A New Sustainable Approach to Enhancing the Subtractive Process in the Additive–Subtractive Hybrid Manufacturing of AISI H13 Dry Machining

Abstract

1. Introduction

2. Experimental Procedures

2.1. Laser Powder Bed Fusion (LPBF) Samples

2.2. Machining Setup and Parameters

2.3. New Coating Process: Pre-Machining

3. Results and Discussion

3.1. Machining Results

3.1.1. Tool Wear Readings

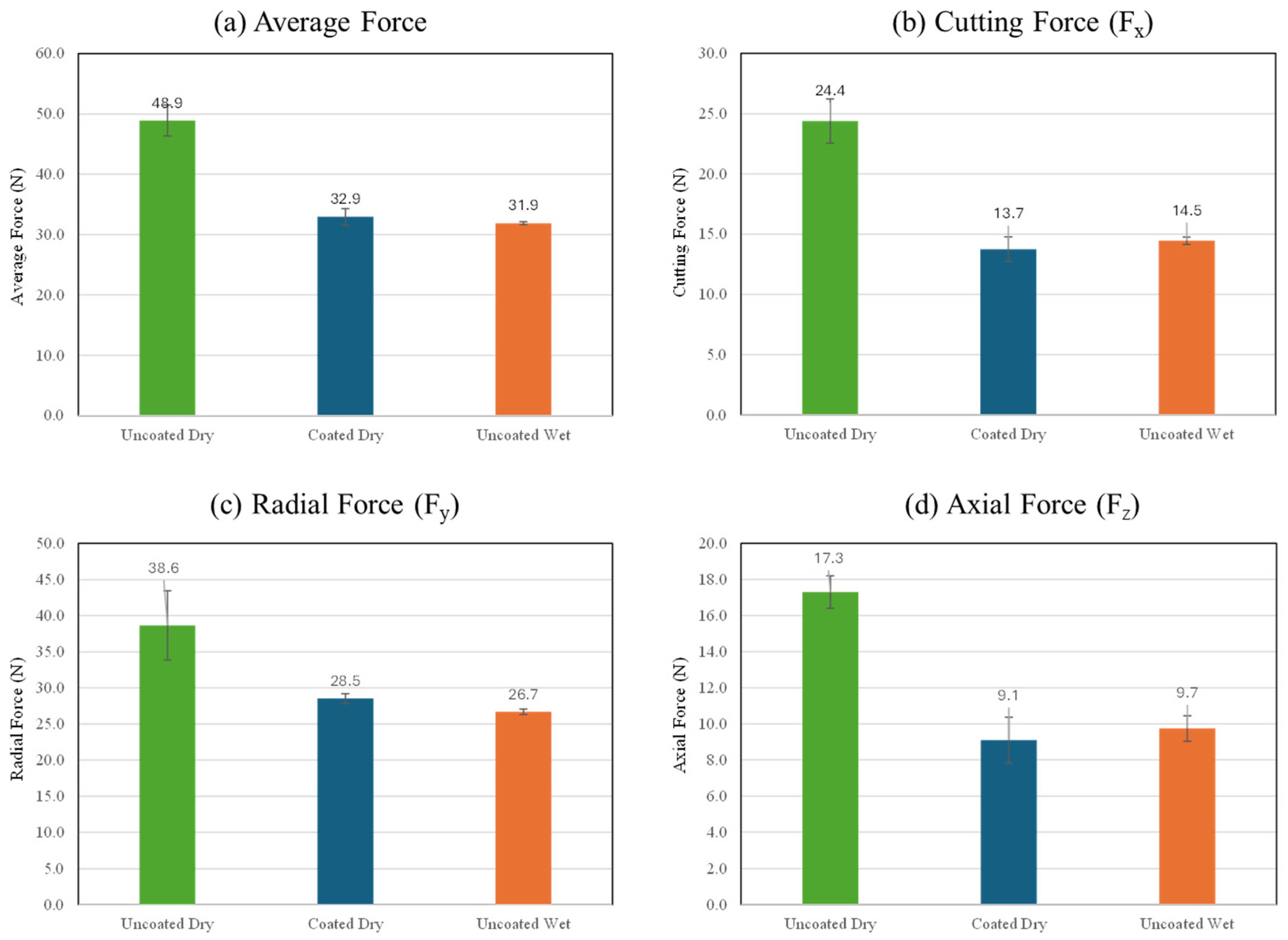

3.1.2. Force Analysis

3.2. Surface Integrity Analysis

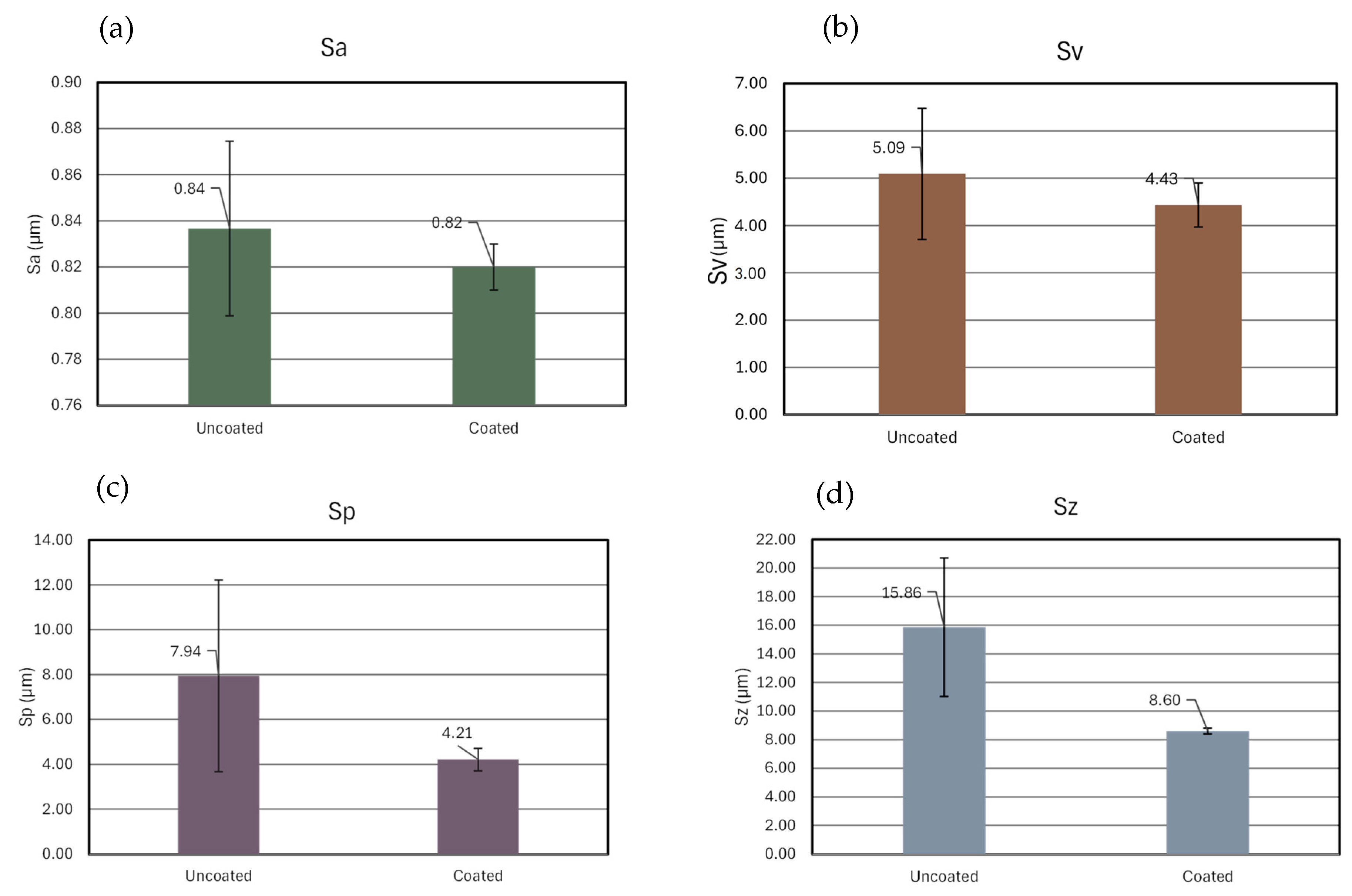

3.2.1. Surface Analysis

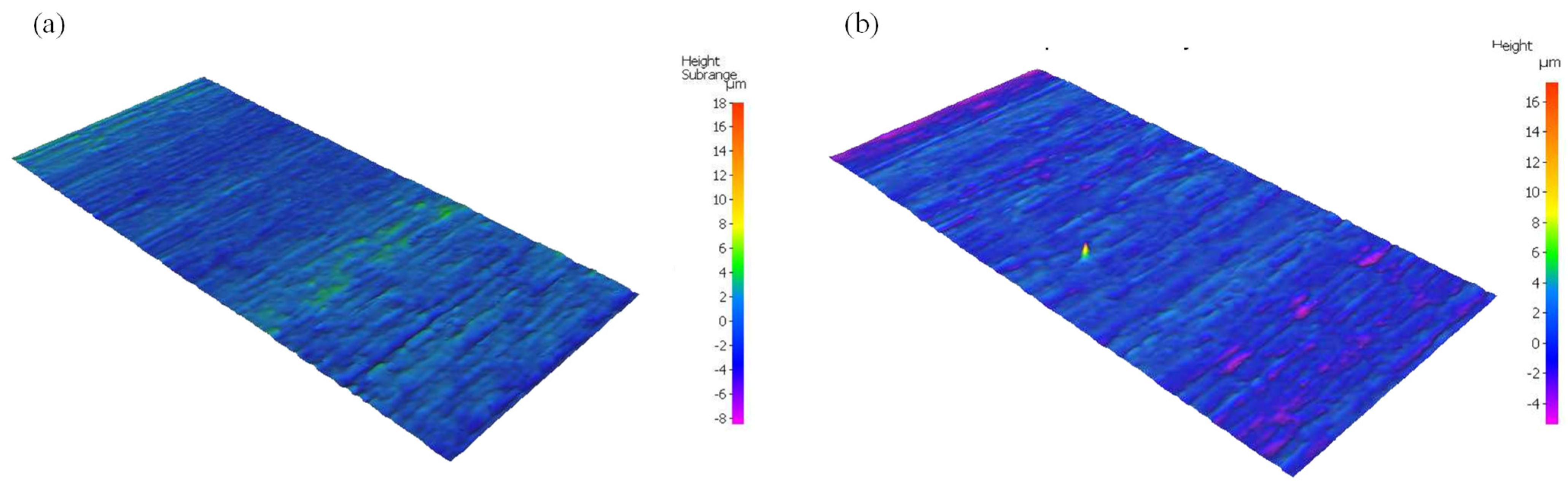

Surface Topography

Surface Roughness

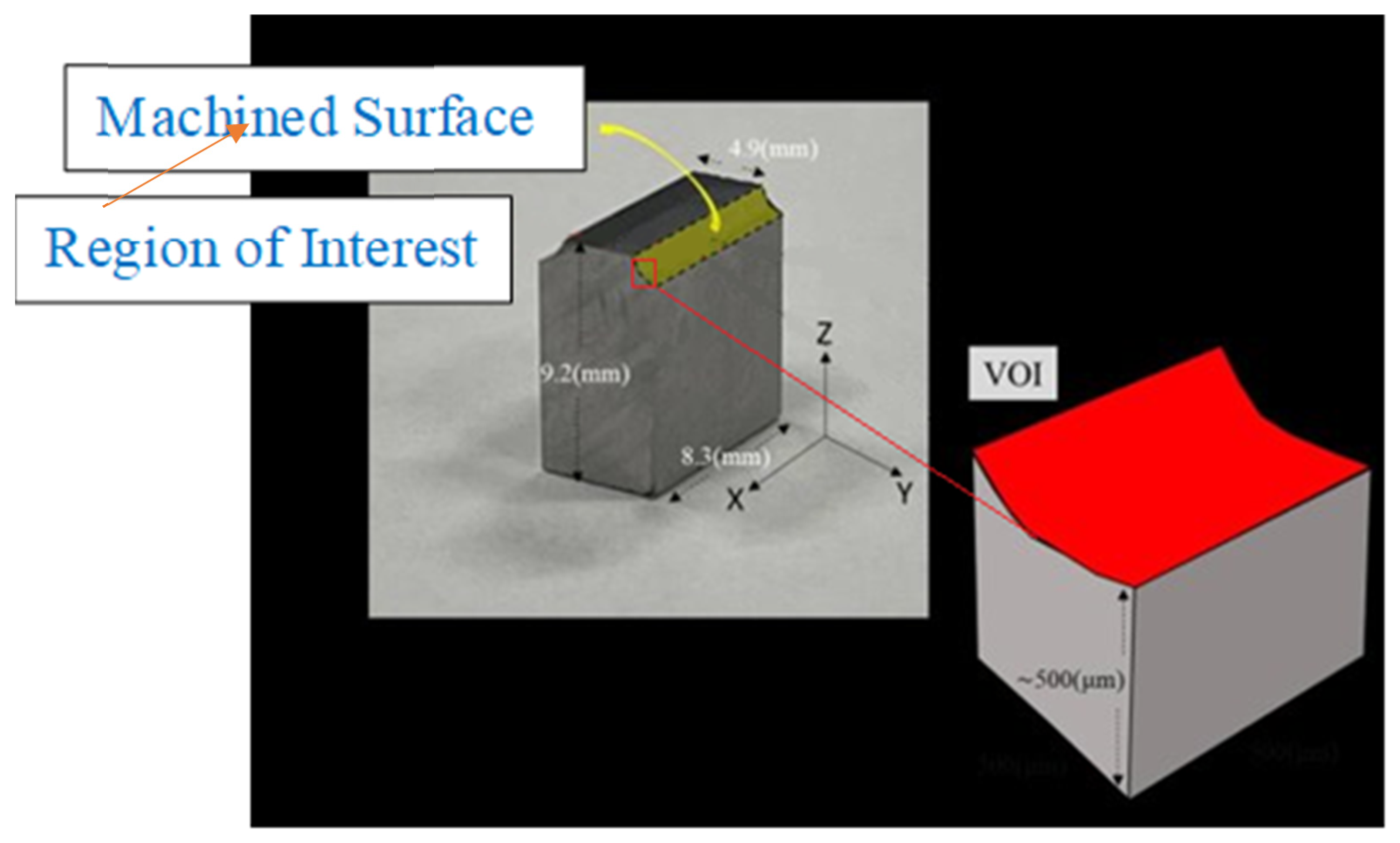

3.2.2. Subsurface Analysis

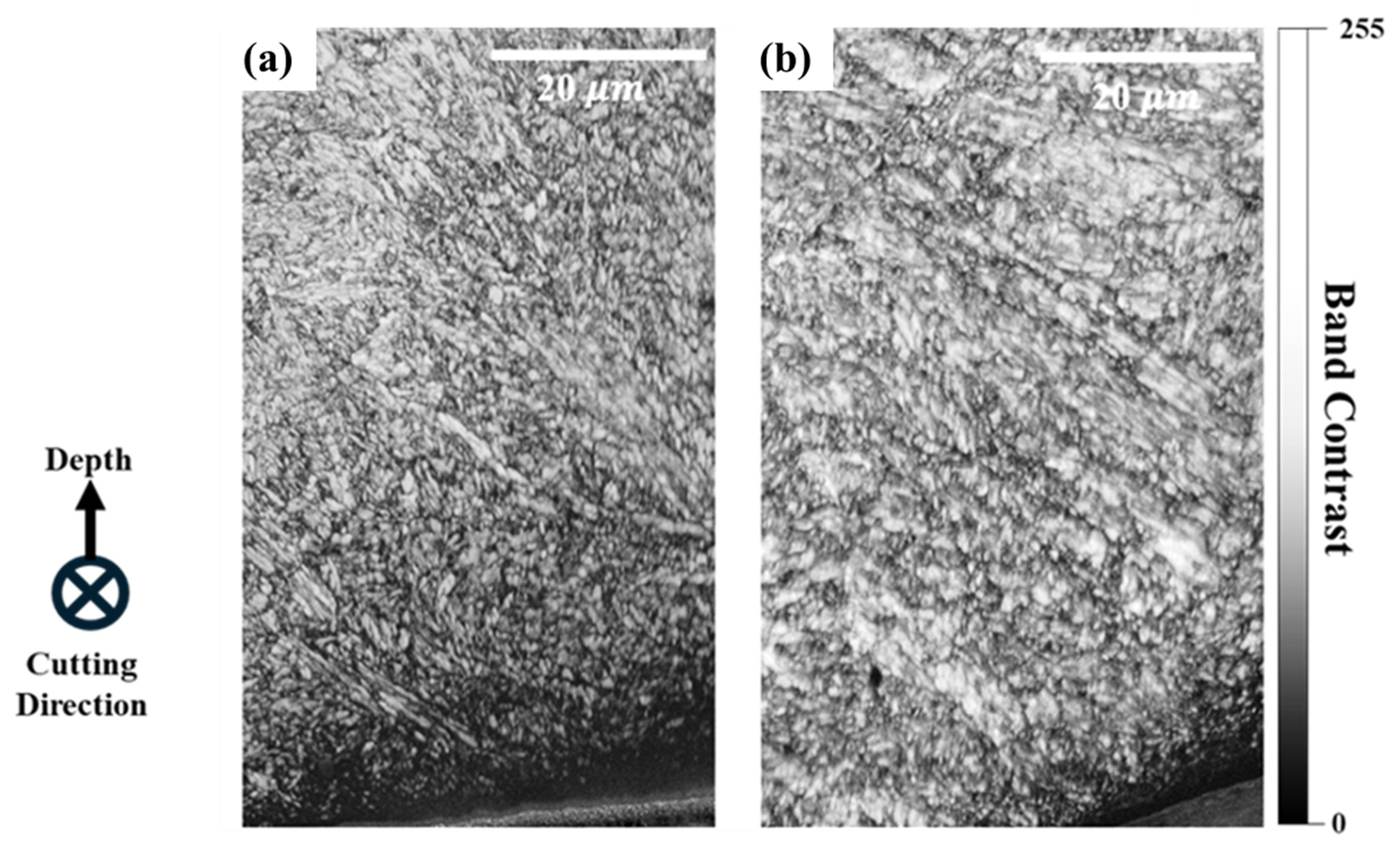

