Rheological Properties and Lubricating Film Formation Performance of Very Low-Viscosity and Biodegradable Polyalphaolefins

Abstract

1. Introduction

2. Rheological Properties of PAOs

2.1. Experimental Method

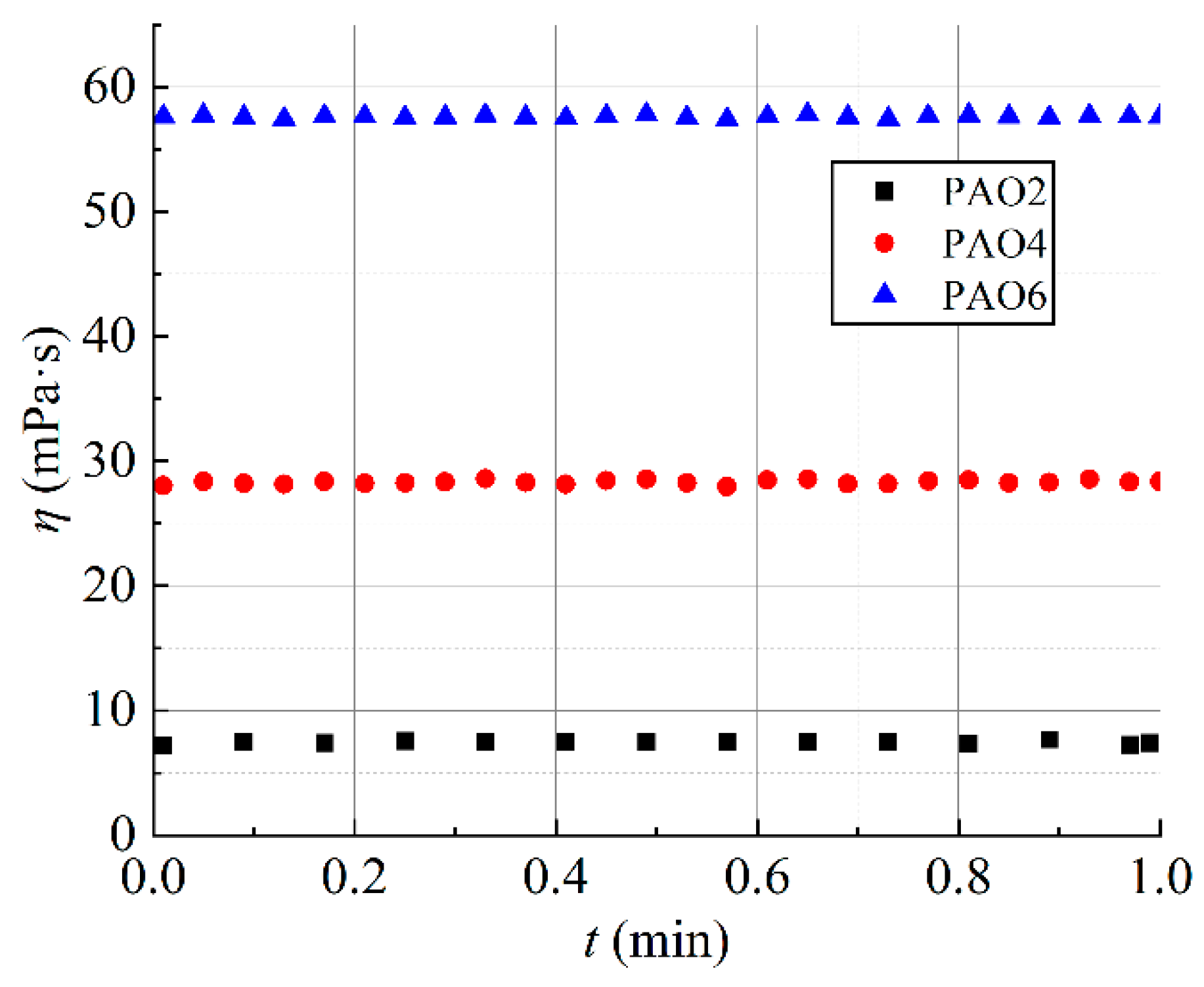

- Test the PAO samples of different viscosities at a constant room temperature and a constant shear rate (1000 s−1) for one minute to assess whether there was shear thinning. Evaluate their thixotropic behavior.

