Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties

Abstract

1. Introduction

2. Ceramic Additive Manufacturing Technology and Process

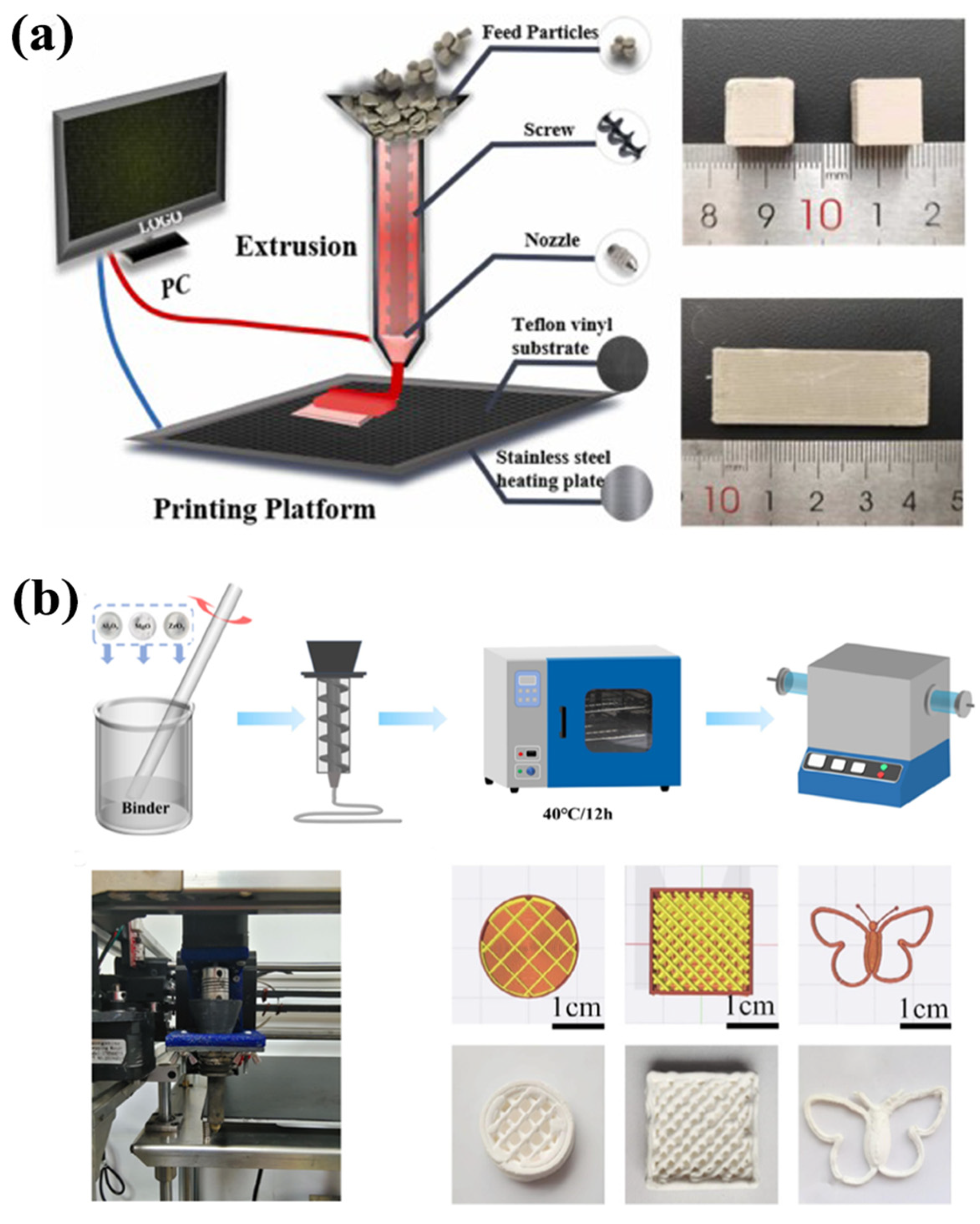

2.1. Ceramic 3D Printing Technology Based on Extrusion Molding Mechanisms

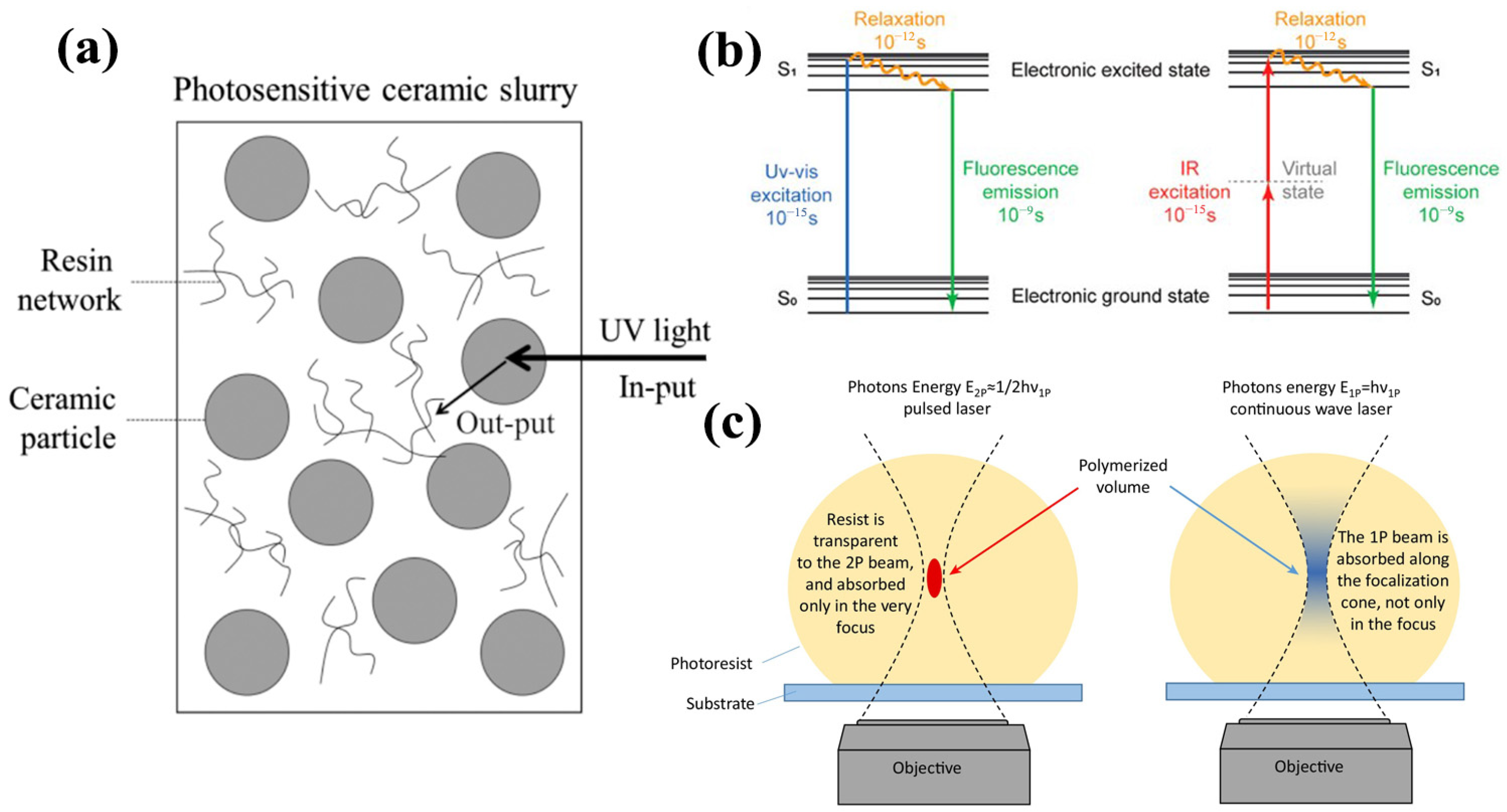

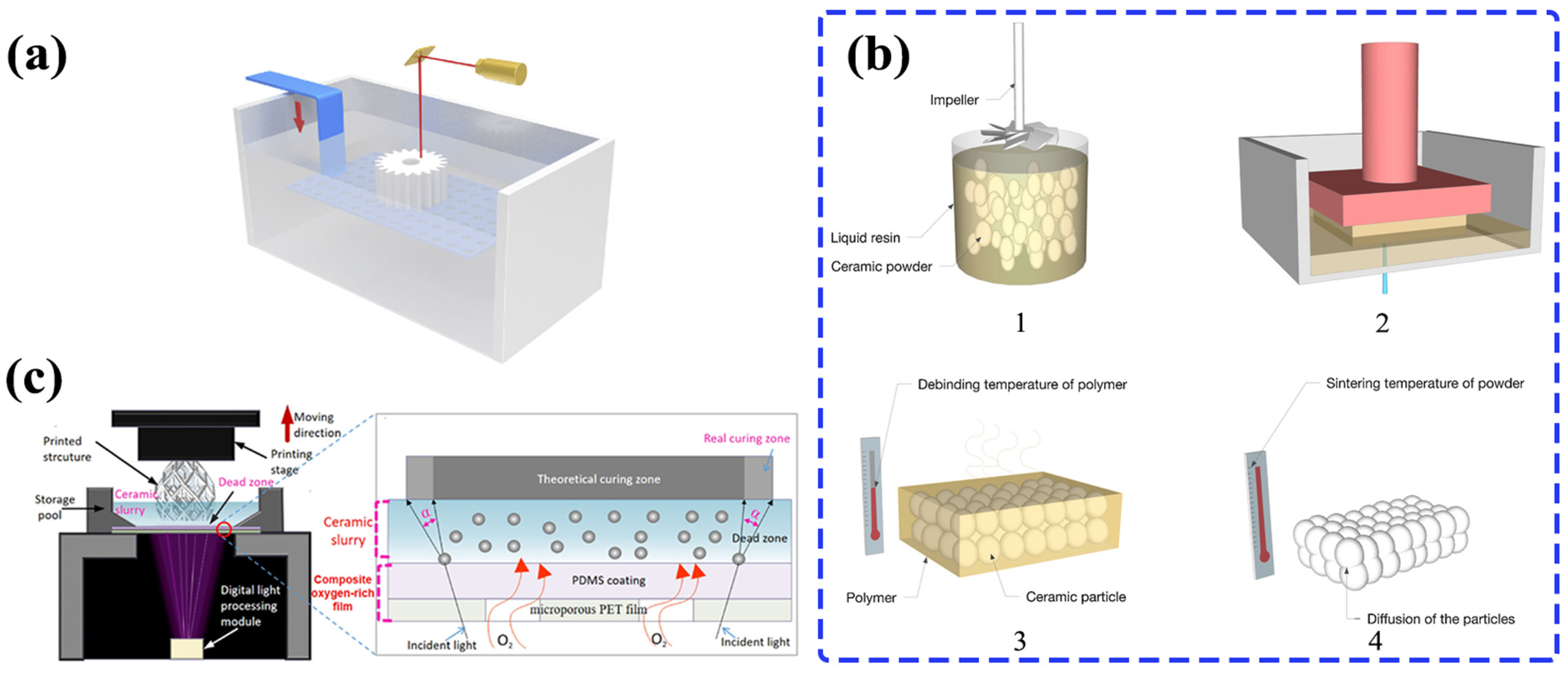

2.2. Ceramic 3D Printing Technology Based on Photopolymerization Mechanisms

2.3. Ceramic 3D Printing Technology Based on a Powder Melting Mechanism

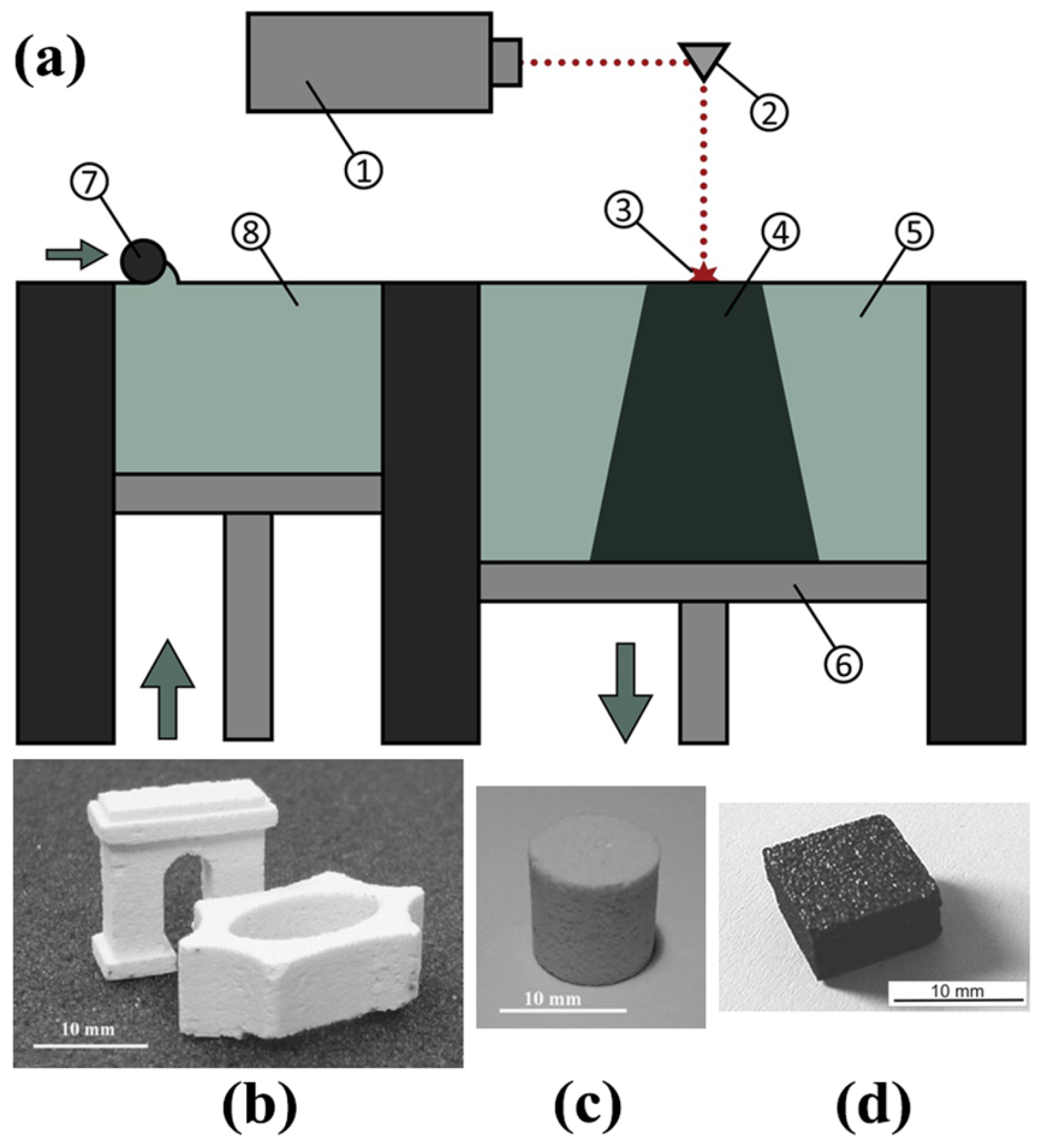

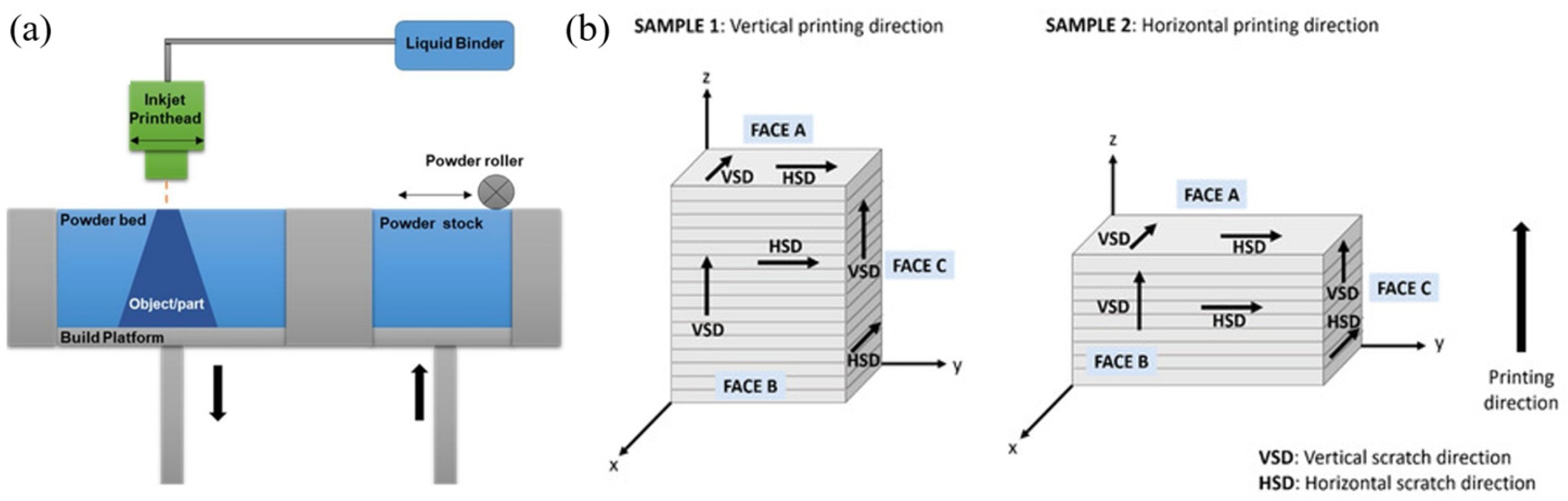

2.4. Ceramic 3D Printing Technology Based on the Powder Bonding Mechanism

2.5. 4D Printing of Structural Ceramics

3. Ceramic Materials Systems for Tribological Applications

3.1. Oxide Ceramics

3.1.1. Al2O3

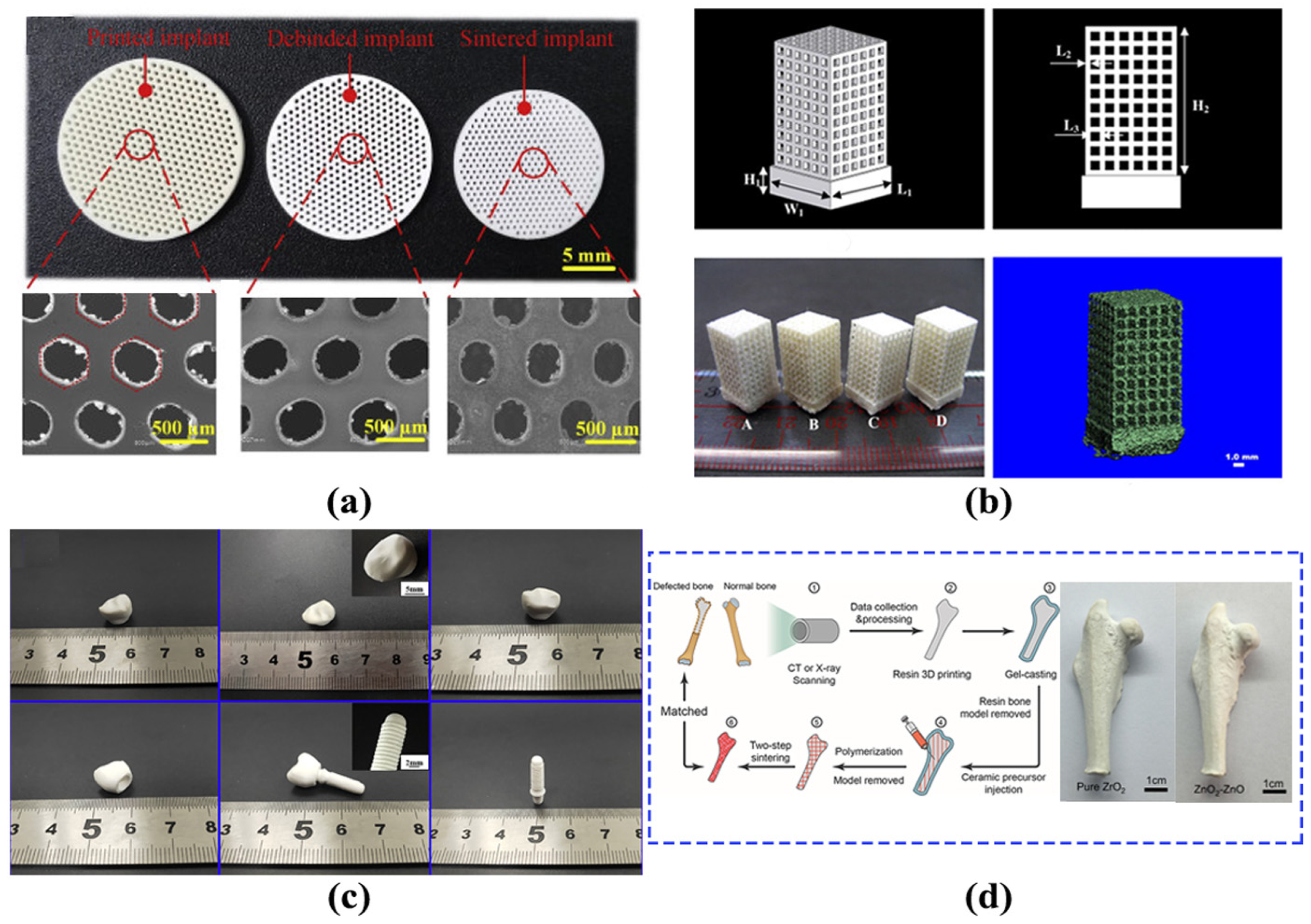

3.1.2. ZrO2

3.2. Non-Oxide Ceramics

3.2.1. SiC

3.2.2. Si3N4

3.3. Bioceramics

| Composition | Sintering Process | Sintering Parameter | Relative Density (%) | Bending Strength (MPa) | Compressive Strength (MPa) | Modulus | Ref. |

|---|---|---|---|---|---|---|---|

| HAP | - | 1200 or 1300 °C (1 h) | 98.0–98.9 | 100 | - | - | [30] |

| PLS 1 in Ar | 1250 °C | - | - | - | - | [25] | |

| CHAP | SLS | Based on SLS parameters | 66.8 ± 2.5 | - | 0.6–0.7 | Compressive: 6.1–7.3 MPa | [41] |

| FAp glass–ceramics | PLS | 1000 °C (0.5 h) | - | 205.97 | - | Elastic: 97.06 GPa | [108] |

3.4. MAX Phases

3.5. Composite Ceramics

