Nano-Enhanced Cactus Oil as an MQL Cutting Fluid: Physicochemical, Rheological, Tribological, and Machinability Insights into Machining H13 Steel

Abstract

1. Introduction

2. Materials and Methods

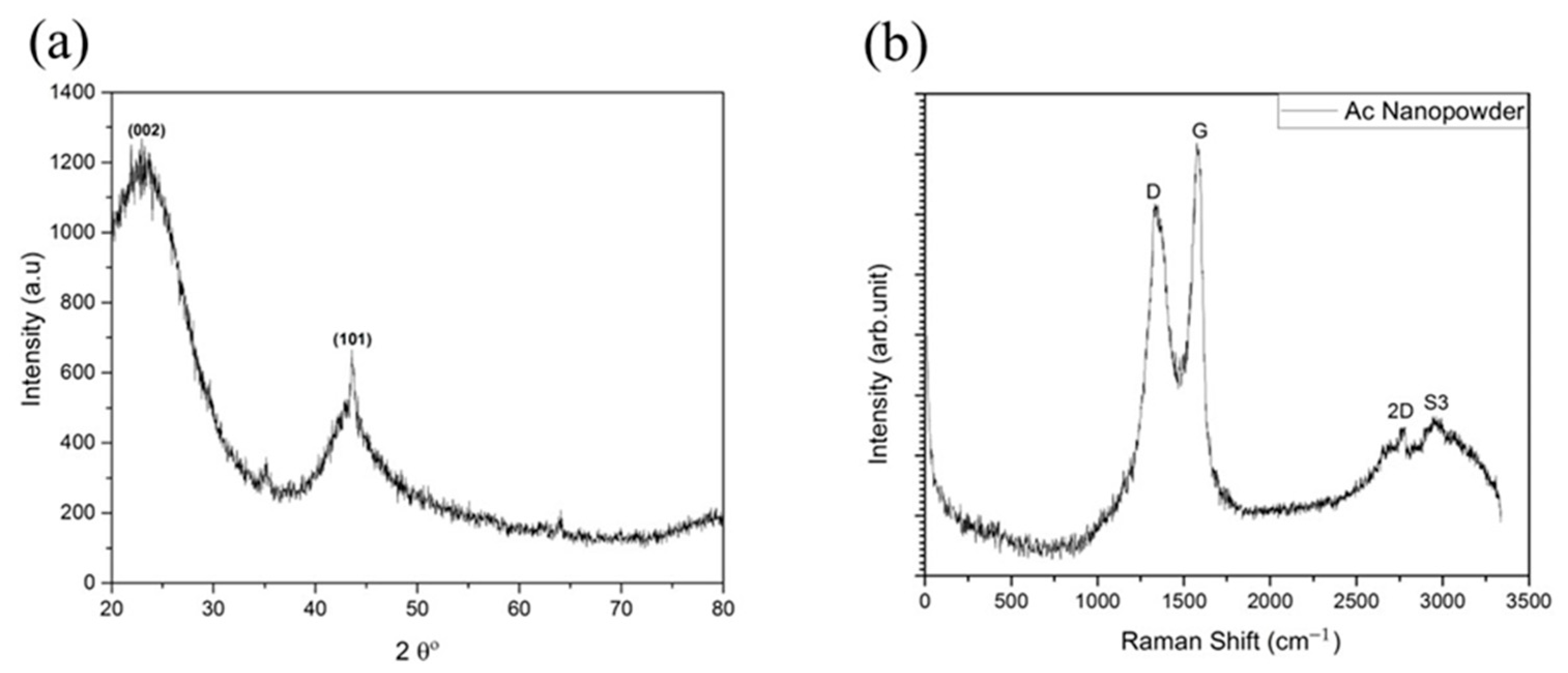

2.1. Nano-Additive Synthesis and Characterization

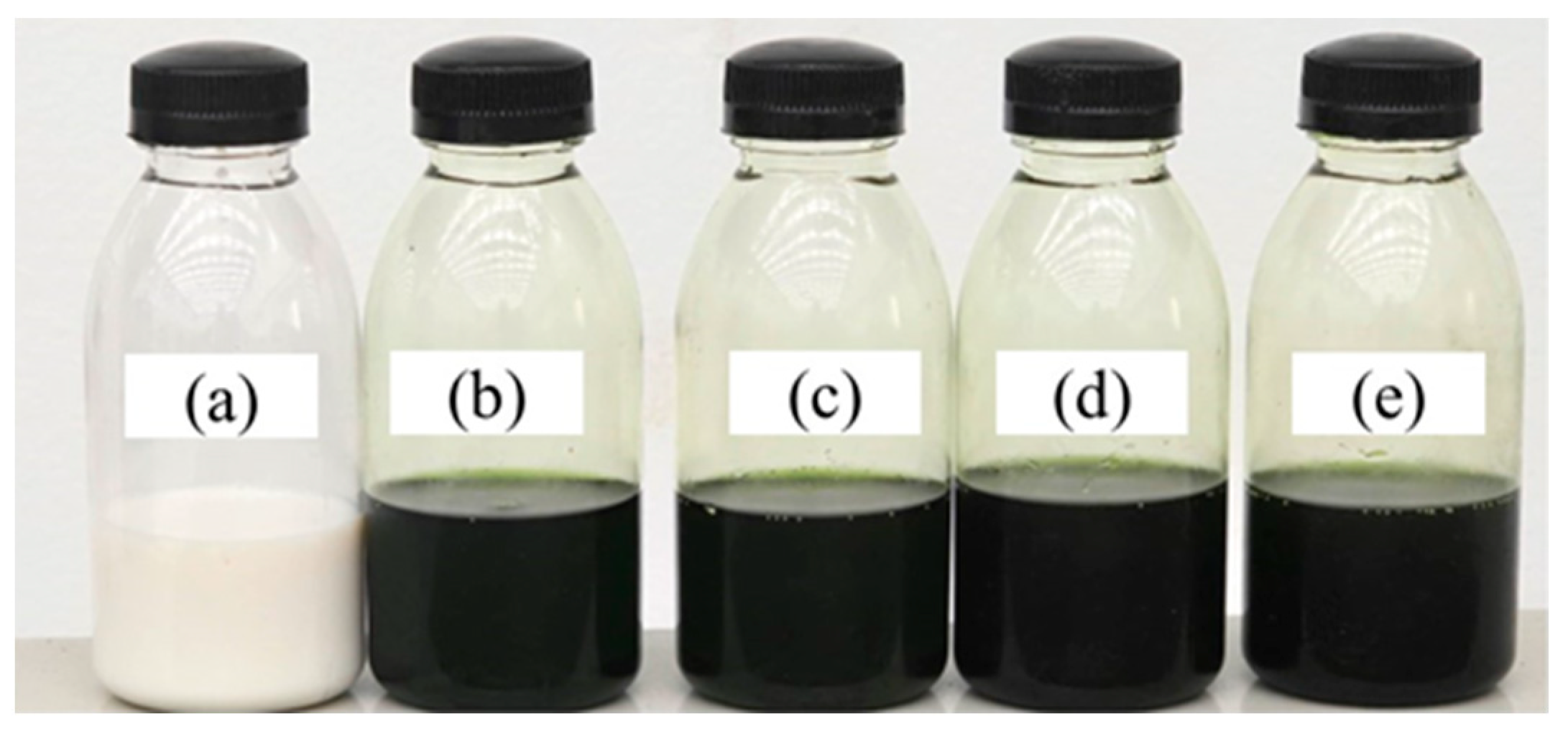

