Study on the Effect of Laser Shock Angle on Surface Integrity and Wear Performance of H13 Steel

Abstract

1. Introduction

2. Materials and Methods

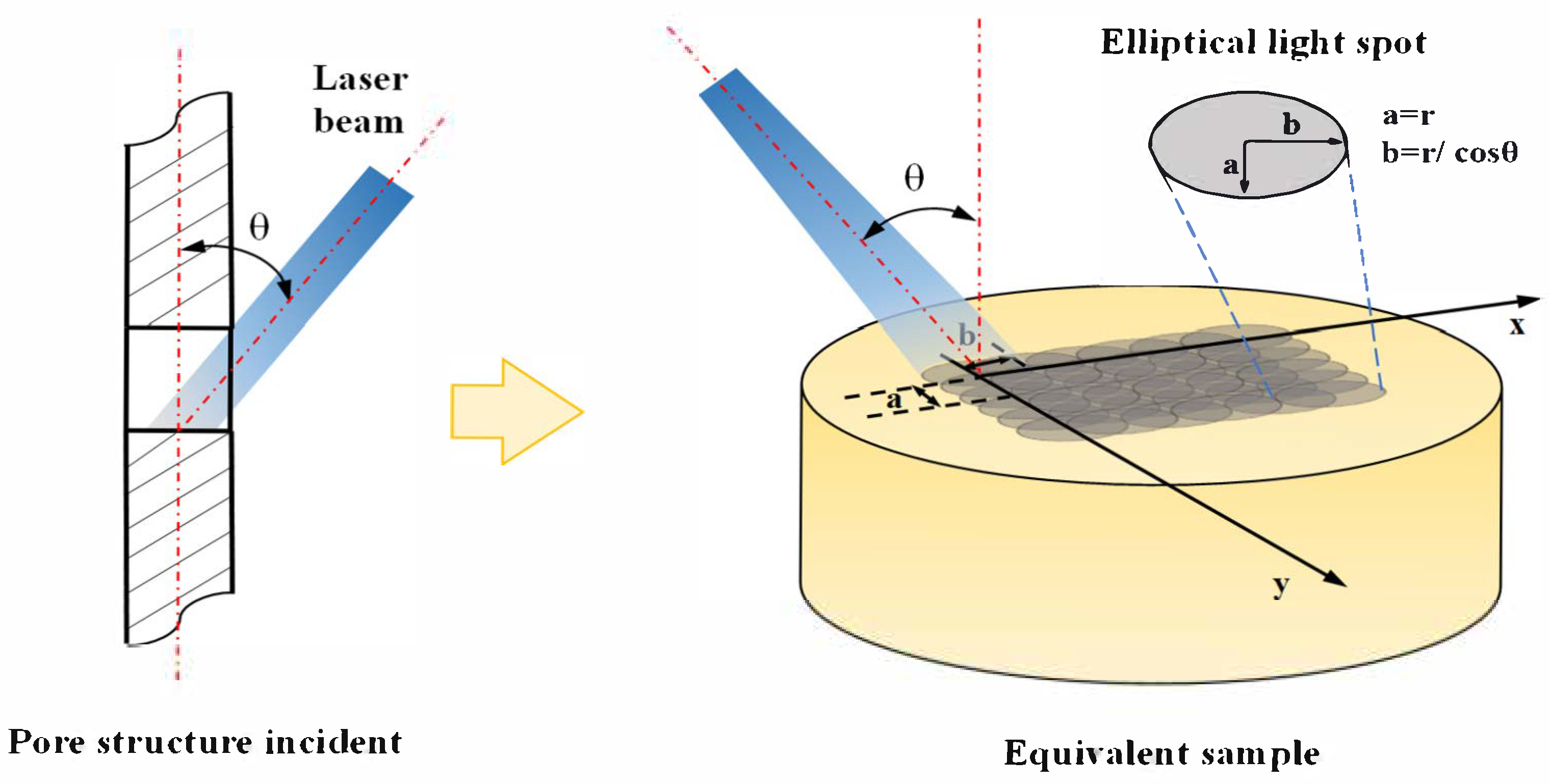

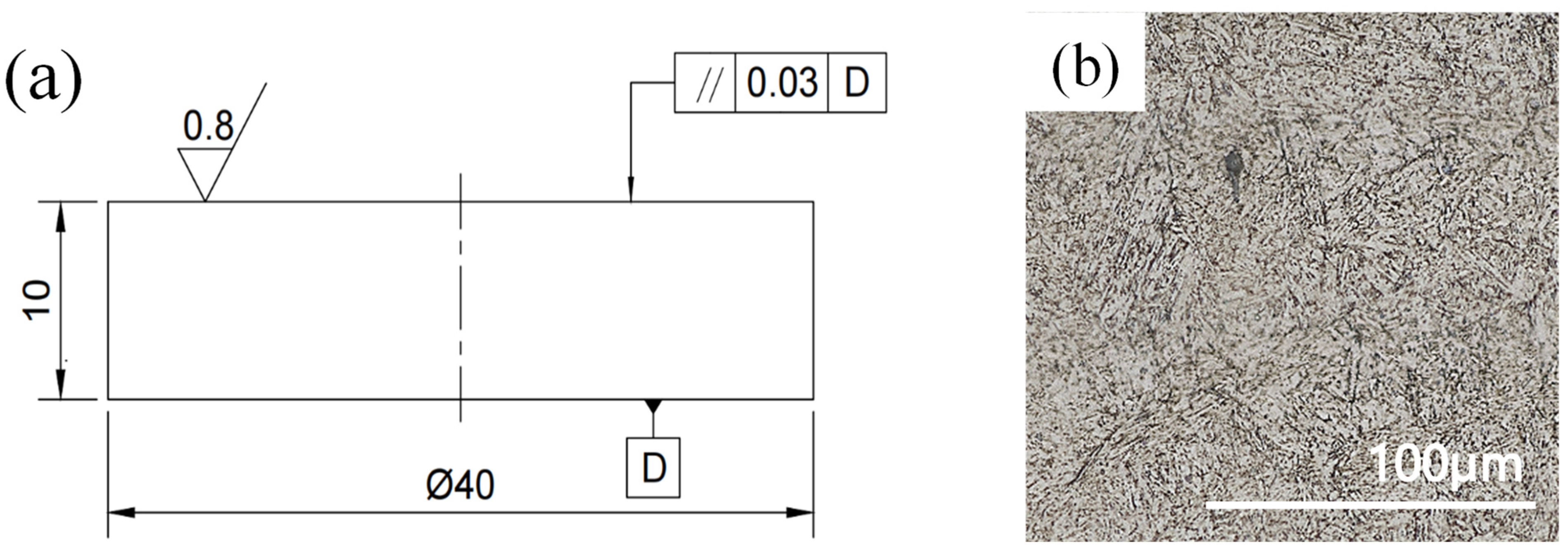

2.1. Materials and LSP Experiment

2.2. Detection and Characterization

3. Results

3.1. Surface Topography

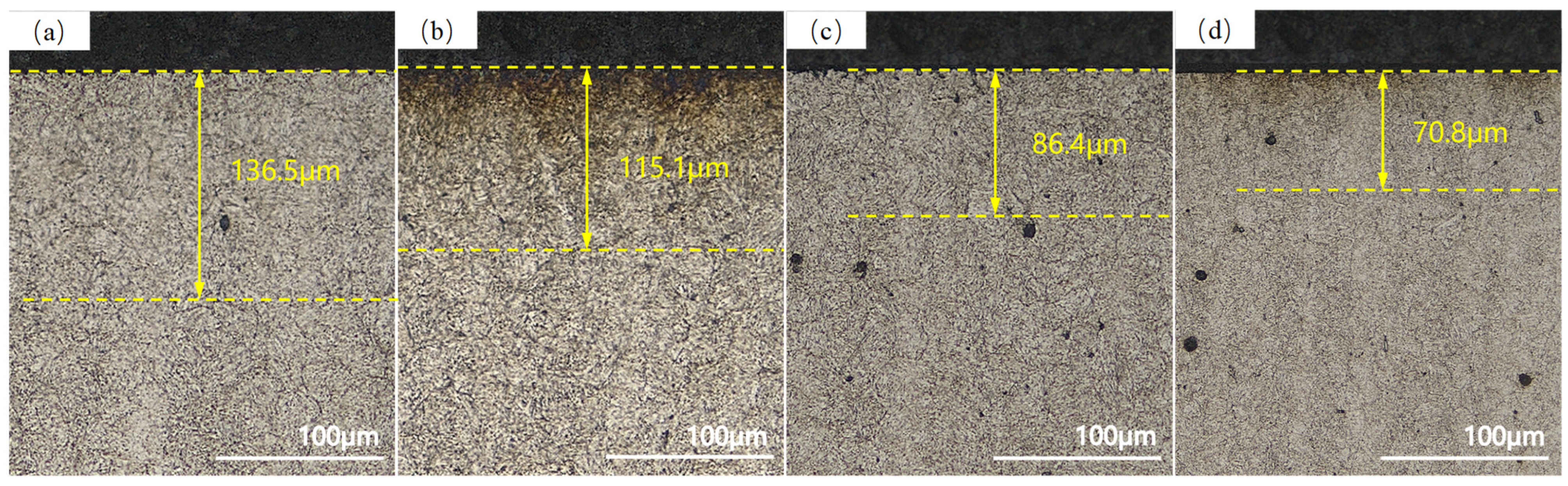

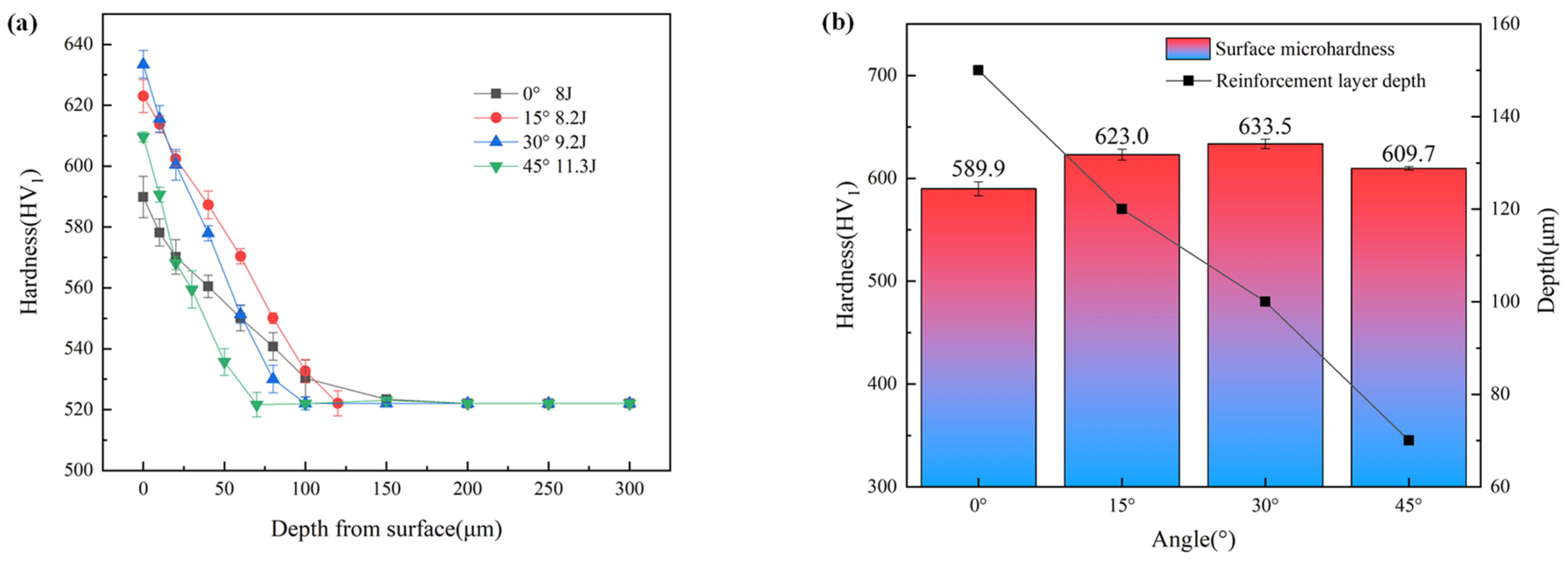

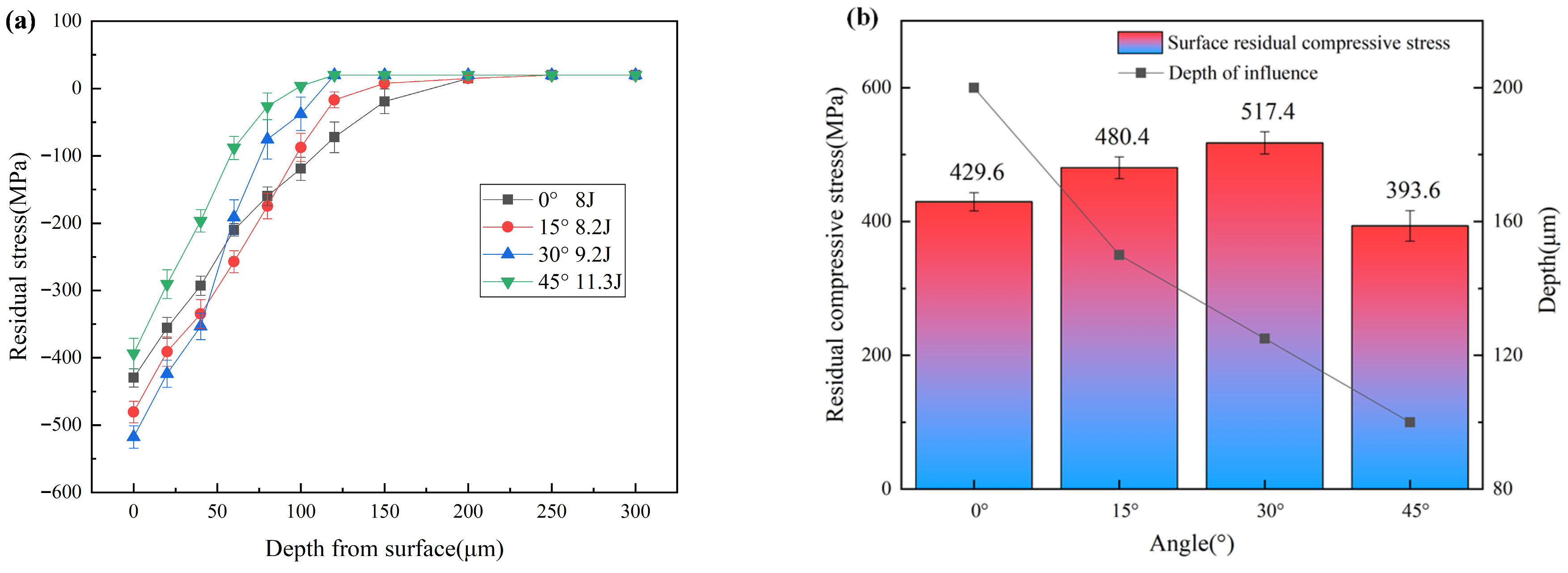

3.2. Metallographic Structure, Microhardness and Residual Stress

3.3. Friction and Wear Performances

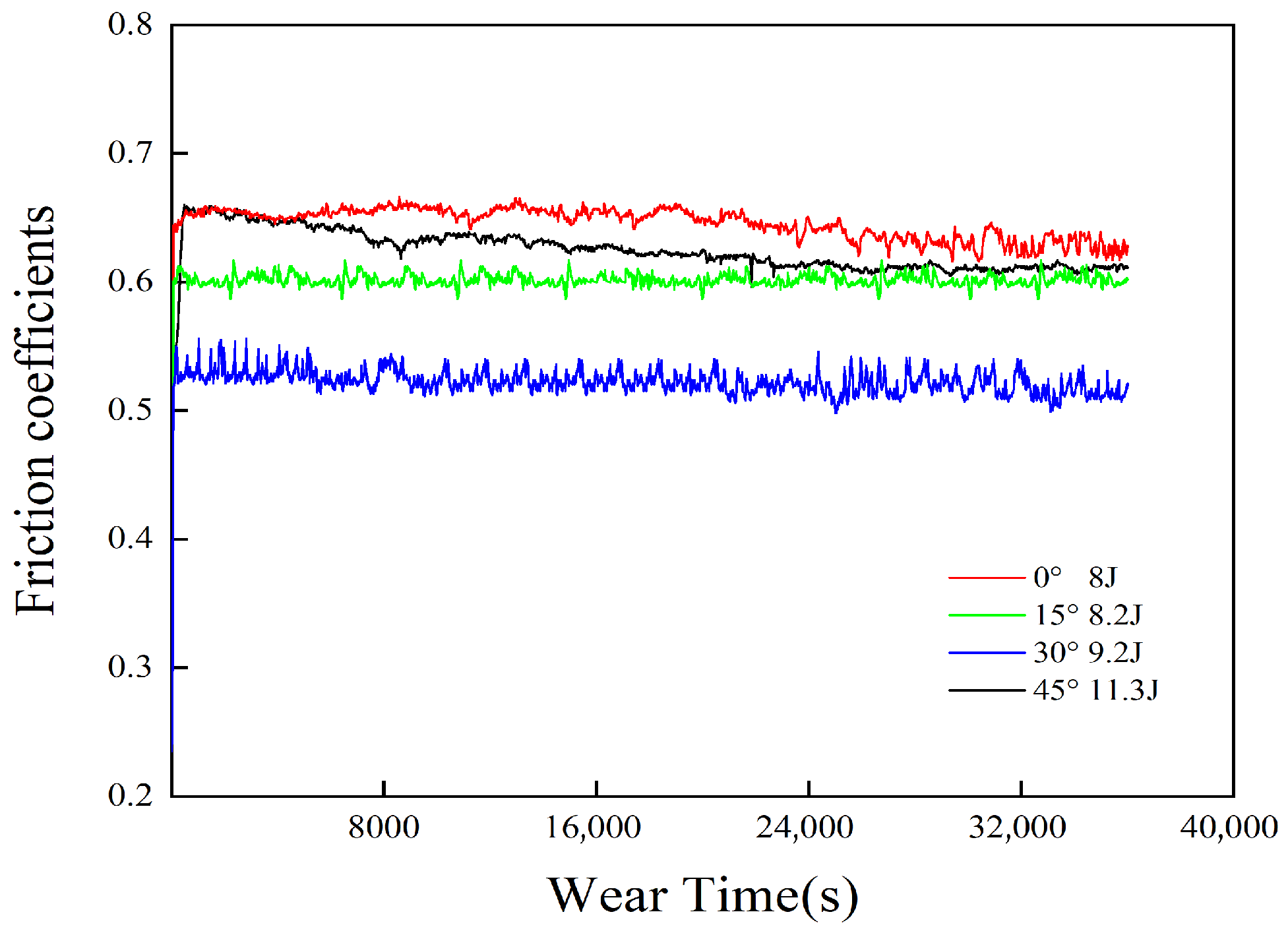

