Tribological Evaluation and Model of Wear Behavior in the Boundary Lubrication of the Contact Surfaces of Cycloidal Reducers

Abstract

1. Introduction

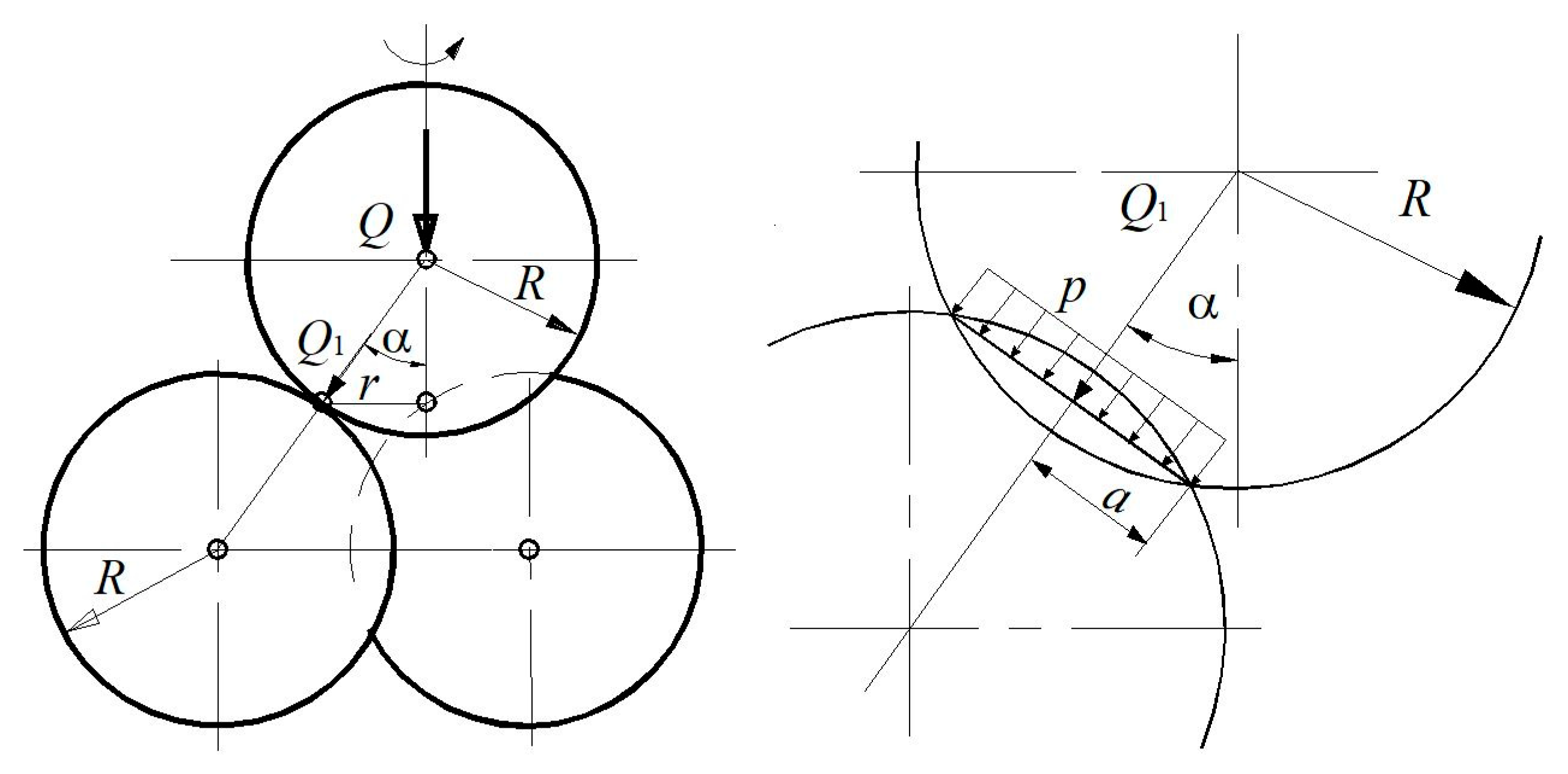

2. Model and Methods

2.1. Wear Model and Theoretical Methods

2.2. Tribological Tests and Surface Investigation

3. Results

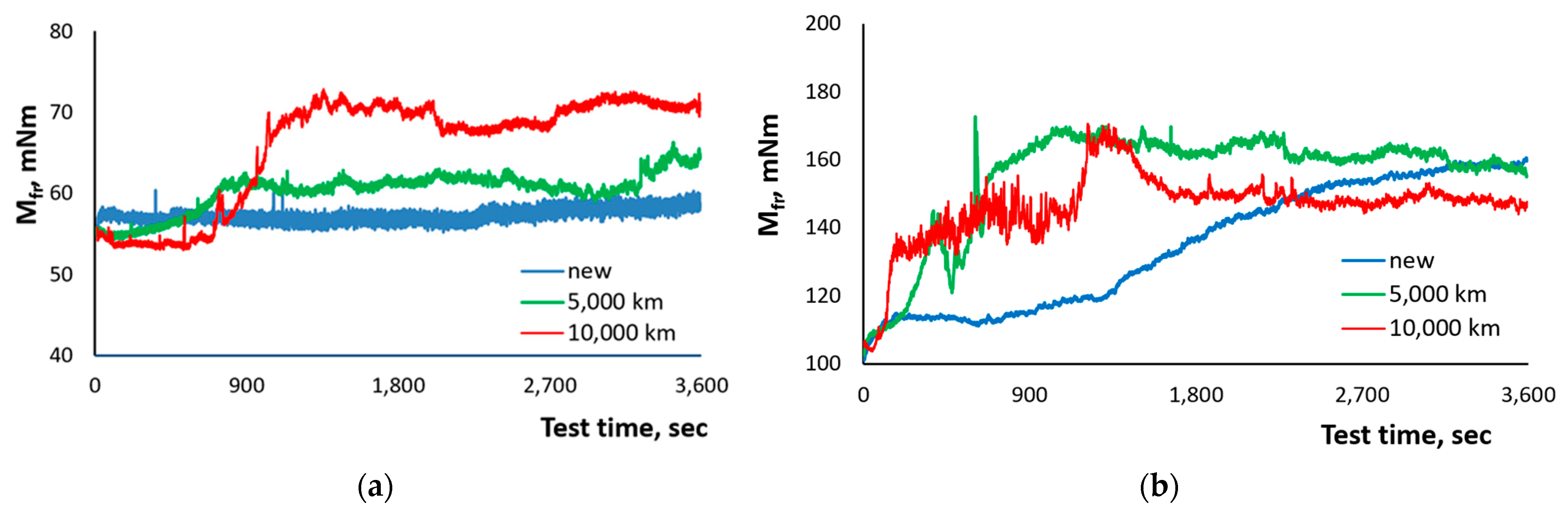

