Programmable Control of Droplets on Phase-Change Lubricant-Infused Surfaces Under Low Voltage

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Materials

2.2. Preparation of Transparent Flexible Electrode (TFH)

2.3. Preparation of Porous PVDF-HFP Layer

2.4. Preparation of Phase-Change Materials (PCMs)

2.5. Preparation of Phase-Change Transparent Flexible Heater (PTFH)

2.6. Characterization

3. Results

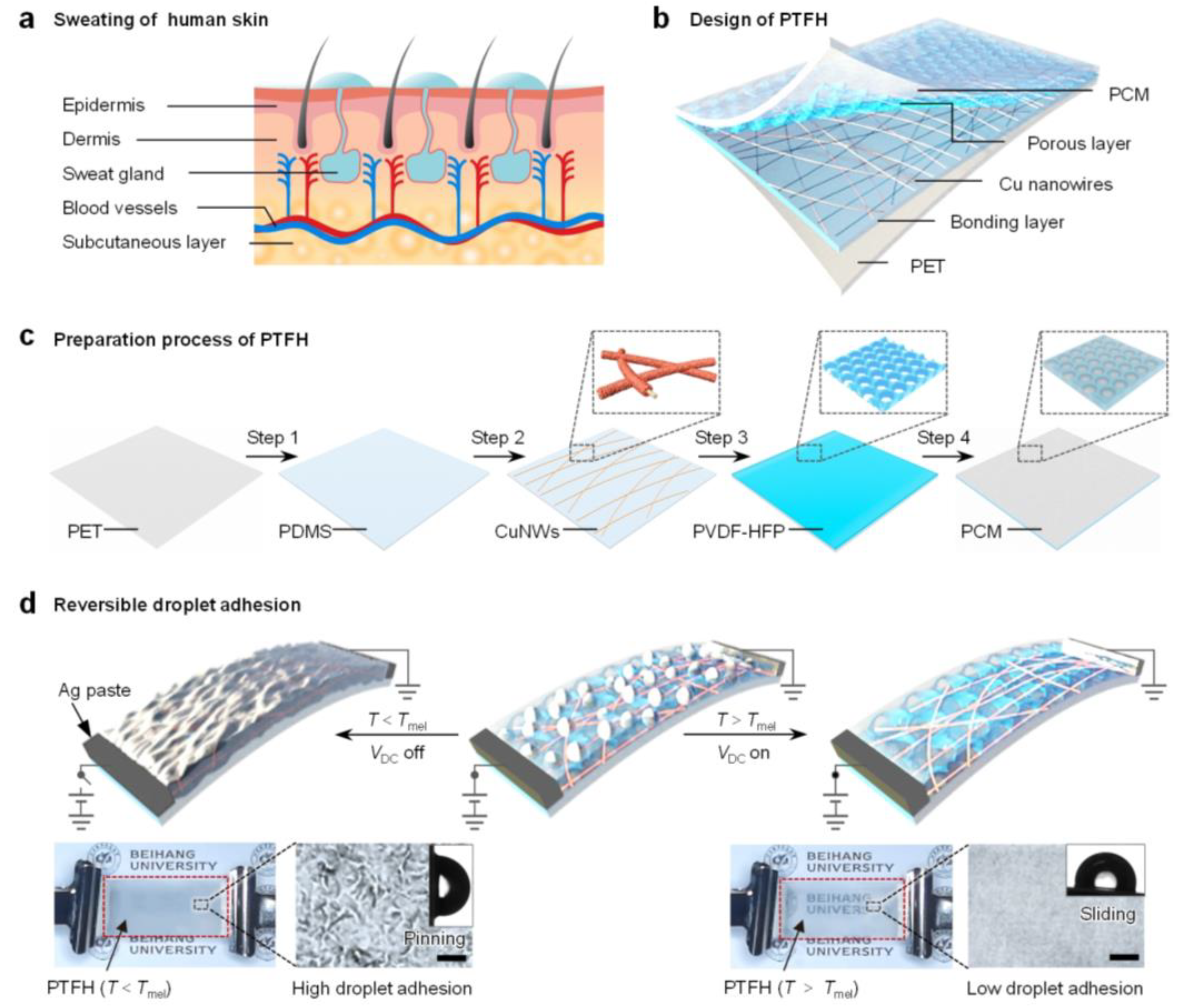