2.2. Cutting Fluid Sample Preparation

2.3. Wettability Test

2.4. Flash Point Test

2.5. Rheological Test

2.6. Tribological Test

2.7. Metal Cutting Test

2.8. Workpiece Surface Roughness and Tool Flank Wear

3. Results and Discussion

3.1. ACNP Characterization Results

3.2. Physical–Chemical Results

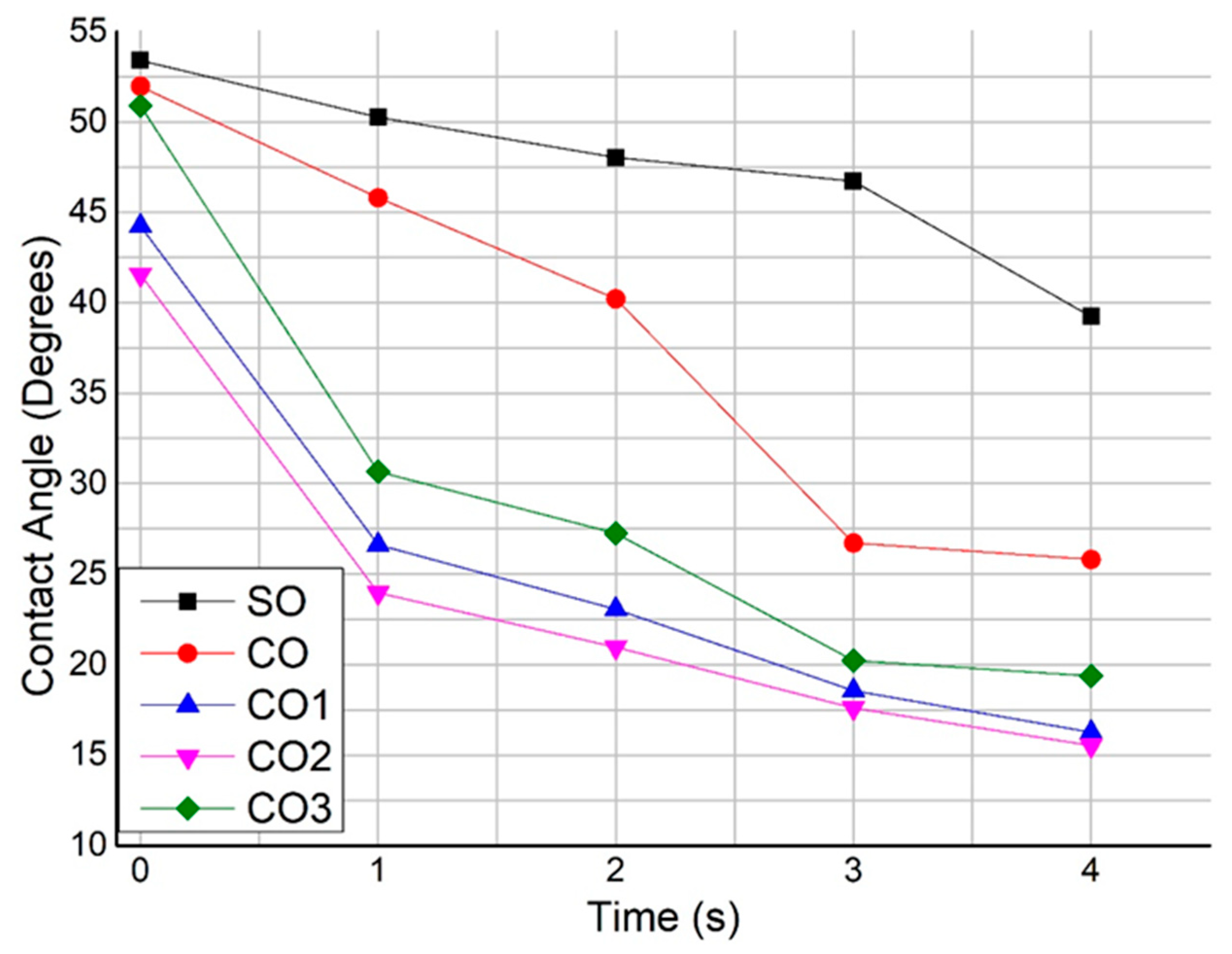