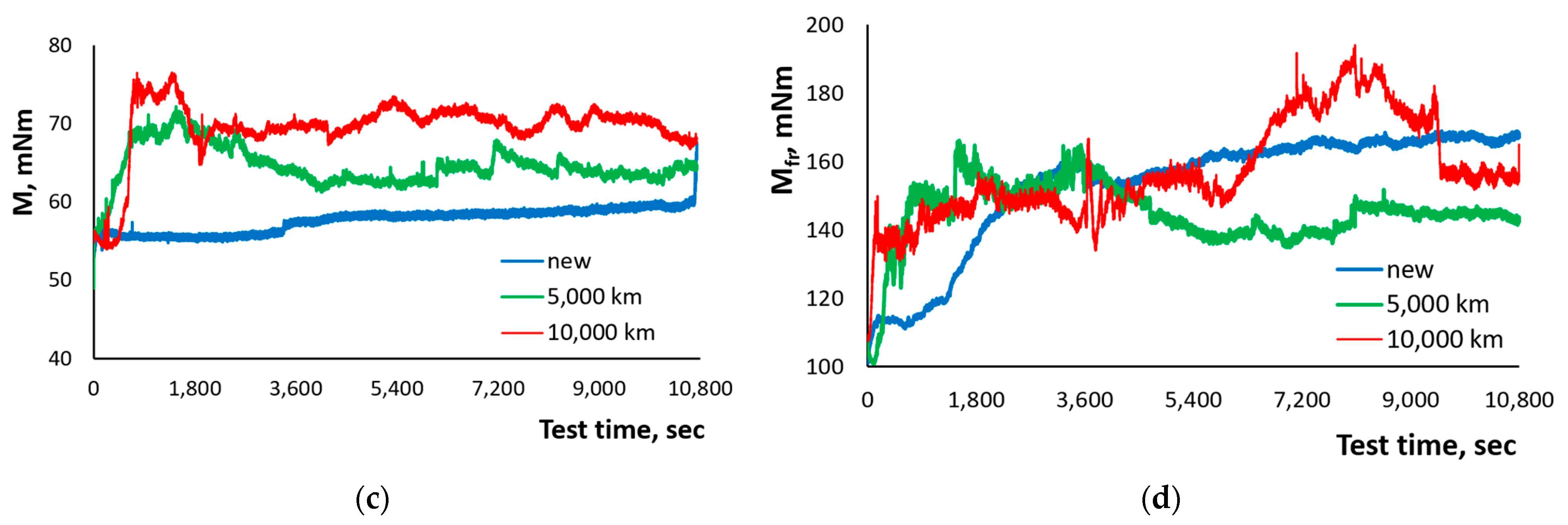

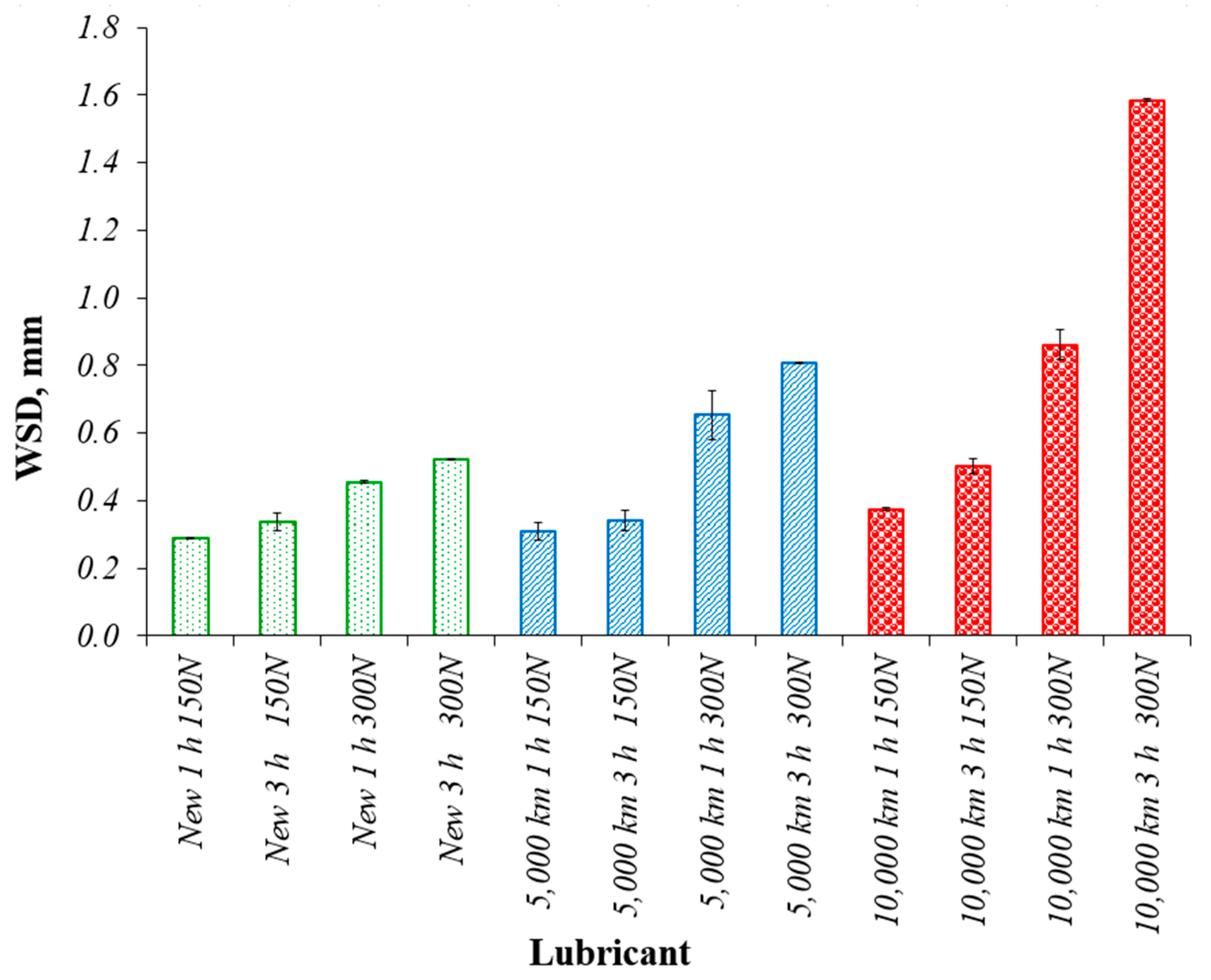

3.1. Tribological Testing Results

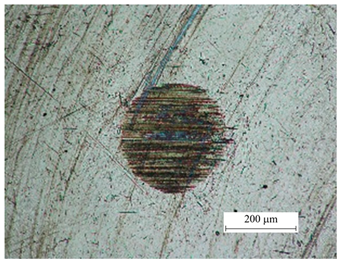

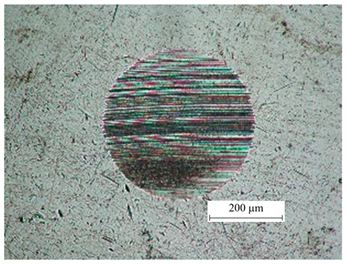

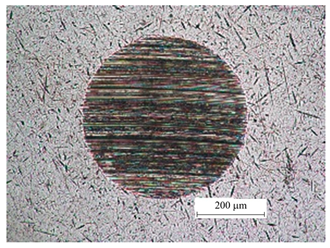

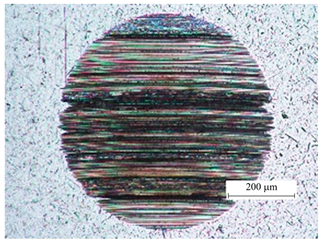

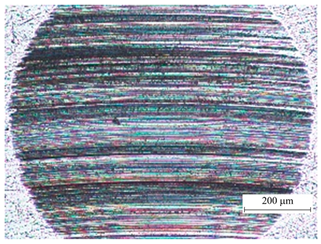