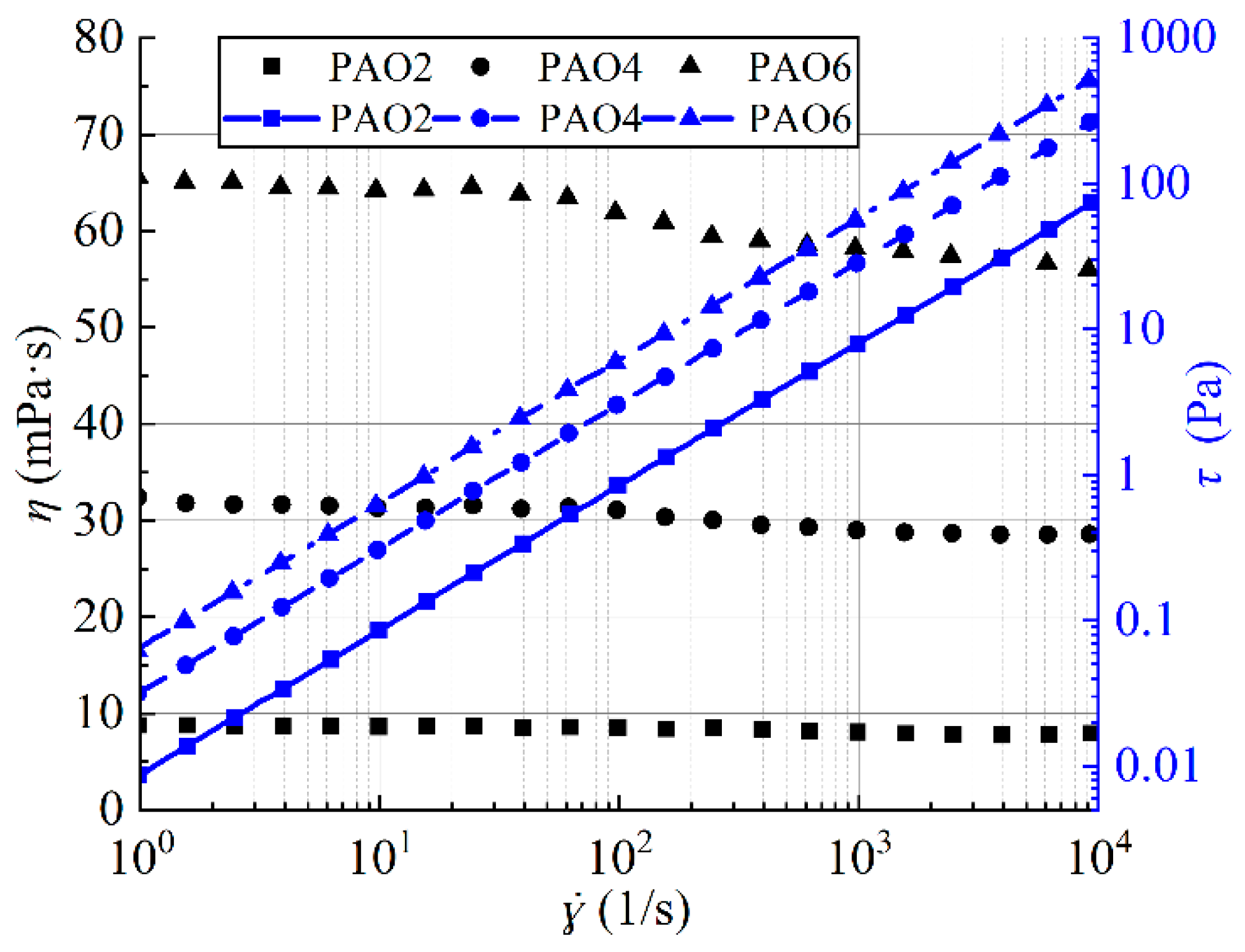

- Examine the PAO samples with different viscosities as they were sheared from zero or a low rate to 10,000 s−1 in 1.5 min at room temperature to determine whether there was shear rate thinning. Assess their non-Newtonian properties.

