineral oil, the depth of cut emerges as the primary factor, accounting for 54.8% of the overall results. The feed rate contributes 31.2%, while spindle speed has a relatively minor effect, representing only 4.6% of the total influence on the trial outcomes. The ANOVA analysis indicated an experimental error of 9.4%, which is considered statistically acceptable.

Table 8.

Analysis of variance for dry machining, palm kernel and mineral oils.

In the case of palm kernel oil, the contributions of the input parameters are as follows: the spindle speed (67.21%), feed rate (19.87%), and depth of cut (7.01%). The data suggest that the feed rate significantly impacts the various responses observed during the turning process. The influence of spindle speed on multiple responses is recorded at 25.5%, while the effect of the depth of cut remains minimal [53,54].

For dry machining, the ANOVA results reveal that the cutting parameters—the spindle speed (17.0%), feed rate (62.1%), and depth of cut (18.1%)—all exert a significant influence. Notably, the feed rate is identified as the most critical factor affecting the multi-responses in dry machining, followed by the depth of cut. In contrast, spindle speed has a negligible effect on the overall responses. The confidence level established for this analysis is 95%, ensuring a robust evaluation of the factors at play.

4. Conclusions

Thus, this study successfully showcased the application of Taguchi and grey relational analysis in optimizing the entire turning procedure by considering different performance indicators. An analysis of variance was conducted to examine the impact of factors on GRG. Below, you will find a summary of the analytical findings:

- The superior machining performance of palm kernel nut oil (PKNO) compared to mineral oil can be attributed to its favourable physicochemical properties. PKNO possesses a higher viscosity index, better lubricity, and a higher flash point, which contribute to enhanced lubrication, reduced friction, and lower tool wear during machining. Additionally, its biodegradable nature and polar functional groups improve its ability to form an effective lubricating film, thereby reducing cutting forces and improving surface finish.

- The data obtained for surface roughness for dry machining, palm kernel oil, and mineral oil lubricants were 0.164 ± 0.070 µm, 1.327 ± 0.509 µm, and 0.584 ± 0.049 µm, respectively. In terms of surface roughness, palm kernel oil is the best with 71.8% improvement over mineral oil. Dry machining was poor in performance, and this was expected due to the absence of lubrication.

- It can be inferred from the results and discussions that the cutting temperature results for dry machining, palm kernel oil, and mineral oil lubricants were 36.10 ± 0.69 °C, 21.34 ± 0.59 °C, and 31.74 ± 0.53 °C, respectively. This shows that machining with PKNO cutting fluids reduced heat the most in the cutting zone.

- The values obtained for the optimum spindle speed, feed rate, and depth of cut are 660 rpm, 0.15 mm/rev and 1.00 mm for dry machining, 415 rpm, 0.15 mm/rev and 0.75 mm for palm kernel oil, and 415 rpm, 0.15 mm/rev and 0.75 mm for mineral oils, respectively.

- The ANOVA findings for GRG were used for estimating the percentage contribution of the input variables. When considering response minimization, the feed rate has the most impact on the grey relational grade for the turning process under MQL.

Author Contributions

Conceptualization, O.M.I. and R.A.K.; methodology, O.M.I. and R.A.K.; software, R.A.K., O.M.I., O.T.L. and P.O.; validation; R.A.K. and T.T.T.; formal analysis, O.M.I., R.A.K. and P.O.; investigation, O.M.I., O.T.L. and T.T.T.; resources, T.T.T. and O.T.L.; data curation, O.M.I., R.A.K. and T.T.T.; writing—original draft preparation, O.M.I. and R.A.K.; writing—review and editing, T.T.T., P.O., R.A.K. and O.T.L.; visualization, O.T.L., P.O. and T.T.T.; supervision, O.T.L. and T.T.T.; project administration, O.M.I., P.O. and R.A.K.; funding acquisition, O.T.L. and T.T.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Guntreddi, B.; Ghosh, A. High-speed machining of aluminium alloy using vegetable oil based small quantity lubrication. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 237, 1999–2014. [Google Scholar] [CrossRef]

- Azarhoushang, B. Abrasive Machining Processes. In Tribology and Fundamentals of Abrasive Machining Processes, 3rd ed.; William Andrew: Norwich, NY, USA, 2021. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Doloi, B. Machining processes utilizing thermal energy. In Modern Machining Technology; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Hadad, M.; Hadi, M. An investigation on surface grinding of hardened stainless steel S34700 and aluminum alloy AA6061 using minimum quantity of lubrication (MQL) technique. Int. J. Adv. Manuf. Technol. 2013, 68, 2145–2158. [Google Scholar] [CrossRef]

