Abstract

Palm oil is among the most produced plant oils in the world and is solid at room temperature. This study aims to produce a palm oil-based lapping solution that contributes to sustainable manufacturing. A palm oil-based lapping solution was compared with grease and industrial lapping solutions. Lapping processes were conducted on cylindrical spur gear wheels following the Taguchi L27 experimental design, utilizing three distinct RPMs and varying times. The average surface roughness value after the lapping procedure diminished by 39.45% with the palm oil lapping solution, demonstrating greater effectiveness than the other treatments. The most significant percentage change among all lapping solutions was −59.06%, achieved with palm oil at 32 rpm for 10 min. On the other hand, the Taguchi L27 signal-to-noise analysis shows that the palm oil lapping solution yielded the optimal outcome at 50 rpm and 16 min. A palm oil-based lapping solution was seen as capable of replacing mineral oil-based lapping solutions.

1. Introduction

Lapping is the process of eliminating chips from the workpiece surface using abrasive grains to attain dimensional precision, align the surfaces for further processing, or achieve a polished finish. During the lapping process, abrasive particles refine the surface irregularities of the workpiece through sliding or rolling motions. Lapping shafts are utilized for holes, lapping sleeves for cylindrical outer surfaces, and lapping disks for planar surfaces. Nevertheless, research on gear lapping is limited.

The Sn-Bi alloy has been utilized as a lapping plate for hard disk drives; however, the Sn alloy has demonstrated limited effectiveness in the lapping process and has resulted in unstable surface roughness issues [1]. Lapping was conducted at various pressures between 5 and 122 kPa, and it was determined that minimal pressure levels should be utilized to maintain stable surface roughness [1]. A separate investigation found that free abrasive-backed fixed abrasive lapping plates (FAAFALP) were favored for sapphire substrates. An orthogonal experimental design was established to enhance the FAAFALP lapping process, incorporating the variables of lapping pressure, lapping speed, and abrasive concentration. The material clearance rate was seen to rise by 22.2% to 2.48 µm/min [2]. A surface shape prediction model for the lapping process of thin copper plates was developed, incorporating relative velocity and pressure to quantify material removal. This approach revealed that the average error in predicting surface form for thin pure copper was under 10%, and the surface roughness diminished from 54.8 µm to 1.9 µm [3]. A tribochemical lapping plate was designed for the study’s abrasive lapping procedure of 304 stainless steel. The highest material removal rate (MRR) was determined to be 412,524 nm/min with a grain size of 28 mm, a lapping duration of 15 min, a lapping speed of 90 radians/min, and a lapping pressure of 27.58 kPa [4]. A study examined the influence of lapping parameters, including speed, pressure, abrasive grain ratio, and abrasive grain size, on the surface roughness and material removal rate of ABS–carbon fiber composite materials, resulting in the development of artificial neural network and genetic algorithm models. The results from these models indicated that the goodness of fit for MRR was 1.99, while for surface roughness, it was 1.96, demonstrating a high-precision model [5]. Research on the lapping process has also focused on cylindrical rollers. A study was conducted to address the issues associated with lapping high-precision cylindrical rollers, involving studies on friction and wear. The findings indicated that the Al2O3 ceramic lapping plate exhibits a roundness of 0.23 mm, a cylindricity of 0.58 mm, a flatness of 0.489 mm, and a surface roughness of 11.3 nm. The ceramic lapping plate enhances wear resistance, machining precision, and uniformity, and a novel method for ultra-precision machining of rollers has been exhibited [6]. A separate study presenting a novel ring-type lapping technique for precision machining tapered rollers said that stable rotation of the tapered rollers is essential for attaining high manufacturing accuracy [7]. A novel double-disk straight groove lapping (DDSGL) technique was proposed in a study aimed at diminishing roundness and enhancing the surface roughness of tapered rollers. This proposed technology has demonstrated the ability to enhance the roundness of tapered rollers and diminish the surface roughness value [8].