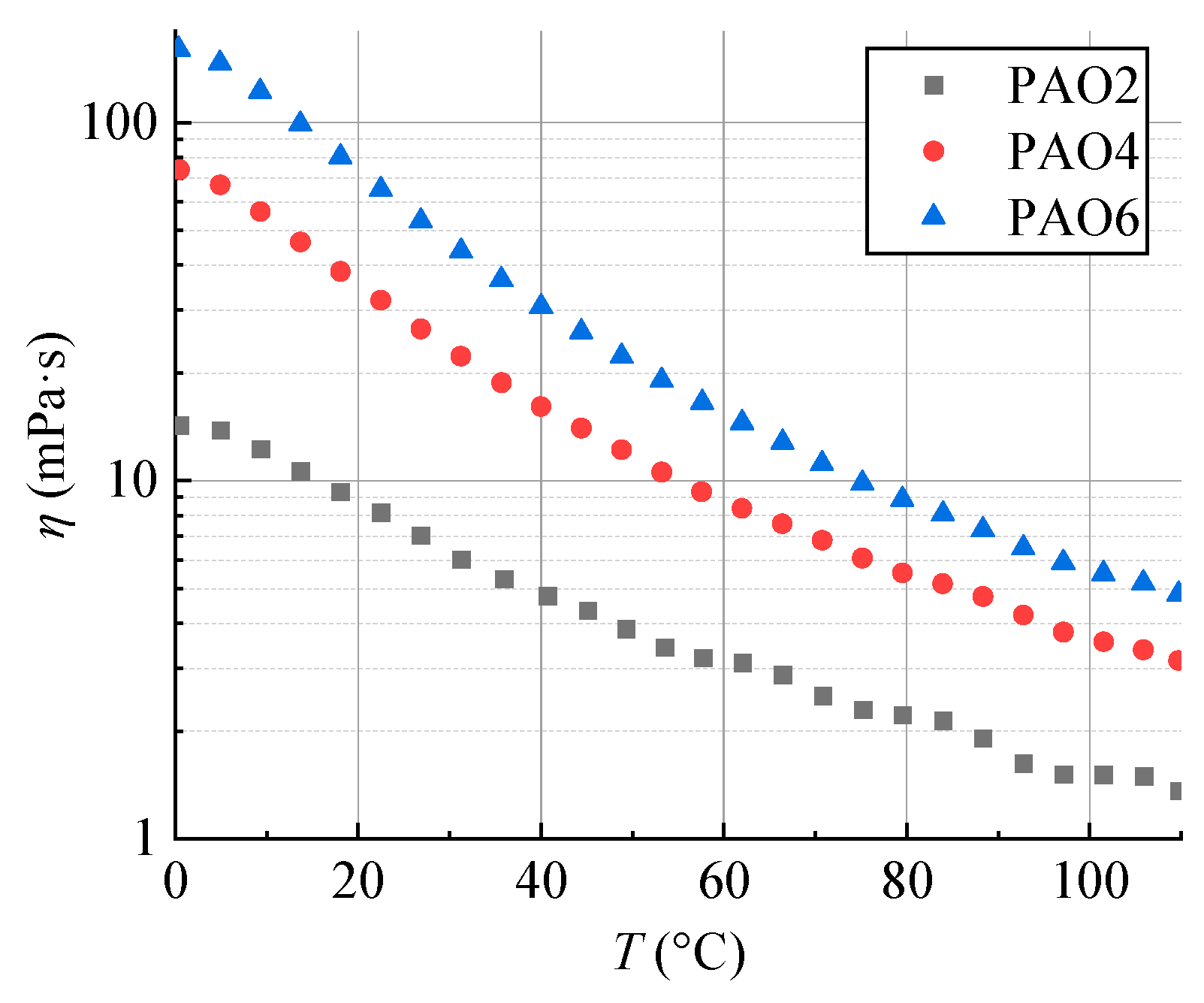

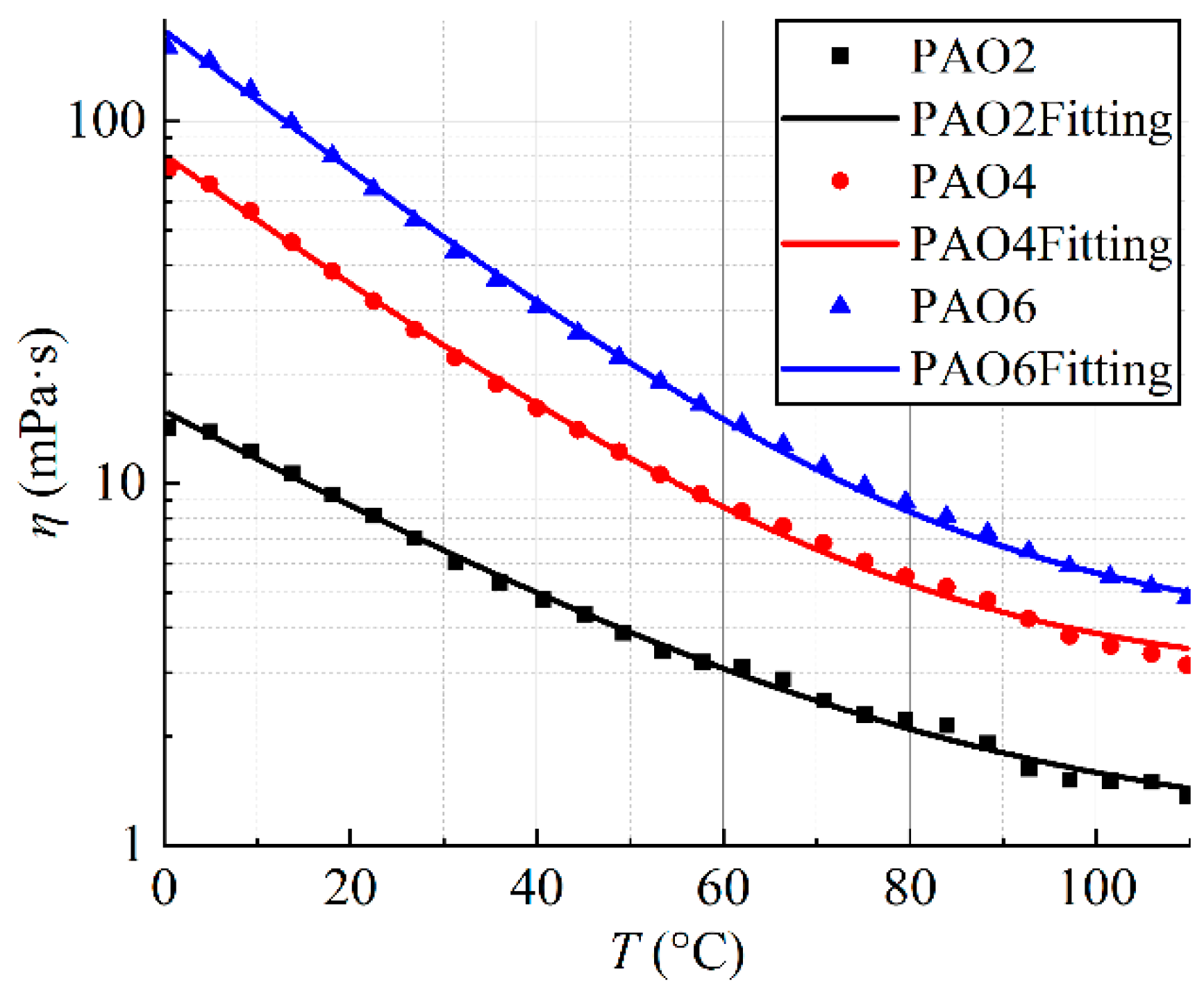

- Investigate the viscosity changes in PAO samples of different viscosities under a constant shear rate (1000 s−1) while varying the temperature from 0 °C to 110 °C in 30 min to evaluate their visco-thermal behavior.