- Kaewsaard, P.; Zhu, H.; Qi, H.; Tangwarodomnukun, V. Laser surface masking of stainless steel for electrochemical machining process. Int. J. Adv. Manuf. Technol. 2021, 116, 1141–1150. [Google Scholar] [CrossRef]

- Salah, N.B.; Ghanem, F.; Atig, K.B. Numerical study of thermal aspects of electric discharge machining process. Int. J. Mach. Tools Manuf. 2006, 46, 908–911. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Kovac, P.; Sekulic, M. An inverse heat transfer problem for optimization of the thermal process in machining. Sadhana-Acad. Proc. Eng. Sci. 2011, 36, 489–504. [Google Scholar] [CrossRef]

- Khan, T.; Broderick, M.; Taylor, C.M. Investigating the industrial impact of hydraulic oil contamination on tool wear during machining and the development of a novel quantification methodology. Int. J. Adv. Manuf. Technol. 2021, 112, 589–600. [Google Scholar] [CrossRef]

- Hof, L.A.; Wuthrich, R. Glass precision micro-cutting using spark assisted chemical engraving. Adv. Ind. Manuf. Eng. 2021, 3, 100056. [Google Scholar] [CrossRef]

- Martin, C.R.; Untaroiu, A.; Xu, K.; Raman, S.M.M. A Study of the Efficacy of Flame Electrical Resistance for Standoff Measurements During the Oxyfuel Cutting Process. J. Manuf. Sci. Eng. 2022, 144, 071010. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear—A review. Tribol. Int. 2021, 155, 106792. [Google Scholar] [CrossRef]

- Belhoussaine, O.; El Kourchi, C.; Harhar, H.; El Moudden, H.; El Yadini, A.; Ullah, R.; Iqbal, Z.; Goh, K.W.; Goh, B.H.; Bouyahya, A.; et al. Phytochemical characterization and nutritional value of vegetable oils from ripe berries of Schinus terebinthifolia raddi and Schinus molle L., through extraction methods. Food Chem. X 2024, 23, 101580. [Google Scholar] [CrossRef]

- Gokarn, N.; Kiran, K.N. Role of Lubricants in Industry: A Review. J. ISAS 2023, 2, 69–83. [Google Scholar] [CrossRef]

- Jeevan, T.P.; Jayaram, S.R. Performance evaluation of jatropha and pongamia oil based environmentally friendly cutting fluids for turning AA 6061. Adv. Tribol. 2018, 2018, 2425619. [Google Scholar] [CrossRef]

- Amiril, S.A.S.; Rahim, E.A.; Syahrullail, S. A review on ionic liquids as sustainable lubricants in manufacturing and engineering: Recent research, performance, and applications. J. Clean. Prod. 2017, 168, 1571–1589. [Google Scholar] [CrossRef]

- Soodoo, N.; Bouzidi, L.; Narine, S.S. Fundamental Structure–Function Relationships in Vegetable Oil-Based Lubricants: A Critical Review. Lubricants 2023, 11, 284. [Google Scholar] [CrossRef]

- Minami, I. Molecular science of lubricant additives. Appl. Sci. 2017, 7, 445. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Zhang, S. The economic and environmental significance of sustainable lubricants. Lubricants 2021, 9, 21. [Google Scholar] [CrossRef]

- Bachchhav, B.; Bagchi, H. Effect of surface roughness on friction and lubrication regimes. Mater. Today Proc. 2020, 38, 169–173. [Google Scholar] [CrossRef]

- Alakhramsing, S.S.; de Rooij, M.B.; Schipper, D.J.; van Drogen, M. Elastohydrodynamic lubrication of coated finite line contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 1077–1092. [Google Scholar] [CrossRef]

- Wong, V.W.; Tung, S.C. Overview of automotive engine friction and reduction trends–Effects of surface, material, and lubricant-additive technologies. Friction 2016, 4, 1–28. [Google Scholar] [CrossRef]

- Abegunde, P.O.; Kazeem, R.A.; Akande, I.G.; Ikumapayi, O.M.; Adebayo, A.S.; Jen, T.C.; Akinlabi, S.A.; Akinlabi, E.T. Performance assessment of some selected vegetable oils as lubricants in turning of AISI 1045 steel using a taguchi-based grey relational analysis approach. Tribol. Mater. Surf. Interfaces 2023, 17, 187–202. [Google Scholar] [CrossRef]