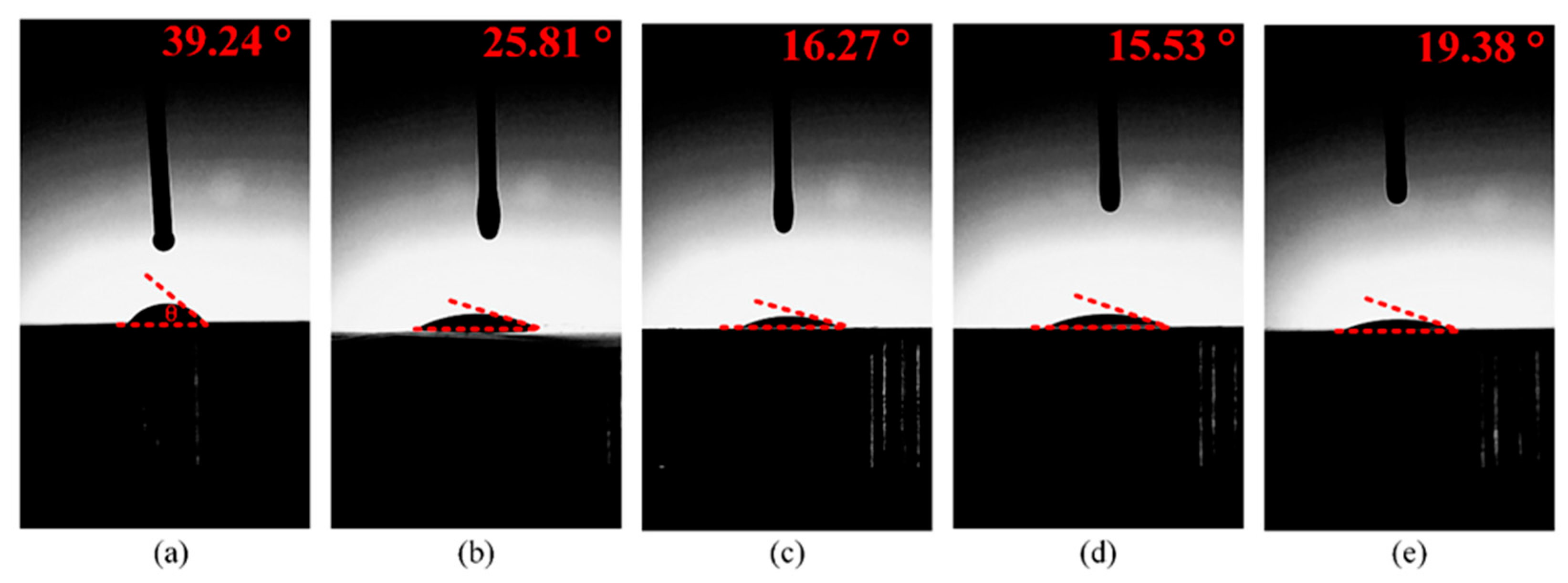

3.3. Wettability Results

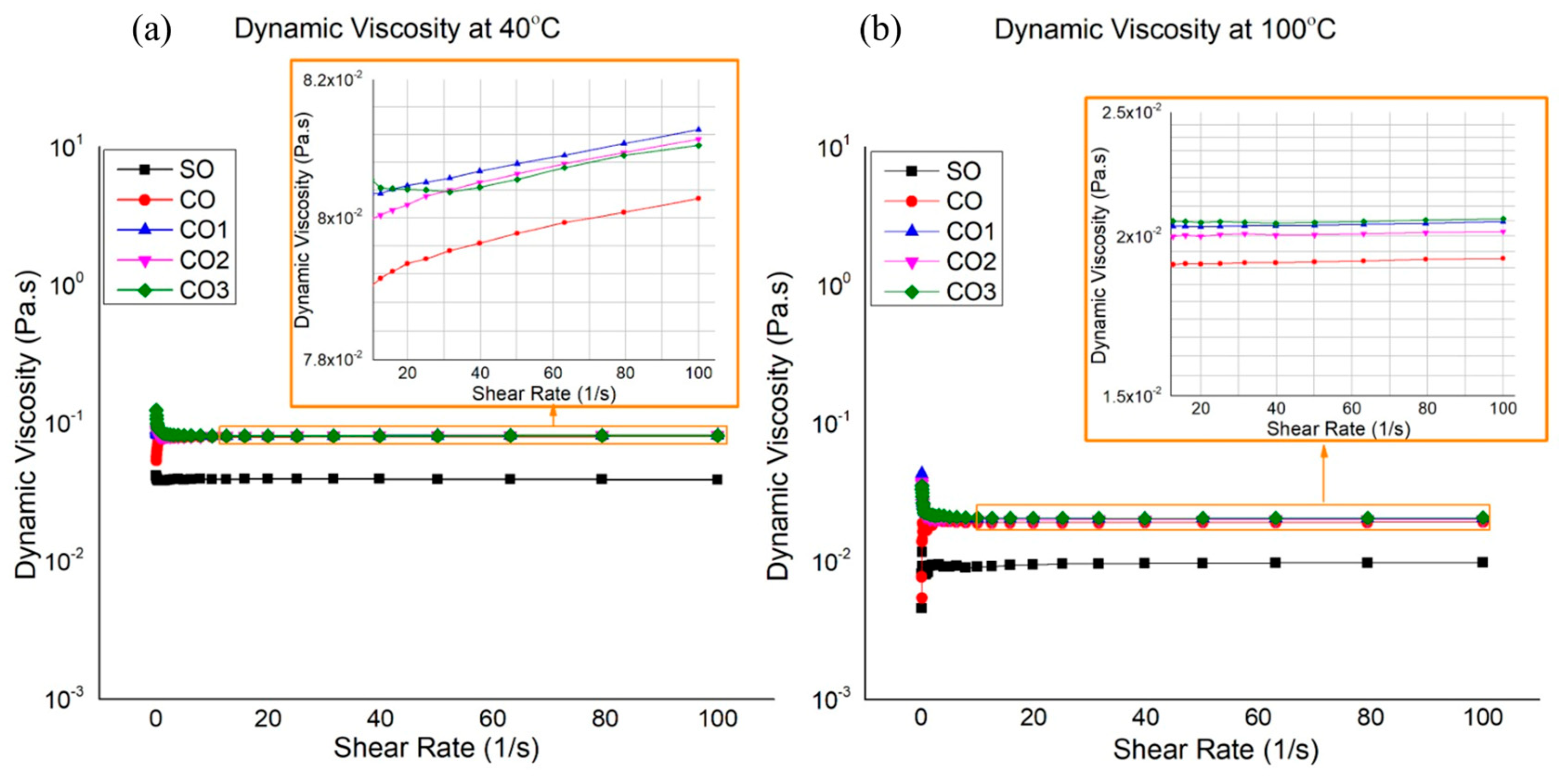

3.4. Rheological Results

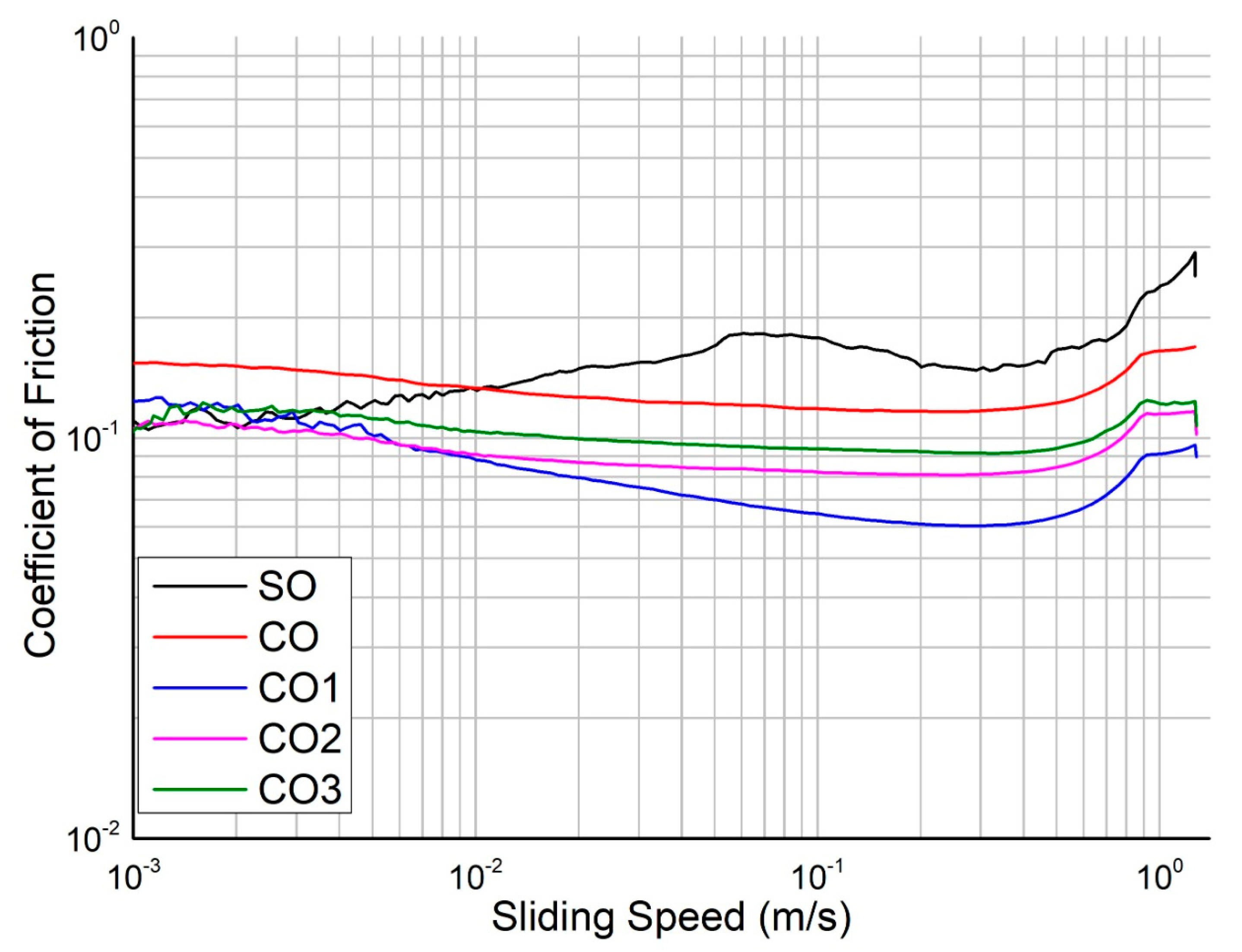

3.5. Tribological Results

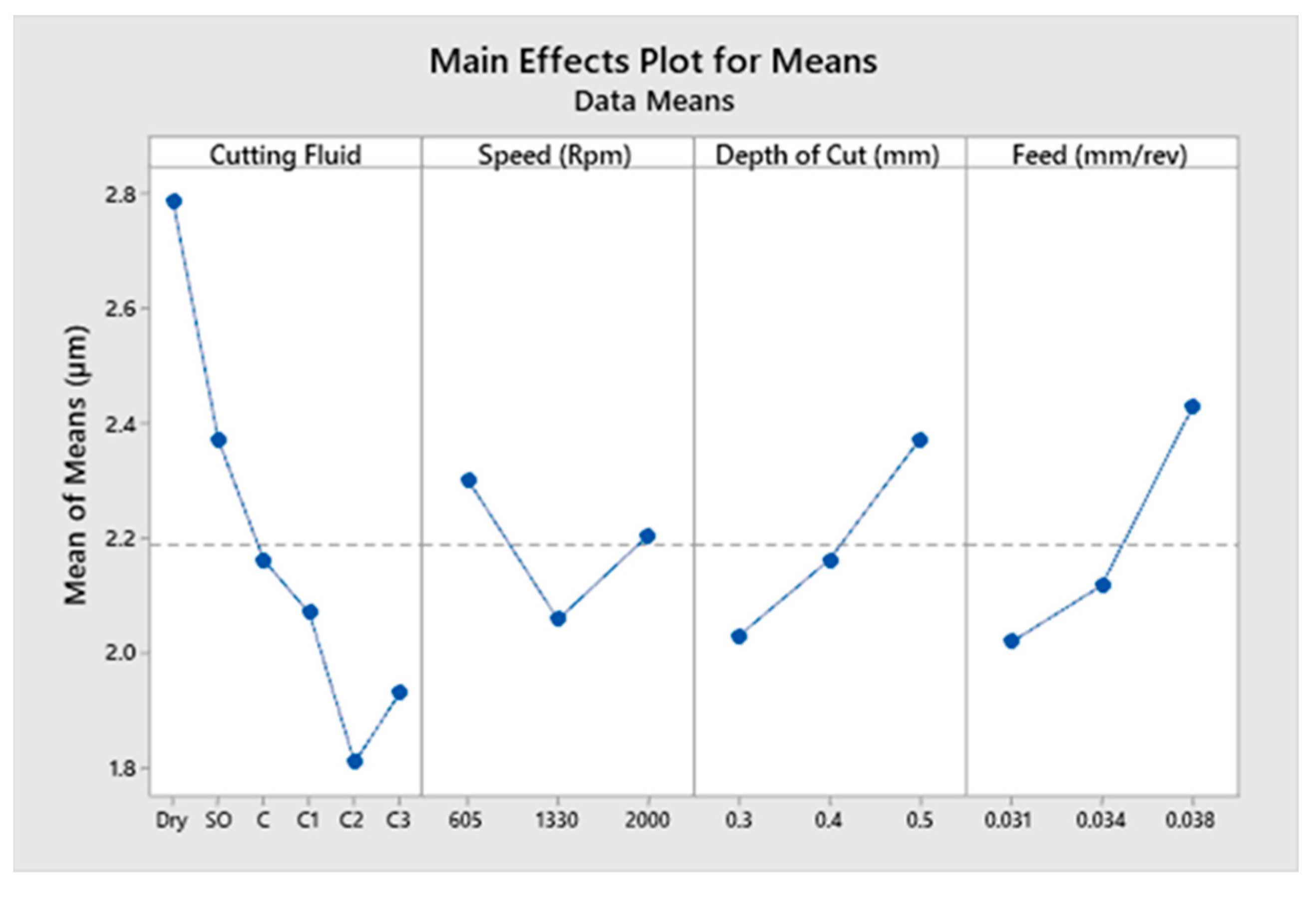

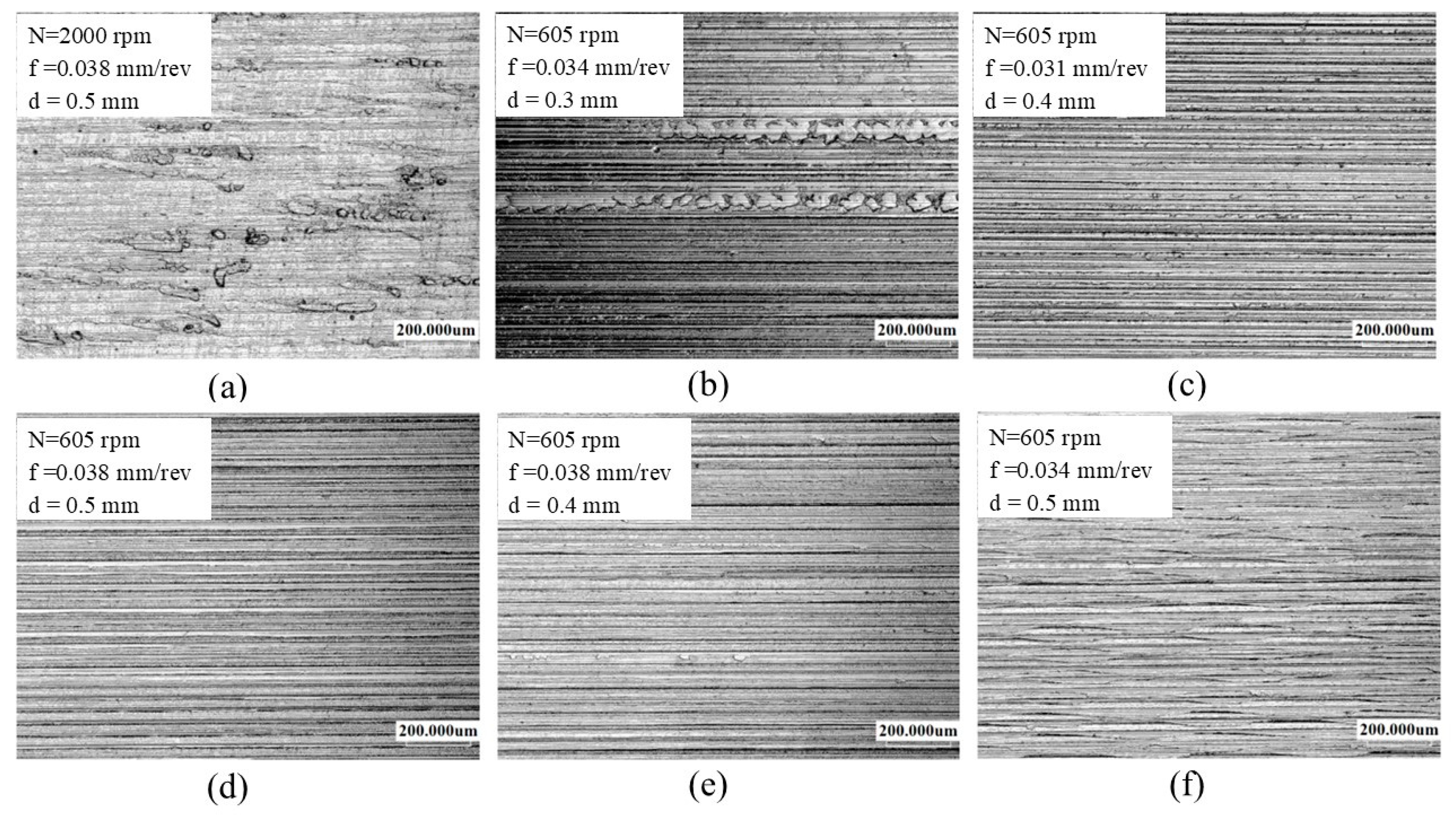

3.6. Metal Cutting Results

- a.

- Workpiece surface roughness

- b.

