Laser Texturing to Improve Wear Resistance of 65Mn Steel Rotary Tiller Blades: Effects of Scanning Speed

Abstract

1. Introduction

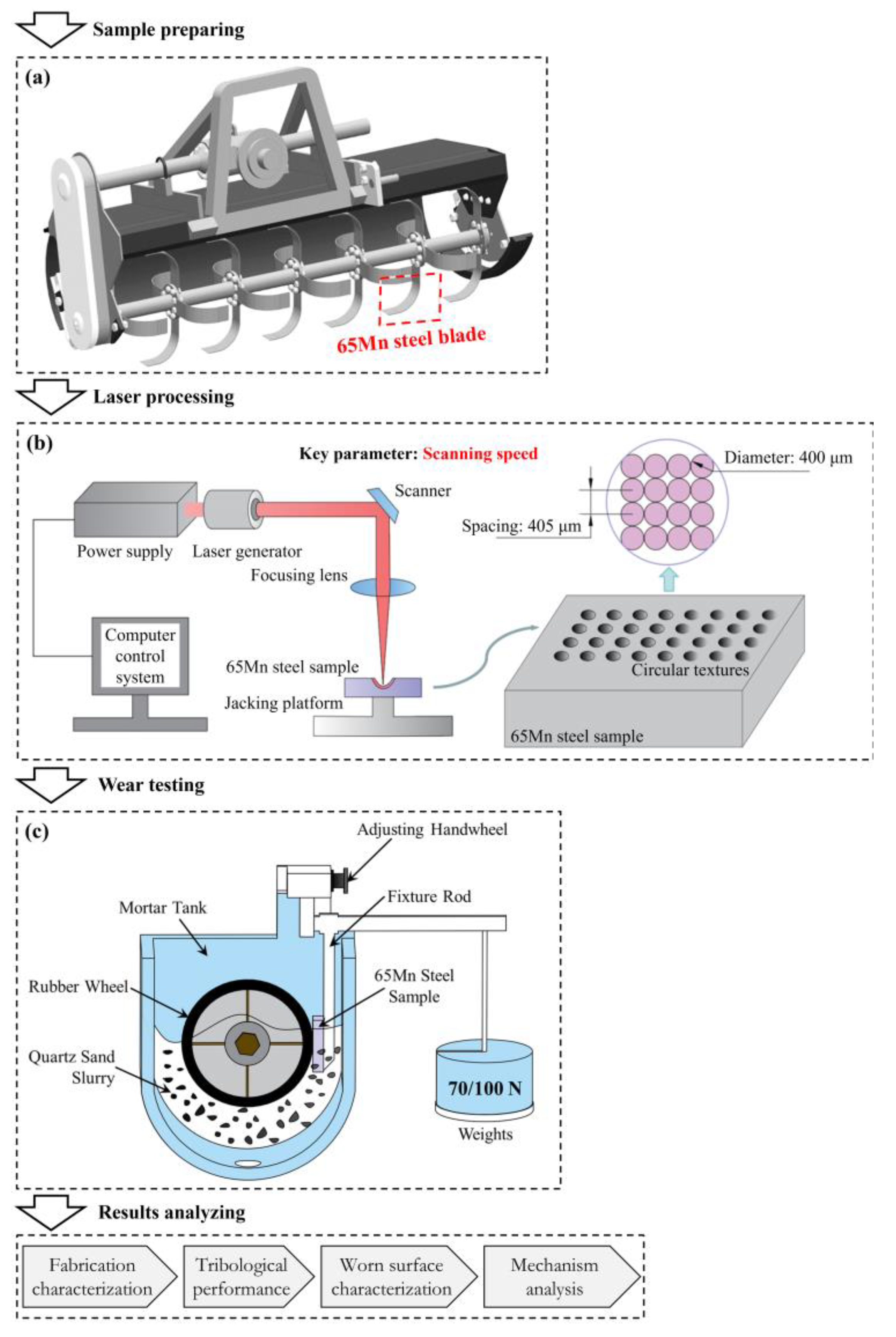