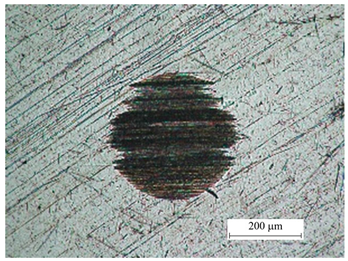

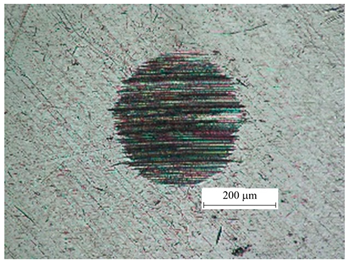

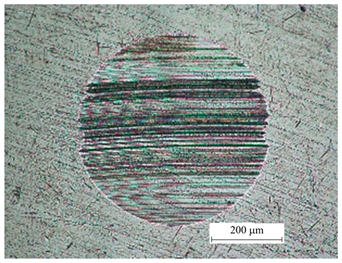

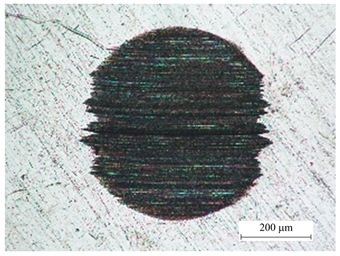

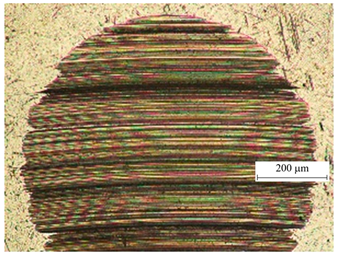

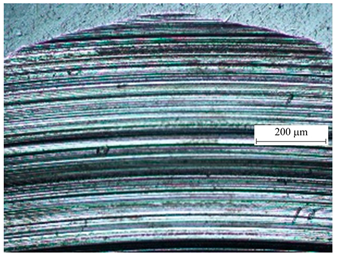

3.2. Friction Surface Investigation

3.3. Physical and Chemical Properties of the Oils

3.4. Identifying the Parameters of the Wear Model and Test Conformity

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Desai, P.S.; Granja, V.; Higgs, C.F., III. Lifetime Prediction Using a Tribology-Aware, Deep Learning-Based Digital Twin of Ball Bearing-Like Tribosystems in Oil and Gas. Processes 2021, 9, 922. [Google Scholar] [CrossRef]