| Composition | Sintering Additives | Sintering Process | Sintering Parameter | Relative Density (%) | Mechanical Properties | Ref. |

|---|---|---|---|---|---|---|

| ZTA | - | PLS 1 in Ar | 1500 °C (1 h) | 89.3 | Fracture toughness: 4.05 MPa·m1/2; Hardness: 14.1 GPa | [24] |

| Y2O3 | PLS in air | 1600 °C (3 h) | 98.79 | - | [35] | |

| ZrO2/leucite | - | VS 2 | 820 °C (5 min) and then 950 °C (10 min) | 61.5–82.5 | - | [115] |

| Graphene /Al2O3 | ZrO2/MgO | PLS in N2 | 1550 °C (2 h) | 96.2 | Fracture toughness: 3.2–4.5 MPa·m1/2 | [12] |

| B4C/Co | - | SLM in Ar | P = 200 W; d = 70 μm | 63 | Hardness: 2900–3200 HV | [40] |

| WC-12%Co | - | PS 3 in Ar | 1485 °C (0.5 h) | ~100 | Fracture toughness: 17 ± 1; Hardness: 1256 HV | [43] |

| 1500 °C, 100 bar | - | Hardness: 11.0–11.8 GPa | [82] | |||

| WC-10Co | Y2O3 | PLS in inert atmosphere | 1440 °C (1 h) | - | Compressive strength: 2449 MPa; Elastic modulus: 38.8 GPa. | [118] |

| WC-Fe-Ni-Co | VC/Cr3C2/NbC/Y2O3/Nd2O3 | VS | 1300 °C (4 h) | 95–99 | Bending strength: 113 MPa; Hardness: 1820 ± 290 HV (Y2O3), 1570 ± 230 HV (Cr3C2) | [119] |

| SiC-Ti3AlC2 | - | VS | 1200–1300 °C (4 h) | - | Hardness: 290 ± 15 HV | [120] |

| TiC-Ti3AlC2 | - | VS | 1200–1300 °C (4 h) | - | Bending strength: 784 ± 9 MPa | [120] |

| - | SLS/SLM in Ar | P = 164–200 W; v = 0.12–0.36 m·s–1 | 93–95 | Hardness: 2.29 ± 0.1 GPa | [121] | |

| TiC-Ti3AlC | - | SLS/SLM in Ar | P = 164–200 W; v = 0.12–0.36 m·s–1 | 93–95 | - | [121] |

