Tribological Aspects of Graphene and Its Derivatives

Abstract

1. Introduction

2. An Overview of Graphene and Its Derivatives

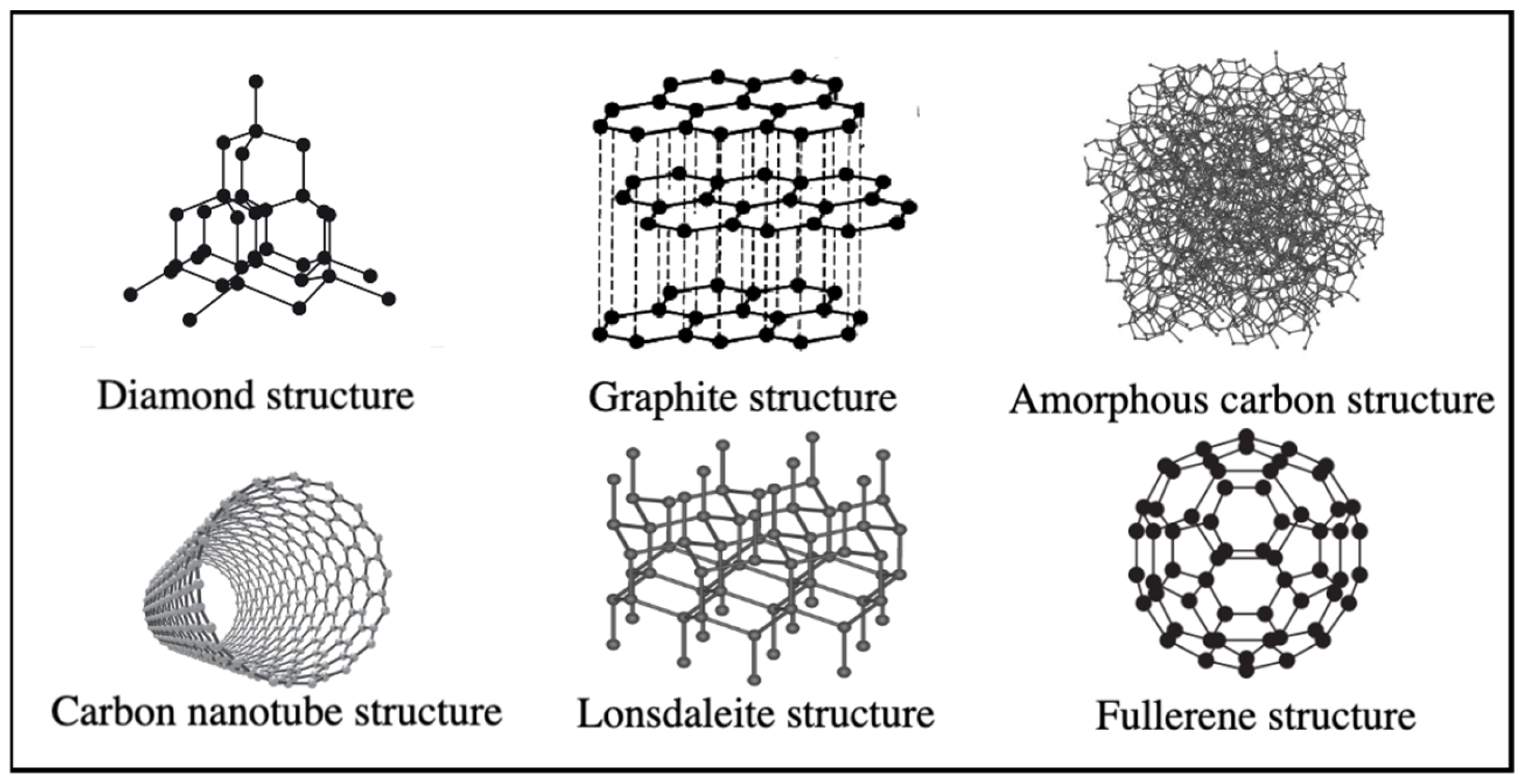

2.1. Carbon

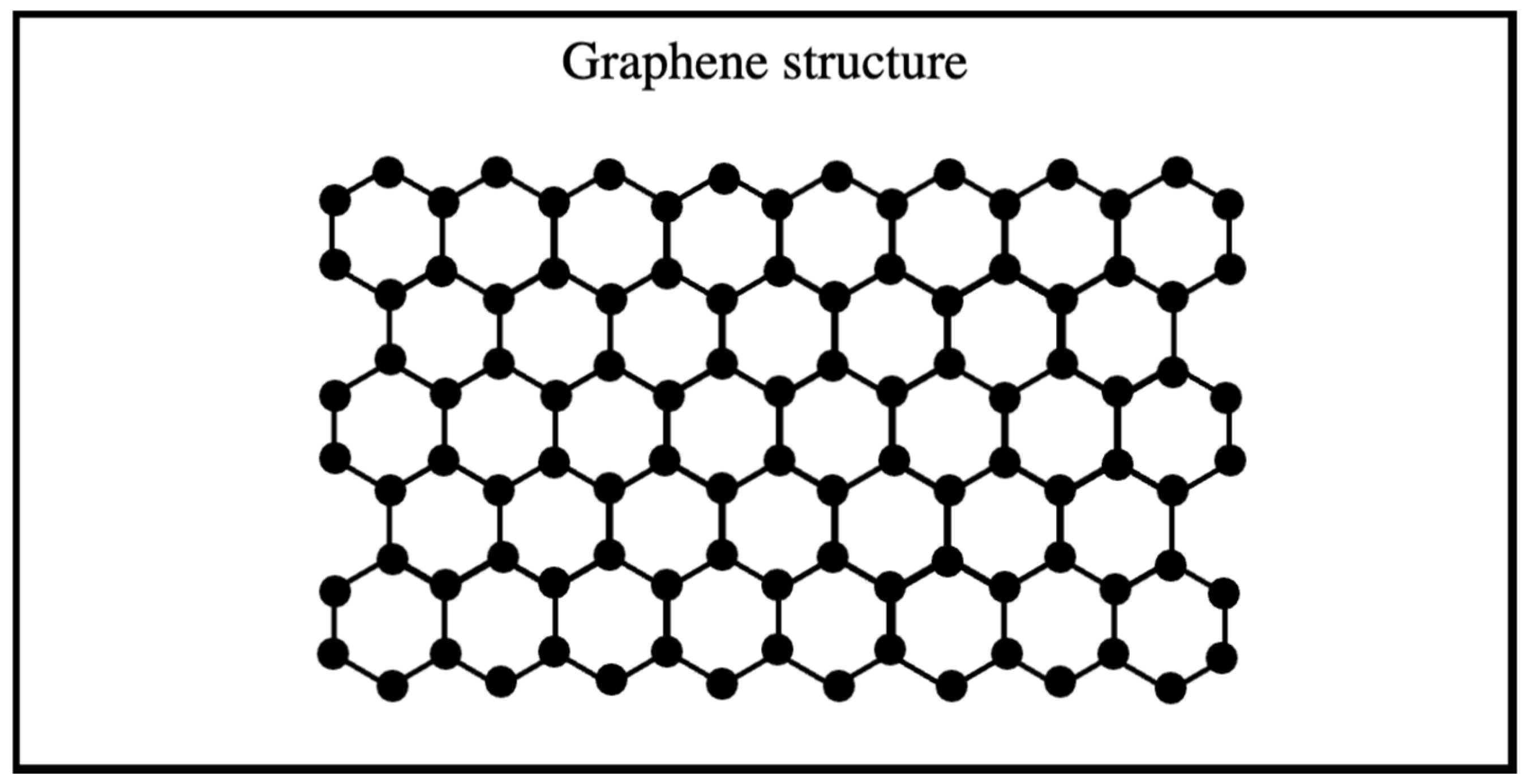

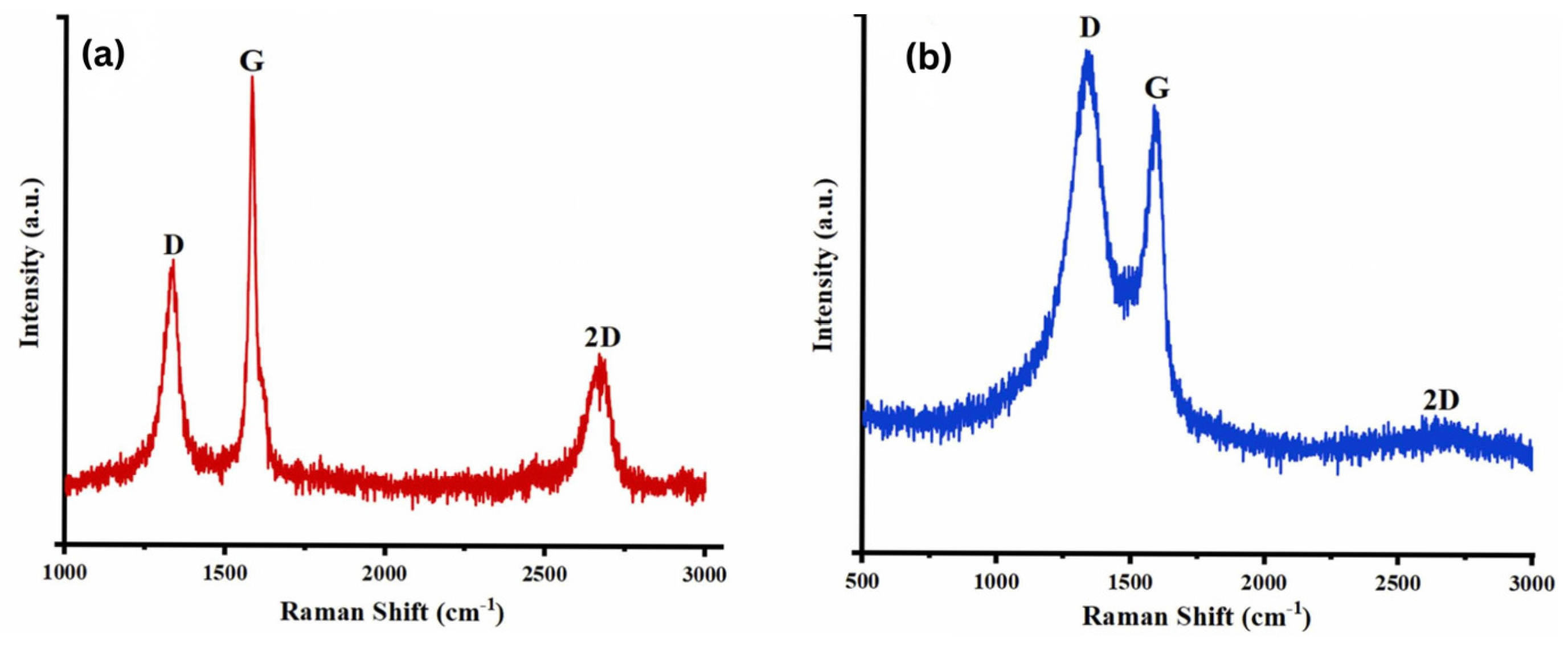

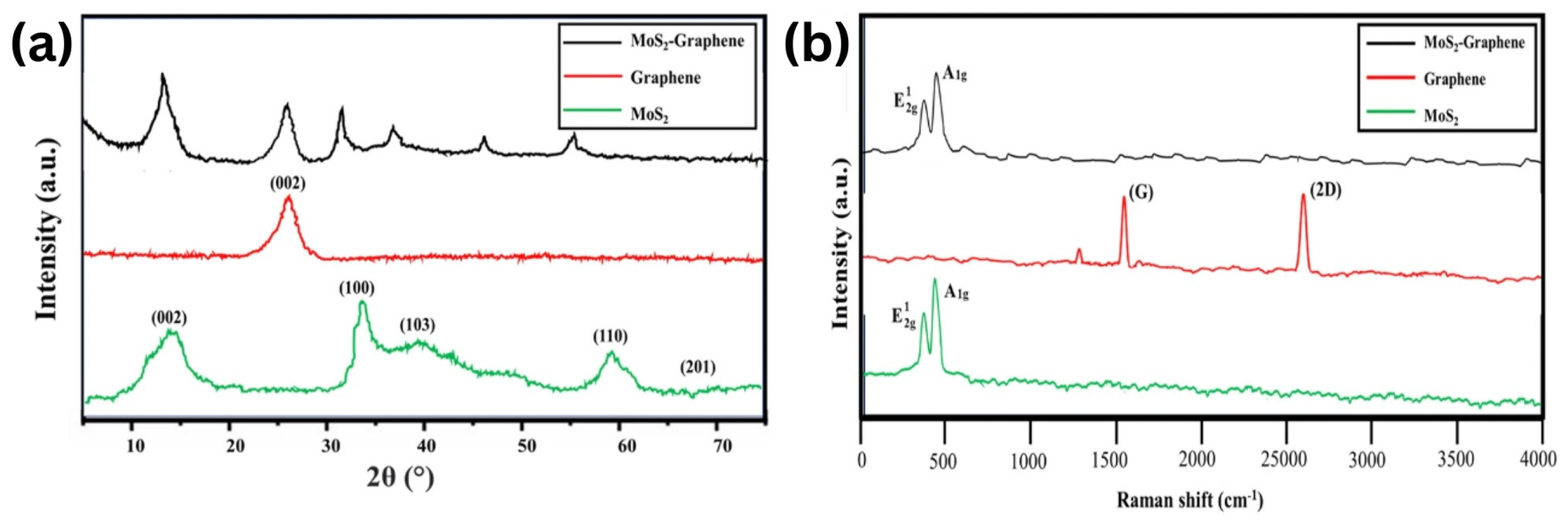

2.2. Graphene

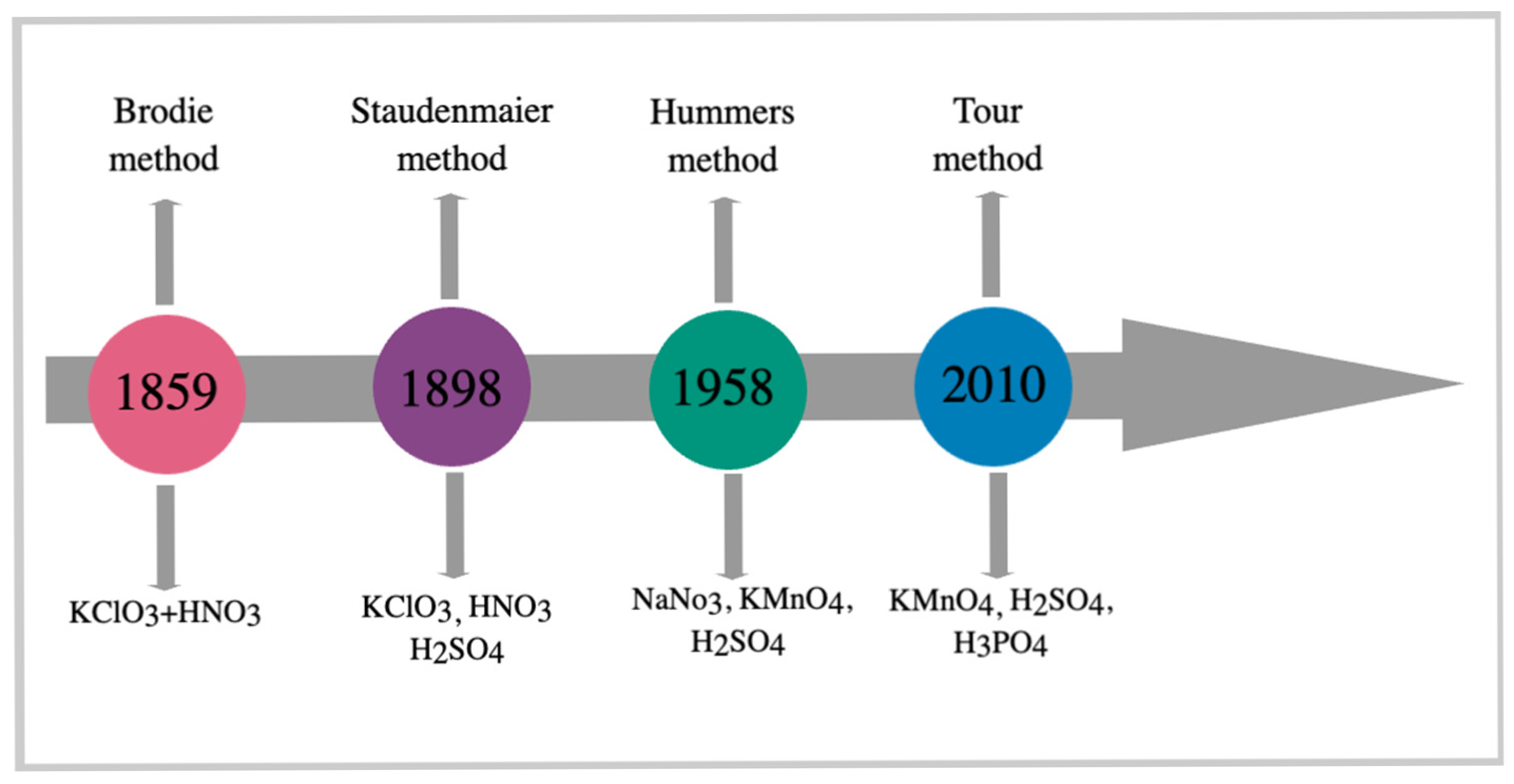

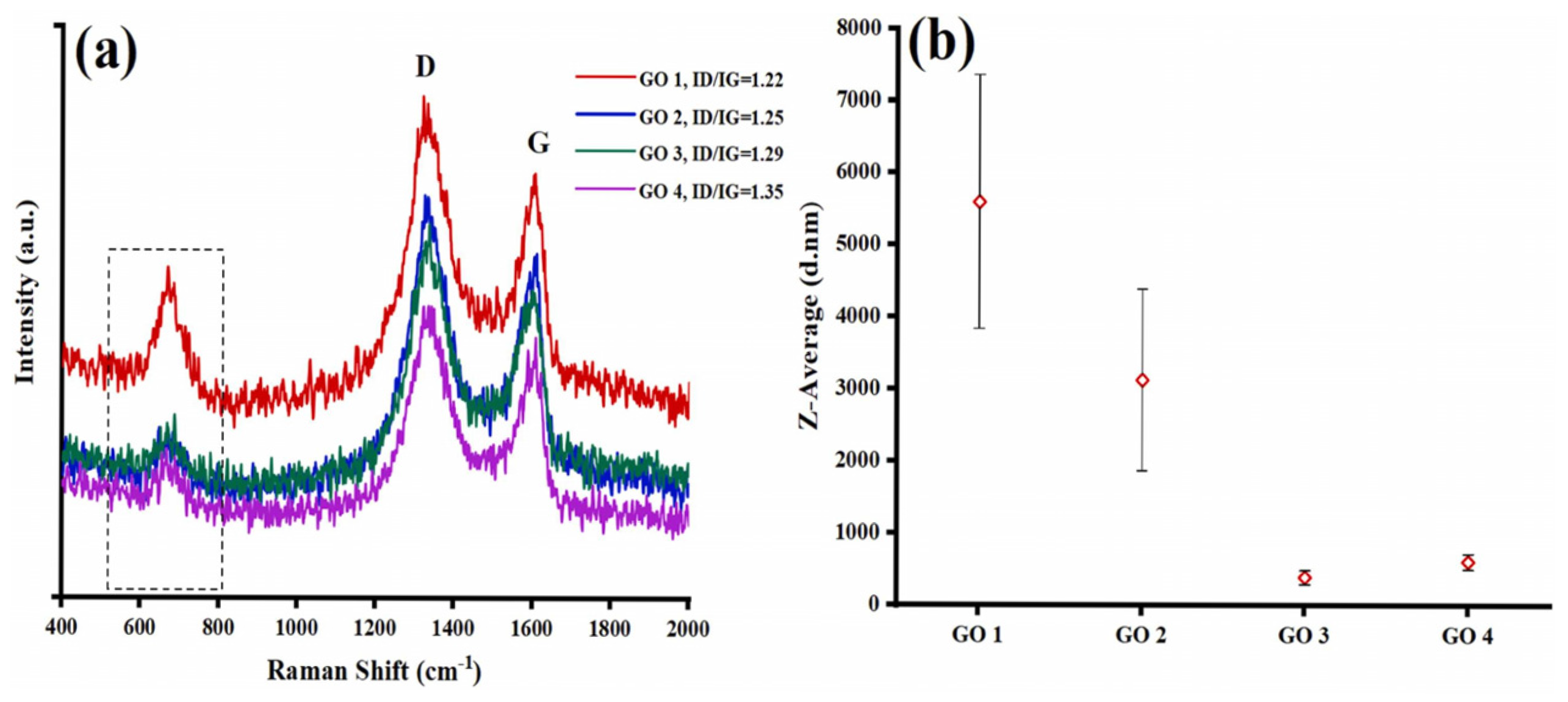

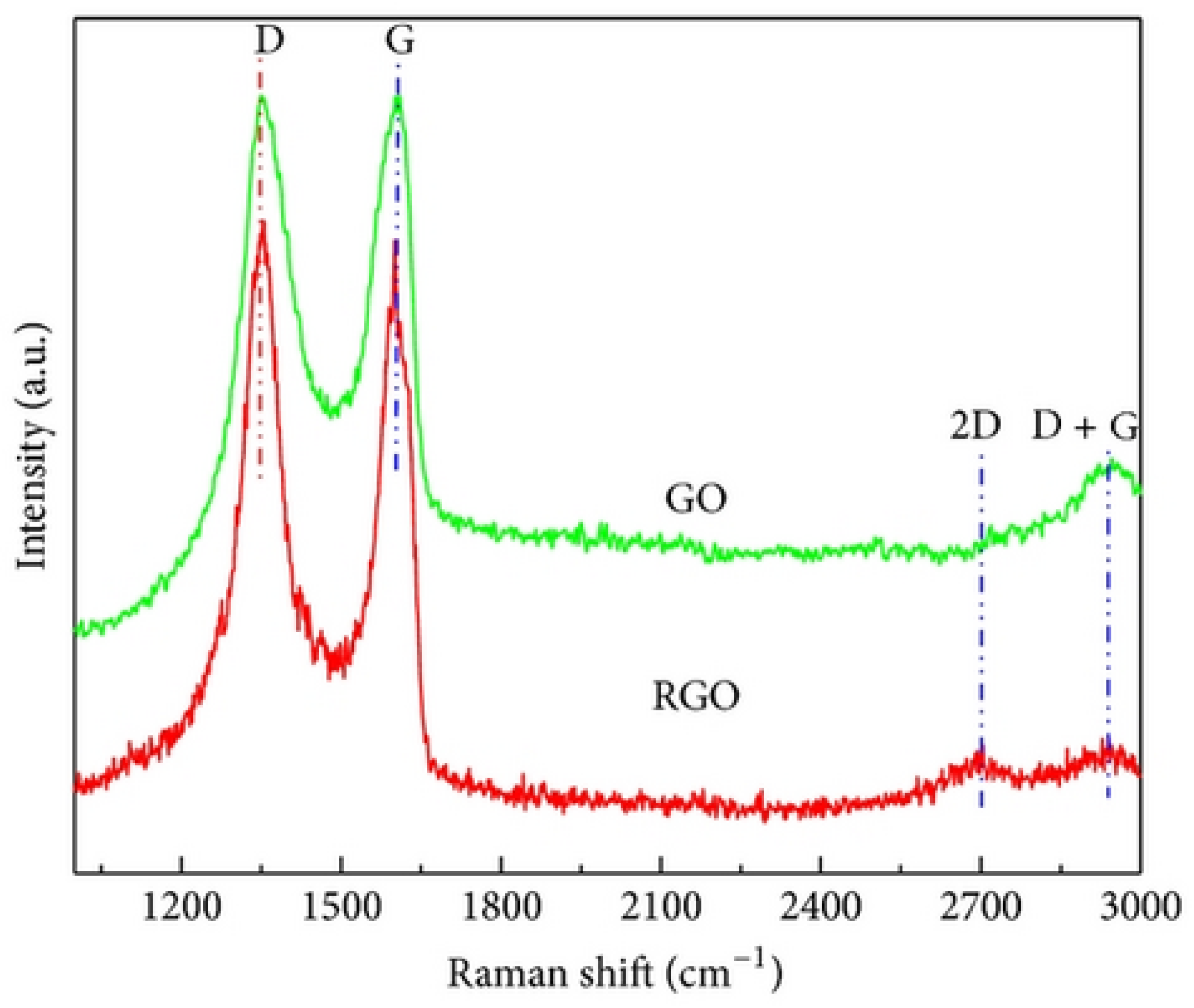

2.3. Graphene Oxide

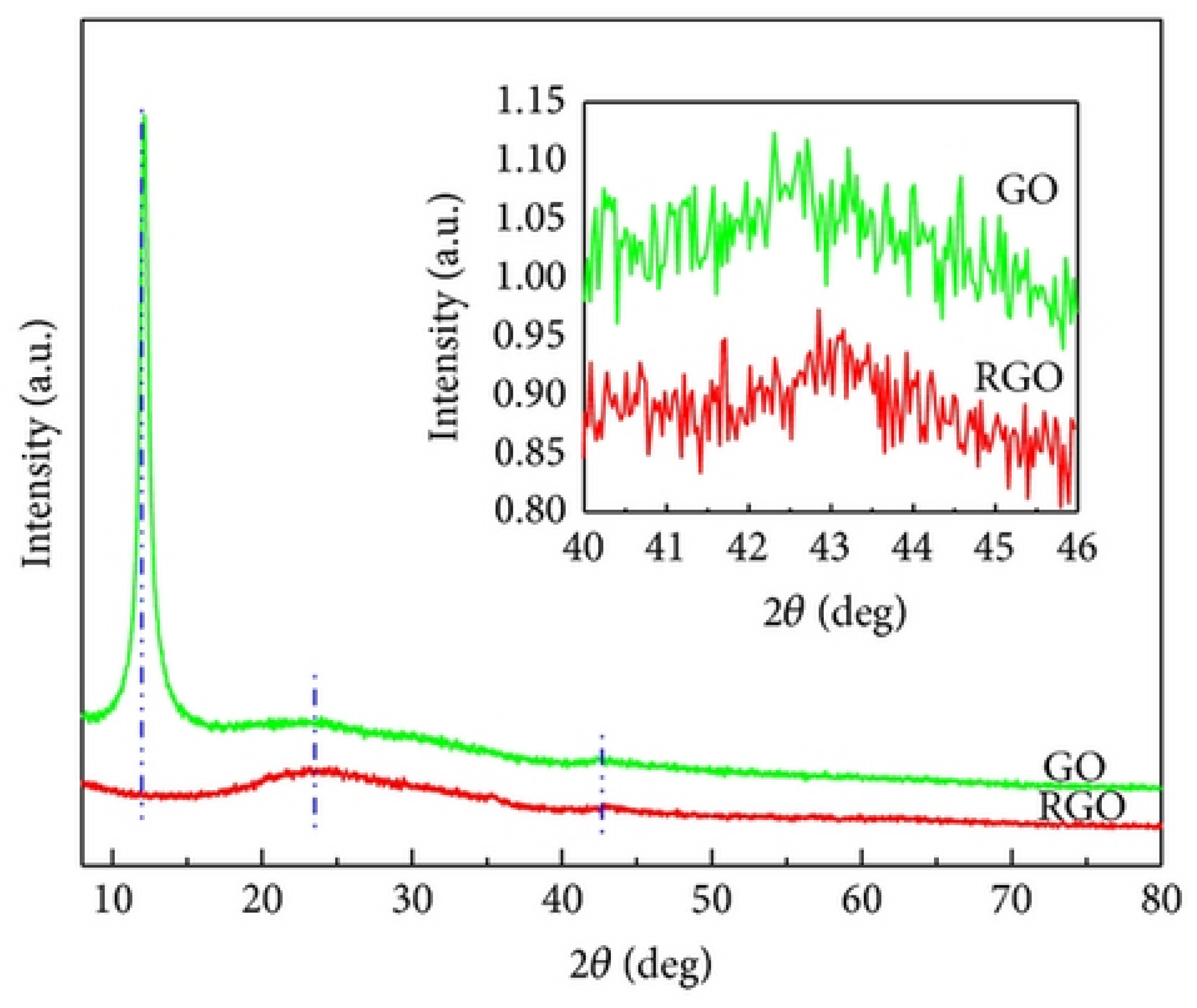

2.4. Reduced Graphene Oxide

3. Tribological Properties of Graphene

- Mechanical strength and thermal stability;

- Low coefficient of friction and surface energy, and well-established lubricity;

- High thermal and electrical conductivity;

- Chemical inertness and shield against abrasion and corrosion;

- Super-hydrophobic coatings;

- Thermal shielding;

- Compatibility with different fluids.

- High temperatures can cause wear debris and degrade graphene-based additives, underscoring the need for more research and their use in various liquid lubricants;

- The high cost and poor dispersion stability of graphene-based additives remain major challenges for their industrial application in liquid lubricants;

- There are no standard guidelines for producing additive compounds, and key parameters like particle size, layer number, type, and functional group concentration for specific applications are still unclear;

- Sulfur compounds present in commonly used organic and inorganic components, such as sodium dodecyl sulfate and molybdenum disulfide, in graphene-based nanomaterials may contribute to the release of pollutants. Additionally, optimizing graphene production methods is essential for cost reduction and enabling large-scale production of additives for future applications.