While the literature on gear lapping is limited, recent years have seen a rise in related studies. A study on ultrasonically assisted lapping of gear wheels revealed that the material removal rate of ultrasonic lapping was thrice superior to that of traditional lapping under the same conditions [9]. A further study examined the influence of various gear characteristics on the lapping process and geometric topography of hypoid gears [10]. A separate investigation on the lapping of hypoid gears indicated that the quality of lapping on the gear surface diminished due to tooth flank deformation and manufacturing faults resulting from heat treatment. This research proposes a lapping adjustment method for hypoid gears, utilizing the lapping process on a bi-cubic B-spline surface [11]. A study on the lapping process of elliptical gear wheels utilized a Taguchi L9 experimental design, incorporating three distinct moduli, three varying tooth counts, and three eccentricity parameters. It was noted that all surface roughness values were enhanced by an average of 27.64% post lapping [12].

Lapping is performed using lapping solutions that contain abrasive particles. These solutions are typically acquired pre-manufactured from the industry or formulated by the lapping firms themselves. Moreover, these solutions typically consist of petroleum-derived substances, such as grease. Palm oil is among the most prevalent vegetable oils globally and possesses the capacity to substitute petroleum-based products, both in the food sector and due to its substantial output [13]. In addition, due to the rising worldwide energy demand, the advancement of renewable energy, particularly from biomass and agricultural waste, is advocated [14]. Tropical goat oil was used with palm oil to inhibit solidification during biodiesel synthesis [14]. It has been established that palm oil is favored in numerous domains. In the literature, palm oil and its byproducts are utilized as biomaterials for uses in sustainable construction materials [15]. A study on friction behavior in open and closed die forming tests indicated that oils utilized in metal forming are environmentally detrimental and produce chemical emissions, with palm oil being favored as a substitute for these oils [16]. The findings indicate that palm stearin lubricants (PS) provide enhanced performance relative to commercial metal forming oil (CMFO). PS exhibited the lowest friction in both experiments, with a coefficient of friction m = 0.1/μ = 0.5 in the open die test [16] A separate study examining the production, assessment, and characterization of palm oil as a cutting fluid for aluminum 6061 alloy revealed that palm kernel oil cutting fluid possesses favorable physical properties, such as ideal viscosity, density, and pH levels, with no hazardous substances identified in the chemical analysis, thereby confirming its status as an environmentally friendly alternative [17] A separate study examined the feasibility of an eco-friendly grease formulated with palm olein as the base oil and glycerol monostearate as the thickener, augmented with conductive multi-walled carbon nanotubes (MWCNTs), for use in electric vehicle bearings. Chemical–physical, tribological, and electrical assessments were performed with and without MWCNTs, and the outcomes were juxtaposed with lithium and sodium greases. A voltage range of 1.0–2.2 V was achieved with 3% MWCNT mixes by weight, demonstrating superior electrical conductivity and safeguarding the bearing surfaces from electrical failures [18].

The main purpose of this study is to produce a natural lapping solution that can be an alternative to industrial lapping solutions. This study employed the Taguchi L27 experimental design to facilitate efficient and systematic experimentation. The Taguchi method facilitates the statistical analysis of process parameters (RPM, duration, leaching solution type) while minimizing the number of experiments, thereby saving time and resources. The efficacy of the palm oil-based lapping solution was evaluated against that of the industrial and grease-based lapping solutions. Cylindrical spur gears were subjected to lapping using three types of lapping solutions at three distinct speeds and durations, while a consistent quantity of Al2O3 powder was fixed. The surface roughness measurements of the gears were collected and analyzed on the involute curves before and after lapping.

2. Materials and Methods

To evaluate the performance of the palm oil lapping solution, 54 cylindrical spur gear hobbing machines were manufactured. Liquid and solid palm oils were obtained to prepare the lapping solution with palm oil. In addition, the performance of the palm oil lapping solution was compared with that of grease and industrial lapping solutions. A fixed amount of Al2O3 powder was mixed into the palm oil and grease lapping solutions. The lapping process was carried out in accordance with the Taguchi L27 experimental set. The Taguchi method was chosen to save both time and money.

2.1. Cylindrical Spur Gear Manufacturing and Measurement of Surface Roughness Values

Fifty-four cylindrical spur gears with modulus m = 3 and number of teeth z = 18 were produced on a hobbing machine. Design and manufacturing parameters of the gears are presented in Table 1. The center hole diameter of the gears was 14 mm, and the keyway was 4 mm. Test numbers were marked on the gears with the help of a marker. The surface roughness values of the gears were measured and recorded both before and after lapping. Five different teeth were randomly selected from each gear and again marked with a marker, and the surface roughness values were determined on the marked teeth.