2. Materials and Methods

2.1. Sample Preparation

2.2. Laser Processing

2.3. Wear Testing

3. Results and Discussion

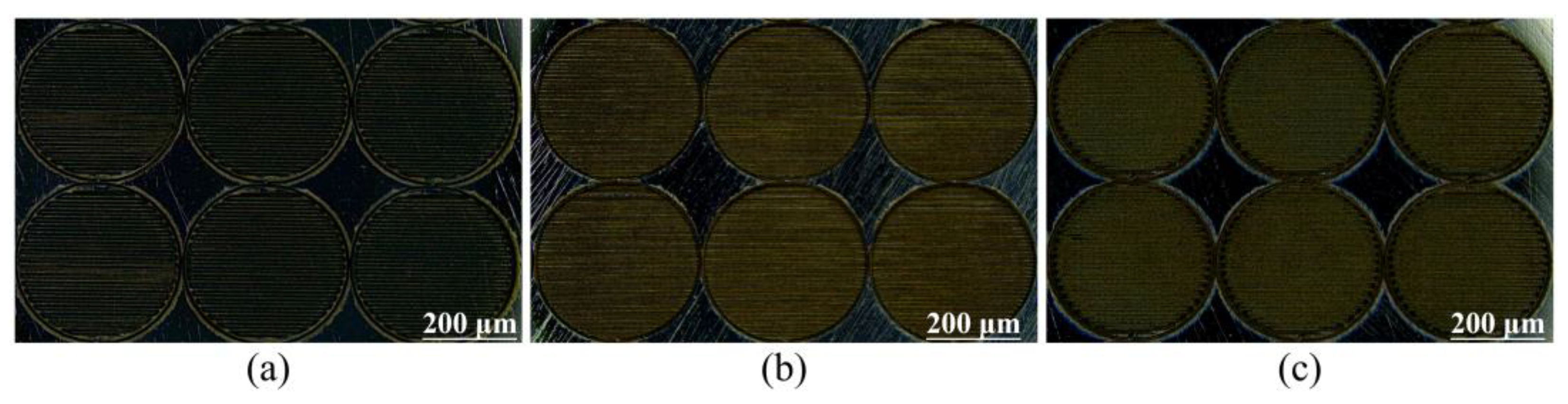

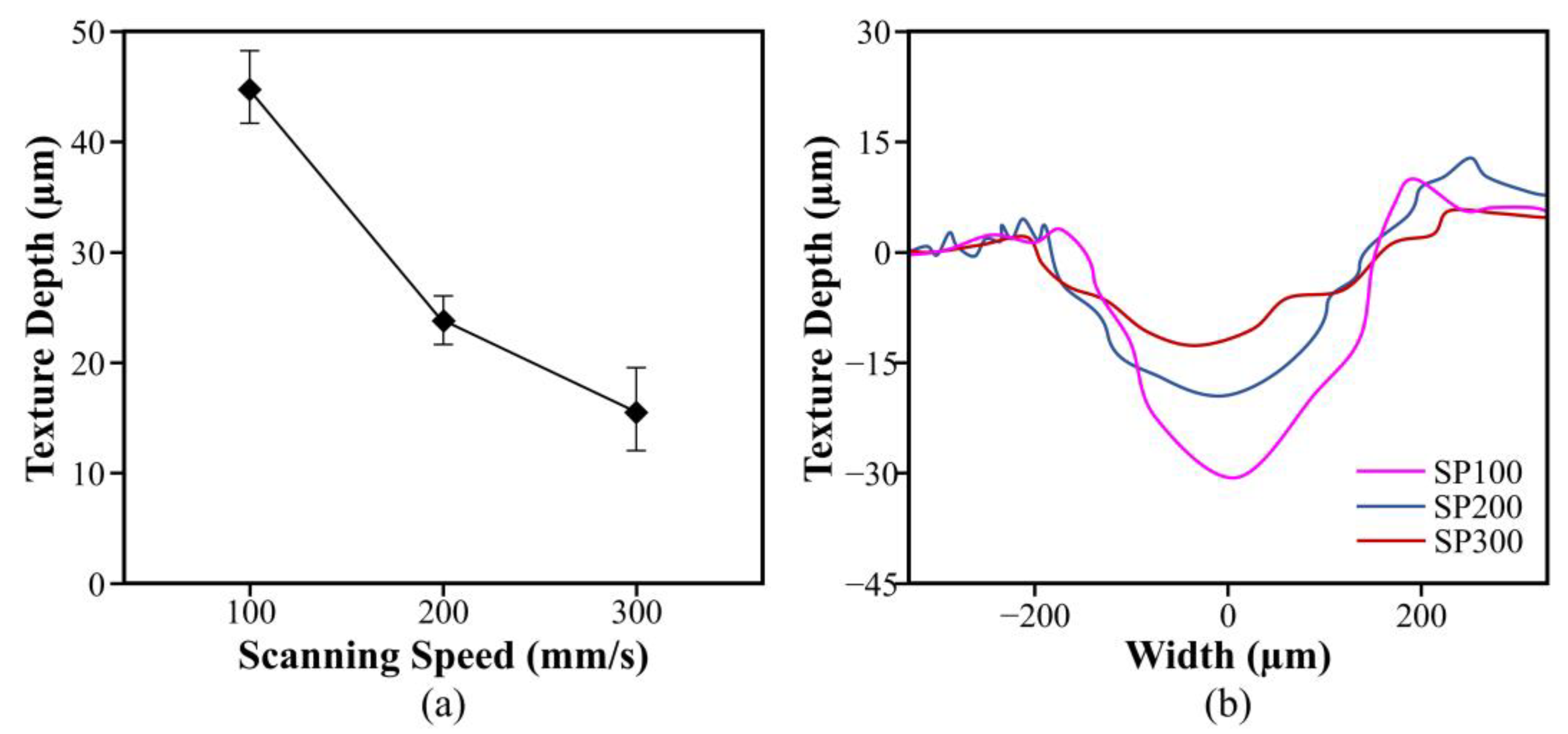