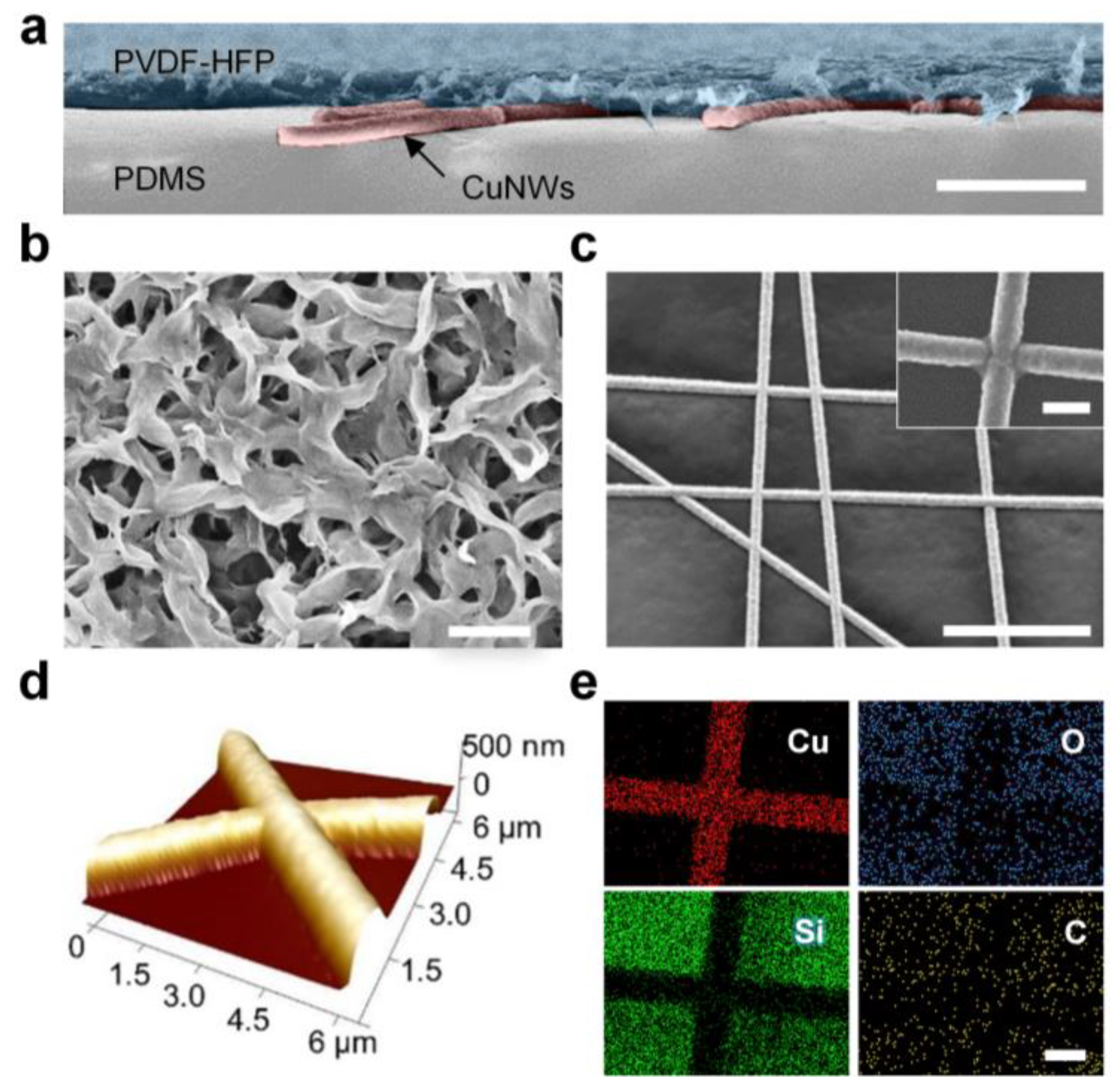

3.1. Structure and Chemical Characterization of PTFH

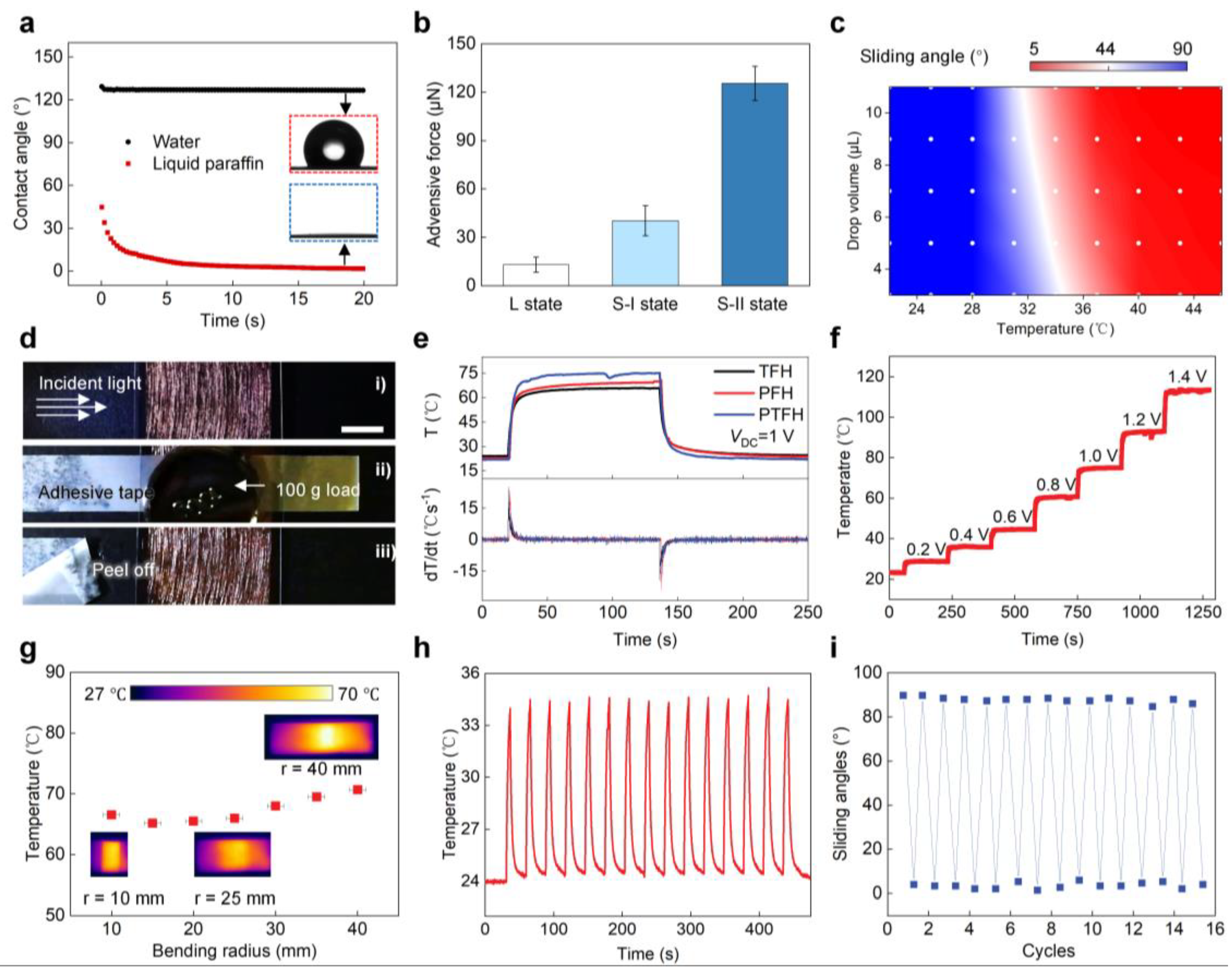

3.2. Wetting, Mechanical, and Joule Heating Characterization of PTFH

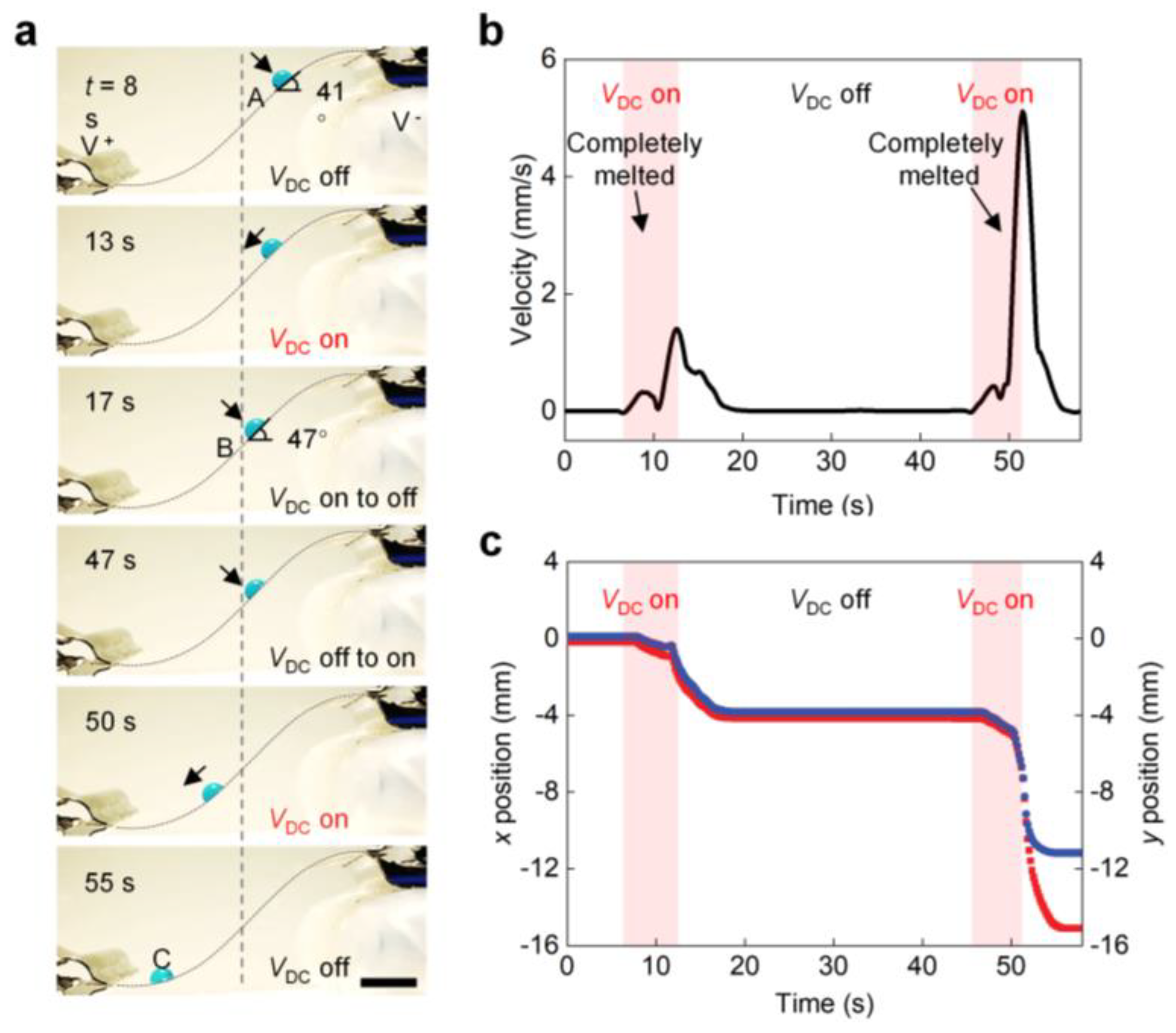

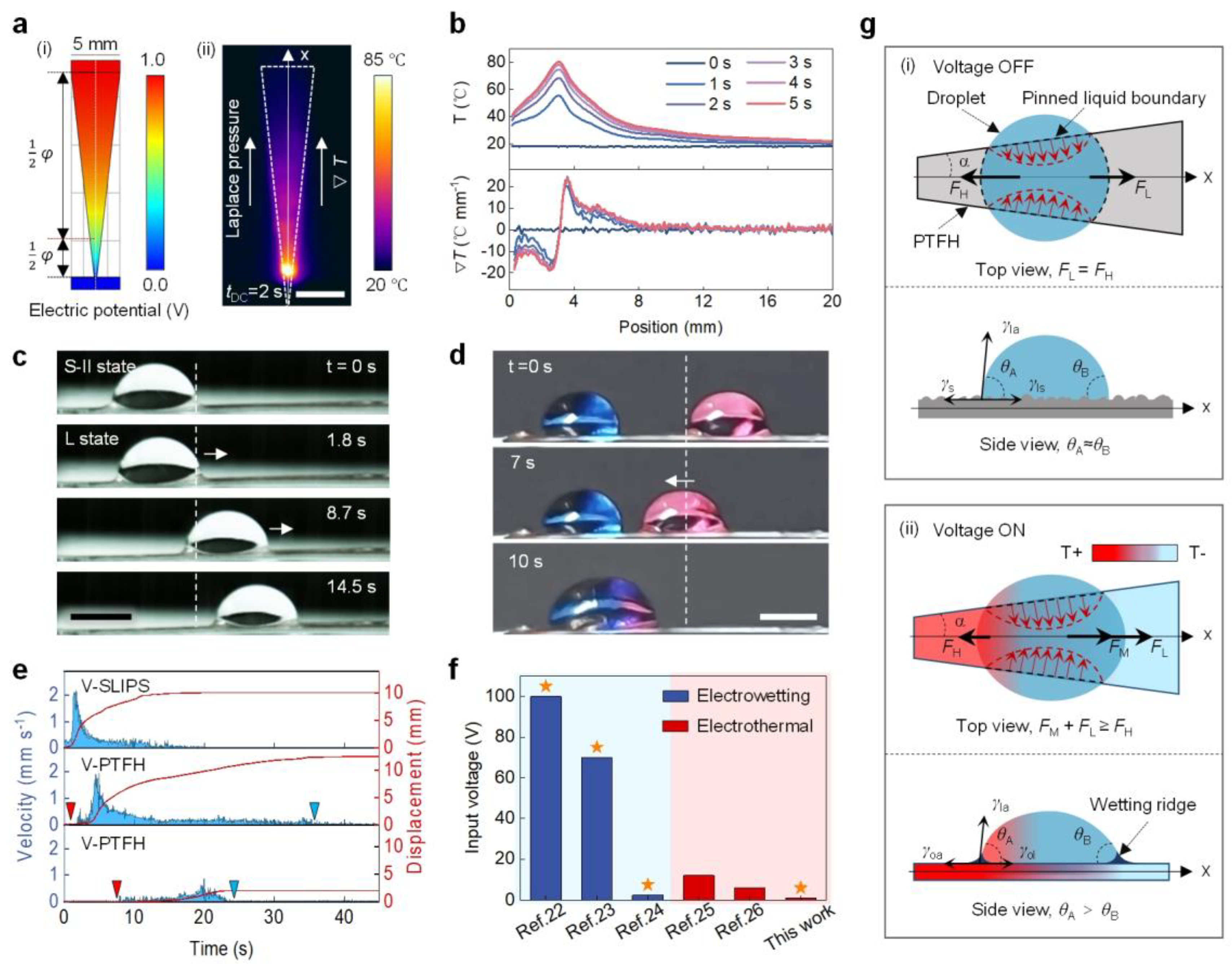

3.3. Programmable Sliding Control of Single Droplets on the PTFH Surface

3.4. Programmable Droplet Actuation on Bioinspired Gradient PTFH Surface