4. Microstructure and Tribological Properties of Additively Manufactured Ceramics

4.1. Tribological Properties of Additively Manufactured Ceramics

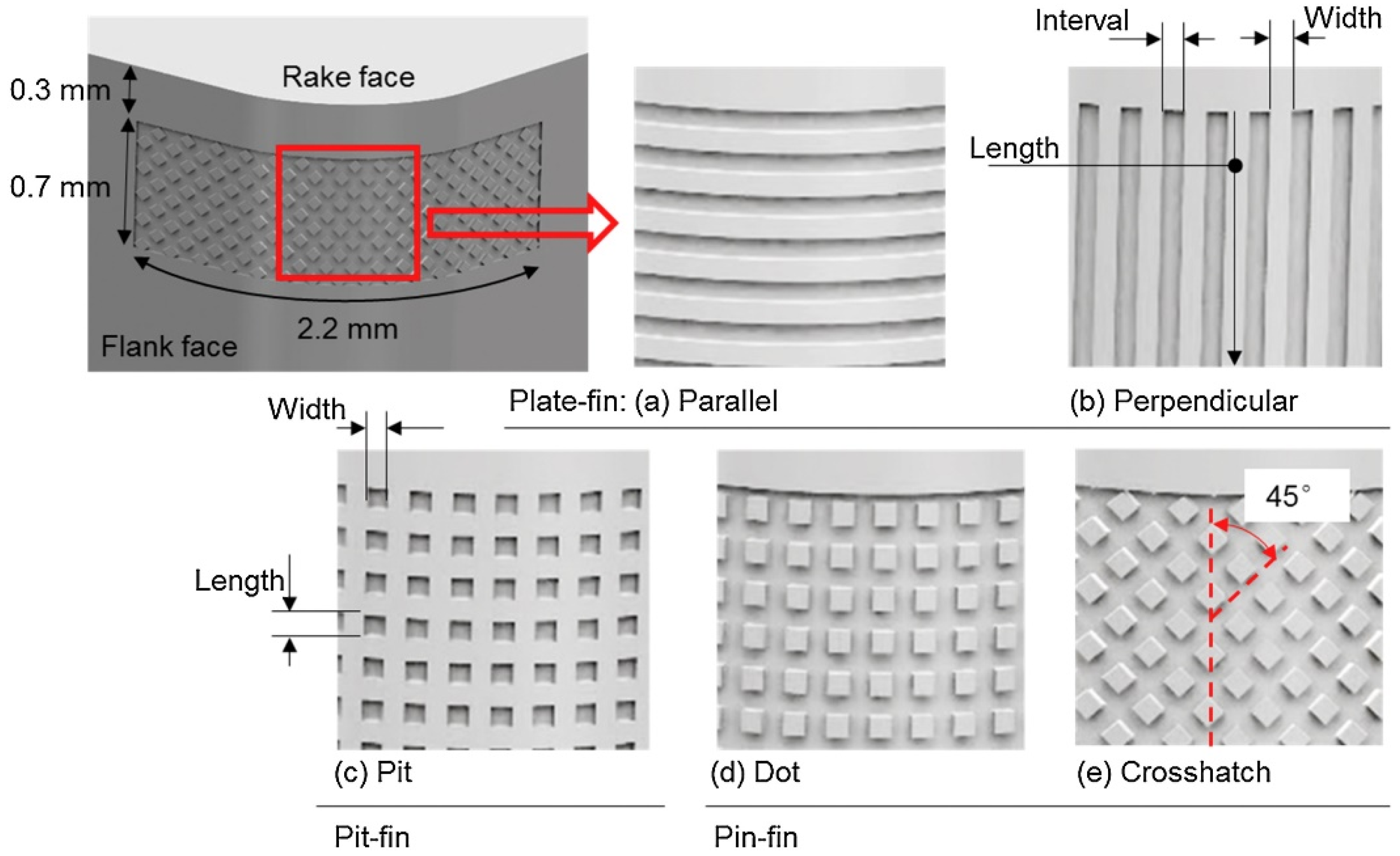

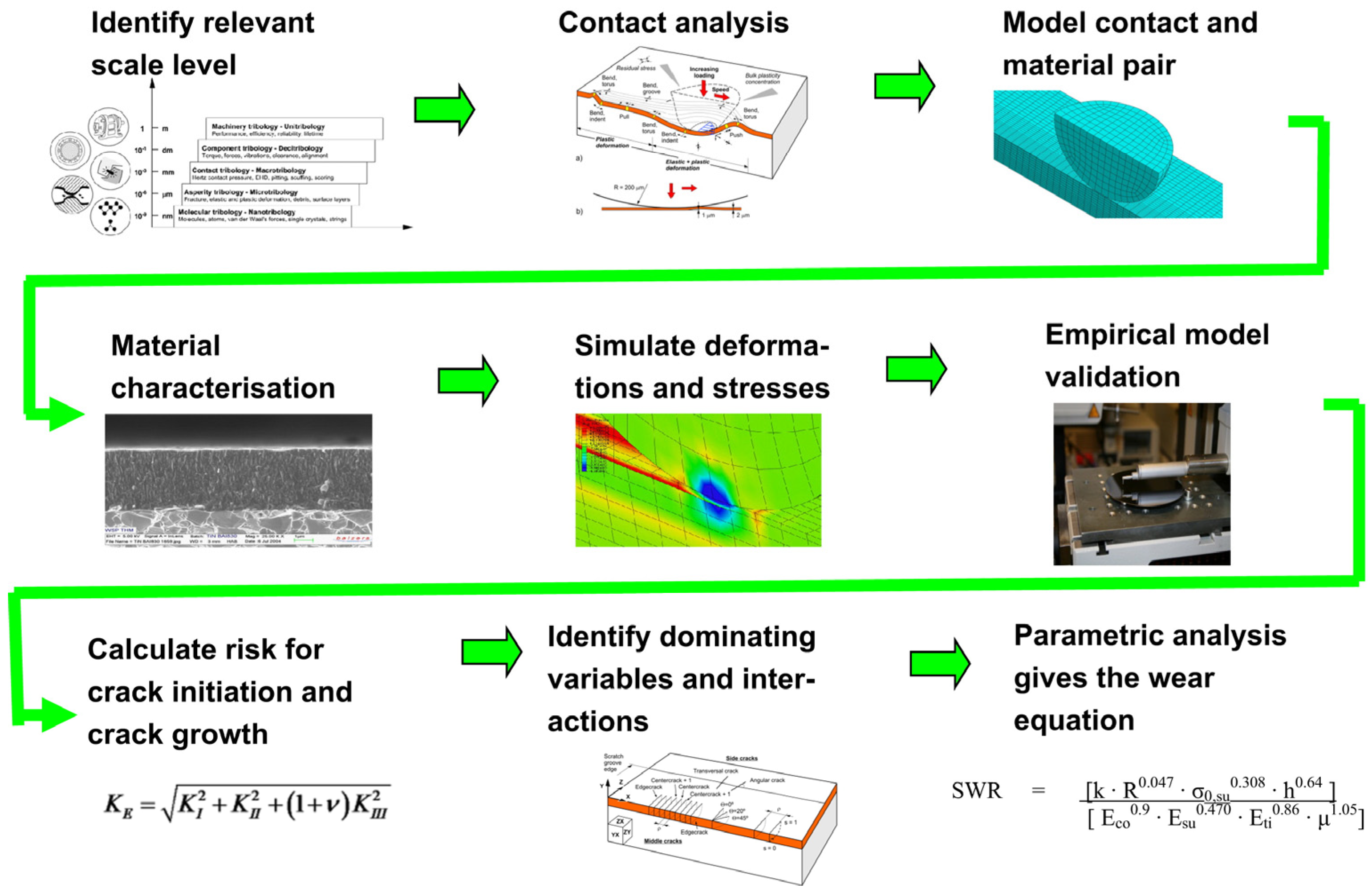

4.2. Surface Texture

4.3. Lubrication

4.4. Surface Coating

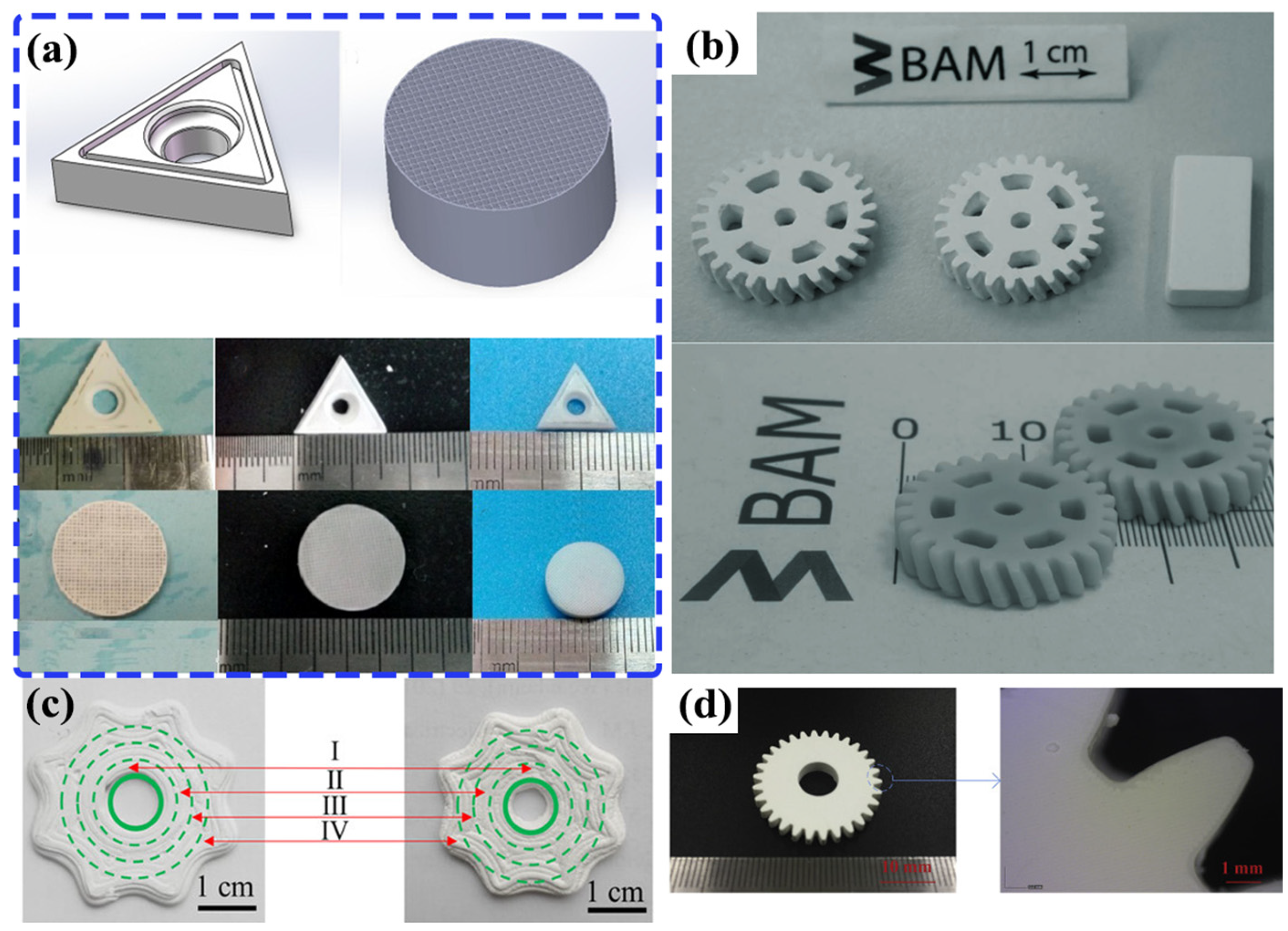

5. Typical Tribological Applications of Ceramic Additive Manufacturing Technology

5.1. Industrial Devices

5.2. Biomedical Applications

6. Summary and Prospects

- Additive manufacturing technology is not yet mature in the field of ceramics, and the manufacturing process is needed to be further improved, such as by improving the high-temperature rheological properties of ceramic powders and adhesive composites in extrusion-based 3D printing, the influence of ceramic powders on the absorbance of slurry in photocuring 3D printing, surface irregularities in powder-melting 3D printing, and the rheological properties of printing inks in powder-bonding 3D printing.