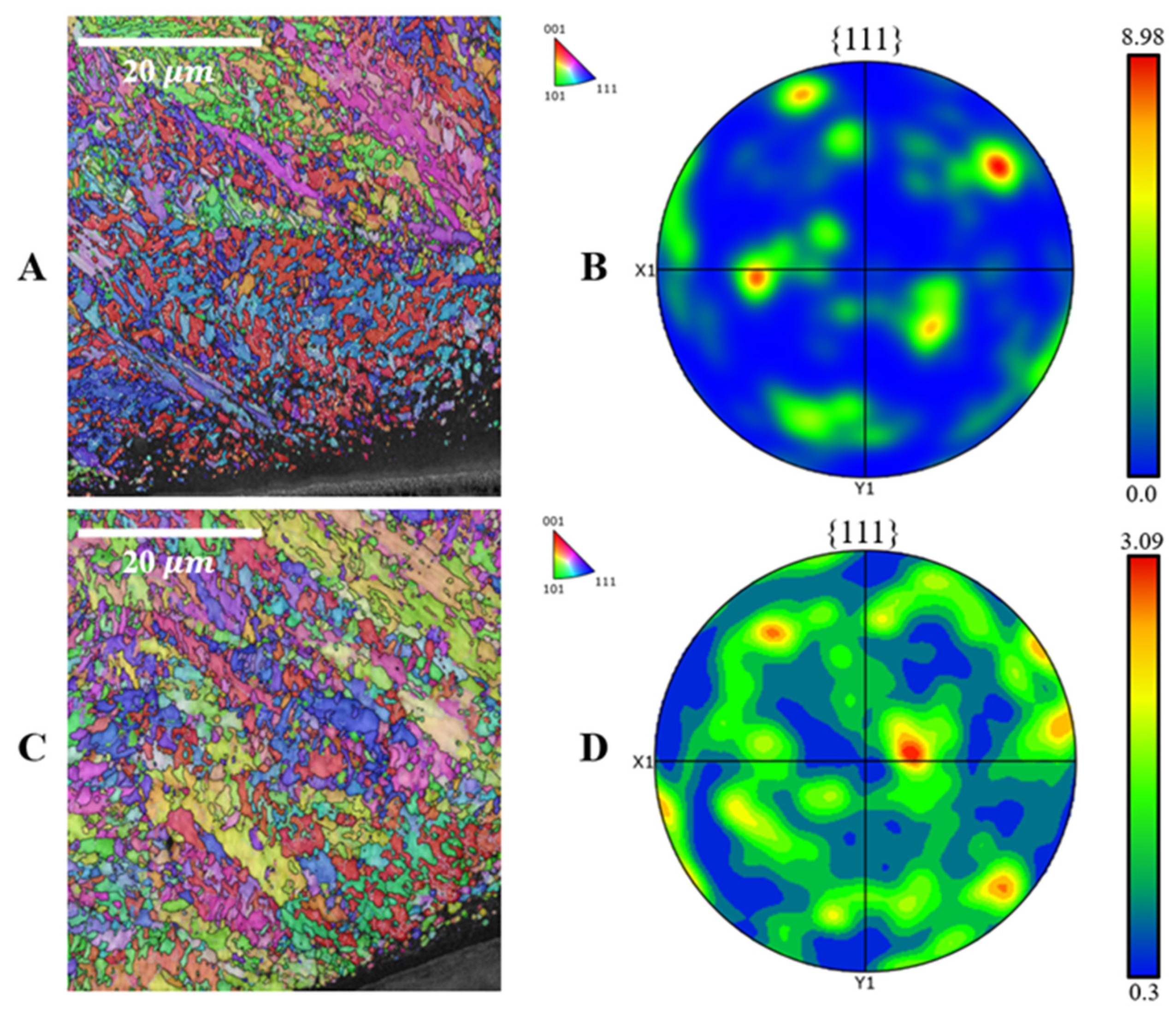

EBSD Analysis of Subsurfaces

XRD Analysis

4. Conclusions

- Tool wear analysis indicated a significant 50% decrease in tool wear resulting from the presence of the Al-Si lubricant coating in the cutting zone.

- Force analysis indicated a notable decrease of 65% in the average cutting force.

- SEM and advanced microscopy revealed improved surface characteristics after machining with the Al-Si-coated tool. The treated surface showed reduced groove formation and defect presence, indicating enhanced surface integrity in the final part.

- Extracted EBSD maps were used to examine subsurface integrity under coated and uncoated conditions. The results aligned with machining outcomes. The band contrast map showed higher