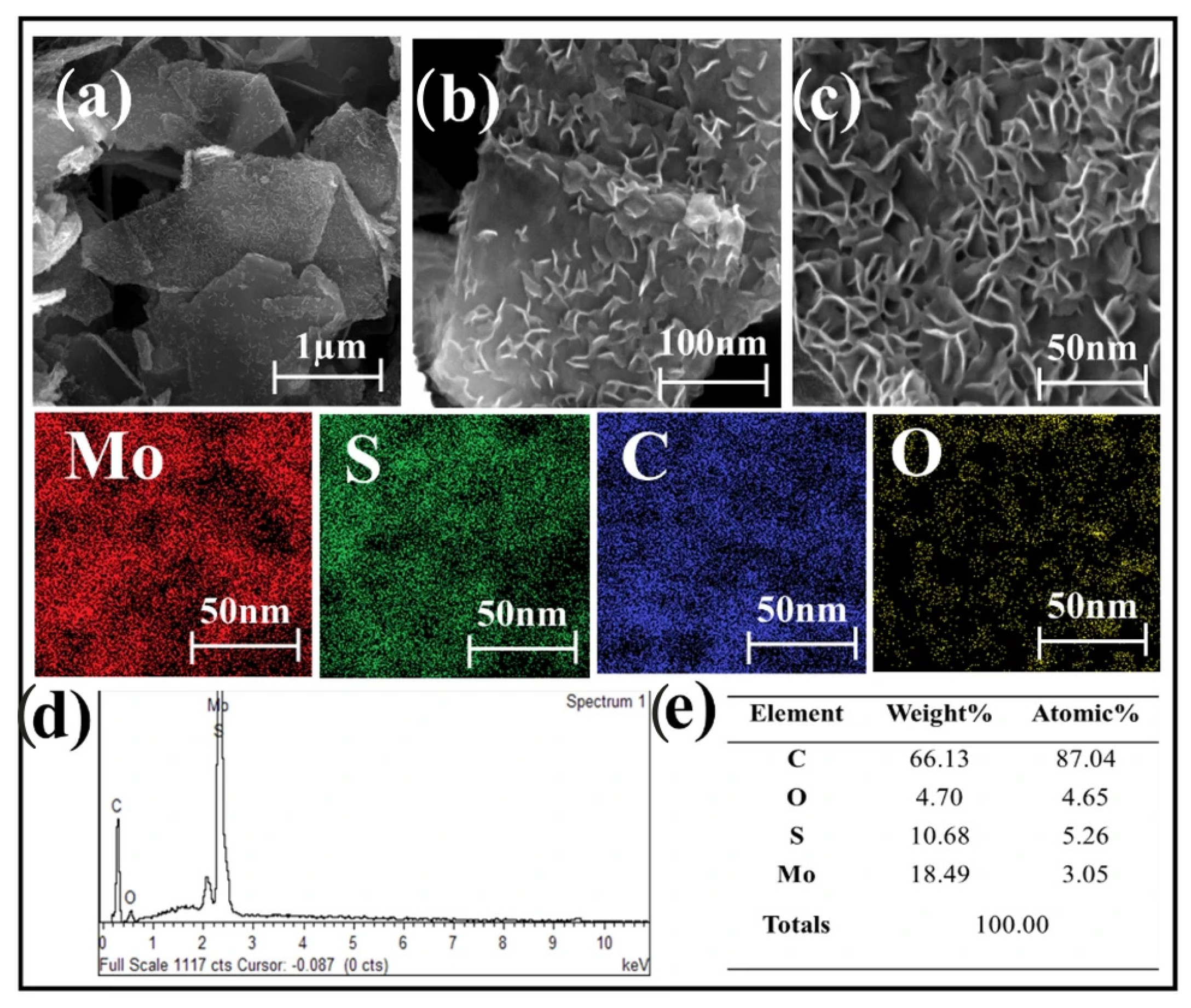

3.1. Graphene and Its Derivatives as an Additive

3.2. Green Reductants

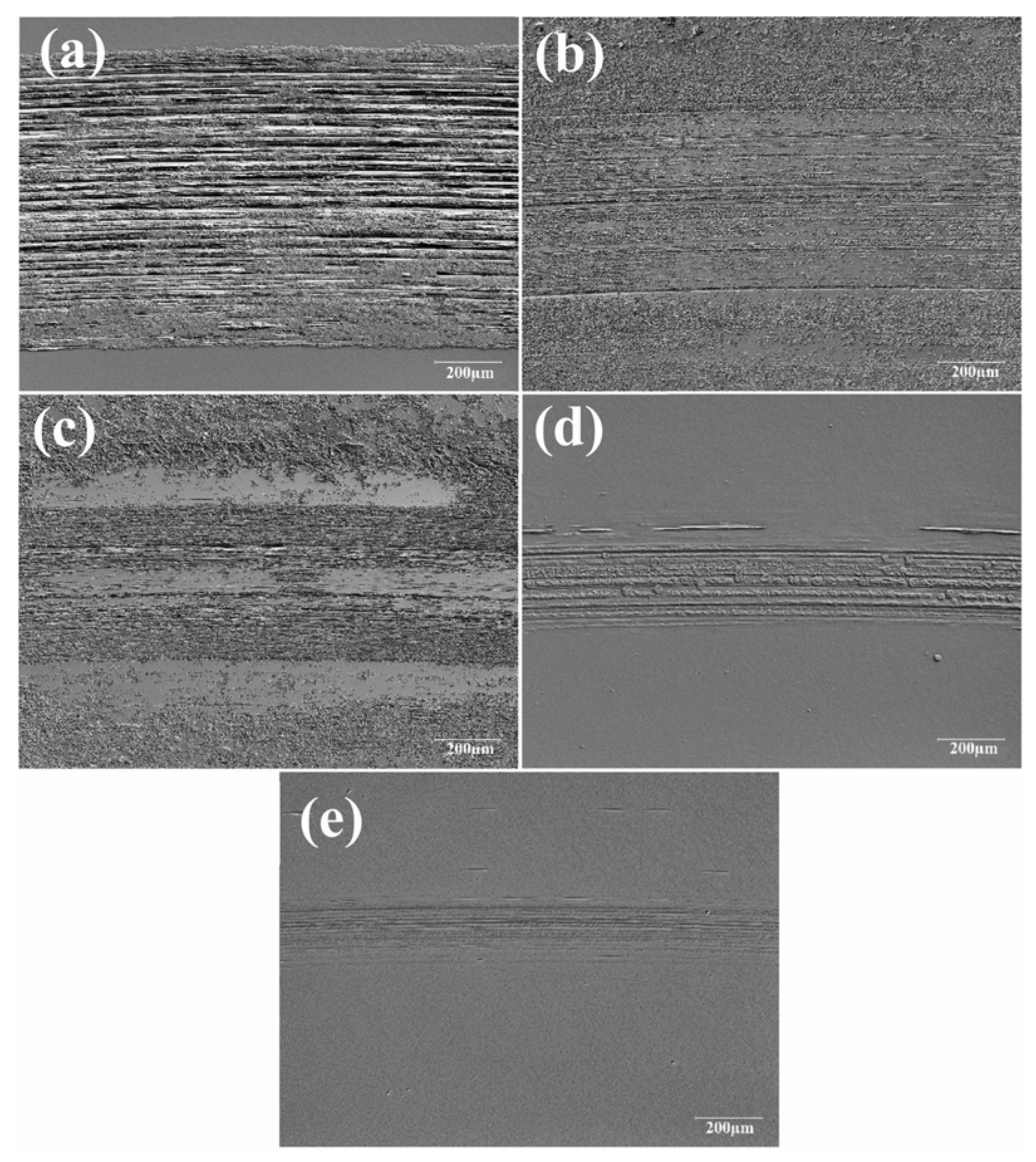

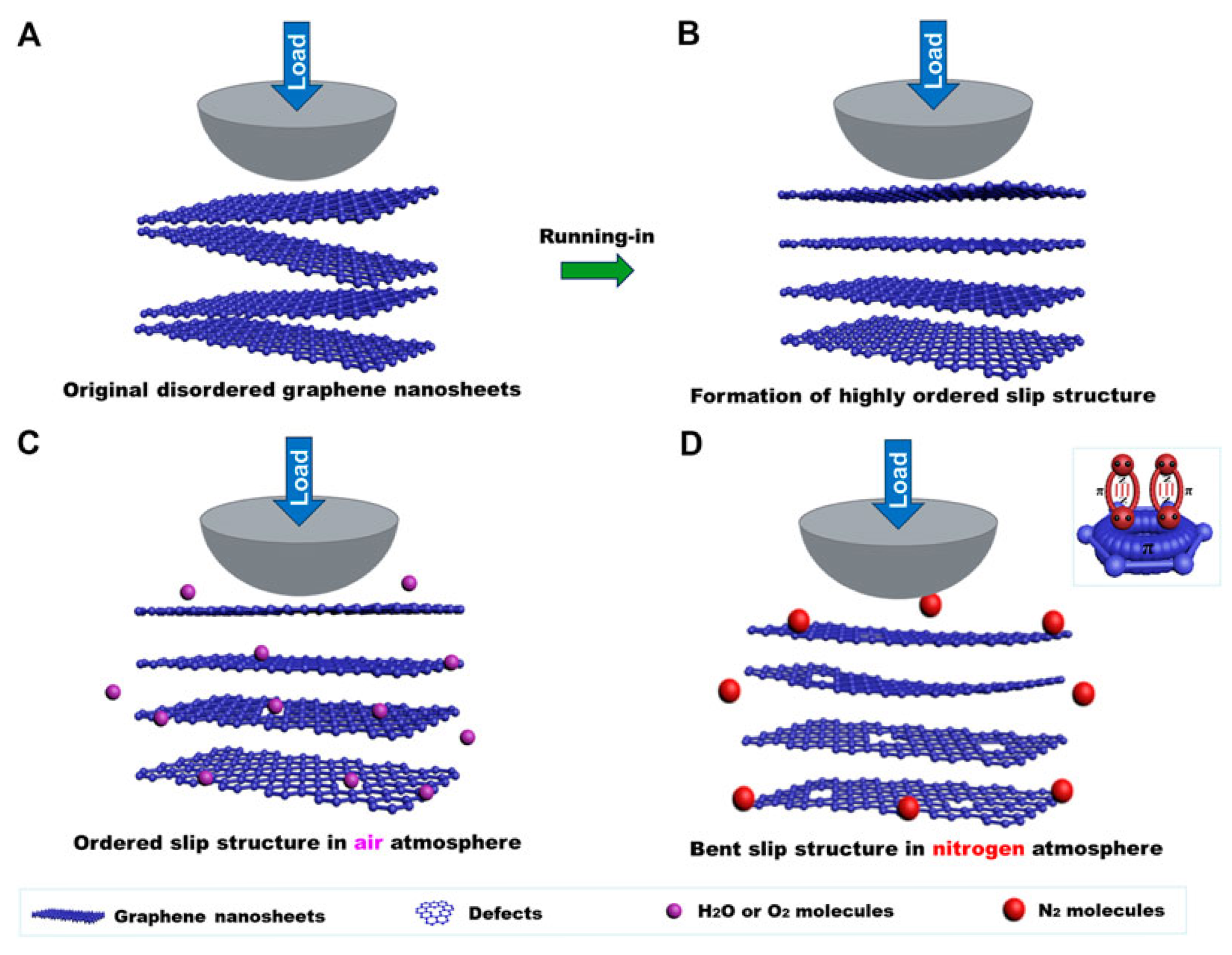

3.3. The Macrotribological Examination of Graphene and Its Derivatives

3.4. The Microtribological Examination of Graphene and Its Derivatives

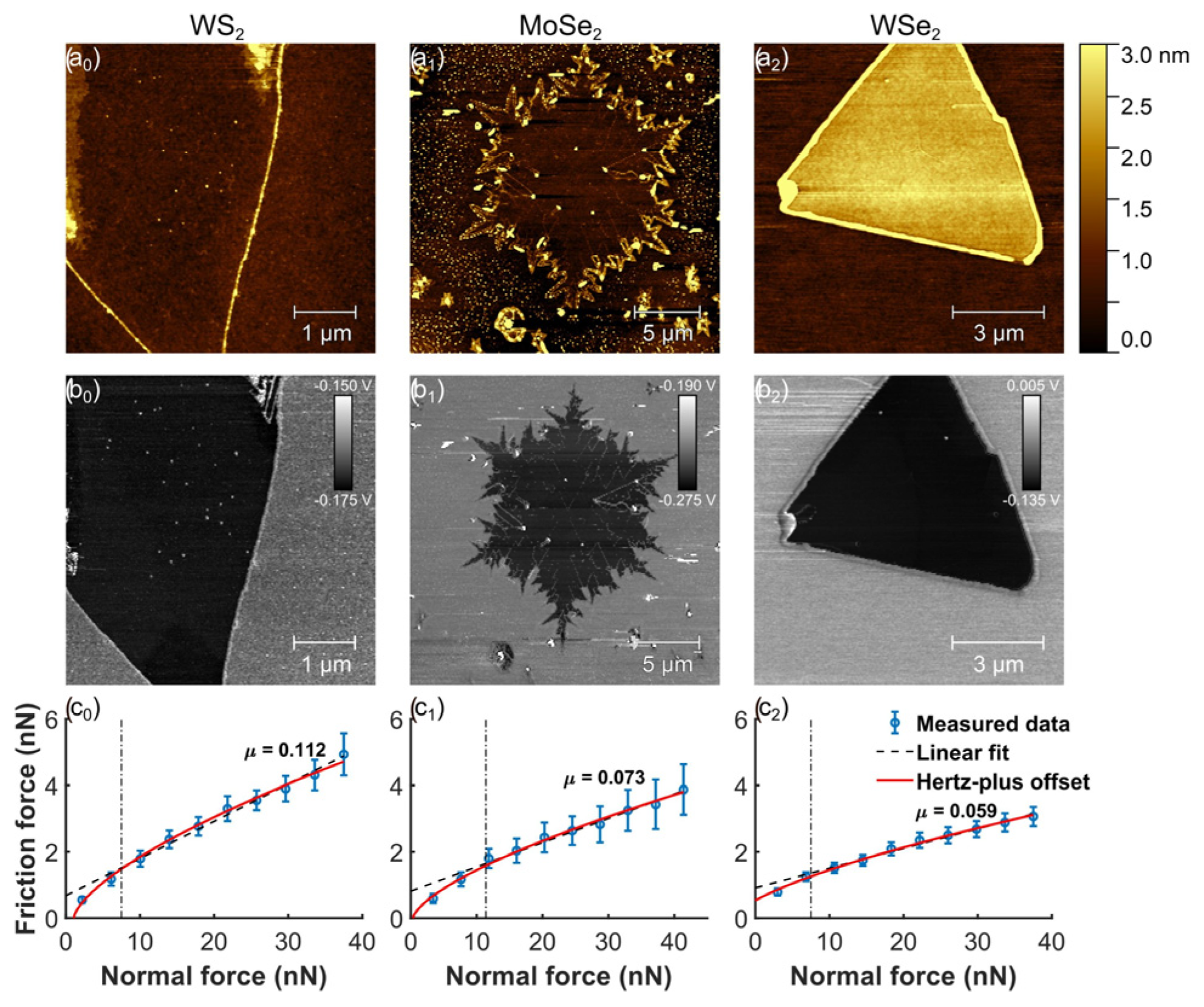

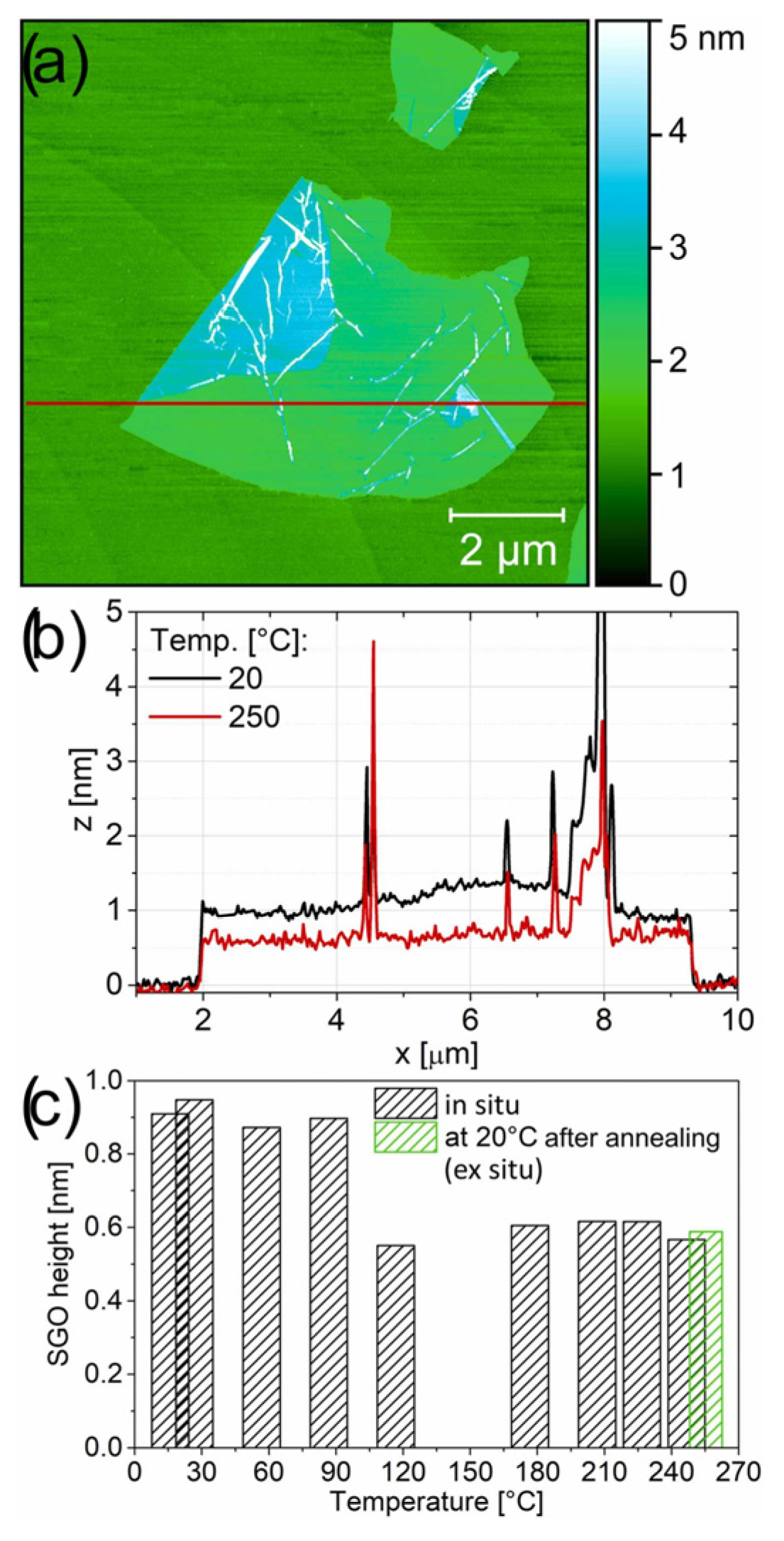

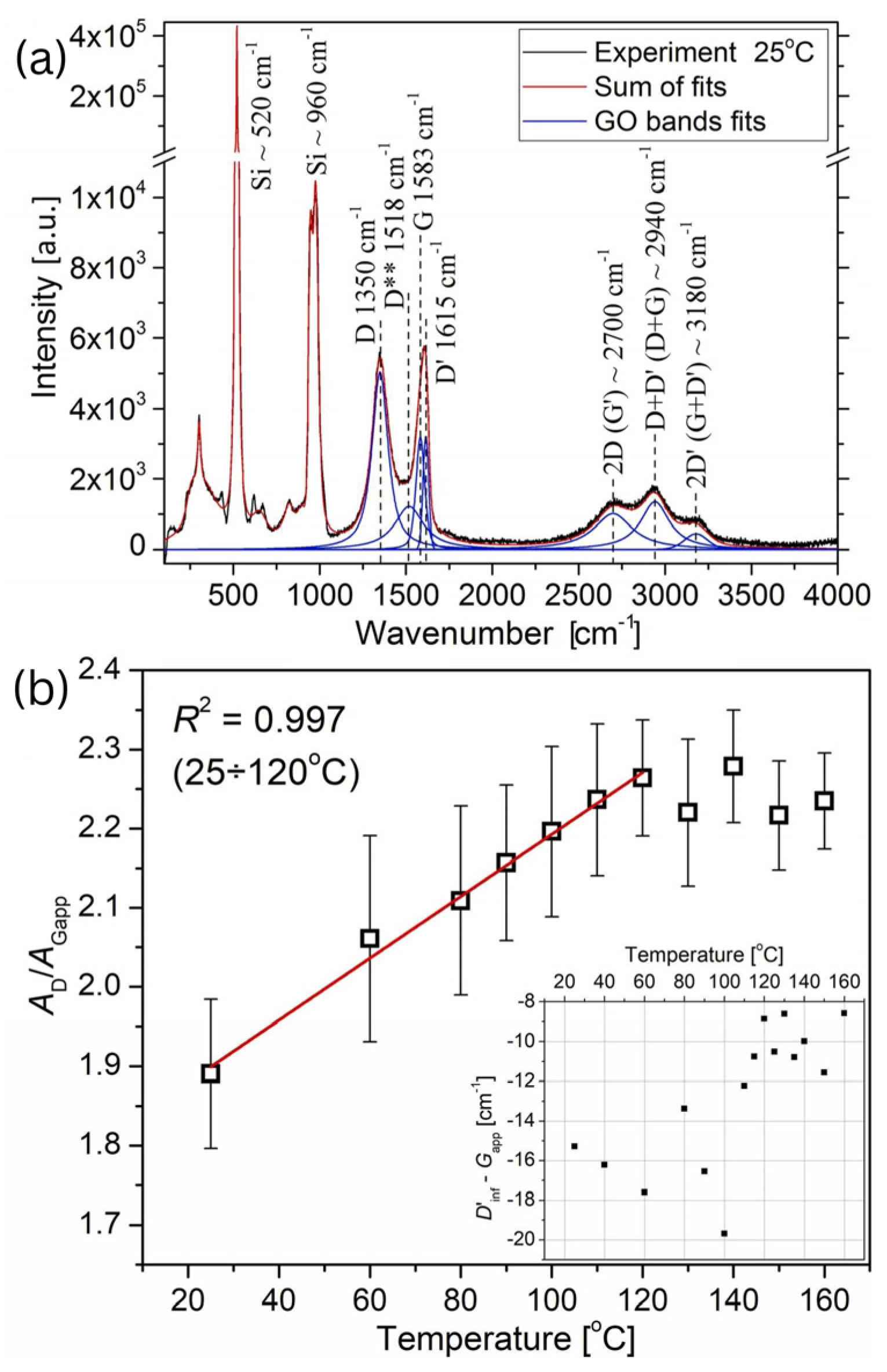

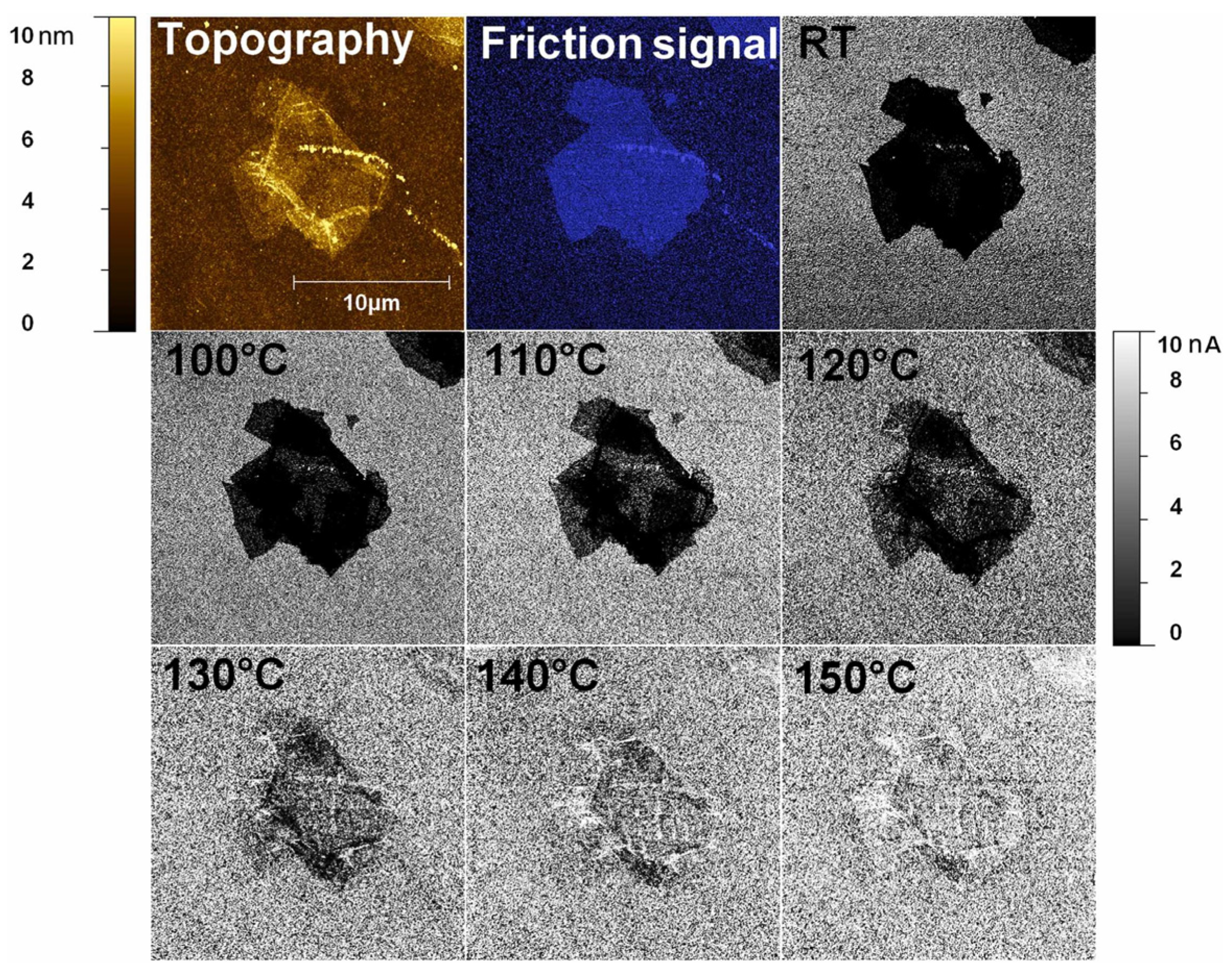

3.5. The Nanotribological Examination of Graphene and Its Derivatives

4. Conclusions

- Graphene and its derivatives offer exceptional specific tribological properties, including low friction coefficients and self-lubricating capabilities, making them ideal additives for complex lubrication systems. For example, graphene’s mechanical stability renders it an excellent material for preventing surface degradation, while the weak van der Waals forces between graphene sheets facilitate smooth sliding over surfaces. Additionally, the one-atom-thick, two-dimensional carbon lattice of graphene enables the formation of highly stable, ultra-thin lubrication layers at the interface between moving surfaces. Furthermore, graphene’s high surface area significantly contributes to its exceptional wear resistance. These materials, therefore, exhibit both anti-wear and low-friction properties, which further enhance their performance.