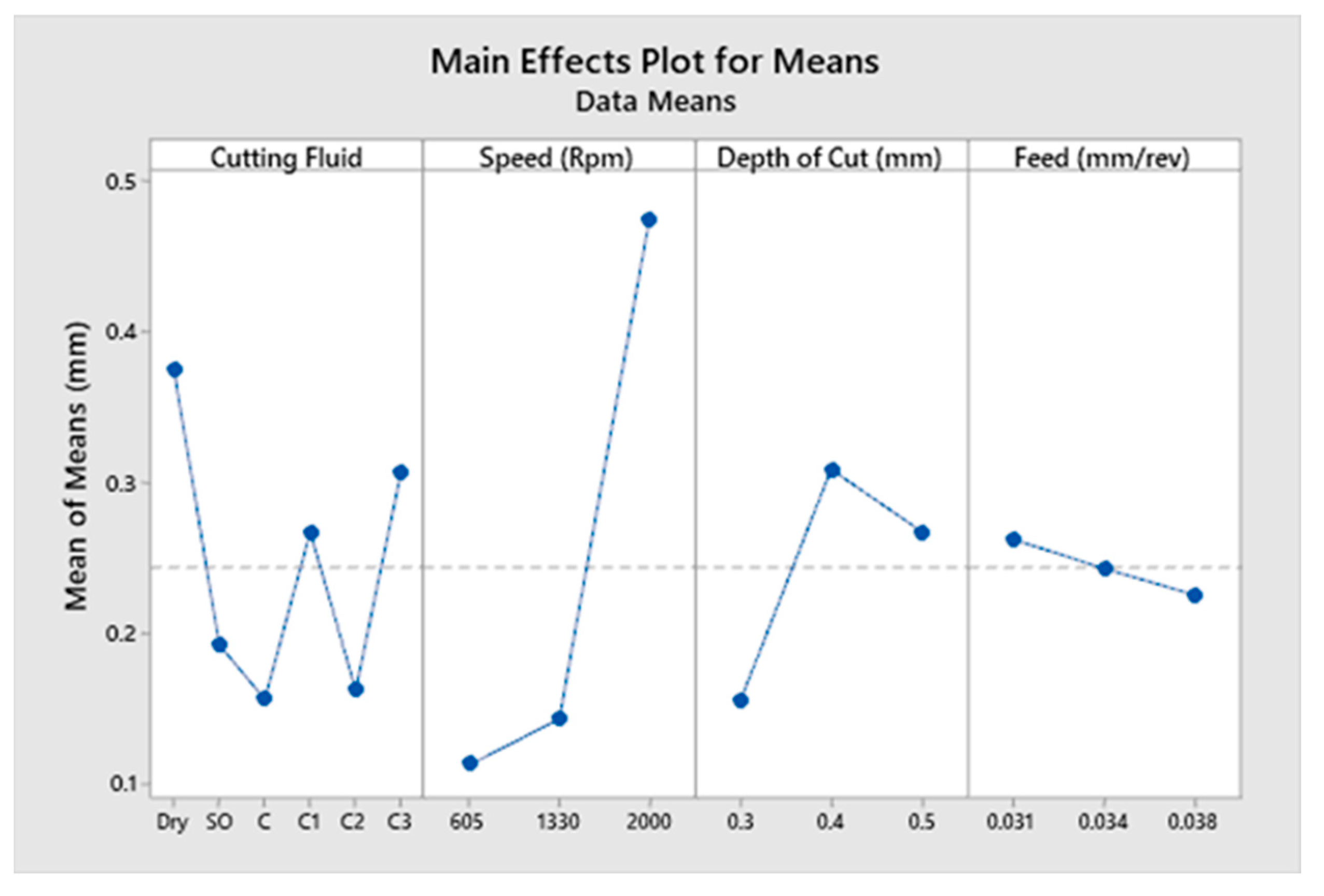

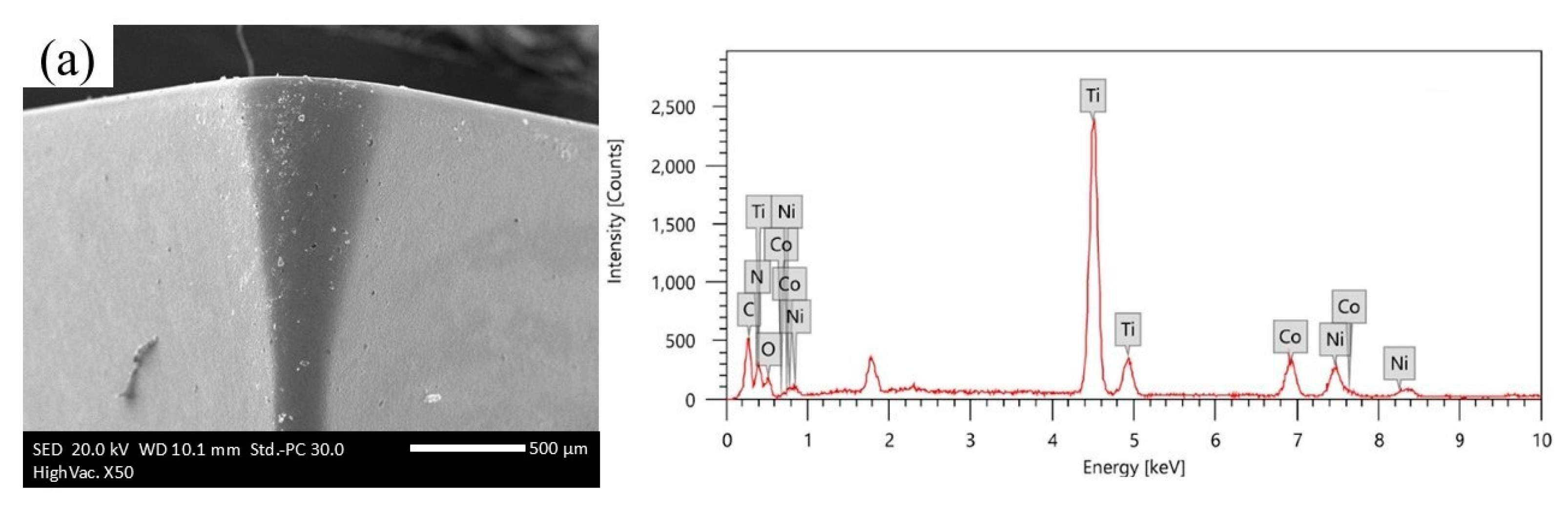

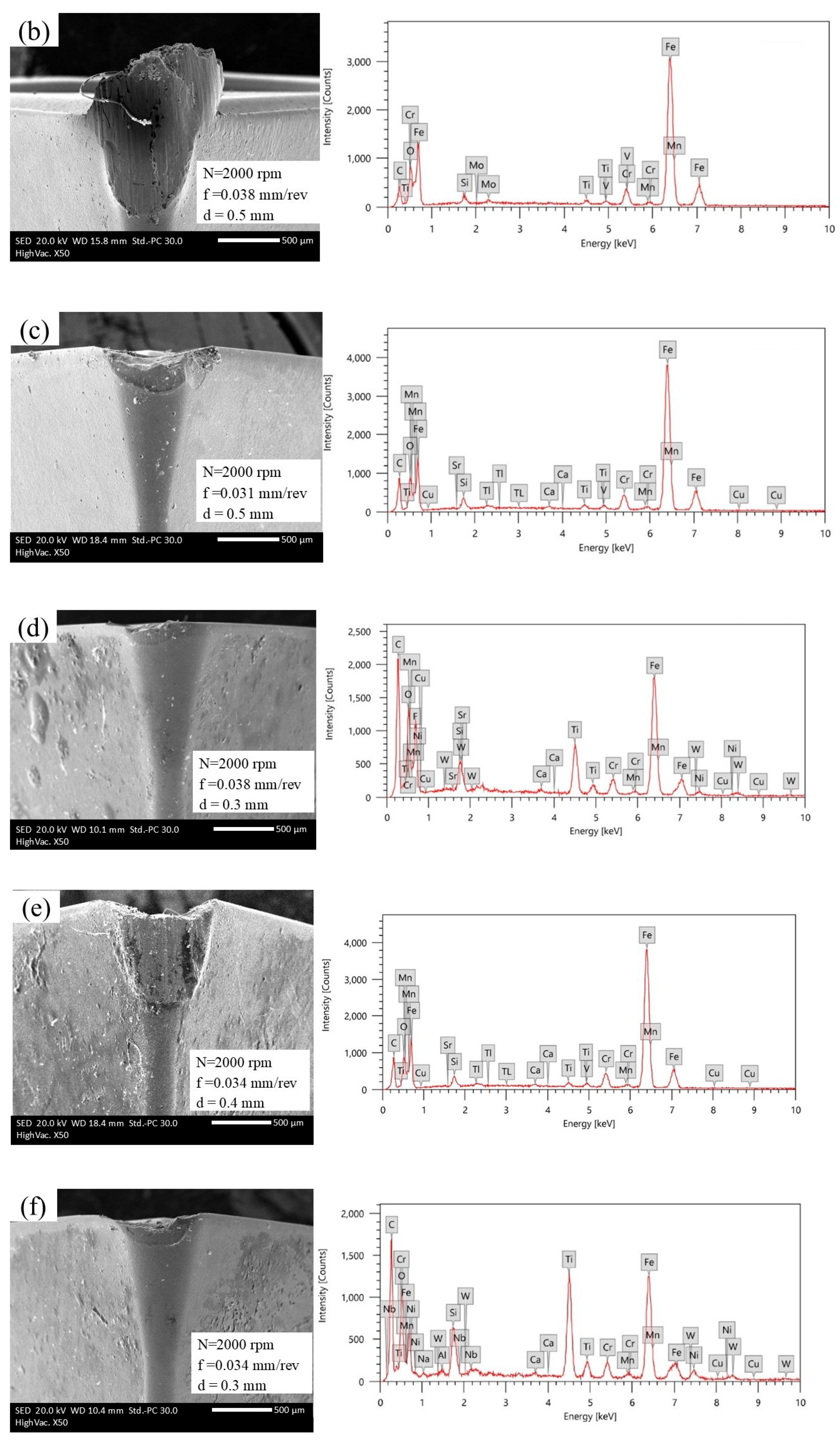

- Tool Flank Wear

3.7. Cost Analysis

4. Conclusions and Future Work

- Plain cactus oil exhibited a 34% improvement in wettability compared to commercial soluble oil, with further enhancements of up to 60% when blended with 0.05 wt.% ACNPs. This suggests adequate fluid penetration into the tool–workpiece interface, reducing friction and heat generation.

- Cactus oil demonstrated Newtonian behavior with a high viscosity index (283.21), outperforming commercial soluble oil. The addition of ACNPs increased the dynamic viscosity of cactus oil by 9–15% at 40 °C. This enhancement demonstrates superior thermal stability and shear resistance compared to plain cactus oil. This viscosity enhancement is critical for maintaining effective lubrication under varying machining conditions. It also promotes the formation of an adequate oil film thickness without compromising fluid flow characteristics, especially during MQL system application.

- Tribological evaluation revealed that nano-enhanced cactus oil formulations substantially outperformed plain cactus oil in boundary lubrication regimes, where metal-to-metal contact is most prevalent during machining operations. The coefficient of friction of the mixtures was reduced by up to 32%, as compared to the plain cactus sample.

- These significant reductions in friction explain the observed 15.5% and 23.6% reductions in tool flank wear and surface roughness in the case of applying cactus oil with 0.05 wt.% ACNP blend, compared to soluble oil. The mechanism can be attributed to the nanoscale ACNP particles effectively filling surface asperities and creating a more stable tribofilm at the tool–workpiece interface, which was further evidenced by post-machining surface analysis showing more uniform wear patterns compared to conventional cutting fluids.

- The integration of recycled nano-additives and non-food-based vegetable oil not only enhances cutting performance but also offers a cost-effective and environmentally responsible solution. This dual benefit positions cactus oil-based nanofluids as promising candidates for widespread adoption in sustainable metalworking operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Malek, J.; Desai, T.N. A Framework for Prioritizing the Solutions to Overcome Sustainable Manufacturing Barriers. Clean. Logist. Supply Chain 2021, 1, 100004. [Google Scholar] [CrossRef]

- Maruthi, G.D.; Rashmi, R. Green Manufacturing: It’s Tools and Techniques That Can Be Implemented in Manufacturing Sectors. Mater. Today Proc. 2015, 2, 3350–3355. [Google Scholar] [CrossRef]