2.2. Results and Discussion

3. Lubricating Film Formation Performance of PAOs

3.1. Experimental Method

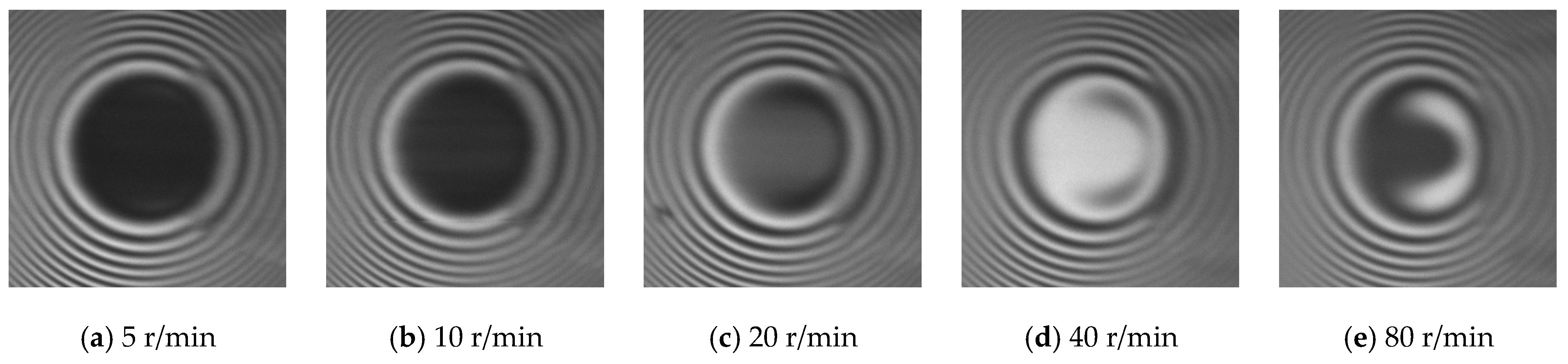

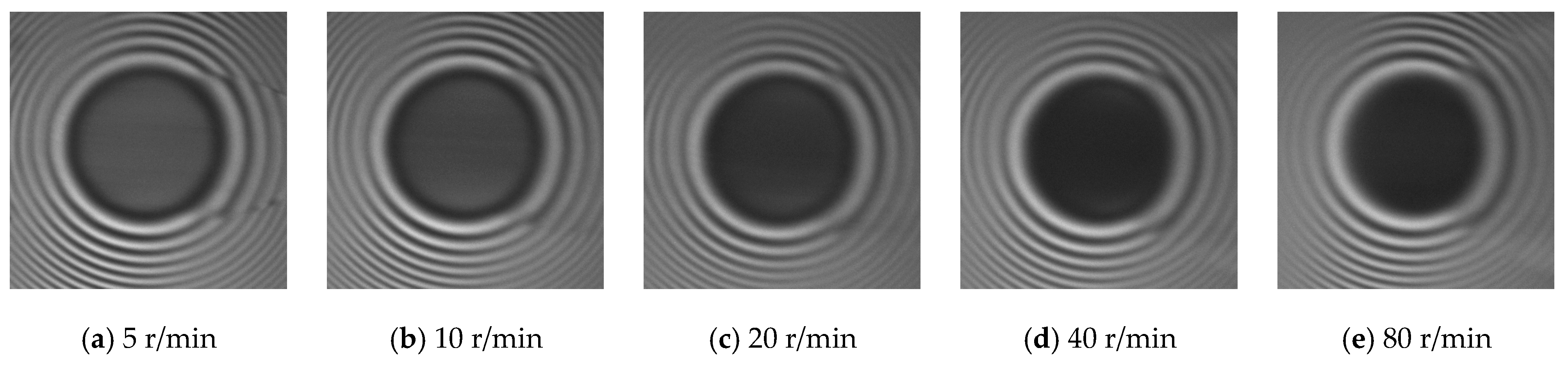

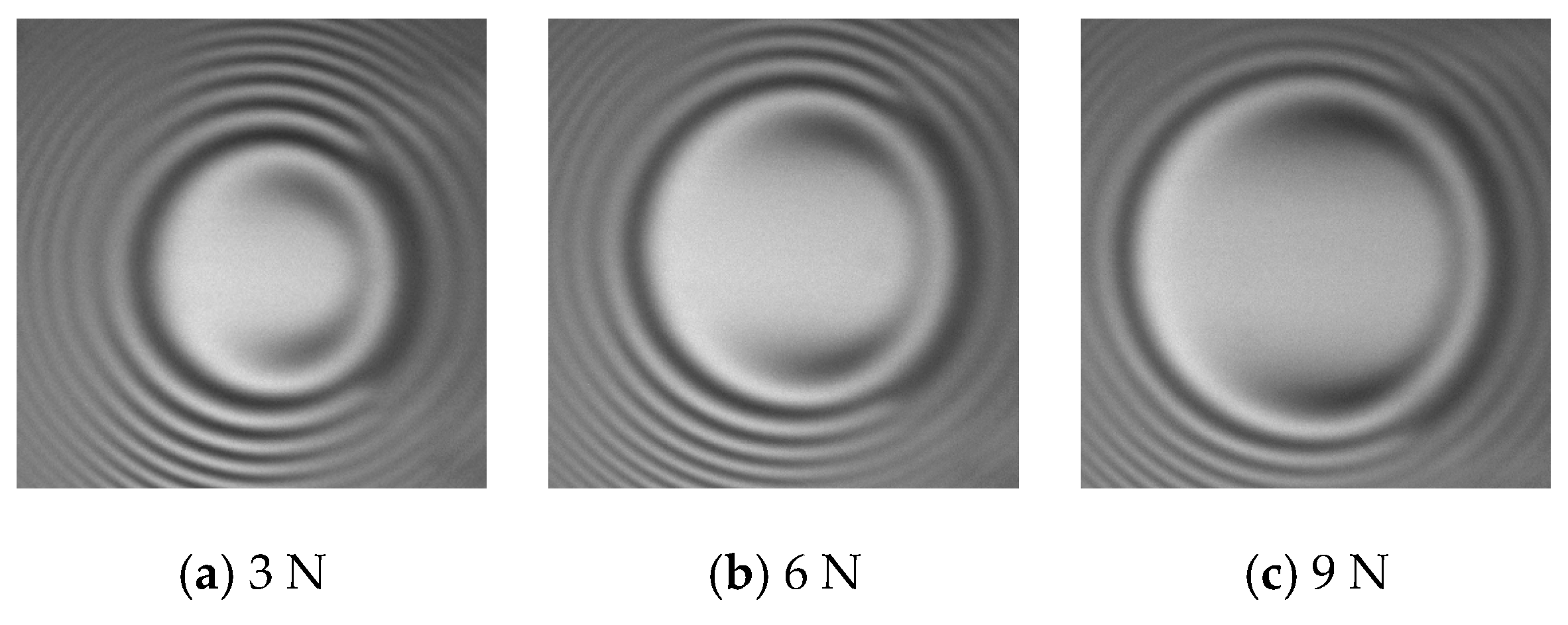

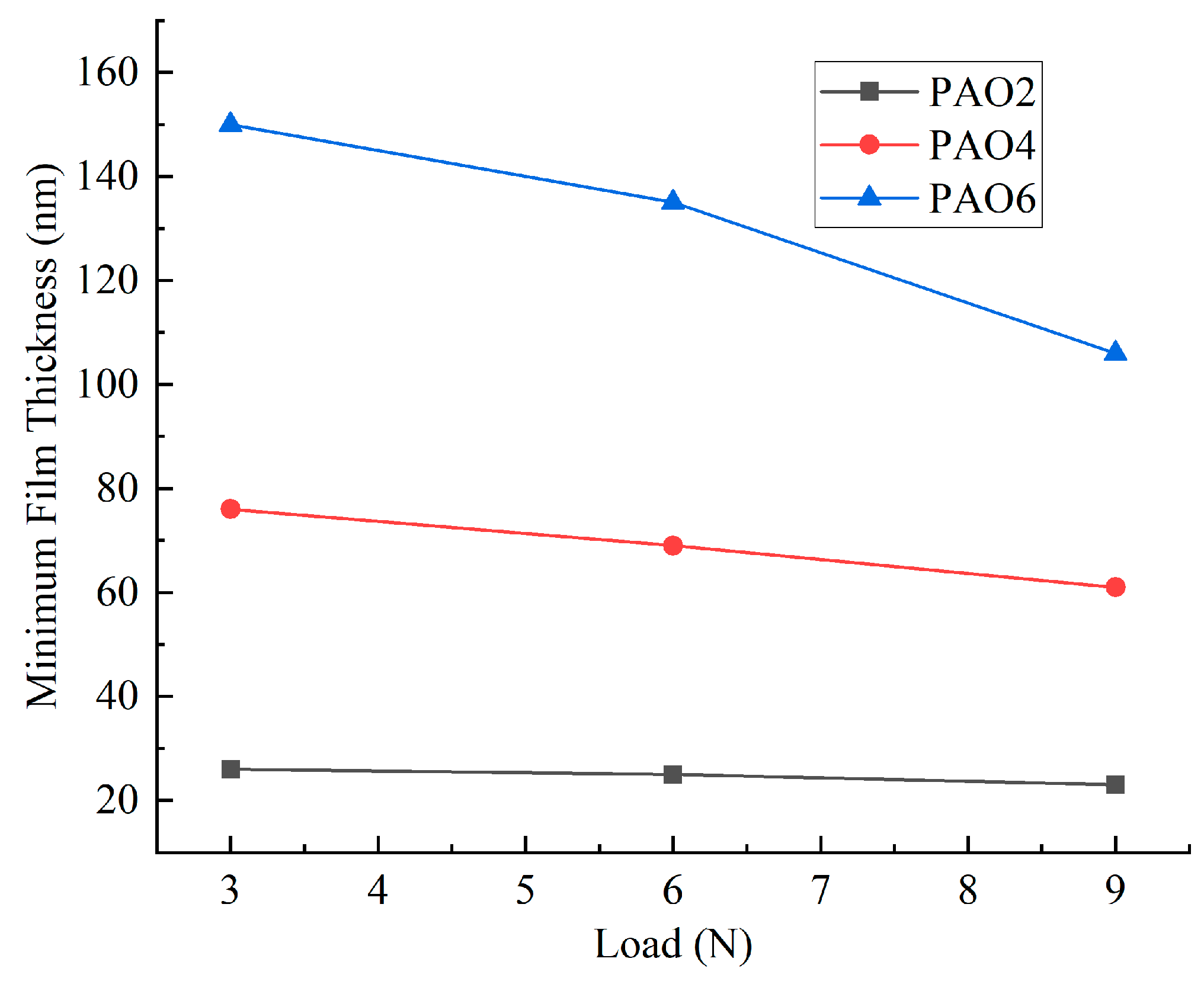

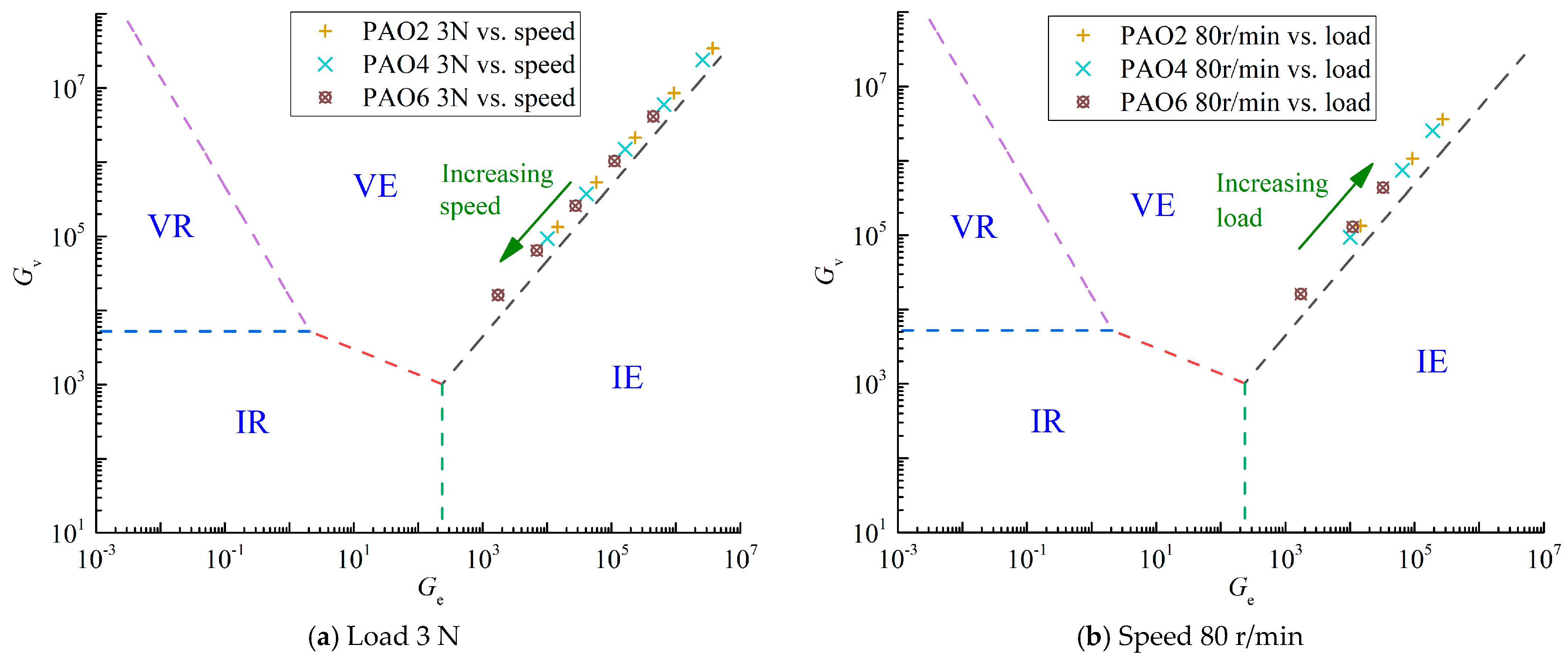

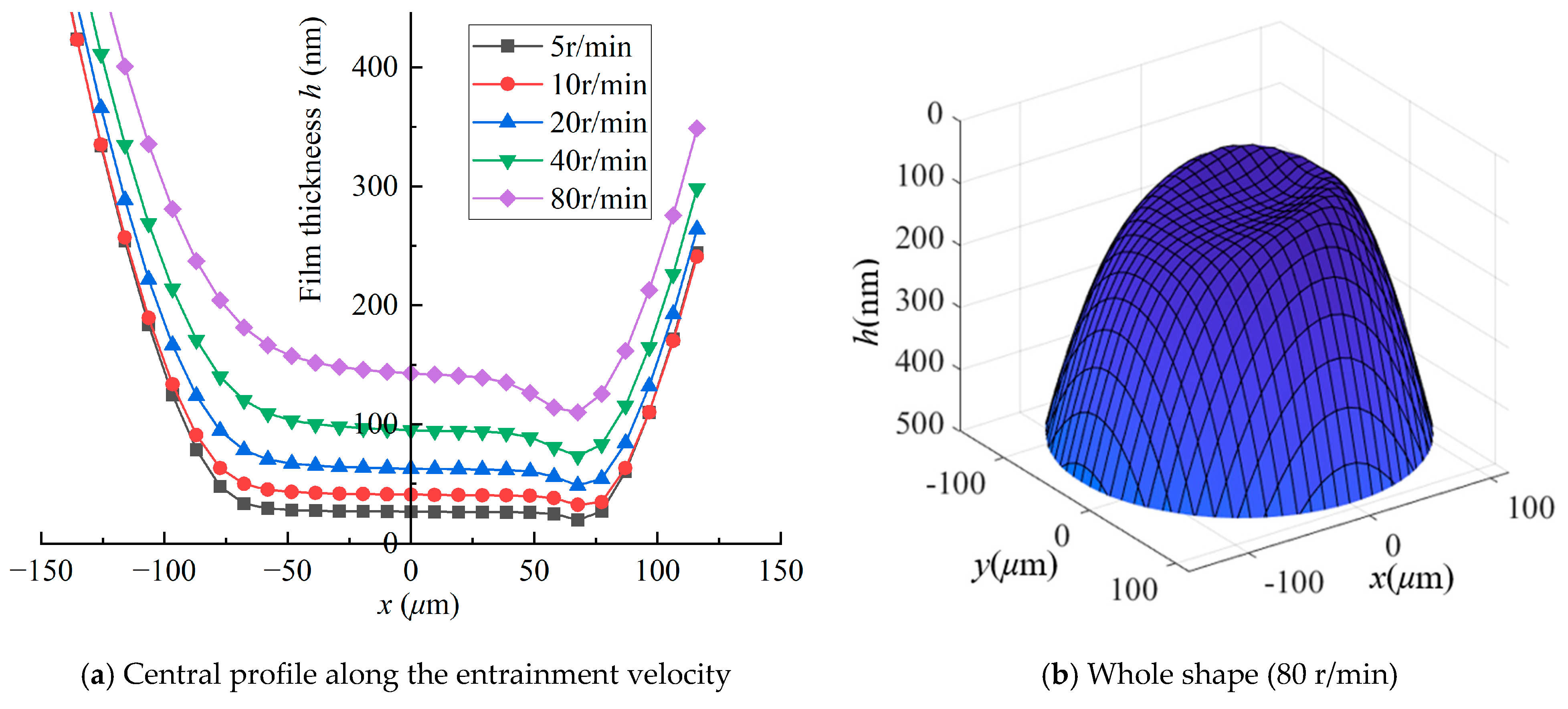

3.2. Results and Discussion

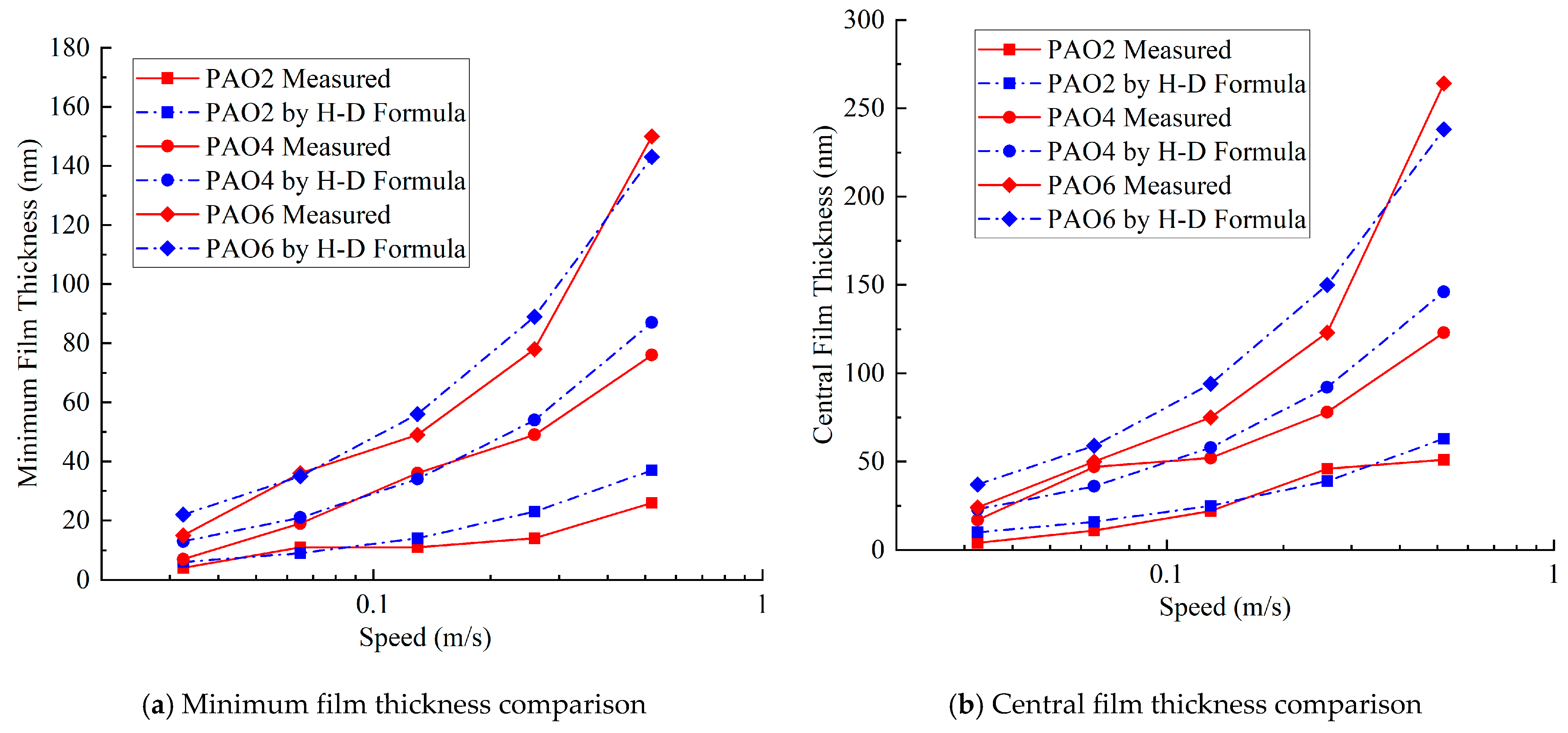

4. Comparison Between Theoretical Calculations and Experimental Results

5. Conclusions

- PAO2 and PAO4, as very low-viscosity PAOs, behave like Newtonian fluids with a viscosity fluctuation of no more than 10% at high shear rates. They do not show significant thixotropic behavior or shear thinning. In contrast, PAO6, a higher-viscosity PAO, exhibits a more significant shear thinning effect with a viscosity fluctuation of ≥15% at high shear rates. This indicates that high-viscosity PAOs need special consideration of non-Newtonian effects in high-shear-rate applications.

- PAO2 has superior low-temperature performance and better cold flow characteristics compared to PAO6. PAO6 is more sensitive to temperature changes, with its viscosity dropping significantly within the 0–60 °C range. A viscosity–temperature equation was derived to predict the viscosities of PAO2, PAO4, and PAO6 at specific temperatures.

- PAO2 and PAO4 films are less likely to form a uniform lubricating film as thick as that of PAO6 under certain conditions, based on the optical interference test results. PAO2 mainly operates in a boundary lubrication regime. Moreover, both speed and load have a smaller effect on the lubricating film thickness of PAO2 and PAO4 compared to PAO6.

