Study of Corrosion, Power Consumption, and Wear Characteristics of Herringbone-Grooved Fan Bearings in High-Temperature and High-Humidity Environments

Abstract

1. Introduction

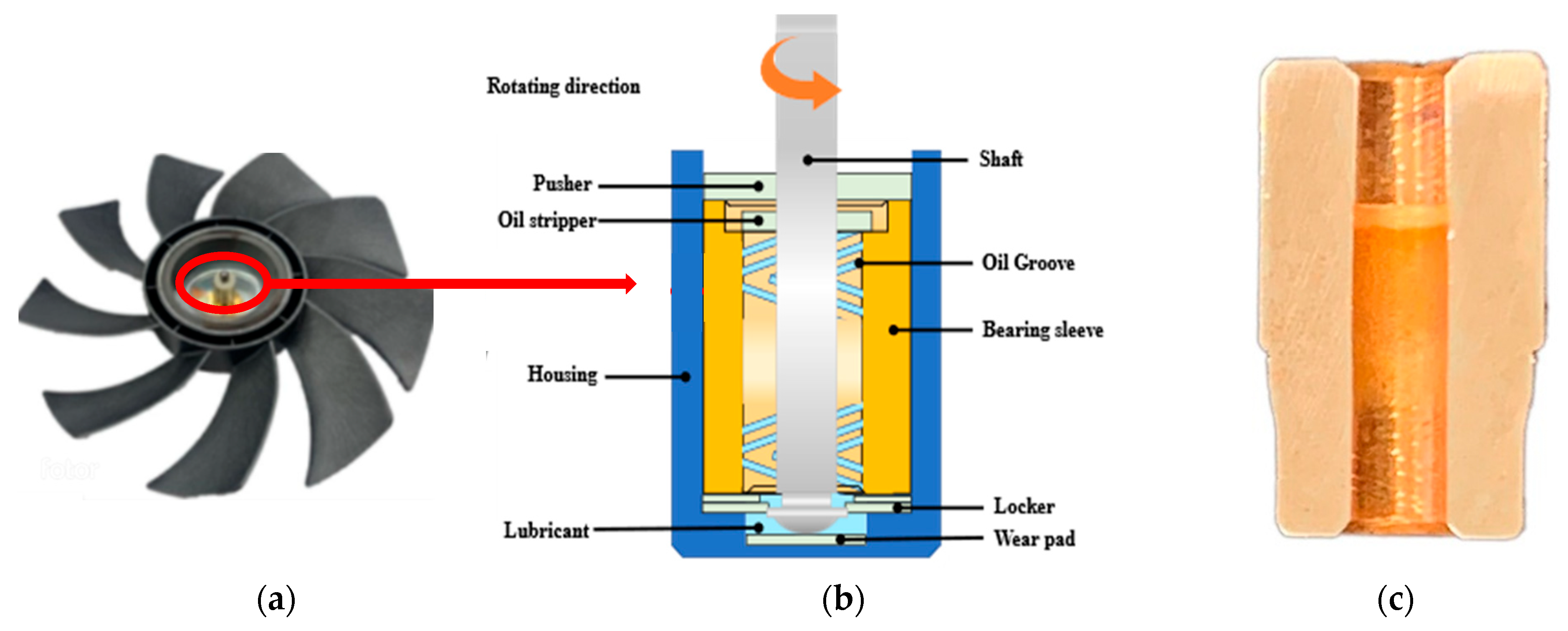

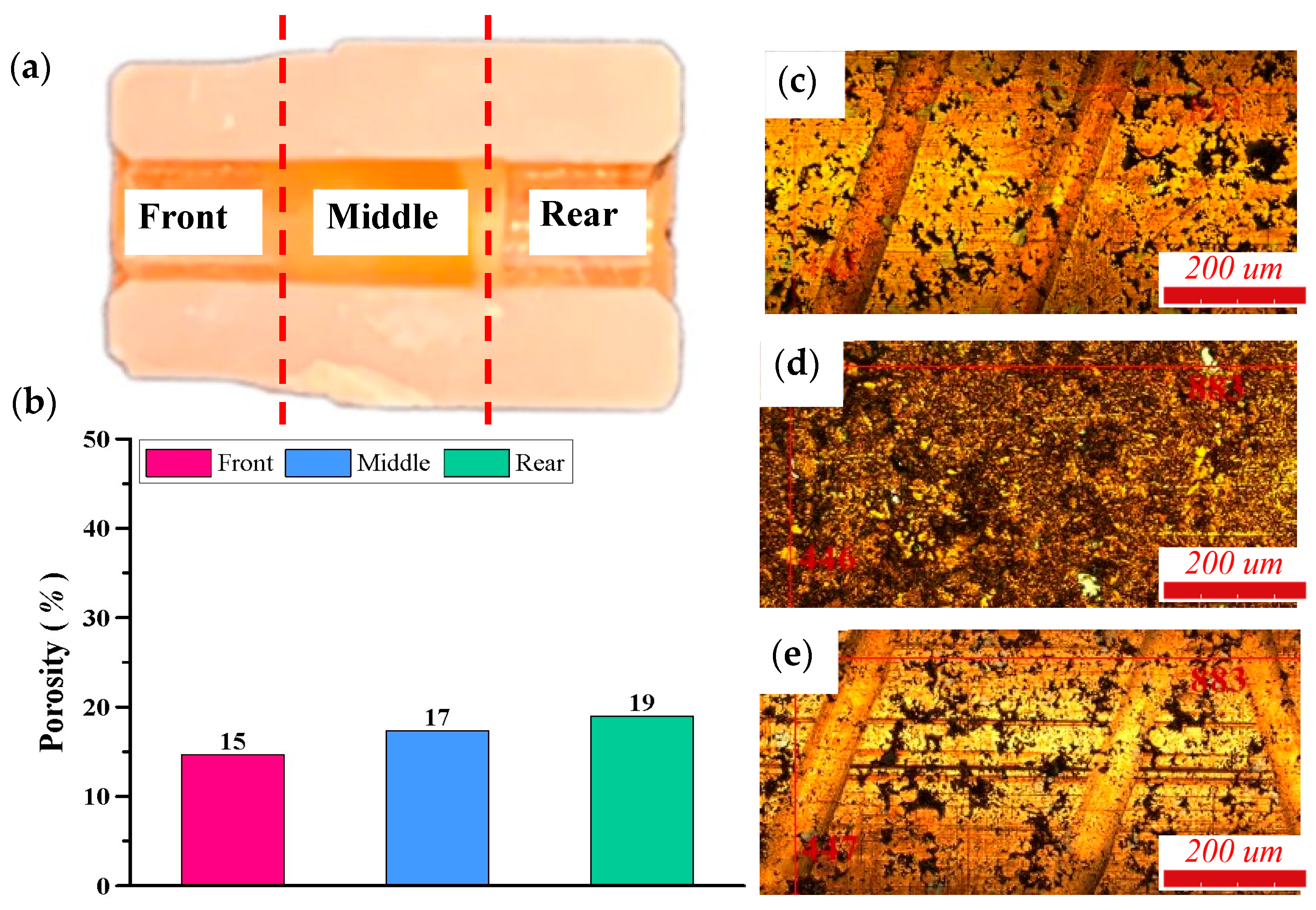