- Andersson, J.; Almqvist, A.; Larsson, R. Numerical simulation of a wear experiment. Wear 2011, 271, 2947–2952. [Google Scholar] [CrossRef]

- Zhu, D.; Martini, A.; Wang, W.; Hu, Y.; Lisowsky, B.; Wang, Q.J. Simulation of Sliding Wear in Mixed Lubrication. J. Tribol. 2007, 129, 544–552. [Google Scholar] [CrossRef]

- Patel, R.; Khan, Z.A.; Saeed, A.; Bakolas, V. A Review of Mixed Lubrication Modelling and Simulation. Tribol. Ind. 2022, 44, 150–168. [Google Scholar] [CrossRef]

- Winkler, A.; Bartz, M.; Wartzack, S. Numerical Wear Modeling in the Mixed and Boundary Lubrication Regime. Lubricants 2022, 10, 334. [Google Scholar] [CrossRef]

- Jia, H.; Li, J.; Wang, J.; Xiao, K.; Han, Y. A lubricated wear model for determining wear surface geometry on journal-bearing surfaces. Surf. Topogr. Metrol. Prop. 2020, 8, 17. [Google Scholar] [CrossRef]

- Pei, X.; Pu, W.; Zhang, Y.; Huang, L. Surface topography and friction coefficient evolution during sliding wear in a mixed lubricated rolling-sliding contact. Tribol. Int. 2019, 137, 303–312. [Google Scholar] [CrossRef]

- Beheshti, A.; Khonsari, M.M. An engineering approach for the prediction of wear in mixed lubricated contacts. Wear 2013, 308, 121–131. [Google Scholar] [CrossRef]

- Li, X.; Yang, H.; Niu, W.; Guo, R.; Sun, L. Investigation on Tooth Surface Wear of Cycloid Drives Considering Tooth Profile Modifications. Lubricants 2023, 11, 323. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, B.; Wang, Z.; Yang, J.; Xu, J. Research on Loaded Contact Analysis and Tooth Wear Calculation Method of Cycloid–Pin Gear Reducer. Lubricants 2023, 11, 445. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, H.; Fu, X.; Fan, Z.; Ma, Q. Study on the influence of tooth surface wear on the lubrication performance of double involute gear transmission. Sci. Rep. 2025, 15, 7612. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Guo, Q.; Xu, B.; Gou, X. Tooth surface contact temperature of spur-face gear drive in point contact considering heat flow distribution. Int. J. Heat Fluid Flow 2025, 112, 109759. [Google Scholar] [CrossRef]

- Jia, C.; Zhang, G.; Li, G. Numerical Analysis of Tooth Contact and Wear Characteristics of Internal Cylindrical Gears with Curved Meshing Line. Appl. Sci. 2024, 14, 5399. [Google Scholar] [CrossRef]

- Gong, J.; Yan, H.; Meng, F.; Jing, X. Thermal-elastohydrodynamic lubrication study of axial-modified greased cycloid drive in rotate vector reducer. Tribol. Int. 2023, 185, 4–17. [Google Scholar] [CrossRef]

- Vasić, M.; Blagojević, M.; Dragoi, M.V. Thermal stability of lubricants in cycloidal reducers. Eng. Today 2022, 1, 7–17. [Google Scholar] [CrossRef]

- Vasić, M.; Blagojević, M.; Banić, M.; Maccioni, L.; Concli, F. Theoretical and experimental investigation of the thermal stability of a cycloid speed reducer. Lubricants 2025, 13, 70. [Google Scholar] [CrossRef]

- Concli, F.; Maccioni, L.; Gorla, C. Lubrication of gearboxes: CFD analysis of a cycloidal gear set. WIT Trans. Eng. Sci. 2019, 123, 101–112. [Google Scholar]

- Mačkić, T.; Blagojevic, M.; Babić, Ž.; Jotić, G.; Škundrić, J. An analysis of lubrication regime between the contact elements of cycloid reducer. In Proceedings of the 11th International Conference on Accomplishments in Electrical and Mechanical Engineering and Information Technology DEMI 2013, Banja Luka, Bosnia and Herzegovina, 30 May–1 June 2013; pp. 77–82. [Google Scholar]

- Shi, J.-F.; Gou, X.-F.; Zhu, L.-Y. Five-state engaging model and dynamics of gear-rotor-bearing system based on time-varying contact analysis considering gear temperature and lubrication. Appl. Math. Model. 2022, 112, 47–77. [Google Scholar] [CrossRef]