dislocation density in the uncoated sample, indicating greater deformation near the surface due to increased machining forces.

- The KAM map also demonstrated increased localized strain in the subsurface of the uncoated sample. Interestingly, the affected zone associated with the uncoated tool was not limited to the machined surface but extended to the core.

- An analysis of IPF maps and pole figures showed a more random crystallographic texture at the subsurface in the coated sample, with a lower maximum intensity than that of the uncoated one. This suggests that higher machining forces lead to more pronounced textural changes.

- Phase maps and the XRD results were consistent with prior findings. The phase maps showed more austenite near the coated surface, indicating reduced transformation to martensite due to lower stresses. XRD confirmed this quantitatively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wohlers, T.; Gornet, T.; Mostow, N.; Campbell, I.; Diegel, O.; Kowen, J.; Huff, R.; Stucker, B.; Fidan, I.; Doukas, A.; et al. Wohlers Report 2022, History of Additive Manufacturing 2022; Wohlers Associates: Fort Collins, CO, USA, 2022. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Ian, G.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin, Germany, 2021; Volume 17. [Google Scholar]

- Zhang, X.; Liou, F. Introduction to additive manufacturing. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–31. [Google Scholar] [CrossRef]

- Khan, N.; Riccio, A. A systematic review of design for additive manufacturing of aerospace lattice structures: Current trends and future directions. Prog. Aerosp. Sci. 2024, 149, 101021. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Bayraktar, Ş.; Alparslan, C. Comparison of the SLM, SLS, and DLMS techniques in additive manufacture of AlSi10Mg alloys. In Innovation and Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2023; pp. 231–253. [Google Scholar] [CrossRef]

- Holesinger, T.G.; Carpenter, J.S.; Lienert, T.J.; Patterson, B.M.; Papin, P.A.; Swenson, H.; Cordes, N.L. Characterization of an Aluminum Alloy Hemispherical Shell Fabricated via Direct Metal Laser Melting. JOM 2016, 68, 1000–1011. [Google Scholar] [CrossRef]

- Felix, S.; Ray Majumder, S.; Mathews, H.K.; Lexa, M.; Lipsa, G.; Ping, X.; Roychowdhury, S.; Spears, T. In situ process quality monitoring and defect detection for direct metal laser melting. Sci. Rep. 2022, 12, 8503. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Gong, X.; Anderson, T.; Chou, K. Review on powder-based electron beam additive manufacturing technology. Manuf. Rev. 2013, 1, 2. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; Fuh, J.Y.H.; Wang, H. A Review of Post-Processing Technologies in Additive Manufacturing. J. Manuf. Mater. Process. 2021, 5, 38. [Google Scholar] [CrossRef]

- Akula, S.; Karunakaran, K.P. Hybrid adaptive layer manufacturing: An Intelligent art of direct metal rapid tooling process. Robot. Comput. Integr. Manuf. 2006, 22, 113–123. [Google Scholar] [CrossRef]