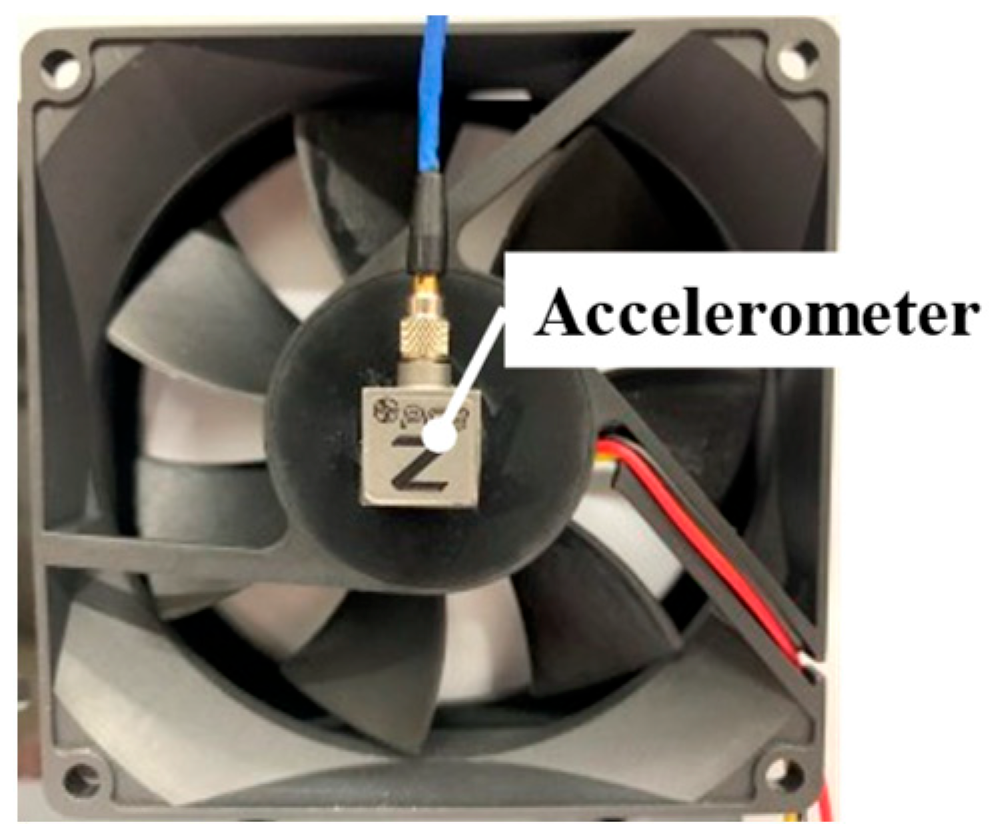

2. Experimental Methods and Workpiece

3. Results and Discussion

3.1. Measurement of Basic Properties

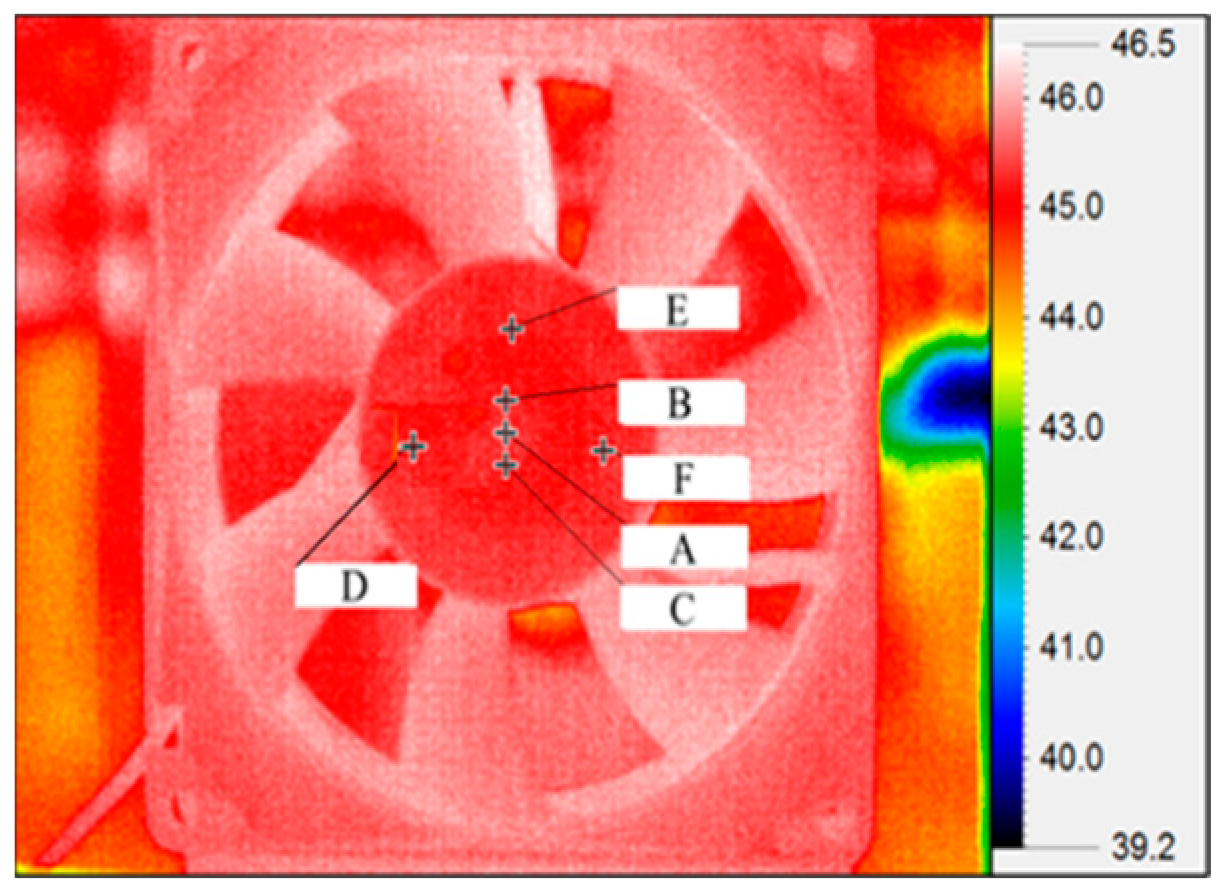

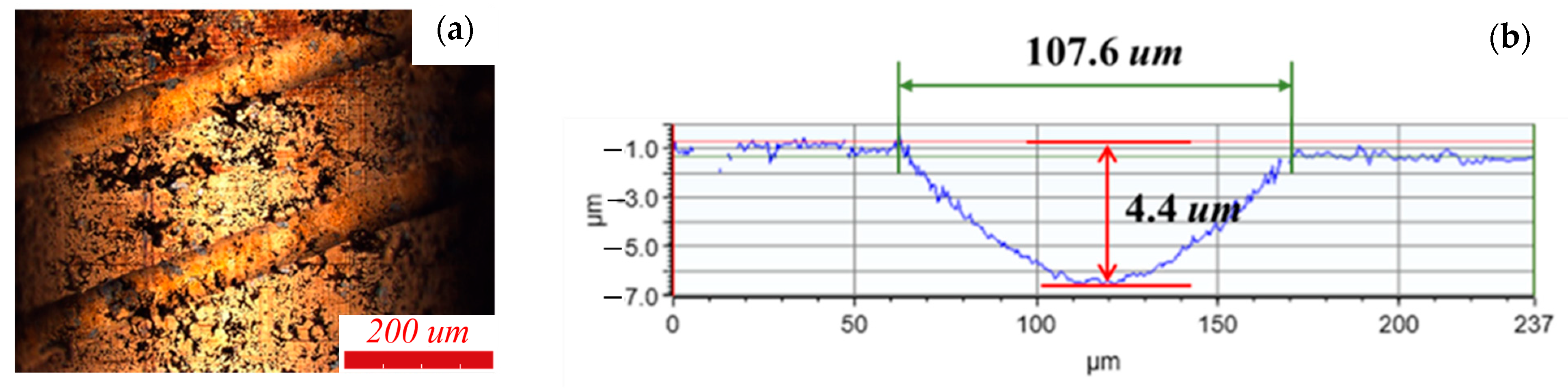

3.2. Performance of Porous Bearing Under High Temperatures and Humidity