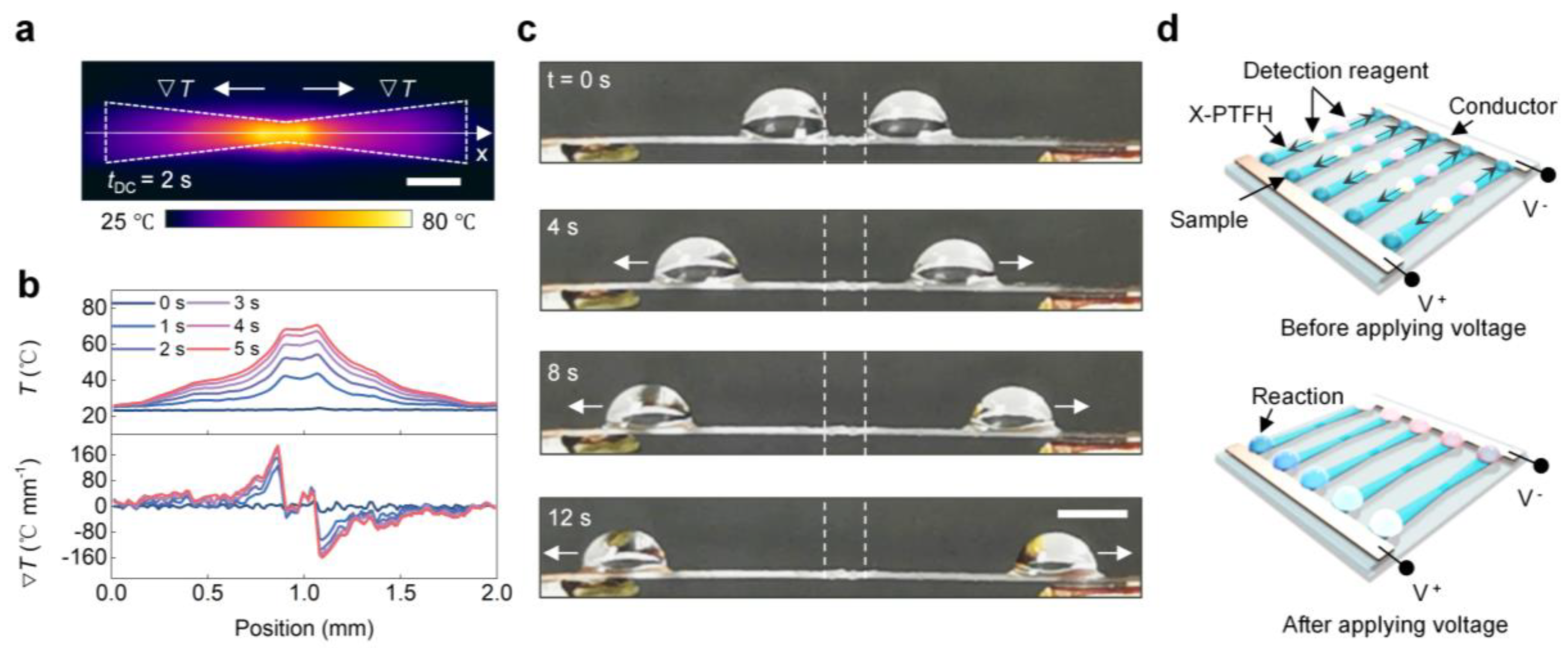

3.5. Programmable Control of Multi-Droplets on the Bioinspired PTFH Surface

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, M.; Wang, S.; Jiang, L. Nature-inspired superwettability systems. Nat. Rev. Mater. 2017, 2, 17036. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, C.; Li, X.; Guo, F.; Zhu, K. Fabrication of a composite groove array surface with gradient wettability which delivers enhanced lubrication performance. Lubricants 2025, 13, 193. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, Z. Robust anti-icing slippery liquid-infused porous surfaces inspired by nature: A review. Mater. Today. Phys. 2024, 46, 101478. [Google Scholar] [CrossRef]

- Xu, W.; Zheng, H.; Liu, Y.; Zhou, X.; Wang, Z. A droplet-based electricity generator with high instantaneous power density. Nature 2020, 578, 392–396. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Shkolyar, E.; Wang, J.; Conti, S.; Pao, A.C.; Liao, J.C.; Wong, T.-S.; Wong, P.K. SLIPS-LAB-A bioinspired bioanalysis system for metabolic evaluation of urinary stone disease. Sci. Adv. 2020, 6, eaba8535. [Google Scholar] [CrossRef]

- Wang, X.; Zhuang, Z.; Yao, L.X. Droplet manipulation on bioinspired slippery surfaces: From design principle to biomedical applications. Small Methods 2024, 8, 2300253. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Yi, G.; Teong, S.P.; Chan, S.P.; Zhang, Y. From waste plastic to artificial lotus leaf: Upcycling waste polypropylene to superhydrophobic spheres with hierarchical micro/nanostructure. Appl. Catal. B-Environ. Energy 2024, 342, 123378. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Han, Z.; Jiang, L. Continuous directional water transport on the peristome surface of Nepenthes alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef]