Table 1.

Design and manufacturing parameters of spur gears.

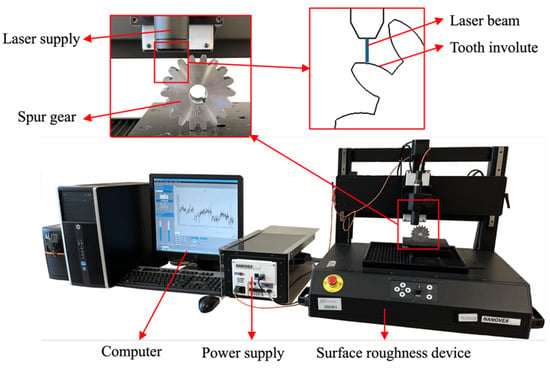

Surface roughness values were measured with the device shown in Figure 1, which is in Afyon Kocatepe University, Faculty of Technology, Micromachining Laboratory. The device features a 200 × 150 mm XY axis and operates at a speed of 40 mm/s. The surface scanning speed is 384,000 points per second. Surface roughness measurements were conducted at a distance of 10 mm in the gear width direction and from the contact areas of the gears. The device is unable to measure roughness values in the involute direction. All surface roughness values obtained were saved as a PDF extension as shown in Figure 2. The average surface roughness (Ra) values measured before and after lapping were transferred to an Excel spreadsheet.

Figure 1.

Surface roughness device and surface roughness measurement.

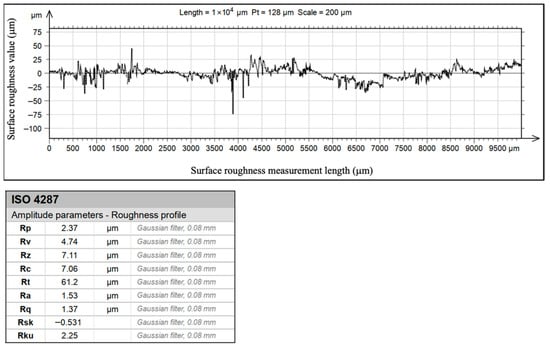

Figure 2.

Surface roughness measurement result.

2.2. Preparation of Lapping Solutions

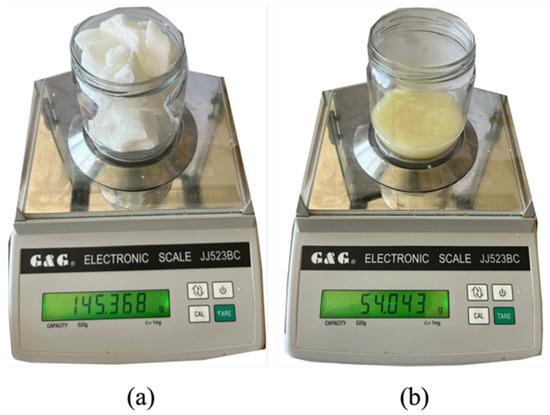

To determine the amount of Al2O3 powder to be added to the palm and grease oil lapping solutions, an industrial lapping solution available on the market was burned in a Proterm brand curing oven at 600 °C for 4 h, and then the Al2O3 powder ratio was determined. The Al2O3 powder ratio was determined to be 49.3441% by mass. The palm and grease oil lapping solutions were prepared in a total amount of 250 g with a mass accuracy of ±0.1 g. The total lapping solution was then adjusted on a precision balance to ensure that it contained 49.3441% by mass of Al2O3 powder. In addition, palm oil is sold in solid and liquid forms on the market (Figure 3).

Figure 3.

(a) Solid palm oil. (b) Liquid palm oil.

The apparatus in Figure 4 was configured to adjust palm oil to the fluidity of grease. Twenty trials were conducted to determine the optimal mixture ratio of palm oil, which was subsequently established. This setup was not intended for the absolute measurement of viscosity but rather for assessing the oil ratio. The purpose of assessing the flow with this configuration is to confirm that palm oil maintains a grease-like consistency at room temperature. Table 2 presents the physical and chemical properties of palm oil [19].