- The Hamrock–Dowson formula overestimates the lubricating film thickness of PAO6 at high speeds. However, for very low-viscosity PAOs (PAO2 and PAO4), the isothermal elastohydrodynamic lubrication theory is applicable, and the Hamrock–Dowson formula can calculate values consistent with experimental measurements, providing a stable prediction of the lubricating film thickness for PAO2 and PAO4 generally.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Shear rate [s−1] | |

| Relative light intensity at the measurement point | |

| Maximum light intensity within the interference half-order | |

| Minimum light intensity within the interference half-order | |

| Relative light intensity at the center of the film with zero thickness | |

| Maximum light intensity at the center of the film with zero thickness | |

| Minimum light intensity at the center of the film with zero thickness | |

| Dimensionless minimum film thickness | |

| Dimensionless central film thickness | |

| ρ | Density [g/m3] |

| A | Constant of relationship between dynamic viscosity of PAO and temperature |

| E′ | Composite Young’s modulus, , [Pa] |

| E1, E2 | Young’s modulus of two surfaces [Pa] |

| G* | Dimensionless material parameter |

| Ge | Dimensionless elasticity parameter |

| Gv | Dimensionless viscosity parameter |

| h | Film thickness [m] |

| h0 | Film thickness parameter to be determined in the calculation [m] |

| I | Absolute light intensity at the measurement point |

| I0 | Absolute light intensity at the center of the film with zero thickness |