- Li, L.; Haghighi, A.; Yang, Y. Theoretical modelling and prediction of surface roughness for hybrid additive–subtractive manufacturing processes. IISE Trans. 2019, 51, 124–135. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, D.; Mazur, M.; Mo, J.P.T.; Li, G.; Ding, S. The State of the Art in Machining Additively Manufactured Titanium Alloy Ti-6Al-4V. Materials 2023, 16, 2583. [Google Scholar] [CrossRef] [PubMed]

- Cortina, M.; Arrizubieta, J.I.; Ruiz, J.E.; Ukar, E.; Lamikiz, A. Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations. Materials 2018, 11, 2583. [Google Scholar] [CrossRef]

- Hedayati, H.; Mofidi, A.; Al-Fadhli, A.; Aramesh, M. Solid Lubricants Used in Extreme Conditions Experienced in Machining: A Comprehensive Review of Recent Developments and Applications. Lubricants 2024, 12, 69. [Google Scholar] [CrossRef]

- Aramesh, M. Ultra Soft Cutting Tool Coatings and Coating Method. U.S. Patent 20210129230A1, 19 July 2019. [Google Scholar]

- Aramesh, M.; Montazeri, S.; Veldhuis, S.C. A novel treatment for cutting tools for reducing the chipping and improving tool life during machining of Inconel 718. Wear 2018, 414–415, 79–88. [Google Scholar] [CrossRef]

- Narvan, M. Laser Powder Bed Fusion of AISI H13 Tool Steel for Tooling Applications in Automotive Industry. McMaster University. 2021. Available online: http://hdl.handle.net/11375/26276 (accessed on 11 June 2021).

- Khosrowshahi, J.H.; Aramesh, M. Application of novel soft solid lubricant coatings on turning tools for sustainable and high-performance machining of INC 718 alloy: A new efficient fluid-free method. J. Manuf. Process. 2025, 143, 387–398. [Google Scholar] [CrossRef]

- Wang, Q.G. Microstructural effects on the tensile and fracture behavior of aluminum casting alloys A356/357. Metall. Mater. Trans. A 2003, 34, 2887–2899. [Google Scholar] [CrossRef]

- Javaheri, V.; Sadeghpour, S.; Karjalainen, P.; Lindroos, M.; Haiko, O.; Sarmadi, N.; Pallaspuro, S.; Valtonen, K.; Pahlevani, F.; Laukkanen, A.; et al. Formation of nanostructured surface layer, the white layer, through solid particles impingement during slurry erosion in a martensitic medium-carbon steel. Wear 2022, 496–497, 204301. [Google Scholar] [CrossRef]

- Wu, S.; Liu, G.; Zhang, W.; Chen, W.; Wang, C. Formation mechanism of white layer in the high-speed cutting of hardened steel under cryogenic liquid nitrogen cooling. J. Mater. Process. Technol. 2022, 302, 117469. [Google Scholar] [CrossRef]

- Liu, S.; Wang, X.; Liu, Z.; Wang, Y.; Chen, H.; Wang, P. Microstructure and micromechanical properties evolution pattern of metamorphic layer subjected to turning process of carbon steel. Appl. Surf. Sci. 2023, 608, 154679. [Google Scholar] [CrossRef]

- Padhan, S.; Das, S.R.; Das, A.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions. Materials 2022, 15, 2368. [Google Scholar] [CrossRef] [PubMed]

- Sharman, A.R.C.; Hughes, J.I.; Ridgway, K. An analysis of the residual stresses generated in Inconel 718TM when turning. J. Mater. Process. Technol. 2006, 173, 359–367. [Google Scholar] [CrossRef]

- Li, B.; Zhang, S.; Zhang, Q.; Chen, J.; Zhang, J. Modelling of phase transformations induced by thermo-mechanical loads considering stress-strain effects in hard milling of AISI H13 steel. Int. J. Mech. Sci. 2018, 149, 241–253. [Google Scholar] [CrossRef]

| Method | Advantages | Limitations | Ref. |

|---|---|---|---|

| SLS | Efficient for rapid tooling and prototyping with materials like polymers, metals, ceramics, and composites. Compatible with particle sizes ranging from 20 to 80 μm. Ideal for producing design test models, low-volume functional parts, and investment casting patterns. Applied in making sand casting molds, polymer molds, sheet metal parts, EDM electrodes, PZT parts, and zirconia molds. Delivers high precision with typical layer thicknesses between 50 and 200 μm. Produces support-free structures. Results in isotropic properties in final parts. Capable of fabricating complex geometries. | The process operates at a slower speed and is limited in the size of parts it can produce. It involves high energy consumption and significant upfront costs. Brittle or heat-resistant materials may crack, and surface finish can be rough. Loose powder can become trapped, so careful design (DfAM) is necessary to prevent this. Common issues include porosity, shrinkage, and unwanted impurities. Surface quality is often subpar without additional work. Final parts usually require post-processing to enhance appearance and finish. | [4,5,6,7] |