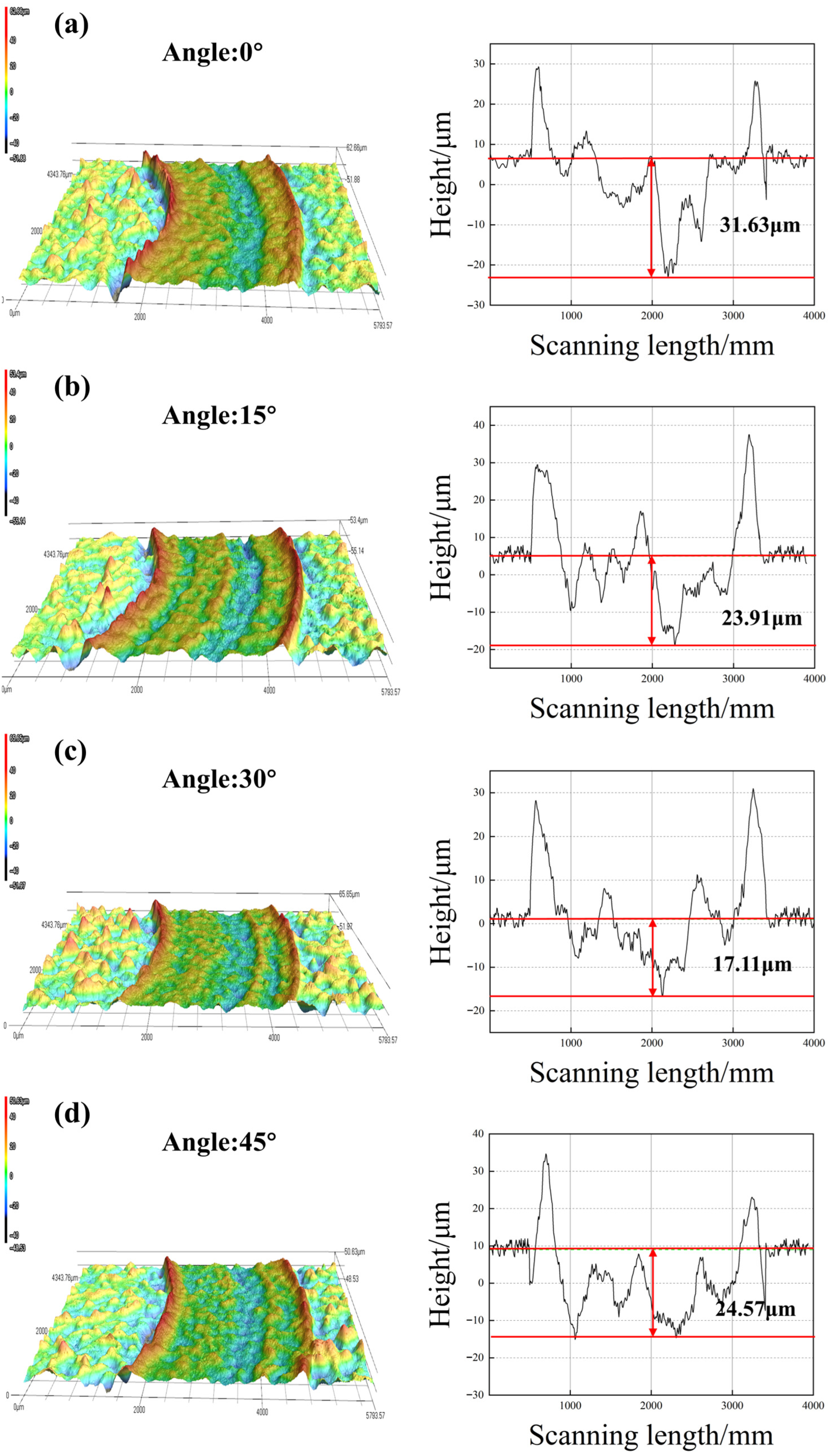

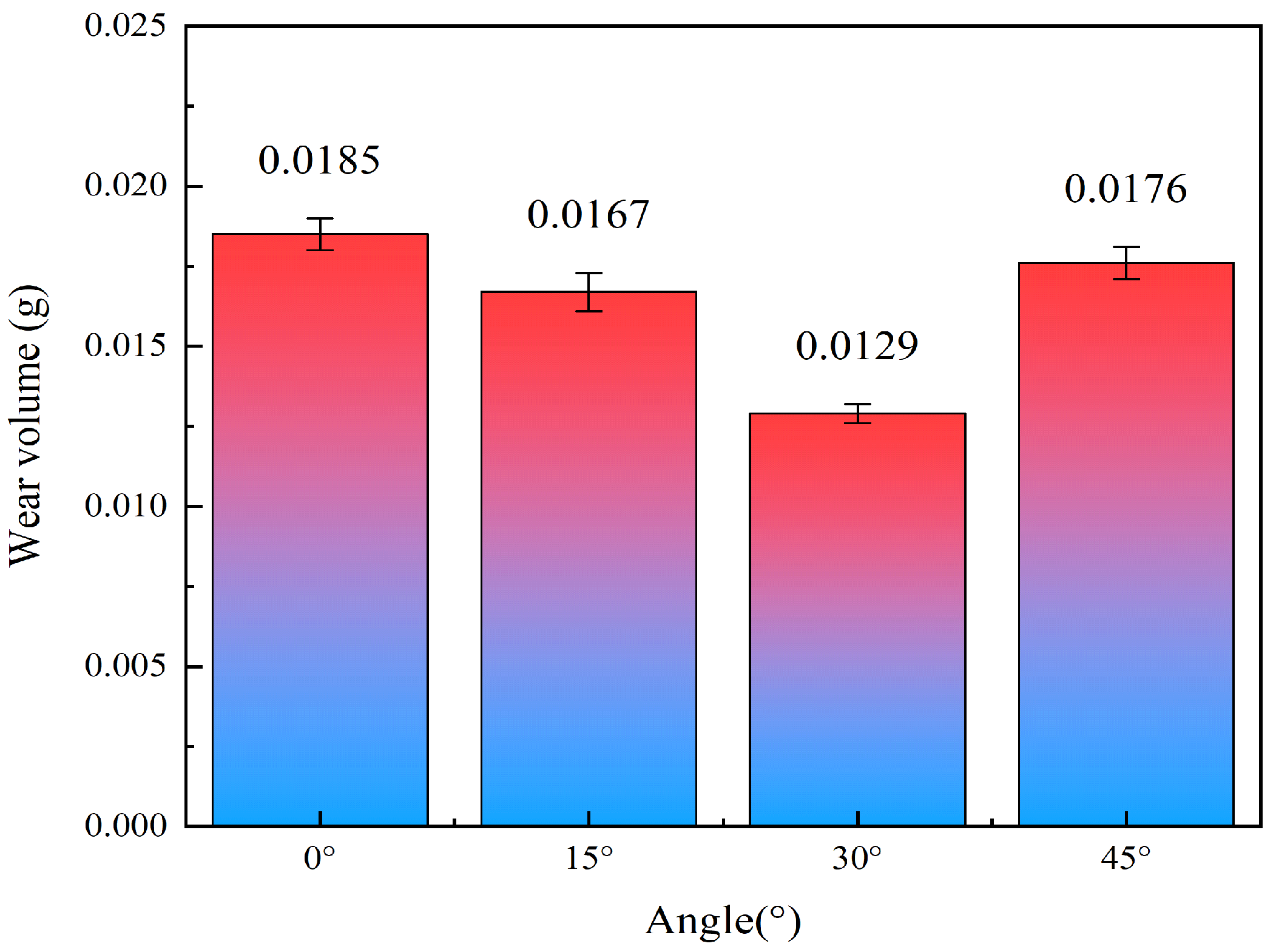

3.3.1. COF, Wear Profile, and Wear Volume

3.3.2. Wear Morphology

4. Discussion

5. Conclusions

- (1)

- By compensating for the laser energy to maintain a constant power density, the influence of the laser incidence angle on the surface integrity of H13 steel was systematically examined. As the incidence angle increased from 0° to 45°, the surface characteristics exhibited distinct and consistent variations. The surface roughness first increased and then decreased, reaching its maximum value at an angle of 15°. In contrast, the thickness of the