Research on the Calculation Method for the Contact Stress of Wind Turbine Main Shaft Bearings Based on Finite Element Analysis

Abstract

1. Introduction

2. Analysis of Operating Characteristics of the Main Shaft Bearings Under Alternating Loads

2.1. Analysis of Alternating Loads on the Main Shaft Bearings

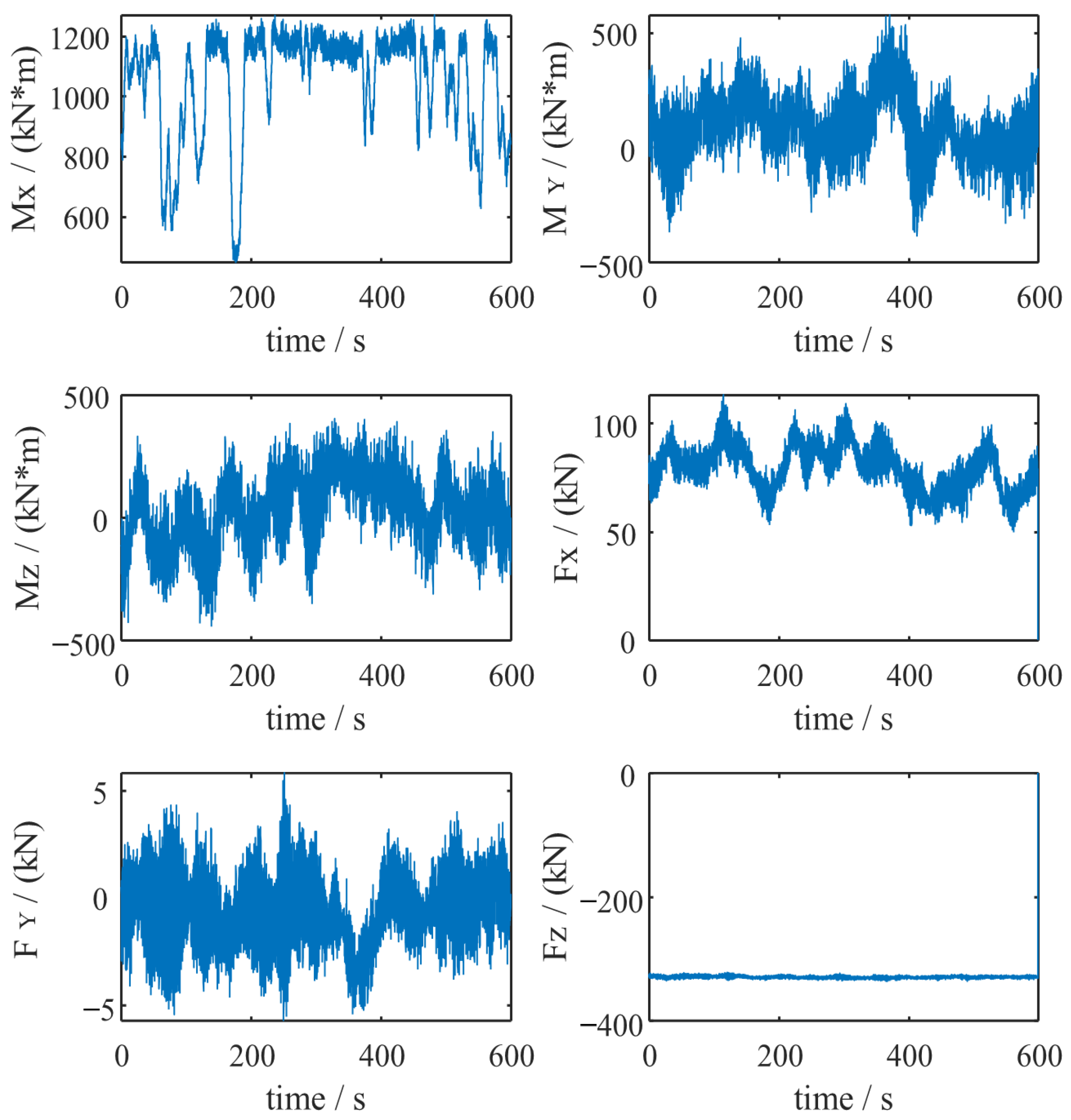

2.1.1. Simulation of Alternating Loads

2.1.2. Equivalent Processing of Alternating Loads

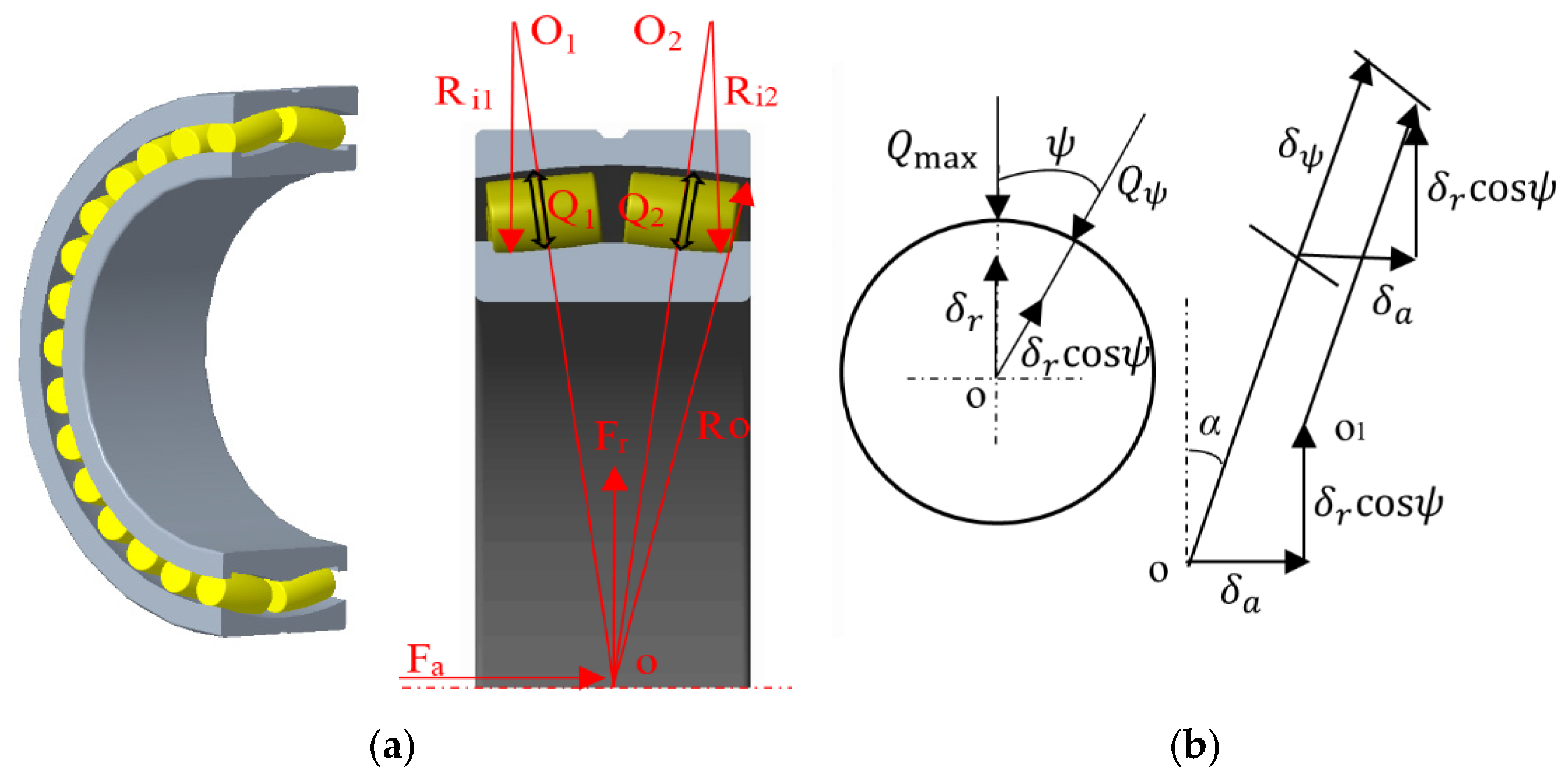

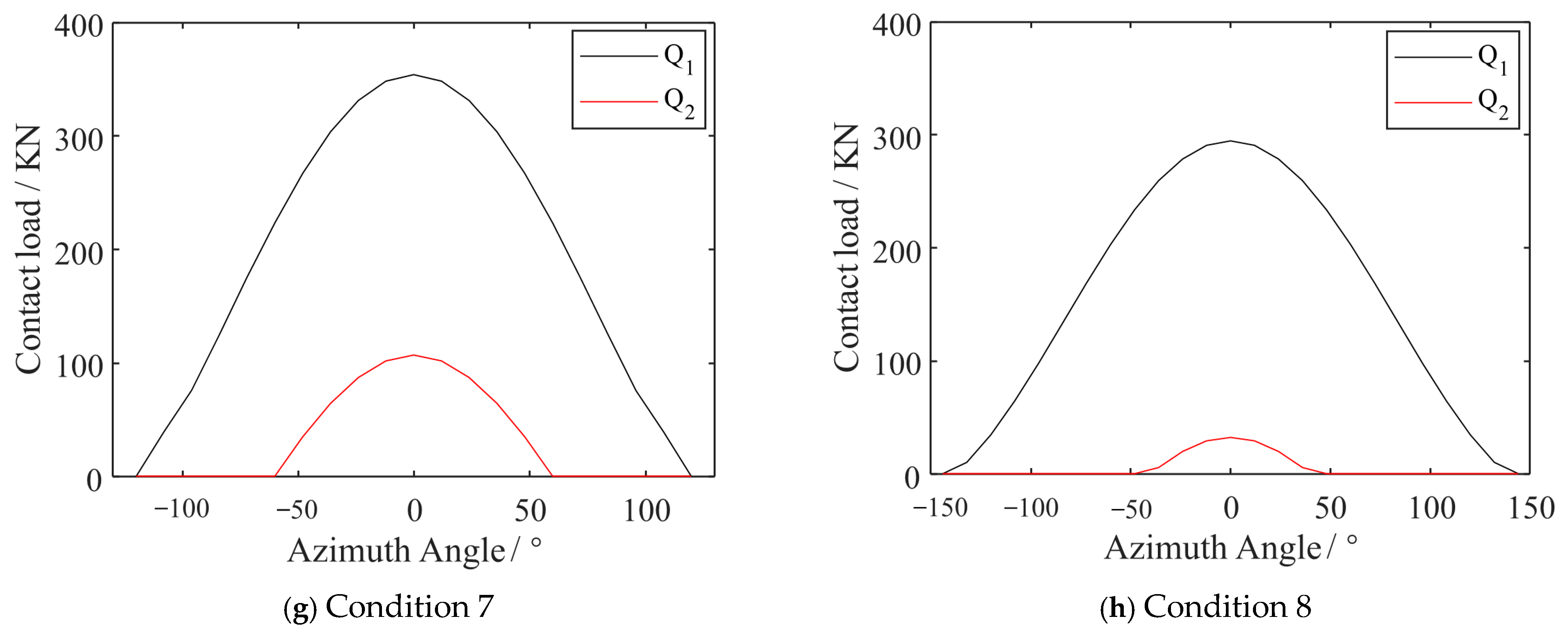

2.2. Analysis of Load Distribution Characteristics of Spindle Bearings Under Alternating Loads

3. Load–Displacement Model of Spindle Bearings Under Alternating Loads

Analysis of Alternating Loads on Main Shaft Bearings

4. Simulation Verification and Comparative Analysis of Results

4.1. Finite Element Simulation and Verification

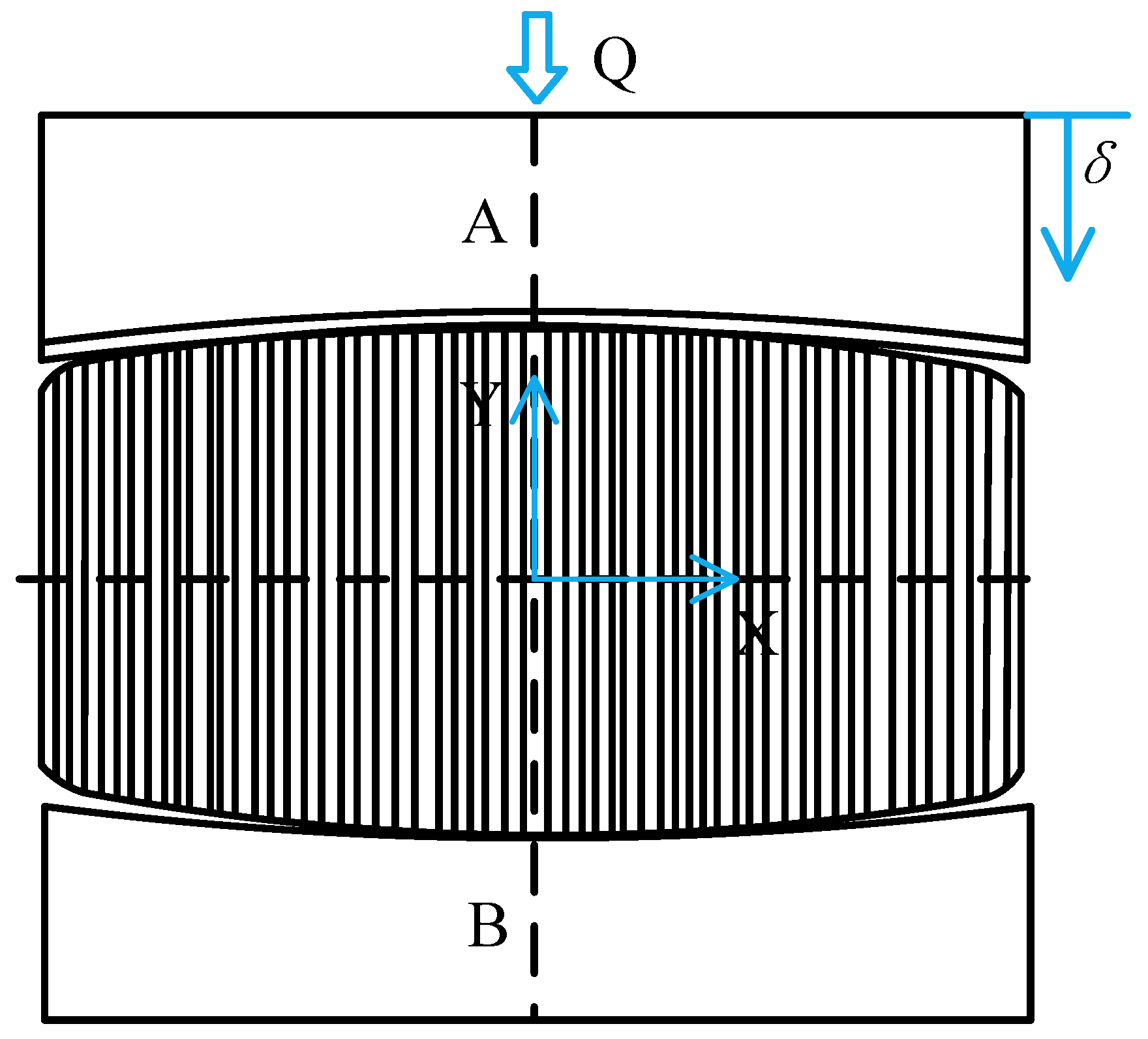

4.1.1. Parameter Settings and Simulation of the Finite Element Model

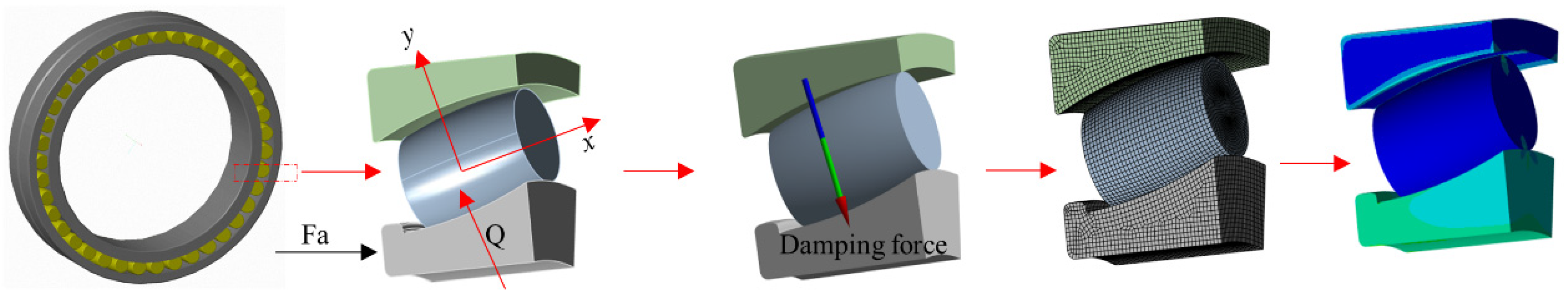