| SLM | Supports a wide range of materials and allows for the customization of part properties. Uses fine metallic powders, typically 15–40 microns in size. Ideal for producing parts close to the final shape with minimal finishing. Can work with many metals like titanium, copper, cobalt, chromium, stainless steel, tool steel, and high-performance alloys. Operates without the need for binding agents. Generally offers faster processing compared to SLS. Enables the efficient reuse of leftover powder. | Has a slower production speed and restrictions on part size. Demands high energy use and costly initial setup. Surface may be rough, with a risk of cracking in fragile or heat-resistant materials. Involves high overall manufacturing costs. Limited options for different material types. Requires support structures during the build process. Needs an inert gas environment to maintain process stability. | [4,5,6,7,8] |

| DMLS | Does not require support structures. Compatible with a wide range of metal alloys. Offers excellent powder reuse efficiency. | Expensive production process. Tendency to exhibit high levels of porosity in parts. Restricted maximum part size. | [7,9] |

| DMLM | Can produce nearly fully dense and geometrically accurate parts. Orientation changes in part geometry relative to the build direction can cause slight, position-dependent microstructural variations. Melt pool geometry and rapid solidification lead to a characteristic cellular structure aligned with thermal gradients. | Porosity throughout the part, especially along the inner surface of the part. Optical microscopy revealed microstructural orientation changes based on position within the part. A lack of sufficient quality control and assurance. | [10,11] |

| EBM | Allows for the fabrication of non-crystalline (amorphous) materials. Applies precise cooling control to prevent cracking in fragile materials during solidification. Produces high-quality material properties. Capable of handling reactive metals safely. Provides a quick and effective production method. | Optimization is challenging due to factors such as beam intensity and size. Only a narrow range of materials are compatible with the process. The machinery involves high capital investment. Printed parts often need further processing to reach final quality. There are limitations in available material options. | [6,7,12,13] |

| Element (wt.%) | Cr | Mo | Si | V | Mn | C | Fe |

|---|---|---|---|---|---|---|---|

| ASTM-A681 | 4.75–5.5 | 1.10–1.75 | 0.8–1.25 | 0.8–1.2 | 0.2–0.6 | 0.32–0.45 | Bal. |

| ICP-OES | 5.27 | 1.34 | 1.08 | 0.97 | 0.40 | 0.39 | Bal. |

| Parameter | Setting | Unit |

|---|---|---|

| Machine | Matsuura Fx-5 | |

| Machining condition | Milling—Dry | |

| Cutting speed | 300 | m/min |

| Tool type | Indexable shoulder milling | |

| Tool ID | R390-11 T3 02E-KM H13A | |

| Tool holder diameter | 19.05 | mm |

| No. of teeth | 1 | |

| Feed per tooth | 0.15 | mm/tooth |

| Cutting length | 30 | mm |

| Depth of cut | 1 | mm |

| Radial/depth of cut | 1 | mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hedayati, H.; Aramesh, M. A New Sustainable Approach to Enhancing the Subtractive Process in the Additive–Subtractive Hybrid Manufacturing of AISI H13 Dry Machining. Lubricants 2025, 13, 278. https://doi.org/10.3390/lubricants13070278

Hedayati H, Aramesh M. A New Sustainable Approach to Enhancing the Subtractive Process in the Additive–Subtractive Hybrid Manufacturing of AISI H13 Dry Machining. Lubricants. 2025; 13(7):278. https://doi.org/10.3390/lubricants13070278

Chicago/Turabian StyleHedayati, Hiva, and Maryam Aramesh. 2025. "A New Sustainable Approach to Enhancing the Subtractive Process in the Additive–Subtractive Hybrid Manufacturing of AISI H13 Dry Machining" Lubricants 13, no. 7: 278. https://doi.org/10.3390/lubricants13070278

APA StyleHedayati, H., & Aramesh, M. (2025). A New Sustainable Approach to Enhancing the Subtractive Process in the Additive–Subtractive Hybrid Manufacturing of AISI H13 Dry Machining. Lubricants, 13(7), 278. https://doi.org/10.3390/lubricants13070278