- Additively manufactured structural ceramic systems used in tribological applications include oxide ceramics, non-oxide ceramics, bioceramics, MAX phases, and composite ceramics, according to the property requirements. MAX-phase ceramics can reduce the friction coefficient and wear, and they represent a very promising material with excellent tribological properties. Combining them with near-net-shape forming technology is a future development direction in additive manufactured ceramics.

- The combination of different additive manufacturing technologies with multi-material systems can integrate their respective advantages for various structural/functional integrated applications. By combining various mechanisms and technologies, the friction and wear performance of ceramics can be maximized by designing novel surface textures, surface lubrication, and surface coatings, which represents a new research direction.

- As an extension of 3D printing technology, 4D printing technology can change the shapes or structures printed using 3D technology under external stimulation, directly embed the deformation design of materials and structures into the material, and simplify the creation process from design concept to physical object. This will allow for a novel design, manufacturing and assembly of integrated ceramic parts.

- The realization of the macroscopic superlubricity phenomenon and bionic structure design are two hot research directions for the future development of friction-reducing and wear-resistant ceramic components. Both the two-dimensional layered structure and the structure of synovial joints have excellent tribological properties. Additive manufacturing for the precision manufacturing of complex structures can be used as a good solution to this problem. However, the high costs and difficulty in the industrialization of these technologies have become major limiting factors.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| FDM | Fused deposition modelling |

| DIW | Direct ink writing |

| SLA | Stereolithography |

| DLP | Digital light processing |

| TPP | Two-photon polymerization |

| SLM | Selective laser melting |

| SLS | Selective laser sintering |

| BJP | Binder jet 3D Printing |

| CSL | Ceramic stereolithography |

| LSD | Layered slurry deposition |

| TEOS | Tetraethyl orthosilicate |

| PRC | Pyrolytic carbon |

| LSI | Liquid silicon infiltration |

| HAP | Hydroxyapatite |

| CHAP | Carbonated hydroxyapatite |

| FAp | Fluorapatite |

| μ | Friction coefficient |

References

- Holmberg, K.; Erdemir, A. Influence of Tribology on Global Energy Consumption, Costs and Emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Wang, Y.M.; Zhou, Y.; Murakami, T.; Sasaki, S. Microstructure and Tribological Properties of ZrO2(Y2O3) Matrix Composites Doped with Different Solid Lubricants from Room Temperature to 800 °C. Wear 2009, 267, 1353–1360. [Google Scholar] [CrossRef]

- Ouyang, J.-H.; Li, Y.-F.; Zhang, Y.-Z.; Wang, Y.-M.; Wang, Y.-J. High-Temperature Solid Lubricants and Self-Lubricating Composites: A Critical Review. Lubricants 2022, 10, 177. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, H.; Chang, P.; Yang, Y.; Cheng, L.; Zhang, L. High-Strength Printed Ceramic Structures for Higher Temperature Lubrication. Compos. Part B Eng. 2021, 221, 109013. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, Y.; Zhao, D.; Chen, Y.; Guan, S.; Liu, Y.; Liu, L.; Peng, S.; Kong, F.; Poplawsky, J.D.; et al. Strong yet Ductile Nanolamellar High-Entropy Alloys by Additive Manufacturing. Nature 2022, 608, 62–68. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Li, Y.; Sheng, P.; Lin, L.; Wang, L.; Lu, D.; Lin, K.; Wu, H.; Wu, S. Vat Photopolymerization versus Conventional Colloidal Processing Methods in Structural Ceramics: Progress, Challenges, and Future Perspectives. Addit. Manuf. Front. 2024, 3, 200110. [Google Scholar] [CrossRef]

- Yao, X.; Liu, S.; Ji, Z.; Guo, R.; Sun, C.; Guo, Y.; Wang, X.; Wang, Q. 3D Printing of PTFE-Filled Polyimide for Programmable Lubricating in the Region Where Lubrication Is Needed. Tribol. Int. 2022, 167, 107405. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, J.; Yan, C.; Chen, Y.; Zhang, X.; Jia, X.; Liu, Y.; Wang, X.; Zhou, F. Direct Ink Writing of High Performance Architectured Polyimides with Low Dimensional Shrinkage. Adv. Eng. Mater. 2019, 21, 1801314. [Google Scholar] [CrossRef]

- Abdelkader, M.; Petrik, S.; Nestler, D.; Fijalkowski, M. Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market. Ceramics 2024, 7, 68–85. [Google Scholar] [CrossRef]

- Ramezani, M.; Dommati, H.; Wang, J.-C.; Pasang, T.; Lee, C. Tribological Characterization of Alumina Ceramic Manufactured by Solvent-Based Slurry Stereolithography. J. Mater. Eng. Perform. 2023, 32, 8325–8336. [Google Scholar] [CrossRef]

- Fan, J.; Guan, R.; Ou, K.; Fu, Q.; Liu, Q.; Li, D.; Zheng, H.; Sun, Y. Direct Ink Writing 3D Printing of Graphene/Al2O3 Composite Ceramics with Gradient Mechanics. Adv. Eng. Mater. 2023, 25, 2201414. [Google Scholar] [CrossRef]

- Lei, B.; Xiong, H.; Chen, K. Comparison of Wear and Marginal Fitness of 3D-Printed Deciduous Molar Crowns: An in Vitro Study. Dent. Mater. J. 2024, 43, 227–234. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, H.; Chang, P.; Yang, Y.; Huang, W.; Liu, Y.; Cheng, L.; Zhang, L. 3D-Printed Topological MoS2 /MoSe2 Heterostructures for Macroscale Superlubricity. ACS Appl. Mater. Interfaces 2021, 13, 34984–34995. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, L.; Liu, Y.; Li, Y.; Xie, G.; Chang, P.; Mei, H.; Cheng, L.; Zhang, L. Internal and External MoS2/GO Heterostructure Enhanced Multi-Point Contact Egg-Box Inspired SiOC for Macroscopic Ultra-Low Friction. Carbon 2024, 221, 118908. [Google Scholar] [CrossRef]

- Yuan, W.; Yao, Y.; Keer, L.; Jiao, Y.; Yu, J.; Li, Q.; Feng, X.-Q. 3D-Printed Biomimetic Surface Structures with Abnormal Friction Properties. Extrem. Mech. Lett. 2019, 26, 46–52. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021(En), Additive Manufacturing—General Principles—Fundamentals and Vocabulary. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 9 December 2024).

- Sun, H.; Zou, B.; Wang, X.; Chen, W.; Zhang, G.; Quan, T.; Huang, C. Advancements in Multi-Material Additive Manufacturing of Advanced Ceramics: A Review of Strategies, Techniques and Equipment. Mater. Chem. Phys. 2024, 319, 129337. [Google Scholar] [CrossRef]

- Cheype, M.; Pateloup, V.; Bernard, S. Straightforward Design Strategy toward 3D Near-Net-Shape Stoichiometric SiC Parts. Adv. Mater. 2024, 36, 2307554. [Google Scholar] [CrossRef]

- Kong, F.; Chen, X.; Li, Y.; Tian, L.; Zheng, F.; Wang, E.; Zhao, G. A Novel Approach to Prepare High Density SiC Ceramics by Powder Extrusion Printing (PEP) Combined with One-Step Sintering Method. J. Eur. Ceram. Soc. 2024, 44, 626–634. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Zhang, W.; Peng, Y.; Zhang, W.; Zhu, X.; Xiong, X.; Wu, M.; Liu, B. Integrating Shape and Performance Control in Polycrystalline Cubic Boron Nitride Fabricated Using Powder Extrusion Printing. Int. J. Refract. Met. Hard Mater. 2023, 115, 106304. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Z.; Liu, Q.; Kuliiev, R.; Orlovskaya, N.; Wu, D. Extrusion-Based Additive Manufacturing of Yttria-Partially-Stabilized Zirconia Ceramics. Ceram. Int. 2020, 46, 5020–5027. [Google Scholar] [CrossRef]

- Mamatha, S.; Biswas, P.; Ramavath, P.; Das, D.; Johnson, R. 3D Printing of Complex Shaped Alumina Parts. Ceram. Int. 2018, 44, 19278–19281. [Google Scholar] [CrossRef]

- Liu, X.; Zou, B.; Xing, H.; Huang, C. The Preparation of ZrO2-Al2O3 Composite Ceramic by SLA-3D Printing and Sintering Processing. Ceram. Int. 2020, 46, 937–944. [Google Scholar] [CrossRef]

- Chen, Q.; Zou, B.; Lai, Q.; Wang, Y.; Xue, R.; Xing, H.; Fu, X.; Huang, C.; Yao, P. A Study on Biosafety of HAP Ceramic Prepared by SLA-3D Printing Technology Directly. J. Mech. Behav. Biomed. Mater. 2019, 98, 327–335. [Google Scholar] [CrossRef]

- Ding, G.; He, R.; Zhang, K.; Zhou, N.; Xu, H. Stereolithography 3D Printing of SiC Ceramic with Potential for Lightweight Optical Mirror. Ceram. Int. 2020, 46, 18785–18790. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, L.Y.; Yuan, J.; Guo, H.; Wang, H.; Ye, P.; Du, Z.; Zhao, Y.; Zhang, H.; Gan, C.L. Stereolithography 3D Printing of Si3N4 Cellular Ceramics with Ultrahigh Strength by Using Highly Viscous Paste. Ceram. Int. 2023, 49, 6984–6995. [Google Scholar] [CrossRef]

- Zhang, G.; Jiang, J.; Wang, H.; Qian, L.; Lan, H. Continuous DLP-Based Ceramic 3D Printing Using a Composite Oxygen-Rich Film. J. Manuf. Process. 2021, 64, 341–348. [Google Scholar] [CrossRef]

- Zhang, F.; Zuo, Y.; Zhang, K.; Gao, H.; Zhang, S.; Chen, H.; Liu, G.; Jin, X.; Yang, J. Fabrication of Zirconia Ceramic Dental Crowns by Digital Light Processing: Effects of the Process on Physical Properties and Microstructure. 3d Print. Addit. Manuf. 2024, 11, e1257–e1270. [Google Scholar] [CrossRef]

- Mohammadi, M.; Coppola, B.; Montanaro, L.; Palmero, P. Digital Light Processing of High-Strength Hydroxyapatite Ceramics: Role of Particle Size and Printing Parameters on Microstructural Defects and Mechanical Properties. J. Eur. Ceram. Soc. 2023, 43, 2761–2772. [Google Scholar] [CrossRef]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of Complex-Shaped Zirconia Ceramic Parts via a DLP- Stereolithography-Based 3D Printing Method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Tang, J.; Guo, X.; Chang, H.; Hu, K.; Shen, Z.; Wang, W.; Liu, M.; Wei, Y.; Huang, Z.; Yang, Y. The Preparation of SiC Ceramic Photosensitive Slurry for Rapid Stereolithography. J. Eur. Ceram. Soc. 2021, 41, 7516–7524. [Google Scholar] [CrossRef]

- Qu, P.; Liang, G.; Hamza, M.; Mo, Y.; Jiang, L.; Luo, X.; Liu, Z.; Liu, C.; Lou, Y.; Chen, Z. 3D Printing of High-Purity Complex SiC Structures Based on Stereolithography. Ceram. Int. 2024, 50, 23763–23774. [Google Scholar] [CrossRef]

- Tang, J.; Chang, H.; Guo, X.; Liu, M.; Wei, Y.; Huang, Z.; Yang, Y. Preparation of Photosensitive SiO2/SiC Ceramic Slurry with High Solid Content for Stereolithography. Ceram. Int. 2022, 48, 30332–30337. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.; Yao, H.; Zeng, Y.; Chen, J. Preparation, Microstructure, and Properties of ZrO2(3Y)/Al2O3 Bioceramics for 3D Printing of All-Ceramic Dental Implants by Vat Photopolymerization. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100023. [Google Scholar] [CrossRef]