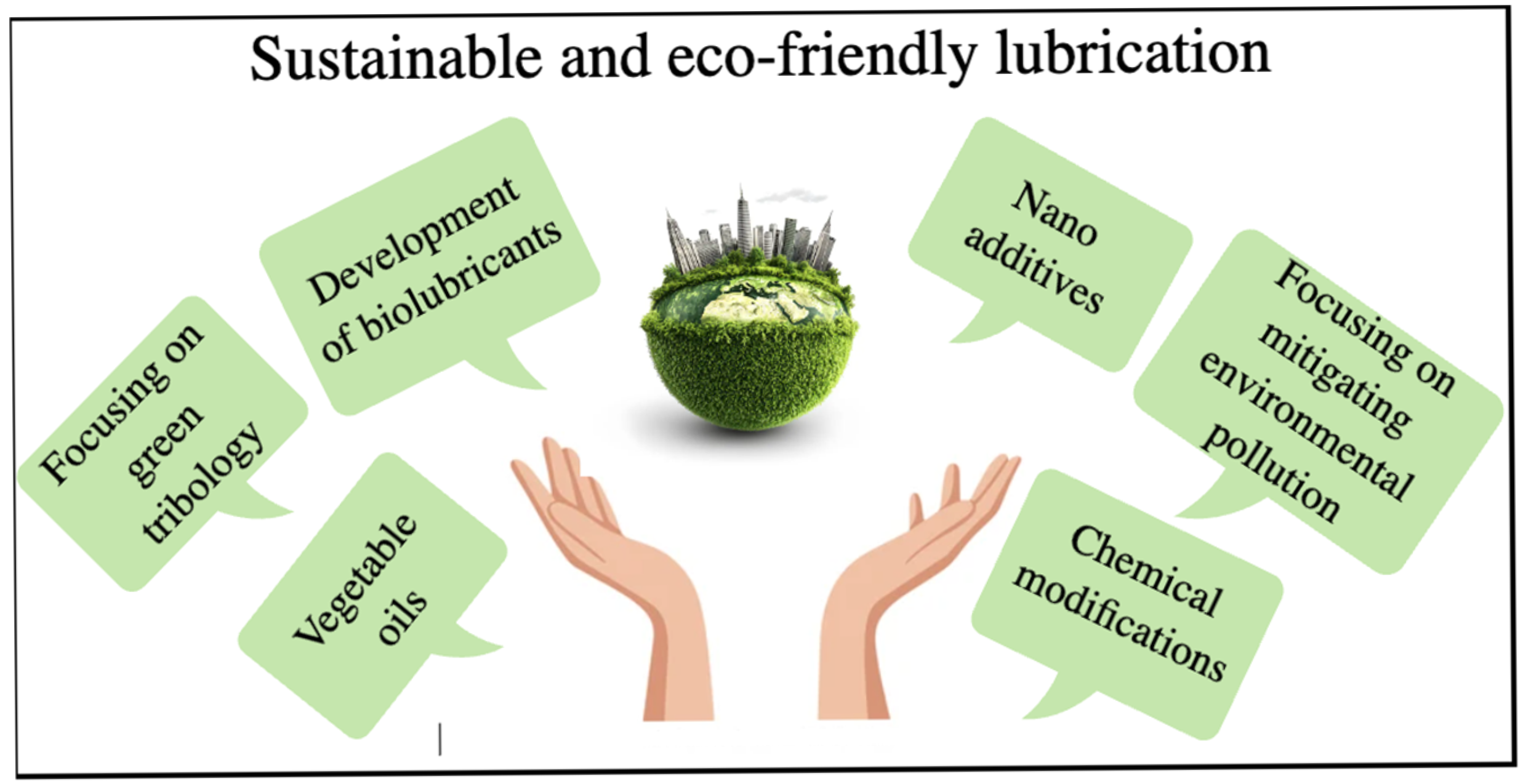

- Graphene-based materials are applicable in various industries, such as automotive, aerospace, and electronics, and are a promising material in energy-efficient systems, self-healing coatings, adaptive lubrication systems, and wearable biomedical devices. The study of graphene family materials in tribology gains valuable insight into how these materials can be engineered and utilized for the application areas, ultimately contributing to more efficient, durable, eco-friendly, and sustainable next-generation systems. Additionally, graphene derivatives (GO and rGO) offer substantial potential in tribological applications, which have unique properties such as low friction, high wear resistance, and tunable surface chemistry. These features make them ideal candidates for developing the performance and sustainability of modern tribological systems.

- Despite graphene’s significant role in tribology, further research is needed to gain a deeper understanding. Therefore, graphene and its derivatives require further development regarding scalability and cost-effectiveness, integration with other materials, long-term performance and stability, and eco-friendly synthesis methods. On the other hand, graphene derivatives require further evaluation concerning synthesis methods using green reductants, and comprehending how these approaches may affect systems at various scales (macro, micro, nano) and across different application fields, such as the development of eco-friendly lubricants, advanced coatings, and composite materials.

- Gaining insights into how these materials perform under small-scale contacts, particularly regarding adhesion and friction, will be crucial for developing new materials and creating innovative parts and systems for practical applications. For example, understanding the hydrophilic nature of graphene oxide and the hydrophobic nature of reduced graphene oxide, as well as the in-depth examination of the functional groups within their structures from a tribological perspective, could open the door to new applications. The functional groups in the structure of GO and rGO should be examined with different surfaces, such as metals, polymers, and ceramics. Furthermore, exploring graphene oxide (GO) and reduced graphene oxide (rGO) under varying parameters, concentrations, and modifications is essential to understanding their tribological behavior across macroscale, microscale, and nanoscale systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jin, B.; Chen, G.; He, Y.; Zhang, C.; Luo, J. Lubrication properties of graphene under harsh working conditions. Mater. Adv. 2023, 18, 100369. [Google Scholar] [CrossRef]

- Eregie, S.B.; Sanusi, I.A.; Olaniran, A.O. Bibliometric review of transcriptomic microalgae-based biodegradation of lubricant oil waste hydrocarbon: Current research outlook. Bioresour. Technol. Rep. 2025, 29, 102074. [Google Scholar] [CrossRef]

- Wang, K.; Qi, C.; Li, Y.; Zhang, D.; Sun, H.; Wan, Y. Macroscopic superlubricity achieved by water-based lubricant with green lycium barbarum extract as additives. J. Mol. Liq. 2025, 427, 127414. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K. Nano lubricants in machining and tribology applications: A state of the art review on challenges and future trend. J. Mol. Liq. 2024, 407, 125261. [Google Scholar] [CrossRef]

- Marlinda, A.R.; Thien, G.S.H.; Shahid, M.; Lind, T.Y.; Hashem, A.; Chan, K.; Johan, M.R. Graphene as a lubricant additive for reducing friction and wear in its liquid-based form. Lubricants 2023, 11, 29. [Google Scholar] [CrossRef]

- Wagh, V.P.; Saboo, N.; Gupta, A. Tribology as emerging science for warm mix technology: A review. Constr. Build. Mater. 2022, 359, 129445. [Google Scholar] [CrossRef]

- Sun, J.; Du, S. Application of graphene derivatives and their nanocomposites in tribology and lubrication: A review. RSC Adv. 2019, 9, 40642–40661. [Google Scholar] [CrossRef]

- Jafari, A.; Majdoub, M.; Sengottuvelu, D.; Ucak-Astarlioglu, M.G.; Al-Ostaz, A.; Nouranian, S. Tribological properties of synthetic and biosourced lubricants enhanced by graphene and its derivatives: A review. ACS Omega 2024, 9, 50868–50893. [Google Scholar] [CrossRef]

- Tomanik, E.; Christinelli, W.; Souza, R.M.; Oliveira, V.L.; Ferreira, F.; Zhmud, B. Review of graphene-based materials for tribological engineering applications. Eng 2023, 4, 2764–2811. [Google Scholar] [CrossRef]

- Mariño, F.; Río, J.M.L.; López, E.E.; Fernández, J. Chemically modified nanomaterials as lubricant additive: Time stability, friction, and wear. J. Mol. Liq. 2023, 382, 121913. [Google Scholar] [CrossRef]

- Nugroho, A.; Kozin, M.; Mamat, R.; Bo, Z.; Ghazali, M.F.; Kâmil, M.P.; Puranto, P.; Fitriani, D.A.; Azahra, S.A.; Suwondo, K.P.; et al. Enhancing tribological performance of electric vehicle lubricants: Nanoparticle-enriched palm oil. Heliyon 2024, 10, e39742. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Wang, X.; Chang, C. Preparation and characterization of graphene oxide. J. Nanomater. 2014, 2, 276143. [Google Scholar] [CrossRef]

- Jankovský, O.; Marvan, P.; Nováček, M.; Luxa, J.; Mazánek, V.; Klímová, K.; Sedmidubský, D.; Sofer, Z. Synthesis procedure and type of graphite oxide strongly influence resulting graphene properties. Appl. Mater. Today 2016, 4, 45–53. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Jin, Y.; Chen, G.; Zhang, X. Microwave-assisted solvothermal synthesis of sulfur-doped graphene for electrochemical sensing. J. Electroanal. Chem. 2015, 739, 172–177. [Google Scholar] [CrossRef]

- Viana, M.M.; Lima, M.C.F.S.; Forsythe, J.C.; Gangoli, V.S.; Cho, M.; Cheng, Y.; Silva, G.G.; Wong, M.S.; Caliman, V. Facile graphene oxide preparation by microwave-assisted acid method. J. Braz. Chem. Soc. 2015, 26, 978–984. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Topçu, A.A. A Green Pathway for the Production of Chemically Exfoliated Graphene Sheets with the Assistance of Microwave Irradiation. Master’s Thesis, Koç University, Istanbul, Turkey, 2012. [Google Scholar]

- Kozal, B. Karbon Tabanlı Petek Örgülerin Elektronik Özellikleri. Ph.D. Thesis, Ankara University, Ankara, Turkey, 2014. [Google Scholar]

- Spyrou, K.; Rudolf, P. An Introduction to Graphene; Wiley-VCH: Weinheim, Germany; Hoboken, NJ, USA, 2014; pp. 1–18. [Google Scholar]

- Sengupta, R.; Bhattacharya, M.; Bandyopadhyay, S.; Bhowmick, A.K. A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog. Polym. Sci. 2011, 36, 638–670. [Google Scholar] [CrossRef]

- Er, E. Grafen Oksitin Sülfürik ve Fosforik Asit Varlığında Indirgenmesi ve Elektroanalitik Uygulamalarının Araştırılması. Master’s Thesis, Gazi University, Ankara, Turkey, 2013. [Google Scholar]

- Dalkılıç, Z. Dikey Karbon Nanotüp Üretimi ve Çeşitli Uygulamalar Için Yüzey Özelliklerinin Incelenmesi. Master’s Thesis, Teknik University, Istanbul, Turkey, 2014. [Google Scholar]

- Nasir, S.; Hussein, M.Z.; Zainal, Z.; Yusof, N.A. Carbon-based nanomaterials/allotropes: A glimpse of their synthesis, properties and some applications. Materials 2018, 11, 295. [Google Scholar] [CrossRef]

- Akın, D. Glukoza Duyarlı Grafen Esaslı Yeni Bir Biyosensör Hazırlanması. Master’s Thesis, Gazi University, Ankara, Turkey, 2017. [Google Scholar]