4. Conclusions

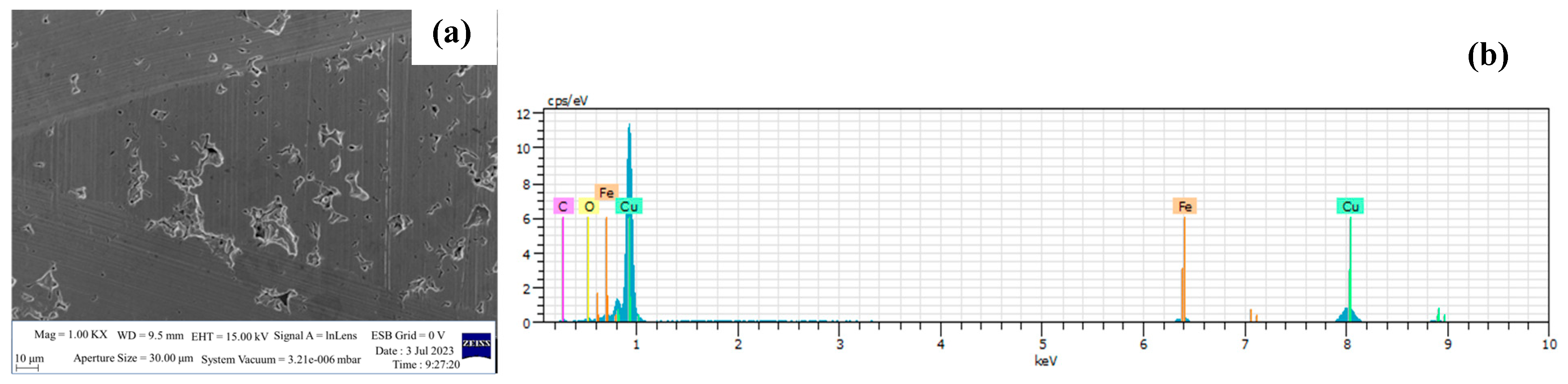

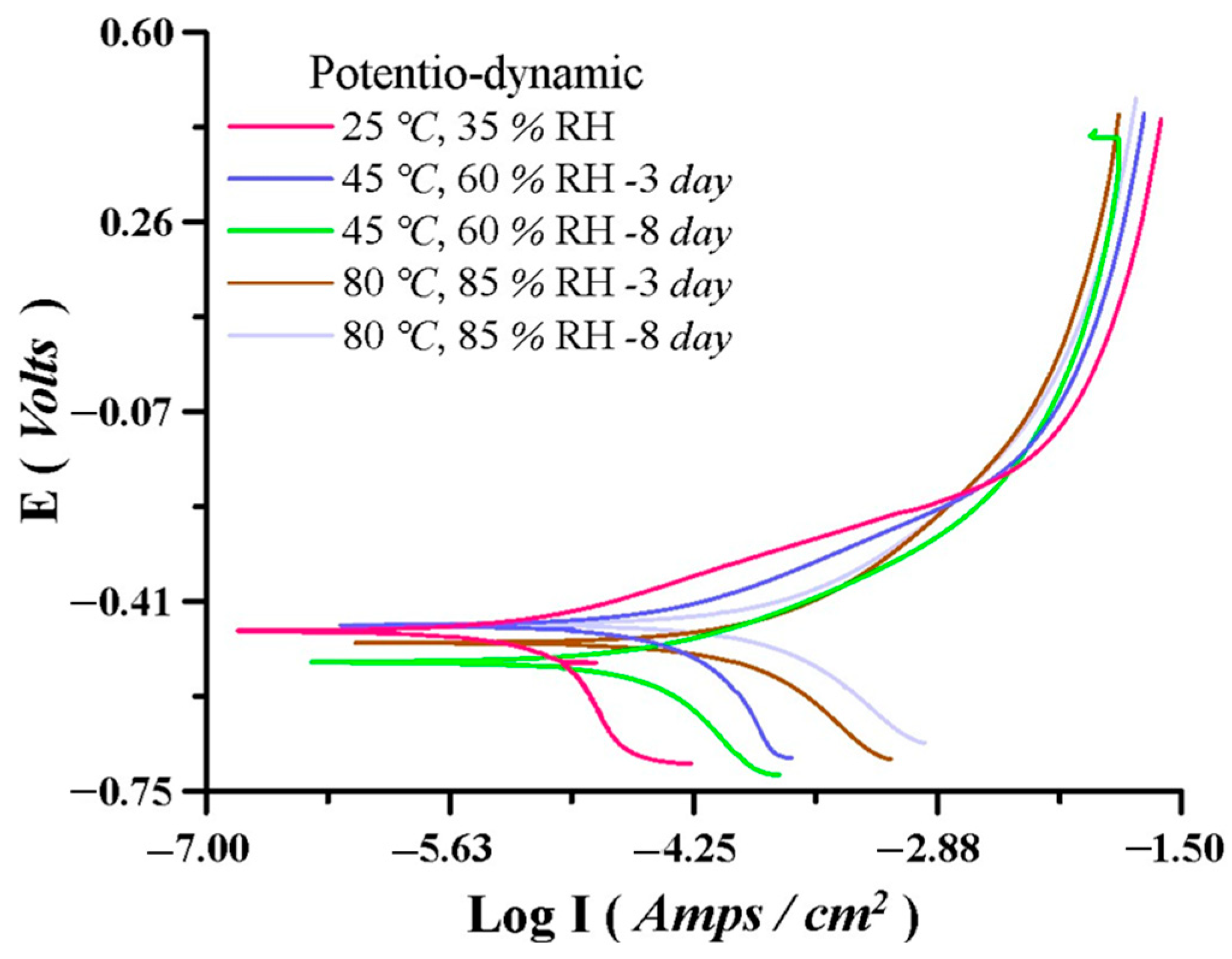

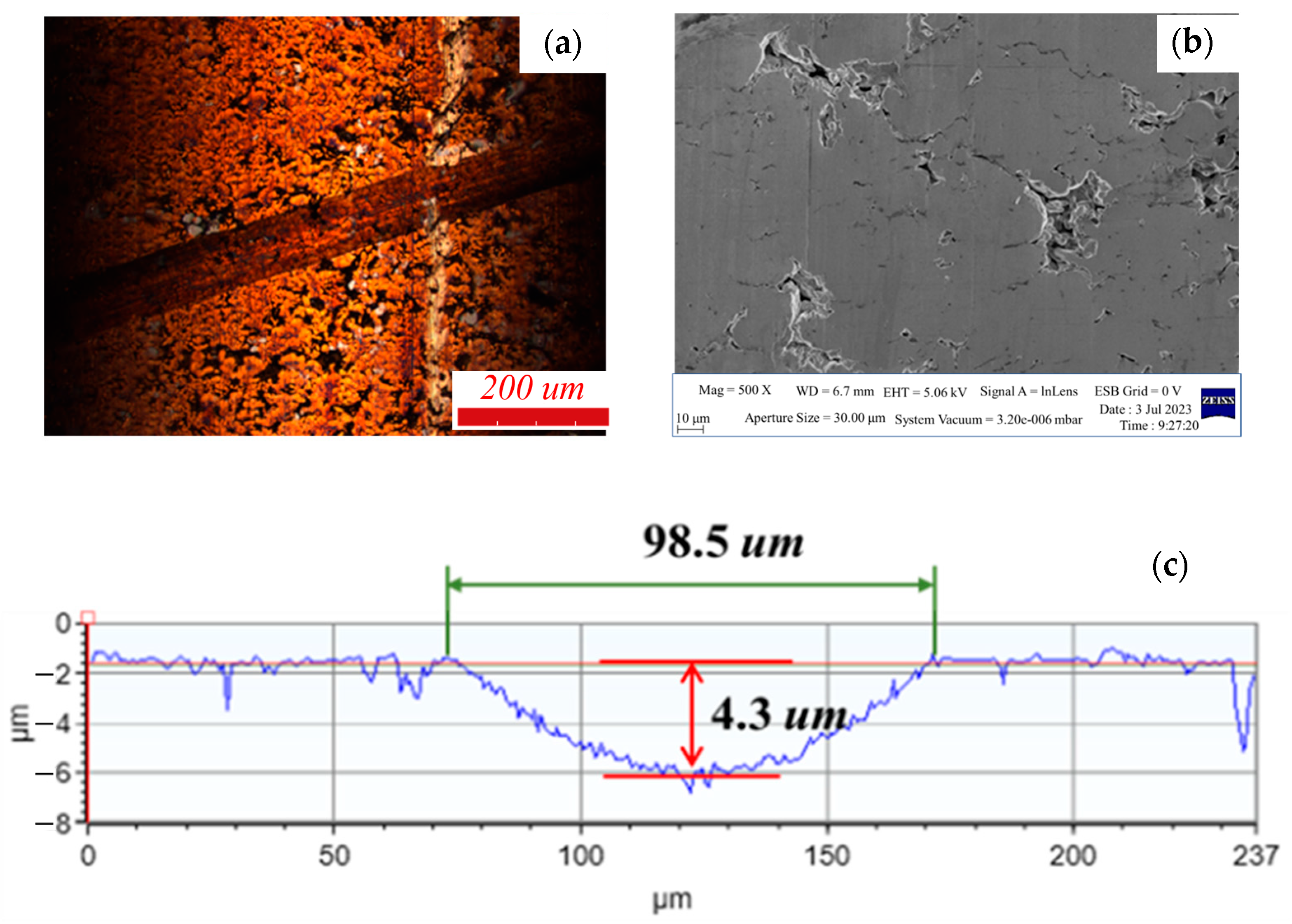

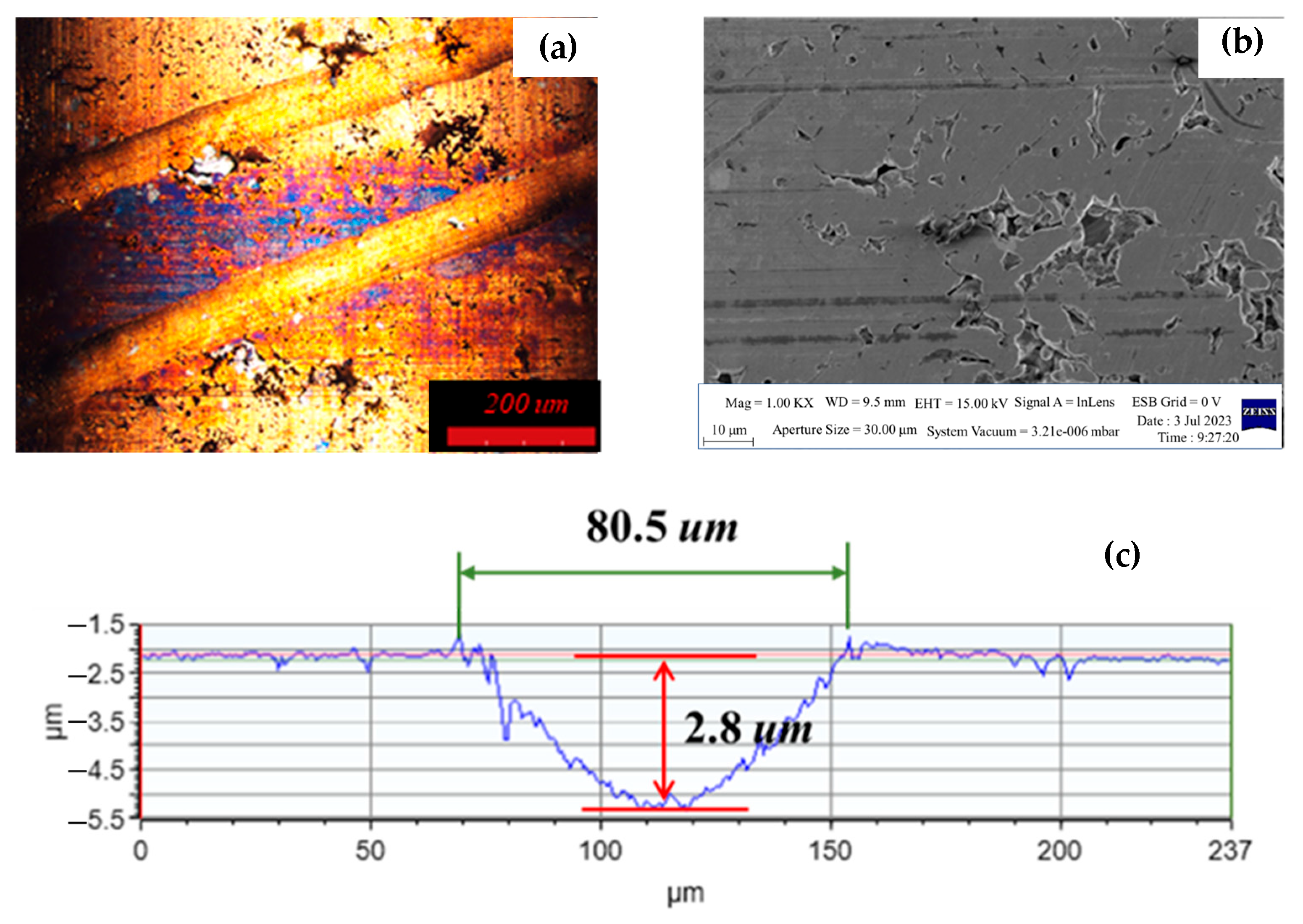

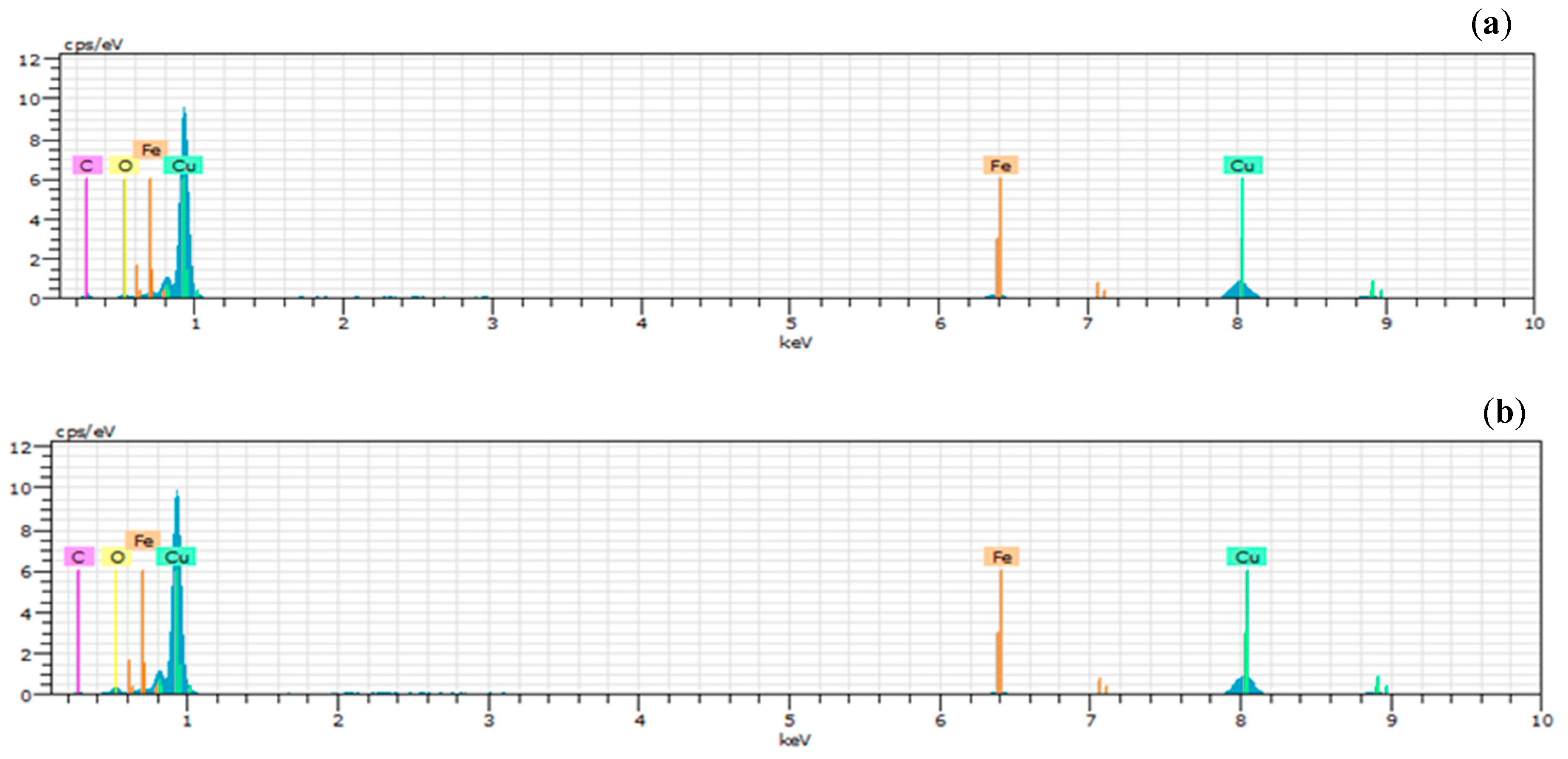