- (1)

- Model simplification: Due to the bearing’s symmetrical properties, a segment including one roller and its immediate surroundings is selected as the subject of study.

- (2)

- Boundary conditions settings: Load–displacement data obtained from Section 2 are imported as boundary conditions. During operation, the outer ring is fixed in the bearing housing [35]; thus, it is fully constrained on its surface, while the inner ring is allowed to rotate, constraining its circumferential displacement. The outer ring is set with elastic support to permit deformations during operation, and both the rollers and the rings are treated as flexible bodies. The roller can move freely in the y-direction, while it is fixed and constrained in the x- and z-directions. The y-direction is perpendicular to the inner ring. The normal load corresponds to the maximum load value for each operational condition, and the axial force direction is perpendicular to the face of the ring [27].

- (3)

- The friction coefficient is set at 0.05. Due to the presence of radial clearance, the “PINB” command in the finite element software is used to close the initial gap. To ensure convergence, artificial damping forces are added in the form , where L = 0.002, representing the damping coefficient. The load is incrementally applied according to time steps, and the damping force is proportional to the velocity. Initially, the roller moves at a high speed, and the presence of the damping force prevents computational divergence. After a period, once the roller contacts the raceway, the damping force becomes zero, not affecting the results.

- (4)

- Multiscale mesh division: To conserve computational resources, the mesh at the contact areas between the roller and the inner/outer rings is finely divided into 0.5 mm areas. Other areas are meshed at 5 mm using a hexahedral sweeping grid division.

4.1.2. Finite Element Model Validation

- (1)

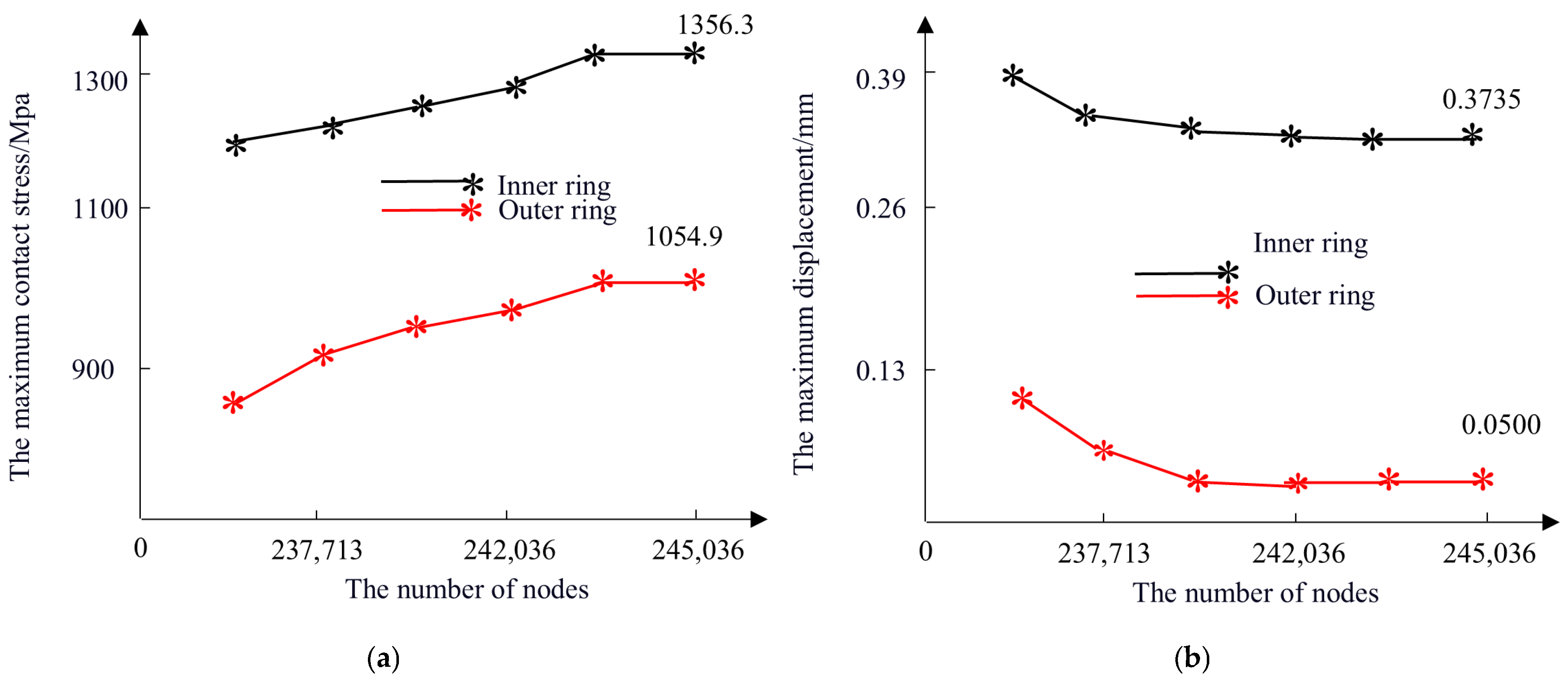

- The influence of the number of meshes on the model

- (2)