| k | Defined interference half-order |

| n | Constant of relationship between dynamic viscosity of PAO and temperature |

| nd | Refractive index |

| p | Pressure [Pa] |

| Rx | Equivalent curvature radius along the direction of the entrainment velocity [m] |

| Ry | Equivalent curvature radius perpendicular to the direction of the entrainment velocity [m] |

| t | Time [min] |

| T | Temperature [°C] |

| U | Entrainment velocity [m/s] |

| U* | Dimensionless speed parameter |

| W | Load [N] |

| W* | Dimensionless load parameter |

| x | Coordinate along the direction of the entrainment velocity [m] |

| y | Coordinate perpendicular to the direction of the entrainment velocity [m] |

| α | Pressure–viscosity coefficient [m2/N] |

| ε | Ellipticity |

| η | Dynamic viscosity [Pa·s] |

| η0 | Viscosity at atmosphere pressure [Pa·s] |

| ηc | Constant of relationship between dynamic viscosity and temperature |

| λ | Wavelength [nm] |

| ν1, ν2 | Poisson’s ratio of two surfaces |

| τ | Shear stress [Pa] |

References

- Rudnick, L.R. Polyalphaolefns. In Synthetics, Mineral Oils, and Bio-Based Lubricants; CRC Press: Boca Raton, FL, USA, 2020; p. 20. [Google Scholar]

- Bartz, W.J. Lubricants and the environment. Tribol. Int. 1998, 31, 35–47. [Google Scholar] [CrossRef]

- Hope, K. PAO Contributions to Energy Efficiency in 0W-20 Passenger Car Engine Oils. Lubricants 2018, 6, 73. [Google Scholar] [CrossRef]

- Kang, G.; Zhang, F.; Liu, H.; Wei, B.; Jin, Z.; Lv, H. Rapid Separation and API Grades Identification of Base Oil in Low Viscosity Gasoline Engine Oil SN 0W-16. ACS Omega 2024, 9, 21270–21275. [Google Scholar] [CrossRef]