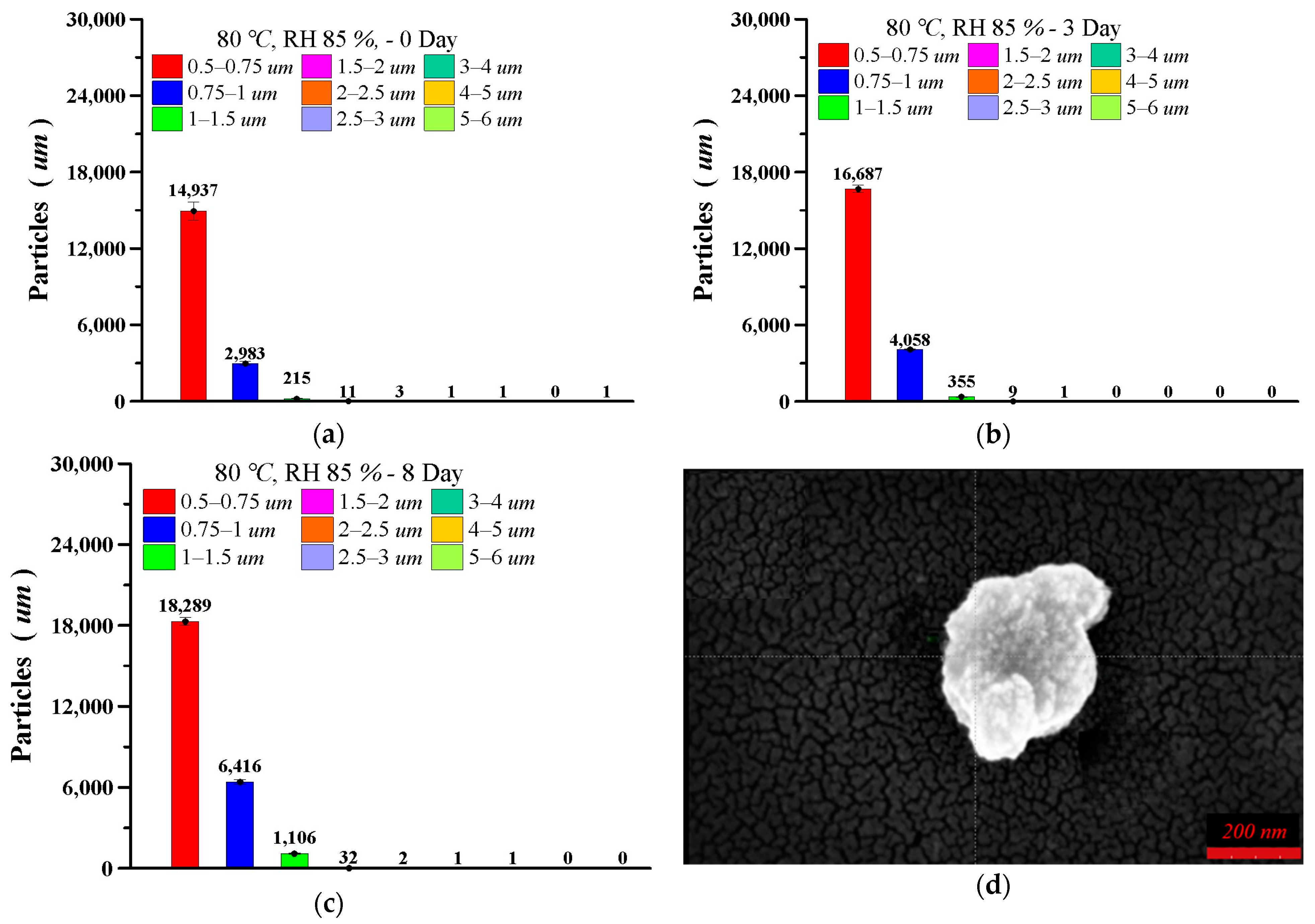

- Under high-temperature and high-humidity conditions (80 °C + 85% RH) for different operating durations, both corrosion and wear occur simultaneously, as evidenced by the corrosion current and surface wear marks. The severity of corrosion and wear increases with the number of operating days. Iron is the primary element subject to corrosion, resulting in a gradual decrease in its surface iron content.

- The powder metallurgy bearing subjected to high-temperature and high-humidity environments exhibits a significant increase in both power consumption and vibration RMS values with longer operating durations. After 8 days of operation in a high-temperature and high-humidity environment, the power consumption is 7.8% higher than that of a new bearing.