3.1. Fabrication Characterization

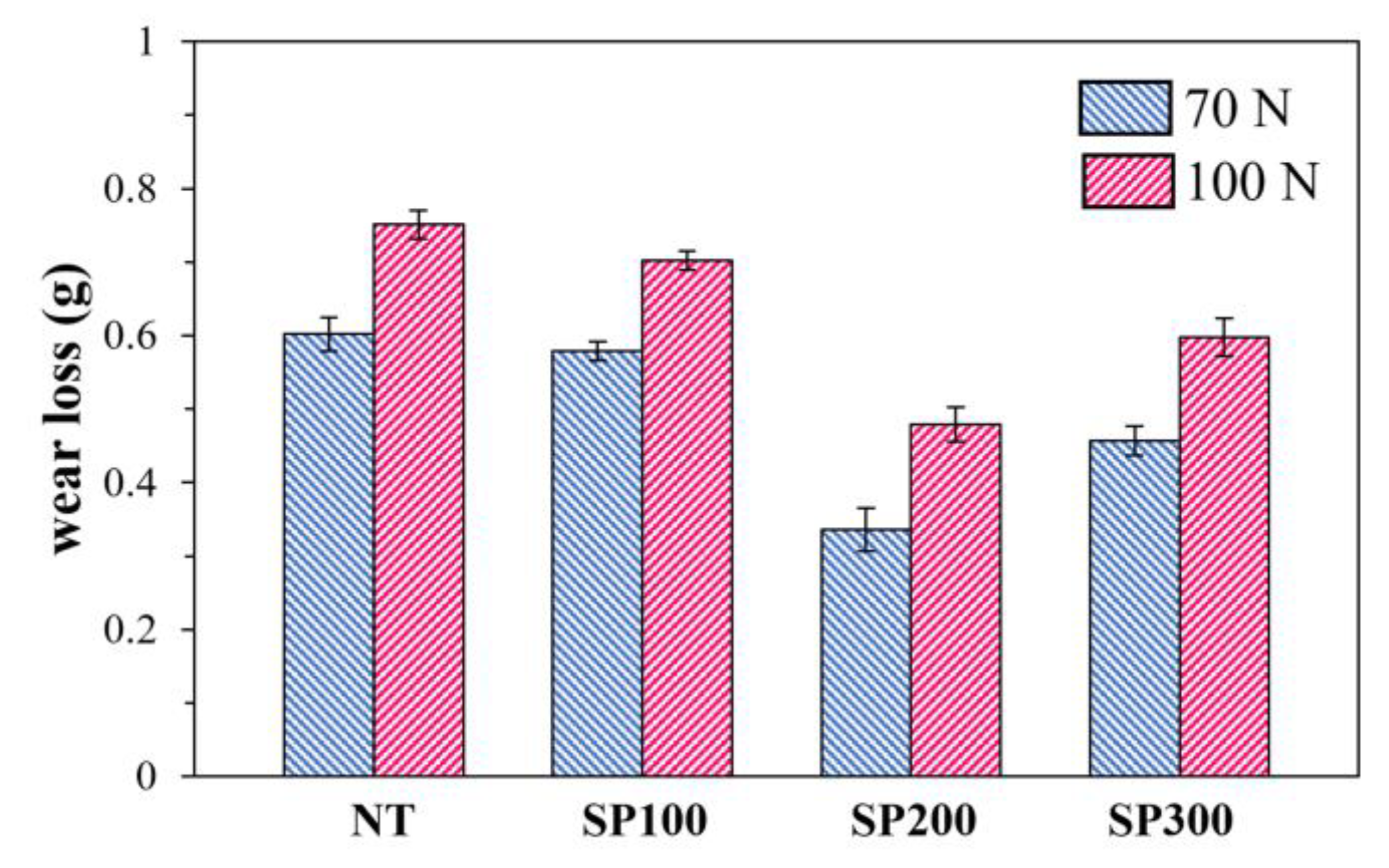

3.2. Tribological Performance

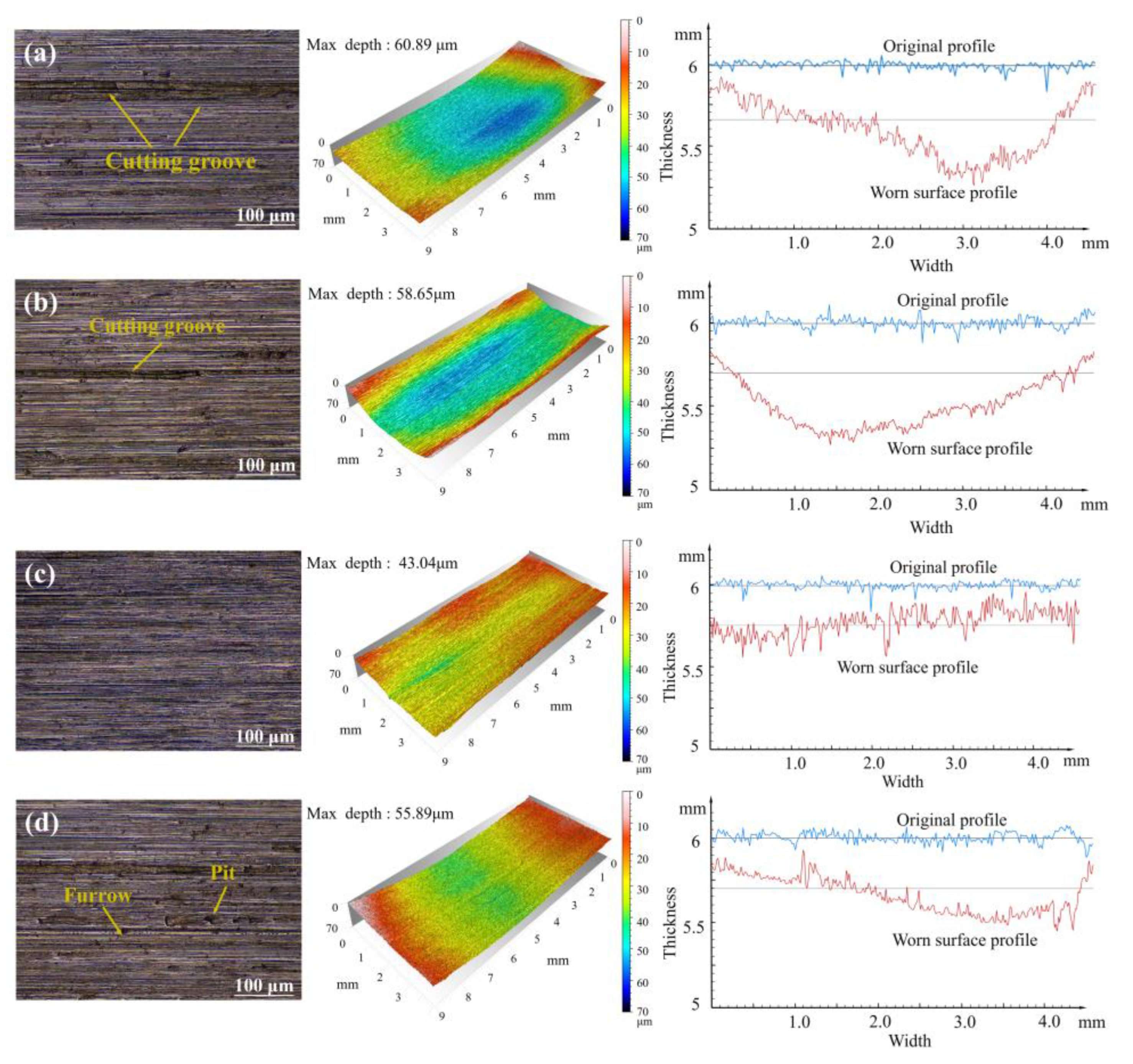