- Ishizaki, K.; Nakano, M. Reduction of CO2 Emissions and Cost Analysis of Ultra-Low Viscosity Engine Oil. Lubricants 2018, 6, 102. [Google Scholar] [CrossRef]

- Benda, R.; Bullen, J.; Plomer, A. Synthetics basics: Polyalphaolefins—Base fluids for high-performance lubricants. J. Synth. Lubr. 1996, 13, 41–57. [Google Scholar] [CrossRef]

- Van Rensselar, J. The bright future for PAOs. Tribol. Lubr. Technol. 2021, 77, 28–32. [Google Scholar]

- Rahim, K.A.; Al-Humairi, S.N.S. Influence of Lubrication Technology on Internal Combustion Engine Performance: An Overview. In Proceedings of the 2020 IEEE 8th Conference on Systems, Process and Control (ICSPC), Melaka, Malaysia, 11–12 December 2020; pp. 184–189. [Google Scholar]

- Harold, S. Biodegradability: Review of the Current Situation; Lubrizol Corporation: Wickliffe, OH, USA, 1993. [Google Scholar]

- Honary, L.; Richter, E. Biobased Lubricants and Greases: Technology and Products, 1st ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2011; pp. 187–190. [Google Scholar]

- Coordinating European Council. Test Method for the Biodegradability of Two-Stroke Cycle Outboard Engine Oils in Water; CEC L-33-T-93; Coordinating European Council: Brussels, Belgium, 1995. [Google Scholar]

- Organisation for Economic Co-Operation and Development. OECD Guidelines for the Testing of Chemicals. Test No. 301: Ready Biodegradability 1992. Available online: https://www.oecd.org/en/publications/test-no-301-ready-biodegradability_9789264070349-en.html (accessed on 1 October 2024).

- ASTM D5864-23; Standard Test Method for Determining Aerobic Aquatic Biodegradation of Lubricants or Their Components. ASTM: Philadelphia, PA, USA, 2023.

- Völtz, M. New CEC test method L-103 for lubricant biodegradability. Tribol. Schmier. 2012, 59, 23–26. [Google Scholar]

- Boyde, S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem. 2002, 4, 293–307. [Google Scholar] [CrossRef]

- Johnson, M.; Miller, M. Eco-friendly fluids for the lubricants industry. Tribol. Lubr. Technol. 2010, 66, 28–34. [Google Scholar]

- Sherman, J.; Totten, G.E.; Shah, R.J.; Forester, D.R. Chapter 13|Synthetic Lubricants: Nonaqueous. In Fuels and Lubricants Handbook: Technology, Properties, Performance, and Testing; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Zwierzycki, W.; Górny, K. Trends in the process of greening lubricants. Q. Tribol. 2020, 290, 91–98. [Google Scholar] [CrossRef]

- Carpenter, J.F. Biodegradability and toxicity of polyalphaolefin base stocks. J. Synth. Lubr. 1995, 12, 13–20. [Google Scholar] [CrossRef]

- Kržan, B.; Vižintin, J.; Vižintin, J.; Kalin, M.; Dohda, K.; Jahanmir, S. Use and Development of Biodegradable Oils. In Tribology of Mechanical Systems: A Guide to Present and Future Technologies; ASME Press: New York, NY, USA, 2004. [Google Scholar]

- Beran, E. Experience with evaluating biodegradability of lubricating base oils. Tribol. Int. 2008, 41, 1212–1218. [Google Scholar] [CrossRef]

- Battersby, N.S. The biodegradability and microbial toxicity testing of lubricants—Some recommendations. Chemosphere 2000, 41, 1011–1027. [Google Scholar] [CrossRef]

- De Wilde, B.; Mortier, N.; van Eekert, M.; Briassoulis, D.; Mistriotis, A.; van der Zee, M. Knowledge Based Bio-Based Products’ Pre-Standardization; Netherlands Standardization Institute (NEN): Delft, The Netherlands, 2015. [Google Scholar]

- Rhee, I.-S. Assessing the Biodegradability of Hydraulic Fluids Using a Bio-Kinetic Model. Tribol. Trans. 2008, 51, 68–73. [Google Scholar] [CrossRef]

- Roell, B.C.; Otto, A.; Kuchta, T. Environmentally Acceptable Hydraulic Lubricants. In Environmentally Friendly and Biobased Lubricants, 1st ed.; Brajendra, K., Sharma, G.B., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 136–139. [Google Scholar]

- Battersby, N.S. Biodegradable Lubricants: What Does ‘Biodegradable’ Really Mean? J. Synth. Lubr. 2005, 22, 3–18. [Google Scholar] [CrossRef]

- Cyriac, F.; Yi, T.X.; Poornachary, S.K.; Chow, P.S. Influence of Base oil Polarity on the Tribological Performance of Surface-Active Engine Oil Additives. Tribol. Lett. 2021, 69, 87. [Google Scholar] [CrossRef]

- Jablonka, K.; Glovnea, R.; Bongaerts, J.; Morales-Espejel, G. The effect of the polarity of the lubricant upon capacitance measurements of EHD contacts. Tribol. Int. 2013, 61, 95–101. [Google Scholar] [CrossRef]

- Dresel, W. Synthetic base oils. In Lubricants and Lubrication; Wilfried Dresel, T.M.P., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2017; pp. 83–116. [Google Scholar]

- Cen, H.; Morina, A.; Neville, A. Effect of base oil polarity on the micropitting behaviour in rolling-sliding contacts. Lubr. Sci. 2019, 31, 113–126. [Google Scholar] [CrossRef]

- Jiang, S.; Li, S.; Liu, L.; Wang, L.; Mominou, N. The tribological properties and tribochemical analysis of blends of poly alpha-olefins with neopentyl polyol esters. Tribol. Int. 2015, 86, 42–51. [Google Scholar] [CrossRef]

- Fan, M.; Yang, D.; Wang, X.; Liu, W.; Fu, H. DOSS– Based QAILs: As Both Neat Lubricants and Lubricant Additives with Excellent Tribological Properties and Good Detergency. Ind. Eng. Chem. Res. 2014, 53, 17952–17960. [Google Scholar] [CrossRef]

- Guimarey, M.J.G.; Comuñas, M.J.P.; López, E.R.; Amigo, A.; Fernández, J. Thermophysical properties of polyalphaolefin oil modified with nanoadditives. J. Chem. Thermodyn. 2019, 131, 192–205. [Google Scholar] [CrossRef]

- LaFountain, A.; Johnston, G.J.; Spikes, H.A. Elastohydrodynamic Friction Behavior of Polyalphaolefin Blends. In Tribology Series; Dowson, D., Taylor, C.M., Childs, T.H.C., Dalmaz, G., Berthier, Y., Flamand, L., Georges, J.M., Lubrecht, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 1998; Volume 34, pp. 465–475. [Google Scholar]

- Larsson, R.; Larsson, P.O.; Eriksson, E.; Sjöberg, M.; Höglund, E. Lubricant properties for input to hydrodynamic and elastohydrodynamic lubrication analyses. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 17–27. [Google Scholar] [CrossRef]