Figure 4.

Determination of palm oil blend ratio.

Table 2.

Physical and chemical properties of palm oil [16].

The blended palm oils and grease were put into 10 mL syringes at a volume of 5 mL, with 1 kg weights positioned atop the syringes. The ratios of palm oil were adjusted until identical fluid volumes were discharged at equal times. Twenty mixes of palm oil were formulated in diverse amounts. The solid-to-liquid palm oil mixing ratio was 77.5% solid and 22.5% liquid. The density of the palm oil mixture was determined to be 0.91 g/cm3.

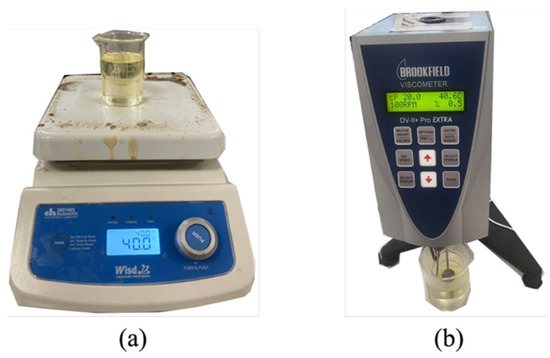

To figure out the viscosity of the obtained palm oil mixture, it was heated to 40 °C using the magnetic heater depicted in Figure 5a, and its viscosity was measured using the Brookfield viscometer (Figure 5b) at Afyon Kocatepe University, Şuhut Vocational School, Food Laboratory. The viscosity was established using a 5 mm diameter disk at a rotational speed of 100 rpm. The viscosity of the mixed palm oil was measured at 20 centipoises.

Figure 5.

Analysis of the viscosity of a palm oil blend. (a) Magnetic heater. (b) Viscometer.

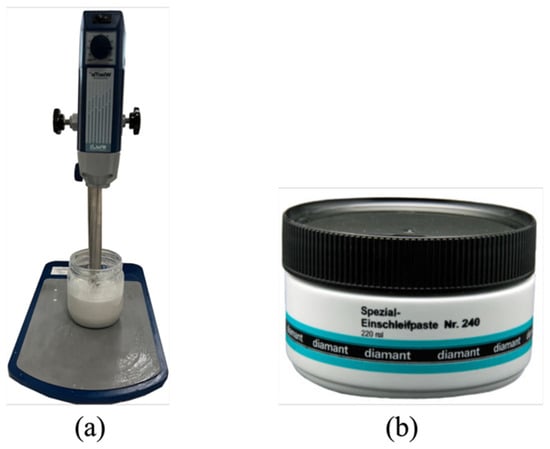

Al2O3 particles were incorporated into a mixture of grease oil and palm oil at a mass ratio of 49.3441% using homogenization equipment (Figure 6a), totaling 250 g. The mean grain size of the Al2O3 powder was determined to be 29.2 μm. This size was selected because the optimal average grain size of Al2O3 powder for the lapping process of gear wheels is 17–51 µm [20]. The particle size of the Al2O3 powder in the industrial lapping solution is 28 µm (Figure 6b). The industrial lapping solution is of the brand ‘Spezial-Einschleifpaste no 240’ and has an average particle size of 28 µm.

Figure 6.

(a) Homogenization device. (b) Industrial lapping solution.

2.3. Lapping Process

Lapping was carried out with three types of lapping solutions, three different speeds, and three times on the lapping device, as shown in Figure 7. The device was designed and produced for the lapping process. The Arduino board regulates the step motor speed and the duration of the lapping operation. The preferred speed and duration can be adjusted using the control panel buttons and are shown on the LCD screen. The lapping process commences with the activation of the start button. The stepper motor can achieve a maximum rotational speed of 400 rpm. The apparatus comprises two shafts: one stationary and one movable. The stationary shaft is linked to the stepper motor with a timing belt. The movable shaft can translate linearly in a single direction, utilizing a linear slide mechanism. This guarantees interaction between the gears. Interaction between the gears is facilitated by affixing a mass to a rope linked to the movable shaft. The contact of the gears was ensured by hanging 1 kg mass. The number of revolutions was chosen as 20 times the numbers 1.00, 1.60, and 2.50 in the R10 column of the standard numbers table [21]. Similarly, the duration values were 10 times the 1.00, 1.60, and 2.50 of the standard numbers table [21]. The reason for selecting low speeds is that the lapping of gear wheels should be performed at speeds less than 80 rpm [20]. The experimental parameters were prepared according to the Taguchi L27 experimental set and are given in Table 3.