- The impact of node count on computational results

- (3)

- The influence of the number of roller slices on computational results

4.2. Simulation Results and Comparative Analysis

4.2.1. Simulation Results Analysis

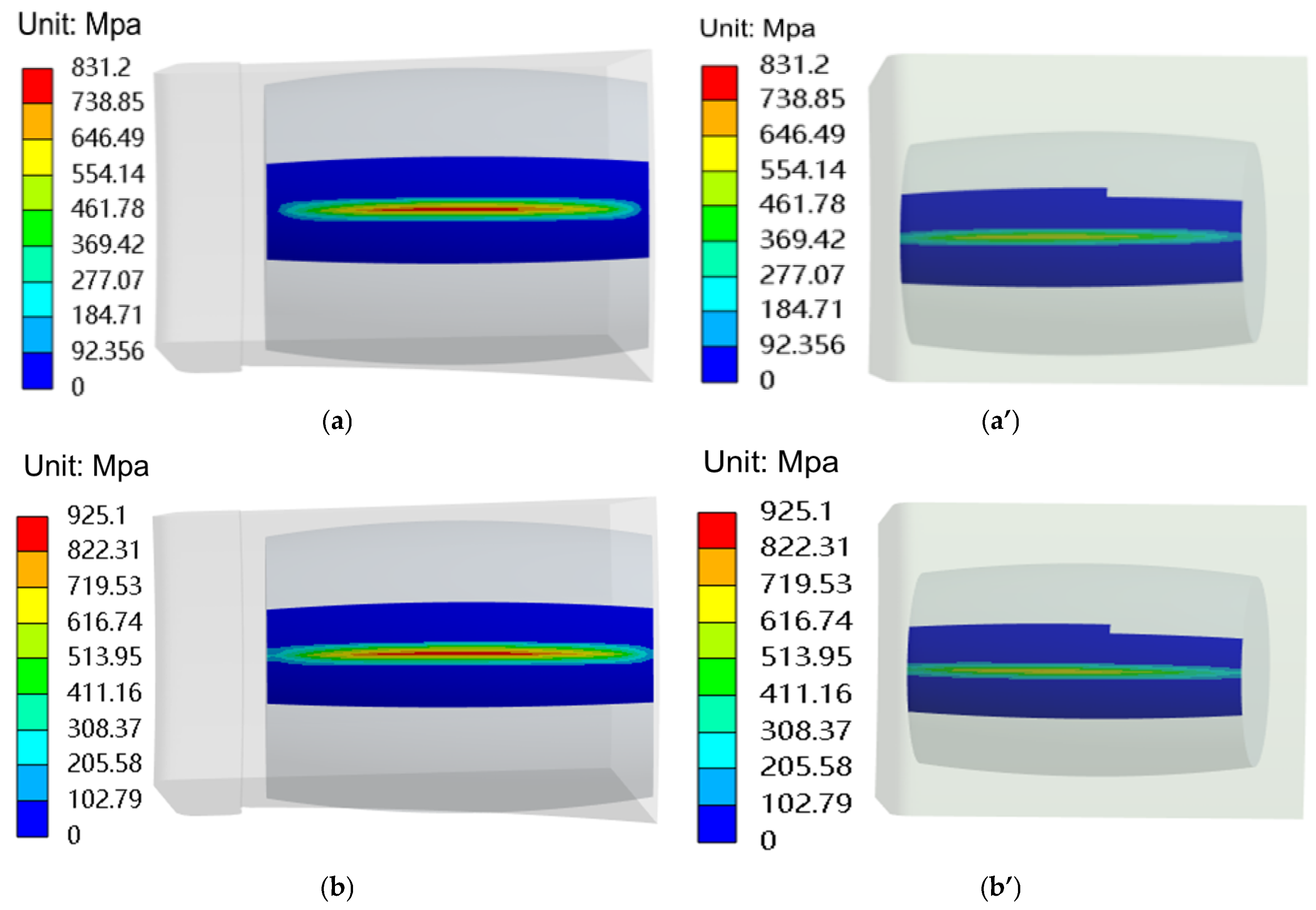

- (1)