- Tiyek, İ.; Dönmez, U.; Yıldırım, B.; Alma, M.; Ersoy, M.S.; Karataş, Ş.; Yazıcı, M. Kimyasal yöntem ile indirgenmiş grafen oksit sentezi ve karakterizasyonu. Sak. Univ. J. Sci. 2016, 20, 349–357. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Chen, J.; Yao, B.; Li, C.; Shi, G. An improved hummers method for eco-friendly synthesis of graphene oxide. Carbon 2013, 64, 225–229. [Google Scholar] [CrossRef]

- Mbayachi, V.B.; Ndayiragije, E.; Sammani, T.; Taj, S.; Mbuta, E.R.; Khan, A.U. Graphene synthesis, characterization and its applications: A review. Results Chem. 2021, 3, 100163. [Google Scholar] [CrossRef]

- Gao, X. Synthesis, Characterization, Chemical Reduction and Biological Application of Graphene Oxide. Master’s Thesis, University of Waterloo, Waterloo, Canada, 2013. [Google Scholar]

- Saleem, H.; Haneef, M.; Abbasi, H.Y. Synthesis route of reduced graphene oxide via thermal reduction of chemically exfoliated graphene oxide. Mater. Chem. Phys. 2018, 204, 1–7. [Google Scholar] [CrossRef]

- Bedeloğlu, A.; Taş, M. Grafen ve grafen üretim yöntemleri. Afyon Kocatepe Univ. J. Sci. Eng. 2016, 16, 544–554. [Google Scholar]

- Özcan, Ş. Kimyasal Yöntemlerle Grafen ve Grafen Oksit Üretimi ve Li-Hava Pil Uygulamaları. Master’s Thesis, Sakarya University, Sakarya, Turkey, 2015. [Google Scholar]

- Warner, J.H.; Schaffel, F.; Rummeli, M.H.; Bachmatiuk, A. Graphene: Fundamentals and Emergent Applications; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Khenfouch, M.; Buttner, U.; Baitoul, M.; Maaza, M. Synthesis and characterization of mass produced high quality few layered graphene sheets via a chemical method. Graphene 2014, 3, 7–13. [Google Scholar] [CrossRef]

- Lalire, T.; Longuet, C.; Taguet, A. Electrical properties of graphene/multiphase polymer nanocomposites: A review. Carbon 2014, 225, 119055. [Google Scholar] [CrossRef]

- Elibol, K. Grafit Soyma ve Epitaksiyel Yöntemlerle Elde Edilmiş Grafenlerde Manyetoiletim ve Yüzey Özellikleri Incelemeleri. Master’s Thesis, Gazi University, Ankara, Turkey, 2012. [Google Scholar]

- Babayiğit, M. Polikristalin Bakır Folyo Üzerinde Büyütülmüş Grafenin Elektriksel Karakterizasyonu. Master’s Thesis, Hacettepe University, Ankara, Turkey, 2013. [Google Scholar]

- Yildiz, G.; Bolton-Warberg, M.; Awaja, F. Graphene and graphene oxide for bio-sensing: General properties and the effects of raphene ripples. Acta Biomater. 2021, 131, 62–79. [Google Scholar] [CrossRef]

- Jiříčková, A.; Jankovský, O.; Sofer, Z.; Sedmidubský, D. Synthesis and applications of graphene oxide. Materials 2022, 15, 920. [Google Scholar] [CrossRef]

- Hu, X.; Yu, Y.; Wang, Y.; Zhou, J.; Song, L. Separating nano graphene oxide from the residual strong-acid filtrate of the modified hummers method with alkaline solution. Appl. Surf. Sci. 2015, 329, 83–86. [Google Scholar] [CrossRef]

- Jasim, D.A.; Lozano, N.; Kostarelos, K. Synthesis of few-layered, high-purity graphene oxide sheets from different graphite sources for biology. 2D Mater. 2016, 3, 014006. [Google Scholar] [CrossRef]

- Musa, N.; Halim, N.F.A.; Ahmad, M.N.; Zakaria, Z.; Hashim, U. Electrical characterization of reduced graphene oxide (rGO) on organic thin film transistor (OTFT). In Proceedings of the 11th Asian Conference on Chemical Sensors, Penang, Malaysia, 13 March 2017. [Google Scholar]

- Zhu, Y.; James, D.K.; Tour, J.M. New routes to graphene, graphene oxide and their related applications. Adv. Mater. 2012, 24, 4924–4955. [Google Scholar] [CrossRef]

- Zaaba, N.I.; Foo, K.L.; Hashim, U.; Tan, S.J.; Liu, W.-W.; Voon, C.H. Synthesis of graphene oxide using modified hummers method: Solvent influence. Procedia Eng. 2017, 184, 469–477. [Google Scholar] [CrossRef]

- Hanifah, M.F.R.; Jaafar, J.; Aziz, M.; İsmail, A.F.; Rahman, M.A.; Othman, M.H.D. Synthesis of graphene oxide nanosheets via modified hummers’ method and its physicochemical properties. J. Teknol. 2015, 74, 195–198. [Google Scholar] [CrossRef]

- Kayhan, E. Graphene: Synthesis, Characterization, Properties and Functional Behavior as Catalyst Support and Gas Sensor. Master’s Thesis, Technical University of Darmstadt, Darmstadt, Germany, 2013. [Google Scholar]

- Yazıcı, M.; Tiyek, İ.; Ersoy, S.M.; Alma, H.M.; Dönmez, U.; Yıldırım, B.; Salan, T.; Karataş, Ş.; Uruş, S.; Karteri, İ.; et al. Modifiye Hummers yöntemiyle grafen oksit sentezi ve karakterizasyonu. Gazi Univ. J. Science. 2016, 4, 41–48. [Google Scholar]

- Stankovich, S.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Synthesis and exfoliation of isocyanate-treated graphene oxide nanoplatelets. Carbon 2006, 44, 3342–3347. [Google Scholar] [CrossRef]

- Yan, Q.; Liu, Q.; Wang, J. A simple and fast microwave assisted approach for the reduction of graphene oxide. Ceram. Int. 2016, 42, 3007–3013. [Google Scholar] [CrossRef]

- Hassan, H.M.A.; Abdelsayed, V.; Khder, S.A.E.R.; AbouZeid, K.M.; Terner, J.; El-Shall, M.S.; Al-Resayes, S.I.; El-Azhary, A. Microwave synthesis of graphene sheets supporting metal nanocrystals in aqueous and organic media. J. Mater. Chem. 2009, 19, 3832–3837. [Google Scholar] [CrossRef]

- Sharma, B.; Shekhar, S.; Malik, P.; Jain, P. Study of mechanism involved in synthesis of graphene oxide and reduced graphene oxide from graphene nanoplatelets. Mater. Res. Express 2018, 5, 065012. [Google Scholar] [CrossRef]

- Muzyka, R.; Drewniak, S.; Pustelny, T.; Chrubasik, M.; Gryglewicz, G. Characterization of graphite oxide and reduced graphene oxide obtained from different graphite precursors and oxidized by different methods using raman spectroscopy. Materials 2018, 11, 1050. [Google Scholar] [CrossRef]

- Aroor, G.; Khan, M.A.; Shetty, A.R.; Rai, R.; Ganesha, H.; Navada, M.K. From chemistry to performance: How nano additives are transforming bio-lubricants for enhanced tribological applications. J. Mol. Liq. 2025, 425, 127242. [Google Scholar] [CrossRef]

- Berman, D.; Farfan-Cabrera, L.I.; Rosenkranz, A.; Erdemir, A. Advancing the frontiers of EV tribology with 2D materials—A critical perspective. Mater. Sci. Eng. R Rep. 2024, 161, 100855. [Google Scholar] [CrossRef]

- Venturi, F. Carbon-based films: A review on mechanical and tribology properties. Mater. Chem. Phys. 2024, 325, 129716. [Google Scholar] [CrossRef]

- Baiocco, G.; Salvi, D.; Ucciardello, N. Optimizing graphene nanoplatelet coating for enhanced wear resistance on copper through electrophoretic deposition parameters. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Mingione, E.; Salvi, D.; Almonti, D.; Ponticelli, G.S. Improvement of thermal, electrical, and tribological performances of GnPs composites produced by selective laser sintering. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Htwe, Y.Z.N.; Al-Janabi, A.S.; Wadzer, Y.; Mamat, H. Review of tribological properties of nanoparticle-based lubricants and their hybrids and composites. Friction 2024, 12, 569–590. [Google Scholar] [CrossRef]

- Kaleli, H.; Demirtaş, S.; Uysal, S.; Karnis, I.; Stylianakis, M.M.; Anastasiadis, S.H.; Kim, D.-E. Tribological performance investigation of a commercial engine oil incorporating reduced graphene oxide as additive. Nanomaterials 2021, 11, 386. [Google Scholar] [CrossRef]

- Kumar, S.S.A.; Bashir, S.; Ramesh, K.; Ramesh, S. A comprehensive review: Super hydrophobic graphene nanocomposite coatings for underwater and wet applications to enhance corrosion resistance. FlatChem 2022, 31, 100326. [Google Scholar] [CrossRef]

- Genna, S.; Salvi, D.; Ucciardello, N. Copper-graphene coatings for improving thermal shielding of CFRPs through electrodeposition techniques. Polym. Compos. 2024, 46, 2030–2046. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Shi, Q.; Ge, X.; Wang, W. Graphene-family lubricant additives: Recent developments and future perspectives. Lubricants 2022, 10, 215. [Google Scholar] [CrossRef]

- Ren, G.; Zhou, C.; Fan, X.; Dienwiebel, M.; Wang, S.; Li, Y. Enhancement of polyurea grease performance through graphene oxide-functionalized polyurea thickeners: A novel hydrogen-bond network approach. Tribol. Int. 2025, 201, 110123. [Google Scholar] [CrossRef]

- Weiss, M.; Majchrzycki, L.; Skonieczny, R.; Florjan, D.; Ptak, A. Influence of the thermal reduction process on the tribological and conductive properties of single-layer graphene oxide. Tribol. Int. 2025, 201, 110203. [Google Scholar] [CrossRef]

- Cai, Z.-B.; Zhao, L.; Zhang, X.; Yue, W.; Zhu, M.-H. Combined effect of textured patterns and graphene flake additives on tribological behavior under boundary lubrication. PLoS ONE 2016, 11, 0152143. [Google Scholar] [CrossRef]

- Kumar, P.; Wani, M.F. Friction and wear behaviour of hypereutectic Al-Si alloy/steel tribopair under dry and lubricated conditions. J. Tribol. 2017, 15, 21–49. [Google Scholar]

- Zhou, Q.; Huang, J.; Wang, J.; Yang, Z.; Liu, S.; Wang, Z.; Yang, S. Preparation of a reduced graphene oxide/zirconia nanocomposite and its application as a novel lubricant oil additive. RSC Adv. 2015, 5, 91802–91812. [Google Scholar] [CrossRef]

- Fan, X.; Xia, Y.; Wang, L.; Li, W. Multilayer graphene as a lubricating additive in bentone grease. Tribol. Lett. 2014, 55, 455–464. [Google Scholar] [CrossRef]

- Wu, C.; Liu, Z.; Zhao, H.; Yang, H.; Li, X.; Ni, J. Effect of the grease thickener on tribological properties of Si3N4/GCr15 contact interface and the performance in hybrid ceramic ball bearing. Ceram. Int. 2023, 49, 16857–16867. [Google Scholar] [CrossRef]