Figure 7.

Lapping device.

Table 3.

Lapping process parameters according to Taguchi L27 experimental set.

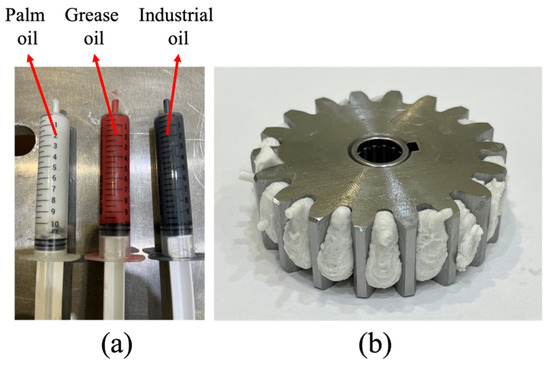

All three types of lapping solutions were placed into 10 mL syringes (Figure 8a) and evenly injected into the tooth cavities of the gear wheel connected to the moving shaft (Figure 8b). In Figure 8a, the white lapping solution is palm oil, the red lapping solution is grease, and the gray lapping solution is a commercially prepared solution from an industrial setting. The gears underwent the lapping procedure at the specified speed and duration, after which the lapping solutions were cleaned using ethyl alcohol.

Figure 8.

(a) Lapping solutions. (b) Filling the solutions into the tooth cavities.

3. Results and Discussion

This study analyzed the performance of the solution–gear pair in palm oil-based lapping solutions relative to alternative lapping solutions. Before and after lapping, the average surface roughness (Ra) values of randomly selected and marked teeth of the spur gears were measured on the involute curves of the gears. Table 4 provides the arithmetic averages and percentage changes in the average surface roughness values obtained. The lapping processes conducted with all lapping solutions resulted in a decrease in Ra values, as evidenced by Table 4. The palm oil lapping solution achieved the best Ra value of −39.45% when the general average of the percentage variations was analyzed. The palm oil lapping solution achieved the most significant percentage change, with a decrease of −59.06% in 10 min at 32 rpm. The industrial lapping solution exhibited the least percentage change, with a decrease of −20.87% in 16 min at 50 rpm.

Table 4.

Average Ra values and percentage changes obtained before and after lapping.

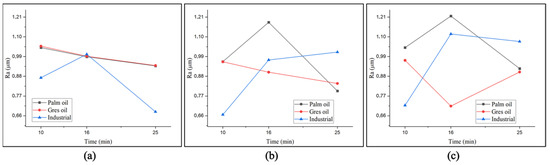

The Ra values obtained at the end of the lapping process at each speed are given in Figure 9. The best Ra value was obtained with the industrial lapping solution at the end of the lapping process, carried out for 10 min at all speeds. In the lapping process at 20 rpm and 16 min, Ra values close to each other were measured in all oil types. The lapping process with the best Ra value was observed in the lapping process with palm oil solution at 32 and 50 rpm for 16 min. After lapping with palm oil solution, the best Ra value was obtained at 32 rpm and 25 min. It was also determined that the lapping process at 50 rpm for 25 min is close to the smallest Ra value.

Figure 9.

Ra values after lapping processes according to rpm. (a) 20 rpm. (b) 32 rpm. (c) 50 rpm.