- Yuan, Y. A System Approach for Reducing the Environmental Impact of Manufacturing and Sustainability Improvement of Nano-Scale Manufacturing; University of California: Berkeley, CA, USA, 2005. [Google Scholar]

- Sarhan, A.A.D.; Matsubara, A. Compensation Method of the Machine Tool Spindle Thermal Displacement for Accurate Monitoring of Cutting Forces. Mater. Manuf. Process. 2011, 26, 1511–1521. [Google Scholar] [CrossRef]

- Hamdan, A.; Sarhan, A.A.D.; Hamdi, M. An Optimization Method of the Machining Parameters in High-Speed Machining of Stainless Steel Using Coated Carbide Tool for Best Surface Finish. Int. J. Adv. Manuf. Technol. 2012, 58, 81–91. [Google Scholar] [CrossRef]

- Adler, D.P.; Hii, W.W.-S.; Michalek, D.J.; Sutherland, J.W. Examining the Role of Cutting Fluids in Machining and Efforts to Address Associated Environmental/Health Concerns. Mach. Sci. Technol. 2006, 10, 23–58. [Google Scholar] [CrossRef]

- Pape, F.; Poll, G.; Ellersiek, L.; Denkena, B.; Liu, H. Tribological Effects of Metalworking Fluids in Cutting Processes. Lubricants 2023, 11, 224. [Google Scholar] [CrossRef]

- Liu, H.C.; Pape, F.; Zhao, Y.; Ellersiek, L.; Denkena, B.; Poll, G. On the Elastohydrodynamic Film-Forming Properties of Metalworking Fluids and Oil-in-Water Emulsions. Tribol. Lett. 2022, 71, 10. [Google Scholar] [CrossRef]

- Talib, N.; Rahim, E.A. Performance of Modified Jatropha Oil in Combination with Hexagonal Boron Nitride Particles as a Bio-Based Lubricant for Green Machining. Tribol. Int. 2018, 118, 89–104. [Google Scholar] [CrossRef]

- Wang, X.; Huang, J.; Guo, Z. Overview of the Development of Slippery Surfaces: Lubricants from Presence to Absence. Adv. Colloid Interface Sci. 2022, 301, 102602. [Google Scholar] [CrossRef]

- Pape, F.; Nassef, B.G.; Schmölzer, S.; Stobitzer, D.; Taubmann, R.; Rummel, F.; Stegmann, J.; Gerke, M.; Marian, M.; Poll, G.; et al. Comprehensive Evaluation of the Rheological, Tribological, and Thermal Behavior of Cutting Oil and Water-Based Metalworking Fluids. Lubricants 2025, 13, 219. [Google Scholar] [CrossRef]

- Huang, J.-W.; Bai, Y.-Y.; Zeeshan, M.; Liu, R.-Q.; Dong, G.-H. Effects of Exposure to Chlorinated Paraffins on Human Health: A Scoping Review. Sci. Total Environ. 2023, 886, 163953. [Google Scholar] [CrossRef] [PubMed]

- Shashidhara, Y.M.; Jayaram, S.R. Vegetable Oils as a Potential Cutting Fluid—An Evolution. Tribol. Int. 2010, 43, 1073–1081. [Google Scholar] [CrossRef]

- Koller, M.F.; Foulds, I.S. Cutting Fluids. In Kanerva’s Occupational Dermatology; John, S.M., Johansen, J.D., Rustemeyer, T., Elsner, P., Maibach, H.I., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 1–19. ISBN 978-3-319-40221-5. [Google Scholar]

- Bennett, E.O.; Bennett, D.L. Minimizing Human Exposure to Chemicals in Metalworking Fluids. Lubr. Eng. 1987, 43, 167–175. [Google Scholar]