- Zou, R.; Bi, L.; Huang, Y.; Wang, Y.; Wang, Y.; Li, L.; Liu, J.; Feng, L.; Jiang, X.; Deng, B. A Biocompatible Silicon Nitride Dental Implant Material Prepared by Digital Light Processing Technology. J. Mech. Behav. Biomed. Mater. 2023, 141, 105756. [Google Scholar] [CrossRef] [PubMed]

- Prediger, R.; Sriyotha, N.; Schell, K.G.; Kluck, S.; Hambitzer, L.; Kotz-Helmer, F. Two-Photon Polymerization of Nanocomposites for Additive Manufacturing of Transparent Magnesium Aluminate Spinel Ceramics. Adv. Sci. 2024, 11, 2307175. [Google Scholar] [CrossRef]

- Chai, N.; Yue, Y.; Chen, X.; Zeng, Z.; Li, S.; Wang, X. Isotropic Sintering Shrinkage of 3D Glass-Ceramic Nanolattices: Backbone Preforming and Mechanical Enhancement. Int. J. Extrem. Manuf. 2024, 6, 025003. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Alumina–Zirconium Ceramics Synthesis by Selective Laser Sintering/Melting. Appl. Surf. Sci. 2007, 254, 966–970. [Google Scholar] [CrossRef]

- Davydova, A.; Domashenkov, A.; Sova, A.; Movtchan, I.; Bertrand, P.; Desplanques, B.; Peillon, N.; Saunier, S.; Desrayaud, C.; Bucher, S.; et al. Selective Laser Melting of Boron Carbide Particles Coated by a Cobalt-Based Metal Layer. J. Mater. Process. Technol. 2016, 229, 361–366. [Google Scholar] [CrossRef]

- Duan, B.; Wang, M.; Zhou, W.Y.; Cheung, W.L.; Li, Z.Y.; Lu, W.W. Three-Dimensional Nanocomposite Scaffolds Fabricated via Selective Laser Sintering for Bone Tissue Engineering. Acta Biomater. 2010, 6, 4495–4505. [Google Scholar] [CrossRef]

- Zocca, A.; Lima, P.; Günster, J. LSD-Based 3D Printing of Alumina Ceramics. J. Ceram. Sci. Technol. 2017, 08, 141–148. [Google Scholar] [CrossRef]

- Enneti, R.K.; Prough, K.C. Wear Properties of Sintered WC-12%Co Processed via Binder Jet 3D Printing (BJ3DP). Int. J. Refract. Met. Hard Mater. 2019, 78, 228–232. [Google Scholar] [CrossRef]

- Huang, S.; Wu, H.; Jiang, C.; Fu, X.; Liu, Y.; Zhang, J.; He, L.; Yang, P.; Deng, X.; Wu, S. Preparation of High-Strength ZrO2 Ceramics by Binder Jetting Additive Manufacturing and Liquid Glass Infiltration. Ceram. Int. 2024, 50, 44175–44185. [Google Scholar] [CrossRef]

- Lu, X.; Liu, G.; Lu, J. Development of Ceramic 3D/4D Printing in China. Addit. Manuf. Front. 2024, 3, 200158. [Google Scholar] [CrossRef]

- Li, L.; Lin, Q.; Tang, M.; Duncan, A.J.E.; Ke, C. Advanced Polymer Designs for Direct-Ink-Write 3D Printing. Chem. A Eur. J 2019, 25, 10768–10781. [Google Scholar] [CrossRef]

- Wang, F.; Luo, F.; Huang, Y.; Cao, X.; Yuan, C. 4D Printing Via Multispeed Fused Deposition Modeling. Adv. Mater. Technol. 2023, 8, 202201383. [Google Scholar] [CrossRef]

- Feilden, E.; Blanca, E.G.-T.; Giuliani, F.; Saiz, E.; Vandeperre, L. Robocasting of Structural Ceramic Parts with Hydrogel Inks. J. Eur. Ceram. Soc. 2016, 36, 2525–2533. [Google Scholar] [CrossRef]

- Wen, J.; Xie, Z.; Cao, W.; Yang, X. Effects of Different Backbone Binders on the Characteristics of Zirconia Parts Using Wax-Based Binder System via Ceramic Injection Molding. J. Adv. Ceram. 2016, 5, 321–328. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Zhao, G. Preparation and Characterization of 3D Printed ZrO2 Ceramic Parts Fabricated by Powder Extrusion Printing. Ceram. Int. 2023, 49, 2721–2729. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Wang, M.-C.; Hon, M.-H. Solvent Debinding Mechanism for Alumina Injection Molded Compacts with Water-Soluble Binders. Ceram. Int. 2003, 29, 745–756. [Google Scholar] [CrossRef]

- Lim, I.Y.; Ting, C.H.; Ng, C.K.; Tey, J.Y.; Yeo, W.H.; Ramesh, S.; Lee, K.Y.S.; Chuah, Y.D.; Teng, W.D. 3D Printing of High Solid Loading Zirconia Feedstock via Screw-Based Material Extrusion. Ceram. Int. 2023, 49, 24852–24860. [Google Scholar] [CrossRef]

- Yi, Z.; Shen, T.; Xiong, H.; Kang, X.; Zhang, L.; Zhou, K. Strong and Densified 3D Metal-Ceramic Composite with Strengthened Layer Structure by Material Extrusion Additive Manufacturing. Addit. Manuf. 2024, 84, 104136. [Google Scholar] [CrossRef]

- Sarraf, F.; Hadian, A.; Churakov, S.V.; Clemens, F. EVA-PVA Binder System for Polymer Derived Mullite Made by Material Extrusion Based Additive Manufacturing. J. Eur. Ceram. Soc. 2023, 43, 530–541. [Google Scholar] [CrossRef]

- Diptanshu; Miao, G.; Ma, C. Vat Photopolymerization 3D Printing of Ceramics: Effects of Fine Powder. Manuf. Lett. 2019, 21, 20–23. [Google Scholar] [CrossRef]

- Li, Q.; Pan, Z.; Liang, J.; Zhang, Z.; Li, J.; Zhou, Y.; Sun, X. Ceramic Composites Toughened by Vat Photopolymerization 3D Printing Technology. J. Mater. Sci. Technol. 2023, 146, 42–48. [Google Scholar] [CrossRef]

- Ding, G.; He, R.; Zhang, K.; Xie, C.; Wang, M.; Yang, Y.; Fang, D. Stereolithography-based Additive Manufacturing of Gray-colored SiC Ceramic Green Body. J. Am. Ceram. Soc. 2019, 102, 7198–7209. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dmensonal Objects by Stereothography. United. States Patent 4,575,330, 11 March 1986. [Google Scholar]

- Subedi, S.; Liu, S.; Wang, W.; Naser Shovon, S.M.A.; Chen, X.; Ware, H.O.T. Multi-Material Vat Photopolymerization 3D Printing: A Review of Mechanisms and Applications. npj Adv. Manuf. 2024, 1, 9. [Google Scholar] [CrossRef]

- Jian, B.; Li, H.; He, X.; Wang, R.; Yang, H.Y.; Ge, Q. Two-Photon Polymerization-Based 4D Printing and Its Applications. Int. J. Extrem. Manuf. 2024, 6, 012001. [Google Scholar] [CrossRef]

- Bin, F.-C.; Zheng, M.-L. Perspective on Water-Soluble Two-Photon Initiator for Two-Photon Polymerization. ACS Appl. Mater. Interfaces 2024, 16, 51807–51815. [Google Scholar] [CrossRef]

- Geng, Q.; Wang, D.; Chen, P.; Chen, S.-C. Ultrafast Multi-Focus 3-D Nano-Fabrication Based on Two-Photon Polymerization. Nat. Commun. 2019, 10, 2179. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast Lasers—Reliable Tools for Advanced Materials Processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Bobrin, V.A.; Yao, Y.; Shi, X.; Xiu, Y.; Zhang, J.; Corrigan, N.; Boyer, C. Nano- to Macro-Scale Control of 3D Printed Materials via Polymerization Induced Microphase Separation. Nat. Commun. 2022, 13, 3577. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A Comprehensive Review of the Photopolymerization of Ceramic Resins Used in Stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Q.; Li, Y.; Zhu, T.; Liang, X.; Xu, Y. Wettability and Infiltration of Si Melt on SiO2-Si3N4 Composite Ceramic. J. Eur. Ceram. Soc. 2021, 41, 389–399. [Google Scholar] [CrossRef]

- Lee, M.; Rizzo, R.; Surman, F.; Zenobi-Wong, M. Guiding Lights: Tissue Bioprinting Using Photoactivated Materials. Chem. Rev. 2020, 120, 10950–11027. [Google Scholar] [CrossRef]

- Lemma, E.D.; Spagnolo, B.; Vittorio, M.D.; Pisanello, F. Studying Cell Mechanobiology in 3D: The Two-Photon Lithography Approach. Trends Biotechnol. 2019, 37, 358–372. [Google Scholar] [CrossRef]

- Zimbeck, W.; Rice, R. Stereolithography of Ceramics and Metals. In Proceedings of the IS&T’s 50th Annual Conference, Cambridge, MA, USA, 18–23 May 1997; pp. 649–655. [Google Scholar]

- Melchels, F.P.W. Preparation of Advanced Porous Structures by Stereolithography for Application in Tissue Engineering. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2010. [Google Scholar]

- Román-Manso, B.; Weeks, R.D.; Truby, R.L.; Lewis, J.A. Embedded 3D Printing of Architected Ceramics via Microwave-Activated Polymerization. Adv. Mater. 2023, 35, 2209270. [Google Scholar] [CrossRef]

- Liu, S.; Mo, L.; Bi, G.; Chen, S.; Yan, D.; Yang, J.; Jia, Y.-G.; Ren, L. DLP 3D Printing Porous β-Tricalcium Phosphate Scaffold by the Use of Acrylate/Ceramic Composite Slurry. Ceram. Int. 2021, 47, 21108–21116. [Google Scholar] [CrossRef]

- Wu, E.-S.; Strickler, J.H.; Harrell, W.R.; Webb, W.W. Two-Photon Lithography for Microelectronic Application; Cuthbert, J.D., Ed.; SPIE: San Jose, CA, USA, 1992; p. 776. [Google Scholar]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-Dimensional Microfabrication with Two-Photon-Absorbed Photopolymerization. Opt. Lett. 1997, 22, 132–134. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, N.; Berto, F.; Sadeghian, Z. A Review of Additive Manufacturing of Cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar]

- Chen, J.; Huang, M.; Fang, Z.Z.; Koopman, M.; Liu, W.; Deng, X.; Zhao, Z.; Chen, S.; Wu, S.; Liu, J.; et al. Microstructure Analysis of High Density WC-Co Composite Prepared by One Step Selective Laser Melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 104980. [Google Scholar] [CrossRef]

- Feng, C.; Guipont, V.; Jeandin, M.; Amsellem, O.; Pauchet, F.; Saenger, R.; Bucher, S.; Iacob, C. B4C/Ni Composite Coatings Prepared by Cold Spray of Blended or CVD-Coated Powders. J. Therm. Spray Technol. 2012, 21, 561–570. [Google Scholar] [CrossRef]

- Wolfe, T.A.; Shah, R.M.; Prough, K.C.; Trasorras, J.L. Binder Jetting 3D Printed Cemented Carbide: Mechanical and Wear Properties of Medium and Coarse Grades. Int. J. Refract. Met. Hard Mater. 2023, 113, 106197. [Google Scholar] [CrossRef]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Adib Kadri, N.; Osman, N.A.A. A Review on Powder-Based Additive Manufacturing for Tissue Engineering: Selective Laser Sintering and Inkjet 3D Printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef] [PubMed]

- Galante, R.; Figueiredo-Pina, C.G.; Serro, A.P. Additive Manufacturing of Ceramics for Dental Applications: A Review. Dent. Mater. 2019, 35, 825–846. [Google Scholar] [CrossRef]

- Cabezas, L.; Berger, C.; Jiménez-Piqué, E.; Pötschke, J.; Llanes, L. Printing Direction Effects on the Sliding Contact Response of a Binder Jetting 3D-Printed WC-Co Hardmetal. Crystals 2024, 14, 573. [Google Scholar] [CrossRef]