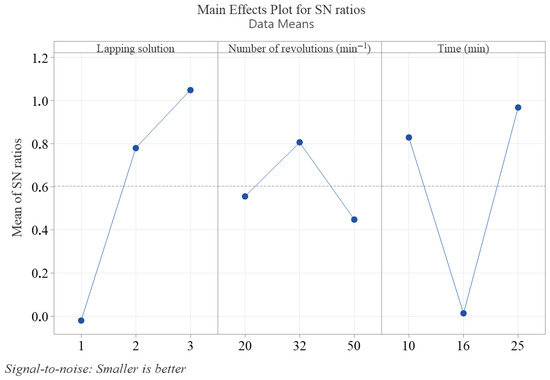

The Taguchi L27 signal-to-noise analysis (SN) was conducted by identifying the “smaller is better” (Figure 10). Analysis of the lapping solutions indicated that the palm oil lapping solution exhibited a value approaching zero, establishing it as the most effective option. Similarly, an examination of the revolutions per minute revealed that increasing the rotation speed from 20 rpm to 32 rpm resulted in an average SN ratio of 0.8, with the 32 rpm value being suboptimal. Conversely, raising the revolutions per minute from 32 rpm to 50 rpm was found to enhance the impact of rotation speed on surface roughness. Analysis of the duration parameter revealed that durations of 10 and 25 min produced average SN values exceeding the target. In contrast, a duration of 16 min resulted in a value near zero. It was determined that a duration of 16 min is optimal. The SN analysis indicated that the palm oil lapping solution yielded optimal results at 50 rpm and 16 min. Consequently, the palm oil lapping solution is a viable alternative to mineral oil lapping solutions.

Figure 10.

Taguchi L27 signal—noise analysis result.

The following topics can be addressed in conjunction with this study to provide researchers who are interested in the lapping process with relevant information.

- -

- Research can be conducted to investigate the impact of the palm oil-based lapping solution on the surface forms of other machine elements and the alteration of gear tooth profiles.

- -

- The internal behavior of the lapping solution can be the sole focus of research.

- -

- Research can be conducted to investigate the behavior of palm oil in industrial settings and to determine how it can be transformed into a truly industrial product.

- -

- Academic research can be conducted on palm oil to investigate its lubrication performance in addition to its use as a lapping solution.

4. Conclusions

The key findings of this study clearly demonstrate the performance and applicability of the developed palm oil-based lapping solution as a sustainable alternative in production processes. The main results are as follows:

- -

- The palm oil-based lapping solution has proven to be the most effective, providing significantly greater improvement in surface smoothness compared to traditional grease and industrial mineral oil-based solutions.

- -

- Under the optimized parameters determined by Taguchi analysis, the palm oil-based lapping solution consistently provided the best surface quality and was found to be reliable for industrial applications.

- -

- In particular, the palm oil solution can provide exceptional surface quality improvements, and one test condition yielded the highest single improvement result recorded throughout the study.

- -

- It was observed that the palm oil lapping solution is practically applicable not only for gear wheels but also for lapping other precision machine components.

- -

- This research has successfully demonstrated that palm oil-based lapping solutions are high-performance, renewable, and effective, serving as a model for sustainable manufacturing applications.

Funding

This study was supported by The Scientific and Technological Research Council of Turkey (TUBITAK) within the scope of 1002 fast-track support with project number 125M118.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

I would like to thank Afyon Kocatepe University, Şuhut Vocational School for providing laboratory facilities for this study.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Hu, B.; Zhou, W.; Tsuchiya, K. Mechanism elucidation of Sn-Bi alloy lapping plate surface instability. J. Alloys Compd. 2023, 965, 171465. [Google Scholar] [CrossRef]

- Deng, J.; Xiong, Q.; Nie, X.; Yan, Q.; Cao, J.; Lu, J. Optimisation of free-abrasive assisted lapping process with vitrified bonded diamond plates for sapphire substrates. Precis. Eng. 2024, 86, 183–194. [Google Scholar] [CrossRef]

- Di, W. Surface generating mechanism in surface shape error control for thin copper plate with large-diameter based on chemical mechanical lapping. J. Manuf. Process. 2023, 101, 639–655. [Google Scholar] [CrossRef]

- Su, J.; Zhang, X.; Xue, M.; Xiao, W.; Zhang, T. Study on Lapping Process of 304 Stainless Steel Using Tribochemical Fixed-Abrasive Lapping Platen. Manuf. Technol. 2022, 22, 231–239. [Google Scholar] [CrossRef]

- Taghizadeh, B.; Ehteshamfar, M.V.; Adibi, H. Lapping optimization of additively manufactured ABS-carbon fiber composite parts using the soft computing technique. Polym. Test. 2023, 128, 108241. [Google Scholar] [CrossRef]