- Woma, T.Y.; Lawal, S.A.; Abdulrahman, A.S.; Olutoye, M.A.; Ojapah, M.M. Vegetable Oil Based Lubricants: Challenges and Prospects. Tribol. Online 2019, 14, 60–70. [Google Scholar] [CrossRef]

- Tavella, R.A.; da Silva Júnior, F.M.R.; Santos, M.A.; Miraglia, S.G.E.K.; Pereira Filho, R.D. A Review of Air Pollution from Petroleum Refining and Petrochemical Industrial Complexes: Sources, Key Pollutants, Health Impacts, and Challenges. ChemEngineering 2025, 9, 13. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Krolczyk, G.M. A Comprehensive Review on Research Developments of Vegetable-Oil Based Cutting Fluids for Sustainable Machining Challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar] [CrossRef]

- Wu, X.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Zhang, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Circulating Purification of Cutting Fluid: An Overview. Int. J. Adv. Manuf. Technol. 2021, 117, 2565–2600. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable Oil-Based Lubricants—A Review of Oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B.; Demirbas, E. Environmentally Friendly Machining: Vegetable Based Cutting Fluids. In Green Manufacturing Processes and Systems; Davim, J.P., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 23–47. ISBN 978-3-642-33792-5. [Google Scholar]

- Pranav, P.; Sneha, E.; Rani, S. Vegetable Oil-Based Cutting Fluids and Its Behavioral Characteristics in Machining Processes: A Review. Ind. Lubr. Tribol. 2021, 73, 1159–1175. [Google Scholar] [CrossRef]

- Bork, C.A.S.; de Gonçalves, J.F.S.; de Gomes, J.O.; Gheller, J. Performance of the Jatropha Vegetable-Base Soluble Cutting Oil as a Renewable Source in the Aluminum Alloy 7050-T7451 Milling. CIRP J. Manuf. Sci. Technol. 2014, 7, 210–221. [Google Scholar] [CrossRef]

- Villarrazo, N.; Caneda, S.; Pereira, O.; Rodríguez, A.; López de Lacalle, L.N. The Effects of Lubricooling Ecosustainable Techniques on Tool Wear in Carbon Steel Milling. Materials 2023, 16, 2936. [Google Scholar] [CrossRef] [PubMed]

- Subramaniam, S.; Thangamuthu, M. Influence of Vegetable Based Cutting Fluids on Cutting Force and Vibration Signature during Milling of Aluminium Metal Matrix Composites. J. Tribol. 2017, 12, 1–17. [Google Scholar]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability Analysis of Lubricant Oils for Minimum Quantity Lubrication Based on Their Tribo-Rheological Performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Winter, M.; Öhlschläger, G.; Dettmer, T.; Ibbotson, S.; Kara, S.; Herrmann, C. Using Jatropha Oil Based Metalworking Fluids in Machining Processes: A Functional and Ecological Life Cycle Evaluation. In Leveraging Technology for a Sustainable World, Proceedings of the 19th CIRP Conference on Life Cycle Engineering, University of California at Berkeley, Berkeley, USA, 23–25 May 2012; Dornfeld, D.A., Linke, B.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 311–316. [Google Scholar]

- Pereira, O.; Català, P.; Rodríguez, A.; Ostra, T.; Vivancos, J.; Rivero, A.; López-De-Lacalle, L.N. The Use of Hybrid CO2+MQL in Machining Operations. Procedia Eng. 2015, 132, 492–499. [Google Scholar] [CrossRef]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; de Lacalle, L.N.L. Internal Cryolubrication Approach for Inconel 718 Milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- López De Lacalle, L.N.; Angulo, C.; Lamikiz, A.; Sánchez, J.A. Experimental and Numerical Investigation of the Effect of Spray Cutting Fluids in High Speed Milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Aguilar-Rosas, O.A.; Pérez-González, J.; Marín-Santibañez, B.M.; Rodríguez-González, F. Viscoelastic Water-Based Lubricants with Nopal Cactus Mucilage as Green Metalworking Fluids. Lubricants 2024, 12, 56. [Google Scholar] [CrossRef]

- Elbadawy, N.K.; Daha, M.A.; Nassef, G.A.; Maher, I. Investigating the Feasibility of Utilising Cactus Oil as a Minimum Quantity Lubrication Eco-Friendly Coolant for Machining 42CrMo4 Stee. Int. J. Mach. Mach. Mater. 2025, 1–27. [Google Scholar] [CrossRef]

- Nounah, I.; El Harkaoui, S.; Hajib, A.; Gharby, S.; Harhar, H.; Bouyahya, A.; Caprioli, G.; Maggi, F.; Matthäus, B.; Charrouf, Z. Effect of Seed’s Geographical Origin on Cactus Oil Physico-Chemical Characteristics, Oxidative Stability, and Antioxidant Activity. Food Chem. X 2024, 22, 101445. [Google Scholar] [CrossRef]

- Al-Naqeb, G.; Fiori, L.; Ciolli, M.; Aprea, E. Prickly Pear Seed Oil Extraction, Chemical Characterization and Potential Health Benefits. Molecules 2021, 26, 5018. [Google Scholar] [CrossRef]

- Loizzo, M.R.; Bruno, M.; Balzano, M.; Giardinieri, A.; Pacetti, D.; Frega, N.G.; Sicari, V.; Leporini, M.; Tundis, R. Comparative Chemical Composition and Bioactivity of Opuntia Ficus-Indica Sanguigna and Surfarina Seed Oils Obtained by Traditional and Ultrasound-Assisted Extraction Procedures. Eur. J. Lipid Sci. Technol. 2019, 121, 1800283. [Google Scholar] [CrossRef]

- Berraaouan, A.; Ziyyat, A.; Mekhfi, H.; Marianne, S.; Fauconnier, M.-L.; Abdelkhaleq, L.; Mohammed, A.; Bnouham, M. Chemical Composition of Cactus Pear Seed Oil: Phenolics Identification and Antioxidant Activity. J. Pharmacopunct. 2022, 25, 121–129. [Google Scholar] [CrossRef]

- El Mannoubi, I.; Barrek, S.; Skanji, T.; Casabianca, H.; Zarrouk, H. Characterization of Opuntia Ficus Indica Seed Oil from Tunisia. Chem. Nat. Compd. 2009, 45, 616–620. [Google Scholar] [CrossRef]

- Chougui, N.; Tamendjari, A.; Hamidj, W.; Hallal, S.; Barras, A.; Richard, T.; Larbat, R. Oil Composition and Characterisation of Phenolic Compounds of Opuntia Ficus-Indica Seeds. Food Chem. 2013, 139, 796–803. [Google Scholar] [CrossRef]

- Sancheti, S.V.; Yadav, G.D. Synthesis of Environment-Friendly, Sustainable, and Nontoxic Bio-Lubricants: A Critical Review of Advances and a Path Forward. Biofuels Bioprod. Biorefining 2022, 16, 1172–1195. [Google Scholar] [CrossRef]

- Berman, D. Plant-Based Oils for Sustainable Lubrication Solutions—Review. Lubricants 2024, 12, 300. [Google Scholar] [CrossRef]

- Bhaumik, S.; Maggirwar, R.; Datta, S.; Pathak, S.D. Analyses of Anti-Wear and Extreme Pressure Properties of Castor Oil with Zinc Oxide Nano Friction Modifiers. Appl. Surf. Sci. 2018, 449, 277–286. [Google Scholar] [CrossRef]

- Talib, N.; Sabri, A.M.; Zolkefli, A.A.; Tan, K.S.; Kunar, S.; Mekanikal, F.K.; Pembuatan, D. Tribological Enhancement of Modified Jatropha Oil by Activated Carbon Nanoparticle for Metalworking Fluid Application. J. Tribol. 2022, 33, 113–124. [Google Scholar]

- Seid Ahmed, Y.; Hernández González, L. Ti6Al4V Grinding Using Different Lubrication Modes for Minimizing Energy Consumption. Int. J. Adv. Manuf. Technol. 2023, 126, 2387–2405. [Google Scholar] [CrossRef]

- Gaurav, G.; Sharma, A.; Dangayach, G.S.; Meena, M.L. Assessment of Jojoba as a Pure and Nano-Fluid Base Oil in Minimum Quantity Lubrication (MQL) Hard-Turning of Ti–6Al–4V: A Step towards Sustainable Machining. J. Clean. Prod. 2020, 272, 122553. [Google Scholar] [CrossRef]

- Liu, W.; Qiao, X.; Liu, S.; Chen, P. A Review of Nanomaterials with Different Dimensions as Lubricant Additives. Nanomaterials 2022, 12, 3780. [Google Scholar] [CrossRef] [PubMed]

- Duan, L.; Li, J.; Duan, H. Nanomaterials for Lubricating Oil Application: A Review. Friction 2023, 11, 647–684. [Google Scholar] [CrossRef]

- Syahir, A.Z.; Zulkifli, N.W.M.; Masjuki, H.H.; Kalam, M.A.; Alabdulkarem, A.; Gulzar, M.; Khuong, L.S.; Harith, M.H. A Review on Bio-Based Lubricants and Their Applications. J. Clean. Prod. 2017, 168, 997–1016. [Google Scholar] [CrossRef]