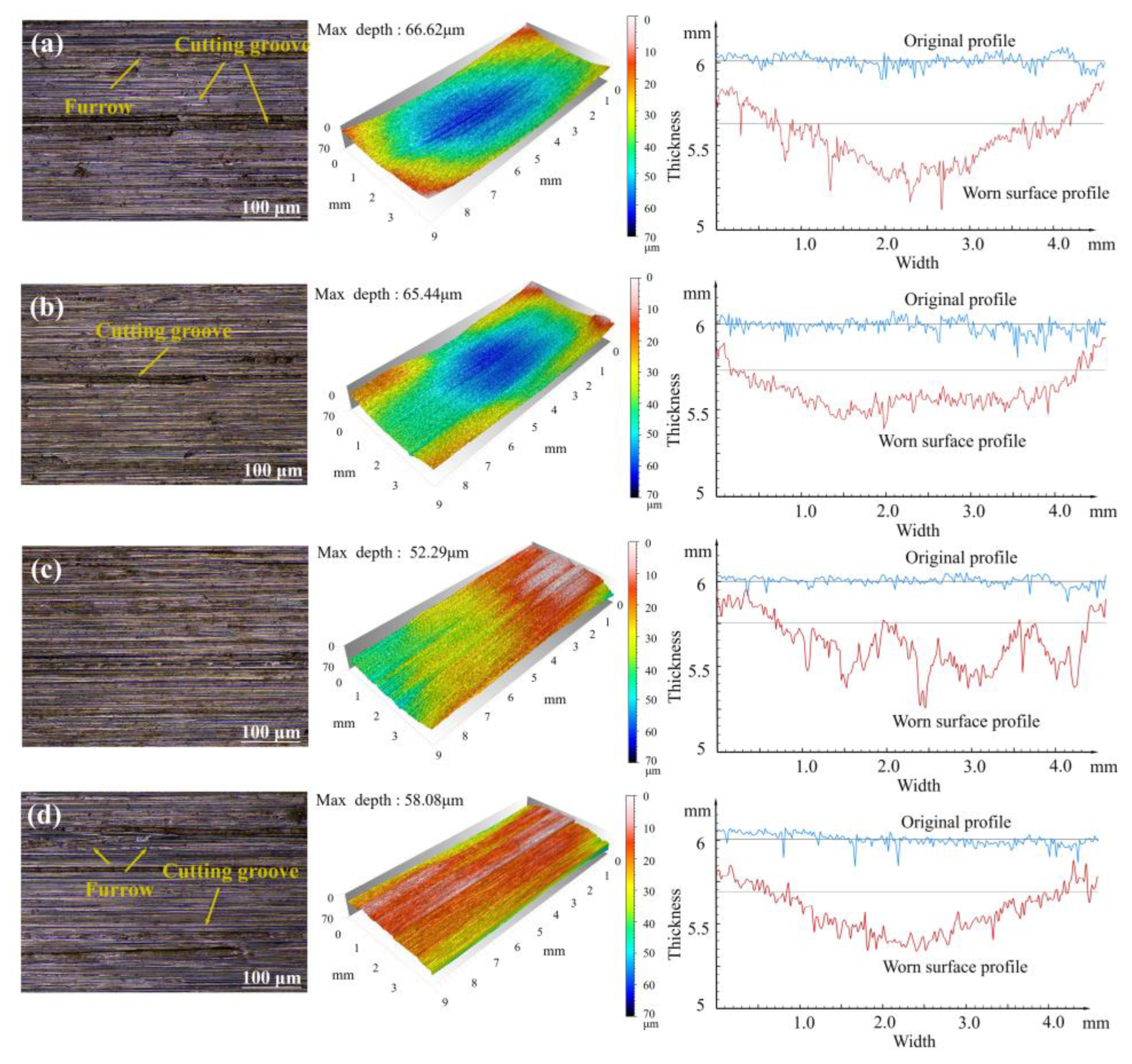

3.3. Worn Surface Characterization

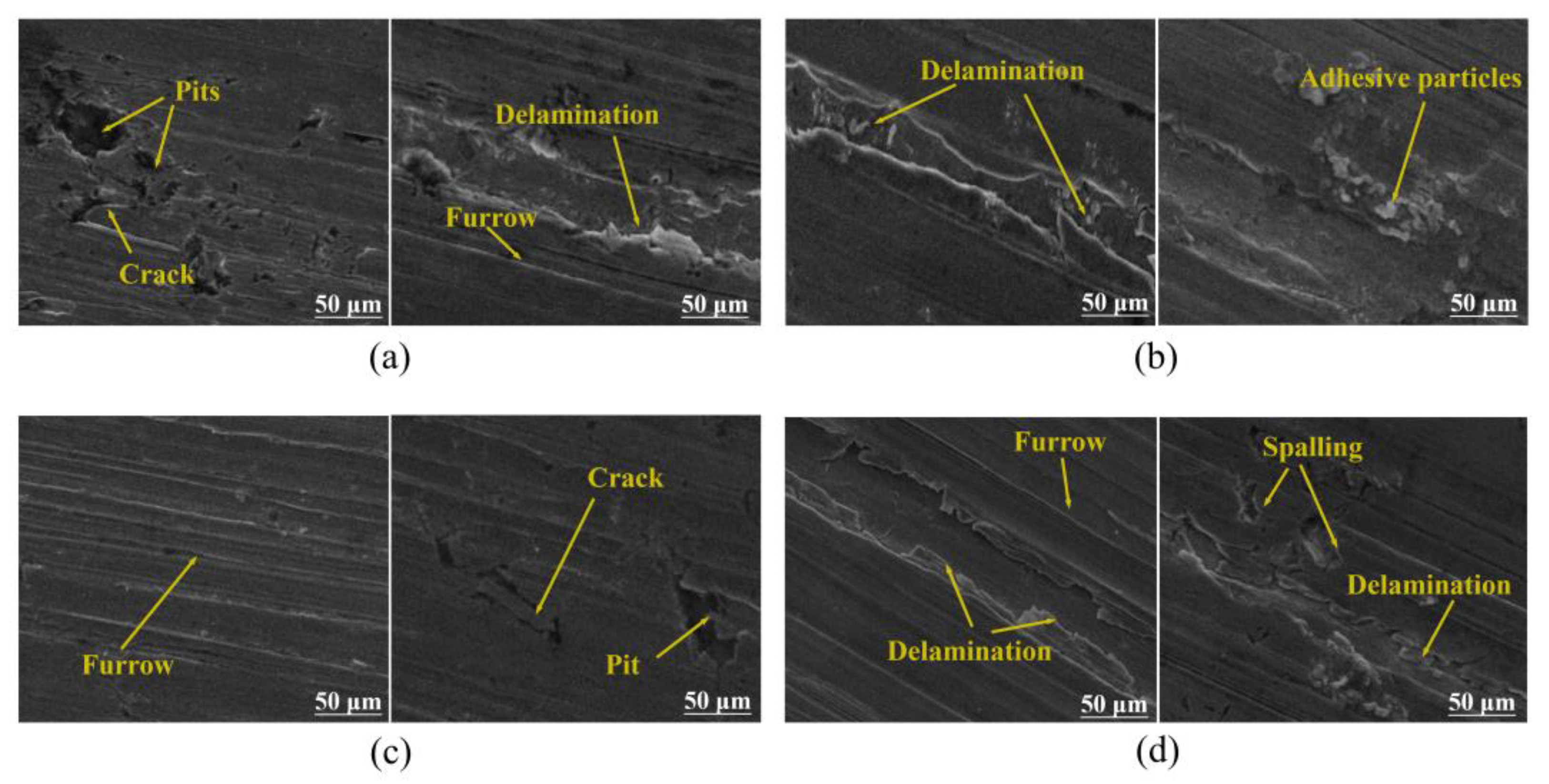

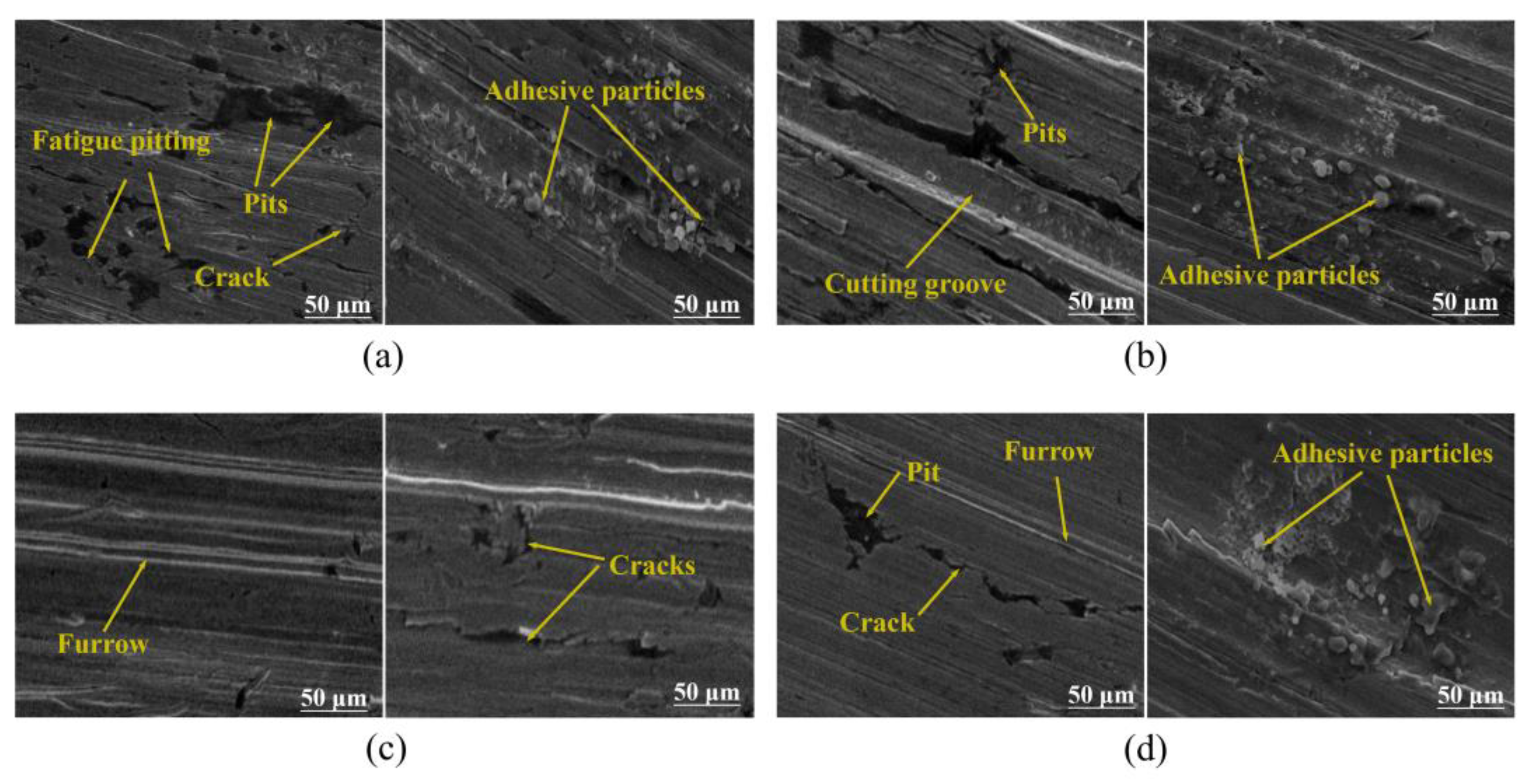

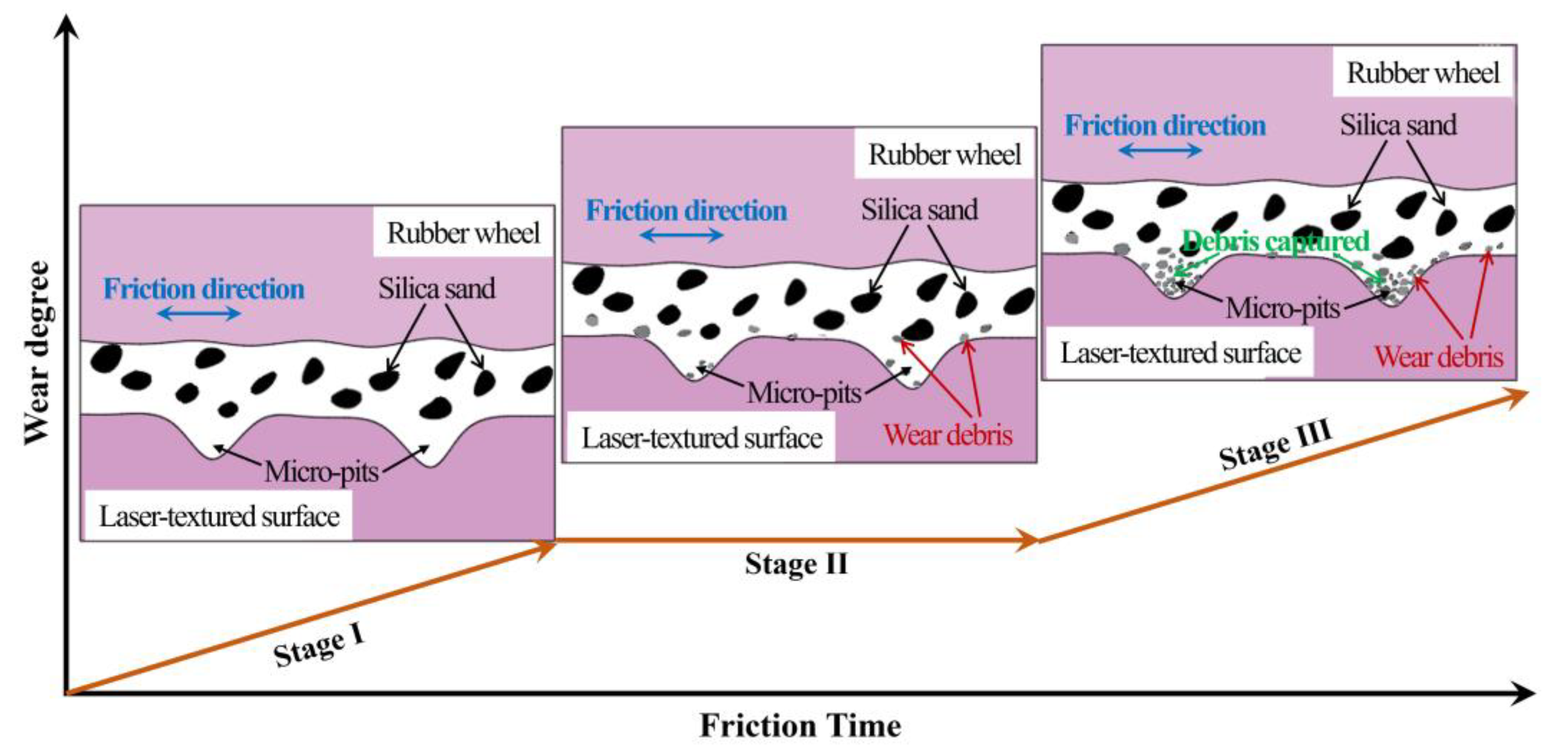

3.4. Wear Mechanism Analysis

4. Conclusions

- (a)

- Laser processing treatment significantly improves the wear resistance of 65Mn steel blade through the lubrication effect due to the wear debris capturing ability of the laser processed micro-pits. The surface texture at the scanning speed of 200 mm/s possesses the best anti-wear effect.