- Wang, S.; Vincent, T.; Faur, C.; Guibal, E. Alginate and Algal-Based Beads for the Sorption of Metal Cations: Cu(II) and Pb(II). Int. J. Mol. Sci. 2016, 17, 1453. [Google Scholar] [CrossRef]

- Carrijo, M.M.M.; Caro, L.G.; Lorenz, H.; Greil, P.; Travitzky, N.; Rambo, C.R. Ti3SiC2-Based Inks for Direct Ink-Jet Printing Technology. Ceram. Int. 2017, 43, 820–824. [Google Scholar] [CrossRef]

- Lee, A.Y.; An, J.; Chua, C.K. Two-Way 4D Printing: A Review on the Reversibility of 3D-Printed Shape Memory Materials. Engineering 2017, 3, 663–674. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29, 1805290. [Google Scholar] [CrossRef]

- Wan, L.; Mao, Z.; Liu, H.; Xie, Y.; Lyu, F.; Cao, Z.; He, Y.; Yin, J.; Han, X.; Chan, W.Y.K.; et al. Direct 4D Printing of Gradient Structure of Ceramics. Chem. Eng. J. 2023, 465, 142804. [Google Scholar] [CrossRef]

- Wang, R.; Yuan, C.; Cheng, J.; He, X.; Ye, H.; Jian, B.; Li, H.; Bai, J.; Ge, Q. Direct 4D Printing of Ceramics Driven by Hydrogel Dehydration. Nat Commun 2024, 15, 758. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Peng, E.; Borayek, R.; Ding, J. Controllable Ceramic Green-Body Configuration for Complex Ceramic Architectures with Fine Features. Adv. Funct. Mater. 2019, 29, 1807082. [Google Scholar] [CrossRef]

- Badev, A.; Abouliatim, Y.; Chartier, T.; Lecamp, L.; Lebaudy, P.; Chaput, C.; Delage, C. Photopolymerization Kinetics of a Polyether Acrylate in the Presence of Ceramic Fillers Used in Stereolithography. J. Photochem. Photobiol. A Chem. 2011, 222, 117–122. [Google Scholar] [CrossRef]

- Li, M.; Tunca, B.; Van Meerbeek, B.; Vleugels, J.; Zhang, F. Tough and Damage-Tolerant Monolithic Zirconia Ceramics with Transformation-Induced Plasticity by Grain-Boundary Segregation. J. Eur. Ceram. Soc. 2023, 43, 2078–2092. [Google Scholar] [CrossRef]

- Ghaemi, M.H.; Reichert, S.; Krupa, A.; Sawczak, M.; Zykova, A.; Lobach, K.; Sayenko, S.; Svitlychnyi, Y. Zirconia Ceramics with Additions of Alumina for Advanced Tribological and Biomedical Applications. Ceram. Int. 2017, 43, 9746–9752. [Google Scholar] [CrossRef]

- Chang, H.; Tang, J.; Guo, X.; Zhu, Y.; Liu, M.; Wei, Y.; Hu, X.; Huang, Z.; Chen, Z.; Yang, Y. Stereolithography-Based Additive Manufacturing of RB-SiC Ceramics by a Two-Step Sintering Method. Ceram. Int. 2023, 49, 1085–1091. [Google Scholar] [CrossRef]

- Tacke, R.; Strecker, M.; Lambrecht, G.; Moser, U.; Mutschler, E. Sila-Pharmaka, 29. Mitt. Bioisosterer C/Si-Austausch bei Parasympatholytika vom Typ des Pridinols. Arch. Der Pharm. 1984, 317, 207–214. [Google Scholar] [CrossRef]

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.; Yang, W. Advances in Modifications and High-Temperature Applications of Silicon Carbide Ceramic Matrix Composites in Aerospace: A Focused Review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Bai, X.; Ding, G.; Zhang, K.; Wang, W.; Zhou, N.; Fang, D.; He, R. Stereolithography Additive Manufacturing and Sintering Approaches of SiC Ceramics. Open Ceram. 2021, 5, 100046. [Google Scholar] [CrossRef]

- Cao, J.; Miao, K.; Xiong, S.; Su, F.; Gao, D.; Lin, X.; Liu, Z.; Wang, P.; Liu, C.; Chen, Z. 3D Printing and in Situ Transformation of SiCnw/SiC Structures. Addit. Manuf. 2022, 58, 103053. [Google Scholar] [CrossRef]

- Guo, X.; Tang, J.; Chang, H.; Zhu, Y.; Wei, Y.; Hu, X.; Huang, Z.; Yang, Y. Application of SiO2-Coated SiC Powder in Stereolithography and Sintering Densification of SiC Ceramic Composites. Ceram. Int. 2023, 49, 25016–25024. [Google Scholar] [CrossRef]

- Dong, X.; Wu, J.; Yu, H.; Zhou, Q.; Wang, W.; Zhang, X.; Zhang, L.; Li, L.; He, R. Additive Manufacturing of Silicon Nitride Ceramics: A Review of Advances and Perspectives. Int. J. Appl. Ceram. Technol. 2022, 19, 2929–2949. [Google Scholar] [CrossRef]

- Wang, L.; Wang, L.; Hao, Z.; Tang, W.; Dou, R. Microstructure and Properties of Silicon Nitride Ceramics Fabricated by Vat Photopolymerization in Combination with Pressureless Sintering. Ceram. Int. 2024, 50, 10485–10496. [Google Scholar] [CrossRef]

- Rasaki, S.A.; Xiong, D.; Xiong, S.; Su, F.; Idrees, M.; Chen, Z. Photopolymerization-Based Additive Manufacturing of Ceramics: A Systematic Review. J. Adv. Ceram. 2021, 10, 442–471. [Google Scholar] [CrossRef]

- Yang, P.; Sun, Z.; Huang, S.; Ou, J.; Jiang, Q.; Li, D.; Wu, S. Digital Light Processing 3D Printing of Surface-Oxidized Si3N4 Coated by Silane Coupling Agent. J. Asian Ceram. Soc. 2022, 10, 69–82. [Google Scholar] [CrossRef]

- Hench, L.L. Bioceramics: From Concept to Clinic. J. Am. Ceram. Soc. 1991, 74, 1487–1510. [Google Scholar] [CrossRef]

- Verheyen, C.C.P.M.; De Wijn, J.R.; Van Blitterswijk, C.A.; De Groot, K.; Rozing, P.M. Hydroxylapatite/Poly(L-lactide) Composites: An Animal Study on Push-out Strengths and Interface Histology. J. Biomed. Mater. Res. 1993, 27, 433–444. [Google Scholar] [CrossRef]

- Mohammadi, M.; Tulliani, J.-M.; Montanaro, L.; Palmero, P. Gelcasting and Sintering of Hydroxyapatite Materials: Effect of Particle Size and Ca/P Ratio on Microstructural, Mechanical and Biological Properties. J. Eur. Ceram. Soc. 2021, 41, 7301–7310. [Google Scholar] [CrossRef]

- Fu, K.; Wang, S.; Wang, G.; Wang, Y. The Effects of Calcium Oxide on Fluorapatite Crystal Morphology and Mechanical Property of Functional Glass-Ceramics. Ceram. Int. 2018, 44, 20531–20538. [Google Scholar] [CrossRef]

- Fatahi Bafghi, M.; Mehrabi, H.A.; Eftekhari Yekta, B. Crystallization Behavior, Mechanical Properties, and Chemical Resistance of Leucite–Fluoroapatite Glass-Ceramic Glazes. Int. J. Appl. Glass Sci. 2013, 4, 266–273. [Google Scholar] [CrossRef]

- Yang, B.; Wang, S.; Wang, G.; Yang, X. Mechanical Properties and Wear Behaviors Analysis of Fluorapatite Glass-Ceramics Based on Stereolithography 3D Printing. J. Mech. Behav. Biomed. Mater. 2021, 124, 104859. [Google Scholar] [CrossRef]

- Tan, Q.; Zhuang, W.; Attia, M.; Djugum, R.; Zhang, M. Recent Progress in Additive Manufacturing of Bulk MAX Phase Components: A Review. J. Mater. Sci. Technol. 2022, 131, 30–47. [Google Scholar] [CrossRef]

- Nan, B.; Yin, X.; Zhang, L.; Cheng, L. Three-Dimensional Printing of Ti3SiC2-Based Ceramics: Rapid Communications of the American Ceramic Society. J. Am. Ceram. Soc. 2011, 94, 969–972. [Google Scholar] [CrossRef]

- Tabares, E.; Kitzmantel, M.; Neubauer, E.; Jimenez-Morales, A.; Tsipas, S.A. Extrusion-Based Additive Manufacturing of Ti3SiC2 and Cr2AlC MAX Phases as Candidates for High Temperature Heat Exchangers. J. Eur. Ceram. Soc. 2022, 42, 841–849. [Google Scholar] [CrossRef]

- Krinitcyn, M.; Ragulina, M.; Firsina, I.; Travitzky, N. Influence of Selective Laser Treatment on Thermal Stability of Ti3AlC2 and Ti3AlC2/Cu Powders. Mater. Lett. 2022, 309, 131354. [Google Scholar] [CrossRef]

- Ma, Y.; Yin, X.; Fan, X.; Travitzky, N.; Greil, P. Fabrication of MAX-Phase-Based Ceramics by Three-Dimensional Printing. J. Ceram. Sci. Tech. 2015, 6, 87–94. [Google Scholar] [CrossRef]

- Rao, P. Preparation and Mechanical Properties of Al2O3–15wt.%ZrO2 Composites. Scr. Mater. 2003, 48, 437–441. [Google Scholar] [CrossRef]

- Branco, A.C.; Santos, T.; Bessa, L.J.; Barahona, I.; Polido, M.; Colaço, R.; Serro, A.P.; Figueiredo-Pina, C.G. Optimized 3D Printed Zirconia-Reinforced Leucite with Antibacterial Coating for Dental Applications. Dent. Mater. 2024, 40, 629–642. [Google Scholar] [CrossRef]

- Rueschhoff, L.M.; Baldwin, L.A.; Hardin, J.O.; Kaufman, J. Future Directions in Ceramic Additive Manufacturing: Fiber Reinforcements and Artificial Intelligence. J. Am. Ceram. Soc. 2024, 107, 1505–1522. [Google Scholar] [CrossRef]

- Shen, W.; Wang, G.; Wang, S.; Kang, J.; Dong, X.; Yang, X.; Wen, D.; Zhang, Y. Effect of Al2O3 Whiskers on Forming Accuracy, Mechanical and Tribological Performances of Translucent Glass-Ceramics Formed by 3D Printing. J. Eur. Ceram. Soc. 2024, 44, 3236–3246. [Google Scholar] [CrossRef]

- Lebedev, M.S.; Promakhov, V.V.; Ivanova, L.Y.; Svarovskaya, N.V.; Kozhukhova, M.I.; Lerner, M.I. Extrusion-Based Additive Manufacturing of WC-10Co Cemented Carbide Produced with Bimodal Ultrafine/Micron WC Particles. Metals 2024, 14, 1308. [Google Scholar] [CrossRef]

- Krinitcyn, M.; Svarovskaya, N.V.; Rodkevich, N.; Ryumin, E.; Lerner, M. Structure and Properties of WC-Fe-Ni-Co Nanopowder Composites for Use in Additive Manufacturing Technologies. Metals 2024, 14, 167. [Google Scholar] [CrossRef]

- Krinitcyn, M.; Kopytov, G.; Ryumin, E. Additive Manufacturing of Ti3AlC2/TiC and Ti3AlC2/SiC Ceramics Using the Fused Granules Fabrication Technique. J. Manuf. Mater. Process. 2024, 8, 123. [Google Scholar] [CrossRef]

- Krinitcyn, M.G. Thermal Stability of TiC–Ti3 AlC2 and TiC–Ti3 AlC Composites during Selective Laser Treatment. Adv. Appl. Ceram. 2022, 121, 138–142. [Google Scholar] [CrossRef]

- Liu, D.; Hentschel, L.; Lin, G.; Kukla, C.; Schuschnigg, S.; Ma, N.; Wallis, C.; Momeni, V.; Kitzmantel, M.; Sui, G. Multifunctional Ti3AlC2-Based Composites via Fused Filament Fabrication and 3D Printing Technology. J. Mater. Eng. Perform. 2023, 32, 9174–9181. [Google Scholar] [CrossRef]