- Liu, C.; Tang, M.; Yang, X.; Ying, J. Influence of Tooth Surface Wear on Dynamic Characteristics of Gear Systems Considering Three-Dimensional Tooth Surface Geometric Errors. Shock. Vib. 2025, 2539671, 18. [Google Scholar] [CrossRef]

- Bosman, R.; Schipper, D.J. Mild Wear Prediction of Boundary-Lubricated Contacts. Tribol. Lett. 2011, 42, 169–178. [Google Scholar] [CrossRef]

- Pei, X.; Pu, W.; Yang, J.; Zhang, Y. Wear law in mixed lubrication based on stress-promoted thermal activation. Friction 2021, 9, 710–722. [Google Scholar] [CrossRef]

- Qin, W.; Zhang, Y.; Li, C. Determination of wear coefficient in mixed lubrication using FEM. Appl. Math. Model. 2018, 59, 629–639. [Google Scholar] [CrossRef]

- Ghanbarzadeh, A.; Wilson, M.; Morina, A.; Dowson, D.; Neville, A. Development of a new mechano-chemical model in boundary lubrication. Tribol. Int. 2016, 93, 573–582. [Google Scholar] [CrossRef]

- Bosman, R.; Schipper, D.J. On the transition from mild to severe wear of lubricated, concentrated contacts: The IRG (OECD) transition diagram. Wear 2010, 269, 581–589. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiža, R.; Prosyčevas, I.; Kreivaitis, R. Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar] [CrossRef]

- Liehpao, O.F. Ashless Antiwear and Extreme-Pressure Additives. In Lubricant Additives: Chemistry and Applications, 2nd ed.; Leslie, R., Rudnick, L.R., Eds.; CRC Press: Boca Raton, FL, USA, 2009; Chapter 8; pp. 214–249. [Google Scholar]

- Farng, L.O.; Deckman, D.E.; Givens, W.A. Ashless Anti-wear additives for Future Engine Oils. In Proceedings of the 14th International Colloquium Tribology, Stuttgart, Germany, 13–15 January 2004. [Google Scholar]

- Farng, L.O.; Deckman, D.E. Novel Anti-Wear Additives for Future Lubricants, Additives 2007. In Proceedings of the Conference Applications for Future Transport, London, UK, 17–19 April 2007. [Google Scholar]

- Zhang, J.; Yamaguchi, E.; Spikes, H. Comparison of Three Laboratory Tests to Quantify Mild Wear Rate. Tribol. Trans. 2013, 56, 919–928. [Google Scholar] [CrossRef]

- Marko, M.D.; Kyle, J.P.; Wang, Y.S.; Terrell, E.J. Tribological investigations of the load, temperature, and time dependence of wear in sliding contact. PLoS ONE 2017, 12, e0175198. [Google Scholar] [CrossRef]

- Totten, G.E.; Westbrook, S.R.; Shah, R.J. Fuels and Lubricants Handbook: Technology, Properties, Performance, and Testing; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Mang, T.; Dresel, W. Lubricants and Lubrication; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2007. [Google Scholar]

- DIN 51350-3; Testing of Lubricants—Testing in the Four-Ball Tester—Part 3: Determination of Wearing Characteristics of Liquid Lubricants. Deutsches Institut für Normung e.V.: Berlin, Germany, 1977. (In Germany)

- Dykha, A.; Sorokatyi, R.; Makovkin, O.; Babak, O. Calculation-experimental modeling of wear of cylindrical sliding bearings. East. Eur. J. Enterp. Technol. 2017, 5, 51–59. [Google Scholar] [CrossRef][Green Version]

- Dykha, A.V.; Marchenko, D.D.; Dytynyuk, V.A. Determination of the Parameters of the Wear Law Based on the Results of Laboratory Tests. J. Frict. Wear 2020, 41, 153–159. [Google Scholar] [CrossRef]

- ASTM D445; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (the Calculation of Dynamic Viscosity). ASTM: West Conshohocken, PA, USA, 2024.

- ASTM D2270; Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C. ASTM: West Conshohocken, PA, USA, 2024.

- ASTM D664; Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. ASTM: West Conshohocken, PA, USA, 2024.