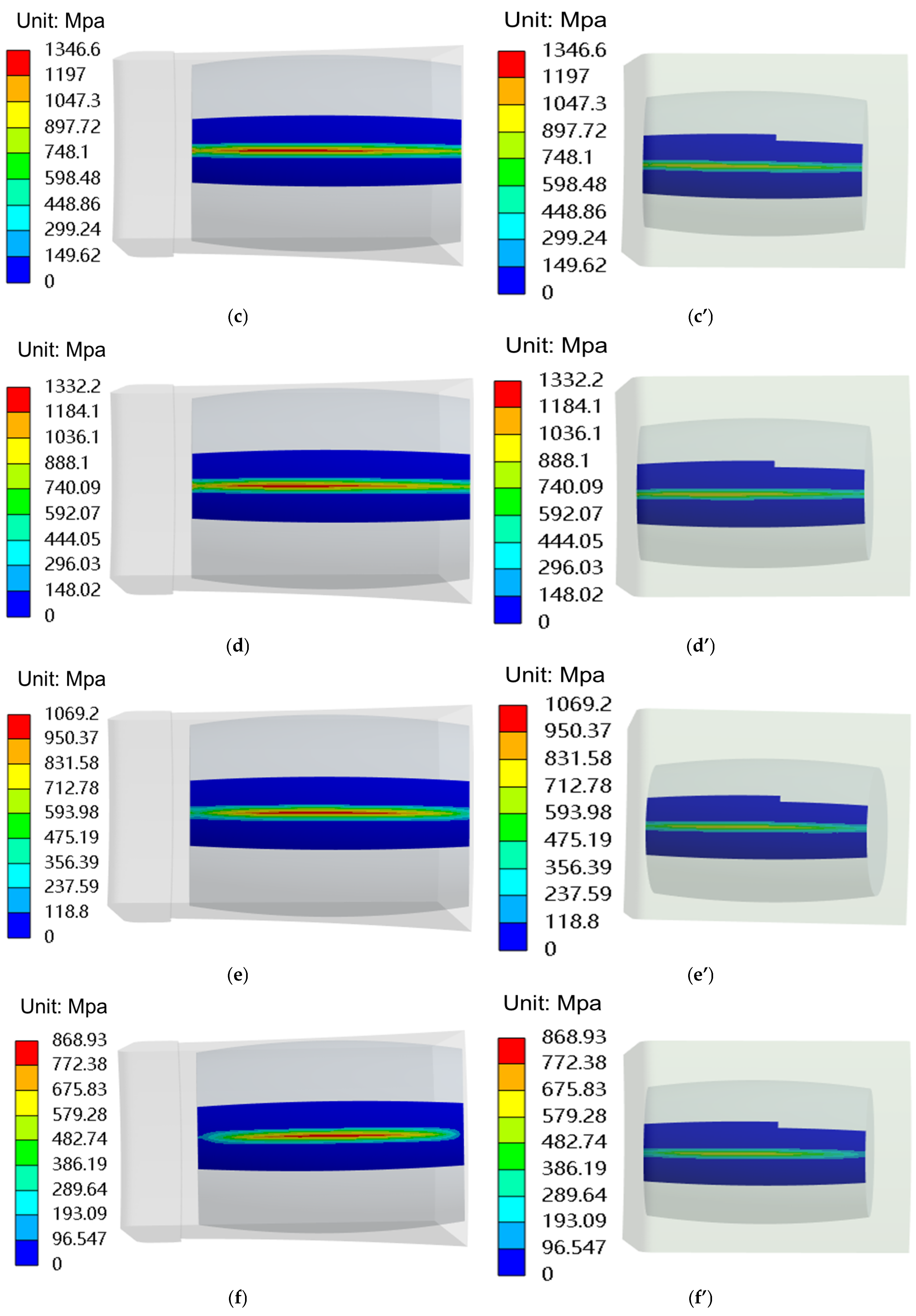

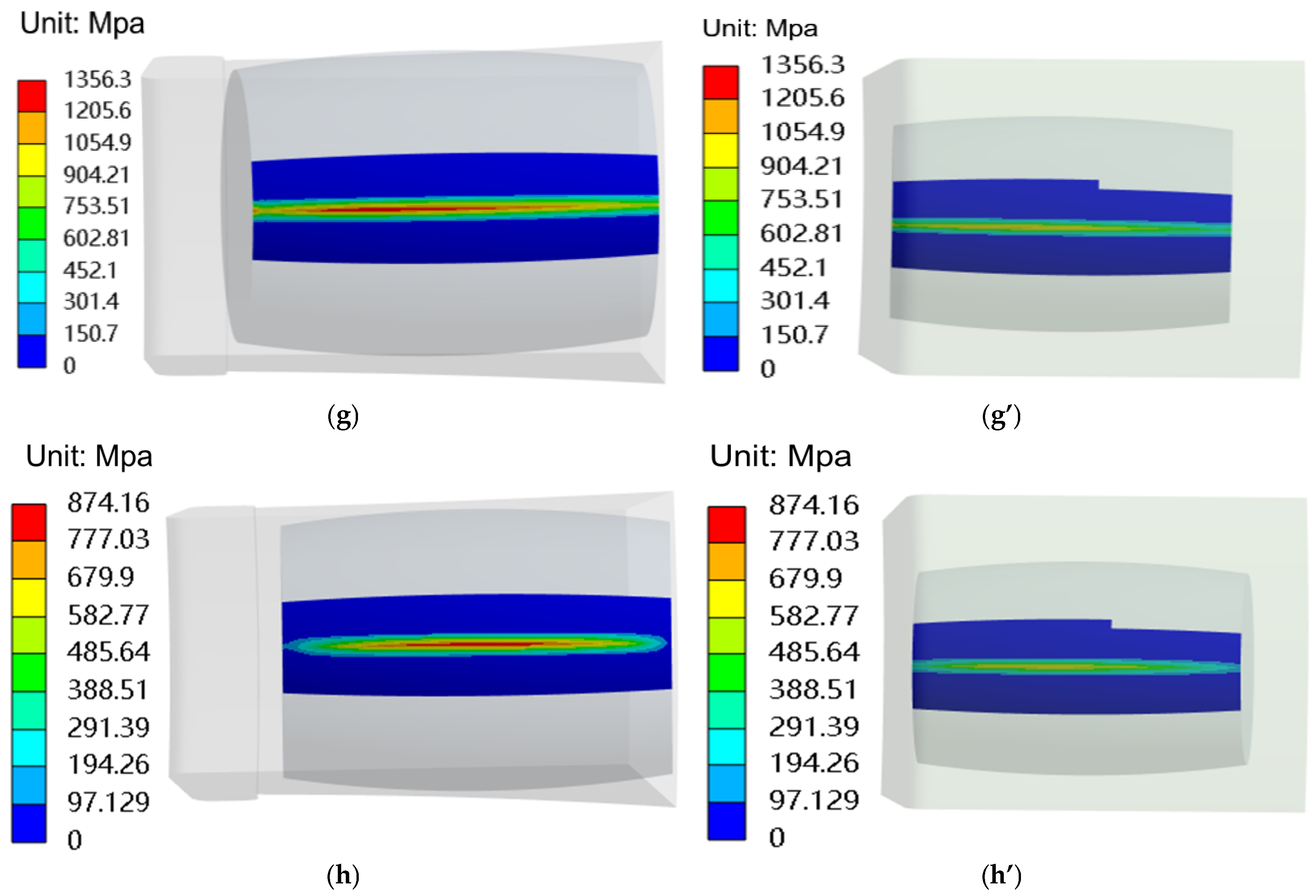

- Regardless of whether the roller contacts the inner race or the outer race, the maximum contact stress consistently occurs at the geometric center of the contact zone. The stress magnitude peaks within the contact region and gradually diminishes with increasing distance from the center, exhibiting a characteristic elliptical stress distribution pattern. This finding aligns with the results reported in references [28,29].

- (2)

- The contact stress magnitudes between the roller and raceway vary significantly under different operating conditions. The inner ring contact stresses are consistently higher than those of the outer ring, and the areas around the contact point tend to be elliptical, with the highest stress occurring in the contact region. Thus, during the operation of the bearing, the contact area is most susceptible to damage, necessitating focused consideration in bearing contact analysis.

- (3)

- Under the specified operating conditions, the maximum contact stress between the roller and inner race reaches 1356.3 MPa, while that between the roller and outer race attains 1054.9 MPa. These findings indicate that, to ensure structurally intact operation of the wind turbine main shaft bearing throughout its service life, the roller–raceway interface must sustain peak contact stresses of at least 1356.3 MPa without failure. According to the literature [16], the limit for roller–raceway contact stress is 1500 MPa, indicating that this design is within acceptable standards and that the bearing has sufficient load capacity.

4.2.2. Verification of the Correctness of the Computational Method

4.2.3. Simulation Results Comparison

- (1)