- Liu, W.; Wu, H.; Xu, Y.; Lin, L.; Li, Y.; Wu, S. Cutting Performance and Wear Mechanism of Zirconia Toughened Alumina Ceramic Cutting Tools Formed by Vat Photopolymerization-Based 3D Printing. Ceram. Int. 2023, 49, 23238–23247. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; Xu, Y.; Lin, L.; Li, Y.; Wu, S. Vat Photopolymerization-Based 3D Printing of Complex-Shaped and High-Performance Al2O3 Ceramic Tool with Chip-Breaking Grooves: Cutting Performance and Wear Mechanism. J. Asian Ceram. Soc. 2023, 11, 159–169. [Google Scholar] [CrossRef]

- Branco, A.C.; Silva, R.; Jorge, H.; Santos, T.; Lorenz, K.; Polido, M.; Colaço, R.; Serro, A.P.; Figueiredo-Pina, C.G. Tribological Performance of the Pair Human Teeth vs 3D Printed Zirconia: An in Vitro Chewing Simulation Study. J. Mech. Behav. Biomed. Mater. 2020, 110, 103900. [Google Scholar] [CrossRef]

- Zhang, L.; Zeng, Y.; Yao, H.; Shi, Z.; Chen, J. Fabrication and Characterization of ZrO2(3Y)/Al2O3 Micro-Ceramic Gears with High Performance by Vat Photopolymerization 3D Printing. Ceram. Int. 2024, 50, 5187–5197. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Z.; Xu, M.; Wang, S.; Li, N.; Yang, J. A Review of 3D Printed Porous Ceramics. J. Eur. Ceram. Soc. 2022, 42, 3351–3373. [Google Scholar] [CrossRef]

- Mu, Y.; Chen, Y.; Li, H.; Sun, J.; Mu, B.; Colombo, P. Improved Precision and Mechanical Properties of 3D-printed Silica Ceramics via Sintering Temperature Optimization. Int. J. Appl. Ceram. Technol. 2025, 22, e14880. [Google Scholar] [CrossRef]

- Patil, A.; Bomze, D.; Gopal, V. Wear Behaviour of Lithography Ceramic Manufactured Dental Zirconia. BMC Oral Health 2023, 23, 276. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Obikawa, T. Cooling Performance of Micro-Texture at the Tool Flank Face under High Pressure Jet Coolant Assistance. Precis. Eng. 2017, 49, 41–51. [Google Scholar] [CrossRef]

- Shi, G.; Wang, J.; Dong, Y.; Hu, S.; Zheng, L.; Ren, L. Effect of Surface Morphology and Internal Structure on the Tribological Behaviors of Snake Scales from Dinodon Rufozonatum. Biomimetics 2024, 9, 617. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhao, Y.; Mei, H.; Kong, Z.; Mao, M.; Cheng, L. Excellent Lubrication Properties of 3D Printed Ceramic Bionic Structures. Ceram. Int. 2020, 46, 23463–23470. [Google Scholar] [CrossRef]

- Guo, R.; Yu, Y.; Zeng, J.; Liu, X.; Zhou, X.; Niu, L.; Gao, T.; Li, K.; Yang, Y.; Zhou, F.; et al. Biomimicking Topographic Elastomeric Petals (E-Petals) for Omnidirectional Stretchable and Printable Electronics. Adv. Sci. 2015, 2, 1400021. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Li, J.; Li, P.; Li, S. Gecko-Inspired Controllable Adhesive: Structure, Fabrication, and Application. Biomimetics 2024, 9, 149. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, H.; Song, J.; Zhang, Y.; Hu, L. Surface Engineering Design of Al2O3/Mo Self-Lubricating Structural Ceramics—Part II: Continuous Lubrication Effects of a Three-Dimensional Lubricating Layer at Temperatures from 25 to 800 °C. Wear 2016, 360–361, 97–103. [Google Scholar] [CrossRef]

- Varenberg, M.; Gorb, S.N. Hexagonal Surface Micropattern for Dry and Wet Friction. Adv. Mater. 2009, 21, 483–486. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.; Zhang, D.; Chen, W.; Dong, G. Optimization of Texture Shape Based on Genetic Algorithm under Unidirectional Sliding. Tribol. Int. 2017, 115, 222–232. [Google Scholar] [CrossRef]

- Fan, H.; Su, Y.; Song, J.; Wan, H.; Hu, L.; Zhang, Y. Surface 3-D Lubrication Structure Design of Al2O3/Ni-Laminated Ceramics to Improve Tribological Properties under Combined Environments. Appl. Surf. Sci. 2019, 480, 572–581. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, H.; Chang, P.; Yang, Y.; Cheng, L.; Zhang, L. Biomimicking Synovial Joints Trans-Scale Structured AgQDs/MXene/SiOC Achieving Macroscale High Lubrication and Superior Wear Resistance. J. Mater. Sci. Technol. 2024, 174, 63–73. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K. Atomistic Locking and Friction. Phys. Rev. B 1990, 41, 11837–11851. [Google Scholar] [CrossRef]

- Shinjo, K.; Hirano, M. Dynamics of Friction: Superlubric State. Surf. Sci. 1993, 283, 473–478. [Google Scholar] [CrossRef]

- Li, Q.; Tullis, T.E.; Goldsby, D.; Carpick, R.W. Frictional Ageing from Interfacial Bonding and the Origins of Rate and State Friction. Nature 2011, 480, 233–236. [Google Scholar] [CrossRef] [PubMed]

- Szlufarska, I.; Chandross, M.; Carpick, R.W. Recent Advances in Single-Asperity Nanotribology. J. Phys. D Appl. Phys. 2008, 41, 123001. [Google Scholar] [CrossRef]

- Wu, F.-B.; Zhou, S.-J.; Ouyang, J.-H.; Wang, S.-Q.; Chen, L. Structural Superlubricity of Two-Dimensional Materials: Mechanisms, Properties, Influencing Factors, and Applications. Lubricants 2024, 12, 138. [Google Scholar] [CrossRef]

- Martin, J.M.; Donnet, C.; Le Mogne, T.; Epicier, T. Superlubricity of Molybdenum Disulphide. Phys. Rev. B 1993, 48, 10583–10586. [Google Scholar] [CrossRef]

- Berman, D.; Deshmukh, S.A.; Sankaranarayanan, S.K.R.S.; Erdemir, A.; Sumant, A.V. Macroscale Superlubricity Enabled by Graphene Nanoscroll Formation. Science 2015, 348, 1118–1122. [Google Scholar] [CrossRef] [PubMed]

- Büch, H.; Rossi, A.; Forti, S.; Convertino, D.; Tozzini, V.; Coletti, C. Superlubricity of Epitaxial Monolayer WS2 on Graphene. Nano Res. 2018, 11, 5946–5956. [Google Scholar] [CrossRef]

- Salam, A.; Xie, G.; Guo, D.; Xu, W. Fabrication and Tribological Behavior of Self-Lubricating Composite Impregnated with Synthesized Inorganic Hollow Fullerene-like MoS2. Compos. Part B Eng. 2020, 200, 108284. [Google Scholar] [CrossRef]

- Cao, M.; Wang, X.; Zhang, M.; Shu, J.; Cao, W.; Yang, H.; Fang, X.; Yuan, J. Electromagnetic Response and Energy Conversion for Functions and Devices in Low-Dimensional Materials. Adv. Funct. Mater. 2019, 29, 1807398. [Google Scholar] [CrossRef]

- Khaleghi, M.; Chaji, M.; Pishbin, F.; Sillanpää, M.; Sheibani, S. A Review of Molybdenum Disulfide-Based 3D Printed Structures for Biomedical Applications. J. Mater. Res. Technol. 2024, 32, 1630–1646. [Google Scholar] [CrossRef]

- Song, J.; Hu, L.; Qin, B.; Fan, H.; Zhang, Y. Fabrication and Tribological Behavior of Al2O3/MoS2–BaSO4 Laminated Composites Doped with in Situ Formed BaMoO4. Tribol. Int. 2018, 118, 329–336. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Y.; Li, D.Y. Mechanical Properties and Erosion Resistance of Ceria Nano-Particle-Doped Ultrafine WC–12Co Composite Prepared by Spark Plasma Sintering. Wear 2013, 301, 406–414. [Google Scholar] [CrossRef]

- Holmberg, K.; Laukkanen, A.; Turunen, E.; Laitinen, T. Wear Resistance Optimisation of Composite Coatings by Computational Microstructural Modelling. Surf. Coat. Technol. 2014, 247, 1–13. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.Y.; Meng, J.S. Advanced Materials for Additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2019, 479, 012088. [Google Scholar] [CrossRef]

- Holmberg, K.; Laukkanen, A.; Ghabchi, A. Computational Modelling Based Wear Resistance Analysis of Thick Composite Coatings. Tribol. Int. 2014, 72, 13–30. [Google Scholar] [CrossRef]

- Loscertales, I.G.; Barrero, A.; Guerrero, I.; Cortijo, R.; Marquez, M.; Gañán-Calvo, A.M. Micro/Nano Encapsulation via Electrified Coaxial Liquid Jets. Science 2002, 295, 1695–1698. [Google Scholar] [CrossRef] [PubMed]

- Bao, Y.; Deng, J.; Ma, K.; Wang, R.; Wu, J.; Lu, Y. Thick-Film Printing of TaS2 Soft Films on the Textured Surface to Enhance Wear Life. Surf. Coat. Technol. 2024, 476, 130231. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; Lin, L.; Chen, Y.; Xu, Y.; Wu, S.; Sun, Z.; An, D.; Wei, S.; Xie, Z. Realization of Complex-Shaped and High-Performance Alumina Ceramic Cutting Tools via Vat Photopolymerization Based 3D Printing: A Novel Surface Modification Strategy through Coupling Agents Aluminic Acid Ester and Silane Coupling Agent. J. Eur. Ceram. Soc. 2023, 43, 1051–1063. [Google Scholar] [CrossRef]

- Ben-Nissan, B.; Choi, A.H.; Roest, R.; Latella, B.A.; Bendavid, A. Adhesion of Hydroxyapatite on Titanium Medical Implants. In Hydroxyapatite (Hap) for Biomedical Applications; Elsevier: Amsterdam, The Netherlands, 2015; pp. 21–51. ISBN 978-1-78242-033-0. [Google Scholar]

- Chile, J.; Dolores, A.; Espinoza-Carhuancho, F.; Alvitez-Temoche, D.; Munive-Degregori, A.; Barja-Ore, J.; Mayta-Tovalino, F. Zirconia Dental Implants as a Different Alternative to Titanium: A Literature Review. J. Int. Soc. Prev. Community Dent. 2023, 13, 357–364. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Liu, K.; Deng, J.; Ye, J.; Ai, F.; Ouyang, H.; Wu, T.; Jia, J.; Cheng, X.; Wang, X. 3D Printed Zirconia Ceramic Hip Joint with Precise Structure and Broad-Spectrum Antibacterial Properties. Int. J. Nanomed. 2019, 14, 5977–5987. [Google Scholar] [CrossRef]