- Jeevan, T.P.; Jayaram, S.R.; Afzal, A.; Ashrith, H.S.; Soudagar, M.E.M.; Mujtaba, M.A. Machinability of AA6061 aluminum alloy and AISI 304L stainless steel using nonedible vegetable oils applied as minimum quantity lubrication. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 159. [Google Scholar] [CrossRef]

- Liu, G.; Wang, J.; Zheng, J.; Ji, M.; Wang, X. An experimental study on ultrasonic vibration-assisted turning of aluminum alloy 6061 with vegetable oil-based Nanofluid minimum quantity lubrication. Lubricants 2023, 11, 470. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, P.; Gan, S.; Hu, X.; Wang, S. A novel approach for identifying gas cavitation in oil jet pumps for lubrication systems. J. Mech. Eng. 2019, 65, 113–122. [Google Scholar] [CrossRef]

- Alaba, E.S.; Kazeem, R.A.; Adebayo, A.S.; Petinrin, M.O.; Ikumapayi, O.M.; Jen, T.C.; Akinlabi, E.T. Evaluation of palm kernel oil as cutting lubricant in turning AISI 1039 steel using taguchi-grey relational analysis optimization technique. Adv. Ind. Manuf. Eng. 2023, 6, 100115. [Google Scholar] [CrossRef]

- Xu, X. Machine Tool 4.0 for the new era of manufacturing. Int. J. Adv. Manuf. Technol. 2017, 92, 1893–1900. [Google Scholar] [CrossRef]

- Liu, W.; Kong, C.; Niu, Q.; Jiang, J.; Zhou, X. A method of NC machine tools intelligent monitoring system in smart factories. Robot. Comput. Integr. Manuf. 2020, 61, 101842. [Google Scholar] [CrossRef]

- Abbasi, A.; Farooq, W.; Khan, S.U.; Riaz, I. Lubricated surface oblique stagnation point flow of second-grade fluid with heat and mass transfer phenomenon: Applications to hydraulic systems. Waves Random Complex Media 2023, 1–20. [Google Scholar] [CrossRef]

- Shukla, A.; Kotwani, A.; Unune, D.R. Performance comparison of dry, flood and vegetable oil based minimum quantity lubrication environments during CNC milling of Aluminium 6061. Mater. Today Proc. 2020, 21, 1483–1488. [Google Scholar] [CrossRef]

- Ponce, M.B.; Vazquez-Martinez, J.M.; Davim, J.P.; Gomez, J.S. Analysis of secondary adhesion wear mechanism on hard machining of titanium aerospace alloy. Materials 2019, 12, 2015. [Google Scholar] [CrossRef]

- Kechagias, J.; Petousis, M.; Vidakis, N.; Mastorakis, N. Plasma Arc Cutting Dimensional Accuracy Optimization employing the Parameter Design approach. ITM Web Conf. 2017, 9, 03004. [Google Scholar] [CrossRef]

- Mustafa, A.M.; Poulsen, T.G.; Xia, Y.; Sheng, K. Combinations of fungal and milling pretreatments for enhancing rice straw biogas production during solid-state anaerobic digestion. Bioresour. Technol. 2017, 224, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, Q.; Sun, P.; Zang, C.; Wang, L.; Ning, Z.; Li, M.; Wang, H. Research Status and Prospect of Laser Scribing Process and Equipment for Chemical Milling Parts in Aviation and Aerospace. Micromachines 2022, 13, 323. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, V.; Kadam, R.; Joshi, S.S. Removal of alpha case on titanium alloy surfaces using chemical milling. Mach. Sci. Technol. 2017, 21, 257–278. [Google Scholar] [CrossRef]

- Ranjan, R.; Bajpai, V. Graphene-based metal matrix nanocomposites: Recent development and challenges. J. Compos. Mater. 2021, 55, 2369–2413. [Google Scholar] [CrossRef]

- Wang, M.; Wang, T.; Cai, P.; Chen, X. Nanomaterials Discovery and Design through Machine Learning. Small Methods 2019, 3, 1900025. [Google Scholar] [CrossRef]

- Zhang, X.; Mao, B.; Mushongera, L.; Kundin, J.; Liao, Y. Laser powder bed fusion of titanium aluminides: An investigation on site-specific microstructure evolution mechanism. Mater. Des. 2021, 201, 109501. [Google Scholar] [CrossRef]

- Bernat, S.; Brink, A.; Lucas, M.; Espallargas, N. Tribological Behavior of Polymer Seal Materials in Water-Based Hydraulic Fluids. J. Tribol. 2018, 140, 061605. [Google Scholar] [CrossRef]