- Ju, J.; Bai, H.; Zheng, Y.; Zhao, T.; Fang, R.; Jiang, L. A multi-structural and multi-functional integrated fog collection system in cactus. Nat. Commun. 2012, 3, 1247. [Google Scholar] [CrossRef]

- Liu, X.; Gao, M.; Li, B.; Liu, R.; Chong, Z.; Gu, Z.; Zhou, K. Bioinspired capillary transistors. Adv. Mater. 2024, 36, 2310797. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, L.; Heng, L. Liquid adhesion regulation on bioinspired slippery surfaces: From theory to application. ACS Nano 2025, 19, 13549–13566. [Google Scholar] [CrossRef] [PubMed]

- Wong, T.-S.; Kang, S.H.; Tang, S.K.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443–447. [Google Scholar] [CrossRef]

- Ma, S.; Liu, L.; Zhao, W.; Li, R.; Zhao, X.; Zhang, Y.; Yu, B.; Liu, Y.; Zhou, F. Earthworm inspired lubricant self-pumping hydrogel with sustained lubricity at high loading. Nat. Commun. 2025, 16, 398. [Google Scholar] [CrossRef]

- Li, J.; Ueda, E.; Paulssen, D.; Levkin, P.A. Slippery lubricant–infused surfaces: Properties and emerging applications. Adv. Funct. Mater. 2019, 29, 1802317. [Google Scholar] [CrossRef]

- Lou, X.; Huang, Y.; Yang, X.; Zhu, H.; Heng, L.; Xia, F. External stimuli responsive liquid–infused surfaces switching between slippery and nonslippery states: Fabrications and applications. Adv. Funct. Mater. 2020, 30, 1901130. [Google Scholar] [CrossRef]

- Tian, L.; Dou, H.; Shao, Y.; Yi, Y.; Fu, X.; Zhao, J.; Fan, Y.; Ming, W.; Ren, L. Magnetically controlled super-wetting surface switching between ultra-low and ultra-high droplet adhesion. Chem. Eng. J. 2023, 456, 141093. [Google Scholar] [CrossRef]

- Wang, W.; Timonen, J.V.; Carlson, A.; Drotlef, D.-M.; Zhang, C.T.; Kolle, S.; Grinthal, A.; Wong, T.-S.; Hatton, B.; Kang, S.H. Multifunctional ferrofluid-infused surfaces with reconfigurable multiscale topography. Nature 2018, 559, 77–82. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Zhou, J.; Zhu, S.; Peng, Y.; Yong, J.; Wu, D. Thermo-induced biomimetic switchable slippery interfaces with strong dual-phase adhesion via femtosecond laser fabrication. Nano Lett. 2025, 25, 4252–4259. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Zhang, Y.; Shen, C.; Xin, Z.; Wei, Z. Bionic Fluorine-Free Multifunctional Photothermal Surface for Anti/de/Driving-Icing and Droplet Manipulation. Adv. Sci. 2024, 11, 2409631. [Google Scholar] [CrossRef]

- Sun, L.; Bian, F.; Wang, Y.; Wang, Y.; Zhang, X.; Zhao, Y. Bioinspired programmable wettability arrays for droplets manipulation. Proc. Natl. Acad. Sci. USA 2020, 117, 4527–4532. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Z.; Zhu, S.; Liu, B.; Li, J.; Hu, Y.; Wu, D.; Chu, J. In situ electric–induced switchable transparency and wettability on laser–ablated bioinspired paraffin–impregnated slippery surfaces. Adv. Sci. 2021, 8, 2100701. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Moon, H.; Fowler, J.; Schoellhammer, T.; Kim, C.-J.J.S. Electrowetting and electrowetting-on-dielectric for microscale liquid handling. Sens. Actuat. A-Phys. 2002, 95, 259–268. [Google Scholar] [CrossRef]