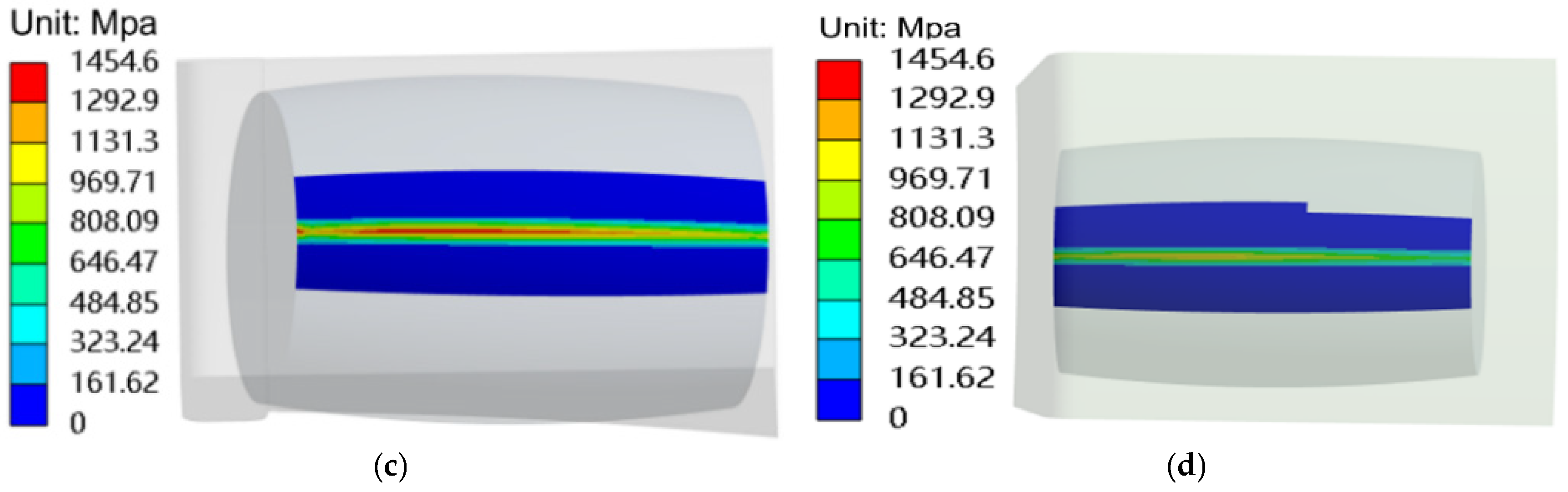

- In the analysis of contact stress for wind turbine main shaft bearings, linear contact models are predominantly used [7,8,9,10,11]. Figure 12 provides a comparison using the linear contact model to derive the load–displacement relationship as a boundary condition, resulting in calculated contact stresses.

- (2)

- Figure 12a,b show the inner and outer ring contact stresses for Condition 1, which are 910.83 MPa and 607 MPa, respectively. Figure 12c,d depict the inner and outer ring contact stresses for Condition 7, which are 1454.6 MPa and 969 MPa, respectively, with the maximum contact stress being 1454.6 MPa.

- (3)

- By integrating the operational conditions (condition 1 and condition 7) illustrated in Figure 11 and Figure 12, the analysis indicates that the maximum contact stresses calculated using the proposed method are lower than those obtained by other methods under the same conditions. For the overall wind turbine, analyzing bearing contact stress using the proposed method is relatively safer and more conservative.

5. Conclusions

- (1)

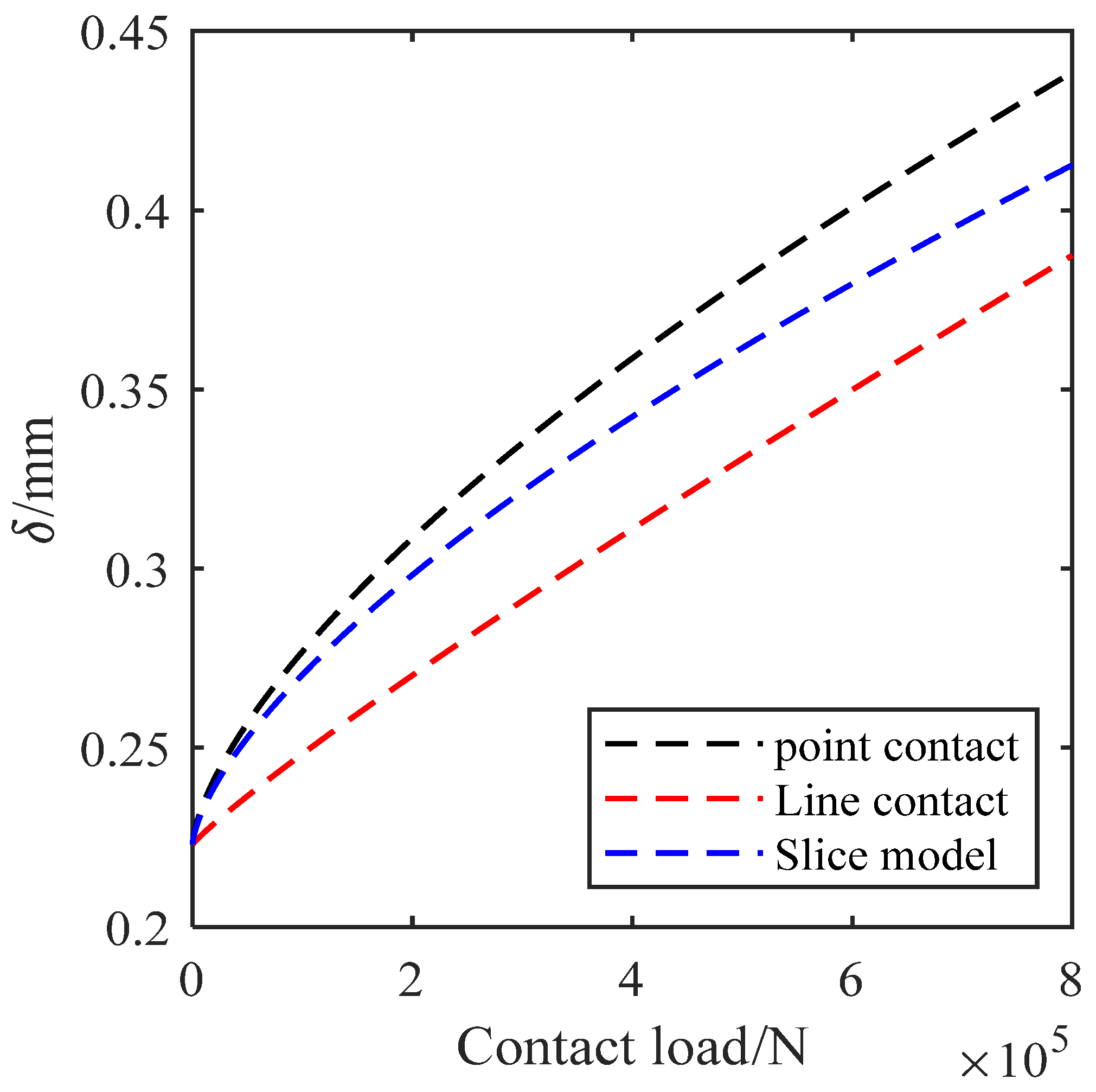

- Under alternating loads, the load–displacement defined by the roller slice model reveals that the contact form of the main shaft bearing involves both point and line contacts.

- (2)

- In the contact area, the local contact area is similar in shape to an ellipse, with the highest stresses at the contact center. As the distance from the contact center gradually increases, the contact stress progressively decreases. This area is more prone to damage; thus, emphasis should be placed on analyzing the stresses in the contact area during research.

- (3)

- When compared with the computational results reported in the literature, the proposed method exhibits a maximum error of 5.3% and an average error of 2.55% for the maximum contact stress value at the inner ring, while the maximum error for the maximum contact stress at the outer ring is 5.06%, with an average error also at 2.48%. These findings collectively validate the high reliability of the proposed method.

- (4)

- When the roller is discretized into 70 slices, the maximum contact stress between the bearing roller and raceway approaches convergence. Similarly, when the mesh node count reaches 245,036, both the maximum contact stress and maximum displacement at the roller–raceway interface exhibit near-convergence behavior. By setting these parameters during simulation, the reliability of the computational model is effectively ensured.