- Bai, X.; Li, C.; Dong, L.; Yin, Q. Experimental Evaluation of the Lubrication Performances of Different Nanofluids for Minimum Quantity Lubrication (MQL) in Milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 101, 2621–2632. [Google Scholar] [CrossRef]

- Nassef, B.G.; Pape, F.; Poll, G. Enhancing the Performance of Rapeseed Oil Lubricant for Machinery Component Applications through Hybrid Blends of Nanoadditives. Lubricants 2023, 11, 479. [Google Scholar] [CrossRef]

- Talib, N.; Sani, A.S.A.; Hamzah, N. Modified Jatropha Nano-Lubricant as Metalworking Fluid for Machining Process. J. Tribol. 2019, 23, 90–96. [Google Scholar]

- Mushtaq, Z. Enhancing the Tribological Characteristics of Jatropha Oil Using Graphene Nanoflakes. J. Tribol. 2021, 28, 129–143. [Google Scholar]

- Sharma, V.S.; GurRaj, S.; Sørby, K. A Review on Minimum Quantity Lubrication for Machining Processes. Mater. Manuf. Process. 2015, 30, 935–953. [Google Scholar] [CrossRef]

- Li, C.H.; Li, J.Y.; Wang, S.; Zhang, Q. Modeling and Numerical Simulation of the Grinding Temperature Field with Nanoparticle Jet of MQL. Adv. Mech. Eng. 2013, 5, 986984. [Google Scholar] [CrossRef]

- Shahrom, M.S.; Yahya, N.M.; Yusoff, A.R. Taguchi Method Approach on Effect of Lubrication Condition on Surface Roughness in Milling Operation. Procedia Eng. 2013, 53, 594–599. [Google Scholar] [CrossRef]

- Patole, P.B.; Kulkarni, V.V.; Bhatwadekar, S.G. MQL Machining with Nano Fluid: A Review. Manuf. Rev. 2021, 8, 13. [Google Scholar] [CrossRef]

- Rifat, M.; Rahman, M.H.; Das, D. A Review on Application of Nanofluid MQL in Machining. In Proceedings of the AIP Conference Proceedings, Provo, UT, USA, 16–21 July 2017; American Institute of Physics Inc.: College Park, MD, USA, 2017; Volume 1919, pp. 1–10. [Google Scholar]

- Bai, X.; Zhou, F.; Li, C.; Dong, L.; Lv, X.; Yin, Q. Physicochemical Properties of Degradable Vegetable-Based Oils on Minimum Quantity Lubrication Milling. Int. J. Adv. Manuf. Technol. 2020, 106, 4143–4155. [Google Scholar] [CrossRef]

- Thakur, A.; Manna, A.; Samir, S. Experimental Investigation of Nanofluids in Minimum Quantity Lubrication during Turning of EN-24 Steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 234, 712–729. [Google Scholar] [CrossRef]

- Sahoo, S.P.; Datta, S. Dry, MQL, and Nanofluid MQL Machining of Ti–6Al–4V Using Uncoated WC–Co Insert: Application of Jatropha Oil as Base Cutting Fluid and Graphene Nanoplatelets as Additives. Arab. J. Sci. Eng. 2020, 45, 9599–9618. [Google Scholar] [CrossRef]

- Nassef, M.G.A.; Hassan, H.S.; Nassef, G.A.; Nassef, B.G.; Soliman, M.; Elkady, M.F. Activated Carbon Nano-Particles from Recycled Polymers Waste as a Novel Nano-Additive to Grease Lubrication. Lubricants 2022, 10, 214. [Google Scholar] [CrossRef]

- Pereira, L.; Castillo, V.; Calero, M.; Blázquez, G.; Solís, R.R.; Martín-Lara, M.Á. Insights into Using Plastic Waste to Produce Activated Carbons for Wastewater Treatment Applications: A Review. J. Water Process. Eng. 2024, 62, 105386. [Google Scholar] [CrossRef]

- ASTM D92-23; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D2196-20; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield Type) Viscometer. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D4172-23; Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method). ASTM International: West Conshohocken, PA, USA, 2023.

- ISO 4287:1997; Geometrical Product Specifications (GPS)—Surface texture: Profile method—Terms, definitions and surface texture parameters. International Organization for Standardization: Geneva, Switzerland, 1997.

- ISO 3685:1993; Tool-life testing with single-point turning tools. International Organization for Standardization: Geneva, Switzerland, 1993.

- El Bouazzaoui, Y.; Habsaoui, A.; Ouaddari, H.; Touhami, M.E. Geographic Impact on Opuntia Ficus-Indica Seeds: Oil and Phenolic Compound Extraction and Characterization. S. Afr. J. Bot. 2023, 159, 605–616. [Google Scholar] [CrossRef]

- Taoufik, F.; Zine, S.; El Hadek, M.; Hassani, L.I.; Gharby, S.; Harhar, H.; Matthäus, B. Oil Content and Main Constituents of Cactus Seed Oils Opuntia Ficus Indica of Different Origin in Morocco. Mediterr. J. Nutr. Metab. 2015, 8, 85–92. [Google Scholar] [CrossRef]

- Sawaya, W.N.; Khan, P. Chemical Characterization of Prickly Pear Seed Oil, Opuntia Ficus-Indica. J. Food Sci. 1982, 47, 2060–2061. [Google Scholar] [CrossRef]

- Lundgren, S.M.; Ruths, M.; Danerlöv, K.; Persson, K. Effects of Unsaturation on Film Structure and Friction of Fatty Acids in a Model Base Oil. J. Colloid Interface Sci. 2008, 326, 530–536. [Google Scholar] [CrossRef]

- Tahoon, M.A.; Siddeeg, S.M.; Alsaiari, N.S.; Mnif, W.; Ben Rebah, F. Effective Heavy Metals Removal Fromwater Using Nanomaterials: A Review. Processes 2020, 8, 645. [Google Scholar] [CrossRef]

- Yang, X.; Wan, Y.; Zheng, Y.; He, F.; Yu, Z.; Huang, J.; Wang, H.; Ok, Y.S.; Jiang, Y.; Gao, B. Surface Functional Groups of Carbon-Based Adsorbents and Their Roles in the Removal of Heavy Metals from Aqueous Solutions: A Critical Review. Chem. Eng. J. 2019, 366, 608–621. [Google Scholar] [CrossRef] [PubMed]

- López-Barrón, C.R.; Wagner, N.J.; Porcar, L. Layering, Melting, and Recrystallization of a Close-Packed Micellar Crystal under Steady and Large-Amplitude Oscillatory Shear Flows. J. Rheol. 2015, 59, 793–820. [Google Scholar] [CrossRef]

- Yan, Y.D.; Dhont, J.K.G.; Smits, C.; Lekkerkerker, H.N.W. Oscillatory-Shear-Induced Order in Nonaqueous Dispersions of Charged Colloidal Spheres. Phys. A Stat. Mech. Its Appl. 1994, 202, 68–80. [Google Scholar] [CrossRef]

- Bao, J.; Heyd, R.; Régnier, G.; Ammar, A.; Peixinho, J. Viscosity of Graphene in Lubricating Oil, Ethylene Glycol and Glycerol. Res. Sq. 2023, 148, 11455–11465. [Google Scholar] [CrossRef]

- Hassan, M.; Samion, S.; Ani, F. The Tribological Characteristics of the Cactus and Mineral Oil Blends Using Four-Ball Tribotester. J. Teknol. 2016, 78, 33–38. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of Tribology on Global Energy Consumption, Costs and Emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Stachowiak, G.; Andrew, W.B. Engineering Tribology, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Neog, S.P.; Kumar, A.R.; Bakshi, S.D.; Das, S. Understanding the complexities of dry sliding wear behaviour of steels. Mater. Sci. Technol. 2021, 37, 504–518. [Google Scholar] [CrossRef]

- Peng, R.; Shen, J.; Tang, X.; Zhao, L.; Gao, J. Performances of a Tailored Vegetable Oil-Based Graphene Nanofluid in the MQL Internal Cooling Milling. J. Manuf. Process. 2025, 134, 814–831. [Google Scholar] [CrossRef]