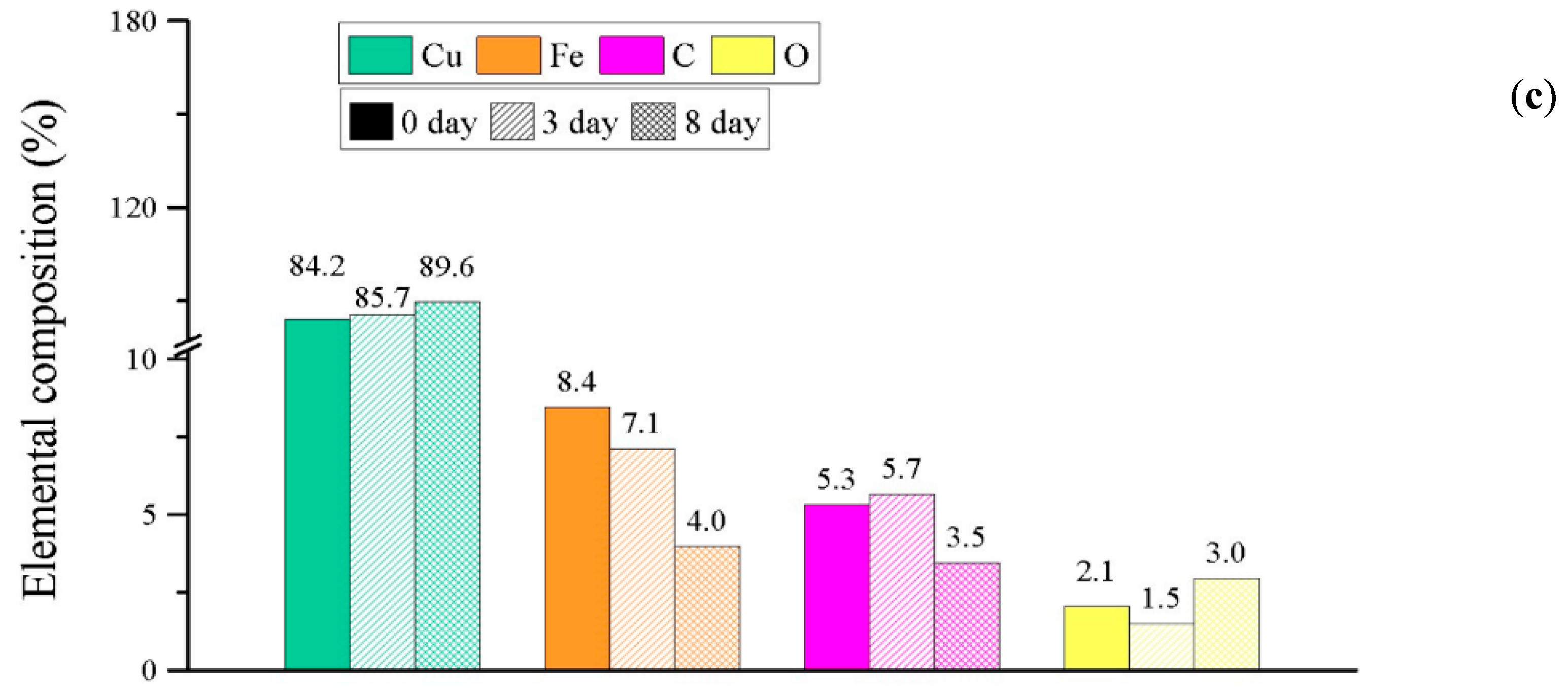

- As the operating duration of the bearing increases in a high-temperature and high-humidity environment, the number of wear debris particles of various sizes in the oil gradually increases. The wear debris particles are predominantly composed of copper.

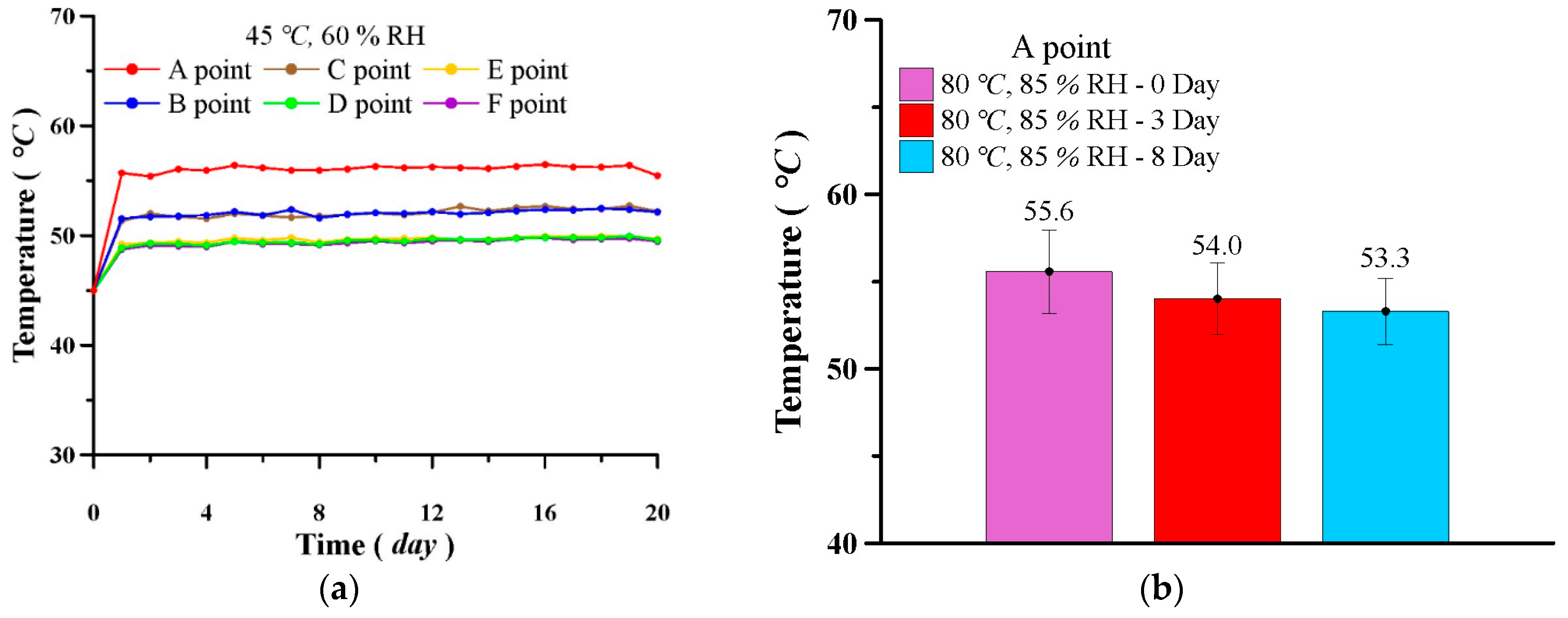

- The surface end cap temperature of the powder metallurgy bearing in this study exhibits a concentric circular temperature distribution, with the highest temperature at the center point and a gradual decrease in surface temperature with increasing distance from the center. As the operating duration of the powder metallurgy bearing in a high-temperature and high-humidity environment increases, wear and corrosion lead to a reduction in the shaft’s diameter, an increase in bearing clearance, and enhanced heat dissipation, resulting in a decrease in surface temperature.

- Based on the industrial demands for high-temperature and high-humidity environments and the experimental results of this paper, the impact of corrosion wear debris creating a three-body interface on porous bearing performance will be an important direction for future research. Furthermore, at the three-body interface, the influence of high-speed conditions to enhance heat dissipation is also a parameter to be considered in future studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, J.A.; Lawley, A.; Smith, W.E.; Robertson, J.M. Structure property and performance relations in self-lubricating bronze bearings: Commercial premixes. Int. J. Powder Metall. 1986, 22, 149–162. [Google Scholar]

- Cantor, B.; Kim, K.B.; Warren, P.J. Novel multicomponent amorphous alloys. J. Metastable Nanocrystalline Mater. 2002, 13, 27–32. [Google Scholar] [CrossRef]

- Chaira, D. Powder metallurgy routes for composite materials production. Encycl. Mater. Compos. 2021, 2, 588–604. [Google Scholar] [CrossRef]

- Luan, W.; Liu, Y.; Wang, Y.; Xu, F. Effect of herringbone groove structure parameters on the static performance of gas foil herringbone groove thrust bearings. Tribol. Int. 2023, 177, 107979. [Google Scholar] [CrossRef]

- Schlums, H.; Hühne, C.; Sinapius, M. Design of a Herringbone-Grooved Bearing for Application in an Electrically Driven Air Compressor. Machines 2022, 10, 662. [Google Scholar] [CrossRef]

- Mishra, H.P.; Behera, S.K. Design of herringbone grooved thrust bearing for locomotive turbocharger rotor. Eng. Res. Express 2024, 6, 025558. [Google Scholar] [CrossRef]