- Mohammed, M.K.; Alahmari, A.; Alkhalefah, H.; Abidi, M.H. Evaluation of Zirconia Ceramics Fabricated through DLP 3d Printing Process for Dental Applications. Heliyon 2024, 10, e36725. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, J.; Li, K.; Liu, A.; Liu, S. 3D Printing of Diamond Tools for Dental Ceramics Processing. Adv. Eng. Mater. 2018, 20, 1700747. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Tang, X.; Zhao, Y.; Li, M.; Zhao, Y.; Luo, H.; Lai, Q.; Xing, H. Biomechanical and Biological Properties of Stereolithography-Based 3D-Printed Zirconia Interference Screws for Anterior Cruciate Ligament Reconstruction. Addit. Manuf. Front. 2024, 3, 200135. [Google Scholar] [CrossRef]

| Forming Mechanism | Technology | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|

| Extrusion | Fused deposition modelling (FDM) | Economy and simplicity; high utilization rate of ceramic consumables. | Slow molding speed and low precision. | [19,20,21] |

| Direct ink writing (DIW) | Printing at normal temperatures; multi-material adaptability. | Small molding size and low precision. | [12,22,23] | |

| Photosensitive polymerization | Stereolithography (SLA) | High-precision large-size molding; | The molding speed is slow and the environment requirements are harsh. | [24,25,26,27] |

| Digital light processing (DLP) | Higher print speeds and accuracy of laying compared with SLA. | Small molding size; the lifting method can easily damage the sample surface. | [4,11,28,29,30,31,32,33,34,35,36] | |

| Two-photon polymerization (TPP) | Complex microscopic 3D structures and nanoscale feature sizes. | High manufacturing cost. | [37,38] | |

| Powder melting | Selective laser melting (SLM) | High ceramic material utilization; high finished product density. | Slow molding speed; rough surface. | [39,40] |

| Selective laser sintering (SLS) | High ceramic material utilization; No debinding and sintering process required. | Rough surface; the instrument needs to be warmed up and cooled down. | [39,41] | |

| Powder Bonding | Binder jet 3D printing (BJP) | Adhesive is easy to remove. | Complex structure molding is limited; difficult to utilize fine powder. | [42,43,44] |

| Process | Ceramics | Solid Content | Binder System | Dispersant | Debinding Process | Ref. |

|---|---|---|---|---|---|---|

| FDM | SiC | - | SMP-730 | - | Heat debinding at 1400 °C in Ar (Including sintering). | [19] |

| 48 vol% | PW/HDPE/LDPE/SA | PEG | Heat debinding at 130, 280, 335 and 570 °C for 5 h. | [20] | ||

| cBN | 60 vol% | Al/TiN/HDPE/EVA/PW | - | N-heptane solvent debinding and heat debinding at 580 °C. | [21] | |

| DIW | Al2O3 | 65 wt.% | Water/methyl cellulose | PEG | Heat debinding at 550 °C for 1 h. | [23] |

| Graphene /Al2O3 | 80.0 wt.% | PVA/CA/TEOA | Na2CO3/H3PO4 | Heat debinding at 350 °C and 700 °C for 2 h and 2 h. | [12] | |

| ZrO2(3Y) | 60 vol% | Methylcellulose/deionized water/ammonium polymethacrylate | Phosphoric acid ester solution | Heat debinding at 300 °C for 3 h and 600 °C for 4 h. | [22] |

| Process | Ceramics | Solid Content | Polymer System | Dispersant | Debinding Process |

|---|---|---|---|---|---|

| SLA | ZrO2/Al2O3 [24] | 46.8 vol% | Di-TMPTA/HDDA/Irgacure 184 | - | Heat debinding at 550 °C for 10 h and 800 °C for 3 h in Ar. |

| HAP [25] | - | Acrylic resin | - | Heat debinding at 1050 °C in Ar. | |

| SiC [26] | 45 vol% | HDDA/TMPTA | KOS110 and 17000 | Heat debinding at 800 °C for 2 h in N2. | |

| Si3N4 [27] | 66 wt.% | TMPTA/TPO | Solsperse 85000 | Heat debinding at 600 °C for 5 h in N2 and then 10 h in air. | |

| DLP | ZrO2 | 40 vol% [28] | RGD840/PAA | KH-570 | Heat debinding at 350 °C for 6 h and at 750 °C for 3 h. |

| 60 wt.% [31] | HDDA/PPTTA/PEG/U600/1-Octanol | - | Heat debinding at 600 °C 3 h in vacuum and then in air. | ||

| 80 wt.% [29] | AAU/HDDA/1-hydroxy cyclohexyl phenyl ketone/SIE-MIX80 | Phosphoric acid ester solution | Heat debinding from 350 °C to 500 °C. | ||

| Al2O3 [11] | 65.7 wt.% | ULC F6/methyl alcohol | dispersion agent 2145 | Heat debinding at 650 °C for 2 h. | |

| ZrO2(3Y)/Al2O3 [35] | 45 vol% | HDDA/photoinitiator | - | Heat debinding 135,340 and 535 °C for a certain amount of time. | |

| HAP [30] | 43 vol% | ADMATEC | Disperbyk-103 | Water debinding at 40 °C for 24 h; heat debinding at 600 °C for 1 h. | |

| SiO2/SiC | 47.5 vol% [32] | HDDA/TMPTA/PEGDA /BAPO/Polyethylene glycol | KOS110 | - | |

| 50–60 vol% [34] | HDDA/TMPTA/3D13/BAPO | KOS110 | - | ||

| 40 vol% [33] | HDDA/TMPTA/PEA/TPO | KH570/BYK111 | Heat debinding at 1000 °C in Ar. [33] | ||

| Si3N4 [36] | 45 vol% | HDDA/TMPTA/Omnirad 380 | - | Heat debinding at 600 °C for 3 h | |

| TPP | MAS [37] | - | polymer photoresist | MEEAA | Heat debinding at 600 °C. |

| ZrO2 glass–ceramic [38] | - | SZ2080 | - | Heat debinding at 600 °C. |

| Ceramics | Solid Content | Binder System | Debinding Process |

|---|---|---|---|

| Al2O3 [42] | 60 vol.% | Sodium alginate/Cu2+ | Water-based debinding. |

| WC-12%Co [43] | 45% (Binder saturation) | - | Heat debinding in air. |

| Glass/ZrO2 [44] | 16.99% (Binder saturation) | - | Heat debinding at 600 °C. |

| Ti3SiC2 [84] | 0.05 vol.% | Deionized water/PEI/Glycerol | - |

| Composition | Sintering Process | Sintering Parameters | Relative Density (%) | Bending Strength (MPa) | Fracture Toughness (MPa·m1/2) | Vickers Hardness (GPa) | Ref. |

|---|---|---|---|---|---|---|---|

| Al2O3 | PLS 1 in air; PS 2 in air. | 1650 °C (1 h); | 97.2/98.7 (PS) | 252 | - | 15/18 | [23] |

| PLS in air | 1600 °C (2 h); | 75.7–85.7 | 130.56–182.25 | - | - | [4] | |

| PLS in air | 1540/1600 °C | 98.0/98.7 | - | - | - | [42] | |

| PLS in air | 1600 °C | 96.91 | 362.24 | - | - | [11] | |

| ZrO2 | PLS in air | 1450 °C (5 h) | 98.3 (Dense); 86.7 (porous) | - | - | 11.92 ± 0.42 (50 vol%); 2.44 (50 vol%) | [28] |

| PLS in air | 1500 °C (2 h) | 99 | - | 6.3 | 12.62 | [29] | |

| PLS in air | 1700–1550 °C Rapid cooling; 1550 °C (5 h) | 98.1 | 488.96 ± 79.84 | 2.63 ± 0.2 | 11.52 ± 0.57 | [22] | |

| PLS in air; LGI 3. | 1400–1550 °C | 54.27/94.49 (LGI) | 76.48 ± 3.25 | - | - | [44] | |

| PLS in air | 1500 °C | 97.14 | - | 6.038 | 13.0597 | [31] |

| Composition | Sintering Additives | Sintering Process | Sintering Parameters | Relative Density (%) | Bending Strength (MPa) | Fracture Toughness (MPa·m1/2) | Vickers Hardness (GPa) | Ref. |

|---|---|---|---|---|---|---|---|---|

| SiC | Al2O3/Y2O3 | PLS 1 in Ar | 1200–1950 °C (1.5 h) | 91.0–96.9 | 225 ± 27 | - | 19.35 ± 0.28 | [20] |

| - | VS 2/LSI 3 | 1650 °C (1 h) | 89.4 | - | - | - | [33] | |

| SiO2 | PLS in Ar and then VS/LSI | 1400 °C (5 h) and then 1550 °C (0.5 h) | 97.7 | 268.66 ± 10.19 | - | - | [93] | |

| SMP-730 | Si/SiC | PLS in Ar | 1400 °C | 71.0 | 47.2 ± 5.5 | - | - | [19] |

| Si3N4 | SiO2/MgO/Y2O3 | PS 4 in N2 | 1700 °C, 2 MPa (2 h) | 96.0 ± 0.5 | - | - | - | [27] |

| Al2O3/Y2O3 | PS in N2 | 1650 °C, 6 MPa (3 h) | 98.5 | 770 ± 35 | 13.3 ± 1.1 | - | [36] |

| Composition | Sintering Process | Sintering Parameters | Relative Density (%) | Bending Strength (MPa) | Vickers Hardness (GPa) | Ref. |

|---|---|---|---|---|---|---|

| Ti3SiC2 | PLS 1 in Ar/LSI 2 | 1600–1700 °C (1 h) | 92–97.6 | 52–293 | 7.2–10.8 | [110] |

| VS 3 | 1300 °C (6 h) | 90 | - | - | [111] | |

| Cr2AlC | PLS in Ar | 1300 °C (4 h) | 93 | - | - | [111] |

| Ti3AlC2 | SLS/SLM in Ar | P = 60 and 80 W; v = 100 mm/s; d = 400 µm | - | - | - | [112] |

| Materials | Methods | Lubricants | Test Conditions | Wear Mechanism | Results | Ref. |

|---|---|---|---|---|---|---|

| Al2O3 | DLP | Deionized water/gear oil/paraffin/vegetable oil | RT-600 °C; Load 30 N; frequency 5 Hz; stroke of 10 mm; counter: WC ball |

|

| [11] |

| DLP/S1 1, S2 2, H1 3, H2 4 | Solid lubricant with MoS2/hBN | RT-700 °C; Load 5 N; frequency 5 Hz; stroke of 2.5 mm; counter: Al2O3 ball |

|

| [4] | |

| SLA/chip-breaking groove | - | Cutting tests: Spindle power 15 kW; maximum spindle speed 4000 rpm; workpiece: HT250 gray cast iron. |

|

| [124] | |

| ZrO2 | DLP | Deionized water | RT; load 2 N; sliding speed 450 r/min; counter: 100 mesh SiC abrasive grains |

|

| [29] |

| DIW | Artificial saliva | RT; chewing simulation tests (CS-4.2 SD Mechatronik); Load 49 N; frequency 1 Hz |

|

| [125] |

| Materials | Methods | Lubricants | Test Conditions | Wear Mechanism | Results | Ref. |

|---|---|---|---|---|---|---|

| Graphene/Al2O3 | DIW/gradient mechanics | - | RT; Taber wear tester (GT-7012-T); load 5 N; testing speed 60 rpm·min−1; counter: H-22 grinding wheel |

|

| [12] |

| ZrO2(3Y)/Al2O3 | DLP | Artificial saliva | ASTM G133-95; Load 20/30/40 N; frequency 3 Hz; counter: Si3N4. |

|

| [35] |

| DLP | - | Load 30 N; friction distance 5 mm; frequency 3 Hz; counter: Si3N4. |

|

| [126] | |

| ZrO2/leucite | DIW/ SDF + KI coating | Artificial saliva | Load 50 N; vertical speed of 40 mm/s, horizontal speed 20 mm/s, vertical movement 2 mm, horizontal movement 0.7 mm and frequency ~1 Hz. |

|

| [115] |

| WC-12%Co | BJP | - | ASTM B611 and ASTM G65 wear test |

|

| [43] |

| FAp glass–ceramics | SLA | - | RT; Load 20 N; Stroke 4.5 mm; Frequency 2 Hz. |

|

| [108] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, W.-J.; Wang, S.-Q.; Wang, Z.-H.; Wu, F.-B.; Zhang, Y.-Z.; Ouyang, J.-H.; Wang, Y.-M.; Zou, Y.-C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants 2025, 13, 112. https://doi.org/10.3390/lubricants13030112

Miao W-J, Wang S-Q, Wang Z-H, Wu F-B, Zhang Y-Z, Ouyang J-H, Wang Y-M, Zou Y-C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants. 2025; 13(3):112. https://doi.org/10.3390/lubricants13030112

Chicago/Turabian StyleMiao, Wei-Jian, Shu-Qi Wang, Zi-Heng Wang, Fan-Bin Wu, Yun-Zhuo Zhang, Jia-Hu Ouyang, Ya-Ming Wang, and Yong-Chun Zou. 2025. "Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties" Lubricants 13, no. 3: 112. https://doi.org/10.3390/lubricants13030112

APA StyleMiao, W.-J., Wang, S.-Q., Wang, Z.-H., Wu, F.-B., Zhang, Y.-Z., Ouyang, J.-H., Wang, Y.-M., & Zou, Y.-C. (2025). Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants, 13(3), 112. https://doi.org/10.3390/lubricants13030112