plastic deformation layer decreased progressively with increasing angle, with the maximum reduction reaching 48.1%. Notably, both surface microhardness and residual compressive stress followed a non-monotonic trend—initially increasing and subsequently decreasing—and simultaneously attained their peak values at an incidence angle of 30°, corresponding to 633.5 HV1 and 517.4 MPa, respectively.

- (2)

- The laser impact angle plays a crucial role in governing the friction and wear behavior of H13 steel. With increasing impact angle, the friction coefficient, wear depth, and wear rate exhibit a non-monotonic variation—initially decreasing and subsequently increasing—achieving optimal performance at approximately 30°. Theoretical analysis indicates that a moderately inclined impact facilitates pronounced grain refinement, thereby enhancing the surface layer’s strength, hardness, and resistance to plastic deformation. Correspondingly, the dominant wear mechanism evolves with impact angle, transitioning from severe adhesive–abrasive composite wear under normal impact to predominantly mild adhesive wear at 30°. However, when the impact angle further increases to 45°, oxidation wear becomes the primary mechanism, resulting in a degradation of wear resistance.

- (3)

- The strengthening mechanism of H13 steel under varying laser impact angles is essentially governed by the synergistic interaction between the normal and tangential stress components during the laser shock process. Within a certain range of inclination angles, the normal stress component gradually decreases, thereby diminishing its direct contribution to the formation of the plastic deformation layer. Meanwhile, the tangential stress component becomes increasingly dominant, inducing pronounced shear deformation. This shear-driven process facilitates dislocation multiplication and grain refinement, leading to a denser surface microstructure and the introduction of higher residual compressive stress. However, when the laser incidence angle exceeds the optimal range, the normal stress decays excessively and fails to provide sufficient driving force for plastic deformation, ultimately resulting in a pronounced reduction in the overall strengthening effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kolomy, S.; Maly, M.; Doubrava, M.; Sedlak, J.; Zouhar, J.; Cupera, J. Effect of microstructure on machinability of extruded and conventional H13 tool steel. Mater. Des. 2025, 254, 114132. [Google Scholar] [CrossRef]