- (b)

- With the increase in applied load, the texture can still reduce the wear damage with an impaired anti-wear effect, due to the gradual flattening of some texture by long-term friction and the crush damage by high load conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, R.-C.; Wen, C.K.; Li, S.Y.; Li, R.; Pu, H.Y.; Jiang, Y.; Song, Z.H. Quality prediction of tractor rotary tillage based on BiConvLSTM with self-attention. Comput. Electron. Agric. 2023, 206, 107643. [Google Scholar] [CrossRef]

- Kang, A.S.; Grewal, J.S.; Cheema, G.S. Effect of thermal spray coatings on wear behavior of high tensile steel applicable for tiller blades. Mater. Today Proc. 2017, 4, 95–103. [Google Scholar] [CrossRef]

- Li, S.; Huang, K.; Zhang, Z.; Zheng, C.; Li, M.; Wang, L.; Wu, K.; Tan, H.; Yi, X. Wear mechanisms and micro-evaluation of WC + TiC particle-reinforced Ni-based composite coatings fabricated by laser cladding. Mater. Charact. 2023, 197, 112699. [Google Scholar] [CrossRef]

- Karoonboonyanan, S.; Salokhe, V.M.; Niranatlumpong, P. Wear resistance of thermally sprayed rotary tiller blades. Wear 2007, 263, 604–608. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Mi, T.; Zheng, C.; Wu, D.; Chen, Z.; Yi, X. Improvement mechanism of Mo element on cracks, microstructure and properties of laser cladding WC-Ni60AA coating. Surf. Coat. Technol. 2024, 489, 131047. [Google Scholar] [CrossRef]

- Wu, X.; Feng, S.; Zhang, W. Microstructure, phase composition and wear properties of iron-based gradient coatings by laser cladding on 65Mn steel. Surf. Coat. Technol. 2024, 477, 130290. [Google Scholar] [CrossRef]

- Zheng, C.; Huang, K.; Mi, T.; Li, M.; Li, S.; Yi, X. Impact of CeO2 modification on the quality and wear performance of Al2O3/SiC reinforced metal-based coatings. Mater. Charact. 2024, 208, 113641. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.; Wang, W.; Zhang, H.; Liu, Z.; Yu, Y.; Zeng, Q.; Wu, Y. Correlation between surface textural parameter and tribological behaviour of four metal materials with laser surface texturing (LST). Appl. Surf. Sci. 2022, 583, 152410. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Zhao, R.; Pang, X.; Niu, Y.; Xie, J.; Huang, S.; Zhang, Y. Effect of laser mixed texture on tribological properties of 45 steel. Trans. Mater. Heat Treat. 2023, 44, 145–154. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, W.; Guo, Q.; Wang, N.; Chi, B.; Yu, J. Effect of picosecond laser surface texturing under Babbitt coating mask on friction and wear properties of GCr15 bearing steel surface. Eng. Fail. Anal. 2024, 157, 107878. [Google Scholar] [CrossRef]

- Guo, J.; Hu, T.; Li, Q.; Liu, Y. Nanosecond laser-induced dimple texturing of TB6 alloy surfaces: Tribological behavior under dry and starved-oil lubrication. Tribol. Int. 2024, 197, 109842. [Google Scholar] [CrossRef]

- Arun, A.; Lakshmanan, P.; Parthiban, K.; Kumanan, G.; Arunkumar, L. Experimental study on laser surface texturing and wear characterization of titanium alloy. Mater. Today Proc. 2022, 62, 615–618. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Z. The research of 9SiCr by laser hardening surface in soil wear. In Proceedings of the 2009 Academic Annual Conference of Chinese Society of Agricultural Engineering in (CSAE 2009), Taigu, China, 22 August 2009; pp. 1627–1632. Available online: https://kns.cnki.net/kcms2/article/abstract?v=eo3P1e0toG7GK_txOYHSosxjYiOey-r80soN6YoAW76uog7Mp9-NX0JNLiLSGxLSawyjsmHSec_Rj4rM7FKvonqZIUQoPYaKOeipHwqg4YjGcDDBiW_eSEq1KvertYzdD09mBWGrgNx_xBloPH_knxJiDXzhZK9QA9V1laZnuKxYmOdNOSy4uA==&uniplatform=NZKPT&language=CHS (accessed on 13 May 2025).

- Wang, Z.; Ye, R.; Xiang, J. The performance of textured surface in friction reducing: A review. Tribol. Int. 2023, 177, 108010. [Google Scholar] [CrossRef]

- Puoza, J.C. Research progress of surface texturing and thermal diffusion technology to improve tribological properties of materials. Prog. Eng. Sci. 2025, 2, 100034. [Google Scholar] [CrossRef]

- Wang, L.; Ji, J.; Fu, Y.; Hua, X.; Kang, Z. Laser Processing Technology of Micro-groove Texture on Surface of 45 Steel. Lubr. Eng. 2016, 41, 94–100. [Google Scholar]

- Liu, Y.; Xie, A.; Dai, L.; Yang, Y.; Xiong, L. Research on Influence Law of Laser Surface Texturing Process Parameters on Temperature Field. Constr. Mach. Equip. 2024, 55, 23–32. [Google Scholar]

- Sun, Q.; Deng, J.; Lu, Y.; Meng, Y.; Wang, R.; Wu, J.; Zhang, Z. Research on Laser Processing Concave-convex Texture and Its Surface Properties. Tool Eng. 2023, 57, 34–39. [Google Scholar]

- De Zanet, A.; Casalegno, V.; Salvo, M. Laser surface texturing of ceramics and ceramic composite materials—A review. Ceram. Int. 2021, 47, 7307–7320. [Google Scholar] [CrossRef]

- Ripoll, M.R.; Podgornik, B.; Vižintin, J. Finite element analysis of textured surfaces under reciprocating sliding. Wear 2011, 271, 952–959. [Google Scholar] [CrossRef]

- Cao, B.; Yang, F.; Yang, Y.; Jiang, F.; Liu, C. Research Progress and Application Analysis of Surface Micro-texture Laser Processing Technology. Mach. Tool Hydraul. 2024, 52, 207–217. [Google Scholar]