- (5)

- Using the proposed method, the maximum contact stress calculated was 1356.3 MPa, compared to using a linear model as the boundary condition. Both computational methods fully comply with the full-lifecycle standards for wind turbine main shaft bearings, but the proposed method enhances the safety of bearing analysis. It is essential to focus on analyzing contact forms to obtain reasonable contact stress results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Q.; Li, M. Digital Twin-Driven Remaining Useful Life Prediction for Rolling Element Bearing. Machines 2023, 11, 678. [Google Scholar] [CrossRef]

- Farajyar, S.; Ghafoorian, F.; Mehrpooya, M.; Asadbeigi, M. CFD Investigation and Optimization on the Aerodynamic Performance of a Savonius Vertical Axis Wind Turbine and Its Installation in a Hybrid Power Supply System: A Case Study in Iran. Sustainability 2023, 15, 5318. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Nejad, A.R. Online condition monitoring of floating wind turbines drivetrain by means of digital twin. Mech. Syst. Signal Process. 2022, 162, 108087. [Google Scholar] [CrossRef]

- Wang, S.S.; Torgeir, M.; Jiang, Z. Influence of variability and uncertainty of wind and waves on fatigue damage of a floating wind power drivetrain. Renew. Energy 2022, 181, 870–897. [Google Scholar] [CrossRef]

- Torsvik, J.; Nejad, A.R.; Pedersen, E. Experimental field study of floater motion effects on a main bearing in a full-scale spar floating wind turbine. Mar. Struct. 2021, 79, 103059. [Google Scholar] [CrossRef]

- Dhanola, A.; Garg, H.C. Tribological challenges and advancements in wind power bearings: A review. Eng. Fail. Anal. 2020, 118, 104885–104914. [Google Scholar] [CrossRef]

- Clarke, B.; Nicholas, G.; Hart, E.; Long, H.; Dwyer-Joyce, R. Loading on a wind turbine high-speed shaft gearbox bearing: Ultrasonic field measurements and predictions from a multi-body simulation. Tribol. Int. 2023, 181, 108319. [Google Scholar] [CrossRef]

- Cheng, S.; Meng, X.; Yin, J.; Yang, L.; Zhang, J. Configuration performance of main shaft bearings for transient-loaded wind turbine. Int. J. Mech. Sci. 2025, 293, 110171. [Google Scholar] [CrossRef]

- Wang, Z.; Pu, W.; Pei, X.; Cao, W. Nonlinear Dynamical Behaviors of Spiral Bevel Gears in Transient Mixed Lubrication. Tribol. Int. 2021, 160, 107022. [Google Scholar] [CrossRef]

- Gao, X.H.; Zhang, Z.K. A simplified spherical roller bearing model and its application in the wind turbine main bearing system finite element modeling. Tribol. Int. 2024, 196, 109678. [Google Scholar] [CrossRef]

- Xu, J.W.; Benson, S.; Wetenhall, B. Comparative analysis of fatigue life of a wind turbine yaw bearing with different support foundations. Ocean Eng. 2021, 235, 109293. [Google Scholar] [CrossRef]

- Jiang, Z.; Huang, X.; Zhu, H.; Jiang, R.; Du, S. A new method for contact characteristic analysis of the tapered roller bearing in wind turbine main shaft. Eng. Fail. Anal. 2022, 141, 106729. [Google Scholar] [CrossRef]

- Smolnicki, T.; Rusi’nski, E. Superelement-based modeling of load distribution in large-size slewing bearings. ASME J. Mech. Des. 2007, 129, 459–463. [Google Scholar] [CrossRef]

- Daidi’e, A.; Chaib, Z.; Ghosn, A. 3D simplified finite elements analysis of load and contact angle in a slewing ball bearing. ASME J. Mech. Des. 2008, 130, 082601. [Google Scholar] [CrossRef]

- Zhao, W.; Jiang, Z.; Zhang, P.; Huang, X. Reliability Sensitivity Analysis of Main Shaft Bearings of Wind Turbines Subject to Subsurface Stress. Machines 2023, 11, 681. [Google Scholar] [CrossRef]

- Jin, S.; Dong, H.; Chen, J.; Xie, X.; Guo, M. Study on accelerated life tests for main shaft bearings in wind turbines. J. Mech. Sci. Technol. 2022, 36, 1197–1207. [Google Scholar] [CrossRef]

- ISO 281; Rolling Bearings—Dynamic Load Ratings and Rating Life. ISO: Geneva, Switzerland, 2007.

- Hu, Y.; He, L.; Luo, Y.; Tan, A.C.; Yi, C. Contact Load Calculation Models for Finite Line Contact Rollers in Bearing Dynamic Simulation Under Dry and Lubricated Conditions. Lubricants 2025, 13, 183. [Google Scholar] [CrossRef]

- Ying, M.; Liu, X. Unbalance Response of a Hydrogen Fuel Cell Vehicle Air Compressor Rotor Supported by Gas Foil Bearings: Experimental Study and Analysis. Lubricants 2025, 13, 181. [Google Scholar] [CrossRef]

- Shah, D.B.; Kaushik, M.P.; Ruchik, D.T. Analyzing Hertzian contact stress developed in a double row spherical roller bearing and its effect on fatigue life. Ind. Lubr. Tribol. 2016, 68, 361–368. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, X.; Yue, Y.; Wang, S.; Han, H.; Wen, M.; Wang, Q.; Cheng, P. Investigation on 3D fatigue crack propagation in pitch bearing raceway of offshore wind powers. Ocean Eng. 2023, 269, 113524. [Google Scholar] [CrossRef]

- IEC 61400-1; Wind Energy Generation Systems—Part 1: Design Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2005.

- Fan, Y.Q.; Liu, S.B.; Wang, G.F.; Feng, Y.J.; Zhuang, Z.Q. Study on the bearing characteristics of hollow rolling elements of double-row spherical bearings for wind turbine spindles. Mach. Tool Hydraul. 2025, 1–8. Available online: http://kns.cnki.net/kcms/detail/44.1259.TH.20250123.1445.002.html (accessed on 17 April 2025).

- Gbashi, S.M.; Olatunji, O.O.; Adedeji, P.A.; Madushele, N. From academic to industrial research: A comparative review of advances in rolling element bearings for wind turbine main shaft. Eng. Fail. Anal. 2024, 163, 23. [Google Scholar] [CrossRef]

- Jin, X.; Yue, Y.; Chen, Y.; Du, J.; Wen, M.; Wu, A.; Tan, J. Structural optimization of pitch bearings for offshore wind turbines. Ocean Eng. 2023, 285, 115272. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, L.; Li, G.; Zheng, H.; Pang, C. High-Precision Main Shaft Displacement Measurement for Wind Turbines Using an Optimized Position-Sensitive Detector. Electronics 2024, 13, 5055. [Google Scholar] [CrossRef]

- Matthis, G.; Florian, S.; Matthias, S. Validation of a finite-element model of a wind turbine blade bearing. Finite Elem. Anal. Des. 2023, 221, 103957. [Google Scholar]

- Gao, X.H.; Huang, X.D.; Wang, H.; Chen, J. Modelling of ball-raceway contacts in a slewing bearing with non-linear springs. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 225, 827–831. [Google Scholar] [CrossRef]

- Sun, E.; Zhao, H.X.; Jiang, X.M. Variable-precision modeling method for double-row self-aligning roller bearings in wind turbines based on finite element analysis. Bearing 2024, 2024, 10–15. [Google Scholar]