- Jamaluddin, N.A.; Talib, N.; Sani, A.S.A. Performance comparative of modified jatropha based nanofluids in orthogonal cutting process. Evergreen 2021, 8, 461–468. [Google Scholar] [CrossRef]

- Pinar, A.M.; Filiz, S.; Ünlü, B.S. A comparison of cooling methods in the pocket milling of AA5083-H36 alloy via Taguchi method. Int. J. Adv. Manuf. Technol. 2016, 83, 1431–1440. [Google Scholar] [CrossRef]

- Ojolo, S.J.; Ohunakin, O.S. Study of rake face action on cutting using palm-kernel oil as lubricant. J. Emerg. Trends Eng. Appl. Sci. 2011, 2, 30–35. [Google Scholar]

- Tan, V.W.G.; Chan, Y.J.; Arumugasamy, S.K.; Lim, J.W. Optimizing biogas production from palm oil mill effluent utilizing integrated machine learning and response surface methodology framework. J. Clean. Prod. 2023, 414, 137575. [Google Scholar] [CrossRef]

- Tarcisio, K.F.; Qianxi, H.; Jose, P.M.; Stephen, C.V. An analysis of different cutting strategies to improve tool life when machining Ti-5Al-5V-5Mo-3Cr alloy. J. Manuf. Process. 2023, 102, 50–66. [Google Scholar] [CrossRef]

- Abutu, J.; Oluleye, M.A.; Okechukwu, C.; Salawu, S.I.; Dame, B.; Unamba, K.U. Performance assessment of vegetable oil-based cutting fluid developed from palm kernel oil using multi-response optimisation technique. Niger. J. Technol. 2022, 41, 99–113. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Enobun, I.O.; Akande, I.G.; Jen, T.C.; Akinlabi, S.A.; Ikumapayi, O.M.; Akinlabi, E.T. Evaluation of palm kernel oil as lubricants in cylindrical turning of AISI 304 austenitic stainless steel using Taguchi-grey relational methodology. Mater. Res. Express 2023, 10, 126505. [Google Scholar] [CrossRef]

- Ojolo, S.; Amuda, M.; Ogunmola, O.; Ononiwu, C. Experimental determination of the effect of some straight biological oils on cutting force during cylindrical turning. Matéria 2008, 13, 650–663. [Google Scholar] [CrossRef]

- Mahadi, M.A.; Choudhury, I.A.; Azuddin, M.; Nukman, Y. Use of boric acid powder aided vegetable oil lubricant in turning AISI 431 steel. Procedia Eng. 2017, 184, 128–136. [Google Scholar] [CrossRef]

- Akeel, A.M.; Kumar, R.; Chandrasekhar, P.; Panda, A.; Sahoo, A.K. Hard to cut metal alloys machining: Aspects of cooling strategies, cutting tools and simulations. Mater. Today Proc. 2022, 62, 3208–3212. [Google Scholar] [CrossRef]

- ASTM D664-18e2; Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ISO 513:2012; Classification and Application of Hard Cutting Materials for Removal with Defined Cutting Edges–Designation of the Main Groups and Groups of Application. International Organization for Standardization: Geneva, Switzerland, 2012.

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Akinlabi, S.A.; Afolalu, S.A.; Akinlabi, E.T. Analysis of the Physicochemical Properties of Some Selected Non-Edible Vegetable Oil-Based Cutting Fluids Using the Design of Experiment (DOE) Approach. Lubricants 2022, 10, 16. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Adediran, A.A.; Aliyu, S.J.; Akinlabi, S.A.; Jen, T.C.; Akinlabi, E.T. Advances in the Application of Vegetable-Oil-Based Cutting Fluids to Sustainable Machining Operations—A Review. Lubricants 2022, 10, 69. [Google Scholar] [CrossRef]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Akinlabi, S.A.; Akinlabi, E.T. Evaluation of Mango Kernel Seed (Mangifera indica) Oil as Cutting Fluid in Turning of AISI 1525 Steel Using the Taguchi-Grey Relation Analysis Approach. Lubricants 2022, 10, 52. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Kazeem, R.A.; Popoola, L.T.; Laseinde, O.T.; Afolalu, S.A.; Nwala, N.C.; Akinlabi, S.A.; Akinlabi, E.T. Development and assessment of African star seed (Chrysophyllum albidum) oil-based cutting fluid in turning AA6061 using Taguchi grey relational approach. Int. J. Interact. Des. Manuf. 2024, 18, 6397–6412. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).