- Padgurskas, J.; Volskis, D.; Rukuiža, R.; Kupčinskas, A.; Basheleishvili, N.; Tučkutė, S. Limitary State of Heavy-Duty Engine Oils and Their Evaluation According to the Change of Tribological Properties during Operation. Lubricants 2023, 11, 236. [Google Scholar] [CrossRef]

- Fernandes, W.; Tomanik, E.; Moreira, H.; Cousseau, T.; Pintaude, G. Effect of Aged Oils on Ring-Liner Wear. SAE Int. J. Fuels Lubr. 2020, 13, 167–176. [Google Scholar] [CrossRef]

| New | 5000 km Run | 10,000 km Run | |

|---|---|---|---|

| 1 h run | |||

| 150 N loading |  |  |  |

| 300 N loading |  |  |  |

| 3 h run | |||

| 150 N loading |  |  |  |

| 300 N loading |  |  |  |

| Parameters | Test Methods | Tested Oil | ||

|---|---|---|---|---|

| New | 5000 km | 10,000 km | ||

| Kinematic viscosity, at 100 °C, cSt | ASTM D445 [37] | 13.62 | 13.36 | 7.84 |

| Kinematic viscosity, at 40 °C, cSt | ASTM D445 [37] | 92.11 | 89.76 | 43.76 |

| Viscosity index | ASTM D2270 [38] | 149.8 | 149.8 | 150.0 |

| Total acidity number (TAN), mg KOH/g | ASTM D664 [39] | 0.91 | 1.7 | 2.9 |

| Test Oil | Load, N | Test Duration, h | WSD/2 (a), mm | L, mm·106 |

|---|---|---|---|---|

| New oil Test 1 | 150 | 1.0 | 0.140 | 3.919 |

| 3.0 | 0.165 | 11.758 | ||

| 300 | 1.0 | 0.220 | 3.919 | |

| 3.0 | 0.260 | 11.758 | ||

| After 5000 km Test 2 | 150 | 1.0 | 0.150 | 3.919 |

| 3.0 | 0.170 | 11.758 | ||

| 300 | 1.0 | 0.320 | 3.919 | |

| 3.0 | 0.440 | 11.758 | ||

| After 10,000 km Test 3 | 150 | 1.0 | 0.190 | 3.919 |

| 180 | 0.335 | 11.758 | ||

| 300 | 60 | 0.425 | 3.919 | |

| 180 | 0.680 | 11.758 |

| Test Oil | Parameter | Load | |

|---|---|---|---|

| Q = 150 N | Q = 300 N | ||

| New oil | c | 0.0993 | 0.1570 |

| β | 0.222 | 0.220 | |

| After 5000 km | c | 0.1338 | 0.256 |

| β | 0.224 | 0.201 | |

| After 10,000 km | c | 0.1709 | 0.323 |

| β | 0.206 | 0.222 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padgurskas, J.; Dykha, O.; Rukuiža, R.; Volskis, D.; Mickevičienė, R.; Abramishvili, G.; Iosebidze, J. Tribological Evaluation and Model of Wear Behavior in the Boundary Lubrication of the Contact Surfaces of Cycloidal Reducers. Lubricants 2025, 13, 268. https://doi.org/10.3390/lubricants13060268

Padgurskas J, Dykha O, Rukuiža R, Volskis D, Mickevičienė R, Abramishvili G, Iosebidze J. Tribological Evaluation and Model of Wear Behavior in the Boundary Lubrication of the Contact Surfaces of Cycloidal Reducers. Lubricants. 2025; 13(6):268. https://doi.org/10.3390/lubricants13060268

Chicago/Turabian StylePadgurskas, Juozas, Oleksandr Dykha, Raimundas Rukuiža, Darius Volskis, Rima Mickevičienė, Giorgi Abramishvili, and Jumber Iosebidze. 2025. "Tribological Evaluation and Model of Wear Behavior in the Boundary Lubrication of the Contact Surfaces of Cycloidal Reducers" Lubricants 13, no. 6: 268. https://doi.org/10.3390/lubricants13060268

APA StylePadgurskas, J., Dykha, O., Rukuiža, R., Volskis, D., Mickevičienė, R., Abramishvili, G., & Iosebidze, J. (2025). Tribological Evaluation and Model of Wear Behavior in the Boundary Lubrication of the Contact Surfaces of Cycloidal Reducers. Lubricants, 13(6), 268. https://doi.org/10.3390/lubricants13060268