- Afonso, I.S.; Nobrega, G.; Lima, R.; Gomes, J.R.; Ribeiro, J.E. Conventional and Recent Advances of Vegetable Oils as Metalworking Fluids (MWFs): A Review. Lubricants 2023, 11, 160. [Google Scholar] [CrossRef]

| Cutting Fluid Type | Sample | ACNP Concentration |

|---|---|---|

| Cactus oil | CO | - |

| CO1 | 0.025 wt.% | |

| CO2 | 0.05 wt.% | |

| CO3 | 0.1 wt.% | |

| Mineral oil-based emulsion lubricant | SO | - |

| Setup Parameters | Description |

|---|---|

| Machine tool | Center lathe (Turnado 230/1000) |

| Workpiece | H13 steel (30 mm diameter) |

| Cutting tool | Cermet Carbide Insert (Tungaloy Tpmt130304- 24ns9530) |

| Cutting fluid System | MQL (NEX Flow) |

| Distance between the MQL nozzle and workpiece | 20 mm |

| Flow rate under MQL | 125 mL/h |

| The pressure of air under MQL | 4-bar |

| MQL nozzle angle | 45° |

| Process Parameter | Values | |||||

|---|---|---|---|---|---|---|

| Depth of cut d (mm) | 0.3 | 0.4 | 0.5 | |||

| Feed rate f (mm/rev) | 0.031 | 0.034 | 0.038 | |||

| Cutting speed N (rpm) | 605 | 1330 | 2000 | |||

| Cutting fluid | Dry | Soluble Oil | Cactus Oil (CO) | Cactus Oil with 0.025 wt.% AC (CO1) | Cactus Oil with 0.05 wt.% AC (CO2) | Cactus Oil with 0.1 wt. % AC (CO3) |

| Sample | BET Surface Area (m2 g−1) | Total Pore Volume (cm3 g−1) | Mean Pore Diameter (nm) |

|---|---|---|---|

| AC | 448.88 | 0.2029 | 1.808 |

| Samples | Cactus Oil | Soluble Oil | Blaser Vasco 6000 [49] | Zubora 67H [49] |

|---|---|---|---|---|

| Kinematic viscosity at 40 °C (cSt) | 85 | 39 | 42 | 40 |

| Kinematic viscosity at 100 °C (cSt) | 21.75 | 10 | 10.3 | 9 |

| Viscosity index | 283.21 | 260.012 | 213 | 216 |

| Density (gm/cm3) | 0.9194 | 0.9898 | 0.99 | 0.9898 |

| Flash point (°C) | 212 | 168 | 129 | 168 |

| PH value | 5.14 | 9.50 | - | 9.50 |

| Chemical structure | Linoleic acid (C18:2), oleic acid (C18:1), palmitic acid (C:16:0) | Water emulsion (10% oil + 90% water) | Water-miscible, ester oil base, boron, formaldehyde, and chlorine-free |

| Cutting Fluid | Speed (rpm) | Depth of Cut (mm) | Feed (mm/rev) | Average Surface Roughness (Vertical) (µm) | Average Surface Roughness (Horizontal) (µm) | Average Surface Roughness (Vertical + Horizontal) (µm) |

|---|---|---|---|---|---|---|

| Dry | 605 | 0.3 | 0.031 | 2.00 | 2.18 | 2.09 |

| Dry | 1330 | 0.4 | 0.034 | 2.10 | 2.26 | 2.18 |

| Dry | 2000 | 0.5 | 0.038 | 4.27 | 3.91 | 4.09 |

| SO | 605 | 0.3 | 0.034 | 2.99 | 2.52 | 2.76 |

| SO | 1330 | 0.4 | 0.038 | 2.57 | 2.19 | 2.38 |

| SO | 2000 | 0.5 | 0.031 | 1.91 | 2.04 | 1.98 |

| CO | 605 | 0.4 | 0.031 | 2.58 | 2.43 | 2.50 |

| CO | 1330 | 0.5 | 0.034 | 2.40 | 1.97 | 2.19 |

| CO | 2000 | 0.3 | 0.038 | 1.93 | 1.66 | 1.80 |

| CO1 | 605 | 0.5 | 0.038 | 2.49 | 2.03 | 2.26 |

| CO1 | 1330 | 0.3 | 0.031 | 2.18 | 1.88 | 2.03 |

| CO1 | 2000 | 0.4 | 0.034 | 2.18 | 1.67 | 1.92 |

| CO2 | 605 | 0.4 | 0.038 | 2.16 | 2.13 | 2.15 |

| CO2 | 1330 | 0.5 | 0.031 | 2.07 | 1.28 | 1.68 |

| CO2 | 2000 | 0.3 | 0.034 | 2.03 | 1.18 | 1.60 |

| CO3 | 605 | 0.5 | 0.034 | 2.20 | 1.91 | 2.06 |

| CO3 | 1330 | 0.3 | 0.038 | 2.18 | 1.61 | 1.90 |

| CO3 | 2000 | 0.4 | 0.031 | 2.13 | 1.55 | 1.84 |

| Cutting Fluid | Speed (RPM) | Depth of Cut (mm) | Feed (mm/rev) | Flank Wear (mm) | Average of Wear (mm) | ||

|---|---|---|---|---|---|---|---|

| Dry | 605 | 0.3 | 0.031 | 0.1395 | 0.1311 | 0.1353 | 0.1353 |

| Dry | 1330 | 0.4 | 0.034 | 0.2366 | 0.241 | 0.2326 | 0.2367 |

| Dry | 2000 | 0.5 | 0.038 | 0.7525 | 0.7526 | 0.7611 | 0.7554 |

| SO | 605 | 0.3 | 0.034 | 0.0844 | 0.0931 | 0.0930 | 0.0901 |

| SO | 1330 | 0.4 | 0.038 | 0.1353 | 0.1330 | 0.1353 | 0.1345 |

| SO | 2000 | 0.5 | 0.031 | 0.3573 | 0.3531 | 0.3488 | 0.3530 |

| CO | 605 | 0.4 | 0.031 | 0.1205 | 0.1120 | 0.1078 | 0.1134 |

| CO | 1330 | 0.5 | 0.034 | 0.1668 | 0.1586 | 0.1628 | 0.1627 |

| CO | 2000 | 0.3 | 0.038 | 0.1966 | 0.1966 | 0.1860 | 0.1930 |

| CO1 | 605 | 0.5 | 0.038 | 0.0972 | 0.0972 | 0.0972 | 0.0972 |

| CO1 | 1330 | 0.3 | 0.031 | 0.1586 | 0.1543 | 0.1586 | 0.1571 |

| CO1 | 2000 | 0.4 | 0.034 | 0.5475 | 0.5475 | 0.5476 | 0.5475 |

| CO2 | 605 | 0.4 | 0.038 | 0.1078 | 0.1078 | 0.0972 | 0.1042 |

| CO2 | 1330 | 0.5 | 0.031 | 0.1015 | 0.0888 | 0.1078 | 0.0993 |

| CO2 | 2000 | 0.3 | 0.034 | 0.2833 | 0.2832 | 0.2874 | 0.2846 |

| CO3 | 605 | 0.5 | 0.034 | 0.1669 | 0.1170 | 0.1274 | 0.1371 |

| CO3 | 1330 | 0.3 | 0.038 | 0.0655 | 0.0761 | 0.0655 | 0.0690 |

| CO3 | 2000 | 0.4 | 0.031 | 0.7130 | 0.7188 | 0.7188 | 0.7168 |

| Cost Factor | Cactus Oil + ACNPs | Commercial Cutting Fluids |

|---|---|---|

| Material Cost | Higher (due to nanoparticle infusion and extraction) | Lower (bulk availability) |

| Preparation Cost | Moderate (requires filtration, nanoparticle mixing) | Low (ready-to-use) |

| Tool Life Impact | Potentially longer (better lubrication reduces wear) | Moderate (depends on additives) |

| Machining Efficiency | Comparable or better (lower friction, heat dissipation) | Standard performance |

| Disposal and Environmental Cost | Low (biodegradable, non-toxic) | High (hazardous waste treatment) |

| Health and Safety Costs | Low (non-toxic, no skin irritation) | High (exposure risks, PPE required) |

| Maintenance and System Longevity | Better (less residue, cleaner machines) | Higher (sludge buildup, corrosion) |

| Component | Cactus Oil + ACNPs | Commercial Synthetic Cutting Fluid |

|---|---|---|

| Base Fluid Cost | USD 8–10/L (extraction and refining) | USD 4/L (petroleum-based) |

| Nanoparticle Additives | USD 10–15/g (activated carbon) | USD 0 (pre-mixed additives) |

| Tool Replacement Cost | USD 50–100 saved per tool | Standard wear |

| Tool Wear Rate | 20–30% lower (due to superior lubrication) | Baseline |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

ElBadawy, N.K.; Nassef, M.G.A.; Maher, I.; Nassef, B.G.; Daha, M.A.; Pape, F.; Nassef, G.A. Nano-Enhanced Cactus Oil as an MQL Cutting Fluid: Physicochemical, Rheological, Tribological, and Machinability Insights into Machining H13 Steel. Lubricants 2025, 13, 267. https://doi.org/10.3390/lubricants13060267

ElBadawy NK, Nassef MGA, Maher I, Nassef BG, Daha MA, Pape F, Nassef GA. Nano-Enhanced Cactus Oil as an MQL Cutting Fluid: Physicochemical, Rheological, Tribological, and Machinability Insights into Machining H13 Steel. Lubricants. 2025; 13(6):267. https://doi.org/10.3390/lubricants13060267

Chicago/Turabian StyleElBadawy, Nada K., Mohamed G. A. Nassef, Ibrahem Maher, Belal G. Nassef, Mohamed A. Daha, Florian Pape, and Galal A. Nassef. 2025. "Nano-Enhanced Cactus Oil as an MQL Cutting Fluid: Physicochemical, Rheological, Tribological, and Machinability Insights into Machining H13 Steel" Lubricants 13, no. 6: 267. https://doi.org/10.3390/lubricants13060267

APA StyleElBadawy, N. K., Nassef, M. G. A., Maher, I., Nassef, B. G., Daha, M. A., Pape, F., & Nassef, G. A. (2025). Nano-Enhanced Cactus Oil as an MQL Cutting Fluid: Physicochemical, Rheological, Tribological, and Machinability Insights into Machining H13 Steel. Lubricants, 13(6), 267. https://doi.org/10.3390/lubricants13060267