- Nakamura, Y.; Hiraiwa, S.; Suzuki, F.; Matsui, M. High-Pressure Viscosity Measurements of Polyalphaorefins at Elevated Temperature. Tribol. Online 2016, 11, 444–449. [Google Scholar] [CrossRef]

- Bair, S.; Flores-Torres, S. The Viscosity of Polyalphaolefins Mixtures at High Pressure and Stress. J. Tribol. 2018, 141, 021802. [Google Scholar] [CrossRef]

- Pichler, J.; Maria Eder, R.; Besser, C.; Pisarova, L.; Dörr, N.; Marchetti-Deschmann, M.; Frauscher, M. A comprehensive review of sustainable approaches for synthetic lubricant components. Green Chem. Lett. Rev. 2023, 16, 2185547. [Google Scholar] [CrossRef]

- Mannekote, J.K.; Kailas, S.V. Biodegradability and Ecotoxicity Evaluation of lubricants. In Environmentally Friendly and Biobased Lubricants; CRC Press: Boca Raton, FL, USA, 2016; pp. 151–165. [Google Scholar]

- Wen, S.; Huang, P. Principles of Tribology, 2nd ed.; Wiley: Singapore, 2017. [Google Scholar]

- Du, S.; Zhang, C.; Luo, Z. Combination of diketone and PAO to achieve macroscale oil-based superlubricity at relative high contact pressures. Friction 2024, 12, 869–883. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, X.; Shen, Y.; Lin, J. Dynamic Viscosity-Temperature Characteristics and Models of Various Lubricating Oils. Recent Pat. Eng. 2023, 17, 23–31. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, P. An Improved Interference Method for Measuring Lubricant Film Thickness Using Monochromatic Light. Tribol. Lett. 2017, 65, 120. [Google Scholar] [CrossRef]

- Panwar, P.; Schweissinger, E.; Maier, S.; Hilf, S.; Sirak, S.; Martini, A. Effect of polymer structure and chemistry on viscosity index, thickening efficiency, and traction coefficient of lubricants. J. Mol. Liq. 2022, 359, 119215. [Google Scholar] [CrossRef]

- Ueda, M.; Wong, J.S.S.; Spikes, H. Influence of dumbbell base oil blends on micropitting. Tribol. Int. 2023, 185, 108578. [Google Scholar] [CrossRef]

- Esfahanian, M.; Hamrock, B.J. Fluid-Film Lubrication Regimes Revisited. Tribol. Trans. 1991, 34, 628–632. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Minimum Film Thickness in Elliptical Contacts for Different Regimes of Fluid-Film Lubrication; NASA: Washington, DC, USA, 1978. [Google Scholar]

- Greenwood, J.A. Elastohydrodynamic Lubrication. Lubricants 2020, 8, 51. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts: Part III—Fully Flooded Results. J. Tribol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Huang, P. Numerical Calculation of Elastohydrodynamic Lubrication: Methods and Programs; Wiley: Singapore, 2015; pp. 84–94. [Google Scholar]

- Gohar, R.; Rahnejat, H. Fundamentals of Tribology; Imperial College Press: London, UK, 2008. [Google Scholar]

- Roeland, C.J.A. Correlation Aspect of the Viscosity-Temperature-Pressure Relation of Lubrication Oils. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1966. [Google Scholar]

- Dowson, D.; Higginson, G.R. A Numerical Solution to the Elasto-Hydrodynamic Problem. J. Mech. Eng. Sci. 1959, 1, 6–15. [Google Scholar] [CrossRef]

- Zolper, T.J.; He, Y.; Delferro, M.; Shiller, P.; Doll, G.; LotfizadehDehkordi, B.; Ren, N.; Lockwood, F.; Marks, T.J.; Chung, Y.-W.; et al. Investigation of Shear-Thinning Behavior on Film Thickness and Friction Coefficient of Polyalphaolefin Base Fluids with Varying Olefin Copolymer Content. J. Tribol. 2016, 139, 021504. [Google Scholar] [CrossRef]

| Kinematic Viscosity (mm2/s) | Viscosity Index | Density (15 °C, g/cm3) | ||

|---|---|---|---|---|

| 40 °C | 100 °C | |||

| PAO2 | 5.0 | 1.70 | - | 0.798 |

| PAO4 | 19.0 | 4.10 | 126 | 0.820 |

| PAO6 | 31.0 | 5.80 | 138 | 0.827 |

| Fitting Visco-Thermal Equation | Adj. R-Square | |

|---|---|---|

| PAO2 | 0.99710 | |

| PAO4 | 0.99862 | |

| PAO6 | 0.99787 |

| Material | Poisson’s Ratio | Modulus of Elasticity/Pa | Radius of Curvature/m | Surface Roughness/nm | |

|---|---|---|---|---|---|

| Steel ball | GCr15 | 0.280 | 2.07 × 1011 | 0.0127 | 2 |

| Glass disk | Crown glass K9 | 0.209 | 8.13 × 1010 | ∞ | 5 |

| Item | Dynamic Viscosity η/mPa·s a | Refractive Index nd b | Pressure–Viscosity Coefficient α/×10−8 m2/N c |

|---|---|---|---|

| PAO2 | 8 | 1.442 | 1.390 |

| PAO4 | 28 | 1.453 | 1.403 |

| PAO6 | 58 | 1.458 | 1.408 |

| Load Parameter W* (×10−6) | Speed Parameter U* (×10−12) | |||||||

|---|---|---|---|---|---|---|---|---|

| 3 N | 6 N | 9 N | 5 r/min | 10 r/min | 20 r/min | 40 r/min | 80 r/min | |

| PAO2 | 0.151 | 0.302 | 0.452 | 0.166 | 0.332 | 0.663 | 1.33 | 2.65 |

| PAO4 | 0.580 | 1.16 | 2.32 | 4.64 | 9.28 | |||

| PAO6 | 1.20 | 2.40 | 4.81 | 9.62 | 19.2 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; He, Z.; Wang, H.; Li, Y.; Wang, H. Rheological Properties and Lubricating Film Formation Performance of Very Low-Viscosity and Biodegradable Polyalphaolefins. Lubricants 2025, 13, 62. https://doi.org/10.3390/lubricants13020062

Chen Y, He Z, Wang H, Li Y, Wang H. Rheological Properties and Lubricating Film Formation Performance of Very Low-Viscosity and Biodegradable Polyalphaolefins. Lubricants. 2025; 13(2):62. https://doi.org/10.3390/lubricants13020062

Chicago/Turabian StyleChen, Yingjun, Zhaorong He, Haiquan Wang, Yueming Li, and Hui Wang. 2025. "Rheological Properties and Lubricating Film Formation Performance of Very Low-Viscosity and Biodegradable Polyalphaolefins" Lubricants 13, no. 2: 62. https://doi.org/10.3390/lubricants13020062

APA StyleChen, Y., He, Z., Wang, H., Li, Y., & Wang, H. (2025). Rheological Properties and Lubricating Film Formation Performance of Very Low-Viscosity and Biodegradable Polyalphaolefins. Lubricants, 13(2), 62. https://doi.org/10.3390/lubricants13020062