- Ko, H.; Lee, J.; Kim, Y.; Lee, B.; Jung, C.-H.; Choi, J.-H.; Kwon, O.-S.; Shin, K. Active digital microfluidic paper chips with inkjet-printed patterned electrodes. Adv. Mater. 2014, 26, 2335–2340. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ha, N.S.; Liu, T.L.; van Dam, R.M.; ‘CJ’Kim, C.-J. Ionic-surfactant-mediated electro-dewetting for digital microfluidics. Nature 2019, 572, 507–510. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Z.; Jiao, Y.; Shi, L.-A.; Zhang, Y.; Li, J.; Li, C.; Lv, X.; Wu, S.; Hu, Y. In situ reversible control between sliding and pinning for diverse liquids under ultra-low voltage. ACS Nano 2019, 13, 5742–5752. [Google Scholar] [CrossRef]

- Wang, J.; Gao, W.; Zhang, H.; Zou, M.; Chen, Y.; Zhao, Y. Programmable wettability on photocontrolled graphene film. Sci. Adv. 2018, 4, eaat7392. [Google Scholar] [CrossRef]

- Cunha, I.; Ferreira, S.H.; Martins, J.; Fortunato, E.; Gaspar, D.; Martins, R.; Pereira, L. Foldable and recyclable iontronic cellulose nanopaper for low--power paper electronics. Adv. Sustain. Sys. 2022, 6, 2200177. [Google Scholar] [CrossRef]

- Mishra, A.; Wallin, T.; Pan, W.; Xu, A.; Wang, K.; Giannelis, E.; Mazzolai, B.; Shepherd, R. Autonomic perspiration in 3D-printed hydrogel actuators. Sci. Robot. 2020, 5, eaat3918. [Google Scholar] [CrossRef]

- Adams, M.J.; Briscoe, B.J.; Johnson, S.A. Friction and lubrication of human skin. Tribol. Lett. 2007, 26, 239–253. [Google Scholar] [CrossRef]

- An, S.; Jo, H.S.; Kim, D.Y.; Lee, H.J.; Ju, B.K.; Al-Deyab, S.S.; Ahn, J.H.; Qin, Y.; Swihart, M.T.; Yarin, A.L.; et al. Self-junctioned copper nanofiber transparent flexible conducting film via electrospinning and electroplating. Adv. Mater. 2016, 28, 7149–7154. [Google Scholar] [CrossRef]

- Okada, I.; Shiratori, S. High-transparency, self-standable gel-SLIPS fabricated by a facile nanoscale phase separation. ACS Appl. Mater. Interfaces 2014, 6, 1502–1508. [Google Scholar] [CrossRef] [PubMed]

- Lorenceau, E.; Quéré, D. Drops on a conical wire. J. Fluid. Mech. 2004, 510, 29–45. [Google Scholar] [CrossRef]

- Bjelobrk, N.; Girard, H.-L.; Bengaluru Subramanyam, S.; Kwon, H.-M.; Quéré, D.; Varanasi, K.K. Thermocapillary motion on lubricant-impregnated surfaces. Phys. Rev. Fluids 2016, 1, 063902. [Google Scholar] [CrossRef]

- Brzoska, J.; Brochard-Wyart, F.; Rondelez, F.J.L. Motions of droplets on hydrophobic model surfaces induced by thermal gradients. Langmuir 1993, 9, 2220–2224. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, K.; Wang, W.; Shahzad, A.; Cheng, Y.; Cai, G. Permeation by electrowetting actuation: Revealing the prospect of a micro-valve based on ionic liquid. J. Colloid Interface Sci. 2022, 608, 114–119. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Gao, C.; Li, W. Programmable Control of Droplets on Phase-Change Lubricant-Infused Surfaces Under Low Voltage. Lubricants 2025, 13, 272. https://doi.org/10.3390/lubricants13060272

Sun L, Gao C, Li W. Programmable Control of Droplets on Phase-Change Lubricant-Infused Surfaces Under Low Voltage. Lubricants. 2025; 13(6):272. https://doi.org/10.3390/lubricants13060272

Chicago/Turabian StyleSun, Lingjie, Chunlei Gao, and Wei Li. 2025. "Programmable Control of Droplets on Phase-Change Lubricant-Infused Surfaces Under Low Voltage" Lubricants 13, no. 6: 272. https://doi.org/10.3390/lubricants13060272

APA StyleSun, L., Gao, C., & Li, W. (2025). Programmable Control of Droplets on Phase-Change Lubricant-Infused Surfaces Under Low Voltage. Lubricants, 13(6), 272. https://doi.org/10.3390/lubricants13060272