- Zhang, Z.; Lu, W.; He, Y.; Zhou, G. Research on optimal laser texture parameters about antifriction characteristics of cemented carbide surface. Int. J. Refract. Met. Hard Mater. 2019, 82, 287–296. [Google Scholar] [CrossRef]

- Wu, W.; Chen, G.; Zhao, N.; Fan, B. Experimental study on the groove surface texture processed by laser on the surface of high-speed steel. Infrared Laser Eng. 2016, 45, 0206008. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Quazi, M.M.; Al Mahmud, K.A.H.; Gulzar, M.; Habibullah, M. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition. Appl. Surf. Sci. 2015, 356, 1135–1149. [Google Scholar] [CrossRef]

- Vishnoi, M.; Kumar, P.; Murtaza, Q. Surface texturing techniques to enhance tribological performance: A review. Surf. Interfaces 2021, 27, 101463. [Google Scholar] [CrossRef]

- Woźniak, A.; Bialas, O.; Adamiak, M.; Hadzima, B.; Szewczenko, J. The influence of laser texturing on the tribological behavior of titanium alloy Ti6Al4V in medical applications. Arch. Civ. Mech. Eng. 2024, 24, 146. [Google Scholar] [CrossRef]

- Lu, G.; Shi, X.; Zhang, J.; Zhou, H.; Xue, Y.; Ibrahim, A.M.M. Effects of surface composite structure with micro-grooves and Sn-Ag-Cu on reducing friction and wear of Ni3Al alloys. Surf. Coat. Technol. 2020, 387, 125540. [Google Scholar] [CrossRef]

- Shi, Z.; Duan, X.; Chen, Z.; Liu, B.; Fu, H.; Ji, J. Precision fabrication of micro-textures array for surface functionalization using picosecond pulse laser. Opt. Laser Technol. 2024, 177, 111200. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

| Element | C | Mn | S | Si | P | Ni | Cr | Cu |

|---|---|---|---|---|---|---|---|---|

| wt% | 0.65 | 1.0 | 0.035 | 0.25 | 0.035 | 0.25 | 0.25 | 0.25 |

| Parameters | Frequency (kHz) | Current (A) | Pulse Width (μs) | Scanning Speed (mm/s) | Number of Cycles | Radiation Power (Kw) | Single-Pulse Energy (mJ) |

|---|---|---|---|---|---|---|---|

| Value | 40 | 1 | 1 | 100/200/300 | 1 | 0.5 | 0.5 |

| Group Name | Specimen Type | Rotate Speed and Duration | Load (N) | Number of Samples |

|---|---|---|---|---|

| NT | Non-textured samples | 100 rpm and 3 h | 70 | 8 |

| 100 | 8 | |||

| SP100 | Laser-textured samples under 100 mm/s scanning speed | 70 | 8 | |

| 100 | 8 | |||

| SP200 | Laser-textured samples under 200 mm/s scanning speed | 70 | 8 | |

| 100 | 8 | |||

| SP300 | Laser-textured samples under 300 mm/s scanning speed | 70 | 8 | |

| 100 | 8 |

| Load (N) | Group | Wear Loss (g) | PoWR (%) | Wear Depth (µm) | Key Observations on Worn Surfaces |

|---|---|---|---|---|---|

| 70 | NT | 0.602 ± 0.023 | / | 60.89 ± 0.25 | Pit, crack, furrow, delamination |

| SP100 | 0.579 ± 0.013 | 3.8 | 58.65 ± 0.23 | Delamination, adhesive particle | |

| SP200 | 0.336 ± 0.029 | 44.2 | 43.04 ± 0.09 | Pit, crack, furrow | |

| SP300 | 0.457 ± 0.02 | 24.1 | 55.89 ± 0.18 | Furrow, spalling, delamination | |

| 100 | NT | 0.751 ± 0.019 | / | 66.62 ± 0.32 | Pit, crack, fatigue pitting, adhesive particle |

| SP100 | 0.702 ± 0.013 | 6.5 | 65.44 ± 0.13 | Pit, cutting groove, adhesive particle | |

| SP200 | 0.479 ± 0.023 | 36.2 | 52.29 ± 0.22 | Crack, furrow | |

| SP300 | 0.598 ± 0.026 | 20.4 | 58.08 ± 0.11 | Pit, crack, furrow, adhesive particle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Yang, D.; Ou, Y.; Zhang, J.; Hu, Y.; Ma, L. Laser Texturing to Improve Wear Resistance of 65Mn Steel Rotary Tiller Blades: Effects of Scanning Speed. Lubricants 2025, 13, 224. https://doi.org/10.3390/lubricants13050224

Xiao H, Yang D, Ou Y, Zhang J, Hu Y, Ma L. Laser Texturing to Improve Wear Resistance of 65Mn Steel Rotary Tiller Blades: Effects of Scanning Speed. Lubricants. 2025; 13(5):224. https://doi.org/10.3390/lubricants13050224

Chicago/Turabian StyleXiao, Heng, Dongyan Yang, Yiding Ou, Junlan Zhang, Yue Hu, and Lei Ma. 2025. "Laser Texturing to Improve Wear Resistance of 65Mn Steel Rotary Tiller Blades: Effects of Scanning Speed" Lubricants 13, no. 5: 224. https://doi.org/10.3390/lubricants13050224

APA StyleXiao, H., Yang, D., Ou, Y., Zhang, J., Hu, Y., & Ma, L. (2025). Laser Texturing to Improve Wear Resistance of 65Mn Steel Rotary Tiller Blades: Effects of Scanning Speed. Lubricants, 13(5), 224. https://doi.org/10.3390/lubricants13050224