- Zhao, T.; Ruan, J.; Feng, K.; Guo, L.; Chen, H.; Lyu, B.; Ding, J.; Jiang, X. Experimental study on the influence of lapping plate materials on the quality of both sides cylindrical rollers machining. Sci. Rep. 2025, 15, 1858. [Google Scholar] [CrossRef] [PubMed]

- Geng, K.; He, C.; Wang, S.; Chen, G.; Ren, C. The rotation stability of the tapered rollers in a novel ring-type lapping process. Precis. Eng. 2024, 88, 927–942. [Google Scholar] [CrossRef]

- Zhang, J.; He, C.; Chen, G.; Luo, M.; Ren, C. Theoretical and experimental investigation on double-disc straight groove lapping: Tool contour and lapping trajectory. Int. J. Adv. Manuf. Technol. 2024, 134, 1507–1531. [Google Scholar] [CrossRef]

- Wei, B.Y.; Deng, X.Z.; Fang, Z.D. Study on ultrasonic-assisted lapping of gears. Int. J. Mach. Tools Manuf. 2007, 47, 2051–2056. [Google Scholar] [CrossRef]

- Wen, J.; Du, W.; Hou, J.; Rong, S.; Zhou, Z.; Wang, Q.; Ding, H. Lapping tooth surface micro-topography prediction for extended epicycloid hypoid gears. Mech. Mach. Theory 2025, 206, 105931. [Google Scholar] [CrossRef]

- Wang, S.; Yang, J.; Li, B.; Zhao, J.; Wang, B.; Xin, W.; Cheng, B. Lapping adjustment method for actual surface of hypoid gears. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 122. [Google Scholar] [CrossRef]

- Pazarkaya, İ.; Yazar, M.; Karabulut, S.; Uzun, G.; Özdemir, A. Effect of lapping process on axis misalignment and surface roughness in elliptical gear pairs. J. Manuf. Process. 2024, 115, 192–201. [Google Scholar] [CrossRef]

- Durango-Giraldo, G.; Zapata-Hernandez, C.; Santa, J.F.; Buitrago-Sierra, R. Palm oil as a biolubricant: Literature review of processing parameters and tribological performance. J. Ind. Eng. Chem. 2022, 107, 31–44. [Google Scholar] [CrossRef]

- Cahyo Kumoro, A.; Saeed, M.T.M. Ultrasound-assisted transesterification of tropical goat fat—Palm oil blend for biodiesel synthesis. Energy Convers. Manag. X 2022, 14, 100213. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Al-Fakih, A.; Noura, S.; Yaghoubi, E.; Alaloul, W.; Al-Mansob, R.A.; Khan, M.I.; Aliyu Yaro, N.S. Utilization of palm oil and its by-products in bio-asphalt and bio-concrete mixtures: A review. Constr. Build. Mater. 2022, 337, 127552. [Google Scholar] [CrossRef]

- Yahaya, A.; Samion, S.; Abidin, U.; Abdul Hamid, M.K. Different Behaviors of Friction in Open and Closed Forging Test Utilizing Palm Oil-Based Lubricants. Lubricants 2023, 11, 114. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Laseinde, O.T.; Kazeem, R.A.; Onu, P.; Ting, T.T. The Development and Performance Assessment of Palm Kernel Nut Oil as a Cutting Fluid for the Turning of AA6061. Lubricants 2025, 13, 279. [Google Scholar] [CrossRef]

- Abozeid, A.A.; Youssef, M.M.; Megahed, T.F.; El-Helaly, M.; Pape, F.; Nassef, M.G.A. Tribo-Electric Performance of Nano-Enhanced Palm Oil-Based Glycerol Grease for Electric Vehicle Bearings. Lubricants 2025, 13, 354. [Google Scholar] [CrossRef]

- Stanciu, L. Evolution of the Rheological Behavior of Palm Oil. In Palm Oil—Current Status and Updates; IntechOpen: London, UK, 2023. [Google Scholar]

- Gupta, K.; Jain, N.K.; Laubscher, R. Advanced Gear Manufacturing and Finishing: Classical and Modern Processes; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–230. [Google Scholar]

- Kutay, M.G. Standart Sayilar. 2009. Available online: https://www.guven-kutay.ch/ozet-konular/01_standartlar.pdf (accessed on 4 November 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).