- Gan, C.; Liang, T.; Li, W.; Fan, X.; Zhu, M. Amine-terminated ionic liquid modified graphene oxide/copper nanocomposite toward efficient lubrication. Appl. Surf. Sci. 2019, 491, 105–115. [Google Scholar] [CrossRef]

- Uniyal, P.; Gaur, P.; Yadav, J.; Khan, T.; Ahmed, O.S. A Review on the effect of metal oxide nanoparticles on tribological properties of biolubricants. ACS Publ. 2024, 9, 12436–12456. [Google Scholar] [CrossRef]

- Malik, M.A.I.; Kalam, M.A.; Mujtaba, M.A.; Almomani, F. A review of recent advances in the synthesis of environmentally friendly, sustainable, and nontoxic bio-lubricants: Recommendations for the future implementations. Environ. Technol. Innov. 2023, 32, 103366. [Google Scholar] [CrossRef]

- Rahmani, A.; Ravazi, H.K.; Dehghani-Soufi, M. Green tribology assessment: A Comprehensive review of bio-lubricants and nano enhancers. Energy Convers. Manag. X 2024, 24, 9. [Google Scholar] [CrossRef]

- Dong, Y.; Ma, B.; Xiong, C.; Liu, Y.; Zhao, Q. Study on the lubricating characteristics of graphene lubricants. Lubricants 2023, 11, 506. [Google Scholar] [CrossRef]

- Zhao, Y.; Geng, Z.; Li, D.; Wang, L.; Lu, Z.; Zhang, G. An investigation on the tribological properties of graphene and ZDDP as additives in PAO4 oil. Diam. Relat. Mater. 2021, 120, 108635. [Google Scholar] [CrossRef]

- Wen, P.; Lei, Y.; Li, W.; Fan, M. Two-dimension layered nanomaterial as lubricant additives: Covalent organic frameworks beyond oxide graphene and reduced oxide graphene. Tribol. Int. 2020, 143, 106051. [Google Scholar] [CrossRef]

- Fuadi, Z.; Rahmadiawan, D.; Kurniawan, R.; Mulana, F.; Abral, H.; Nasruddin, N.; Khalid, M. Effect of graphene nanoplatelets on tribological properties of bacterial cellulose/polyolester oil bio-lubricant. Front. Mech. Eng. 2022, 8, 810847. [Google Scholar] [CrossRef]

- Najari, M.R.; Mohammadpour, M.; Saremi-Yarahmadi, S. Graphene oxide as an additive in aqueous lubricants for electric drive units: Synthesis, preparation, and tribological performance. Tribol. Int. 2025, 205, 110554. [Google Scholar] [CrossRef]

- Nagarajan, T.; Sridewi, N.; Wong, W.P.; Walvekar, R.; Khalid, M. Enhanced tribological properties of diesel-based engine oil through synergistic MoS2-graphene nanohybrid additive. Sci. Rep. 2023, 13, 17424. [Google Scholar] [CrossRef]

- Hettiarachchi, S.J.; Bowen, J.; Kershaw, M.; Baragau, I.; Nicolaev, A.; Kellici, S. Nanostructured Al2O3/graphene additive in bio-based lubricant: A novel approach to improve engine performance. Tribol. Int. 2023, 186, 108619. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, R.; Singh, D.P. Graphene oxide: Strategies for synthesis, reduction and frontier applications. RSC Adv. 2016, 6, 64993–65011. [Google Scholar] [CrossRef]

- Tewatia, K.; Sharma, A.; Sharma, M.; Kumar, A. Synthesis of graphene oxide and its reduction by green reducing agent. Mater. Proc. 2021, 44, 3933–3938. [Google Scholar] [CrossRef]

- De Silva, K.K.H.; Huang, H.-H.; Joshi, R.K.; Yoshimura, M. Chemical reduction of graphene oxide using green reductants. Carbon 2017, 119, 190–199. [Google Scholar] [CrossRef]

- Thakur, S.; Karaj, N. Alternative methods and nature-based reagents for the reduction of graphene oxide: A review. Carbon 2015, 94, 224–242. [Google Scholar] [CrossRef]

- Chua, C.K.; Pumera, M. Chemical reduction of graphene oxide: A synthetic chemistry viewpoint. Chem. Soc. Rev. 2014, 43, 291–312. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Liu, X.; Yang, C.; Chen, G.; Meng, Y.; Zhou, H.; Zhang, S. Insights into robust carbon nanotubes in tribology: From nano to macro. Mater. Today 2024, 74, 203–234. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Li, P.; Wang, B.; Ji, L.; Li, H.; Chen, L.; Liu, X.; Zhou, H.; Chen, J. Environmental molecular effect on the macroscale fricction behaviors of graphene. Front. Chem. 2021, 9, 679417. [Google Scholar]

- Qi, S.; Li, X.; Dong, H. Improving the macro-scale tribology of monolayer graphene oxide coating on stainless steel by a silane bonding layer. Mater. Lett. 2017, 209, 15–18. [Google Scholar] [CrossRef]

- Nadeem, I.; Malok, M.; Kovač, J.; Yaqub, T.B.; Cavaleiro, A.; Kalin, M. Superior macro-scale tribological performance of steel contacts based on graphene quantum dots in aqueous glycerol. Tribol. Int. 2023, 181, 108328. [Google Scholar] [CrossRef]

- Komvopoulus, K. Surface engineering and microtribology for microelectromechanical systems. Wear 1996, 200, 305–327. [Google Scholar] [CrossRef]

- Stoyanov, P.; Chromik, R.R. Scaling Effects on Materials Tribology: From macro to micro scale. Materials 2006, 10, 550. [Google Scholar] [CrossRef]

- Achanta, S.; Liskiewicz, T.; Drees, D.; Celis, J. Friction mechanisms at the micro-scale. Tribol. Int. 2009, 42, 1792–1799. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, G.; Li, Z.; Xu, Y.; Zeng, X.; Zhao, S.; Deng, J.; Hu, H.; Zhang, Y.; Ren, T. Microtribological properties of Ti 6Al 4V alloy treated with self-assembled dopamine and graphene oxide coatings. Tribol. Int. 2019, 137, 46–58. [Google Scholar] [CrossRef]

- White, D.; Chen, M.; Xiao, C.; Huang, W.; Sundararajan, S. Microtribological behavior of MO and W nanoparticle/graphene composites. Wear 2018, 414–415, 310–316. [Google Scholar] [CrossRef]

- Hu, Y.; Ma, H.; Liu, W.; Lin, Q.; Liu, B. Preparation and investigation of the microtribological properties of graphene oxide and graphene films via electrostatic layer-by-layer self-assembly. J. Nanomater. 2015, 19, 282369. [Google Scholar] [CrossRef]

- Ohmae, N. Nanotribology and Nanoscale Materials Coatings for Lubricants; Elsevier: Kobe, Japan, 2011; pp. 419–443. [Google Scholar]

- Cihan, E.; Özoğul, A.; Baykara, M.Z. Structure and nanotribology of thermally deposited gold nanoparticles on graphite. Appl. Surf. Sci. 2015, 354, 429–436. [Google Scholar] [CrossRef]

- Grierson, D.S.; Carpick, R.W. Nanotribology of carbon-based materials. Nano Today 2007, 2, 12–21. [Google Scholar] [CrossRef]

- Zeng, X.; Peng, Y.; Lang, H.; Liu, L. Controllable nanotribological properties of graphene nanosheets. Sci. Rep. 2017, 7, 41891. [Google Scholar] [CrossRef]

- Sierros, K.A.; Ramayanam, S.S.; Stinespring, C.D. Nanotribological properties of few layer graphene surfaces, prepared by bottom-up and top-down methods, in ambient air and liquid environments. J. Mater. Res. 2016, 31, 1924–1931. [Google Scholar] [CrossRef]

- Rapuc, A.; Wang, H.; Polcar, T. Nanotribology of transition metal dichalcogenide flakes deposited by chemical vapour deposition: The influence of chemical composition and sliding speed on nanoscale friction of monolayers. Appl. Surf. Sci. 2021, 556, 149762. [Google Scholar] [CrossRef]

| Diamond | Graphite | Fullerene (C60) | Carbon Nanotube | |

|---|---|---|---|---|

| Color | Colorless | Grey black/black silver | Black/purple | Black |

| Density (g/cm3) | 3.515 | 1.9–2.3 | 1.69 | 1.33–1.4 |

| Specific gravity | 3.52 | 2.2 | 1.7–1.9 | 2 |

| Hardness (mohs) | 10 | 1–2 | 1–2 | 1–2 |

| Melting point (°C) | 3550 | 3652–3697 | >800 (evaporation) | 3652–3697 |

| Boiling point (°C) | 4827 | 4200 | --- | --- |

| Electrical conductivity | Non-conductor | Conductor | Semiconductor | Conductor/semiconductor |

| Hybridization | sp3 | sp2 | sp2 | sp2 |

| Crystal system | Oktahedral | Hexagonal | Tetragonal | Ikosahedral |

| Dimension | Three | Three | Zero | One |

| Thermal conductivity (Wm−1K−1) | 900–2320 | 1500–2000 | 0.4 | 3500 |

| Surface area (m2g−1) | 20–160 | ~10–20 | 80–90 | ~1300 |

| Properties | Graphene | Graphene Oxide | Reduced Graphene Oxide |

|---|---|---|---|

| Synthesis | Exfoliation, CVD, etc. | Oxidation of graphite | Thermal, chemical, etc. |

| C/O | No oxygen groups | 2–3 | 8–246 |

| Young’s Modulus (Tpa) | 1–2 | 2–4 | 2–4 |

| Electron mobility (cm2/V.s) | 25 × 104 | Depends on synthesis method | 0.05–200 |

| Thermal conductivity (W/m.K) | 5000 | 1500–5800 | 0.1–2 |

| Electrical conductivity (S/m) | 2 × 10−2 | 1–5 × 10−5 | 2–7 × 10−3 |

| Production cost | High | Low | Low |

| Amount | Wear Rate | Coefficient of Friction | Materials | References | |

|---|---|---|---|---|---|

| 1 | 0.01 wt% | 90% reduction | 78% reduction | Graphene+PAO | [65] |

| 2 | 0.5 wt% | 60–70% reduction | 0.22 to 0.057 reduction (mm3/N.m) | GO+ SAE20W50 engine oil | [66] |

| 3 | 0.06 wt% | 6.4% reduction | 56% reduction | rGO+paraffin oil | [67] |

| 4 | 0.1 wt% | 25–50% reduction | 10.4% reduction | Multi-layer graphene+bentone grease | [68] |

| 5 | 0.075 wt% | 43% reduction | 27% reduction | Few-layer graphene+ PAO40 base oil | [69] |

| 6 | 0.08 wt% | 47% improvement | 40.1% improvement | Modified GO+PEG 200 | [70] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acar, Ç.G.; Žunda, A. Tribological Aspects of Graphene and Its Derivatives. Lubricants 2025, 13, 232. https://doi.org/10.3390/lubricants13060232

Acar ÇG, Žunda A. Tribological Aspects of Graphene and Its Derivatives. Lubricants. 2025; 13(6):232. https://doi.org/10.3390/lubricants13060232

Chicago/Turabian StyleAcar, Çağla Gizem, and Audrius Žunda. 2025. "Tribological Aspects of Graphene and Its Derivatives" Lubricants 13, no. 6: 232. https://doi.org/10.3390/lubricants13060232

APA StyleAcar, Ç. G., & Žunda, A. (2025). Tribological Aspects of Graphene and Its Derivatives. Lubricants, 13(6), 232. https://doi.org/10.3390/lubricants13060232