- Cameron, A.; Morgan, T.V.; Stainsby, E.A. Critical conditions of hydrodynamic lubrication of porous metal bearings. Proc. Inst. Mech. Eng. 1960, 176, 761–770. [Google Scholar] [CrossRef]

- Cusano, C.; Phelan, R.M. Experimental investigation of porous bronze bearings. J. Lubr. Technol. 1973, 95, 173–180. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Fushchich, O.I.; Danyluk, S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 2012, 290–291, 106–123. [Google Scholar] [CrossRef]

- Suman, P.; Bannaravuri, P.K.; Baburao, G.; Kandavalli, S.R.; Alam, S.; Raju, M.S.; Pulisheru, K.S. Integrity on properties of Cu-based composites with the addition of reinforcement: A review. Mater. Today Proc. 2021, 19, 6609–6613. [Google Scholar] [CrossRef]

- Pelletiers, T.; Nadkarni, A.; Ijeoma, R.; Murphy, T. Improving performance from self-lubricating bronze bearings. Met. Powder Rep. 2007, 62, 26–31. [Google Scholar] [CrossRef]

- Durak, E. Experimental investigation of porous bearings under different lubricant and lubricating conditions. KSME Int. J. 2003, 17, 1276–1286. [Google Scholar] [CrossRef]

- Wei, X.U.; Rui, H.U.; Li, J.S. Tribological behavior of CNTs-Cu and graphite- Cu composites with electric current. Trans. Nonferrous Met. Soc. China 2012, 22, 78–84. [Google Scholar] [CrossRef]

- Unlu, B.S. Tribological and mechanical properties of PM journal bearings. Powder Metall. 2011, 54, 338–342. [Google Scholar] [CrossRef]

- Parveez, B.; Wani, M.F. Tribological behaviour of nano-zirconia reinforced iron-based self-lubricating composites for bearing applications. Tribol. Int. 2021, 159, 106969. [Google Scholar] [CrossRef]

- Tomioka, J.; Miyanaga, N. Stability Threshold of Herringbone Grooved Aerodynamic Journal Bearings with External Stiffness and Damping Elements. J. Adv. Mech. Des. Syst. Manuf. 2013, 7, 876–887. [Google Scholar] [CrossRef][Green Version]

- Pawlak, Z.; Urbaniak, W.; Kaldonski, T.; Oloyede, A. Importance of bearing porosity in engineering and natural lubrication. In Biomaterials and Medical Tribology; Woodhead Publishing: Sawston, UK, 2013; pp. 311–354. [Google Scholar] [CrossRef]

- Jang, G.H.; Yoon, J.W. Dynamic characteristics of a coupled journal and thrust hydrodynamic bearing in a HDD spindle system due to its groove location. Microsyst. Technol. 2002, 8, 261–270. [Google Scholar] [CrossRef]

- Nabhan, A.; Rashed, A.; Ghazay, N.M.; Abdo, J.; Haneef, M.D. Tribological Properties of Al2O3 Nanoparticles as Lithium Grease Additives. Lubricants 2021, 9, 9. [Google Scholar] [CrossRef]

- Ta, T.N.; Horng, J.H.; Hwang, Y.L. Correlation between tribological and vibration behaviors in sliding lubricated contacts. ASME J. Tribol. 2022, 144, 111603. [Google Scholar] [CrossRef]

- Horng, J.H.; Yu, C.C.; Chen, Y.Y. Effect of third-particle material and contact mode on tribology contact characteristics at interface. Lubricants 2023, 11, 184. [Google Scholar] [CrossRef]

- Santos, F.I. Controllable sliding bearings and controllable lubrication principles—An overview. Lubricants 2018, 6, 16. [Google Scholar] [CrossRef]

- Horng, J.H.; Yu, C.C.; Chen, Y.Y. Tribological characteristics and load-sharing of point-contact interface in three-body mixed lubrication. ASME J. Tribol. 2022, 144, 052201. [Google Scholar] [CrossRef]

- Lu, C.R.; Wei, C.C.; Xiao, B.T. Transmission study of high-speed journal bearing with herringbone pattern. In Proceedings of the International Conference on Engineering Tribology and Applied Technology, Nantou, Taiwan, 18–20 October 2024; pp. 1–2. [Google Scholar]

- Chern, S.Y.; Ta, T.N.; Horng, J.H.; Wu, Y.S. Wear and vibration behavior of ZDDP-Containing oil considering scuffing failure. Wear 2021, 478-479, 203923. [Google Scholar] [CrossRef]

| Property | Value | |

|---|---|---|

| Viscosity (cSt) | 40 °C | 155.8 |

| 100 °C | 14.5 | |

| Density (g/cm3) | 20 °C | 0.979 |

| Condition | Corrosion Current (amp/cm2) |

|---|---|

| 25 °C + 35% RH | 1.29 × 10−6 |

| 45 °C + 35% RH—3 days | 1.38 × 10−5 |

| 45 °C + 35% RH—8 days | 1.41 × 10−5 |

| 80 °C + 35% RH—3 days | 6.04 × 10−5 |

| 80 °C + 35% RH—8 days | 7.55 × 10−5 |

| Element | Atom.% |

|---|---|

| C | 75.90 |

| O | 16.97 |

| Cu | 7.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeh, J.-C.; Lee, Y.-C.; Huang, C.-H.; Li, M.-Y.; Wei, C.-C. Study of Corrosion, Power Consumption, and Wear Characteristics of Herringbone-Grooved Fan Bearings in High-Temperature and High-Humidity Environments. Lubricants 2025, 13, 245. https://doi.org/10.3390/lubricants13060245

Yeh J-C, Lee Y-C, Huang C-H, Li M-Y, Wei C-C. Study of Corrosion, Power Consumption, and Wear Characteristics of Herringbone-Grooved Fan Bearings in High-Temperature and High-Humidity Environments. Lubricants. 2025; 13(6):245. https://doi.org/10.3390/lubricants13060245

Chicago/Turabian StyleYeh, Jim-Chwen, Yu-Chang Lee, Chun-Hsiang Huang, Ming-Yuan Li, and Chin-Chung Wei. 2025. "Study of Corrosion, Power Consumption, and Wear Characteristics of Herringbone-Grooved Fan Bearings in High-Temperature and High-Humidity Environments" Lubricants 13, no. 6: 245. https://doi.org/10.3390/lubricants13060245

APA StyleYeh, J.-C., Lee, Y.-C., Huang, C.-H., Li, M.-Y., & Wei, C.-C. (2025). Study of Corrosion, Power Consumption, and Wear Characteristics of Herringbone-Grooved Fan Bearings in High-Temperature and High-Humidity Environments. Lubricants, 13(6), 245. https://doi.org/10.3390/lubricants13060245