- Lv, S.J.; Jiang, X.M.; Zhao, H.X. Efficient Estimation of Fatigue Life for Wind Turbine Bearings Based on Surrogate Models. Chin. J. Turbomach. 2023, 65, 72–79. [Google Scholar]

- Yu, Y.; Ma, R.; Xue, Y.; Liu, Y. Study on Thermal Characteristics of Angular Contact Ball Bearings Considering Roundness Error. Lubricants 2024, 12, 43. [Google Scholar] [CrossRef]

- Liu, X. (Ed.) Advances in Mechanism, Machine Science and Engineering in China: Proceedings of IFToMM CCMMS 2022; Springer: Singapore, 2023. [Google Scholar]

- Zou, Y.; Sun, W.; Wang, H.; Xu, T.; Wang, B. Research on Bearing Remaining Useful Life Prediction Method Based on Double Bidirectional Long Short-Term Memory. Appl. Sci. 2025, 15, 4441. [Google Scholar] [CrossRef]

- Li, F.; Li, X.; Guo, Y.; Shang, D. Analysis of Contact Mechanical Characteristics of Flexible Parts in Harmonic Gear Reducer. Shock. Vib. 2021, 2021, 5521320. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, D. Strength check of a three-row roller slewing bearing based on a mixed finite element model. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 3393–3400. [Google Scholar] [CrossRef]

- Chen, Z.; Long, W.; Song, L.; Li, X. Experiment and simulation analysis of tribological and dynamic characteristics in aeroengine hybrid ceramic bearing. Aircr. Eng. Aerosp. Technol. 2023, 95, 1694–1705. [Google Scholar] [CrossRef]

| Items | Values |

|---|---|

| Hub center height/H | 90 m |

| Rotor radius/rwind | 46.5 m |

| Hub radius/rhub | 0.92 m |

| Geometric chord length of blade/f | 3.58 m |

| Total twist angle n/° | 16° |

| Lift coefficient/C1 | 1.079 |

| Drag coefficient/Cd | 0.026 |

| Inflow angle/φ(°) | 11.22° |

| Cut in wind speed/Vin | 4 m/s |

| Cut out wind speed/Vout | 25 m/s |

| Distance from hub center to the bearing/l1 | 1.78 m |

| Distance from main shaft center of gravity to gearbox/l2 | 1.64 m |

| Distance from main shaft center of gravity to gearbox/l3 | 0.9 m |

| Mass of main shaft center of gravity/Gs | 9800 kg |

| Conditions | MY | Mz | FX | FY | Fz |

|---|---|---|---|---|---|

| 1 | −358 | 590 | 201 | −12 | −531 |

| 2 | 501 | 590 | 217 | −12 | −533 |

| 3 | −358 | 590 | 198 | −6.2 | −527 |

| 4 | −358 | −251 | 219 | −12 | −534 |

| 5 | 501 | 590 | 203 | 6.2 | −531 |

| 6 | 501 | −251 | 214 | −12 | −531 |

| 7 | −358 | −251 | 210 | 6.2 | −533 |

| 8 | 501 | −251 | 216 | 6.2 | −524 |

| Conditions | Fr/KN | Fa/KN |

|---|---|---|

| 1 | 749 | 201 |

| 2 | 821 | 217 |

| 3 | 1159 | 198 |

| 4 | 1145 | 219 |

| 5 | 930 | 203 |

| 6 | 778 | 214 |

| 7 | 1169 | 210 |

| 8 | 782 | 216 |

| Symbol | Items | Values |

|---|---|---|

| Z | Number of rollers per row | 30 |

| Rw | Outer diameter | 1090 mm |

| RN | Inner diameter | 750 mm |

| W | Width | 335 mm |

| c | Bearing clearance | 0.223 |

| α | Contact angle | 10.41° |

| Dw | Raceway pitch diameter | 928 mm |

| l | Roller length | 123 mm |

| Ro | Outer raceway radius | 513 mm |

| Ri1, Ri2 | Inner raceway radius | 516.8 mm |

| d | Roller diameter | 82 mm |

| Condition | Load/KN | Maximum Contact Stress in the Inner Ring/Mpa | Maximum Contact Stress in the Inner Ring/Mpa | |||||

|---|---|---|---|---|---|---|---|---|

| Fr/KN | Fa/KN | Reference [30] | Proposed Method | Error (%) | Reference [30] | Proposed Method | Error (%) | |

| 1 | 687 | 245 | 1270 | 1257 | 1.02% | 1077 | 1047 | 2.7% |

| 2 | 1019 | 156 | 1483 | 1498 | 1.01% | 1258 | 1249 | 0.07% |

| 3 | 1352 | 207 | 1612 | 1599 | 0.8% | 1367 | 1386 | 1.38% |

| 4 | 3677 | −184 | 1998 | 1969 | 1.45% | 1695 | 1689 | 0.35% |

| 5 | 2447 | 106 | 1750 | 1782 | 1.82% | 1485 | 1457 | 1.89% |

| 6 | 3147 | 123 | 1879 | 1862 | 0.9% | 1595 | 1522 | 4.57% |

| 7 | 846 | 80 | 1351 | 1333 | 1.33% | 1146 | 1101 | 3.9% |

| 8 | 1100 | 651 | 1616 | 1635 | 1.17% | 1370 | 1329 | 3% |

| 9 | 1670 | −371 | 1742 | 1699 | 2.46% | 1478 | 1499 | 1.4% |

| 10 | 500 | −26 | 1118 | 1178 | 5.3% | 948 | 900 | 5.06% |

| 11 | 1291 | −13 | 1404 | 1379 | 1.8% | 1191 | 1163 | 2.4% |

| 12 | 294 | 34 | 1023 | 1078 | 5.3% | 868 | 899 | 3.5% |

| 13 | 405 | 332 | 1240 | 1201 | 3.1% | 1051 | 1022 | 2.7% |

| 14 | 330 | 20 | 1000 | 1011 | 1.1% | 849 | 833 | 1.8% |

| Mean error | 2.55% | 2.48% | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Sun, W.; Wang, H.; Xu, T.; Wang, B. Research on the Calculation Method for the Contact Stress of Wind Turbine Main Shaft Bearings Based on Finite Element Analysis. Lubricants 2025, 13, 226. https://doi.org/10.3390/lubricants13050226

Zou Y, Sun W, Wang H, Xu T, Wang B. Research on the Calculation Method for the Contact Stress of Wind Turbine Main Shaft Bearings Based on Finite Element Analysis. Lubricants. 2025; 13(5):226. https://doi.org/10.3390/lubricants13050226

Chicago/Turabian StyleZou, Yi, Wenlei Sun, Hongwei Wang, Tiantian Xu, and Bingkai Wang. 2025. "Research on the Calculation Method for the Contact Stress of Wind Turbine Main Shaft Bearings Based on Finite Element Analysis" Lubricants 13, no. 5: 226. https://doi.org/10.3390/lubricants13050226

APA StyleZou, Y., Sun, W., Wang, H., Xu, T., & Wang, B. (2025). Research on the Calculation Method for the Contact Stress of Wind Turbine Main Shaft Bearings Based on Finite Element Analysis. Lubricants, 13(5), 226. https://doi.org/10.3390/lubricants13050226