- Wegener, T.; Krochmal, M.; Möller, T.R.; Le, M.T.; Czap, A.; Marianek, F.; Fakesch, H.; Niendorf, T. On the low-cycle fatigue behavior of a novel high-strength mold steel. Int. J. Fatigue 2023, 175, 107754. [Google Scholar] [CrossRef]

- Ivanaki, M.K.; Afshari, D.; Poursaeidi, E. Effects of Friction Stir Welding of 6061-T6 To 5083-H11 Aluminum Alloys Reinforced with Al2O3 on Microstructure, Hardness, and Wear Resistance. Int. J. Precis. Eng. Manuf. 2025, 1–13. [Google Scholar] [CrossRef]

- Li, C.; Yang, H.; Dong, B.; Chen, D.; Shu, S.; Qiu, F.; Jiang, Q.; Zhang, L. Thermal fatigue failure mechanisms and enhancement strategies of die steel. J. Mater. Res. Technol.-JMR&T 2025, 38, 4567–4599. [Google Scholar] [CrossRef]

- Ding, R.; Yang, H.; Li, S.; Hu, G.; Mo, J.; Chu, M.; Paddea, S.; Zhang, S.; Zhang, P.; Liu, Z.; et al. Failure analysis of H13 steel die for high pressure die casting Al alloy. Eng. Fail. Anal. 2021, 124, 105330. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, X.; Li, W.; Qin, M.; Gu, J. Effect of nitrided-layer microstructure control on wear behavior of AISI H13 hot work die steel. Appl. Surf. Sci. 2018, 431, 39–43. [Google Scholar] [CrossRef]

- Fu, Q.; Gui, X.; Gyawali, G.; Yang, Y.; Li, D.; Xiang, T.; Nouri, M.; Zhang, S. Improved tribo-corrosion performance of duplex treatment on H13 steel by plasma nitriding and CrAlN coating. Surf. Interfaces 2025, 56, 105738. [Google Scholar] [CrossRef]

- Zheng, K.; Lin, Y.; Cai, J.; Lei, C. Corrosion Resistance and Tribological Properties of Laser Cladding Layer of H13 Die Steel Strengthened by Ultrasonic Rolling. Chin. J. Mech. Eng. 2022, 35, 137. [Google Scholar] [CrossRef]

- Lu, H.F.; Xue, K.N.; Xu, X.; Luo, K.Y.; Xing, F.; Yao, J.H.; Lu, J.Z. Effects of laser shock peening on microstructural evolution and wear property of laser hybrid remanufactured Ni25/Fe104 coating on H13 tool steel. J. Mater. Process. Technol. 2021, 291, 117016. [Google Scholar] [CrossRef]

- Lu, J.Z.; Xue, K.N.; Lu, H.F.; Xing, F.; Luo, K.Y. Laser shock wave-induced wear property improvement and formation mechanism of laser cladding Ni25 coating on H13 tool steel. J. Mater. Process. Technol. 2021, 296, 117202. [Google Scholar] [CrossRef]

- Yin, M.; Cai, Z.; Li, Z.; Zhou, Z.; Wang, W.; He, W. Improving impact wear resistance of Ti-6Al-4V alloy treated by laser shock peening. Trans. Nonferrous Met. Soc. China 2019, 29, 1439–1448. [Google Scholar] [CrossRef]

- Feng, A.; Wei, Y.; Liu, B.; Chen, C.; Pan, X.; Xue, J. Microstructure and mechanical properties of composite strengthened high-chromium cast iron by laser quenching and laser shock peening. J. Mater. Res. Technol.-JMR&T 2022, 20, 4342–4355. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Dai, F.Z.; Zhong, J.W.; Xu, L.Z.; Yang, C.J.; Zhang, L.; Wang, Q.W.; Zhong, J.S.; Yang, D.K.; et al. Effects of multiple laser shock processing (LSP) impacts on mechanical properties and wear behaviors of AISI 8620 steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2012, 536, 57–63. [Google Scholar] [CrossRef]

- Tang, Y.; Li, S.; Liao, Y.; Ma, Y.; Wu, X.; Chi, Y.; Lin, C.; Zhang, Y. Improvement of fatigue life of Ti-6Al-4V alloy treated by double-sided symmetric oblique laser shock peening. Mater. Today Commun. 2024, 39, 109121. [Google Scholar] [CrossRef]

- Lin, C.; Wu, H.; Li, Z.; Yu, L.; Zeng, J.; Xia, C.; Liao, Y.; Xu, H.; Zhang, Y. Evaluation of oblique laser shock peening effect of FGH95 superalloy turbine disk material. Mater. Today Commun. 2022, 31, 103534. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Y.; Ge, M.; Ma, Y.; Wu, Q. Influence of double-side symmetric oblique laser shock peening on shape deviation, surface integrity, and fatigue properties of the blades in small-sized blisk. Int. J. Fatigue 2024, 186, 108427. [Google Scholar] [CrossRef]

- Wu, J.; Yang, A.; Li, W. Flexible ultrablack surface with high absorption performance. Opt. Precis. Eng. 2024, 32, 2334–2343. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, X.; Wang, X.; Liu, Z.; Liu, S.; Wan, W.; Wang, P. Influence of laser shock peening on surface integrity and tensile property of high strength low alloy steel. Chin. J. Aeronaut. 2021, 34, 199–208. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Zhou, J.; Feng, A.; Zhang, L.; Ge, T.; Ren, X. Oblique angle laser shock experiment and theoretic analyse. Zhongguo Jiguang Chin. J. Lasers 2005, 32, 1437–1440. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, W.; Chen, K.; Narayan, R.L.; Ramamurty, U.; Zhou, L.; He, W. Twin and dislocation induced grain subdivision and strengthening in laser shock peened Ti. Int. J. Plast. 2022, 159, 103476. [Google Scholar] [CrossRef]

- Luo, J.; Wang, J.; Xu, J. Effect of laser shock peening on plasma nitriding microstructure and properties of H13 steel. Surf. Coat. Technol. 2023, 473, 130004. [Google Scholar] [CrossRef]

- Guo, K.; Liu, W. Improving mechanical properties of additively manufactured H13 steel through residual stress modulation by laser shock peening. Int. J. Adv. Manuf. Technol. 2024, 132, 5289–5303. [Google Scholar] [CrossRef]

- Zhang, Y.; Lai, F.; Qu, S.; Ji, V.; Liu, H.; Li, X. Effect of shot peening on residual stress distribution and tribological behaviors of 17Cr2Ni2MoVNb steel. Surf. Coat. Technol. 2020, 386, 125497. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, L.; An, J. Dry wear behavior and mild-to-severe wear transition in an Mg-Gd-Y-Zr alloy. Surf. Topogr.-Metrol. Prop. 2021, 9, 25032. [Google Scholar] [CrossRef]

- Lu, Y.; Li, S.X.; Qiao, H.C.; Qu, N.; Zhao, J.B.; Hu, T.Y. Surface microstructure evolution analysis of TiAl alloy by laser shock peening. Rare Met. Mater. Eng. 2019, 48, 841–846. [Google Scholar] [CrossRef]

- Lin, C.; Yu, L.; Zeng, J.; Wu, H.; Guo, X.; Liu, J.; Zhang, Y. Experimental Study on FGH95 Superalloy Turbine Disk Joint Material by Oblique Laser Shock Processing. Metals 2021, 11, 1770. [Google Scholar] [CrossRef]

- Cao, Y.; Yao, C.; Tan, L.; Zhang, Z.; Shi, G.; Xiang, S.; Zhou, W.; Xue, S. A novel methodology of surface integrity anisotropy in ATI718 plus alloy by oblique laser shock peening. J. Manuf. Process. 2025, 152, 346–363. [Google Scholar] [CrossRef]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

| Element wt% | |||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | V | S | P |

| 0.39 | 0.83 | 0.38 | 5.0 | 1.22 | 0.86 | 0.005 | 0.022 |

| Process Parameter | Parameter Values |

|---|---|

| Spot diameter (mm) | 3 |

| Incidence angle | 0°, 15°, 30°, 45° |

| Energy (J) | 8, 8.2, 9.2, 11.3 |

| Power density (GW/cm2) | 1.41 |

| Wavelength (nm) | 1064 |

| Pulse width (ns) | 20 |

| Overlap rate | 50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, K.; Zhu, J.; Li, Z.; Chen, S.; Zhang, Y.; Yan, Y.; Hao, Q.; Guo, B.; Zhong, F.; Chen, W.; et al. Study on the Effect of Laser Shock Angle on Surface Integrity and Wear Performance of H13 Steel. Lubricants 2025, 13, 502. https://doi.org/10.3390/lubricants13110502

Tang K, Zhu J, Li Z, Chen S, Zhang Y, Yan Y, Hao Q, Guo B, Zhong F, Chen W, et al. Study on the Effect of Laser Shock Angle on Surface Integrity and Wear Performance of H13 Steel. Lubricants. 2025; 13(11):502. https://doi.org/10.3390/lubricants13110502

Chicago/Turabian StyleTang, Ke, Jiang Zhu, Zejie Li, Shiqi Chen, Yuqiang Zhang, Yunfeng Yan, Qing Hao, Bicheng Guo, Fasheng Zhong, Weiwen Chen, and et al. 2025. "Study on the Effect of Laser Shock Angle on Surface Integrity and Wear Performance of H13 Steel" Lubricants 13, no. 11: 502. https://doi.org/10.3390/lubricants13110502

APA StyleTang, K., Zhu, J., Li, Z., Chen, S., Zhang, Y., Yan, Y., Hao, Q., Guo, B., Zhong, F., Chen, W., Liu, S., & Gao, J. (2025). Study on the Effect of Laser Shock Angle on Surface Integrity and Wear Performance of H13 Steel. Lubricants, 13(11), 502. https://doi.org/10.3390/lubricants13110502